Abstract

Acrylic fibres, as synthetic polymers, have been used extensively in the textile industry to create a wide variety of products, ranging from apparel and home furnishings to car rooftops and carbon fibres. Their widespread application is attributed to a combination of desirable properties, including a soft, wool-like texture, chemical stability, and robust mechanical characteristics. Furthermore, the chemical structure of acrylic fibres can be modified to imbue them with additional features, such as antimicrobial properties, fire resistance, conductivity, water repellency, and ultraviolet protection. This review explores the technological methods employed to functionalise acrylic fibres and discusses future trends in their development.

1. Introduction

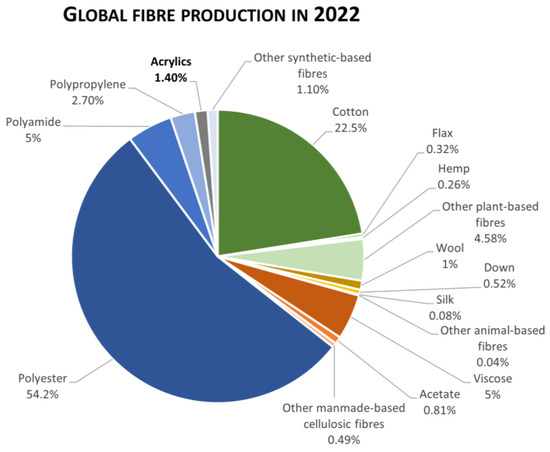

The global market of textiles in 2022 was valued at USD 1695.13 billion, with polyester being the most produced material, accounting for approximately 54%, followed by cotton (22%) and polyamide (~5%) [1]. Among the synthetic polymers, acrylic fibres, also known as polyacrylonitrile fibres (PAN), “Aulon”, and/or “Cashmiron”, are widely used in the textile industry. Originally created by the DuPont Corporation in 1941 under the trademark “Orlon,” acrylic fibre is now used in the fabrication of a wide range of products, such as clothes, blankets, apparel, carpets, home furnishings, awnings, hand knitting and craft yarn, and stuffed toys [2]. As shown in Figure 1, in 2022 acrylic fibres accounted for 1.4% of the total global fibre market and 2.1% of the synthetic fibre market, with a global market share of USD 23.73 billion [1,3]. Moreover, it is the third most recycled synthetic fibre, where it is estimated that 50% of the total acrylic market share was derived from recycled fibres [1]. Furthermore, because of the low cost and versatility, it is anticipated that the global acrylic fibre market will grow by 46.4% by 2033, with significant demand coming from the Asia–Pacific region, the Middle East, Africa, and Latin America [4].

Figure 1.

Global fibre production in 2022. Total acrylic fibres production is in bold. Data adapted from Textile Exchange [1].

Although other fibres have an economic advantage over acrylic fibres because of better raw material availability, large-scale production, and recyclability, in the awning and outdoor furnishing textile market, acrylic fibres remain the predominant material (accounting for more than 90% of production), thanks to their unmatchable performance and properties [5]. Acrylic fibres have shown wool-like characteristics, like being soft when handled, warm, and lustery [6]. They also have demonstrated minimal water absorption, good ultraviolet (UV) light exposure tolerance, and average elongation at break and tensile strength compared to polyester fibres [7,8,9]. Moreover, they are resistant to a wide range of chemicals and can effectively endure acids and mild alkalis. However, exposure to strong alkalis at high temperatures can lead to rapid deterioration [7].

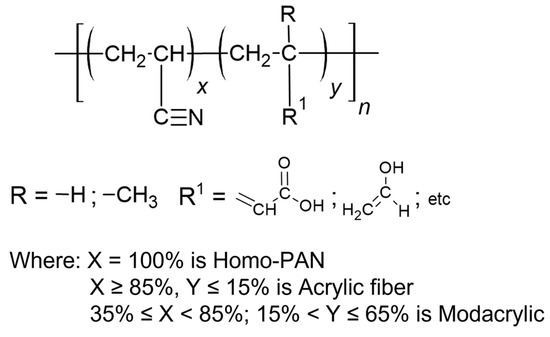

Normally, acrylic fibres are mainly synthesised by the polymerisation or copolymerisation of acrylonitrile and other vinyl monomers, such as acrylic acid, vinyl alcohol, vinyl chloride, vinyl acetate, vinylidene chloride, methacrylic acid, and methacrylate esters, with a variable degree of polymerisation (Figure 2) [10,11]. Although PAN fibres can also be synthesised through anionic photopolymerisation, the radical-initiated polymerisation or copolymerisation method is the predominant method of production [12]. According to the International Synthetic Fiber Standardization Office (BISFA), a fibre can only be defined as “acrylic fibres” if the polymer matrix has at least 85% of acrylonitrile units (–CH2–CH(CN)–). If the acrylonitrile content is between 35 and 85%, then the fibres are denominated as modacrylic, which can be used to add specific properties to the textile (e.g., dyeability) [13]. On the other hand, fibres made exclusively from acrylonitrile are considered homopolymer polyacrylonitrile (homo-PAN), typically used in the production of carbon fibres and filtration systems [14,15]. In all three types of acrylic fibres, the carbon-nitrogen triple bond is a distinctive feature that allows for their identification in the range between 2240 cm−1 and 2260 cm−1, distinct from other fibres, using IR spectroscopy [16,17].

Figure 2.

Acrylic fibre structure.

Most acrylic fibres have number and weight average molecular weights of 40,000–70,000 g/mol and 90,000–170,000 g/mol, respectively, a density of 1.16–1.18 g/cm3, are soluble in polar aprotic solvents, and possess moderate strength and elongation at break. Their elongation at break can vary between 20 and 50%, depending on the fibre composition; however, at two percent elongation, the fibre recovery is 99%, while at five percent, it drops to 50–95%. Nevertheless, these fibres have shown excellent resiliency and recovery from bending deformation. Dry acrylic fibres have a tenacity that varies from 2 to 4 g/d (18–36 g/tex), which decreases to 1.5–3 g/d (13–27 g/tex) on exposure to moisture. They also have a moisture regain of 1.5–2% (at 25 °C and 65% relative humidity). Finally, these fibres have demonstrated good electrical and heat insulation properties [18].

Textiles are produced from acrylic fibres through two main methods: wet and dry spinning. The first method, wet spinning, is a low-temperature process generally used to fabricate unsuitable fibres for melt spinning [19]. This method stands out for its ability to create fibres of varied cross-sectional shapes and sizes [20]. During this process, a polymeric solution is extruded through small orifices of a spinneret into a coagulating bath. This bath effectively removes the solvent, solidifying the polymer filaments. The fibres are then collected and merged to form a continuous strand or rope [21,22]. The success of fibre formation in the wet spinning of acrylics is influenced by several factors, including the composition of the coagulation bath, the extrusion rate, temperature, solubility, take-up velocity, and spinning pressure [20,23].

The second method, dry spinning, is normally used to produce textiles requiring durable, wear-resistant fibres, such as carpets [24]. This process begins by dissolving the polymer using an organic solvent, such as acetone or ether. Following this, additives are mixed into the solution to create a viscous mixture referred to as “dope”. The dope is then filtered, de-aired, pre-heated, and transferred to an evaporation chamber, also known as a spinning tube, and is kept there awaiting extrusion. During extrusion, the dope is forced through fine openings (spinneret or jets) at a controlled rate. At this stage, the polymer solution is exposed to a stream of hot gas, which evaporates the solvent and increases the polymer concentration, thereby solidifying it. The resulting solid filaments are then collected by rotation rolls and put onto bales (or bobbins). Alternatively, the filaments may be further processed through stretching, twisting, or combining with other fibres, such as cotton or wool, to enhance their properties or functionality [25,26,27,28].

Depending on their intended application, acrylic fibres may undergo a process commonly referred to as textile finishing, wherein their chemical structure is functionalised to enhance or introduce desired properties. These properties may include improved dyeability, electrical conductivity, fire resistance, water repellency, antimicrobial activity, mechanical strength, and other characteristics not inherent to neat polymers [29]. However, this makes the management of acrylic textile waste a challenge. The EU-funded REACT (REcycling of Waste ACrylic Textiles) project aimed to identify possible processes to treat and recycle textile waste in an ecological and economic way [30]. Therefore, there is a strong need for innovative, high-quality products that are designed, engineered, and processed to meet specifications for different economies and societies; this includes rethinking the raw materials, processes, and services involved as well as investing in technology. The increasing attention of consumers regarding environmental questions is also creating a positive context for new recycling chains.

This review focuses on applying recent methods for acrylic fabric finishing, using surface modifications by plasma or chemical grafting, the sol-gel technique, layer-by-layer deposition of thin films, and other aqueous methods. As a result, the newly developed finishes based on nanoscience appear as valuable tools that can project an enhanced image of chemicals for the next textile industry revolution. Thanks to the comprehensive scheme of this review, it is possible to deduce that the use of novel and environmentally friendly finishes to produce durable and/or high-performance products, as well as more easily recyclable PAN or its use in the conversion of polymers into oligomers or monomers for specialty chemical production, seems the most promising for the future use of acrylic fabrics on the market.

2. Functional Finishing of Acrylic Fibres

This section explores the various functionalisation techniques for acrylic fibres by focusing on enhancing properties, such as durability, water repellency, flame retardancy, and antimicrobial resistance. In particular, we show how these modifications improve textile performance and open new application possibilities by highlighting the intersection of technology and textile innovation.

2.1. Antimicrobial Fibres

With the passage of time, antimicrobial and antifungal properties have become crucial for all types of textiles. Not only do they prevent material degradation, they also offer protection against the spread and transmission of pathogenic microorganisms, which has become of paramount concern for public health and safety in the post-COVID-19 landscape [31,32]. The pandemic underscored the importance of materials that can effectively inhibit the growth and spread of viruses and bacteria, highlighting the need for textiles with enhanced antimicrobial and antifungal capabilities in various applications, from medical settings to everyday clothing and home furnishings [33,34]. Specifically, acrylic fibres can be enhanced with various finishing agents to improve their protective capabilities, as shown in Table 1. For instance, El-Sayed et al. demonstrated that acrylic fibres could be combined with a polyurethane–chitosan solution, using hydrazine hydrate to increase its uptake by the fabric. The resulting modified acrylic fabric exhibited superior bacterial resistance compared to its untreated counterpart, maintaining its effectiveness even after 15 washing cycles [35].

Silver has long been recognised for its effective antimicrobial properties against viruses, fungi, and most bacteria [36,37]. Due to its properties, it has also been tested for modifying textiles. Yu et al. used a dry jet–wet spinning technique to produce a silver-loaded hollow fibre. Since the silver was inside the fibre, it was noted that the fabric retained its silver content even after being washed with water for over 60 days, with only a 0.1% reduction in the silver. Furthermore, the acrylic acted as a barrier, releasing the silver particles and thereby continuously replenishing its antimicrobial properties [38]. Allehyani et al. functionalised acrylic fabric with amidoxime groups to act as ligands for the immobilisation of silver ions. The functionalised fabrics showed good tensile strength and excellent antimicrobial properties, so much so that, in the latter case, the AgNP-loaded acrylic fabric completely eliminated E. coli after 24 h [39]. Wang et al. incorporated silver nanoparticles (AgNPs) into PAN fibres during the electrospinning process. Their findings revealed that the PAN fibre with three percent AgNPs exhibited remarkable antibacterial effectiveness, achieving a 99.99% reduction rate for both E. coli and S. aureus [40].

Other types of antimicrobial materials and polymers have also been tested in acrylic fabrics. Lee et al. combined poly(styrene hydantoin) (PSH) with PAN using a wet spinning process. The resulting fabric was then soaked in a commercial sodium hypochlorite solution for 30 min to imbue it with antibacterial properties. Their findings indicated a direct correlation between chlorine concentration and antibacterial efficiency. Moreover, the functionalised acrylic fibres retained their protective properties even after 50 washing cycles, showcasing the durability of the antimicrobial treatment [41].

Table 1.

The effectiveness of various antimicrobial treatments on E. coli and S. aureus.

Table 1.

The effectiveness of various antimicrobial treatments on E. coli and S. aureus.

| Author | Material Used | Inhibition Zone Diameters (mm) | Ref. | |

|---|---|---|---|---|

| E. coli | S. aureus | |||

| Houng et al. | Silver/graphene oxide (Ag/GO) nanocomposite | - | 24.00 ± 0.34 | [37] |

| Okay et al. | Silver nanoparticles, acrylic acid, and acrylamide | 10.25 ± 0.35 | 11.00 ± 1.41 | [42] |

| Patel et al. | Zinc oxide and silver nanoparticles | 10.00 | - | [43] |

| Mofidfar et al. | Poly(acrylic acid) fibres with silver nanoparticles | - | 3.00 ± 0.3 | [44] |

| Chen et. al. | Tannic acid and silver nanoparticles | 11.00 ± 0.5 a | 11.60 ± 0.5 a | [45] |

| Sarwar et al. | Diclofenac Sodium Salt | 16 ± 0.46 | 15.5 ± 0.28 | [46] |

| Wahab et al. | Titania/AgNP composite nanoparticles | 3.23 | 4.1 | [47] |

a Approximate value.

2.2. Electronic Textiles

Electronic textiles, commonly known as e-textiles, are fabrics or textile materials capable of conducting electricity; alternatively, electronic components can be embedded in their structure [48]. These textiles can be used in many applications, such as creating protective clothing that shields against electromagnetic radiation [49,50], developing wearable sensors for health monitoring (glucose, electrocardiography, dehydration) [51,52,53], measuring pressure and humidity [54,55], and producing energy storage and generation devices, such as solar cells and supercapacitors [56]. The surge in the popularity of e-textiles can be attributed to two main factors: First, the unique properties of textile materials, such as stretchability, foldability, and porosity, provide the ideal conditions for supporting electronic devices. Second, integrating such devices with the Internet of Things can enable rapid analyses of the data from these devices, providing the user with real-time information [57,58].

Through the electrical or electronic integration method, e-textiles can be categorised into three main types [59]. The first type combines conventional electronic components, such as conducting wires, integrated circuits, LEDs, and batteries, into garments. For reasons of simplicity and low cost, this is the most frequently used type of integration [60,61]. The second type integrates electronic components directly into textile fibres, including both passive (e.g., wires or conducting fibres) and active (e.g., transistors, diodes, and solar cells) elements [62,63]. The third category is the most advanced form of integration, where the textile fibres themselves function as sensors or actuators. In this approach, the fibres are designed or functionalised to possess inherent sensing or actuating capabilities, making them an integral part of the e-textile system [48].

There are various approaches to coating acrylic fibres, fabrics, and textiles with conductive materials (Table 2) [64]. For instance, Baseri et al. investigated the coating of PAN with copper sulphide in order to add electrical conductivity to it. The authors studied how the concentration of copper (II) sulphate, temperature, and the ratio of reducing agents influenced coating conductibility performance. According to them, the mixture containing 1.2 g/dm3 of copper (II) sulphate, 3.6 g/dm3 of sodium thiosulfate, 1.6 g/dm3 of hydroxylamine sulphate, and 3.0 g/dm3 of sodium dithionite showed the best results. The resistance of the neat acrylic decreased from 1012 O per square to 102 O per square. The authors also found that when the reaction was performed at higher temperatures (85 °C), the acrylic fibres became more porous, resulting in better copper attachment. However, increasing the temperature above this point showed no significant improvement in the conductivity of the fibre [65].

Ahn et al. explored enhancing the electrical conductivity of PAN fibres using neat and modified carbon black nanoparticles (CB). The latter had its structure modified using 4-aminobenzoyl, benzoxazine, and Ag metal particles. The results showed that when neat CB and its modification were combined with PAN fibres, conductivity and tensile strength increased drastically in all cases. In particular, the fibres containing CB and benzoxazine achieved a tensile strength and conductivity of 110.4 MPa and 8.9 × 10−4 S/cm, respectively [66]. Kayabaşi et al. also conducted tests using CB to decrease the electrical resistance of different textiles, including acrylic fibres, by integrating CB into the fibrous structure before yarn and fabric production. This was done to maintain the softness, breathability, and flexibility of the textiles, improving their wearability. As reported by the authors [67], when 0.5 wt.% of CB was impregnated into the acrylic yarns, the sample resistance decreased to approximately 1000 kΩ. However, the resistance increased between 1.5 and three times after the yarns were washed. Furthermore, the results showed that the incorporation of CB did not affect the tenacity and elongation of the mechanical characteristics of the materials at break.

Table 2.

Conductivity analysis of various nanomaterials.

Table 2.

Conductivity analysis of various nanomaterials.

| Author | Material | Amount | Final Conductive (µS/cm) | Ref. |

|---|---|---|---|---|

| Ahn et al. | Carbon black nanoparticles | 12% | 890 | [66] |

| Rehan et al. | Silver nanoparticles | 0.05% | 324 ± 0.5 | [68] |

| Karbownik et al. | Polyaniline fibres | 1% | 100 | [69] |

| Mustafov et al. | Lignin with graphite | 20%, 1 wt.% | 19.2 × 103 | [70] |

| Xi et al. | Poly (3,4-ethylene dioxythiophene) (PEDOT) | 150 µL/10 mL | 20.51 × 106 | [71] |

| Deng et al. | Multi-walled carbon nanotubes (MWCNTs) | 6 wt.% | 51.6 × 106 | [72] |

| Mpukuta et al. | Silica nanoparticles | 1 wt.% | 8.11 × 103 | [73] |

2.3. Flame Resistance

Acrylic fibres are known for their high flammability, characterised by a limiting oxygen index (LOI) of 18, which places them in the category of materials with a potential fire risk [74,75,76]. Consequently, there has been a significant effort to develop efficient flame retardants (FRs) for them, particularly between the 1950s and 1980s—often referred to as the golden era of FR development. These retardants mainly consisted of halogens, organohalogens, and formaldehyde-based products [77,78]. However, due to the high toxicity of these materials and their combustion by-products, most halogenated and formaldehyde-based FRs have been phased out or completely banned in recent years. This led to companies to invest in the development of alternative products, like the Kanecaron®/Protex® (produced by Kaneka), which not only increased the LOI of treated PAN fibres to 31 but also conferred them high chemical resistance against acid and alkali [79,80]. Additionally, there has also been a surge in academia in the research and development of less hazardous and more environmentally friendly FRs in recent years (see Table 3) [81].

Table 3.

Types of flame-retardant treatment methods and their LOI improvement efficiency of PAN fibres.

Zhou et al. enhanced the flame resistance of PAN fibres by introducing sodium ions via a post-treatment process involving hydrazine hydrate (HHA) and a sodium hydroxide solution (NaOH). The fibres underwent testing through sequential immersion in two solutions at 95 °C: first, a 40 wt.% aqueous solution of HHA, followed by a 15 wt.% aqueous sodium hydroxide solution, each for varying durations. The PAN fibres immersed for 60 min in HHA and 30 min in the NaOH solution showed an LOI increase of 163% (from 19 to 60), with the residue from the Na-PAN combustion acting as a protective barrier against further combustion. However, submerging PAN fibres for longer than 30 min in HHA embrittles the fibres, reducing their tensile strength [82]. To counteract this and improve the mechanical properties of the PAN fibre, Zhou et al. continued by reinforcing acrylic fibres with poly(vinyl alcohol) (PVA). The addition of PVA doubled the tensile strength of the fibres, increasing from 1.96 to 4.01 cN/dtex. However, the Na-PAN LOI decreased by 51.5% to 29.1, although its value remained above what is considered combustible (LOI ≤ 21) [83,92].

Using another approach, Carosio et al. coated acrylic fabrics by alternating layers of ammonium polyphosphate and octapropyl ammonium polyhedral oligomeric silsesquioxane. They created a fabric with a total of 12 layers, suppressing melt dripping and proving effective against a 35 kW/m2 heat flux. Additionally, its LOI increased by 10%. Although the LOI increase was modest (from 20.5 for the neat acrylic to 22), the treated fabric retained 40.7% of its mass after burning tests, significantly outperforming the untreated acrylic, which was completely consumed [84,93].

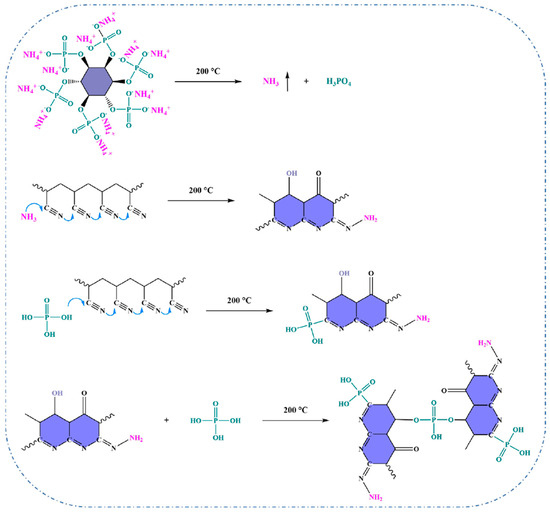

More recently, Zou et al. produced FR PAN fibres (O-AP-PAN) by immersing the PAN fibres in an ammonium phytate (AP) solution, which was prepared by neutralising phytic acid with urea, followed by a thermal oxidation treatment (Figure 3). The treated fibres demonstrated an increase in LOI value to 36.6% and significant reductions in total heat release and heat release capacity by 39.9% and 52.7%, respectively. Furthermore, the fibres maintained their FR characteristics even after 50 wash cycles, with a post-wash LOI value of 30.5%. When the fibres were subjected to fire, the O-AP-PAN fibres generated a stable layer of graphitised carbon, effectively preventing the inner fibres from being exposed to oxygen and heat [91].

Figure 3.

Possible formation mechanism of O-AP-PAN fibres. Reproduced under the terms of the Creative Commons CC BY-NC-ND 4.0 license. Copyright 2023, the Authors [91]. Published by Elsevier.

2.4. Water Repellency and Waterproof Finishes

Textiles with water repellency are beneficial for numerous applications, ranging from simple waterproof cycling suits to personal protective equipment that shields against hazardous liquids [94,95]. The key to water repellency is based on the surface tension value of the fabric, which does not allow the fabric to become wet as long as it is lower than the surface tension of water. Common finishing chemicals, such as silicones, fluorochemicals, wax, and resins, are used to add or improve the water repellency of textiles [96].

However, over the last decade, it has been discovered that fluorocarbon-based compounds, in particular, perfluorooctane sulfonate (PFOS) and perfluorooctanoic acid (PFOA), are a serious threat to the environment and a health risk to humans due to their bio-accumulative and toxic nature [97]. Therefore, several governmental regulatory agencies around the world have imposed restrictions on their usage. An immediate measure was to shorten the fluorocarbon chain length from C8 to C6 or C4, mitigating environmental and health impacts; at the same time, this has resulted in the loss of FR efficacy. This challenge has prompted research into new techniques and materials (as shown in Table 4) to either improve or replace fluorocarbon-based compounds [98].

Ceria et al. used atmospheric plasma treatment as a preliminary step to improve the durability of the conventional pad-dry-cure finishing method for acrylic fabrics. The finish consisted of a mixture of perfluoroalkyl acrylate copolymer emulsion and methoxymethyl melamine resin as a crosslinking agent. They found that the plasma-treated samples performed better than the untreated samples in maintaining their water repellency property after 50 washing cycles. Initially, both the treated and untreated samples achieved a water repellency grade of 8, but this decreased to 4.5 for the untreated and 6.5 for the treated samples after repeated washing [99].

Li et al. proposed a one-step fluorine-free method to fabricate waterproof and breathable fabrics. First, PAN and blocked isocyanate prepolymer (BIP) were combined using an electrospinning technique, which allows the manufacturing of fibrous membranes with controllable fine fibre diameter, stacking density, and ease of surface modification. Following the production of the fabrics, they were dip-coated with a hydroxyl acrylic resin (HAR) emulsion, and their water repellency was evaluated. Optimal results were obtained when the PAN/BIP fibrous membranes were coated with two percent of HAR. Initially, the PAN/BIP membranes had a water contact angle of about 60°, which increased to 151° (indicating high hydrophobicity) post-coating. Furthermore, the PAN/BIP membranes with two percent of HAR also demonstrated a tensile strength of 12.3 MPa, a waterproofness of 112.5 kPa, and a water vapour transmission of 12.7 kg m−2 d−1, performance levels comparable to those of high-end fluorinated finishes [100].

Table 4.

The effectiveness of different water repellency methods on acrylic-based textiles.

Table 4.

The effectiveness of different water repellency methods on acrylic-based textiles.

| Author | Materials/Method | Amount | Final Contact Angle | Water Vapour Transmittance (kg m−2 d−1) | Hydrostatic Pressure (kPa) | Ref. |

|---|---|---|---|---|---|---|

| Li et al. | Blocked isocyanate prepolymer (BIP) and fluorine-free waterborne hydroxyl acrylic resin (HAR) | 2 wt.% of BIP and 2% of HAR | 151° | 12.7 | 112.5 | [100] |

| Wang et al. | Polyurethane (PU) and silicon dioxide nanoparticles (SiO2) | 50 wt.% of SiO2 | 151.2° | 10.8 | 85.7 | [101] |

| Zhang et al. | Amino functional modified polysiloxane (AMP) and 4, 4′-methyl diphenylene diisocyanate (MDI) | 1 wt.% of AMP and 2 wt.% of MDI | 139.2° | 4.7 | 93.8 | [102] |

| Gu et al. | Polyvinylidene fluoride (PVDF) | 3 wt.% | 137° | 4.65 | 18.04 | [103] |

| Yu et al. | PU and SiO2 nanoparticles | 3 wt.% of SiO2 | 137.2° | 10.3 | - | [104] |

| Liu et al. | (3-aminopropyl) triethoxysilane (APS) and hexadecyltrimethoxysilane (HDTMS) | 10 wt.% of APS | 150.1° | 3.92 | - | [105] |

2.5. UV Protection

UV radiation is non-ionising radiation emitted by the sun and artificial sources, such as UV lamps. UV radiation can be divided into three types: UV-A (320–400 nm), UV-B (290–320 nm), and UV-C (200–290 nm), but the latter does not reach Earth [106]. While moderate UV light exposure has shown health benefits, such as being partly responsible for producing vitamin D in organisms, prolonged exposure can lead to skin cancer. Therefore, developing textiles with UV protection offers a valuable means to shield human skin from excessive exposure to UV-A and UV-B rays, minimising the potential for skin damage [107,108].

Titanium dioxide is widely used to add UV-blocking properties to acrylic fibre (Table 5). It is very attractive for the functionalisation of textiles due to its chemical stability at high temperatures, nontoxicity, and permanent stability under UV light [109]. Accordingly, Nazari et al. evaluated the performance of acrylic fabrics coated in a solution of TiO2 nanoparticles and polysiloxane. The optimal concentration of TiO2 and polysiloxane was defined as 0.68% and 2.19%, respectively. The acrylic fabrics treated with nano TiO2/polysiloxane not only absorbed light with a wavelength lower than 400 nm, but their self-cleaning and soft handling properties were also enhanced [110].

Silver, commonly used to add antimicrobial properties, can also provide UV protection to treated fabrics (Table 5) [111]. Hassan et al. produced multifunctional acrylic fibres by coating them with Ag particles at varying concentrations. It was observed that UV protection increased according to the Ag concentration. When three percent of Ag was applied, the UV transmission through the fabric reduced from 17.72% (undyed acrylic yarns) to 0.6%, a 97% decrease. Furthermore, the fabrics also showed good antistatic and antimicrobial properties [107].

El Gabry et al. employed eco-friendly methods to functionalise acrylic fibres for UV protection, moisture retention, and air permeability. They employed the pad-dry-cure technique using sodium polyacrylate/bentonite nanocomposites to modify the fibres. Thereafter, nanoclays, such as nano bentonite and its nanocomposites, were used as a coating. This treatment boosted the ultraviolet protection factor (UPF) from 9 to 36, a substantial increase, indicating excellent protection against UVA and UVB rays. The authors suggested that the bentonite nanocomposite acted as a barrier, blocking UV radiation from penetrating the fabric [29]. Singh A. and Sheikh J. evaluated the usage of ethyl anthranilate to create a dye for acrylic textiles to add UV protection and mosquito repellency. The fabrics dyed with 3 wt.% of ethyl anthranilate had an increase of 1358% in their UV protection (from 18.72 to 272.95) while showing a mosquito repellency of 97.67% [112].

Table 5.

Types of materials and their influence on UPF and UV protection.

Table 5.

Types of materials and their influence on UPF and UV protection.

| Author | Material | Amount (%) | UPF | UV Protection Improvement (%) | Ref. |

|---|---|---|---|---|---|

| Hassan et al. | Silver nanoparticles | 3 | - | 94.8 | [107] |

| El Gabry et al. | Sodium polyacrylate/bentonite nanocomposite | - | 36 | 300 | [29] |

| Rehan et al. | Silver nanoparticles | 0.05 | 541 | 1400 | [68] |

| Jiang et al. | Titanium dioxide (TiO2) nanoparticles | 10 | 175 | - | [113] |

| Koozekonan et al. | Titanium dioxide nanoparticles | 15 | 133 | 1425 | [114] |

| Carbon nanotubes (CNT) | 10 | 48 | 450 | ||

| TiO2 with CNT | 15 | 685 | 7755 | ||

| Nasouri et al. | Multi-walled carbon nanotubes (MWCNTs) | 10 | 677 | - | [115] |

3. Recent Technologies in Acrylic Textile Finishing

This section explores the advancements in acrylic textile finishing and focuses on plasma treatment, sol-gel techniques, and bio-based finishes. These technologies not only improve fabric performance but also help the textile industry shift towards more sustainable and environmentally friendly practices.

3.1. Plasma Treatment

Plasma technology offers a dry, solvent-free, environmentally friendly, and worker-safe alternative for modifying the surface of textiles and requires minimal energy and time [116]. Unlike other textile processes, plasma modification is limited to the first atomic layers of the fibre surface and does not change the properties of the whole fibre. Atmospheric cold plasmas are usually used for textile finishing processes, as most of them are sensitive to heat [117]. Additionally, as it is more environmentally friendly than other traditional methods and is driven by new technological advancements, its adoption has been growing in recent years [118,119].

Plasma is a mixture of activated ionised gases used to modify the surface and coating of textiles [117]. It utilises a variety of gases, including polymerisable, non-polymerisable, and chemically inert types, such as nitrogen (N2), argon (Ar), and helium (He), to induce a range of properties in textiles. These include surface activation, oxidation, modification of surface energy, coatings, alteration of roughness, and the creation of micro/nanostructures [116].

Plasma treatment has been demonstrated to be an effective method to enhance the water repellent properties of acrylic fibres [99,120] and improve the dyeability of natural dyes [121]. In the first case, Pane S. et al. developed a viable method for cleaning and coating fabric surfaces, achieving outcomes comparable to those of traditional approaches [120]. Moreover, the process was also able to improve the durability of fluorocarbon finishes over long washing cycles [99]. In the second case, Haji A. et al. used plasma treatment to improve the dyeability of acrylic fabrics by grafting amide and carboxyl groups onto their surface. The introduction of these polar groups increased moisture penetration, reduced the fibre contact angle, and enhanced the surface energy and surface roughness [121].

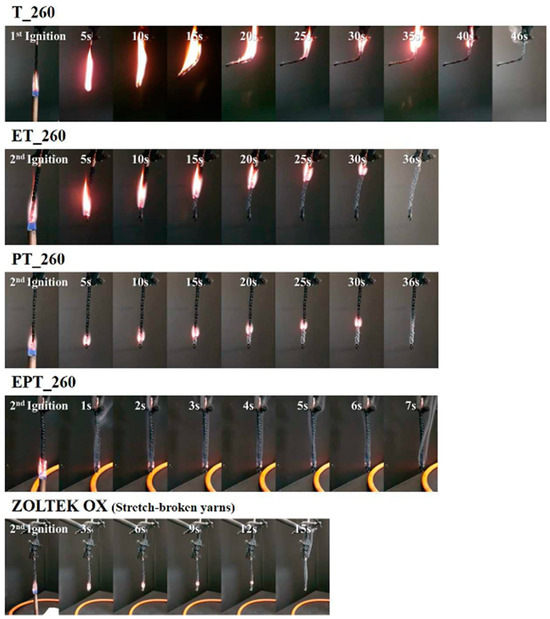

Another application where plasma treatment has shown promising results is in enhancing the flame retardancy of PAN fibres. Kil H. and Lee S. demonstrated that plasma-assisted thermal stabilisation in combination with electron-beam irradiation can significantly improve the flame retardancy of PAN fibres. According to their results, the sample stabilised for 60 min (EPT_260) showed the best performance, with an LOI value of 50.9%. Furthermore, compared to the precursor PAN, the PHRR and THR of neat PAN (T_260) and EPT_260 dropped from 588 to 143 and 52 kW/m2, and from 35.4 to 16.9 and 7.3 MJ/m2, respectively. These results indicate a substantial enhancement in the flame-retardant properties, as shown in Figure 4 [122].

Figure 4.

Combustion processes of T_260, ET_260, PT_260, EPT_260, and ZOLTEK OX during the UL 94 vertical burning test at different times. Reproduced under the terms of the Creative Commons CC BY-NC-ND 4.0 license. Copyright 2019, the Authors [122]. Published by Elsevier.

3.2. Sol-Gel

Sol-gel technology is another important system for functionalising textile materials, due to its cost-effectiveness, efficiency, reduced chemical usage, functional versatility, chemical stability, and minimal environmental impact [123]. The technology consists of creating an inorganic network through the formation of a colloidal suspension (sol) and a gelation process in a continuous liquid phase (gel) [124]. The resulting sol-gel solution is applied to the fabric and then heat-treated, forming a durable coating that can be combined with various organic and inorganic components [125].

The production of a sol-gel solution begins with the selection of suitable precursors in water or water-miscible organic solvents, such as ethanol or propanol. Subsequently, condensation reactions commence between the precursors, leading to the formation of an inorganic network [124]. When applied to textile substrates, the colloidal particles in the solution condense and aggregate, forming a wet layer that, upon evaporation of the solvent, leaves behind a ceramic film. The characteristics and mechanical properties of this film are greatly influenced by the parameters of the sol-gel process [124]. In recent years, sol-gel technology has become one of the most important types of chemical finishing, with the increased demand for innovative and environmentally friendly fabrics [123]. The method has been used to produce textiles with various properties, such as flame retardance, water repellency, self-cleaning, UV protection, and antibacterial activity. In the case of acrylic textiles, sol-gel has shown promising results in a range of applications [125].

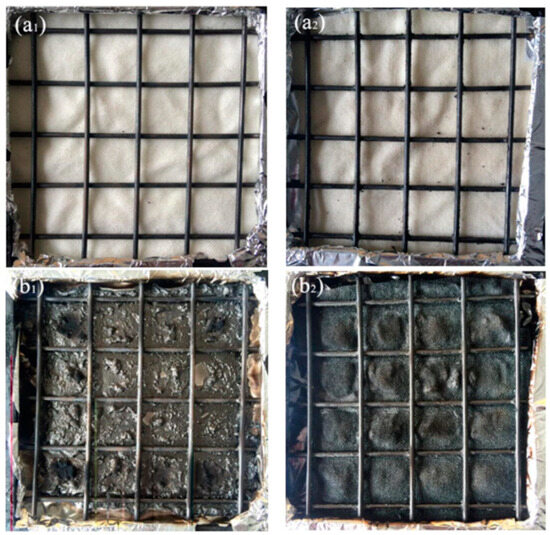

Ren et al. investigated the FR finishing of PAN based on sol-gel technology. They first prepared a cationic silicon hydrogel solution using 3-aminopropyltriethoxysilane as a precursor and nitrogen source. Then, an anionic solution was prepared from phytic acid, which acted as the phosphorus source. The PAN fabrics were coated by alternating (10 times) silicon hydrogel and phytic acid solution and then dried in a vacuum oven at 60 °C for 30 min, followed by curing in the oven at 160 °C for 5 min. Their results showed that the coated fabrics possessed a LOI of 94% higher than the non-treated fabrics (increasing from 17 to 33). Moreover, as shown in Figure 5, after ignition, the FR-PAN formed a continuous and dense char layer across the fabric, which acted as an insulator blocking the transfer of heat and oxygen to the fabric, thereby preventing further combustion of the PAN fabrics [126]. Ying et al. tested the usage of tetraethyl orthosilicate (TEOS) to develop efficient oil-in-water emulsion membranes. To do this, PAN membranes, prepared via electrospinning, were coated with a TEOS-based silica sol-gel. To promote the condensation reaction, NH4OH was used. The PAN membranes were highly efficient for emulsion separation. For the toluene oil-in-water emulsion, the membranes achieved a 99.50% separation efficiency, while for the n-heptane, paraffin liquid, n-hexane, and xylene oil-in-water emulsion, the efficiency exceeded 99.68% [127].

Figure 5.

The digital photographs of the fabrics before and after CC testing. (a1) PAN fabric; (a2) FR-PAN fabric; (b1) PAN fabric after burning; (b2) FR-PAN fabric after burning. Reproduced under the terms of the Creative Commons CC BY 4.0 license. Copyright 2018, the Authors [126]. Published by MDPI, Basel, Switzerland.

3.3. Bio-Based Finishings

Bio-based polymers, which are derived from renewable sources, such as plants, microorganisms, fungi, and algae, have been gaining attention for their potential to reduce waste and dependence on non-renewable resources [128]. While the production of textiles from biopolymers is established, particularly in fabrics combining natural and synthetic fibres, the integration of bio-based and biodegradable materials into textile finishes is still being developed. Therefore, there is a high demand for bio-based and/or biodegradable finishing development [128].

Chitosan is a bio-based and biodegradable polymer with promising dye adsorption properties. It is derived from chitin, which is the second most abundant biopolymer on earth, and obtained from fungi, insects, and fishery waste [129]. Lou et al. explored the use of chitosan to improve the dyeability of Acid Blue 113 in PAN fibres. The finishing process consisted of a two-step process: creating a nanofibrous PAN mat via electrospinning and then immersing it in a chitosan solution, followed by 1 h in a vacuum to achieve a uniform coating. Using this process, chitosan homogeneously adhered to the PAN nanofibres, improving their hydrophilicity. The hydrophilicity improvement resulted in better dye adsorption, where the samples coated with chitosan achieved the maximal adsorption capacity of Acid Blue 113 (1708 mg/g) [130].

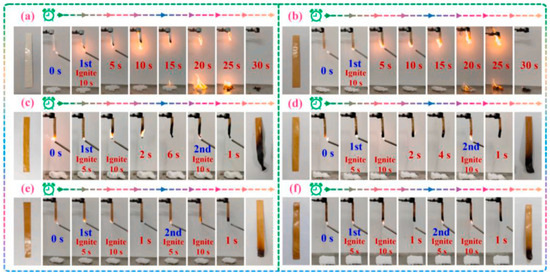

Other types of biomaterials were explored in the PAN fibres. For instance, Zou et al. tried to enhance the FR of PAN fibres by immersing them in an ammonium phytate solution and subsequently subjecting them to a thermal oxidation process. According to the results, fibres with a 5.4% weight gain had a significant improvement in their LOI, which increased from 17.0% to 36.6%. In addition, there was a substantial reduction in the total heat release and heat release capacity by 46.8% and 52.7%, respectively. Finally, it was also observed that even after undergoing 50 cycles of laundering, the LOI value of the treated fibres remained impressively high, at 30.5%, showcasing their superior washing durability [91]. In another work by the same research group, Guo et al. used lignin, casein, and phytic acid to improve the FR of the PAN fibres. Fibres treated with 10 wt.% (FR-PAN-10) and 12 wt.% (FR-PAN-12) of phytic acid demonstrated outstanding self-exhaustion properties (as shown by Figure 6), where the 12 wt.% samples had a 91.18% LOI increase (from 17% to 32.5%). Moreover, the modified PAN fibres also exhibited a remarkable reduction in both the peak heat release rate and the smoke production rate by 71.4% and 64.8%, respectively, demonstrating exceptional flame resistance and smoke suppression capabilities [131].

Figure 6.

UL-94 test photos of PAN (a), L/C/PAN (b), FR-PAN-5 (c), FR-PAN-8 (d), FR-PAN-10 (e), and FR-PAN-12 (f). Reproduced under the terms of the Creative Commons CC BY-NC-ND 4.0 license. Copyright 2023, the Authors [131]. Published by Elsevier.

3.4. Grafting

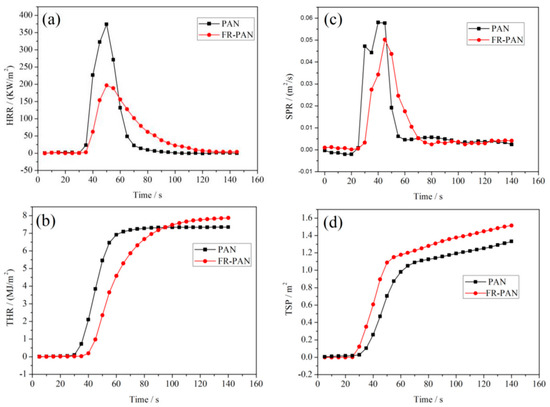

The surface modification of PAN fibres through grafting techniques has been continuously explored as an interesting method to introduce different properties to them [132,133]. The process is usually performed by UV, since it is affordable, simple, and results in minimal to non-existent damage to the material structure [132]. For instance, Ren et al. used UV light to graft modified glycidyl methacrylate (GMA) into PAN fabrics in order to improve their fire resistance. They found that the treated fabrics had a 38.4% reduction in the total heat release (THR) rate and a 60.2% decrease in the peak heat release rate (PHRR). Furthermore, the treated fabrics achieved an LOI of 32.3%, remaining at 29.3% after 30 washing cycles [90]. In another work by the same research group, PAN fabrics were grafted with GMA and chitosan. As shown in Figure 7, both the THR and the PHRR of the FR-PAN fibres demonstrated a reduction of 18.6% and 47.4%, respectively, when compared with the control samples. Moreover, the time to ignite increased by 36%, and the fire growth rate index decreased by 28.6%, indicating an enhancement in fire safety. Overall, the UV-induced graft coating provided the PAN fabrics with excellent flame resistance [134]. Liu et al. used UV radiation to graft GMA into the PAN chemical structure and then reacted with L-arginine (Agr) to add fire-resistance properties to it. Compared with neat PAN fibres, the PAN-g-GMA/Agr showed 51.6% of residual charts at 800 °C, and the PHHR and THR were significantly reduced by 36.3% and 8.1%, respectively, indicating an improvement in thermal stability. Furthermore, the grafted fabrics also showed a 53.6% increase in elongation at break and an LOI of 34.7%. The latter remained at 27% after 40 washing cycles, indicating excellent durability [135].

Figure 7.

HRR (a), THR (b), SPR (c), and TSP (d) curves of PAN and FR-PAN fabrics. Reproduced under the terms of the Creative Commons CC BY 4.0 license. Copyright 2019, the Authors [134]. Published by MDPI, Basel, Switzerland.

Using a different approach, Basuoni et al. used keratin to graft PAN fibres in order to improve a range of properties. The treated fibres demonstrated superior wettability, anti-static characteristics, and enhanced UV resistance compared to the non-treated fibres, all without compromising the strength of the fabric. Additionally, the final product maintained its washing durability, withstanding up to 20 cycles [136]. Wang et al. used L-cystine as a coupling agent to graft casein or collagen into the PAN structure to improve its ability to retain moisture. Their results showed that the modified fibres substantially increased moisture retention, increasing from 2.01% (neat PAN) to 6.08% with casein and 6.31% with collagen [137].

3.5. Carbonisation

Carbon fibres, known for their light weight, superior strength and modulus, and exceptional heat resistance, have been used as a reinforcement material across various sectors, including aerospace, automotive industries, and civil engineering [138]. PAN is the primary precursor for producing high-performance carbon fibres, accounting for nearly 90% of the global market share [139].

The transformation of PAN into carbon fibres is a thermal process involving three main steps: oxidative stabilisation, high-temperature carbonisation, and graphitisation. The initial stage, oxidative stabilisation, generally takes place at lower temperatures (200–300 °C) in an air setting. This stage forms a ladder-like structure, stabilising the precursor for higher-temperature processing. Afterwards, during the carbonisation stage, the fibres are subjected to heat in a nitrogen atmosphere up to 1600 °C. This process eliminates noncarbon atoms like hydrogen, nitrogen, and oxygen. Lastly, the fibres undergo graphitisation, where they are further heated (up to 2000 °C) in an inert atmosphere. This final stage improves the orientation of the basal planes and enhances the stiffness of the fibres [140].

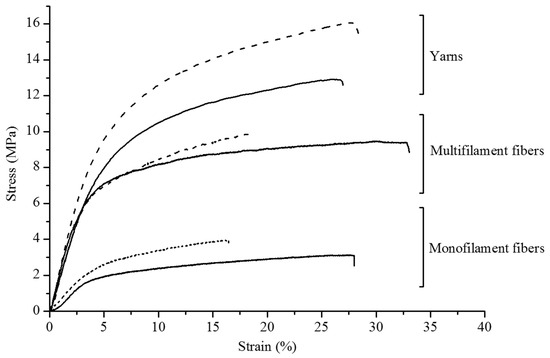

A great deal of research has been conducted with the aim of improving the carbonisation of PAN fibres. Liu et al. developed a new precursor for PAN-based carbon fibres using 2-acrylamido-2-methylpropane acid (AMPS) and itaconic acid as the control. The P(AN-co-AMPS) nanofibres required less activation energy for cyclisation (Ea1 = 26.6 kcal/mol and Ea2 = 27.5 kcal/mol), and the carbon nanofibres derived from them showed a better graphite-like structure [138]. In another work, Xu et al. combined PAN with 1 wt.% of cellulose nanofibres (CNFs) through electrospinning and evaluated the carbonisation process. Their results indicated that the addition of CNFs enhanced the tensile strength and electrical conductivity of the PAN carbon nanofiber membrane. Furthermore, the presence of CNFs accelerated the carbonisation process and reduced the reaction requirements of the PAN nanofiber membranes [141]. Sayyar S et al. developed graphene/PAN-based fibres in the forms of monofilaments, multifilaments, and yarns using a wet-spinning technique. After that, the fibres were oxidised and carbonised at 900 °C to produce various types of carbon fibre samples (PANb-CCG). Their results showed that the addition of ~0.5 wt.% of graphene could increase the tensile strength and Young’s modulus of the PANb-CCG fibres by ~28% and ~20%, respectively. The improvement was more evident in multifilament and monofilament fibres (Figure 8), where the graphene could act as crosslinking points, helping to distribute stress uniformly throughout the fibres [22]. Sabantina et al. added varied concentrations of TiO2 nanoparticles into PAN fibres before carbonisation in order to apply carbon fibres to batteries or dye-sensitised solar cells. The final samples exhibited a fascinating pattern, whereby after electrospinning, a bead-like cluster structure of TiO2 was formed and became increasingly apparent along the fibres following stabilisation, especially after carbonisation. Moreover, greater concentrations of TiO2 appeared to reinforce the sample structure during the stabilisation process [142].

Figure 8.

Stress–strain curves of PANb (solid) and PANb-CCG (dashed) fibres and yarns. Reproduced under the terms of the Creative Commons CC BY-NC-ND 4.0 license. Copyright 2019, the Authors [22]. Published by Willey.

3.6. Dyeing Process

Dyes have been used by mankind for thousands of years, serving as essential materials in various aspects of life. From ancient times to the present day, the knowledge and application of dyes have evolved significantly. In terms of chemical structure, dyes can be classified as either organic or inorganic, where both categories can be further subdivided into natural or synthetic [143].

In the case of acrylic fibres, homo-PAN is highly resistant to dyeing due to its homopolymer’s dense structure and elevated glass transition temperature. The acrylic fibres with one or more comonomers instead are easier to dye, since these monomers reduce the structural regularity of the homopolymers, which reduces both the heat and solvent resistance and increases the fibres’ termoplasticity [144].

One way to dye acrylic fibres is through the use of disperse dyes. Disperse dyes are applied to acrylic fibres in the pH range between 3.5 and 6, usually in the presence of a levelling agent using dyeing procedures. Individual disperse dyes exhibit wide variations in dye uptake, with some providing much deeper and more brilliant shades, particularly through transfer printing techniques. Unfortunately, under normal dyeing conditions, disperse dyes are only suitable for achieving pale to medium shades. Better exhaustion can be achieved at higher temperatures, but 110 °C should be considered the maximum temperature due to the risk of excessive shrinkage in acrylic fibres at higher temperatures [144].

The presence of cyanide and acidic groups in the PAN structure can make them highly receptive to cationic dyes, due to their highly electronegative charge. When these fibres are immersed in a cationic dye bath, the dyes quickly bind to the anionic groups on the fibre surface. However, the dyeing process happens so fast that it often results in uneven dye distribution [145]. Typically, this issue is addressed by increasing the dye bath temperature or by adding surfactants, such as levelling agents. However, the addition of levelling agents (which increases wastewater discharge) and the rise in temperature makes the dyeing procedure less sustainable [146].

Trying to make the dyeing process more sustainable, Popescu et al. investigated the use of potassium hydroxide (KOH) and iodine-potassium iodide (I2/KI) to functionalise polyacrylonitrile (PAN) fibres and improve their tinctorial capacity. According to their results, KOH provided the necessary alkaline conditions for the functionalisation reactions to occur and increased the reactivity of the PAN fibres, facilitating the incorporation of new functional groups. Additionally, when combined with the I2/KI solution, it enabled the formation of iodine-oxime and iodinehydrin groups within the fibres, as shown by Figure 9. This process improved the dyeing properties of PAN fibres, allowing them to bond with a broader range of dyes, including acid dyes, such as C.I. Acid Red 57 and C.I. Acid Violet 48 [146]. Using a different approach, El Gabry et al. enhanced the transfer printability of acrylic fibres by treating them with sodium hydroxide, sodium polyacrylate, and bentonite nanocomposites. The acrylic fibres treated with sodium polyacrylate and sodium polyacrylate/bentonite nanocomposites showed higher colour intensity values than the untreated ones. According to the authors, the absorption improvement was due to the decrease in air permeability, which improved the absorption of the C.I. Disperse Red 60 dye vapours. Moreover, the nanobentonite addition also increased the fastness properties (washing, perspiration, and rubbing) of the acrylic fibres [29].

Figure 9.

Polyacrylonitrile functionalised with iodine-oxime groups. Reproduced under the terms of the Creative Commons CC BY 4.0 license. Copyright 2021, the Authors [147]. Published by MDPI, Basel, Switzerland.

Dyes can also be used to give antimicrobial properties to acrylic fibres. Ma et al. utilised an exhaustion dyeing process to incorporate cationic dyes, composed of sodium sulphate and Triton X-100, into spun Orlan 75 (sulfonate-containing acrylic fabrics). The resulting treated fabrics demonstrated 99.9% effectiveness against E. coli and S. aureus proliferation before washing. However, the antibacterial efficacy diminished after 10 washing cycles, dropping to 45.5% [148]. Similarly, Abedi et al. explored a different dye composition by incorporating CI Direct Blue 168 with copper sulphate as a mordanting agent. The dyeing process consisted of three steps: pre-mordanting, dyeing, and post-mordanting. The pre and post samples with one percent and two percent of copper sulphate, respectively, exhibited the best antimicrobial activities, retaining an average efficacy of 96% even after eight washing cycles. Additionally, these fabrics showed minimal colour fading upon washing, showing the resilience of the dye solution [149]. Mehrizi et al. evaluated the antimicrobial performance of other dyes functionalised with copper and zinc sulphates, such as CI Direct Yellow 12, CI Direct Red 23, CI Direct Red 31, and CI Direct Black 38. The effectiveness of these fabrics varied significantly based on the chemical structure of the dyes. Notably, CI Direct Yellow 12 achieved the highest antimicrobial activity as well as good properties such as high molecular weight, washing fastness, linear structure, and ionic sulfonate groups [150].

4. Conclusions and Future Prospects

Acrylic-based fabrics are used in several applications due to their wool-like feeling and well-defined properties. Furthermore, through a range of processes, these fabrics can have their chemical structure modified, including the addition of new properties. However, many of the chemical substances used to perform these modifications have been banned because of their toxicity and health risks. Therefore, there has been a great deal of research and development into new sustainable materials.

Sol-gel and grafting technology are proving to be effective methods for substituting halogenated and formaldehyde-based products for flame-resistant finishing products. Using this method, some authors have achieved a substantial increase in the LOI values of their textile samples while maintaining their FR properties after various washing cycles. Another approach with promising results is the use of bio-based materials, such as chitosan, PVA, and hydrazine hydrate, with cases showing improvement in both the flame resistance and mechanical properties of the fibres.

In the case of water repellency, much effort has been made to substitute fluorocarbon-based compounds, especially PFOS and PFOA. Plasma treatment has been attracting significant attention as a new method to add water repellency properties to fabrics. Pre (cleaning) and post (fixing) treatments have been shown to improve the efficacy and durability of water-repellent coatings, with some results showing similarities with those of fabrics treated with traditional techniques.

Many types of fillers, such as silver, titanium, and carbon nanotubes, have demonstrably provided good UV and/or antimicrobial protection. For instance, some studies have shown that silver nanoparticles not only provide protection against E. coli and S. aureus (in some cases exceeding 90%) but are also able to significantly improve the UPF factor of PAN fabrics. Other particles, such as TiO2 and carbon nanotubes, have also exhibited promising results in terms of improving PAN UV protection, exceeding 100% in some cases. Nevertheless, other properties of such particles, such as conductivity, photocatalysis, and self-cleaning, are yet to be fully explored.

Moreover, thanks to a systematic investigation into the stabilisation and carbonisation of textile-grade PAN fibres, carbon fibres prepared from textile-grade PAN fibres were found to be comparable with those of commercial PAN fibres. Thus, PAN precursors from textiles could be an alternative for low-cost carbon fibre production, and this process could represent an interesting up-cycling option in the future.

Although finishing methods for acrylic textiles are becoming eco-friendly and more efficient, there is still a great deal of research to be done into alternatives to reduce the impact of these fibres, which are derived from petroleum. Furthermore, most acrylic fibres have not been recycled due to difficulties relating to the removal of contaminants from the textile. Therefore, more research needs to be done to remove chemicals from acrylic fabrics in order to break down the hazardous chemicals used during textile finishing into non-toxic substances, thereby promoting recycling.

Author Contributions

All the authors have contributed equally to this work. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Exchange Textile Materials Market Report. Available online: https://textileexchange.org/knowledge-center/reports/materials-market-report-2023/ (accessed on 11 July 2024).

- Masson, J. (Ed.) Acrylic Fiber Technology and Applications; CRC Press: Boca Raton, FL, USA, 1995; ISBN 9780429189913. [Google Scholar]

- Gojic, A.; Bukhonka, N. Recycled Textile Fibers and Materials—Current State and Development Perspectives. In Proceedings of the ICPAE, Zrenjanin, Serbia, 24–26 August 2023; pp. 95–100. [Google Scholar]

- Kaitwade, N. Acrylic Fibre Market Outlook (2023 to 2033). Available online: https://www.futuremarketinsights.com/reports/acrylic-fibre-market (accessed on 10 May 2024).

- Muthu, S.S. Introduction to Sustainability and the Textile Supply Chain and Its Environmental Impact. In Assessing the Environmental Impact of Textiles and the Clothing Supply Chain; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–32. [Google Scholar]

- Seddik, K.M.; El-Gabry, L.K.; Ali, M.A. Improving Some Functional Utility Properties of Garment Using Cross-Linked Acrylic Fabrics. Res. J. Text. Appar. 2023, in press. [Google Scholar] [CrossRef]

- Mather, R.R. Synthetic Textile Fibres. In Textiles and Fashion; Elsevier: Amsterdam, The Netherlands, 2015; pp. 115–138. [Google Scholar]

- Danish, A.; Ozbakkaloglu, T. Fiber Classifications and Physical and Mechanical Properties of Different Fibers Used in Alkali-Activated Composites. In Advanced Fiber-Reinforced Alkali-Activated Composites; Elsevier: Amsterdam, The Netherlands, 2023; pp. 23–58. [Google Scholar]

- Ghalia, M.A.; Abdelrasoul, A. Compressive and Fracture Toughness of Natural and Synthetic Fiber-Reinforced Polymer. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 123–140. [Google Scholar]

- Gupta, B.S.; Afshari, M. Polyacrylonitrile Fibers. In Handbook of Properties of Textile and Technical Fibres; Elsevier: Amsterdam, The Netherlands, 2018; pp. 545–593. [Google Scholar]

- Rebenfeld, L. Chapter VI—Fibers and Fibrous Materials. In Absorbent Technology; Chatterjee, P.K., Gupta, B.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2002; Volume 13, pp. 199–232. ISBN 0920-4083. [Google Scholar]

- Nogaj, A.; Süling, C.; Schweizer, M. Fibers, 8. Polyacrylonitrile Fibers. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Niaounakis, M. The Problem of Marine Plastic Debris. In Management of Marine Plastic Debris; Elsevier: Amsterdam, The Netherlands, 2017; pp. 1–55. [Google Scholar]

- Rudin, A.; Choi, P. Introductory Concepts and Definitions. In The Elements of Polymer Science & Engineering; Elsevier: Amsterdam, The Netherlands, 2013; pp. 1–62. ISBN 978-0-12-382178-2. [Google Scholar]

- Adegbola, T.A.; Agboola, O.; Fayomi, O.S.I. Review of Polyacrylonitrile Blends and Application in Manufacturing Technology: Recycling and Environmental Impact. Results Eng. 2020, 7, 100144. [Google Scholar] [CrossRef]

- Hesse, M.; Meier, H.; Zeeh, B. (Eds.) Spectroscopic Methods in Organic Chemistry; Georg Thieme Verlag: Stuttgart, Germany, 2008; ISBN 9783131060426. [Google Scholar]

- Mahltig, B. High-Performance Fibres—A Review of Properties and IR-Spectra. Tekstilec 2021, 64, 96–118. [Google Scholar] [CrossRef]

- Moody, V.; Needles, H.L. Major Fibers and Their Properties. In Tufted Carpet; Elsevier: Amsterdam, The Netherland, 2004; pp. 35–59. [Google Scholar]

- El-Sayed, H.; Vineis, C.; Varesano, A.; Mowafi, S.; Andrea Carletto, R.; Tonetti, C.; Abou Taleb, M. A Critique on Multi-Jet Electrospinning: State of the Art and Future Outlook. Nanotechnol. Rev. 2019, 8, 236–245. [Google Scholar] [CrossRef]

- Rohani Shirvan, A.; Nouri, A.; Sutti, A. A Perspective on the Wet Spinning Process and Its Advancements in Biomedical Sciences. Eur. Polym. J. 2022, 181, 111681. [Google Scholar] [CrossRef]

- Temesgen, S.; Rennert, M.; Tesfaye, T.; Nase, M. Review on Spinning of Biopolymer Fibers from Starch. Polymers 2021, 13, 1121. [Google Scholar] [CrossRef] [PubMed]

- Sayyar, S.; Moskowitz, J.; Fox, B.; Wiggins, J.; Wallace, G. Wet-spinning and Carbonization of Graphene/PAN-based Fibers: Toward Improving the Properties of Carbon Fibers. J. Appl. Polym. Sci. 2019, 136, 47932. [Google Scholar] [CrossRef]

- Ozipek, B.; Karakas, H. Wet Spinning of Synthetic Polymer Fibers. In Advances in Filament Yarn Spinning of Textiles and Polymers; Elsevier: Amsterdam, The Netherland, 2014; pp. 174–186. [Google Scholar]

- Choi, D.; Kil, H.-S.; Lee, S. Fabrication of Low-Cost Carbon Fibers Using Economical Precursors and Advanced Processing Technologies. Carbon N. Y. 2019, 142, 610–649. [Google Scholar] [CrossRef]

- Shang, L.; Yu, Y.; Liu, Y.; Chen, Z.; Kong, T.; Zhao, Y. Spinning and Applications of Bioinspired Fiber Systems. ACS Nano 2019, 13, 2749–2772. [Google Scholar] [CrossRef]

- Hu, J.; Jahid, M.A.; Harish Kumar, N.; Harun, V. Fundamentals of the Fibrous Materials. In Handbook of Fibrous Materials; Wiley: Hoboken, NJ, USA, 2020; pp. 1–36. [Google Scholar]

- Kim, T.; Kim, D.; Park, Y. Recent Progress in Regenerated Fibers for “Green” Textile Products. J. Clean. Prod. 2022, 376, 134226. [Google Scholar] [CrossRef]

- Imura, Y.; Hogan, R.M.C.; Jaffe, M. Dry Spinning of Synthetic Polymer Fibers. In Advances in Filament Yarn Spinning of Textiles and Polymers; Elsevier: Amsterdam, The Netherland, 2014; pp. 187–202. [Google Scholar]

- El Gabry, L.K.; Abou El-Kheir, A.A.; El-Sayad, H.S.; El-Kashouty, M.A. Ecofriendly Modification of Acrylic Fabrics for Enhanced Transfer Printability. Fibers Polym. 2021, 22, 421–429. [Google Scholar] [CrossRef]

- Commission, E. Recycling of Waste ACrylic Textiles (REACT) Project; European Commission: Brussels, Belgium, 2022. [Google Scholar]

- Gulati, R.; Sharma, S.; Sharma, R.K. Antimicrobial Textile: Recent Developments and Functional Perspective. Polym. Bull. 2022, 79, 5747–5771. [Google Scholar] [CrossRef] [PubMed]

- Selvasudha, N.; Sweety, J.P.; Dhanalekshmi, U.M.; Devi, N.S.D. Smart Antimicrobial Textiles for Healthcare Professionals and Individuals. In Antimicrobial Textiles from Natural Resources; Elsevier: Amsterdam, The Netherland, 2021; pp. 455–484. [Google Scholar]

- McQueen, R.H.; Ehnes, B.L. Antimicrobial Textiles and Infection Prevention—Clothes and Inanimate Environment. In Infection Prevention; Springer International Publishing: Cham, Switzerland, 2022; pp. 139–149. [Google Scholar]

- Aguda, O.N.; Lateef, A. Recent Advances in Functionalization of Nanotextiles: A Strategy to Combat Harmful Microorganisms and Emerging Pathogens in the 21st Century. Heliyon 2022, 8, e09761. [Google Scholar] [CrossRef] [PubMed]

- Atef El-Sayed, A.; El Gabry, L.K.; Allam, O.G. Application of Prepared Waterborne Polyurethane Extended with Chitosan to Impart Antibacterial Properties to Acrylic Fabrics. J. Mater. Sci. Mater. Med. 2010, 21, 507–514. [Google Scholar] [CrossRef] [PubMed]

- Fromm, K.M. Silver Coordination Compounds with Antimicrobial Properties. Appl. Organomet. Chem. 2013, 27, 683–687. [Google Scholar] [CrossRef]

- Huong, Q.T.T.; Nam, N.T.H.; Hai, N.D.; Dat, N.M.; Linh, N.T.T.; Tinh, N.T.; Chau, N.M.; Phuc, N.V.H.; Le Hoai Nhi, T.; Phong, M.T.; et al. Surface Modification and Antibacterial Activity Enhancement of Acrylic Fabric by Coating Silver/Graphene Oxide Nanocomposite. J. Polym. Res. 2023, 30, 109. [Google Scholar] [CrossRef]

- Yu, D. Characterization and Inhibitory Effect of Antibacterial PAN-Based Hollow Fiber Loaded with Silver Nitrate. J. Memb. Sci. 2003, 225, 115–123. [Google Scholar] [CrossRef]

- Allehyani, E.S.; Almulaiky, Y.Q.; Al-Harbi, S.A.; El-Shishtawy, R.M. Polydopamine-AgNPs Coated Acrylic Fabric for Antimicrobial and Antioxidant Textiles. J. Coat. Technol. Res. 2022, 20, 1133–1143. [Google Scholar] [CrossRef]

- Wang, C.; Wang, W.; Zhang, L.; Zhong, S.; Yu, D. Electrospinning of PAN/Ag NPs Nanofiber Membrane with Antibacterial Properties. J. Mater. Res. 2019, 34, 1669–1677. [Google Scholar] [CrossRef]

- Lee, J.; Broughton, R.M.; Liang, J.; Worley, S.D.; Huang, T.S. Antimicrobial Acrylic Fiber. Res. J. Text. Appar. 2006, 10, 61–66. [Google Scholar] [CrossRef]

- Okay, Z.; Erdoğan, M.K.; Karaca, B.; Karakişla, M.; Saçak, M. Investigation of Antibacterial Properties of Polyacrylonitrile Fibers Modified by New Functional Groups and Silver Nanoparticles. Turk. J. Chem. 2022, 46, 1137–1151. [Google Scholar] [CrossRef] [PubMed]

- Patel, S.; Konar, M.; Sahoo, H.; Hota, G. Surface Functionalization of Electrospun PAN Nanofibers with ZnO–Ag Heterostructure Nanoparticles: Synthesis and Antibacterial Study. Nanotechnology 2019, 30, 205704. [Google Scholar] [CrossRef] [PubMed]

- Mofidfar, M.; Kim, E.S.; Larkin, E.L.; Long, L.; Jennings, W.D.; Ahadian, S.; Ghannoum, M.A.; Wnek, G.E. Antimicrobial Activity of Silver Containing Crosslinked Poly(Acrylic Acid) Fibers. Micromachines 2019, 10, 829. [Google Scholar] [CrossRef] [PubMed]

- Chen, P.; Chai, M.; Mai, Z.; Liao, M.; Xie, X.; Lu, Z.; Zhang, W.; Zhao, H.; Dong, X.; Fu, X.; et al. Electrospinning Polyacrylonitrile (PAN) Based Nanofiberous Membranes Synergic with Plant Antibacterial Agent and Silver Nanoparticles (AgNPs) for Potential Wound Dressing. Mater. Today Commun. 2022, 31, 103336. [Google Scholar] [CrossRef]

- Sarwar, M.N.; Ullah, A.; Haider, M.K.; Hussain, N.; Ullah, S.; Hashmi, M.; Khan, M.Q.; Kim, I.S. Evaluating Antibacterial Efficacy and Biocompatibility of PAN Nanofibers Loaded with Diclofenac Sodium Salt. Polymers 2021, 13, 510. [Google Scholar] [CrossRef] [PubMed]

- Wahab, J.A.; Mamun, S. Al Polyacrylonitrile Nanofiber Mats Containing Titania/AgNP Composite Nanoparticles for Antibacterial Applications. Mater. Res. Express 2020, 7, 015416. [Google Scholar] [CrossRef]

- Stegmaier, T. Recent Advances in Textile Manufacturing Technology. In The Global Textile and Clothing Industry; Elsevier: Amsterdam, The Netherland, 2012; pp. 113–130. [Google Scholar]

- Kim, S.-C.; Son, J.S. Double-Layered Fiber for Lightweight Flexible Clothing Providing Shielding from Low-Dose Natural Radiation. Sci. Rep. 2021, 11, 3676. [Google Scholar] [CrossRef] [PubMed]

- Šafářová, V.; Militký, J. Multifunctional Metal Composite Textile Shields against Electromagnetic Radiation—Effect of Various Parameters on Electromagnetic Shielding Effectiveness. Polym. Compos. 2017, 38, 309–323. [Google Scholar] [CrossRef]

- Emaminejad, S.; Gao, W.; Wu, E.; Davies, Z.A.; Yin Yin Nyein, H.; Challa, S.; Ryan, S.P.; Fahad, H.M.; Chen, K.; Shahpar, Z.; et al. Autonomous Sweat Extraction and Analysis Applied to Cystic Fibrosis and Glucose Monitoring Using a Fully Integrated Wearable Platform. Proc. Natl. Acad. Sci. USA 2017, 114, 4625–4630. [Google Scholar] [CrossRef]

- Steinberg, C.; Philippon, F.; Sanchez, M.; Fortier-Poisson, P.; O’Hara, G.; Molin, F.; Sarrazin, J.-F.; Nault, I.; Blier, L.; Roy, K.; et al. A Novel Wearable Device for Continuous Ambulatory ECG Recording: Proof of Concept and Assessment of Signal Quality. Biosensors 2019, 9, 17. [Google Scholar] [CrossRef]

- Gao, W.; Brooks, G.A.; Klonoff, D.C. Wearable Physiological Systems and Technologies for Metabolic Monitoring. J. Appl. Physiol. 2018, 124, 548–556. [Google Scholar] [CrossRef] [PubMed]

- Kario, K. Management of Hypertension in the Digital Era. Hypertension 2020, 76, 640–650. [Google Scholar] [CrossRef] [PubMed]

- Bi, S.; Hou, L.; Lu, Y. An Integrated Wearable Strain, Temperature and Humidity Sensor for Multifunctional Monitoring. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106504. [Google Scholar] [CrossRef]

- Ilén, E.; Elsehrawy, F.; Palovuori, E.; Halme, J. Washable Textile Embedded Solar Cells for Self-Powered Wearables. Res. J. Text. Appar. 2024, 28, 133–151. [Google Scholar] [CrossRef]

- Fernández-Caramés, T.; Fraga-Lamas, P. Towards The Internet-of-Smart-Clothing: A Review on IoT Wearables and Garments for Creating Intelligent Connected E-Textiles. Electronics 2018, 7, 405. [Google Scholar] [CrossRef]

- Sundriyal, P.; Bhattacharya, S. Textile-Based Supercapacitors for Flexible and Wearable Electronic Applications. Sci. Rep. 2020, 10, 13259. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, M.M.; Ahuja, K. E-Textiles: A Revolutionary Technology. Int. J. Syst. Assur. Eng. Manag. 2023, 14, 2031–2047. [Google Scholar] [CrossRef]

- Maity, S.; Singha, K.; Pandit, P. Advanced Applications of Green Materials in Wearable E-Textiles. In Applications of Advanced Green Materials; Elsevier: Amsterdam, The Netherland, 2021; pp. 239–263. [Google Scholar]

- Ruckdashel, R.R.; Khadse, N.; Park, J.H. Smart E-Textiles: Overview of Components and Outlook. Sensors 2022, 22, 6055. [Google Scholar] [CrossRef] [PubMed]

- Singha, K.; Kumar, J.; Pandit, P. Recent Advancements in Wearable & Smart Textiles: An Overview. Mater. Today Proc. 2019, 16, 1518–1523. [Google Scholar] [CrossRef]

- Ismar, E.; Kurşun Bahadir, S.; Kalaoglu, F.; Koncar, V. Futuristic Clothes: Electronic Textiles and Wearable Technologies. Glob. Chall. 2020, 4, 1900092. [Google Scholar] [CrossRef]

- Younes, B. Smart E-Textiles: A Review of Their Aspects and Applications. J. Ind. Text. 2023, 53, 15280837231215493. [Google Scholar] [CrossRef]

- Baseri, S.; Zadhoush, A.; Morshed, M.; Amirnasr, M.; Azarnasab, M. Synthesis and Optimization of Copper Sulfide-coated Electrically Conducting Poly(Acrylonitrile) Fibers. J. Appl. Polym. Sci. 2007, 104, 2579–2586. [Google Scholar] [CrossRef]

- Ahn, D.; Choi, H.-J.; Kim, H.; Yeo, S.Y. Properties of Conductive Polyacrylonitrile Fibers Prepared by Using Benzoxazine Modified Carbon Black. Polymers 2020, 12, 179. [Google Scholar] [CrossRef] [PubMed]

- Kayabaşı, G.; Özen, Ö.; Yılmaz, D. A Novel Yarn Spinning Method for Fabricating Conductive and Nanofiber-Coated Hybrid Yarns. J. Ind. Text. 2022, 51, 953–976. [Google Scholar] [CrossRef]

- Rehan, M.; Nada, A.A.; Khattab, T.A.; Abdelwahed, N.A.M.; El-Kheir, A.A.A. Development of Multifunctional Polyacrylonitrile/Silver Nanocomposite Films: Antimicrobial Activity, Catalytic Activity, Electrical Conductivity, UV Protection and SERS-Active Sensor. J. Mater. Res. Technol. 2020, 9, 9380–9394. [Google Scholar] [CrossRef]

- Karbownik, I.; Rac-Rumijowska, O.; Fiedot-Toboła, M.; Rybicki, T.; Teterycz, H. The Preparation and Characterization of Polyacrylonitrile-Polyaniline (PAN/PANI) Fibers. Materials 2019, 12, 664. [Google Scholar] [CrossRef] [PubMed]

- Demiroğlu Mustafov, S.; Mohanty, A.K.; Misra, M.; Seydibeyoğlu, M.Ö. Fabrication of Conductive Lignin/PAN Carbon Nanofibers with Enhanced Graphene for the Modified Electrodes. Carbon N. Y. 2019, 147, 262–275. [Google Scholar] [CrossRef]

- Zhang, X.; Shiu, B.; Li, T.-T.; Liu, X.; Ren, H.-T.; Wang, Y.; Lou, C.-W.; Lin, J.-H. Photo-Thermoelectric Nanofiber Film Based on the Synergy of Conjugated Polymer and Light Traps for the Solar-Energy Harvesting of Textile Solar Panel. Sol. Energy Mater. Sol. Cells 2021, 232, 111353. [Google Scholar] [CrossRef]

- Deng, B.; Fang, L.; Fang, K.; Han, X.; Liang, Y. Scalable Preparation of MWCNTs/PAN Conductive Composite Fibers with Tai Chi Structure for Thermotherapy Textiles. Compos. Sci. Technol. 2023, 232, 109866. [Google Scholar] [CrossRef]

- Mukongo Mpukuta, O.; Dincer, K.; Okan Erdal, M. Investigation of Electrical Conductivity of PAN Nanofibers Containing Silica Nanoparticles Produced by Electrospinning Method. Mater. Today Proc. 2019, 18, 1927–1935. [Google Scholar] [CrossRef]

- Zhang, J.; Silcock, G.W.H.; Shields, T.J. Study of the Combustion and Fire Retardancy of Polyacrylonitrile and Its Copolymers by Using Cone Calorimetry. J. Fire Sci. 1995, 13, 141–161. [Google Scholar] [CrossRef]

- Tretsiakova-McNally, S.; Arun, M.; Guerrieri, M.; Joseph, P. An Overview of Some Reactive Routes to Flame-Retardant Fibre-Forming Polymers: Polypropylene and Polyacrylonitrile. Organics 2023, 4, 386–402. [Google Scholar] [CrossRef]

- Horrocks, A.R. Fundamentals: Flammability, Ignition, and Fire Spread in Polymers. In Analysis of Flame Retardancy in Polymer Science; Elsevier: Amsterdam, The Netherland, 2022; pp. 1–72. [Google Scholar]

- Mazumder, N.; Islam, M.T. Flame Retardant Finish for Textile Fibers. In Innovative and Emerging Technologies for Textile Dyeing and Finishing; Wiley: Hoboken, NJ, USA, 2021; pp. 373–405. [Google Scholar]

- Visakh, P.M.; Arao, Y. (Eds.) Flame Retardants; Engineering Materials; Springer International Publishing: Cham, Switzerland, 2015; ISBN 978-3-319-03466-9. [Google Scholar]

- Mahltig, B.; Grethe, T. High-Performance and Functional Fiber Materials—A Review of Properties, Scanning Electron Microscopy SEM and Electron Dispersive Spectroscopy EDS. Textiles 2022, 2, 209–251. [Google Scholar] [CrossRef]

- Kaneka Chemical Resistance The Advantages of Kanecaron®. Available online: https://www.modacrylic.com/en/about/advantage05 (accessed on 11 July 2024).

- Yusuf, M. A Review on Flame Retardant Textile Finishing: Current and Future Trends. Curr. Smart Mater. 2019, 3, 99–108. [Google Scholar] [CrossRef]

- Zhou, W.; Yan, X.; Liu, P.; Jiang, M.; Xu, J. Flame Retardant Modification of Acrylic Fiber with Hydrazine Hydrate and Sodium Ions. J. Appl. Polym. Sci. 2015, 132, 41996. [Google Scholar] [CrossRef]

- Zhou, W.; Yan, X.; Jiang, M.; Liu, P.; Xu, J. Study of Flame-Resistant Acrylic Fibers Reinforced by Poly(Vinyl Alcohol). J. Appl. Polym. Sci. 2016, 133, 43006. [Google Scholar] [CrossRef]

- Carosio, F.; Alongi, J. Flame Retardant Multilayered Coatings on Acrylic Fabrics Prepared by One-Step Deposition of Chitosan/Montmorillonite Complexes. Fibers 2018, 6, 36. [Google Scholar] [CrossRef]

- Kim, J.; You, N.-H.; Ku, B.-C. Highly Efficient Halogen-Free Flame Retardants of Thermally-Oxidized Polyacrylonitrile Copolymers Containing Bio-Derived Caffeic Acid Derivatives. Polym. Chem. 2020, 11, 6658–6669. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, Y.; Gu, Y.; Zeng, Q. Flame Retardant Polyacrylonitrile Fabrics Prepared by Organic-Inorganic Hybrid Silica Coating via Sol-Gel Technique. Prog. Org. Coat. 2017, 112, 225–233. [Google Scholar] [CrossRef]

- Yan, X.; Zhou, W.; Zhao, X.; Xu, J.; Liu, P. Preparation, Flame Retardancy and Thermal Degradation Behaviors of Polyacrylonitrile Fibers Modified with Diethylenetriamine and Zinc Ions. J. Therm. Anal. Calorim. 2016, 124, 719–728. [Google Scholar] [CrossRef]

- Dong, X.; Zhou, Q.; Li, L.; Li, Y.; Zhu, M. Flame Retardance Enhancement of Polyacrylonitrile with Dimethyl Vinylphosphonate. J. Appl. Polym. Sci. 2021, 138. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, Y.; Liu, X.; Huo, T.; Qin, Y. Preparation of Durable Flame Retardant PAN Fabrics Based on Amidoximation and Phosphorylation. Appl. Surf. Sci. 2018, 428, 395–403. [Google Scholar] [CrossRef]

- Ren, Y.; Jiang, L.; Tian, T.; Liu, X.; Han, Z. Durable Flame Retardant Polyacrylonitrile Fabric via UV-Induced Grafting Polymerization and Surface Chemical Modification. RSC Adv. 2018, 8, 41389–41396. [Google Scholar] [CrossRef]

- Zuo, C.; Guo, Y.; Jiang, L.; Yu, D.; Chen, X.; Ren, Y.; Liu, X. Fabrication of Durable Flame Retardant PAN Fibers through Bio-Based Ammonium Phytate Surface Modification and Highly Efficient Thermal Oxidation. Eur. Polym. J. 2023, 196, 112304. [Google Scholar] [CrossRef]

- John, M.J. Flammability Performance of Biocomposites. In Green Composites for Automotive Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 43–58. [Google Scholar]

- Carosio, F.; Alongi, J. Influence of Layer by Layer Coatings Containing Octapropylammonium Polyhedral Oligomeric Silsesquioxane and Ammonium Polyphosphate on the Thermal Stability and Flammability of Acrylic Fabrics. J. Anal. Appl. Pyrolysis 2016, 119, 114–123. [Google Scholar] [CrossRef]

- Schellenberger, S.; Hill, P.J.; Levenstam, O.; Gillgard, P.; Cousins, I.T.; Taylor, M.; Blackburn, R.S. Highly Fluorinated Chemicals in Functional Textiles Can Be Replaced by Re-Evaluating Liquid Repellency and End-User Requirements. J. Clean. Prod. 2019, 217, 134–143. [Google Scholar] [CrossRef]

- Kwon, J.; Jung, H.; Jung, H.; Lee, J. Micro/Nanostructured Coating for Cotton Textiles That Repel Oil, Water, and Chemical Warfare Agents. Polymers 2020, 12, 1826. [Google Scholar] [CrossRef]

- Loghin, C.; Ciobanu, L.; Ionesi, D.; Loghin, E.; Cristian, I. Introduction to Waterproof and Water Repellent Textiles. In Waterproof and Water Repellent Textiles and Clothing; Elsevier: Amsterdam, The Netherlands, 2018; pp. 3–24. [Google Scholar]

- Whittaker, M.H.; Heine, L. Toxicological and Environmental Issues Associated with Waterproofing and Water Repellent Formulations. In Waterproof and Water Repellent Textiles and Clothing; Elsevier: Amsterdam, The Netherlands, 2018; pp. 89–120. [Google Scholar]

- Mohsin, M.; Farooq, A.; Abbas, N.; Noreen, U.; Sarwar, N.; Khan, A. Environment Friendly Finishing for the Development of Oil and Water Repellent Cotton Fabric. J. Nat. Fibers 2016, 13, 261–267. [Google Scholar] [CrossRef]

- Ceria, A.; Hauser, P.J. Atmospheric Plasma Treatment to Improve Durability of a Water and Oil Repellent Finishing for Acrylic Fabrics. Surf. Coat. Technol. 2010, 204, 1535–1541. [Google Scholar] [CrossRef]

- Li, P.; Feng, Q.; Chen, L.; Zhao, J.; Lei, F.; Yu, H.; Yi, N.; Gan, F.; Han, S.; Wang, L.; et al. Environmentally Friendly, Durably Waterproof, and Highly Breathable Fibrous Fabrics Prepared by One-Step Fluorine-Free Waterborne Coating. ACS Appl. Mater. Interfaces 2022, 14, 8613–8622. [Google Scholar] [CrossRef]

- Wang, J.; Wei, C.; Yuan, Y.; Shi, Q.; Zhong, D.; Wang, X. UV-Assisted Stabilization of Superhydrophobic Nanofibrous Membranes for Waterproof, Breathable and Thermal Insulation Applications. Colloids Surf. A Physicochem. Eng. Asp. 2024, 680, 132634. [Google Scholar] [CrossRef]

- Zhang, L.; Sheng, J.; Yao, Y.; Yan, Z.; Zhai, Y.; Tang, Z.; Li, H. Fluorine-Free Hydrophobic Modification and Waterproof Breathable Properties of Electrospun Polyacrylonitrile Nanofibrous Membranes. Polymers 2022, 14, 5295. [Google Scholar] [CrossRef] [PubMed]

- Gu, J.; Quan, Z.; Wang, L.; Zhang, H.; Wang, N.; Qin, X.; Wang, R.; Yu, J. Fiber-Microsphere Binary Structured Composite Fibrous Membranes for Waterproof and Breathable Applications. Fibers Polym. 2022, 23, 1500–1509. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, F.; Liu, Y.; Zheng, Y.; Xin, B.; Jiang, Z.; Peng, X.; Jin, S. Waterproof and Breathable Polyacrylonitrile/(Polyurethane/Fluorinated-Silica) Composite Nanofiber Membrane via Side-by-Side Electrospinning. J. Mater. Res. 2020, 35, 1173–1181. [Google Scholar] [CrossRef]

- Liu, R.; Zhou, C.; Wang, Y.; Wang, H.; Li, N. In-Situ Grown SiO2 on Amino-Silane Modified Polyacrylonitrile Nanofibrous Membranes and Its Waterproof-Breathable and Light-Shielding Properties. Appl. Surf. Sci. 2024, 642, 158536. [Google Scholar] [CrossRef]

- Bashari, A.; Shakeri, M.; Shirvan, A.R. UV-Protective Textiles. In The Impact and Prospects of Green Chemistry for Textile Technology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 327–365. [Google Scholar]

- Hassan, M.M.; Koyama, K. Multifunctional Acrylic Fibers Prepared via In-Situ Formed Silver Nanoparticles: Physicochemical, UV Radiation Protection, and Antistatic Properties. Dye. Pigment. 2018, 159, 517–526. [Google Scholar] [CrossRef]