Environmental Impact of Fused Filament Fabrication: What Is Known from Life Cycle Assessment?

Abstract

1. Introduction

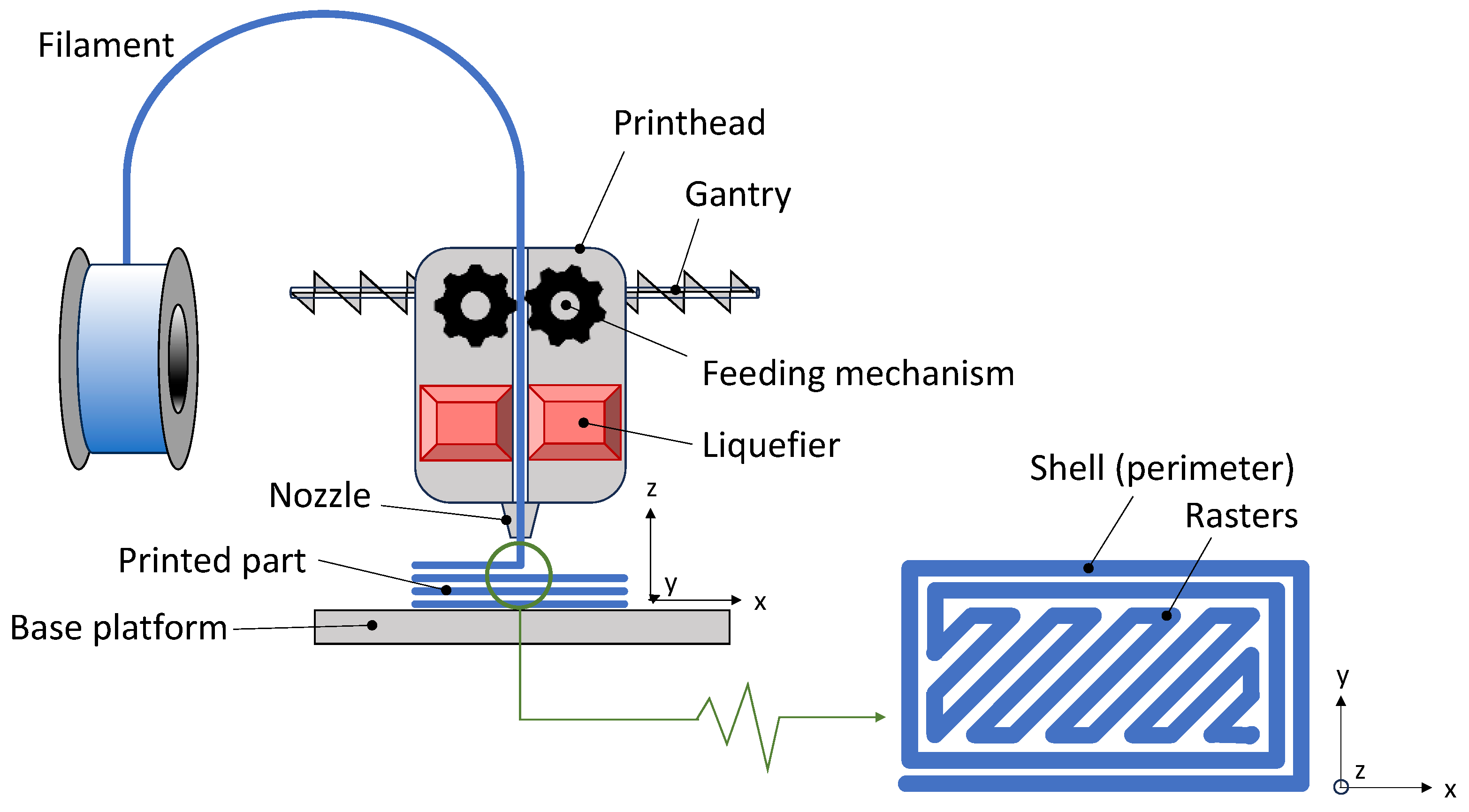

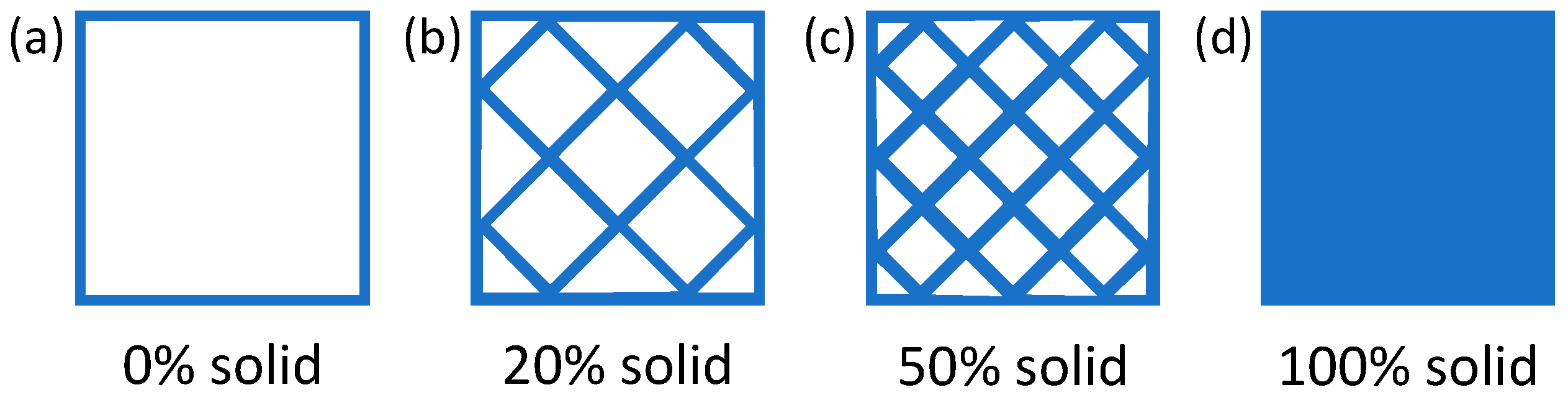

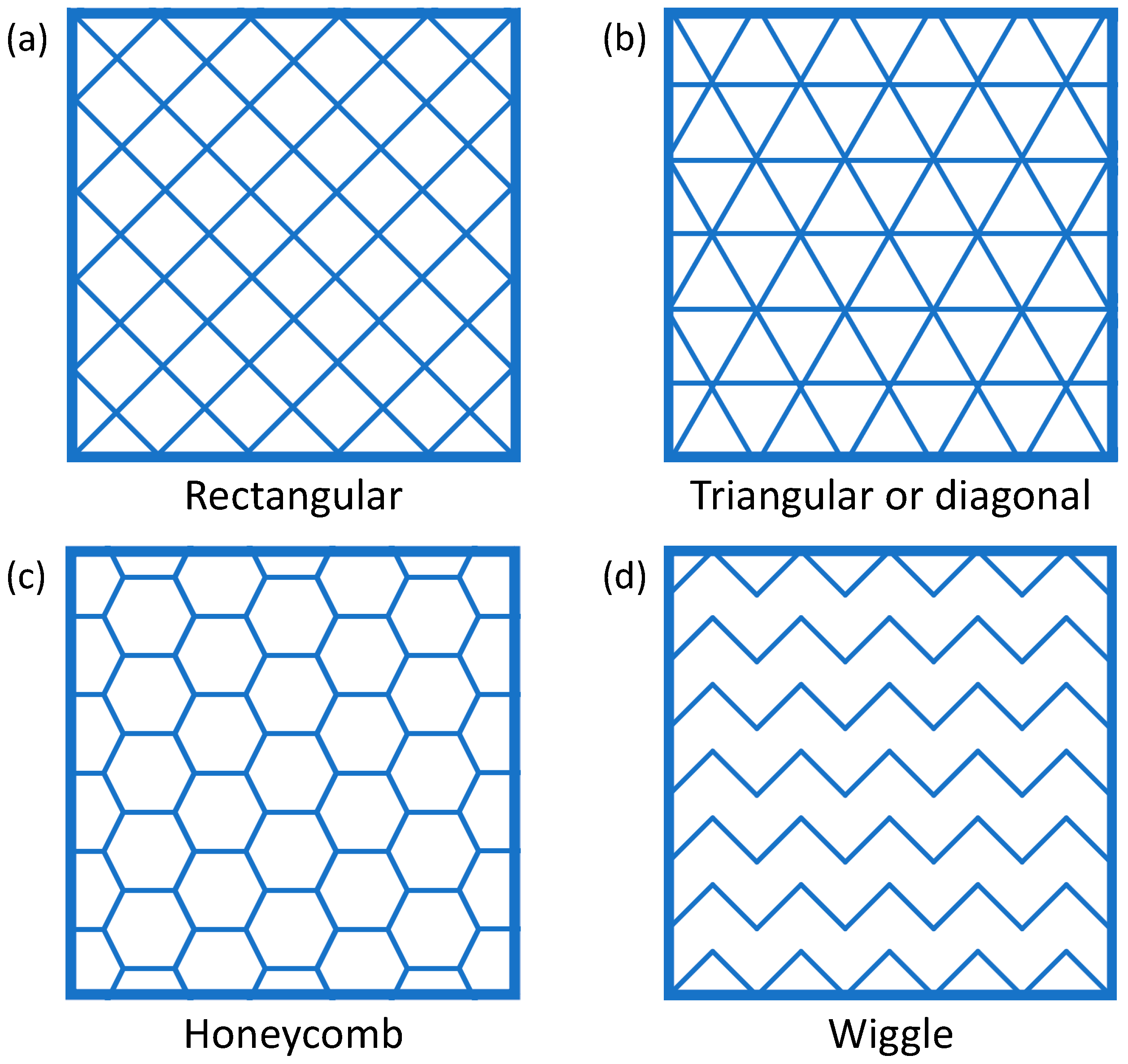

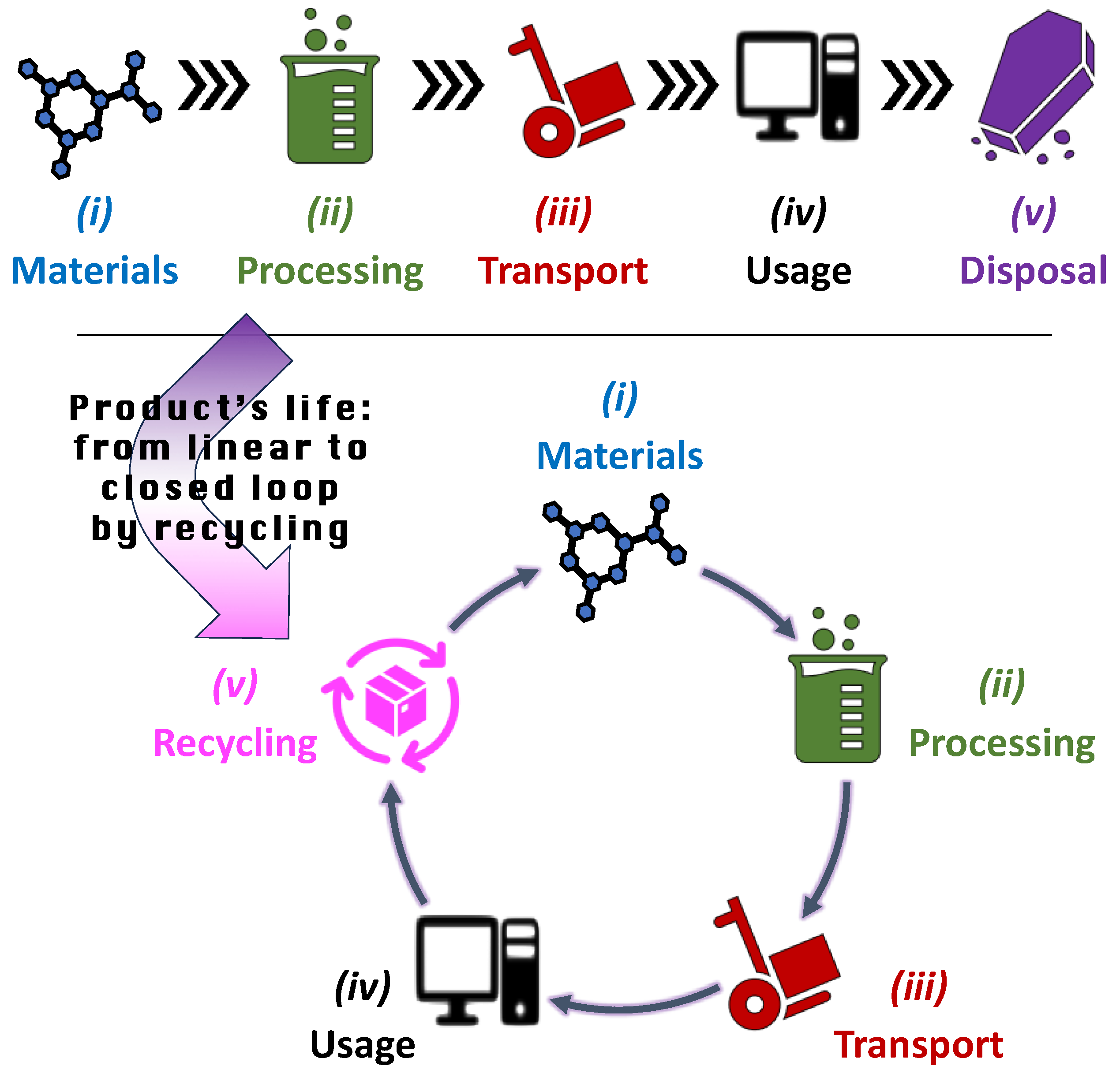

2. Functioning Mechanism of FFF

3. Basic Principles of LCA

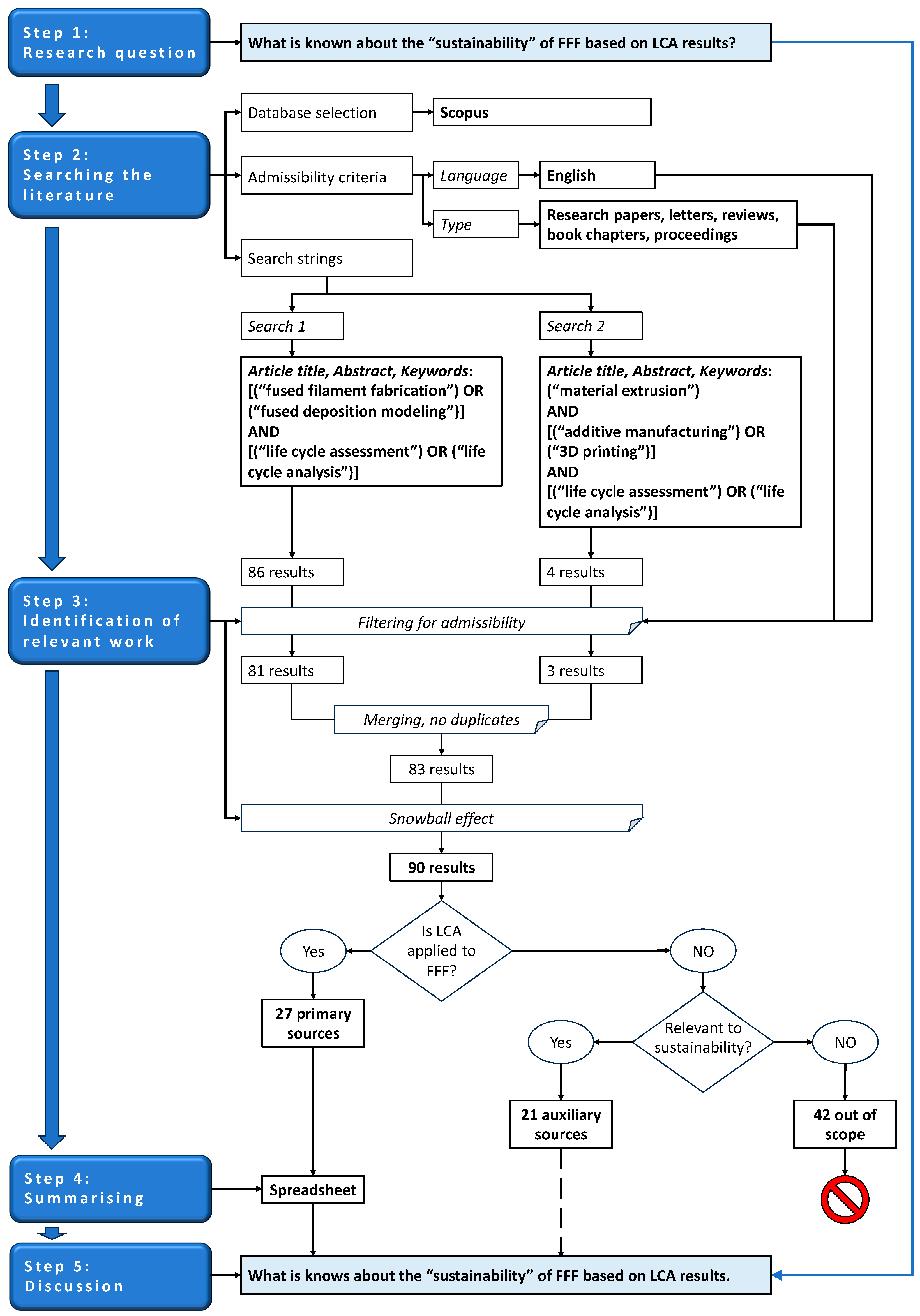

4. Systematic Review: Protocol

4.1. Framing the Question (Step 1)

4.2. Searching the Literature: Database, Admissibility Criteria, and Search Strings (Step 2)

4.3. Identification of Relevant Work (Step 3)

4.4. Summary of the Relevant Literature (Step 4)

4.5. Critical Analysis (Step 5)

5. Results and Discussion

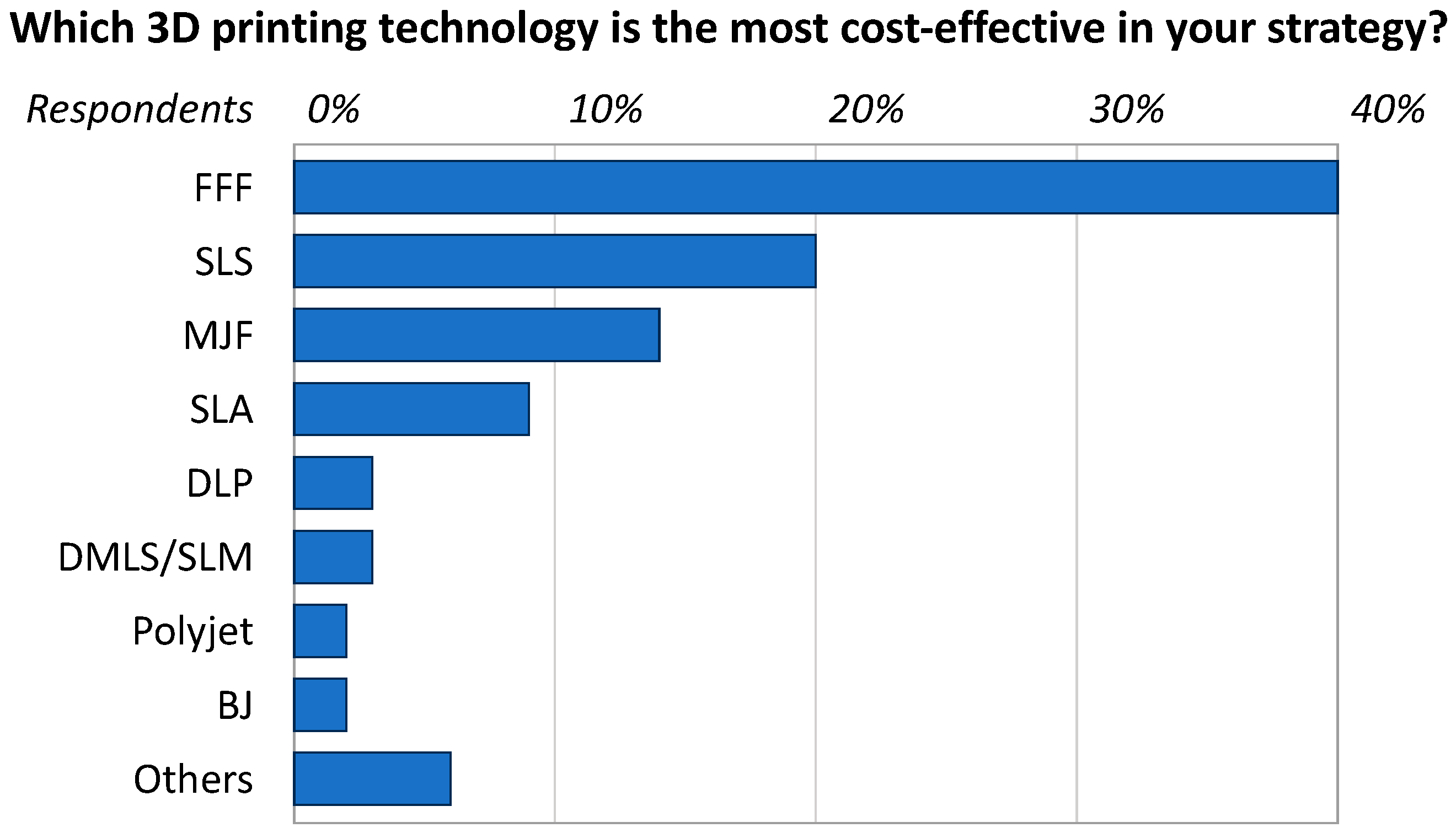

5.1. Statistics and Demography

5.2. LCA Outcomes

5.2.1. How Does FFF Compare to Other Manufacturing Technologies?

Conventional Manufacturing Technologies

Other AM Technologies

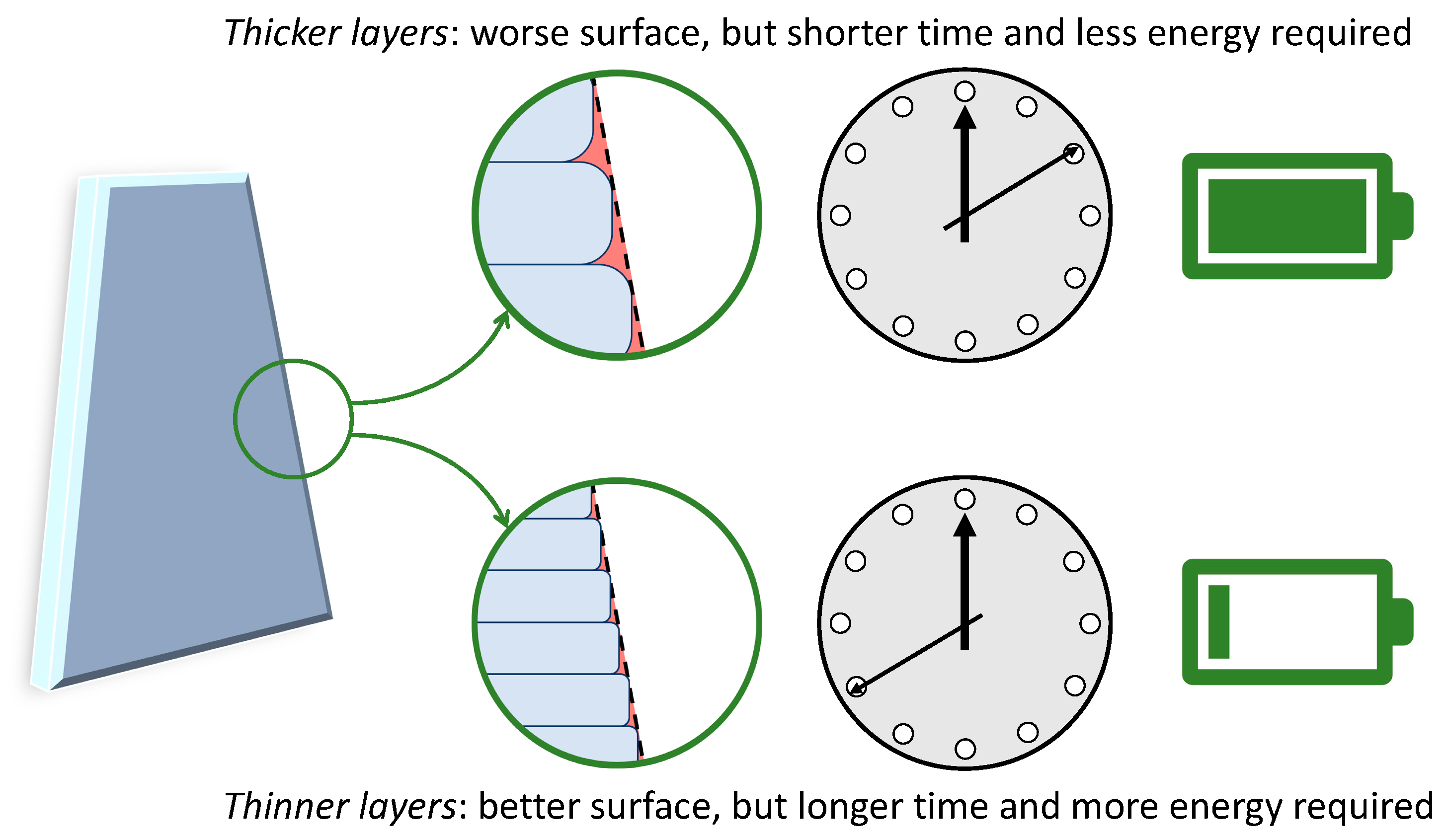

5.2.2. What Is the Effect of the Printing Parameters on the EIs of FFF?

5.2.3. What Is the Effect of the Feedstock Material on the EI of FFF?

5.2.4. Can Recycling Be the Way Forward and Reduce the EIs of FFF?

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiménez, M.; Romero, L.; Domínguez, I.A.; Espinosa, M.d.M.; Domínguez, M. Additive Manufacturing Technologies: An Overview about 3D Printing Methods and Future Prospects. Complexity 2019, 2019, 9656938. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive Manufacturing and Sustainability: An Exploratory Study of the Advantages and Challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Kunovjanek, M.; Reiner, G. How Will the Diffusion of Additive Manufacturing Impact the Raw Material Supply Chain Process? Int. J. Prod. Res. 2020, 58, 1540–1554. [Google Scholar] [CrossRef]

- Liu, J.; Gaynor, A.T.; Chen, S.; Kang, Z.; Suresh, K.; Takezawa, A.; Li, L.; Kato, J.; Tang, J.; Wang, C.C.L.; et al. Current and Future Trends in Topology Optimization for Additive Manufacturing. Struct. Multidiscip. Optim. 2018, 57, 2457–2483. [Google Scholar] [CrossRef]

- Zhu, J.; Zhou, H.; Wang, C.; Zhou, L.; Yuan, S.; Zhang, W. A Review of Topology Optimization for Additive Manufacturing: Status and Challenges. Chin. J. Aeronaut. 2021, 34, 91–110. [Google Scholar] [CrossRef]

- Czerwinski, F. Current Trends in Automotive Lightweighting Strategies and Materials. Materials 2021, 14, 6631. [Google Scholar] [CrossRef] [PubMed]

- Fan, J.; Njuguna, J. 1—An Introduction to Lightweight Composite Materials and Their Use in Transport Structures. In Lightweight Composite Structures in Transport; Njuguna, J., Ed.; Woodhead Publishing: Sawston, Cambridge, UK, 2016; pp. 3–34. ISBN 978-1-78242-325-6. [Google Scholar]

- Durach, C.F.; Kurpjuweit, S.; Wagner, S.M. The Impact of Additive Manufacturing on Supply Chains. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 954–971. [Google Scholar] [CrossRef]

- McCarthy, E.; Brabazon, D. Additive Manufacturing for Sustainability of Composite Materials Production. In Encyclopedia of Materials: Composites; Brabazon, D., Ed.; Elsevier: Oxford, UK, 2021; pp. 263–275. ISBN 978-0-12-819731-8. [Google Scholar]

- Kellens, K.; Mertens, R.; Paraskevas, D.; Dewulf, W.; Duflou, J.R. Environmental Impact of Additive Manufacturing Processes: Does AM Contribute to a More Sustainable Way of Part Manufacturing? Procedia CIRP 2017, 61, 582–587. [Google Scholar] [CrossRef]

- Sculpteo The State of 3D Printing Report: 2022 by Sculpteo. Sculpteo 2023. Available online: https://www.sculpteo.com/en/ebooks/state-of-3d-printing-report-2022/ (accessed on 7 June 2024).

- Sola, A.; Trinchi, A. Recycling as a Key Enabler for Sustainable Additive Manufacturing of Polymer Composites: A Critical Perspective on Fused Filament Fabrication. Polymers 2023, 15, 4219. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Ghabezi, P.; Steinbach, J.; Flanagan, T.; Finnegan, W.; Mitchell, S.; Harrison, N. Experimental Study on Mechanical Properties of Material Extrusion Additive Manufactured Parts from Recycled Glass Fibre-Reinforced Polypropylene Composite. Compos. Sci. Technol. 2023, 241, 110125. [Google Scholar] [CrossRef]

- Sealy, C. Thermoplastic Waste Recycled into Useful Composite. Mater. Today 2023, 69, 4–6. [Google Scholar] [CrossRef]

- Peng, T. Analysis of Energy Utilization in 3D Printing Processes. Procedia CIRP 2016, 40, 62–67. [Google Scholar] [CrossRef]

- Peng, T.; Sun, W. Energy Modelling for FDM 3D Printing from a Life Cycle Perspective. Int. J. Manuf. Res. 2017, 12, 83–98. [Google Scholar] [CrossRef]

- Song, R.; Clemon, L.; Telenko, C. Uncertainty and Variability of Energy and Material Use by Fused Deposition Modeling Printers in Makerspaces. J. Ind. Ecol. 2019, 23, 699–708. [Google Scholar] [CrossRef]

- Song, R.; Telenko, C. Material and Energy Loss Due to Human and Machine Error in Commercial FDM Printers. J. Clean. Prod. 2017, 148, 895–904. [Google Scholar] [CrossRef]

- Lithner, D.; Larsson, Å.; Dave, G. Environmental and Health Hazard Ranking and Assessment of Plastic Polymers Based on Chemical Composition. Sci. Total Environ. 2011, 409, 3309–3324. [Google Scholar] [CrossRef] [PubMed]

- Stefaniak, A.B.; Bowers, L.N.; Cottrell, G.; Erdem, E.; Knepp, A.K.; Martin, S.B.; Pretty, J.; Duling, M.G.; Arnold, E.D.; Wilson, Z.; et al. Towards Sustainable Additive Manufacturing: The Need for Awareness of Particle and Vapor Releases during Polymer Recycling, Making Filament, and Fused Filament Fabrication 3-D Printing. Resour. Conserv. Recycl. 2022, 176, 105911. [Google Scholar] [CrossRef] [PubMed]

- Stefaniak, A.B.; Bowers, L.N.; Cottrell, G.; Erdem, E.; Knepp, A.K.; Martin, S.; Pretty, J.; Duling, M.G.; Arnold, E.D.; Wilson, Z.; et al. Use of 3-Dimensional Printers in Educational Settings: The Need for Awareness of the Effects of Printer Temperature and Filament Type on Contaminant Releases. ACS Chem. Health Saf. 2021, 28, 444–456. [Google Scholar] [CrossRef] [PubMed]

- Stefaniak, A.B.; Johnson, A.R.; Du Preez, S.; Hammond, D.R.; Wells, J.R.; Ham, J.E.; LeBouf, R.F.; Martin, S.B.; Duling, M.G.; Bowers, L.N.; et al. Insights into Emissions and Exposures from Use of Industrial-Scale Additive Manufacturing Machines. Saf. Health Work 2019, 10, 229–236. [Google Scholar] [CrossRef] [PubMed]

- Bours, J.; Adzima, B.; Gladwin, S.; Cabral, J.; Mau, S. Addressing Hazardous Implications of Additive Manufacturing: Complementing Life Cycle Assessment with a Framework for Evaluating Direct Human Health and Environmental Impacts. J. Ind. Ecol. 2017, 21, S25–S36. [Google Scholar] [CrossRef]

- Mastura, M.T.; Alkahari, M.R.; Syahibudil Ikhwan, A.K. Life Cycle Analysis of Fused Filament Fabrication: A Review. In Design for Sustainability; Elsevier: Amsterdam, The Netherlands, 2021; pp. 415–434. ISBN 978-0-12-819482-9. [Google Scholar]

- Schulze, C.; Juraschek, M.; Herrmann, C.; Thiede, S. Energy Analysis of Bioplastics Processing. 24th CIRP Conf. Life Cycle Eng. 2017, 61, 600–605. [Google Scholar] [CrossRef]

- Kreiger, M.A.; Mulder, M.L.; Glover, A.G.; Pearce, J.M. Life Cycle Analysis of Distributed Recycling of Post-Consumer High Density Polyethylene for 3-D Printing Filament. J. Clean. Prod. 2014, 70, 90–96. [Google Scholar] [CrossRef]

- Saade, M.R.M.; Yahia, A.; Amor, B. How Has LCA Been Applied to 3D Printing? A Systematic Literature Review and Recommendations for Future Studies. J. Clean. Prod. 2020, 244, 118803. [Google Scholar] [CrossRef]

- ISO/ASTM ISO/ASTM 52900:2021; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. ISO: Geneva, Switzerland, 2021.

- Sola, A. Materials Requirements in Fused Filament Fabrication: A Framework for the Design of Next-generation 3D Printable Thermoplastics and Composites. Macromol. Mater. Eng. 2022, 307, 2200197. [Google Scholar] [CrossRef]

- Turner, B.N.; Strong, R.; Gold, S.A. A Review of Melt Extrusion Additive Manufacturing Processes: I. Process Design and Modeling. Rapid Prototyp. J. 2014, 20, 192–204. [Google Scholar] [CrossRef]

- 3space Infill for FDM 3D Printing. 3 Space 2020. Available online: https://3space.com/infill-for-fdm-3d-printing/ (accessed on 7 June 2024).

- Hubs What Are the Optimal Shell and Infill Parameters for FDM 3D Printing? Available online: https://www.hubs.com/knowledge-base/selecting-optimal-shell-and-infill-parameters-fdm-3D-printing/ (accessed on 7 December 2023).

- Fafenrot, S.; Grimmelsmann, N.; Wortmann, M.; Ehrmann, A. Three-Dimensional (3D) Printing of Polymer-Metal Hybrid Materials by Fused Deposition Modeling. Materials 2017, 10, 1199. [Google Scholar] [CrossRef]

- Quist, Z. Life Cycle Assessment (LCA)—Complete Beginner’s Guide. Ecochain. Available online: https://ecochain.com/blog/life-cycle-assessment-lca-guide/ (accessed on 7 June 2024).

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Environmental Footprint Methods. Available online: https://green-business.ec.europa.eu/environmental-footprint-methods_en (accessed on 8 December 2023).

- EEA Cradle to Grave—European Environment Agency. Available online: https://www.eea.europa.eu/help/glossary/eea-glossary/cradle-to-grave (accessed on 11 December 2023).

- Bjørn, A.; Hauschild, M.Z. Cradle to Cradle and LCA. In Life Cycle Assessment: Theory and Practice; Hauschild, M.Z., Rosenbaum, R.K., Olsen, S.I., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 605–631. ISBN 978-3-319-56475-3. [Google Scholar]

- Toniolo, S.; Mazzi, A.; Pieretto, C.; Scipioni, A. Allocation Strategies in Comparative Life Cycle Assessment for Recycling: Considerations from Case Studies. Resour. Conserv. Recycl. 2017, 117, 249–261. [Google Scholar] [CrossRef]

- Arena, U.; Mastellone, M.L.; Perugini, F. Life Cycle Assessment of a Plastic Packaging Recycling System. Int. J. Life Cycle Assess. 2003, 8, 92–98. [Google Scholar] [CrossRef]

- Tian, X.; Stranks, S.D.; You, F. Life Cycle Assessment of Recycling Strategies for Perovskite Photovoltaic Modules. Nat. Sustain. 2021, 4, 821–829. [Google Scholar] [CrossRef]

- Kallitsis, E.; Korre, A.; Kelsall, G.H. Life Cycle Assessment of Recycling Options for Automotive Li-Ion Battery Packs. J. Clean. Prod. 2022, 371, 133636. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Tam, V.W.Y. A Closed-Loop Life Cycle Assessment of Recycled Aggregate Concrete Utilization in China. Waste Manag. 2016, 56, 367–375. [Google Scholar] [CrossRef] [PubMed]

- Colangelo, F.; Petrillo, A.; Cioffi, R.; Borrelli, C.; Forcina, A. Life Cycle Assessment of Recycled Concretes: A Case Study in Southern Italy. Sci. Total Environ. 2018, 615, 1506–1517. [Google Scholar] [CrossRef] [PubMed]

- Choi, B.-C.; Shin, H.-S.; Lee, S.-Y.; Hur, T. Life Cycle Assessment of a Personal Computer and Its Effective Recycling Rate. Int. J. Life Cycle Assess. 2006, 11, 122–128. [Google Scholar] [CrossRef]

- Lam, K.L.; Zlatanović, L.; van der Hoek, J.P. Life Cycle Assessment of Nutrient Recycling from Wastewater: A Critical Review. Water Res. 2020, 173, 115519. [Google Scholar] [CrossRef] [PubMed]

- Kokare, S.; Oliveira, J.P.; Godina, R. Life Cycle Assessment of Additive Manufacturing Processes: A Review. J. Manuf. Syst. 2023, 68, 536–559. [Google Scholar] [CrossRef]

- Finnveden, G.; Potting, J. Life Cycle Assessment. In Encyclopedia of Toxicology; Elsevier: Amsterdam, The Netherlands, 2014; pp. 74–77. ISBN 978-0-12-386455-0. [Google Scholar]

- Reap, J.; Roman, F.; Duncan, S.; Bras, B. A Survey of Unresolved Problems in Life Cycle Assessment. Part 1: Goal and Scope and Inventory Analysis. Int. J. Life Cycle Assess. 2008, 13, 290–300. [Google Scholar] [CrossRef]

- Reap, J.; Roman, F.; Duncan, S.; Bras, B. A Survey of Unresolved Problems in Life Cycle Assessment. Part 2: Impact Assessment and Interpretation. Int. J. Life Cycle Assess. 2008, 13, 374–388. [Google Scholar] [CrossRef]

- Khan, K.S.; Kunz, R.; Kleijnen, J.; Antes, G. Five Steps to Conducting a Systematic Review. J. R. Soc. Med. 2003, 96, 118–121. [Google Scholar] [CrossRef] [PubMed]

- Torgerson, C. Systematic Reviews (Continuum Research Methods), 1st ed.; Bloomsbury Publishing: London, UK; New York, NY, USA, 2003; ISBN 978-0-8264-6580-1. [Google Scholar]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Page, M.J.; Moher, D.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. PRISMA 2020 Explanation and Elaboration: Updated Guidance and Exemplars for Reporting Systematic Reviews. BMJ 2021, 372, n160. [Google Scholar] [CrossRef]

- Scopus Content|Elsevier. Available online: https://beta.elsevier.com/products/scopus/content (accessed on 26 October 2023).

- Scopus Content Policy and Selection|Elsevier. Available online: https://beta.elsevier.com/products/scopus/content/content-policy-and-selection (accessed on 26 October 2023).

- Kwon, J.; Kim, N.; Ma, J. Case study of different additive manufacturing (AM) processes from environmental impact assessment. J. Korean Soc. Precis. Eng. 2019, 36, 431–439. [Google Scholar] [CrossRef]

- Luo, Y.; Ji, Z.; Leu, M.C.; Caudill, R. Environmental Performance Analysis of Solid Freedom Fabrication Processes. In Proceedings of the 1999 IEEE International Symposium on Electronics and the Environment (Cat. No.99CH36357), Danvers, MA, USA, 13 May 1999; IEEE: Danvers, MA, USA, 1999; pp. 1–6. [Google Scholar]

- Conserving Earth. Available online: https://education.nationalgeographic.org/resource/conserving-earth (accessed on 3 November 2023).

- Climate Change. Available online: https://education.nationalgeographic.org/resource/resource-library-climate-change (accessed on 3 November 2023).

- Sola, A.; Trinchi, A. Chapter 1—Introduction to “Fused Deposition Modeling of Composite Materials”. In Fused Deposition Modeling of Composite Materials; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1–7. ISBN 978-0-323-98823-0. [Google Scholar]

- Sola, A.; Trinchi, A. Chapter 2—Basic Principles of Fused Deposition Modeling. In Fused Deposition Modeling of Composite Materials; Elsevier: Amsterdam, The Netherlands, 2023; pp. 7–39. ISBN 978-0-323-98823-0. [Google Scholar]

- Hrabe, N.; Barbosa, N.; Daniewicz, S.; Shamsaei, N. Findings from the NIST/ASTM Workshop on Mechanical Behavior of Additive Manufacturing Components; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2016; pp. 1–256.

- Suárez, L.; Domínguez, M. Sustainability and Environmental Impact of Fused Deposition Modelling (FDM) Technologies. Int. J. Adv. Manuf. Technol. 2020, 106, 1267–1279. [Google Scholar] [CrossRef]

- Issue Information, Cover, and Table of Contents. J. Ind. Ecol. 2017, 21, S1–S5. [CrossRef][Green Version]

- COM (2019) 190 Final. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX%3A52019DC0190 (accessed on 17 October 2023).

- Cimpan, C.; Bjelle, E.L.; Budzinski, M.; Wood, R.; Strømman, A.H. Effects of Circularity Interventions in the European Plastic Packaging Sector. Environ. Sci. Technol. 2023, 57, 9984–9995. [Google Scholar] [CrossRef] [PubMed]

- Plastics in a Circular Economy. Available online: https://research-and-innovation.ec.europa.eu/research-area/environment/circular-economy/plastics-circular-economy_en (accessed on 16 November 2023).

- Bezzina, C.M.; Refalo, P. Fused Filament Fabrication and Injection Moulding of Plastic Packaging: An Environmental and Financial Comparative Assessment. Machines 2023, 11, 634. [Google Scholar] [CrossRef]

- Faludi, J.; Bayley, C.; Bhogal, S.; Iribarne, M. Comparing Environmental Impacts of Additive Manufacturing vs Traditional Machining via Life-Cycle Assessment. Rapid Prototyp. J. 2015, 21, 14–33. [Google Scholar] [CrossRef]

- Reddy, R.D.P.; Elgazzar, H.; Sharma, V. Investigations of Personalized and Sustainable Approach of Oral Drug Delivery Systems through Additive Manufacturing. Rapid Prototyp. J. 2022, 28, 855–872. [Google Scholar] [CrossRef]

- Garcia, F.L.; Nunes, A.O.; Martins, M.G.; Belli, M.C.; Saavedra, Y.M.B.; Silva, D.A.L.; Moris, V.A.D.S. Comparative LCA of Conventional Manufacturing vs. Additive Manufacturing: The Case of Injection Moulding for Recycled Polymers. Int. J. Sustain. Eng. 2021, 14, 1604–1622. [Google Scholar] [CrossRef]

- Thomas, D.S.; Gilbert, S.W. Costs and Cost Effectiveness of Additive Manufacturing; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2014; p. NIST SP 1176. [CrossRef]

- Nsiempba, K.M.; Wang, M.; Vlasea, M. Geometrical Degrees of Freedom for Cellular Structures Generation: A New Classification Paradigm. Appl. Sci. 2021, 11, 3845. [Google Scholar] [CrossRef]

- Lussenburg, K.; Sakes, A.; Breedveld, P. Design of Non-Assembly Mechanisms: A State-of-the-Art Review. Addit. Manuf. 2021, 39, 101846. [Google Scholar] [CrossRef]

- Attaran, M. The Rise of 3-D Printing: The Advantages of Additive Manufacturing over Traditional Manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Dawoud, M.; Taha, I.; Ebeid, S.J. Mechanical Behaviour of ABS: An Experimental Study Using FDM and Injection Moulding Techniques. J. Manuf. Process. 2016, 21, 39–45. [Google Scholar] [CrossRef]

- Ponticelli, G.S.; Venettacci, S.; Tagliaferri, F.; Guarino, S. Fused Deposition Modelling for Aeronautics: Techno-Economic and Environmental Assessment for Overhead Locker Supports Replacement. Int. J. Adv. Manuf. Technol. 2023, 128, 3817–3840. [Google Scholar] [CrossRef]

- Jayawardane, H.; Davies, I.J.; Leadbeater, G.; John, M.; Biswas, W.K. ‘Techno-Eco-Efficiency’ Performance of 3D Printed Impellers: An Application of Life Cycle Assessment. Int. J. Sustain. Manuf. 2021, 5, 44–80. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Design for Additive Manufacturing. In Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing; Gibson, I., Rosen, D., Stucker, B., Eds.; Springer: New York, NY, USA, 2015; pp. 399–435. ISBN 978-1-4939-2113-3. [Google Scholar]

- Top, N.; Sahin, I.; Mangla, S.K.; Sezer, M.D.; Kazancoglu, Y. Towards Sustainable Production for Transition to Additive Manufacturing: A Case Study in the Manufacturing Industry. Int. J. Prod. Res. 2023, 61, 4450–4471. [Google Scholar] [CrossRef]

- Krishna, S.R.L.; Srikanth, P.J. Evaluation of Environmental Impact of Additive and Subtractive Manufacturing Processes for Sustainable Manufacturing. Mater. Today Proc. 2021, 45, 3054–3060. [Google Scholar] [CrossRef]

- Kreiger, M.; Pearce, J.M. Environmental Life Cycle Analysis of Distributed Three-Dimensional Printing and Conventional Manufacturing of Polymer Products. ACS Sustain. Chem. Eng. 2013, 1, 1511–1519. [Google Scholar] [CrossRef]

- Naef Spiel. Mus. Für Gestalt. EGuide. Available online: https://www.eguide.ch/en/objekt/naef-spiel/ (accessed on 7 June 2024).

- Nagarajan, H.P.N.; Haapala, K.R. Characterizing the Influence of Resource-Energy-Exergy Factors on the Environmental Performance of Additive Manufacturing Systems. J. Manuf. Syst. 2018, 48, 87–96. [Google Scholar] [CrossRef]

- Ulkir, O. Energy-Consumption-Based Life Cycle Assessment of Additive-Manufactured Product with Different Types of Materials. Polymers 2023, 15, 1466. [Google Scholar] [CrossRef]

- Chen, Z.; Yang, M.; Ji, M.; Kuang, X.; Qi, H.J.; Wang, T. Recyclable Thermosetting Polymers for Digital Light Processing 3D Printing. Mater. Des. 2021, 197, 109189. [Google Scholar] [CrossRef]

- Tagliaferri, V.; Trovalusci, F.; Guarino, S.; Venettacci, S. Environmental and Economic Analysis of FDM, SLS and MJF Additive Manufacturing Technologies. Materials 2019, 12, 4161. [Google Scholar] [CrossRef] [PubMed]

- Kwon, J.; Kim, N.; Ma, J. Environmental Sustainability Evaluation of Additive Manufacturing Using the NIST Test Artifact. J. Mech. Sci. Technol. 2020, 34, 1265–1274. [Google Scholar] [CrossRef]

- Moylan, S.; Slotwinski, J.; Cooke, A.; Jurrens, K.; Donmez, M.A. An Additive Manufacturing Test Artifact. J. Res. Natl. Inst. Stand. Technol. 2014, 119, 429. [Google Scholar] [CrossRef] [PubMed]

- Enemuoh, E.U.; Menta, V.G.; Abutunis, A.; O’Brien, S.; Kaya, L.I.; Rapinac, J. Energy and Eco-Impact Evaluation of Fused Deposition Modeling and Injection Molding of Polylactic Acid. Sustainability 2021, 13, 1875. [Google Scholar] [CrossRef]

- Mele, M.; Pisaneschi, G.; Ciotti, M.; Campana, G.; Zucchelli, A.; Fiorini, M. Environmental Drawbacks of Lightweight Design Algorithms in Material Extrusion Additive Manufacturing: A Case Study. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 530. [Google Scholar] [CrossRef]

- Freeformer. Available online: https://www.arburg.com/en/product-world/additive-manufacturing/freeformer/ (accessed on 17 November 2023).

- Coogan, T.J.; Kazmer, D.O. Modeling of Interlayer Contact and Contact Pressure during Fused Filament Fabrication. J. Rheol. 2019, 63, 655–672. [Google Scholar] [CrossRef]

- Tao, Y.; Kong, F.; Li, Z.; Zhang, J.; Zhao, X.; Yin, Q.; Xing, D.; Li, P. A Review on Voids of 3D Printed Parts by Fused Filament Fabrication. J. Mater. Res. Technol. 2021, 15, 4860–4879. [Google Scholar] [CrossRef]

- Mecheter, A.; Tarlochan, F. Fused Filament Fabrication Three Dimensional Printing: Assessing the Influence of Geometric Complexity and Process Parameters on Energy and the Environment. Sustainability 2023, 15, 12319. [Google Scholar] [CrossRef]

- Campana, G.; Mele, M.; Ciotti, M.; Rocchi, A. Environmental Impacts of Self-Replicating Three-Dimensional Printers. Sustain. Mater. Technol. 2021, 30, e00335. [Google Scholar] [CrossRef]

- Ma, H.; Zhang, Y.; Jiao, Z.; Yang, W.; He, X.; Xie, G.; Li, H. Comprehensive Assessment of the Environmental Impact of Fused Filament Fabrication Products Produced under Various Performance Requirements. J. Inst. Eng. India Ser. C 2021, 102, 59–73. [Google Scholar] [CrossRef]

- Spoerk, M.; Gonzalez-Gutierrez, J.; Sapkota, J.; Schuschnigg, S.; Holzer, C. Effect of the Printing Bed Temperature on the Adhesion of Parts Produced by Fused Filament Fabrication. Plast. Rubber Compos. 2018, 47, 17–24. [Google Scholar] [CrossRef]

- Pejak Simunec, D.; Jacob, J.; Kandjani, A.E.Z.; Trinchi, A.; Sola, A. Facilitating the Additive Manufacture of High-Performance Polymers through Polymer Blending: A Review. Eur. Polym. J. 2023, 201, 112553. [Google Scholar] [CrossRef]

- Chatzipanagiotou, K.-R.; Antypa, D.; Petrakli, F.; Karatza, A.; Pikoń, K.; Bogacka, M.; Poranek, N.; Werle, S.; Amanatides, E.; Mataras, D.; et al. Life Cycle Assessment of Composites Additive Manufacturing Using Recycled Materials. Sustainability 2023, 15, 12843. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; De Carolis, V.; Montagna, F.; Palumbo, E.; Corcione, C.E. Development and Characterization of Sustainable PLA/Olive Wood Waste Composites for Rehabilitation Applications Using Fused Filament Fabrication (FFF). J. Build. Eng. 2022, 56, 104673. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; Casciaro, R.; Esposito Corcione, C. A Review of Polymer-Based Materials for Fused Filament Fabrication (FFF): Focus on Sustainability and Recycled Materials. Polymers 2022, 14, 465. [Google Scholar] [CrossRef] [PubMed]

- Chong, W.J.; Pejak Simunec, D.; Trinchi, A.; (Louis) Kyratzis, I.; Li, Y.; Wright, P.; Shen, S.; Sola, A.; Wen, C. Advancing the Additive Manufacturing of PLA-ZnO Nanocomposites by Fused Filament Fabrication. Virtual Phys. Prototyp. 2024, 19, e2285418. [Google Scholar] [CrossRef]

- Chong, W.J.; Shen, S.; Li, Y.; Trinchi, A.; Pejak, D.; (Louis) Kyratzis, I.; Sola, A.; Wen, C. Additive Manufacturing of Antibacterial PLA-ZnO Nanocomposites: Benefits, Limitations and Open Challenges. J. Mater. Sci. Technol. 2022, 111, 120–151. [Google Scholar] [CrossRef]

- Bay, C.; Nagengast, N.; Schmidt, H.-W.; Döpper, F.; Neuber, C. Environmental Assessment of Recycled Petroleum and Bio Based Additively Manufactured Parts via LCA. In Manufacturing Driving Circular Economy; Kohl, H., Seliger, G., Dietrich, F., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2023; pp. 669–677. ISBN 978-3-031-28838-8. [Google Scholar]

- Bianchi, I.; Forcellese, A.; Gentili, S.; Greco, L.; Simoncini, M. Comparison between the Mechanical Properties and Environmental Impacts of 3D Printed Synthetic and Bio-Based Composites. Procedia CIRP 2022, 105, 380–385. [Google Scholar] [CrossRef]

- Bianchi, I.; Forcellese, A.; Mancia, T.; Simoncini, M.; Vita, A. Process Parameters Effect on Environmental Sustainability of Composites FFF Technology. Mater. Manuf. Process. 2022, 37, 591–601. [Google Scholar] [CrossRef]

- Yip, W.C.; Yusuf, Y.; Mastura, M.T. Life Cycle Analysis (LCA) Using CES-Edupack Software of New Wood Dust Reinforced Recycled Polypropylene Composite Filament for Fused Deposition Modelling (FDM). In Proceedings of the 7th International Conference and Exhibition on Sustainable Energy and Advanced Materials (ICE-SEAM 2021), Melaka, Malaysia, 23 November 2021; Abdollah, M.F.B., Amiruddin, H., Phuman Singh, A.S., Abdul Munir, F., Ibrahim, A., Eds.; Lecture Notes in Mechanical Engineering. Springer Nature: Singapore, 2022; pp. 236–240, ISBN 978-981-19317-8-9. [Google Scholar]

- Zhao, P.; Rao, C.; Gu, F.; Sharmin, N.; Fu, J. Close-Looped Recycling of Polylactic Acid Used in 3D Printing: An Experimental Investigation and Life Cycle Assessment. J. Clean. Prod. 2018, 197, 1046–1055. [Google Scholar] [CrossRef]

- Calisto Friant, M.; Vermeulen, W.J.V.; Salomone, R. Analysing European Union Circular Economy Policies: Words versus Actions. Sustain. Prod. Consum. 2021, 27, 337–353. [Google Scholar] [CrossRef]

- Mhatre, P.; Panchal, R.; Singh, A.; Bibyan, S. A Systematic Literature Review on the Circular Economy Initiatives in the European Union. Sustain. Prod. Consum. 2021, 26, 187–202. [Google Scholar] [CrossRef]

- Shan, H.; Yang, J. Promoting the Implementation of Extended Producer Responsibility Systems in China: A Behavioral Game Perspective. J. Clean. Prod. 2020, 250, 119446. [Google Scholar] [CrossRef]

- Ragab, A.; Elazhary, R.; Schmauder, S.; Ramzy, A. Plastic Waste Valorization for Fused Deposition Modeling Feedstock: A Case Study on Recycled Polyethylene Terephthalate/High-Density Polyethylene Sustainability. Sustainability 2023, 15, 13291. [Google Scholar] [CrossRef]

- Sola, A.; Trinchi, A. Chapter 3—The Need for Fused Deposition Modeling of Composite Materials. In Fused Deposition Modeling of Composite Materials; Sola, A., Trinchi, A., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2023; pp. 39–89. ISBN 978-0-323-98823-0. [Google Scholar]

- Trinchi, A.; Sola, A. Embedding Function within Additively Manufactured Parts: Materials Challenges and Opportunities. Adv. Eng. Mater. 2023, 25, 2300395. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Kalman, J.; Henri, R.; Fayazbakhsh, K.; Lessard, L. Recycled Glass Fiber Composites from Wind Turbine Waste for 3D Printing Feedstock: Effects of Fiber Content and Interface on Mechanical Performance. Materials 2019, 12, 3929. [Google Scholar] [CrossRef] [PubMed]

- Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Recycling of Fiberglass Wind Turbine Blades into Reinforced Filaments for Use in Additive Manufacturing. Compos. Part B Eng. 2019, 175, 107101. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Mechanical and Thermal Study of 3D Printing Composite Filaments from Wind Turbine Waste. Polym. Compos. 2021, 42, 2305–2316. [Google Scholar] [CrossRef]

- Witten, E.; Mathes, V. The European Market for Fiber-Reinforced Plastics/Composites 2023. 2024. Available online: https://eucia.eu/wp-content/uploads/2024/05/avk_marketreport_2024_final_eng.pdf (accessed on 7 June 2024).

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.-J.; Kuiper, P.; de Wit, H. Recycling of Composite Materials. Delft Skyline Debate 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Morgan, L.M.; Weager, B.M.; Hare, C.M.; Bishop, G.R.; Smith, G.M. Self Reinforced Polymer Composites: Coming of Age. 2009. Available online: https://iccm-central.org/Proceedings/ICCM17proceedings/papers/ID12.15%20Morgan.pdf (accessed on 7 June 2024).

- Zhang, M.; Tian, X.; Cao, H.; Liu, T.; Akmal Zia, A.; Li, D. 3D Printing of Fully Recyclable Continuous Fiber Self-Reinforced Composites Utilizing Supercooled Polymer Melts. Compos. Part Appl. Sci. Manuf. 2023, 169, 107513. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sola, A.; Rosa, R.; Ferrari, A.M. Environmental Impact of Fused Filament Fabrication: What Is Known from Life Cycle Assessment? Polymers 2024, 16, 1986. https://doi.org/10.3390/polym16141986

Sola A, Rosa R, Ferrari AM. Environmental Impact of Fused Filament Fabrication: What Is Known from Life Cycle Assessment? Polymers. 2024; 16(14):1986. https://doi.org/10.3390/polym16141986

Chicago/Turabian StyleSola, Antonella, Roberto Rosa, and Anna Maria Ferrari. 2024. "Environmental Impact of Fused Filament Fabrication: What Is Known from Life Cycle Assessment?" Polymers 16, no. 14: 1986. https://doi.org/10.3390/polym16141986

APA StyleSola, A., Rosa, R., & Ferrari, A. M. (2024). Environmental Impact of Fused Filament Fabrication: What Is Known from Life Cycle Assessment? Polymers, 16(14), 1986. https://doi.org/10.3390/polym16141986