Optimizing Processing Parameters for NR/EBC Thermoplastic Vulcanizates: A Comprehensive Full Factorial Design of Experiments (DOE) Strategy

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of TPVs via Dynamic Vulcanization

3. Mechanical Testing, Rheological and Dynamic Properties, and Morphology Analysis

3.1. Tensile and Tear Properties

3.2. Hardness (Shore A)

3.3. Compression Set

3.4. Overall Crosslink Density

3.5. Rheological Properties (RPA)

3.6. Dynamic Mechanical Properties (DMA)

3.7. Morphology Analysis

4. Experimental Design

5. Results

5.1. Analysis of Variance (ANOVA)

5.1.1. Tensile Properties of NR/EBC TPVs

5.1.2. Compression Set of NR/EBC TPVs

5.1.3. Tear Strength of NR/EBC TPVs

5.1.4. Hardness (Shore A) of NR/EBC TPVs

5.2. Effect of Mixing Parameters on Mechanical Properties of TPVs

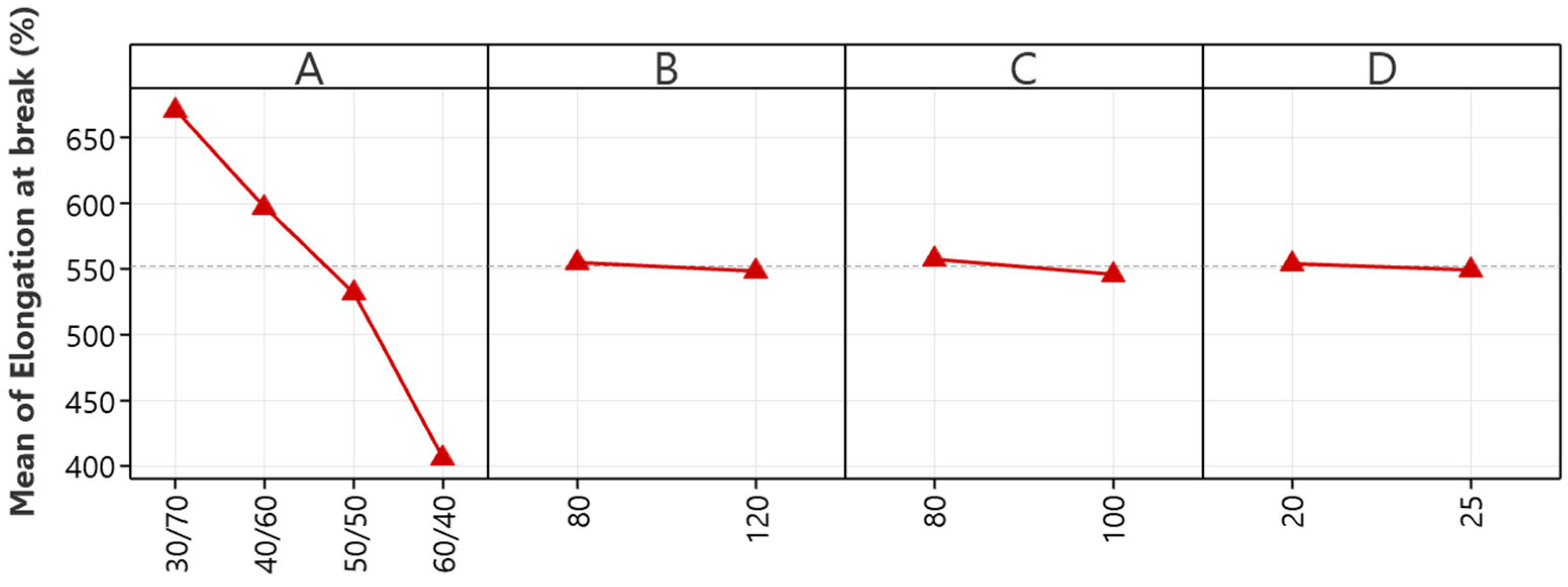

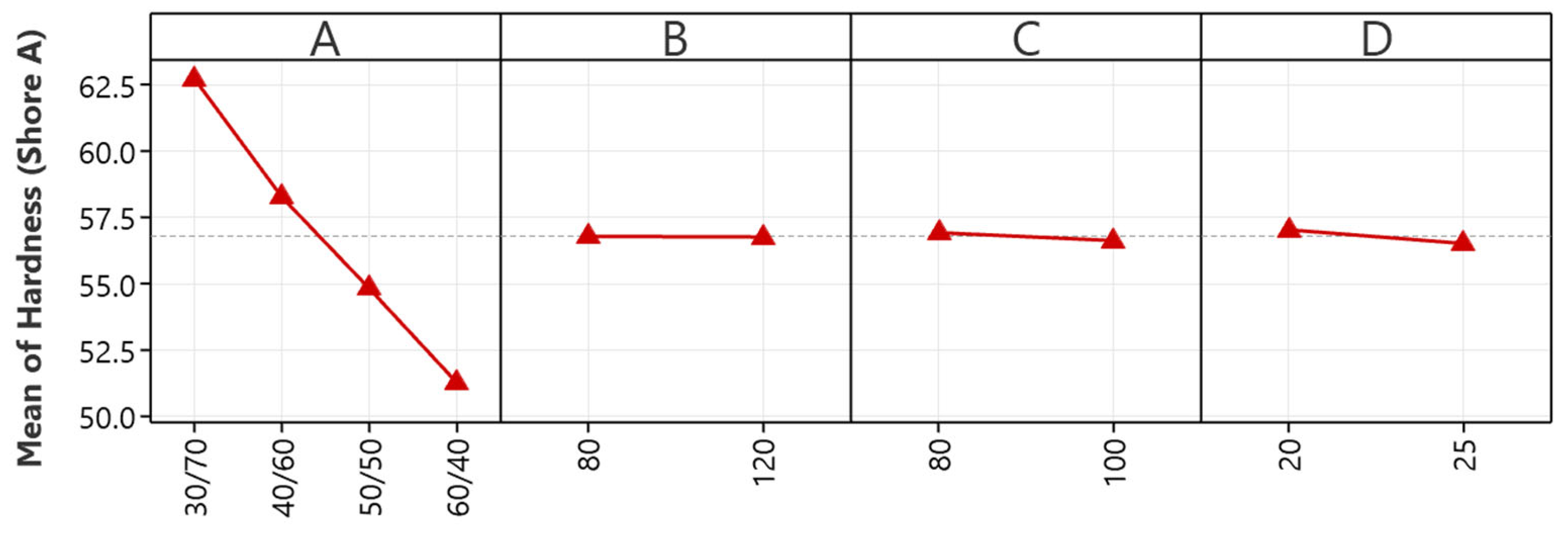

5.2.1. Tensile Properties

5.2.2. Compression Set

5.2.3. Tear Strength

5.2.4. Hardness

5.3. The Predictive Models for Mechanical Properties of TPVs

5.4. Optimization of NR/EBC TPVs Properties

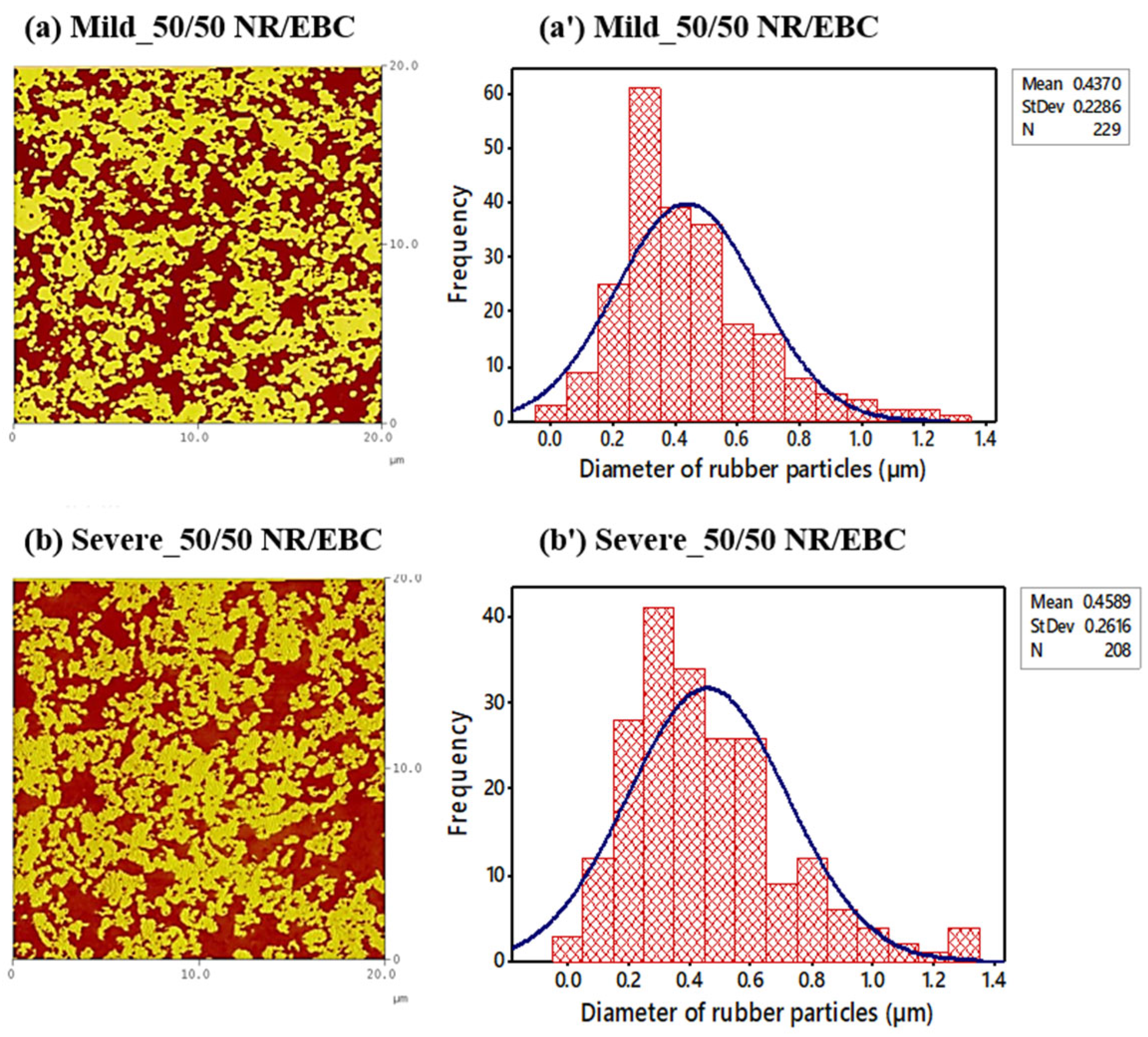

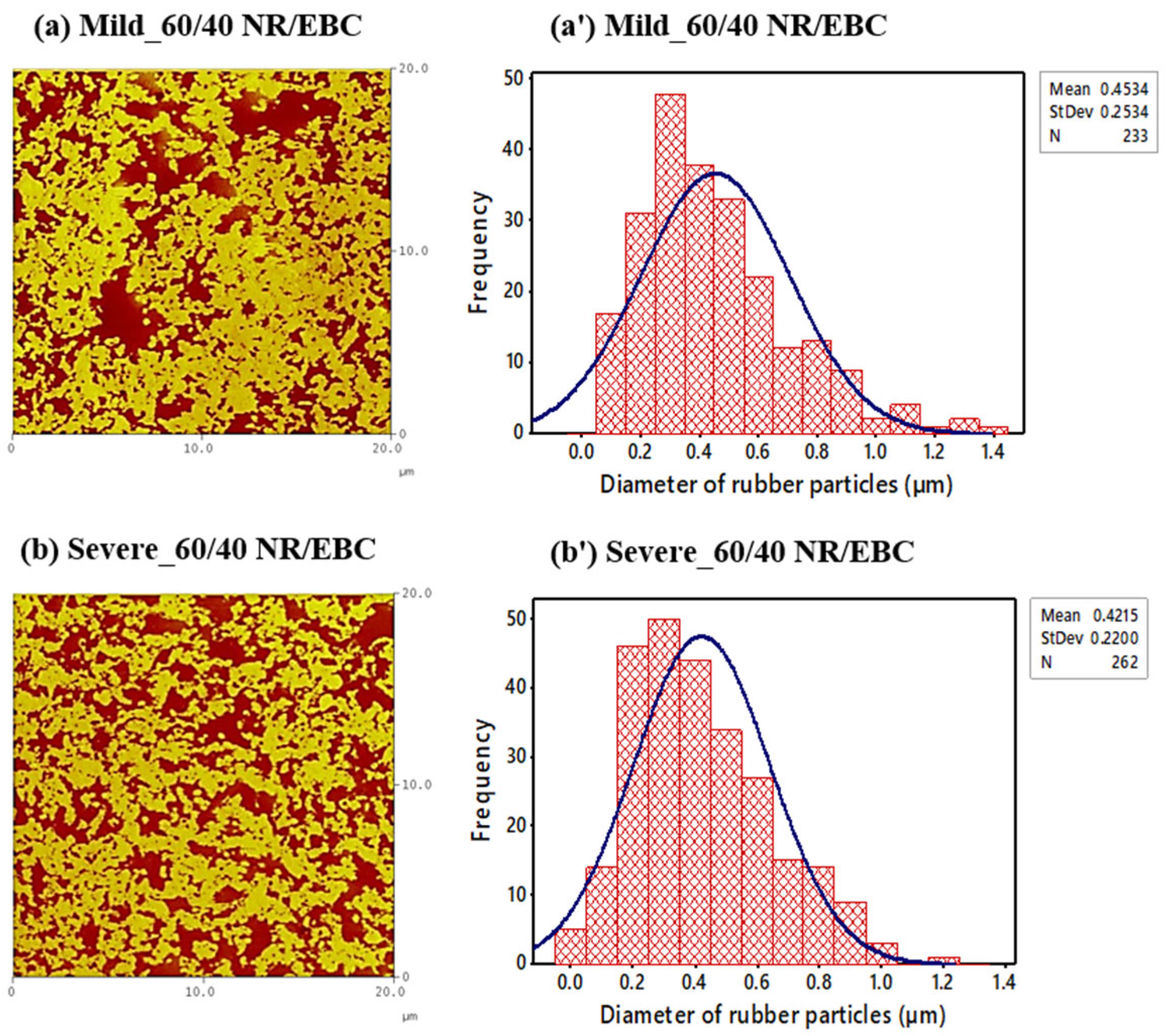

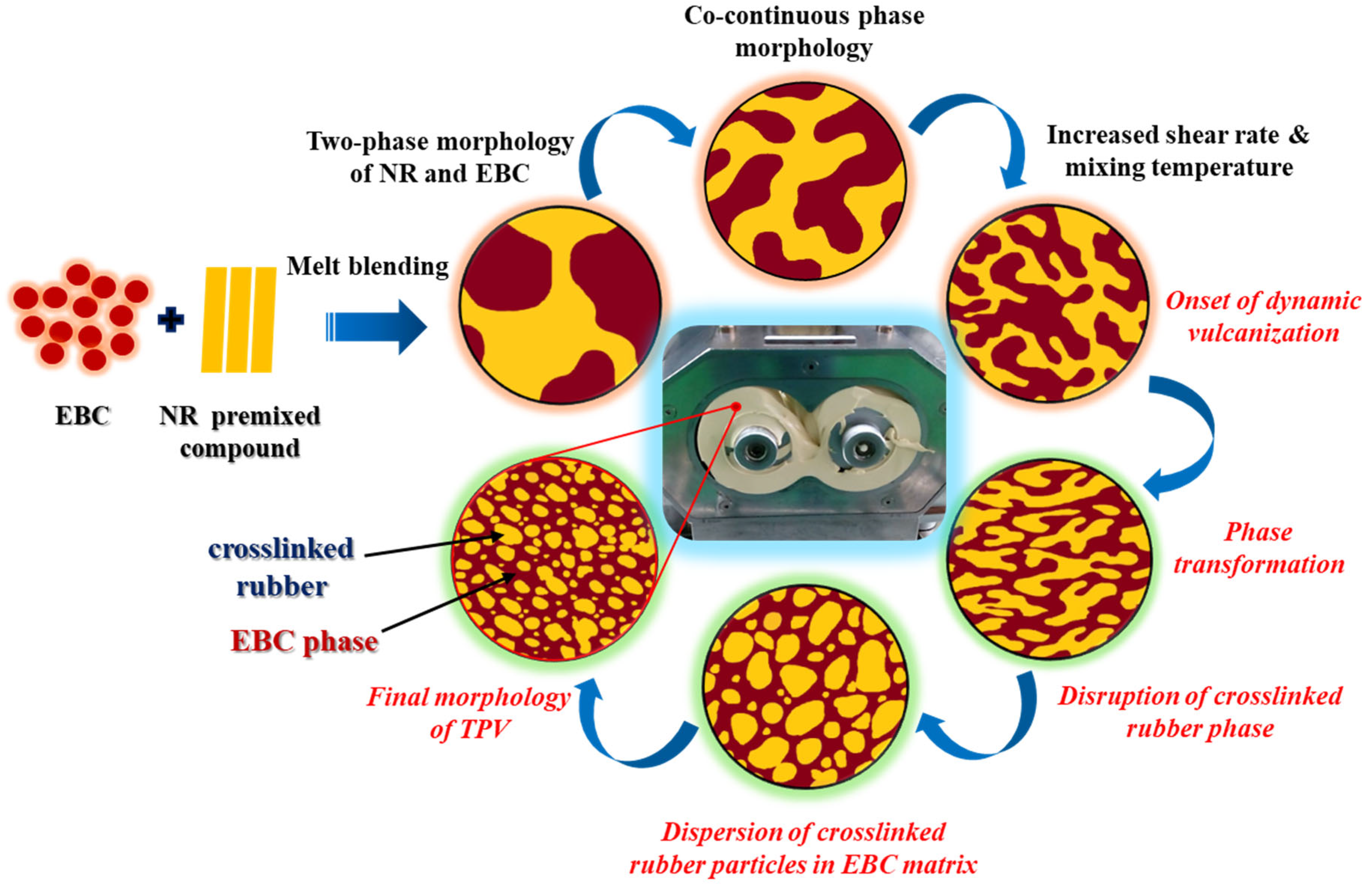

5.5. The Relationship between Phase Morphology, Crosslink Density, and Mixing/Blending Conditions

5.6. Mechanical, Rheological, and Dynamic Mechanical Properties

5.6.1. Physico-Mechanical Properties

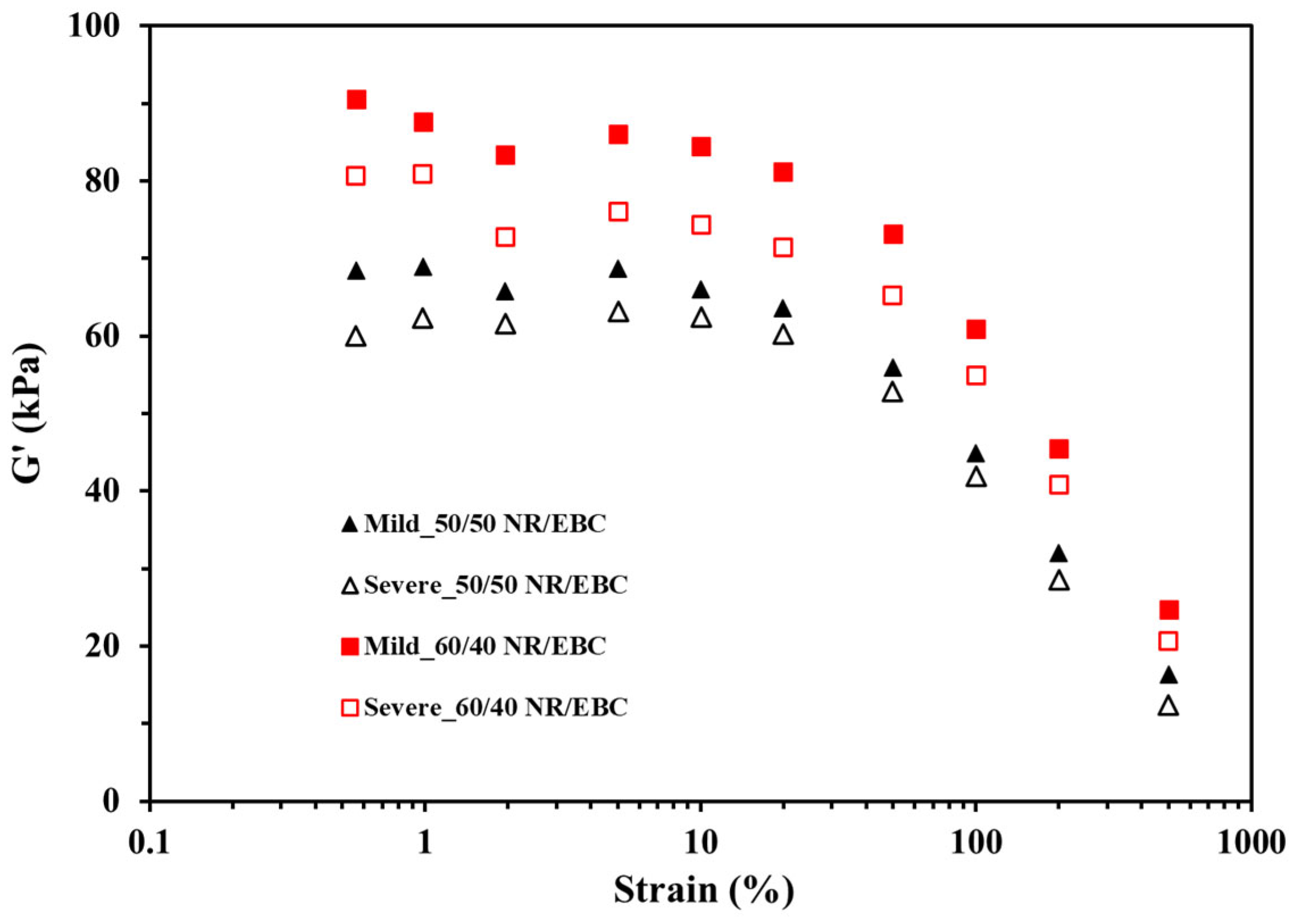

5.6.2. Viscoelastic Properties of NR/EBC TPVs

5.6.3. Dynamic Mechanical Properties of TPVs

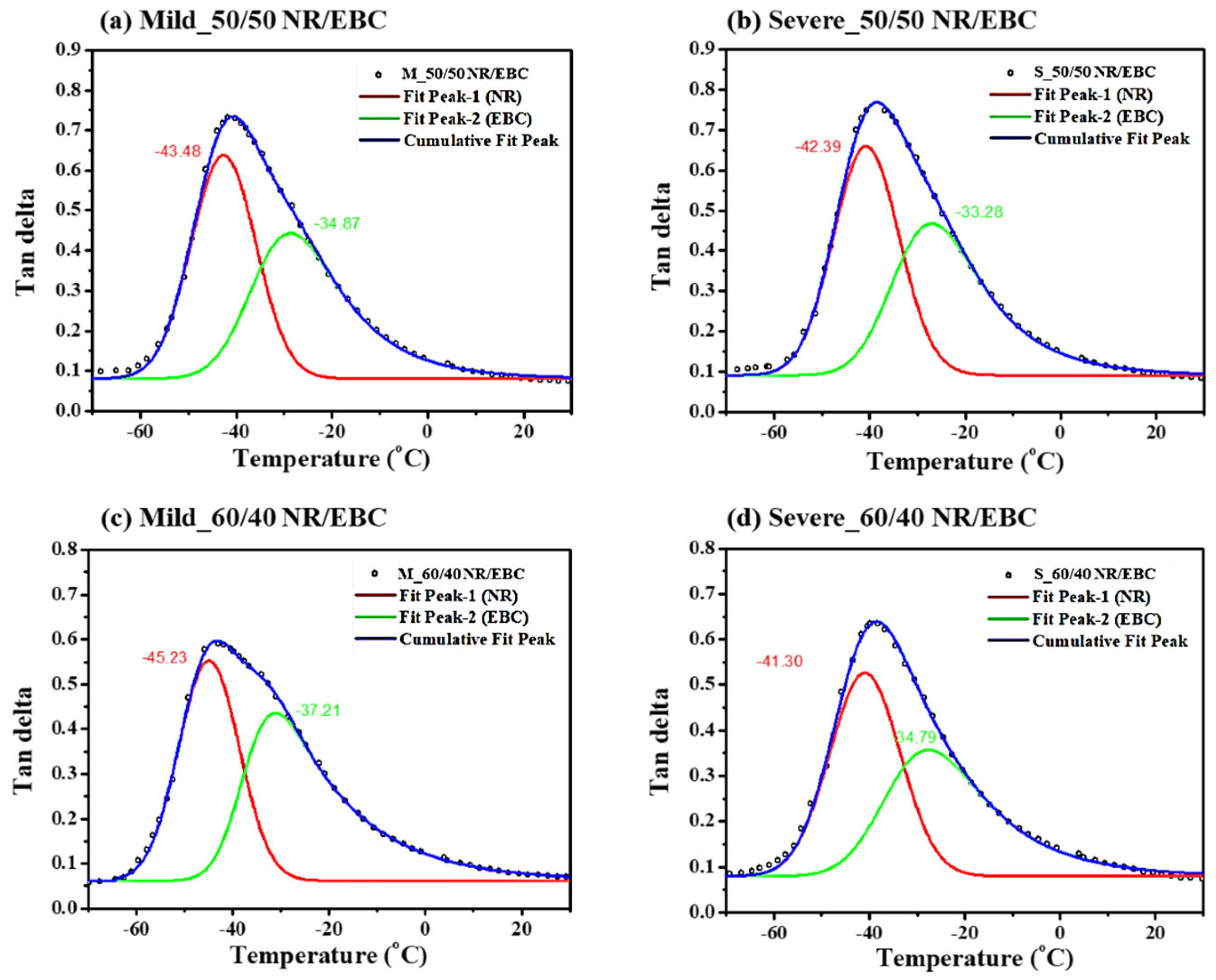

5.6.4. Glass Transition Temperature of NR/EBC TPVs

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Statistical Analysis of Processing Parameters’ Impacts on Mechanical Properties of NR/EBC TPVs

| Run Order | A | B | C | D | TS (MPa) | EB (%) | CS (%) | Tear Strength (N/mm) | Hardness (Shore A) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 30/70 | 80 | 80 | 20 | 4.12 | 697 | 27.64 | 41.90 | 63.60 |

| 2 | 30/70 | 80 | 80 | 25 | 3.98 | 706 | 27.51 | 40.60 | 63.10 |

| 3 | 30/70 | 80 | 100 | 20 | 3.85 | 698 | 27.17 | 39.90 | 63.10 |

| 4 | 30/70 | 80 | 100 | 25 | 3.58 | 733 | 27.45 | 38.00 | 62.80 |

| 5 | 30/70 | 120 | 80 | 20 | 3.72 | 714 | 26.94 | 40.80 | 64.00 |

| 6 | 30/70 | 120 | 80 | 25 | 3.51 | 706 | 26.02 | 38.80 | 63.60 |

| 7 | 30/70 | 120 | 100 | 20 | 3.47 | 708 | 25.91 | 40.00 | 64.20 |

| 8 | 30/70 | 120 | 100 | 25 | 3.21 | 701 | 25.37 | 38.10 | 63.50 |

| 9 | 40/60 | 80 | 80 | 20 | 4.42 | 633 | 21.49 | 40.80 | 58.30 |

| 10 | 40/60 | 80 | 80 | 25 | 4.12 | 645 | 21.95 | 38.80 | 57.90 |

| 11 | 40/60 | 80 | 100 | 20 | 4.14 | 620 | 20.87 | 39.70 | 58.90 |

| 12 | 40/60 | 80 | 100 | 25 | 3.92 | 607 | 21.59 | 37.60 | 57.70 |

| 13 | 40/60 | 120 | 80 | 20 | 4.14 | 638 | 21.71 | 41.00 | 58.40 |

| 14 | 40/60 | 120 | 80 | 25 | 3.93 | 630 | 20.56 | 37.70 | 58.30 |

| 15 | 40/60 | 120 | 100 | 20 | 3.99 | 646 | 20.12 | 37.60 | 58.10 |

| 16 | 40/60 | 120 | 100 | 25 | 4.05 | 581 | 20.67 | 35.90 | 58.10 |

| 17 | 50/50 | 80 | 80 | 20 | 5.23 | 567 | 21.01 | 39.70 | 55.80 |

| 18 | 50/50 | 80 | 80 | 25 | 5.15 | 542 | 20.38 | 41.30 | 55.40 |

| 19 | 50/50 | 80 | 100 | 20 | 4.92 | 536 | 20.39 | 40.50 | 55.60 |

| 20 | 50/50 | 80 | 100 | 25 | 4.63 | 524 | 19.93 | 38.30 | 55.00 |

| 21 | 50/50 | 120 | 80 | 20 | 5.25 | 526 | 19.76 | 41.60 | 55.40 |

| 22 | 50/50 | 120 | 80 | 25 | 4.77 | 532 | 19.45 | 38.80 | 54.70 |

| 23 | 50/50 | 120 | 100 | 20 | 4.85 | 536 | 18.54 | 40.20 | 55.10 |

| 24 | 50/50 | 120 | 100 | 25 | 4.53 | 555 | 20.13 | 39.60 | 54.20 |

| 25 | 60/40 | 80 | 80 | 20 | 5.48 | 419 | 17.58 | 42.70 | 52.60 |

| 26 | 60/40 | 80 | 80 | 25 | 4.61 | 427 | 17.46 | 38.90 | 52.10 |

| 27 | 60/40 | 80 | 100 | 20 | 4.94 | 415 | 17.07 | 35.00 | 51.50 |

| 28 | 60/40 | 80 | 100 | 25 | 4.19 | 386 | 17.67 | 33.60 | 50.20 |

| 29 | 60/40 | 120 | 80 | 20 | 4.86 | 415 | 17.24 | 38.30 | 51.50 |

| 30 | 60/40 | 120 | 80 | 25 | 4.45 | 406 | 17.29 | 35.60 | 50.80 |

| 31 | 60/40 | 120 | 100 | 20 | 4.47 | 377 | 16.50 | 35.40 | 51.40 |

| 32 | 60/40 | 120 | 100 | 25 | 4.32 | 371 | 18.11 | 31.90 | 50.30 |

| 33 | 30/70 | 80 | 80 | 20 | 3.65 | 619 | 26.59 | 38.70 | 63.00 |

| 34 | 30/70 | 80 | 80 | 25 | 3.47 | 672 | 25.70 | 37.20 | 62.50 |

| 35 | 30/70 | 80 | 100 | 20 | 3.12 | 638 | 25.32 | 36.20 | 61.70 |

| 36 | 30/70 | 80 | 100 | 25 | 3.25 | 627 | 26.02 | 33.90 | 61.50 |

| 37 | 30/70 | 120 | 80 | 20 | 3.44 | 662 | 26.10 | 36.30 | 61.70 |

| 38 | 30/70 | 120 | 80 | 25 | 3.29 | 624 | 25.35 | 34.80 | 61.10 |

| 39 | 30/70 | 120 | 100 | 20 | 3.06 | 627 | 23.92 | 34.90 | 62.60 |

| 40 | 30/70 | 120 | 100 | 25 | 3.02 | 616 | 25.78 | 33.40 | 61.78 |

| 41 | 40/60 | 80 | 80 | 20 | 4.07 | 563 | 22.28 | 38.30 | 58.10 |

| 42 | 40/60 | 80 | 80 | 25 | 3.81 | 581 | 22.08 | 35.50 | 57.60 |

| 43 | 40/60 | 80 | 100 | 20 | 3.66 | 572 | 21.72 | 35.30 | 57.50 |

| 44 | 40/60 | 80 | 100 | 25 | 3.51 | 560 | 22.06 | 34.40 | 58.20 |

| 45 | 40/60 | 120 | 80 | 20 | 3.61 | 546 | 21.43 | 35.70 | 59.00 |

| 46 | 40/60 | 120 | 80 | 25 | 3.39 | 570 | 21.05 | 35.10 | 58.50 |

| 47 | 40/60 | 120 | 100 | 20 | 3.38 | 569 | 21.78 | 34.40 | 59.30 |

| 48 | 40/60 | 120 | 100 | 25 | 3.05 | 598 | 22.39 | 33.90 | 58.50 |

| 49 | 50/50 | 80 | 80 | 20 | 4.77 | 519 | 19.53 | 40.00 | 55.10 |

| 50 | 50/50 | 80 | 80 | 25 | 4.81 | 503 | 19.55 | 39.00 | 54.50 |

| 51 | 50/50 | 80 | 100 | 20 | 4.27 | 545 | 18.44 | 37.00 | 54.30 |

| 52 | 50/50 | 80 | 100 | 25 | 3.99 | 513 | 18.93 | 36.90 | 54.30 |

| 53 | 50/50 | 120 | 80 | 20 | 4.45 | 534 | 18.46 | 39.00 | 54.80 |

| 54 | 50/50 | 120 | 80 | 25 | 4.40 | 540 | 18.66 | 36.70 | 54.50 |

| 55 | 50/50 | 120 | 100 | 20 | 4.44 | 521 | 18.46 | 38.40 | 54.40 |

| 56 | 50/50 | 120 | 100 | 25 | 4.19 | 520 | 19.02 | 37.40 | 54.10 |

| 57 | 60/40 | 80 | 80 | 20 | 5.40 | 439 | 17.81 | 39.30 | 50.90 |

| 58 | 60/40 | 80 | 80 | 25 | 4.88 | 441 | 17.30 | 38.80 | 51.50 |

| 59 | 60/40 | 80 | 100 | 20 | 5.19 | 426 | 18.77 | 35.30 | 52.00 |

| 60 | 60/40 | 80 | 100 | 25 | 4.66 | 392 | 17.57 | 36.30 | 51.00 |

| 61 | 60/40 | 120 | 80 | 20 | 5.09 | 419 | 17.43 | 35.40 | 52.00 |

| 62 | 60/40 | 120 | 80 | 25 | 4.81 | 407 | 18.63 | 34.20 | 51.40 |

| 63 | 60/40 | 120 | 100 | 20 | 4.79 | 392 | 18.03 | 36.30 | 51.30 |

| 64 | 60/40 | 120 | 100 | 25 | 4.24 | 369 | 18.54 | 33.20 | 50.00 |

Appendix B

Appendix B.1. Mechanical and Dynamic Mechanical Properties

| Mixing Conditions | NR/EBC Blend Ratios | Tensile Properties | DMA | |||

|---|---|---|---|---|---|---|

| TS (MPa) | EB (%) | Tan δ | E’ (MPa) | Tg (°C) | ||

| Mild (selected optimal) | 50/50 | 4.80 ± 0.02 | 510 ± 8 | 0.590 | 170.96 | −43.00 |

| 60/40 | 4.77 ± 0.14 | 436 ± 8 | 0.731 | 122.94 | −41.70 | |

| Severe | 50/50 | 4.32 ± 0.13 | 520 ± 5 | 0.634 | 119.02 | −38.10 |

| 60/40 | 4.15 ± 0.08 | 368 ± 7 | 0.748 | 183.35 | −40.60 | |

Appendix B.2. Deconvolution for Glass Transition Temperature (Tg) Analysis of NR/EBC TPVs

References

- Zheng, M.; Zhang, S.; Chen, Y.; Wu, Q.; Li, Q.; Wang, S. Structure evolution of bio-based PLA/ENR thermoplastic vulcanizates during dynamic vulcanization processing. Polym. Test. 2020, 82, 106324. [Google Scholar] [CrossRef]

- Ning, N.; Li, S.; Wu, H.; Tian, H.; Yao, P.; Hu, G.-H.; Tian, M.; Zhang, L. Preparation, microstructure, and microstructure-properties relationship of thermoplastic vulcanizates (TPVs): A review. Prog. Polym. Sci. 2018, 79, 61–97. [Google Scholar] [CrossRef]

- Pichaiyut, S.; Faibunchan, P.; Kummerlöwe, C.; Vennemann, N.; Nakason, C. Investigation of rheological, morphological, and mechanical properties, thermal stability, biodegradability of the dynamically cured natural rubber/polyester blends. J. Polym. Environ. 2023, 31, 1051–1070. [Google Scholar] [CrossRef]

- Coran, A.Y.; Patel, R. Rubber-thermoplastic compositions. Part I. EPDM-polypropylene thermoplastic vulcanizates. Rubber Chem. Technol. 1980, 53, 141–150. [Google Scholar] [CrossRef]

- Liang, Y.; Wang, H.; Li, J.; Wu, S.; Han, W.; Kang, H.; Fang, Q. Green thermoplastic vulcanizates based on silicone rubber and poly(butylene succinate) via in situ interfacial compatibilization. ACS Omega 2021, 6, 4461–4469. [Google Scholar] [CrossRef] [PubMed]

- Dey, P.; Naskar, K.; Dash, B.; Nair, S.; Unnikrishnan, G.; Nando, G.B. Thermally crosslinked and sulphur-cured soft TPVs based on S-EB-S and S-SBR blends. RSC Adv. 2014, 4, 35879–35895. [Google Scholar] [CrossRef]

- Coran, A.Y.; Das, B.; Patel, R.P. Thermoplastic Vulcanizates of Olefin Rubber and Polyolefin Resin. U.S. Patent 4130535, 19 December 1978. [Google Scholar]

- Abdou-Sabet, S.; Fath, M.A. Thermoplastic Elastomeric Blends of Olefin Rubber and Polyolefin Resin. U.S. Patent 4311628, 19 January 1982. [Google Scholar]

- Naskar, K. Thermoplastic elastomers based on PP/EPDM blends by dynamic vulcanization. Rubber Chem. Technol. 2007, 80, 504–519. [Google Scholar] [CrossRef]

- Bhattacharya, A.B.; Chatterjee, T.; Naskar, K. Automotive applications of thermoplastic vulcanizates. J. Appl. Polym. Sci. 2020, 137, 49181. [Google Scholar] [CrossRef]

- Mohite, A.S.; Rajpurkar, Y.D.; More, A.P. Bridging the gap between rubbers and plastics: A review on thermoplastic polyolefin elastomers. Polym. Bull. 2022, 79, 1309–1343. [Google Scholar] [CrossRef]

- Sengupta, P.; Noordermeer, J.W. Effects of composition and processing conditions on morphology and properties of thermoplastic elastomer blends of SEBS-PP-oil and dynamically vulcanized EPDM-PP-oil. J. Elastomers Plast. 2004, 36, 307–331. [Google Scholar] [CrossRef]

- Shibryaeva, L.; Lunis, G.; Popov, A. Polymer compounds based on the three-component blend PP-EPDM-oil: Effect of their structure on physical properties. Polym.-Plast. Technol. Eng. 2001, 40, 715–725. [Google Scholar] [CrossRef]

- De, S.; Bhowmick, A.K. Thermoplastic Elastomers from Rubber-Plastic Blends; Ellis Horwood: New York, NY, USA, 1990. [Google Scholar]

- Ibrahim, A.; Dahlan, M. Thermoplastic natural rubber blends. Prog. Polym. Sci. 1998, 23, 665–706. [Google Scholar] [CrossRef]

- Passador, F.R.; Alzate Rojas, G.J.; Pessan, L.A. Thermoplastic elastomers based on natural rubber/polypropylene blends: Effect of blend ratios and dynamic vulcanization on rheological, thermal, mechanical, and morphological properties. J. Macromol. Sci. Part B 2013, 52, 1142–1157. [Google Scholar] [CrossRef]

- Chen, L.; Cao, B.; Guo, X.; Quan, Y.; Yan, S. Realizing simultaneous high-temperature strength and low-temperature elongation in polyolefin elastomer toughened polypropylene via controlling the dispersed phase size. J. Appl. Polym. Sci. 2023, 140, e53537. [Google Scholar] [CrossRef]

- Wang, K.; Chen, L.; Gao, Y.; Jiang, D.; Quan, Y.; Yan, S. Effect of morphology development on the low-temperature tensile properties of PP/POE blends. J. Appl. Polym. Sci. 2022, 139, 52192. [Google Scholar] [CrossRef]

- Dey, P.; Naskar, K.; Dash, B.; Nair, S.; Unnikrishnan, G.; Nando, G.B. Selective dispersion of carbon fillers into dynamically vulcanized rubber/plastic blends: A thermodynamic approach to evaluate polymer reinforcement and conductivity enhancement. RSC Adv. 2015, 5, 31886–31900. [Google Scholar] [CrossRef]

- McNally, T.; McShane, P.; Nally, G.; Murphy, W.; Cook, M.; Miller, A. Rheology, phase morphology, mechanical, impact and thermal properties of polypropylene/metallocene catalysed ethylene 1-octene copolymer blends. Polymer 2002, 43, 3785–3793. [Google Scholar] [CrossRef]

- Babu, R.R.; Naskar, K. Recent Developments on Thermoplastic Elastomers by Dynamic Vulcanization. In Advanced Rubber Composites; Heinrich, G., Ed.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 219–247. [Google Scholar] [CrossRef]

- Babu, R.R.; Singha, N.; Naskar, K. Phase morphology and melt rheological behavior of uncrosslinked and dynamically crosslinked polyolefin blends: Role of macromolecular structure. Polym. Bull. 2011, 66, 95–118. [Google Scholar] [CrossRef]

- Yan, X.; Xu, X.; Zhu, T.; Zhang, C.; Song, N.; Zhu, L. Phase morphological evolution and rheological properties of polypropylene/ethylene–octene copolymer blends. Mater. Sci. Eng. A 2008, 476, 120–125. [Google Scholar] [CrossRef]

- Flory, P.J.; Rehner, J. Statistical mechanics of crosslinked polymer networks II. Swelling. J. Chem. Phys. 1943, 11, 521–526. [Google Scholar] [CrossRef]

- Bhattacharya, A.B.; Raju, A.T.; Chatterjee, T.; Naskar, K. Development and characterizations of ultra-high molecular weight EPDM/PP based TPV nanocomposites for automotive applications. Polym. Compos. 2020, 41, 4950–4962. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: New York, NY, USA, 2020. [Google Scholar]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Reactive compatibilization of poly trimethylene terephthalate (PTT) and polylactic acid (PLA) using terpolymer: Factorial design optimization of mechanical properties. Mater. Des. 2016, 110, 581–591. [Google Scholar] [CrossRef]

- Palanikumar, K.; Davim, J.P. Mathematical model to predict tool wear on the machining of glass fibre reinforced plastic composites. Mater. Des. 2007, 28, 2008–2014. [Google Scholar] [CrossRef]

- Reffai Syed Ismail, S.M.; Chatterjee, T.; Naskar, K. Development of novel polar thermoplastic vulcanizates based on ethylene acrylic elastomer and polyamide 12 with special reference to heat and oil aging. J. Appl. Polym. Sci. 2015, 132, 41. [Google Scholar] [CrossRef]

- Awasthi, P.; Banerjee, S.S. Fused deposition modeling of thermoplastic elastomeric materials: Challenges and opportunities. Addit. Manuf. 2021, 46, 102177. [Google Scholar] [CrossRef]

- Banerjee, S.S.; Bhowmick, A.K. Dynamic vulcanization of novel nanostructured polyamide 6/fluoroelastomer thermoplastic elastomeric blends with special reference to morphology, physical properties and degree of vulcanization. Polymer 2015, 57, 105–116. [Google Scholar] [CrossRef]

- He, M.; Li, Y.; Qiao, B.; Ma, X.; Song, J.; Wang, M. Effect of dicumyl peroxide and phenolic resin as a mixed curing system on the mechanical properties and morphology of TPVs based on HDPE/ground tire rubber. Polym. Compos. 2015, 36, 1907–1916. [Google Scholar] [CrossRef]

- Dey, P.; Naskar, K.; Nando, G.B.; Dash, B.; Nair, S.; Unnikrishnan, G. Meticulous analysis and consequences of microstructure changes on melt rheology and dynamic viscoelasticity of thermoplastic vulcanizates upon reprocessing. J. Appl. Polym. Sci. 2014, 131, 23. [Google Scholar] [CrossRef]

- Li, S.; Tian, H.; Zhang, B.; Hu, G.-H.; Liu, C.-Y.; Zhang, L.; Tian, M. Non-linear and linear viscoelastic behaviors of thermoplastic vulcanizates containing rubber nanoparticle agglomerates. Polymer 2019, 181, 121793. [Google Scholar] [CrossRef]

- Menard, K.P.; Menard, N. Dynamic Mechanical Analysis; CRC Press: New York, NY, USA, 2020. [Google Scholar]

- Hui, S.; Chaki, T.K.; Chattopadhyay, S. Dynamic and capillary rheology of LDPE-EVA–based thermoplastic elastomer: Effect of silica nanofiller. Polym. Compos. 2010, 31, 377–391. [Google Scholar] [CrossRef]

- Payne, A.R. The dynamic properties of carbon black-loaded natural rubber vulcanizates. Part I. J. Appl. Polym. Sci. 1962, 6, 57–63. [Google Scholar] [CrossRef]

- Goharpey, F.; Katbab, A.; Nazockdast, H. Mechanism of morphology development in dynamically cured EPDM/PP TPEs. I. Effects of state of cure. J. Appl. Polym. Sci. 2001, 81, 2531–2544. [Google Scholar] [CrossRef]

- Faibunchan, P.; Pichaiyut, S.; Chueangchayaphan, W.; Kummerlöwe, C.; Venneman, N.; Nakason, C. Influence type of natural rubber on properties of green biodegradable thermoplastic natural rubber based on poly(butylene succinate). Polym. Adv. Technol. 2019, 30, 1010–1026. [Google Scholar] [CrossRef]

- Wu, Q.; Fang, J.; Zheng, M.; Luo, Y.; Wang, X.; Xu, L.; Zhang, C. Morphology evolution and rheological behaviors of PP/SR thermoplastic vulcanizate. Polymers 2019, 11, 175. [Google Scholar] [CrossRef] [PubMed]

| Materials | Amount (phr) |

|---|---|

| Natural rubber (STR 5L) | 100 |

| Zinc oxide (ZnO) | 5 |

| Stearic acid | 1 |

| Phenolic resin (SP1045) | 10 |

| Stannous chloride (SnCl2) | 1 |

| Wingstay L | 1 |

| Time (min) | Action |

|---|---|

| 0 | Add NR |

| 3 | Add stearic acid and ZnO |

| 5 | Add phenolic resin and SnCl2 |

| 10 | Add Wingstay L |

| 12 | Discharge |

| NR/EBC Blend Ratios | NR Premixed Compound (%wt) | EBC (%wt) |

|---|---|---|

| 30/70 | 30 | 70 |

| 40/60 | 40 | 60 |

| 50/50 | 50 | 50 |

| 60/40 | 60 | 40 |

| Parameter | Mixing Conditions |

|---|---|

| Rotor geometry type | Cam rotor |

| Fill factor | 0.75 |

| NR/EBC blend ratios (by weight) | 30/70, 40/60, 50/50, 60/40 |

| Initial mixing temperature (°C) | 80, 120 |

| Rotor speed (rpm) | 80, 100 |

| Mixing time (min) | 20, 25 |

| Parameter Variables | Units | Factors | Levels | |||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| NR/EBC Blend Ratio | %wt | A | 30/70 | 40/60 | 50/50 | 60/40 |

| Mixing Temperature | °C | B | 80 | 120 | - | - |

| Rotor Speed | rpm | C | 80 | 100 | - | - |

| Mixing Time | min | D | 20 | 25 | - | - |

| Source | DF | SS | MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 18 | 23.4103 | 1.30057 | 15.97 | 0.000 * |

| A | 3 | 19.1977 | 6.39922 | 78.59 | 0.000 * |

| B | 1 | 0.9084 | 0.90845 | 11.16 | 0.002 * |

| C | 1 | 1.6272 | 1.62722 | 19.98 | 0.000 * |

| D | 1 | 1.1329 | 1.13289 | 13.91 | 0.001 * |

| AB | 3 | 0.0878 | 0.02926 | 0.36 | 0.783 |

| AC | 3 | 0.0530 | 0.01766 | 0.22 | 0.884 |

| AD | 3 | 0.3238 | 0.10795 | 1.33 | 0.278 |

| BC | 1 | 0.0686 | 0.06858 | 0.84 | 0.364 |

| BD | 1 | 0.0106 | 0.01063 | 0.13 | 0.719 |

| CD | 1 | 0.0002 | 0.00024 | 0.00 | 0.957 |

| Error | 45 | 3.6641 | 0.08142 | ||

| Lack of Fit | 13 | 0.2214 | 0.01703 | 0.16 | 0.999 |

| Pure Error | 32 | 3.4427 | 0.10758 | ||

| Total | 63 | 27.0744 | |||

| Model Summary: S = 0.285349; R2 = 86.47%; R2(adj) = 81.05%; R2(pred) = 72.63% | |||||

| Source | DF | SS | MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 18 | 616,839 | 34,269 | 33.64 | 0.000 * |

| A | 3 | 608,833 | 202,944 | 199.24 | 0.000 * |

| B | 1 | 683 | 683 | 0.67 | 0.417 |

| C | 1 | 2093 | 2093 | 2.05 | 0.159 |

| D | 1 | 365 | 365 | 0.36 | 0.552 |

| AB | 3 | 1613 | 538 | 0.53 | 0.665 |

| AC | 3 | 2055 | 685 | 0.67 | 0.573 |

| AD | 3 | 522 | 174 | 0.17 | 0.916 |

| BC | 1 | 0 | 0 | 0.00 | 0.993 |

| BD | 1 | 55 | 55 | 0.05 | 0.817 |

| CD | 1 | 619 | 619 | 0.61 | 0.440 |

| Error | 45 | 45,836 | 1019 | ||

| Lack of Fit | 13 | 3839 | 295 | 0.23 | 0.997 |

| Pure Error | 32 | 41,997 | 1312 | ||

| Total | 63 | 662,675 | |||

| Model Summary: S = 31.9152; R2 = 93.08%; R2(adj) = 90.32%; R2(pred) = 86.01% | |||||

| Source | DF | SS | MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 18 | 658.693 | 36.594 | 68.65 | 0.000 * |

| A | 3 | 645.845 | 215.282 | 403.86 | 0.000 * |

| B | 1 | 4.759 | 4.759 | 8.93 | 0.005 * |

| C | 1 | 0.930 | 0.930 | 1.74 | 0.193 |

| D | 1 | 0.268 | 0.268 | 0.50 | 0.482 |

| AB | 3 | 2.454 | 0.818 | 1.53 | 0.219 |

| AC | 3 | 1.385 | 0.462 | 0.87 | 0.466 |

| AD | 3 | 0.215 | 0.072 | 0.13 | 0.939 |

| BC | 1 | 0.067 | 0.067 | 0.13 | 0.724 |

| BD | 1 | 0.424 | 0.424 | 0.80 | 0.377 |

| CD | 1 | 2.346 | 2.346 | 4.40 | 0.042 * |

| Error | 45 | 23.988 | 0.533 | ||

| Lack of Fit | 13 | 3.342 | 0.257 | 0.40 | 0.960 |

| Pure Error | 32 | 20.645 | 0.645 | ||

| Total | 63 | 682.681 | |||

| Model Summary: S = 0.730107; R2 = 96.49%; R2(adj) = 95.08%; R2(pred) = 92.89% | |||||

| Source | DF | SS | MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 18 | 227.893 | 12.6607 | 3.42 | 0.000 * |

| A | 3 | 66.783 | 22.2610 | 6.01 | 0.002 * |

| B | 1 | 23.766 | 23.7656 | 6.42 | 0.015 * |

| C | 1 | 61.623 | 61.6225 | 16.65 | 0.000 * |

| D | 1 | 41.281 | 41.2806 | 11.15 | 0.002 * |

| AB | 3 | 10.888 | 3.6294 | 0.98 | 0.410 |

| AC | 3 | 11.014 | 3.6713 | 0.99 | 0.405 |

| AD | 3 | 1.721 | 0.5735 | 0.15 | 0.926 |

| BC | 1 | 9.302 | 9.3025 | 2.51 | 0.120 |

| BD | 1 | 1.266 | 1.2656 | 0.34 | 0.562 |

| CD | 1 | 0.250 | 0.2500 | 0.07 | 0.796 |

| Error | 45 | 166.567 | 3.7015 | ||

| Lack of Fit | 13 | 14.997 | 1.1536 | 0.24 | 0.995 |

| Pure Error | 32 | 151.570 | 4.7366 | ||

| Total | 63 | 394.459 | |||

| Model Summary: S = 1.92392; R2 = 57.77%; R2(adj) = 40.88%; R2(pred) = 14.59% | |||||

| Source | DF | SS | MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 18 | 1158.01 | 64.334 | 147.48 | 0.000 * |

| A | 3 | 1148.32 | 382.774 | 877.46 | 0.000 * |

| B | 1 | 0.01 | 0.008 | 0.02 | 0.892 |

| C | 1 | 1.42 | 1.416 | 3.25 | 0.078 |

| D | 1 | 4.26 | 4.264 | 9.78 | 0.003 * |

| AB | 3 | 2.17 | 0.723 | 1.66 | 0.190 |

| AC | 3 | 0.98 | 0.326 | 0.75 | 0.530 |

| AD | 3 | 0.31 | 0.105 | 0.24 | 0.868 |

| BC | 1 | 0.24 | 0.235 | 0.54 | 0.467 |

| BD | 1 | 0.15 | 0.152 | 0.35 | 0.558 |

| CD | 1 | 0.15 | 0.152 | 0.35 | 0.558 |

| Error | 45 | 19.63 | 0.436 | ||

| Lack of Fit | 13 | 2.13 | 0.164 | 0.30 | 0.988 |

| Pure Error | 32 | 17.50 | 0.547 | ||

| Total | 63 | 1177.64 | |||

| Model Summary: S = 0.660478; R2 = 98.33%; R2(adj) = 97.67%; R2(pred) = 96.63% | |||||

| Response | Regression Equation | R2 | R2(adj) | R2(pred) |

|---|---|---|---|---|

| Tensile strength (MPa) | Y = 4.1868 − 0.7034A1 − 0.3624A2 + 0.4788A3 + 0.5870A4 + 0.1191B1 − 0.1191B2 + 0.1595C1 − 0.1595C2 + 0.1330D1 − 0.1330D2 | 84.46% | 82.82% | 80.41% |

| Elongation at break (%) | Y = 551.87 + 119.84A1 + 45.61A2 − 19.77A3 − 145.67A4 + 3.27B1 − 3.27B2 + 5.72C1 − 5.72C2 + 2.39D1 − 2.39D2 | 92.35% | 91.54% | 90.35% |

| Compression set (%) | Y = 21.1903 + 4.985A1 + 0.293A2 − 1.775A3 − 3.503A4 + 0.2727B1 − 0.2727B2 + 0.1206C1 − 0.1206C2 − 0.0647D1 + 0.0647D2 + 0.1915(CD)11 − 0.1915(CD)12 − 0.1915(CD)21 + 0.1915(CD)22 | 95.82% | 95.30% | 94.54% |

| Tear strength (kN/mm) | Y = 37.497 + 0.222A1 − 0.516A2 + 1.528A3 − 1.234A4 + 0.609B1 − 0.609B2 + 0.981C1 − 0.981C2 + 0.803D1 − 0.803D2 + 0.381(BC)11 − 0.381(BC)12 − 0.381(BC)21 + 0.381(BC)22 | 51.40% | 45.33% | 36.52% |

| Hardness (Shore A) | Y = 56.7794 + 5.957A1 + 1.496A2 − 1.954A3 − 5.498A4 + 0.0113B1 − 0.0113B2 + 0.1488C1 − 0.1488C2 + 0.2581D1 − 0.2581D2 | 97.99% | 97.78% | 97.47% |

| Variable Parameters | Code Level | Condition Setting |

|---|---|---|

| NR/EBC blend ratio | A4 | 60/40 |

| Mixing temperature (°C) | B1 | 80 |

| Rotor speed (rpm) | C1 | 80 |

| Mixing time (min) | D1 | 20 |

| Response | Target | Fit | SE Fit | 95%CI | 95%PI |

|---|---|---|---|---|---|

| Tensile strength (MPa) | max. | 5.39 | 0.155 | (5.081, 5.707) | (4.739, 6.048) |

| Elongation at break (%) | min. | 406.2 | 7.490 | (391.22, 421.18) | (344.43, 467.96) |

| Compression set (%) | min. | 18.21 | 0.252 | (17.701, 18.712) | (16.690, 19.723) |

| Tear strength (kN/mm) | max. | 39.04 | 0.654 | (37.727, 40.348) | (35.106, 42.969) |

| Hardness (Shore A) | min. | 51.7 | 0.213 | (51.273, 52.126) | (50.341, 53.057) |

| Mixing Conditions | Parameter Setting | ||

|---|---|---|---|

| Mixing Temperature (°C) | Rotor Speed (rpm) | Mixing Time (min) | |

| Mild (selected optimal) | 80 | 80 | 20 |

| Severe | 120 | 100 | 25 |

| Mixing Conditions | NR/EBC Blend Ratios | Diameter (µm) | Crosslink Density (1 × 10−5 mol/cm3) | |

|---|---|---|---|---|

| Mean | SD | |||

| Mild (selected optimal) | 50/50 | 0.4370 | 0.2286 | 7.68 ± 0.03 |

| 60/40 | 0.4534 | 0.2534 | 9.83 ± 0.30 | |

| Severe | 50/50 | 0.4589 | 0.2616 | 7.83 ± 0.05 |

| 60/40 | 0.4215 | 0.2200 | 9.03 ± 0.39 | |

| Mixing Conditions | NR/EBC Blend Ratios | Tg of TPVs (°C) | Mixing Conditions | |

|---|---|---|---|---|

| Tg-NR Phase (°C) | Tg-EBC Phase (°C) | |||

| NR | 100/0 | −40.60 | - | - |

| EBC | 0/100 | −32.70 | - | - |

| Mild condition (selected optimal) | 50/50 | −43.00 | −45.23 | −37.21 |

| 60/40 | −41.70 | −43.48 | −34.87 | |

| Severe condition | 50/50 | −38.10 | −41.30 | −34.79 |

| 60/40 | −40.60 | −42.39 | −33.28 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Phupewkeaw, N.; Sae-Oui, P.; Sirisinha, C. Optimizing Processing Parameters for NR/EBC Thermoplastic Vulcanizates: A Comprehensive Full Factorial Design of Experiments (DOE) Strategy. Polymers 2024, 16, 1963. https://doi.org/10.3390/polym16141963

Phupewkeaw N, Sae-Oui P, Sirisinha C. Optimizing Processing Parameters for NR/EBC Thermoplastic Vulcanizates: A Comprehensive Full Factorial Design of Experiments (DOE) Strategy. Polymers. 2024; 16(14):1963. https://doi.org/10.3390/polym16141963

Chicago/Turabian StylePhupewkeaw, Nataphon, Pongdhorn Sae-Oui, and Chakrit Sirisinha. 2024. "Optimizing Processing Parameters for NR/EBC Thermoplastic Vulcanizates: A Comprehensive Full Factorial Design of Experiments (DOE) Strategy" Polymers 16, no. 14: 1963. https://doi.org/10.3390/polym16141963

APA StylePhupewkeaw, N., Sae-Oui, P., & Sirisinha, C. (2024). Optimizing Processing Parameters for NR/EBC Thermoplastic Vulcanizates: A Comprehensive Full Factorial Design of Experiments (DOE) Strategy. Polymers, 16(14), 1963. https://doi.org/10.3390/polym16141963