Electromechanical Performances of Polyvinyl Chloride Gels Using (Polyvinyl Chloride-Co-Vinyl Acetate) (P(VC-VA)) Synergistic Plasticization

Abstract

1. Introduction

2. Material and Methods

2.1. Preparation of PVC Gels

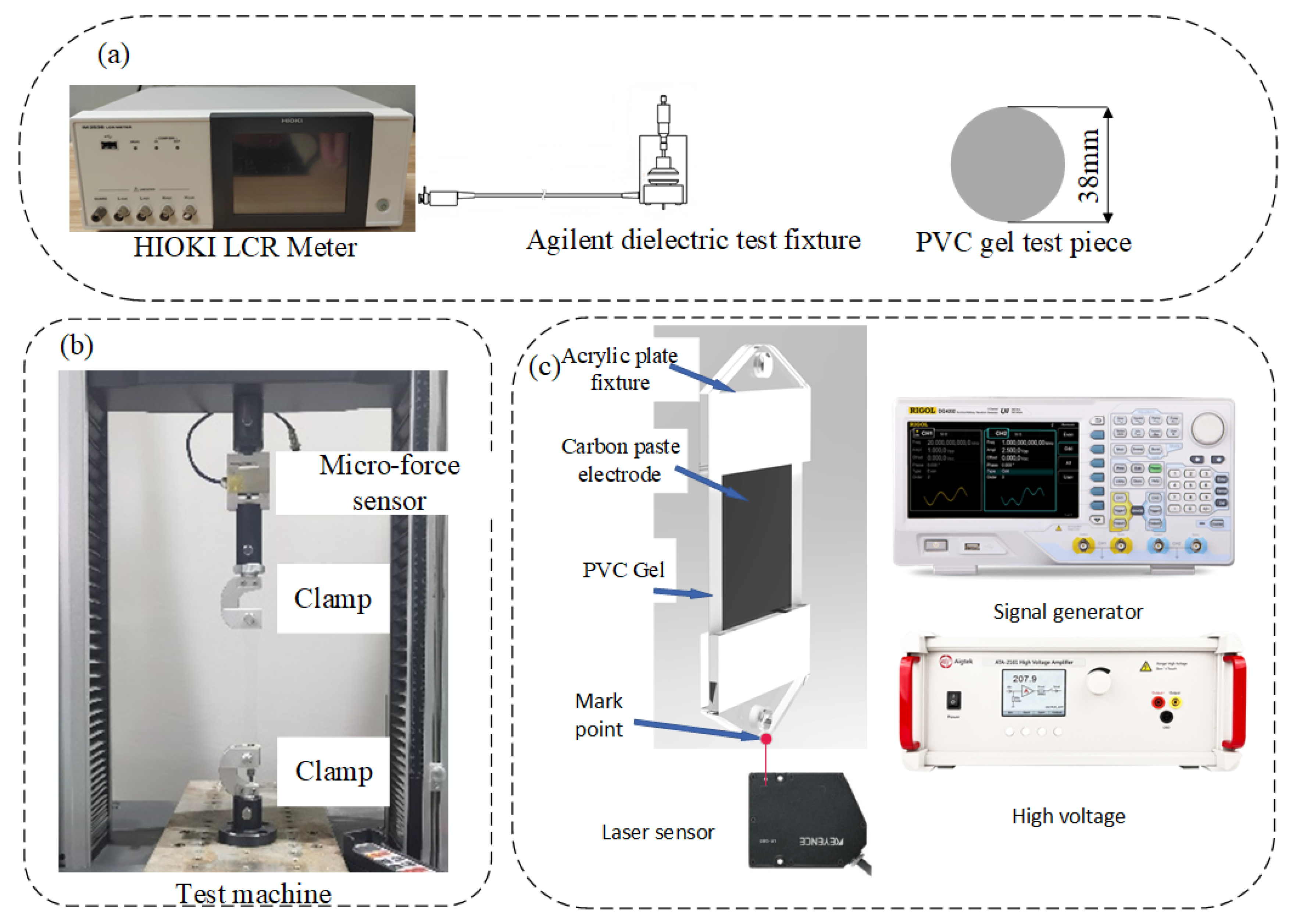

2.2. Relative Dielectric Constant Measurements

2.3. Mechanical Tension Measurements

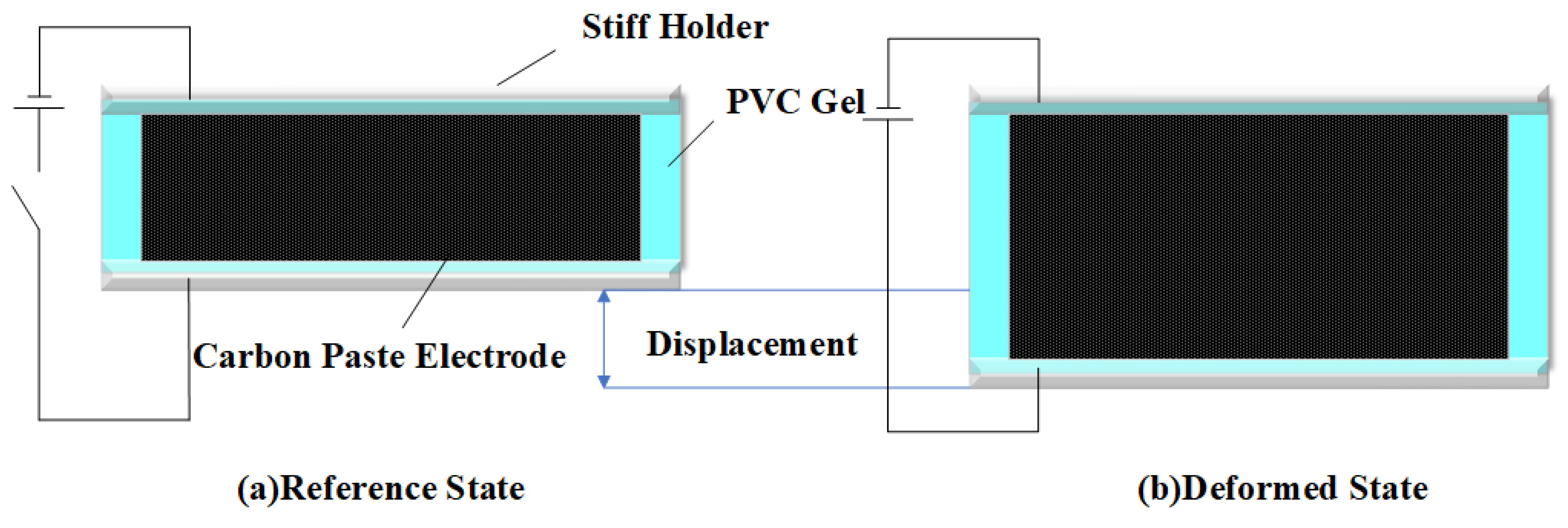

2.4. Electromechanical Displacement Measurements

3. Results and Discussion

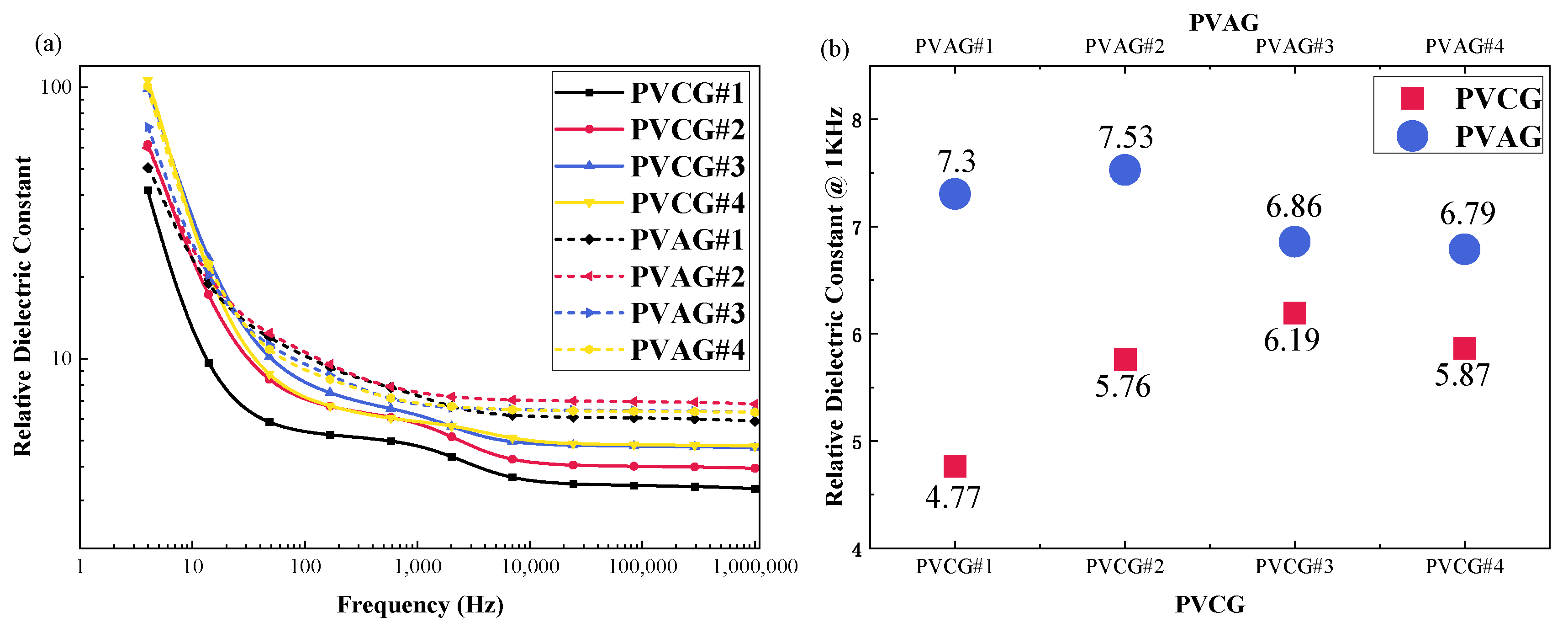

3.1. Relative Dielectric Constant Measurements

3.1.1. Effects of DBA and P(VC-VA) on Relative Dielectric Constant

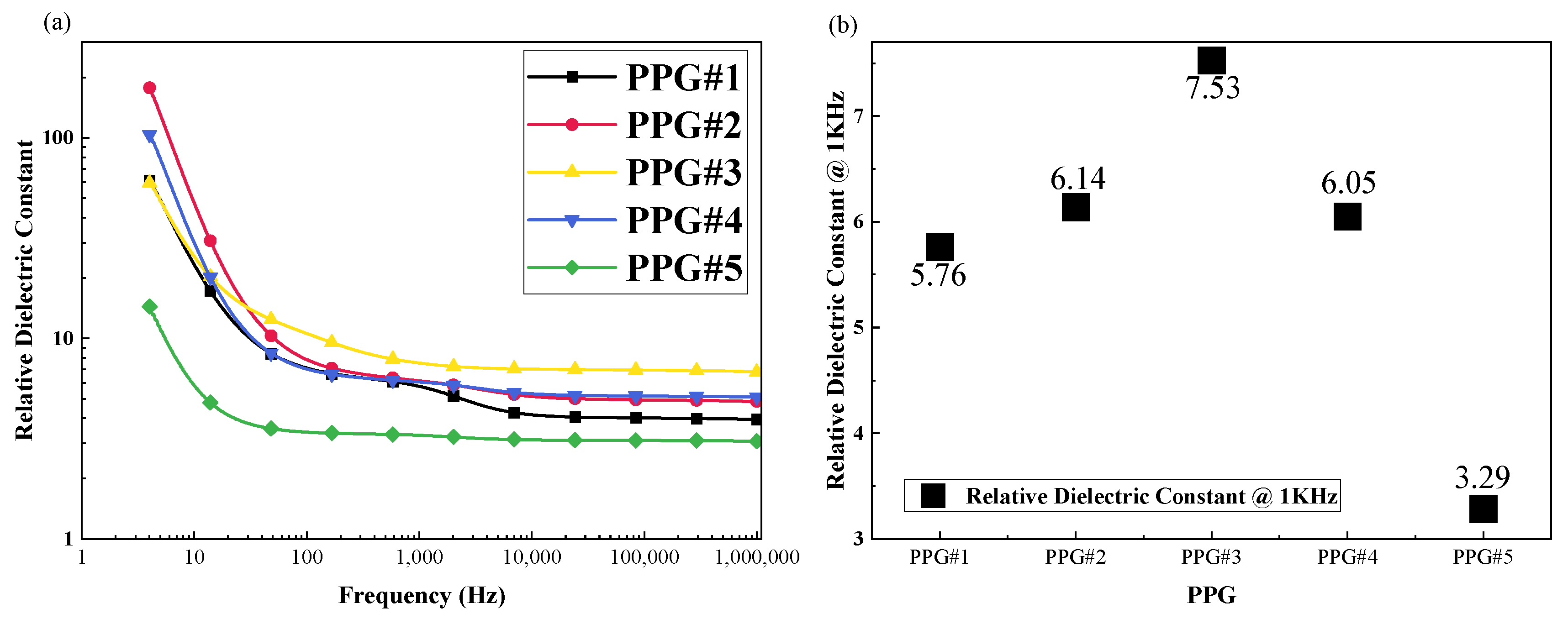

3.1.2. Effect of P(VC-VA) on Relative Dielectric Constant

3.2. Mechanical Tension Measurements

3.2.1. The Joint Effect of DBA and P(VC-VA) on the Mechanical Modulus

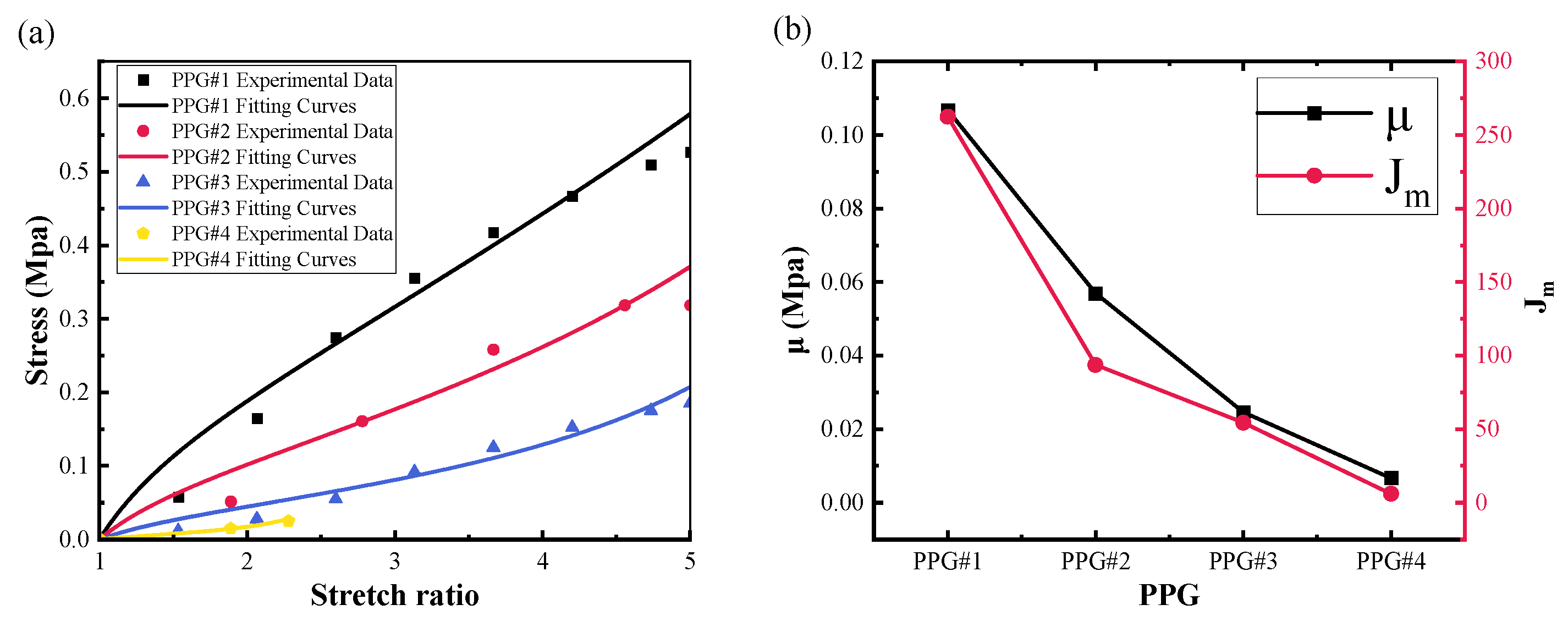

3.2.2. Effect of P(VC-VA) on Mechanical Modulus

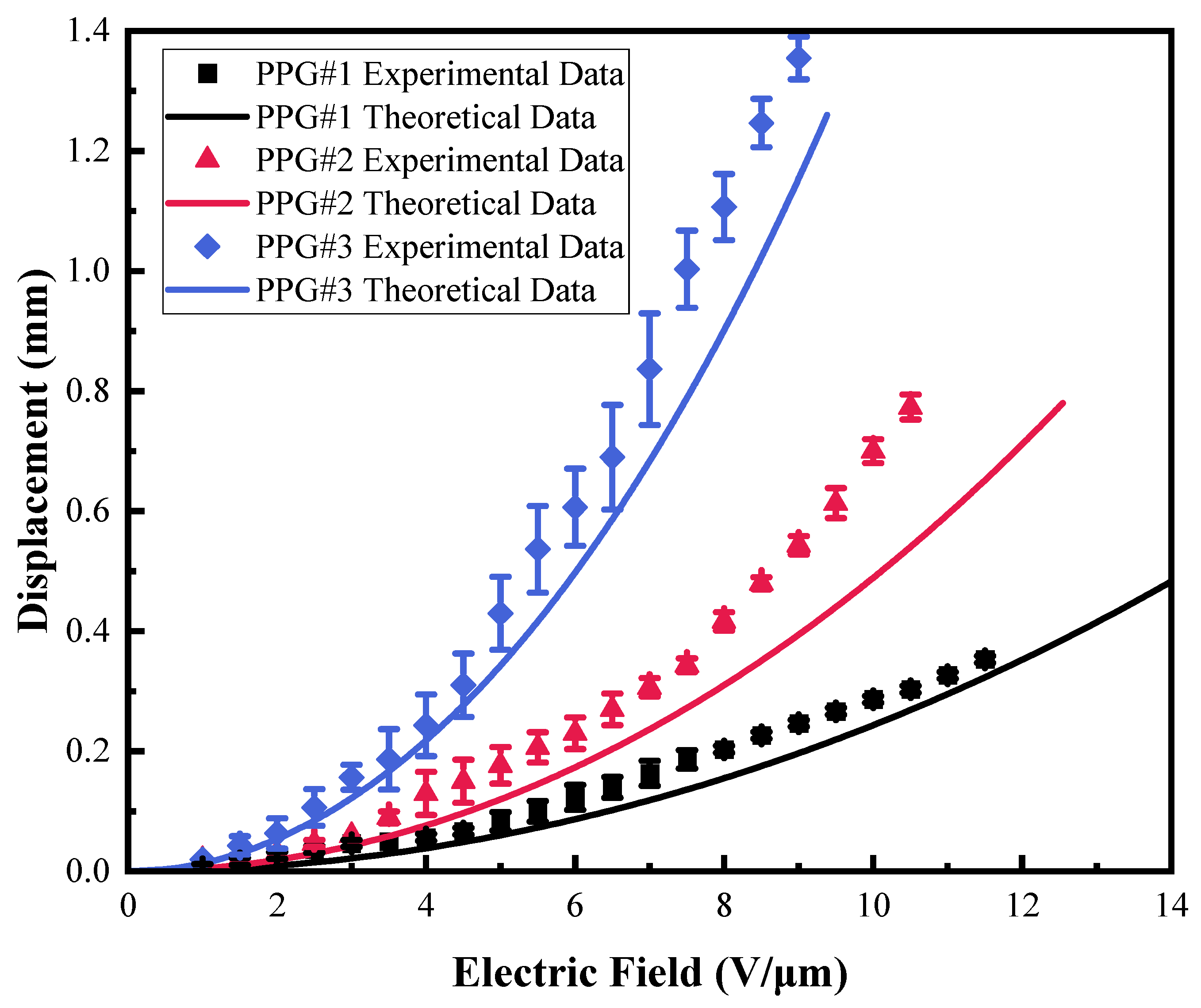

3.3. Voltage-Induced Actuation Performance Measurements

3.3.1. The Joint Effect of DBA and P(VC-VA) on Actuation Performance

3.3.2. Effect of P(VC-VA) on Actuation Performance

4. Conclusions

- Conclusions can be drawn from the comparison between the PVCG (PVC/DBA) experimental group and the PVAG (PVC/P(VC-AC)/DBA) experimental group. After the introduction of P(VC-VA), the dielectric constant of the synergistically plasticized PVC gel is improved. The dielectric constant of PVCG#1 is increased from 4.77 to 7.3 of PVAG#1. This improvement is beneficial to improving the electric drive performance of PVC gel.

- After the introduction of P(VC-VA), the elastic modulus of synergistically plasticized PVC gel has a certain change. The electromechanical actuation performance increases by 150%. We used the Gent model to fit the experimental results, and the experimental results are in good agreement with the theoretical data.

- The driving electric field intensity of the synergistically plasticized PVC gel is reduced after the introduction of P(VC-VA). We also found that P(VC-VA) cannot completely replace PVC in PVC gel synthesis, the mass fraction of P(VCVA) does not exceed 75%, and PVC gel with a P(VC-VA) content of 75% can be prepared, but it is too soft and is difficult to prepare the actuator, as evidenced by the inability to construct an actuator with PPG#5.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Carpi, F. (Ed.) Electromechanically Active Polymers: A Concise Reference; Springer International Publishing: Cham, Switzerland, 2016; ISBN 978-3-319-31528-7. [Google Scholar]

- Kaneto, K. Research Trends of Soft Actuators Based on Electroactive Polymers and Conducting Polymers. J. Phys. Conf. Ser. 2016, 704, 012004. [Google Scholar] [CrossRef]

- Hines, L.; Petersen, K.; Lum, G.Z.; Sitti, M. Soft Actuators for Small-Scale Robotics. Adv. Mater. 2017, 29, 1603483. [Google Scholar] [CrossRef] [PubMed]

- Hirai, T. Dielectric Gels. In Soft Actuators: Materials, Modeling, Applications, and Future Perspectives; Asaka, K., Okuzaki, H., Eds.; Springer: Singapore, 2019; pp. 245–258. ISBN 9789811368509. [Google Scholar]

- Li, Y.; Guo, M.; Li, Y. Recent Advances in Plasticized PVC Gels for Soft Actuators and Devices: A Review. J. Mater. Chem. C 2019, 7, 12991–13009. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.; Hashimoto, M. Low-Voltage Planar PVC Gel Actuator with High Performances. Sens. Actuators B Chem. 2019, 282, 482–489. [Google Scholar] [CrossRef]

- Bar-Cohen, Y.; Anderson, I.A. Electroactive Polymer (EAP) Actuators—Background Review. Mech. Soft. Mater. 2019, 1, 5. [Google Scholar] [CrossRef]

- Pelrine, R.; Kornbluh, R.; Pei, Q.B.; Joseph, J. High-Speed Electrically Actuated Elastomers with Strain Greater than 100%. Science 2000, 287, 836–839. [Google Scholar] [CrossRef] [PubMed]

- Brochu, P.; Pei, Q. Advances in Dielectric Elastomers for Actuators and Artificial Muscles. Macromol. Rapid Commun. 2010, 31, 10–36. [Google Scholar] [CrossRef] [PubMed]

- Kornbluh, R. High-Performance Acrylic and Silicone Elastomers. In Dielectric Elastomers as Electromechanical Transducers; Elsevier: Amsterdam, The Netherlands, 2008; pp. 33–42. ISBN 978-0-08-047488-5. [Google Scholar]

- Kornbluh, R.D.; Pelrine, R.; Pei, Q.; Heydt, R.; Stanford, S.; Oh, S.; Eckerle, J. Electroelastomers: Applications of Dielectric Elastomer Transducers for Actuation, Generation, and Smart Structures. Proc. SPIE 2002, 4698, 254–270. [Google Scholar] [CrossRef]

- Romasanta, L.J.; Lopez-Manchado, M.A.; Verdejo, R. Increasing the Performance of Dielectric Elastomer Actuators: A Review from the Materials Perspective. Prog. Polym. Sci. 2015, 51, 188–211. [Google Scholar] [CrossRef]

- Li, Y.; Hashimoto, M. PVC Gel Based Artificial Muscles: Characterizations and Actuation Modular Constructions. Sens. Actuators A Phys. 2015, 233, 246–258. [Google Scholar] [CrossRef]

- Gent, A.N.; Shimizu, N. Elasticity, Tear Strength, and Strength of Adhesion of Soft PVC Gels. J. Appl. Polym. Sci. 1986, 32, 5385–5398. [Google Scholar] [CrossRef]

- Jackson, R.S.; Bower, D.I.; Maddams, W.F. A Study of Wet PVC Gels by Raman Spectroscopy. J. Polym. Sci. B Polym. Phys. 1990, 28, 837–859. [Google Scholar] [CrossRef]

- Hirai, T. Electroactive Nonionic Polymer Gel-Swift Bending and Crawling Motion. MRS Online Proc. Libr. 2000, 600, 267–272. [Google Scholar] [CrossRef]

- Bae, J.W.; Choi, D.S.; Yun, I.H.; Han, D.H.; Oh, S.-J.; Kim, T.H.; Cho, J.H.; Lin, L.; Kim, S.Y. Electrically Adaptive and Shape-Changeable Invertible Microlens. ACS Appl. Mater. Interfaces 2021, 13, 10397–10408. [Google Scholar] [CrossRef] [PubMed]

- Huang, J. Polyvinyl Chloride-Based Dielectric Elastomer with High Permittivity and Low Viscoelasticity for Actuation and Sensing. Nat. Commun. 2023, 14, 1–10. [Google Scholar] [CrossRef]

- Ali, I.; Latif, A.; Hussain, K.; Shehzad, F.K.; Ali, A.; Faisal, R.; Xudong, L.; Dias, O.A.T.; Weimin, Y.; Haoyi, L. Ionic Liquids Enhanced Performance of PVC Gels Actuator. J. Appl. Polymer. Sci. 2021, 138, 50710. [Google Scholar] [CrossRef]

- Maiti, J.; Kakati, N.; Basumatary, P.; Woo, S.P.; Yoon, Y.S. Imidazolium Functionalized Poly(Vinyl Chloride-Co-Vinyl Acetate)-Based Anion Exchange Membrane. Int. J. Hydrogen Energy 2016, 41, 5776–5782. [Google Scholar] [CrossRef]

- Hu, C.; Xu, W.; Conrads, C.M.; Wu, J.; Pich, A. Visible Light and Temperature Dual-Responsive Microgels by Crosslinking of Spiropyran Modified Prepolymers. J. Colloid Interface Sci. 2021, 582, 1075–1084. [Google Scholar] [CrossRef] [PubMed]

- Ogawa, N.; Hashimoto, M.; Takasaki, M.; Hirai, T. Characteristics Evaluation of PVC Gel Actuators. In Proceedings of the 2009 IEEE-RSJ International Conference on Intelligent Robots and Systems (IROS’09), St. Louis, MO, USA, 10–15 October 2009; pp. 2898–2903. [Google Scholar]

- Ali, M.; Ueki, T.; Tsurumi, D.; Hirai, T. Influence of Plasticizer Content on the Transition of Electromechanical Behavior of PVC Gel Actuator. Langmuir 2011, 27, 7902–7908. [Google Scholar] [CrossRef]

- Mooney, M. A Theory of Large Elastic Deformation. J. Appl. Phys. 1940, 11, 582–592. [Google Scholar] [CrossRef]

- Yeoh, O.H. Characterization of Elastic Properties of Carbon-Black-Filled Rubber Vulcanizates. Rubber Chem. Technol. 1990, 63, 792–805. [Google Scholar] [CrossRef]

- Dorfmann, A.; Ogden, R.W. Nonlinear Electroelasticity. Acta Mech. 2005, 174, 167–183. [Google Scholar] [CrossRef]

- Boyce, M.C.; Arruda, E.M. Constitutive Models of Rubber Elasticity: A Review. Rubber Chem. Technol. 2000, 73, 504–523. [Google Scholar] [CrossRef]

| PVCG#1 | PVCG#2 | PVCG#3 | PVCG#4 | |

|---|---|---|---|---|

| PVC | 10 g | 10 g | 10 g | 10 g |

| DBA | 30 g | 40 g | 60 g | 80 g |

| PVAG#1 | PVAG#2 | PVAG#3 | PVAG#4 | |

|---|---|---|---|---|

| PVC | 5 g | 5 g | 5 g | 5 g |

| P(VC-VA) | 5 g | 5 g | 5 g | 5 g |

| DBA | 30 g | 40 g | 60 g | 80 g |

| PPG#1 | PPG#2 | PPG#3 | PPG#4 | PPG#5 | |

|---|---|---|---|---|---|

| PVC | 20 g | 15 g | 10 g | 5 g | 0 g |

| P(VC-VA) | 0 g | 5 g | 10 g | 15 g | 20 g |

| DBA | 80 g | 80 g | 80 g | 80 g | 80 g |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, H.; Wei, C.; Wang, Z.; Liu, L.; Zhu, Z.; Zhang, J.; Zhu, J.; Zhang, W. Electromechanical Performances of Polyvinyl Chloride Gels Using (Polyvinyl Chloride-Co-Vinyl Acetate) (P(VC-VA)) Synergistic Plasticization. Polymers 2024, 16, 1904. https://doi.org/10.3390/polym16131904

Yan H, Wei C, Wang Z, Liu L, Zhu Z, Zhang J, Zhu J, Zhang W. Electromechanical Performances of Polyvinyl Chloride Gels Using (Polyvinyl Chloride-Co-Vinyl Acetate) (P(VC-VA)) Synergistic Plasticization. Polymers. 2024; 16(13):1904. https://doi.org/10.3390/polym16131904

Chicago/Turabian StyleYan, Han, Chang Wei, Zexing Wang, Lei Liu, Zicai Zhu, Junshi Zhang, Jihong Zhu, and Weihong Zhang. 2024. "Electromechanical Performances of Polyvinyl Chloride Gels Using (Polyvinyl Chloride-Co-Vinyl Acetate) (P(VC-VA)) Synergistic Plasticization" Polymers 16, no. 13: 1904. https://doi.org/10.3390/polym16131904

APA StyleYan, H., Wei, C., Wang, Z., Liu, L., Zhu, Z., Zhang, J., Zhu, J., & Zhang, W. (2024). Electromechanical Performances of Polyvinyl Chloride Gels Using (Polyvinyl Chloride-Co-Vinyl Acetate) (P(VC-VA)) Synergistic Plasticization. Polymers, 16(13), 1904. https://doi.org/10.3390/polym16131904