Effect of Thermal Shock Conditions on the Low-Cycle Fatigue Performance of 3D-Printed Materials: Acrylonitrile Butadiene Styrene, Acrylonitrile-Styrene-Acrylate, High-Impact Polystyrene, and Poly(lactic acid)

Abstract

1. Introduction

2. Materials and Methods

2.1. Manufacturing Details

2.2. Thermal Shock Cycles

2.3. Static Tests

2.4. Cyclic Tests

2.5. Porosity Measurement

2.6. Statistics

3. Results

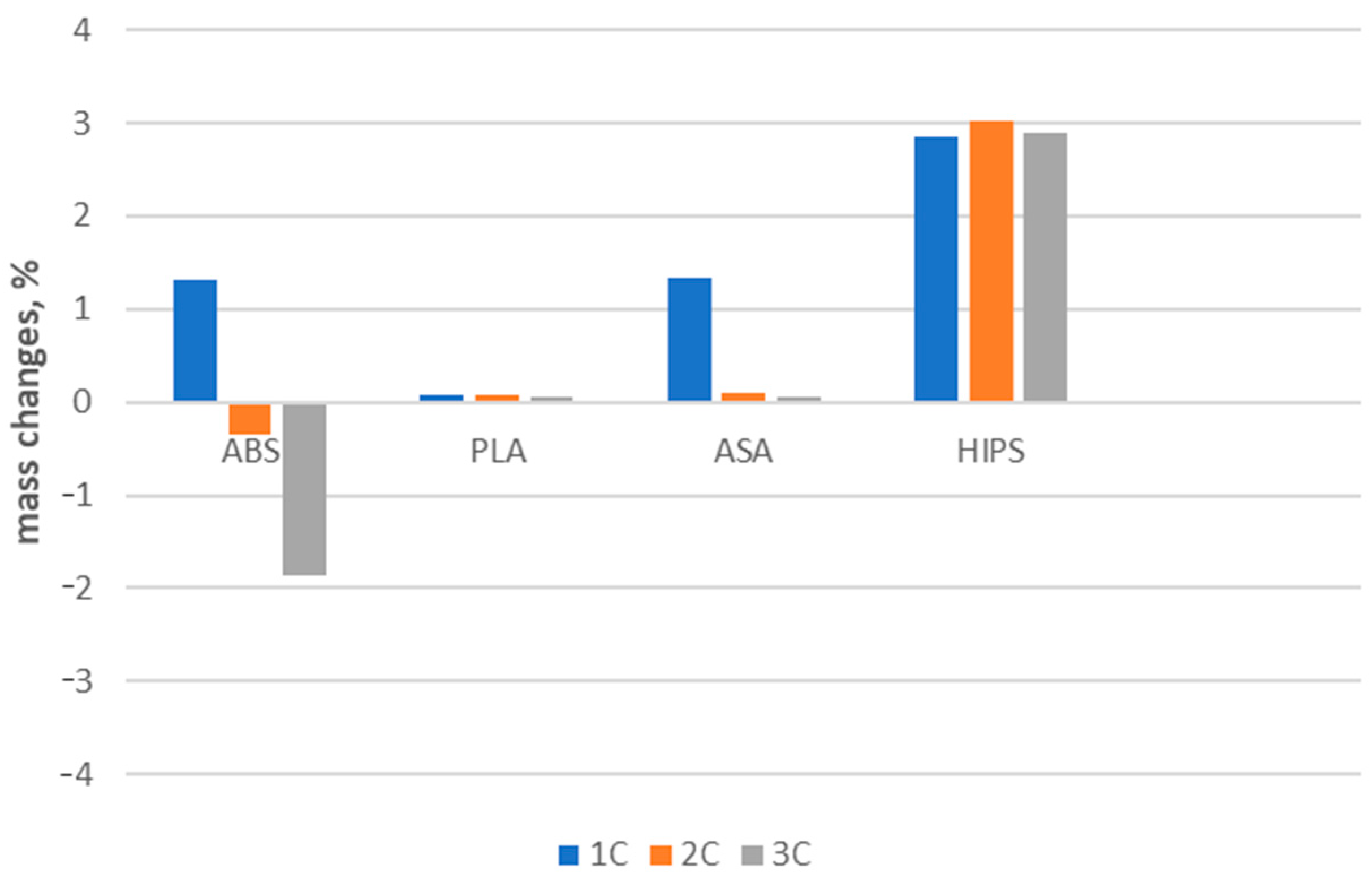

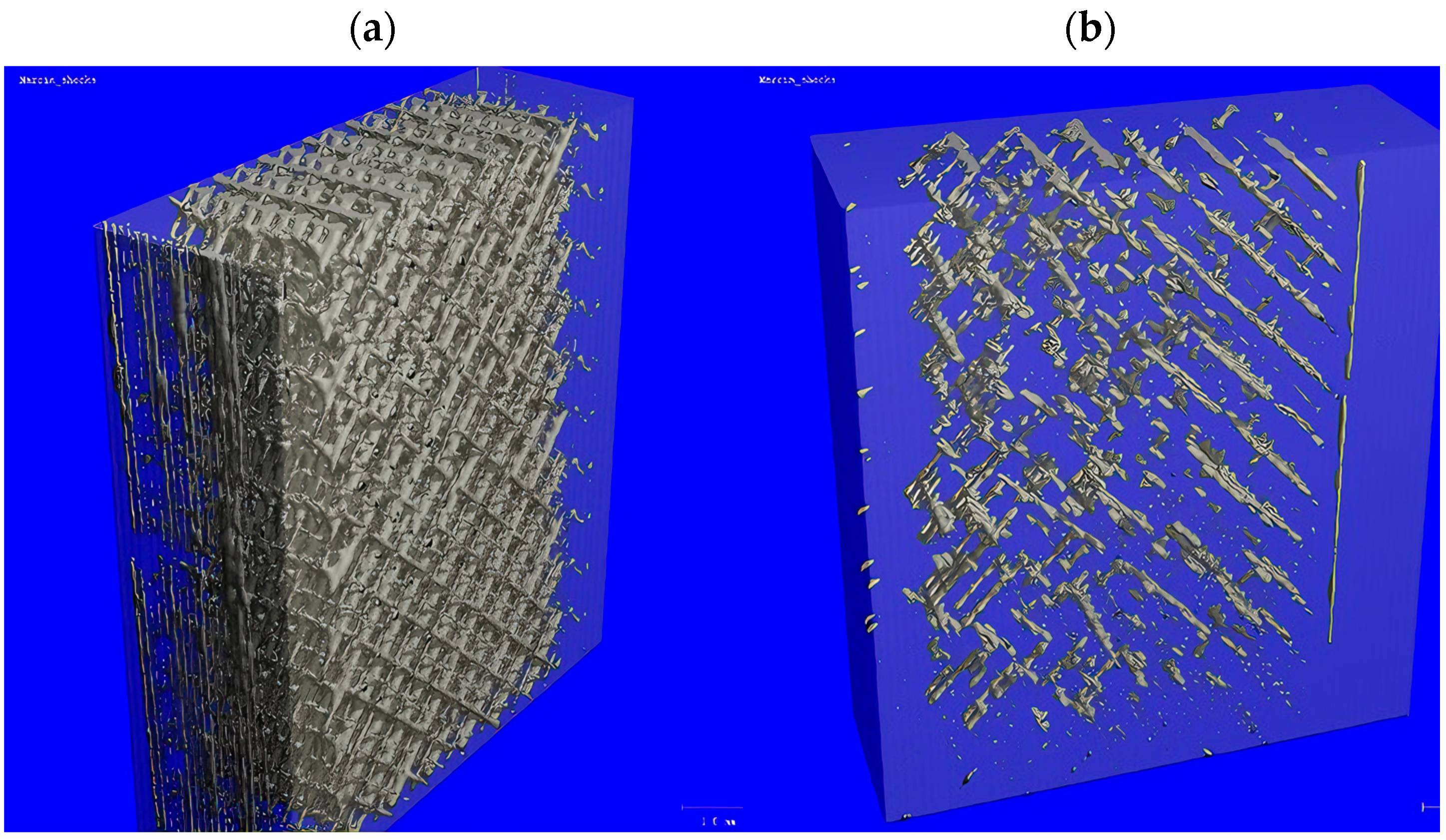

3.1. Structure Evaluation Using Microcomputed Tomography (microCT)

3.1.1. Sample Preparation and Testing Process

3.1.2. Results and Statistical Analysis of Porosity Changes

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Pataky, K.; Brugger, J. Rapid Prototyping Techniques for the Fabrication of Biosensors. Rapid Prototyp. Biomater. Princ. Appl. 2014, 75–96. [Google Scholar] [CrossRef]

- Onuh, S.O.; Yusuf, Y.Y. Rapid Prototyping Technology: Applications and Benefits for Rapid Product Development. J. Intell. Manuf. 1999, 10, 301–311. [Google Scholar] [CrossRef]

- Lakkala, P.; Munnangi, S.R.; Bandari, S.; Repka, M. Additive Manufacturing Technologies with Emphasis on Stereolithography 3D Printing in Pharmaceutical and Medical Applications: A Review. Int. J. Pharm. X 2023, 5, 100159. [Google Scholar] [CrossRef] [PubMed]

- Ansari, A.A.; Kamil, M. Effect of Print Speed and Extrusion Temperature on Properties of 3D Printed PLA Using Fused Deposition Modeling Process. Mater. Today Proc. 2021, 45, 5462–5468. [Google Scholar] [CrossRef]

- Zárybnická, L.; Machotová, J.; Pagáč, M.; Rychlý, J.; Vykydalová, A. The Effect of Filling Density on Flammability and Mechanical Properties of 3D-Printed Carbon Fiber-Reinforced Nylon. Polym. Test. 2023, 120, 107944. [Google Scholar] [CrossRef]

- Ahn, S.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic Material Properties of Fused Deposition Modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef]

- He, F.; Khan, M. Effects of Printing Parameters on the Fatigue Behaviour of 3D-Printed ABS under Dynamic Thermo-Mechanical Loads. Polymers 2021, 13, 2362. [Google Scholar] [CrossRef]

- Safai, L.; Cuellar, J.S.; Smit, G.; Zadpoor, A.A. A Review of the Fatigue Behavior of 3D Printed Polymers. Addit. Manuf. 2019, 28, 87–97. [Google Scholar] [CrossRef]

- Głowacki, M.; Mazurkiewicz, A.; Słomion, M.; Skórczewska, K. Resistance of 3D-Printed Components, Test Specimens and Products to Work under Environmental Conditions—Review. Materials 2022, 15, 6162. [Google Scholar] [CrossRef]

- Kristiawan, R.B.; Imaduddin, F.; Ariawan, D.; Ubaidillah; Arifin, Z. A Review on the Fused Deposition Modeling (FDM) 3D Printing: Filament Processing, Materials, and Printing Parameters. Open Eng. 2021, 11, 639–649. [Google Scholar] [CrossRef]

- Sionkowski, T.; Halecki, W.; Chmielowski, K. Advancing Urban Wastewater Management: Optimizing Sewer Performance through Innovative Material Selection for the Armlet with a Wet Circuit Measurement System. Appl. Sci. 2023, 13, 10892. [Google Scholar] [CrossRef]

- Tyler, B.; Gullotti, D.; Mangraviti, A.; Utsuki, T.; Brem, H. Polylactic Acid (PLA) Controlled Delivery Carriers for Biomedical Applications. Adv. Drug Deliv. Rev. 2016, 107, 163–175. [Google Scholar] [CrossRef] [PubMed]

- Gu, J.; Wensing, M.; Uhde, E.; Salthammer, T. Characterization of Particulate and Gaseous Pollutants Emitted during Operation of a Desktop 3D Printer. Environ. Int. 2019, 123, 476–485. [Google Scholar] [CrossRef] [PubMed]

- Głowacki, M.; Skórczewska, K.; Lewandowski, K.; Szewczykowski, P.; Mazurkiewicz, A. Effect of Shock-Variable Environmental Temperature and Humidity Conditions on 3D-Printed Polymers for Tensile Properties. Polymers 2024, 16, 1. [Google Scholar] [CrossRef] [PubMed]

- Fotopoulou, K.N.; Karapanagioti, H.K. Degradation of Various Plastics in the Environment. In Hazardous Chemicals Associated with Plastics in the Marine Environment; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Upadhyay, R.K.; Mishra, A.K.; Kumar, A. Mechanical Degradation of 3D Printed PLA in Simulated Marine Environment. Surf. Interfaces 2020, 21, 100778. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Zolfagharian, A.; Jennings, M.; Reinicke, T. Structural Performance of 3D-Printed Composites under Various Loads and Environmental Conditions. Polym. Test. 2020, 91, 106770. [Google Scholar] [CrossRef]

- Pérez, J.M.; Vilas, J.L.; Laza, J.M.; Arnáiz, S.; Mijangos, F.; Bilbao, E.; Rodríguez, M.; León, L.M. Effect of Reprocessing and Accelerated Ageing on Thermal and Mechanical Polycarbonate Properties. J. Mater. Process Technol. 2010, 210, 727–733. [Google Scholar] [CrossRef]

- Saenz, F.; Otarola, C.; Valladares, K.; Rojas, J. Influence of 3D Printing Settings on Mechanical Properties of ABS at Room Temperature and 77 K. Addit. Manuf. 2021, 39, 101841. [Google Scholar] [CrossRef]

- Niu, F.; Jiang, H.; Su, W.; Jiang, W.; He, J. Performance Degradation of Polymer Material under Freeze-Thaw Cycles: A Case Study of Extruded Polystyrene Board. Polym. Test. 2021, 96, 107067. [Google Scholar] [CrossRef]

- Gaweł, A.; Kuciel, S.; Liber-Kneć, A.; Mierzwiński, D. Examination of Low-Cyclic Fatigue Tests and Poisson’s Ratio Depending on the Different Infill Density of Polylactide (PLA) Produced by the Fused Deposition Modeling Method. Polymers 2023, 15, 1651. [Google Scholar] [CrossRef]

- Müller, M.; Šleger, V.; Kolář, V.; Hromasová, M.; Piš, D.; Mishra, R.K. Low-Cycle Fatigue Behavior of 3D-Printed PLA Reinforced with Natural Filler. Polymers 2022, 14, 1301. [Google Scholar] [CrossRef] [PubMed]

- Głowacki, M.; Mazurkiewicz, A.; Skórczewska, K.; Martínez Valle, J.M.; Smyk, E. Change in the Low-Cycle Performance on the 3D-Printed Materials ABS, ASA, HIPS, and PLA Exposed to Mineral Oil. Polymers 2024, 16, 1120. [Google Scholar] [CrossRef] [PubMed]

- Spectrumfilaments. Manufacturer of 3D Printing Filament. Available online: https://spectrumfilaments.com/ (accessed on 1 June 2024).

- EN ISO 527-1:2012; Plastics—Determination of Mechanical Properties in Static Tension—General Principles. Polish Standards Institution: Warszawa, Poland, 2012.

- Tsouknidas, A.; Pantazopoulos, M.; Katsoulis, I. Impact absorption capacity of 3D-printed components fabricated by fused deposition modelling. Mater. Des. 2016, 102, 41–44. [Google Scholar] [CrossRef]

- Kwon, Y.; Seo, S.; Lee, J.; Berezvai, S. 3D-printed polymer foams maintain stiffness and energy dissipation under repeated loading. Compos. Commun. 2023, 37, 101453. [Google Scholar] [CrossRef]

- Topoliński, T.; Cichański, A.; Mazurkiewicz, A.; Nowicki, K. Fatigue Energy Dissipation in Trabecular Bone Samples with Step-wise-Increasing Amplitude Loading. Mater. Test. 2011, 53, 344–350. [Google Scholar] [CrossRef]

- Yazdani Sarvestani, H.; Akbarzadeh, A.H.; Niknam, H.; Hermenean, K. 3D printed architected polymeric sandwich panels: Energy absorption and structural performance. Compos. Struct. 2018, 200, 886–909. [Google Scholar] [CrossRef]

- Vidinha, H.; Branco, R.; Amaro, A.M.; Neto, M.A.; Reis, P.N.B.; Costa, J.D.M. Monotonic and fatigue behaviour of notched glass fibre-reinforced polymer laminates immersed in seawater. Theor. Appl. Fract. Mech. 2023, 126, 103977. [Google Scholar] [CrossRef]

- Vidinha, H.; Durães, L.; Neto, M.A.; Amaro, A.M.; Branco, R. Understanding seawater-induced fatigue changes in glass/epoxy laminates: A SEM, EDS, and FTIR study. Polym. Degrad. Stab. 2024, 224, 110752. [Google Scholar] [CrossRef]

- Cichanski, A.; Mazurkiewicz, A.; Nowicki, K.; Topolinski, T. Investigation of statistical relationships between quantities describing bone architecture, its fractal dimensions and mechanical properties. Acta Bio-Eng. Biomech. 2010, 12, 69–77. [Google Scholar]

- Topoliński, T.; Cichański, A.; Mazurkiewicz, A.; Nowicki, K. The Relationship between Trabecular Bone Struc-ture Modeling Methods and the Elastic Modulus as Calculated by FEM. Sci. World J. 2012, 2012, 827196. [Google Scholar] [CrossRef][Green Version]

- De Carolis, S.; Putignano, C.; Soria, L.; Carbone, G. Effect of porosity and pore size distribution on elastic mod-ulus of foams. Int. J. Mech. Sci. 2024, 261, 108661. [Google Scholar] [CrossRef]

- Seuba, J.; Maire, E.; Adrien, J.; Meille, S.; Deville, S. Mechanical properties of unidirectional, porous poly-mer/ceramic composites for biomedical applications. Open Ceram. 2021, 8, 100195. [Google Scholar] [CrossRef]

- Mazurkiewicz, A.; Topoliński, T. Relationships between structure, density and strength of human tra-becular bone. Acta Bioeng. Biomech. 2009, 11, 55–61. [Google Scholar] [PubMed]

- Wang, X.; Zhao, L.; Ying Hsi Fuh, J.; Pueh Lee, H. Effect of Porosity on Mechanical Properties of 3D Printed Polymers: Experiments and Micromechanical Modeling Based on X-ray Computed Tomography Anal-ysis. Polymers 2019, 11, 1154. [Google Scholar] [CrossRef]

| Material | ABS | ASA | PLA | HIPS |

|---|---|---|---|---|

| σuts (MPa) | 28.5 (0.86) | 16.82 (0.31) | 29 (0.07) | 21.27 (0.37) |

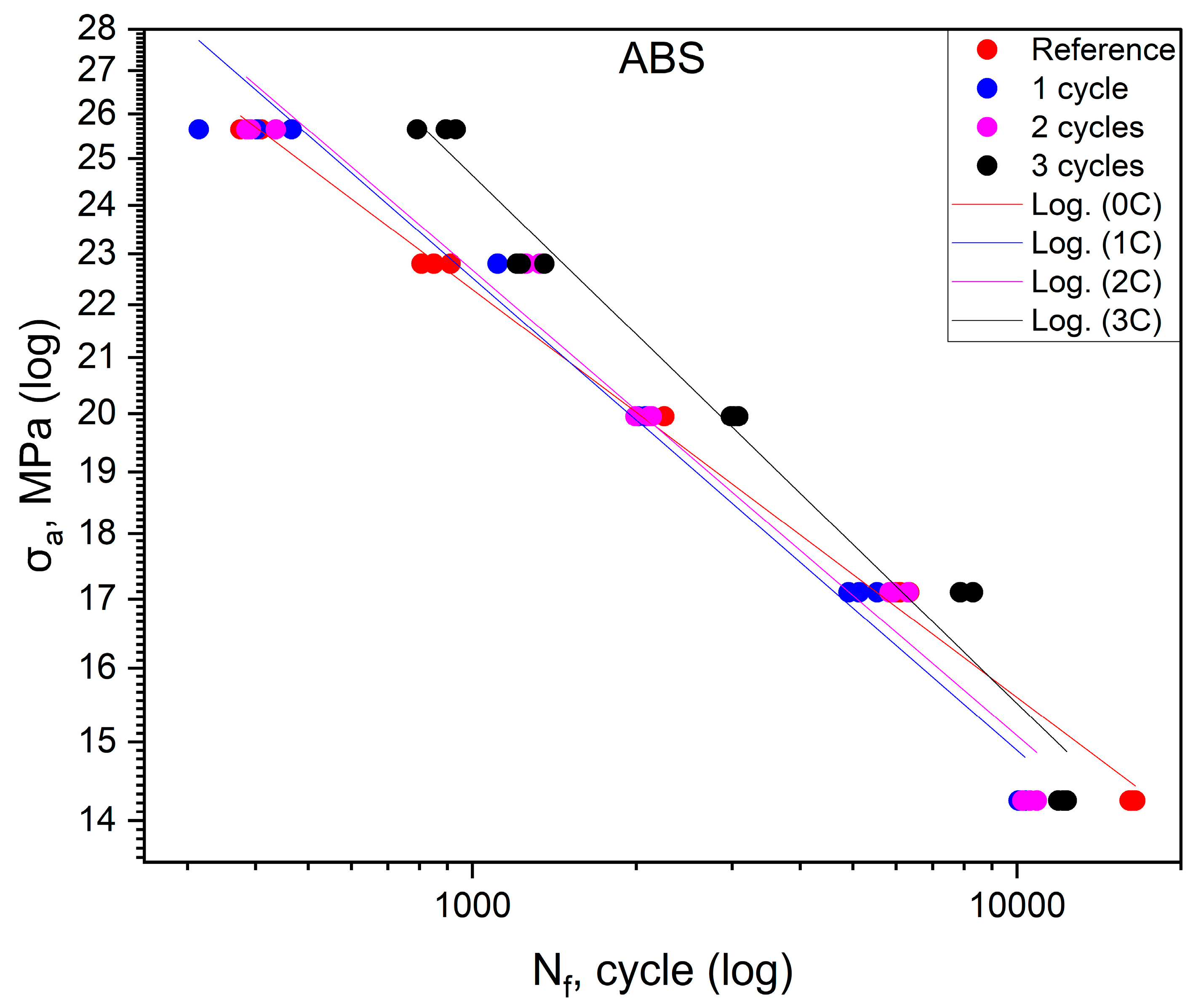

| ABS | Reference | One Cycle | Two Cycles | Three Cycles | |

|---|---|---|---|---|---|

| σa MPa | Nf, Cycle | Nf, Cycle | Nf, Cycle | Nf, Cycle | |

| 90% | 25.6 | 390 b (14.3) | 394 b (75.8) | 404 b (27.6) | 873 a (73) |

| 80% | 22.8 | 856 b (43.3) | 1265 a (131.9) | 1270 a (57.4) | 1264 a (80.9) |

| 70% | 19.9 | 2127 b (97.9) | 2031 b (46.3) | 2082 b (76.3) | 3027 a (47.2) |

| 60% | 17.1 | 6145 b (149.4) | 5193 c (320.4) | 5554 b (252.1) | 8016 a (253) |

| 50% | 14.2 | 16,309 a (159.9) | 10,193 c (132.3) | 10,557 c (321.6) | 12,139 b (221.8) |

| ASA | Reference | One Cycle | Two Cycles | Three Cycles | |

|---|---|---|---|---|---|

| σa, MPa | Nf, Cycle | Nf, Cycle | Nf, Cycle | NF, CYCLE | |

| 90% | 15.1 | 7628 a (254.4) | 6182 b (255.7) | 5969 b (244.6) | 4417 c (227.1) |

| 80% | 13.5 | 18,190 a (565.6) | 8802 b (240.3) | 8523 b (430.4) | 8964 b (320) |

| 70% | 11.8 | 44,750 a (544) | 14,939 b (451.4) | 13,863 b,c (326.7) | 13,658 c (290) |

| 60% | 10 | 47,531 a (427.4) | 23,977 c (411) | 20,023 d (307.2) | 26,976 b (340.1) |

| 50% | 8.4 | 99,530 a (149) | 76,306 b (523.3) | 65,493 c (545.1) | 60,542 d (564.4) |

| PLA | Reference | One Cycle | Two Cycles | Three Cycles | |

|---|---|---|---|---|---|

| σa, MPa | Nf, Cycle | Nf, Cycle | Nf, Cycle | Nf, Cycle | |

| 90% | 26.1 | 729 c (29.1) | 2577 a (438.6) | 2894 a (111) | 1372 b (137.1) |

| 80% | 23.2 | 1263 c (52.3) | 3956 a (230) | 4392 a (368.6) | 2220 b (211.3) |

| 70% | 20.3 | 3280 c (41.6) | 4800 b (461.3) | 8518 a (495.5) | 4449 b (99.8) |

| 60% | 10 | 5038 d (87.4) | 8344 b (148.1) | 9626 a (343.2) | 6234 c (230.6) |

| 50% | 14.5 | 39,267 b (420.6) | 21,343 c (558.5) | 59,129 a (546.3) | 19,472 d (556.8) |

| HIPS | Reference | One Cycle | Two Cycles | Three Cycles | |

|---|---|---|---|---|---|

| σa, MPa | Nf, Cycle | Nf, Cycle | Nf, Cycle | Nf, Cycle | |

| 90% | 19.1 | - | - | - | - |

| 80% | 17 | - | - | - | - |

| 70% | 14.9 | - | - | - | - |

| 60% | 12.8 | 43 a (3.7) | 5 c (1) | 8 b,c (2) | 12 b (2) |

| 50% | 10.6 | 451 a (18) | 95 b (9) | 107 b (7) | 112 b (11) |

| Group | ABS | ASA | PLA | HIPS |

|---|---|---|---|---|

| G0 | log (Nf) = −3.01 log (σa) + 43.308 R2 = 0.9912 | log (Nf) = −2.61 log (σa) + 38.779 R2 = 0.946 | log (Nf) = −2.861 log (σa) + 43.724 R2 = 0.9232 | log (Nf) = −1.062 log (σa) + 16.99 R2 = 0.9968 |

| 1C | log (Nf) = −3.57 log (σa) + 47.681 R2 = 0.9876 | log (Nf) = −2.637 log (σa) + 37.489 R2 = 0.9446 | log (Nf) = −5.359 log (σa) + 67.029 R2 = 0.9231 | log (Nf) = −1.277 log (σa) + 18.265 R2 = 0.9919 |

| 2C | log (Nf) = −3.513 log (σa) + 47.408 R2 = 0.9878 | log (Nf) = −2.771 log (σa) + 38.533 R2 = 0.93 | log (Nf) = −3.686 log (σa) + 53.891 R2 = 0.8672 | log (Nf) = −1.137 log (σa) + 15.956 R2 = 0.9969 |

| 3C | log (Nf) = −3.969 log (σa) + 52.171 R2 = 0.9881 | log (Nf) = −2.624 log (σa) + 37.087 R2 = 0.989 | log (Nf) = −4.398 log (σa) + 57.188 R2 = 0.9625 | log (Nf) = −1.631 log (σa) + 17.776 R2 = 0.9923 |

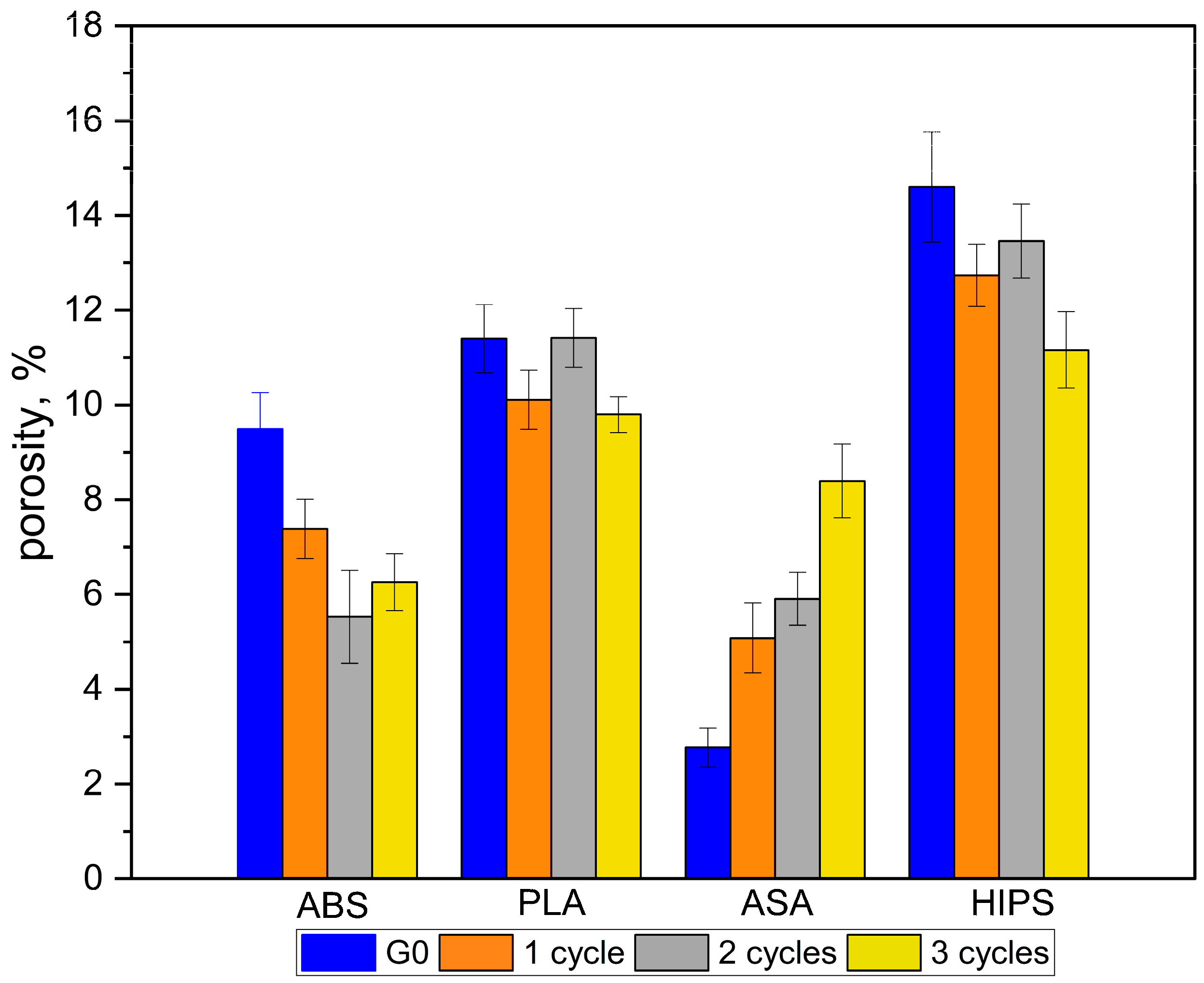

| Group | ABS | ASA | HIPS | PLA |

|---|---|---|---|---|

| G0 | 9.52 | 2.71 | 14.83 | 11.45 |

| 1C | 7.37 | 5.01 | 12.64 | 10.05 |

| 2C | 5.55 | 5.94 | 13.43 | 11.45 |

| 3C | 6.25 | 8.44 | 11.19 | 9.83 |

| ABS | ASA | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| group | G0 | 1C | 2C | 3C | group | G0 | 1C | 2C | 3C |

| G0 | - | S | S | S | G0 | - | NS | S | S |

| 1C | - | - | S | NS | 1C | - | - | NS | S |

| 2C | - | - | - | NS | 2C | - | - | - | S |

| HIPS | PLA | ||||||||

| group | G0 | 1C | 2C | 3C | group | G0 | 1C | 2C | 3C |

| G0 | - | S | NS | S | G0 | - | S | NS | S |

| 1C | - | - | NS | S | 1C | - | - | S | NS |

| 2C | - | - | - | S | 2C | - | - | - | S |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Głowacki, M.; Mazurkiewicz, A.; Skórczewska, K.; Lewandowski, K.; Smyk, E.; Branco, R. Effect of Thermal Shock Conditions on the Low-Cycle Fatigue Performance of 3D-Printed Materials: Acrylonitrile Butadiene Styrene, Acrylonitrile-Styrene-Acrylate, High-Impact Polystyrene, and Poly(lactic acid). Polymers 2024, 16, 1823. https://doi.org/10.3390/polym16131823

Głowacki M, Mazurkiewicz A, Skórczewska K, Lewandowski K, Smyk E, Branco R. Effect of Thermal Shock Conditions on the Low-Cycle Fatigue Performance of 3D-Printed Materials: Acrylonitrile Butadiene Styrene, Acrylonitrile-Styrene-Acrylate, High-Impact Polystyrene, and Poly(lactic acid). Polymers. 2024; 16(13):1823. https://doi.org/10.3390/polym16131823

Chicago/Turabian StyleGłowacki, Marcin, Adam Mazurkiewicz, Katarzyna Skórczewska, Krzysztof Lewandowski, Emil Smyk, and Ricardo Branco. 2024. "Effect of Thermal Shock Conditions on the Low-Cycle Fatigue Performance of 3D-Printed Materials: Acrylonitrile Butadiene Styrene, Acrylonitrile-Styrene-Acrylate, High-Impact Polystyrene, and Poly(lactic acid)" Polymers 16, no. 13: 1823. https://doi.org/10.3390/polym16131823

APA StyleGłowacki, M., Mazurkiewicz, A., Skórczewska, K., Lewandowski, K., Smyk, E., & Branco, R. (2024). Effect of Thermal Shock Conditions on the Low-Cycle Fatigue Performance of 3D-Printed Materials: Acrylonitrile Butadiene Styrene, Acrylonitrile-Styrene-Acrylate, High-Impact Polystyrene, and Poly(lactic acid). Polymers, 16(13), 1823. https://doi.org/10.3390/polym16131823