Study on Phenol–Formaldehyde Resin–Montmorillonite Impregnation and Compression Modification of Chinese Fir

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Modified Solution Preparation

2.3. Modified Fir Preparation

2.4. Performance Testing

2.4.1. Performance of Modified Liquid

2.4.2. Properties of Modified Fir in Optimal Treatment Conditions

3. Results and Discussion

3.1. Effect of Montmorillonite Addition on the Performance of Modified Liquids

3.1.1. Basic Properties of Modified Liquid

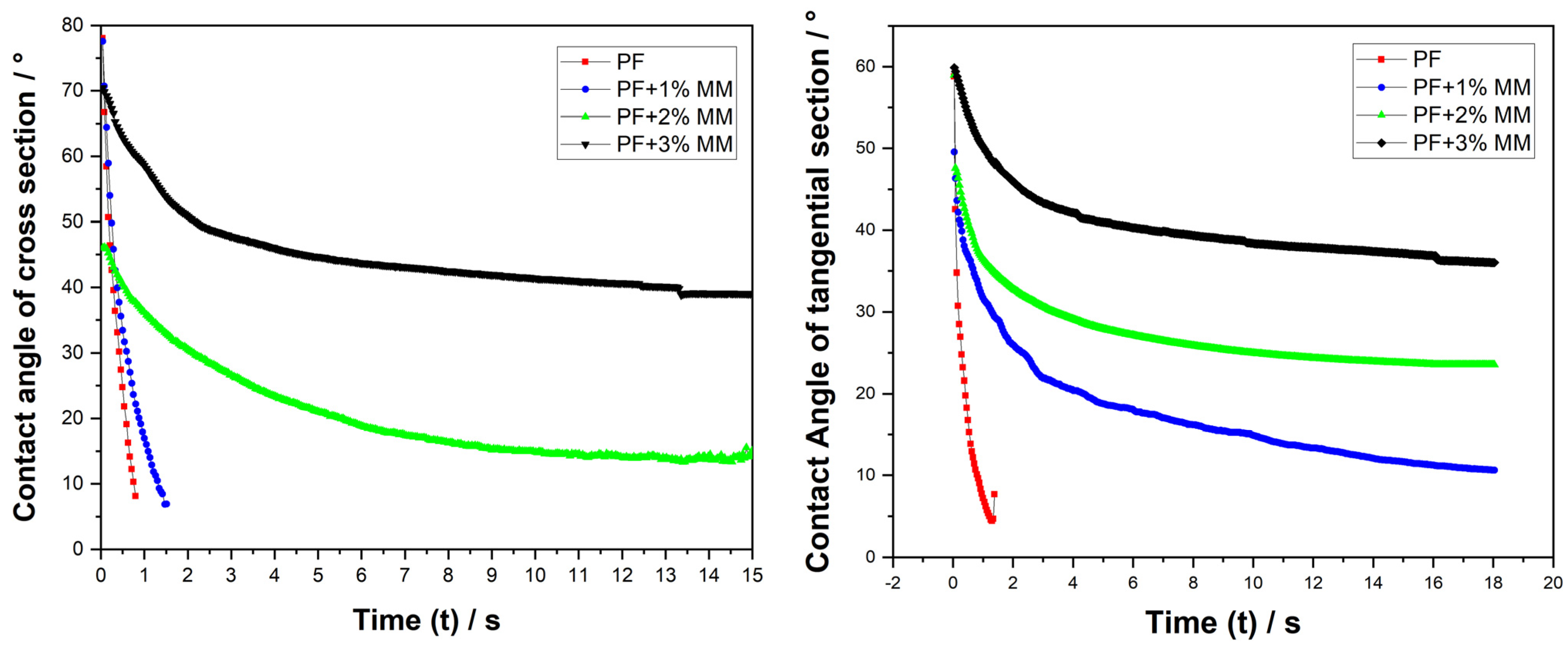

3.1.2. Wetting Performance

3.2. Optimization of the Impregnation- and Compression-Modified Fir Process

3.2.1. Optimization of the Dipping Process

3.2.2. Impact of Compression Rate on the Physical and Mechanical Properties of Modified Fir Wood

3.3. Analysis of Immersion–Compression Modification Mechanism

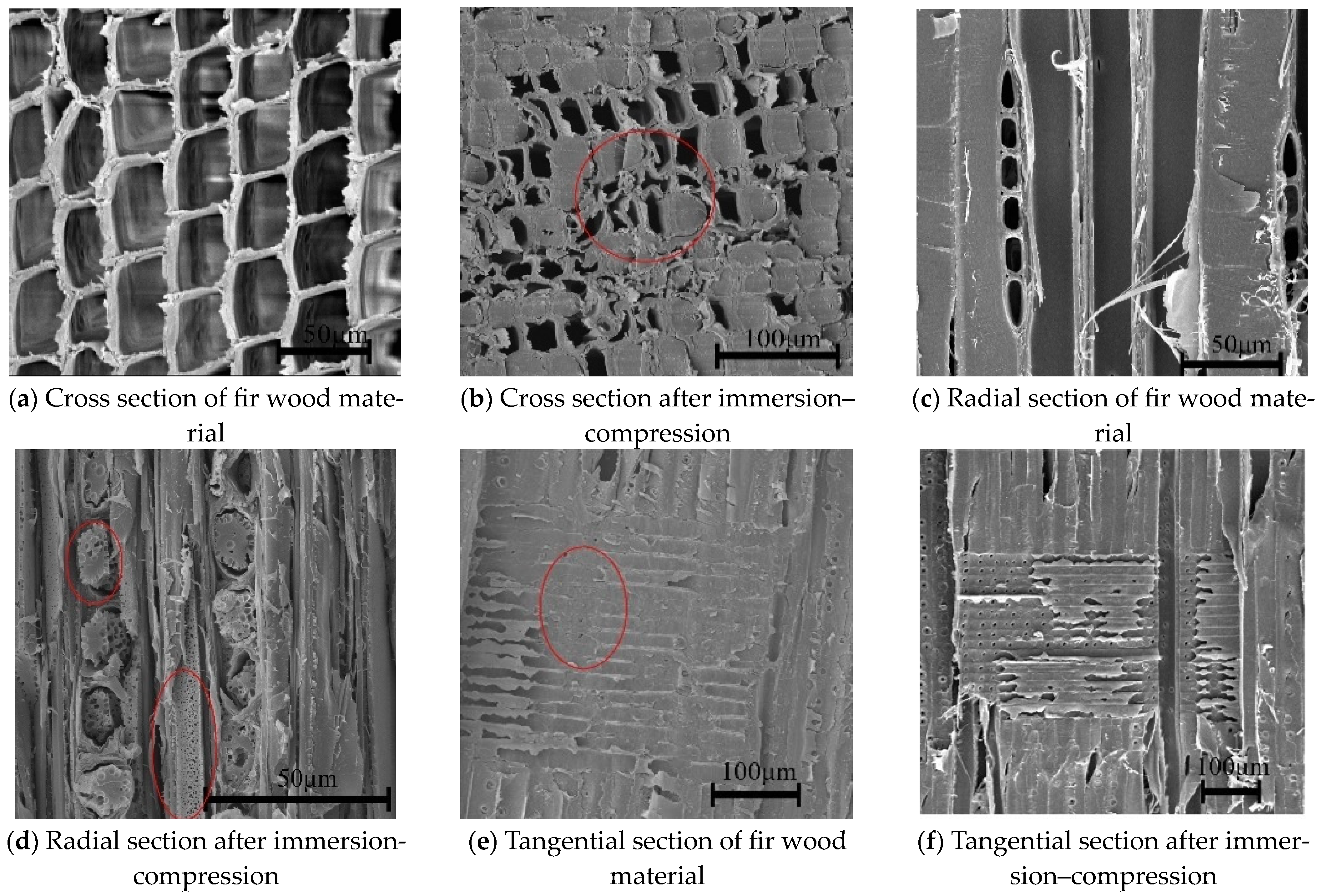

3.3.1. Micromorphological Analysis

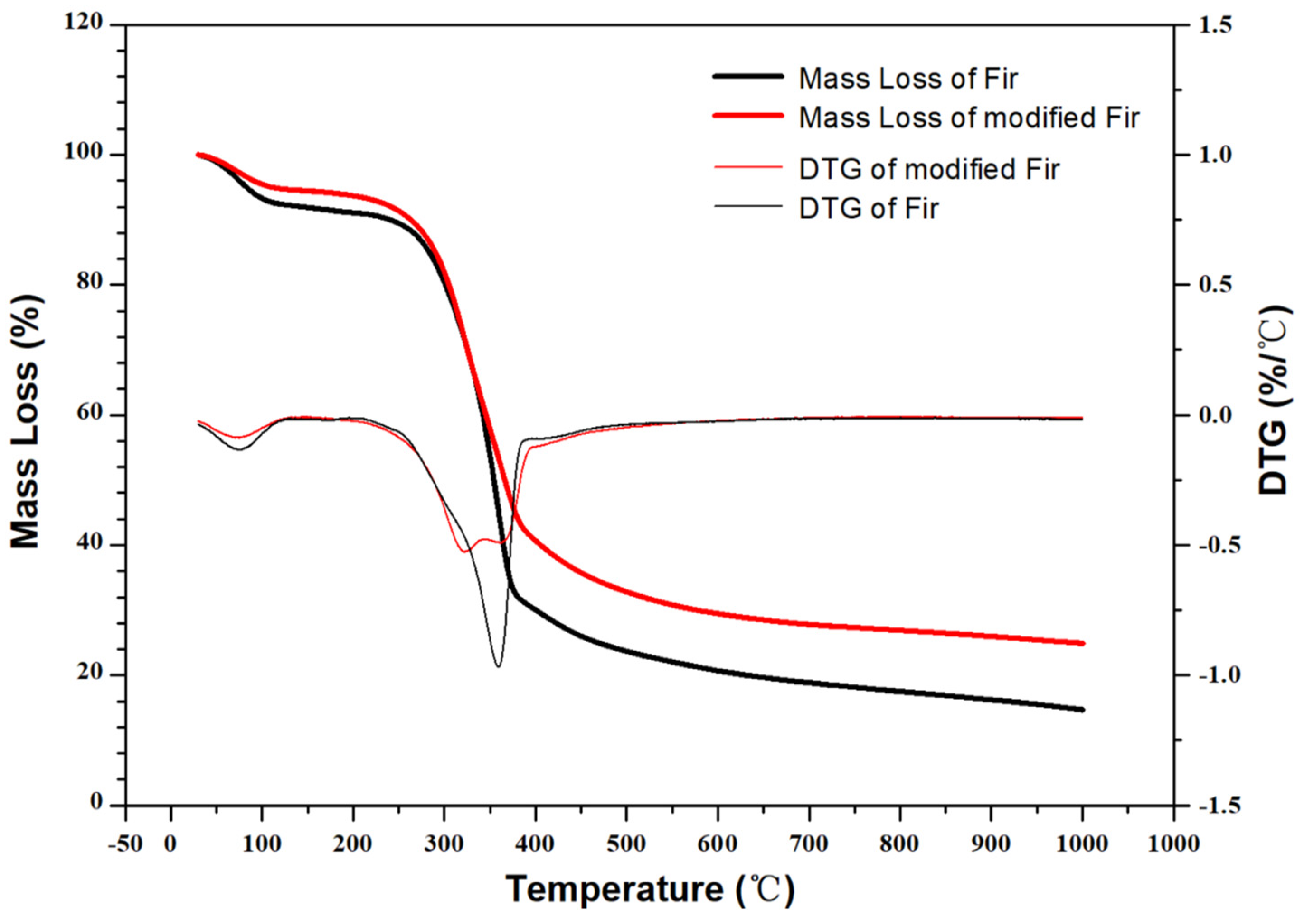

3.3.2. Thermal Performance Analysis

4. Discussion

5. Conclusions

- Our results show that the addition of montmorillonite had a small effect on the heat-curing performance of the modified liquid, but it increased the viscosity of the modified liquid and reduced the wettability. When the amount of montmorillonite added was 1%, the modified liquid had the best wettability on the fir wood, and the infiltration could be completed in 18 s. The curing time was 17.5 min, and the maximum energy storage modulus after curing was 1.8 × 107 Pa.

- The influence on the dry weight gain rate was in the order of montmorillonite content > PF solid content > dipping time. The optimal process was 25% of the PF solid content and 120 min of dipping time, and the dry weight gain rate reached 12.54% when the montmorillonite additive amount was 1%.

- Under the optimal PF–montmorillonite impregnation process, the impregnated Chinese fir was hot-pressed. The physical and mechanical properties were the best when the compression rate was 33%. Compared with ordinary Chinese fir, the density increased from 0.35 g/cm3 to 0.58 g/cm3, and the surface hardness increased from 37.9 HD to 70.9 HD. The static bending strength increased from 73.4 MPa to 98.7 MPa, the elastic modulus increased from 8640.7 MPa to 11,498 MPa, and the compressive rebound rate was 3.97% after aging for 30 days. Compared with pure PF impregnation–compression-modified Chinese fir, all of the detection properties were improved.

- The PF–montmorillonite solution enters the cell cavity and cell interstices of the fir, and the PF, montmorillonite, and fir form a certain chemical combination that plays the role of filling and densification, thus improving the water resistance, heat resistance, and physical and mechanical properties of the fir. Compared with ordinary fir, the overall heat loss of the impregnation–compression-modified fir was less than 10 percent, and the final residual carbon rate increased from 14.9 percent to 24.88 percent.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ling, Q.; Le, T.; Zhe, W.; Ximing, W.; Jianfang, Y. Current status of research on wood modification and drying. For. Prod. Ind. 2023, 60, 73–76. [Google Scholar] [CrossRef]

- Zhang, B.; Petrissans, M.; Petrissans, A.; Pizzi, A.; Colin, B. Furanic Polymerization Causes the Change, Conservation and Recovery of Thermally-Treated Wood Hydrophobicity before and after Moist Conditions Exposure. Polymers 2022, 15, 221. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Guo, Q.; Huang, X.; Zhang, Q.; Fan, J.; Huang, J. Research Progress of Reinforced Modification of Fast-Growing Wood. Coatings 2023, 14, 53. [Google Scholar] [CrossRef]

- Wu, Z.; Deng, X.; Li, L.; Xi, X.; Tian, M.; Yu, L.; Zhang, B. Effects of heat treatment on interfacial properties of Pinus Massoniana wood. Coatings 2021, 11, 543. [Google Scholar] [CrossRef]

- Tian, M.; Zhang, B.; Wu, Z.; Yu, L.; Li, L.; Xi, X. Effects of steam heat-treatment on properties of Pinus massoniana wood and its bonding performance. J. Renew. Mater. 2021, 9, 789–801. [Google Scholar] [CrossRef]

- Liu, Y.X. Effect of thinning retention density on carbon storage of middle-aged Chinese fir forest. Fujian For. Sci. Technol. 2023, 50, 17–22. [Google Scholar] [CrossRef]

- State Forestry Administration. China Forest Resources Report: The Ninth National Forest Resources Inventory; Forestry Publishing House: Beijing, China, 2019. [Google Scholar]

- Yao, M.; Yang, Y.; Song, J.; Yu, Y.; Jin, Y. Lignin-based catalysts for Chinese fir furfurylation to improve dimensional stability and mechanical properties. Ind. Crops Prod. 2017, 107, 38–44. [Google Scholar] [CrossRef]

- Min, X.; Qing, M.; Tianlong, W. Research progress on the modification of fast-growing Chinese fir. Packag. Eng. 2017, 38, 143–148. [Google Scholar] [CrossRef]

- Liu, X.F. Preparation and Application of New Organic Bentonite; Chengdu University of Technology: Chengdu, China, 2004. [Google Scholar]

- Jiantuan, T.; Wei, Z.; Yalin, G. Preparation and properties of phenolic resin/montmorillonite nanocomposites. Plast. Ind. 2007, 35, 370–372. [Google Scholar]

- Wenhua, L.; Guangjie, Z. Preparation of wood/montmorillonite (MMT) nanointercalation composites. Sci. Silvae Sin. 2005, 41, 181–188. [Google Scholar]

- Jun, J. Study on Intercalation of Poplar/Montmorillonite Nanocomposites; Nanjing Forestry University: Nanjing, China, 2008. [Google Scholar]

- Jian, Z.; Kuihong, W.; Qin, L. Preliminary study on improving properties of artificial rapid growing materials with nano-organic montmorillonite. China Wood Based Panels 2010, 17, 16–18+30. [Google Scholar]

- GB/T 14074-2006; Testing methods for wood adhesives and their resins. Standardization Administration of China: Beijing, China, 2006.

- GB/T 1933-2009; Method for determination of wood density. Standardization Administration of China: Beijing, China, 2009.

- GB/T 1936.2-2009; Determination method of bending elastic modulus of wood. Standardization Administration of China: Beijing, China, 2009.

- GB/T 1934.2-2009; Method for determination of wet swelling of wood. Standardization Administration of China: Beijing, China, 2009.

- GB/T 1936.1-2009; Test method for bending strength of wood. Standardization Administration of China: Beijing, China, 2009.

- Yuxuan, S.; Jie, Z.; Yang, Z.; Xiaoyu, W. Effect of hydrothermal densification process on performance of poplar veneer. For. Prod. Ind. 2015, 42, 21–24. [Google Scholar] [CrossRef]

- Xianglin, F.; Xinzhou, W.; Yuhe, D.; Shanshan, J.; An, C.Q.; Geping, D.; Toi, T.M. Study on technology of montmorillonite modified poplar wood sheet I: Impregnation treatment technology. J. Cent. South Univ. For. Technol. 2016, 36, 94–102. [Google Scholar] [CrossRef]

- Chunyu, Z.; Qing, M. Composition analysis of phenolic composites by infrared and thermogravimetric analysis. Thermosetting Resins 2006, 21, 49–50. [Google Scholar]

- Fanshuai, M. Research on Temperature Resistance and Alkaline Resistance of Impregnated Water-Based Phenolic Resin; Shanghai University of Applied Science: Shanghai, China, 2020. [Google Scholar] [CrossRef]

- Jambreković, B.; Govorčin Bajsić, E.; Španić, N.; Sedlar, T.; Sinković, T. Viscoelastic and Thermal Properties of Styrene Modified Fir Wood. Polymers 2022, 14, 78–86. [Google Scholar] [CrossRef] [PubMed]

| Level | Influence Factor | Assessment Indicators | ||

|---|---|---|---|---|

| PF Solid Content/% | Infiltration Time/min | Montmorillonite Addition/% | ||

| 1 | 20 | 60 | 1 | Dry weight gain rate |

| 2 | 25 | 90 | 2 | |

| 3 | 30 | 120 | 3 | |

| Montmorillonite Addition/% | Viscosity/mPa s | pH Value | Water Hybrid | Free Aldehyde/% | Initial Exothermic Temperature/°C | Maximum Exothermic Temperature/°C |

|---|---|---|---|---|---|---|

| 0 | 15.5 | 9.81 | >20 | 0.056 | 118.07 | 157.05 |

| 1 | 506 | 9.68 | - | 0.055 | 119.59 | 155.81 |

| 2 | 1118 | 9.70 | - | 0.055 | 119.76 | 155.83 |

| 3 | 1916 | 9.58 | - | 0.054 | 119.16 | 155.82 |

| Test Number | Solid Content (%) A | Infiltration Time (min) B | Montmorillonite Addition (%) C | Mean Value of Dry Weight Gain Rate by Immersion (%) |

|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 8.58 |

| 2 | 1 | 2 | 2 | 7.30 |

| 3 | 1 | 3 | 3 | 8.18 |

| 4 | 2 | 1 | 2 | 9.45 |

| 5 | 2 | 2 | 3 | 9.35 |

| 6 | 2 | 3 | 1 | 12.11 |

| 7 | 3 | 1 | 3 | 8.98 |

| 8 | 3 | 2 | 1 | 11.35 |

| 9 | 3 | 3 | 2 | 9.08 |

| Control group | 2 | 3 | 0 | 6.54 |

| Variance Analysis | |||||

|---|---|---|---|---|---|

| Source of Variance | Sum of Squared Deviations | Degrees of Freedom | Sum of Mean Square | F | p-Value |

| A | 25.93 | 2 | 12.96 | 12.87 | 0.09 |

| B | 2.81 | 2 | 1.40 | 1.39 | 0.01 |

| C | 23.24 | 2 | 11.62 | 11.54 | 0.08 |

| Compression Ratio (%) | Modified Leaching Solution | Absorbent Thickness Expansion/% | Density/(kg·m−3) | Surface Hardness/HD | Static Bending Strength /MPa | Modulus of Elasticity /MPa | Note |

|---|---|---|---|---|---|---|---|

| 20% | PF–montmorillonite Modified liquid | 8.3 | 0.500 | 69.8 | 82.4 | 10 866.0 | |

| PF | 3.1 | 0.523 | 74.1 | 78.7 | 10 822.3 | ||

| 33% | PF–montmorillonite Modified liquid | 11.6 | 0.581 | 70.9 | 98.7 | 11 498.0 | |

| PF | 26.8 | 0.592 | 83.3 | 90.6 | 9 876.6 | ||

| 53% | PF–montmorillonite Modified liquid | 12.3 | 0.538 | 53.8 | 86.5 | 9 424.0 | burst |

| PF | - | - | - | - | - | severe bulging | |

| Uncompressed | - | - | 0.328 | 33.6 | 60.4 | 6390.8 |

| Compression Ratio/% | Compression Resilience/% | |||

|---|---|---|---|---|

| 1 Day | 7 Days | 14 Days | 30 Days | |

| 20 | 0.20 | 1.29 | 3.03 | 2.89 |

| 33 | 0.10 | 1.43 | 3.81 | 3.97 |

| 53 | 0.15 | 1.80 | 5.27 | 5.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, L.; Zhang, Q.; Zhang, B.; Qiu, H.; Guo, J.; Sun, F.; Jiang, Z.; Zhou, W. Study on Phenol–Formaldehyde Resin–Montmorillonite Impregnation and Compression Modification of Chinese Fir. Polymers 2024, 16, 1385. https://doi.org/10.3390/polym16101385

He L, Zhang Q, Zhang B, Qiu H, Guo J, Sun F, Jiang Z, Zhou W. Study on Phenol–Formaldehyde Resin–Montmorillonite Impregnation and Compression Modification of Chinese Fir. Polymers. 2024; 16(10):1385. https://doi.org/10.3390/polym16101385

Chicago/Turabian StyleHe, Lei, Qian Zhang, Bengang Zhang, Hongyun Qiu, Jie Guo, Fengwen Sun, Zengfu Jiang, and Weidong Zhou. 2024. "Study on Phenol–Formaldehyde Resin–Montmorillonite Impregnation and Compression Modification of Chinese Fir" Polymers 16, no. 10: 1385. https://doi.org/10.3390/polym16101385

APA StyleHe, L., Zhang, Q., Zhang, B., Qiu, H., Guo, J., Sun, F., Jiang, Z., & Zhou, W. (2024). Study on Phenol–Formaldehyde Resin–Montmorillonite Impregnation and Compression Modification of Chinese Fir. Polymers, 16(10), 1385. https://doi.org/10.3390/polym16101385