Research on Microwave Pyrolysis Recovery and Reuse Performance of Carbon Fiber Composites

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Experimental Procedure

2.3. Characterization Methods

3. Results and Discussion

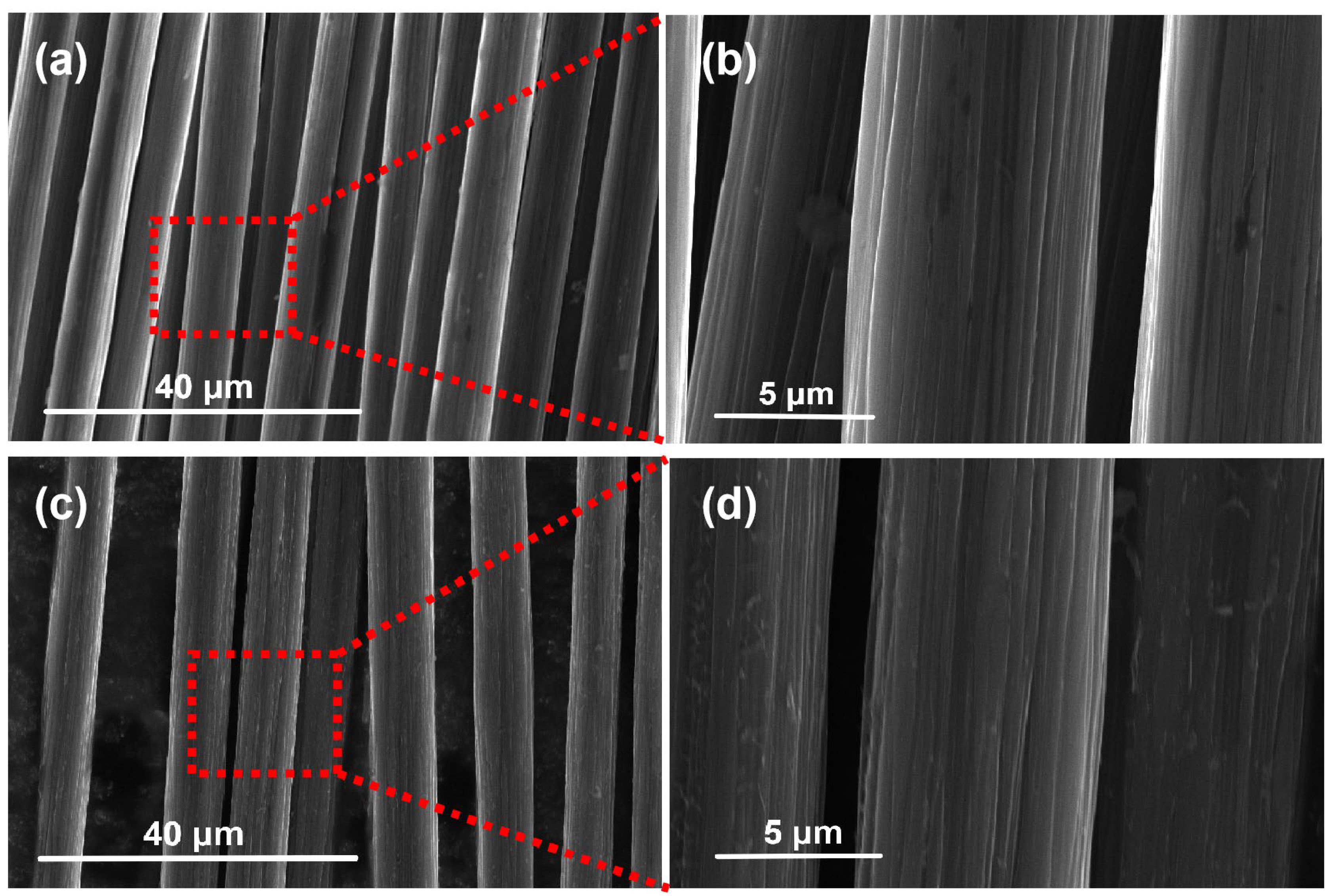

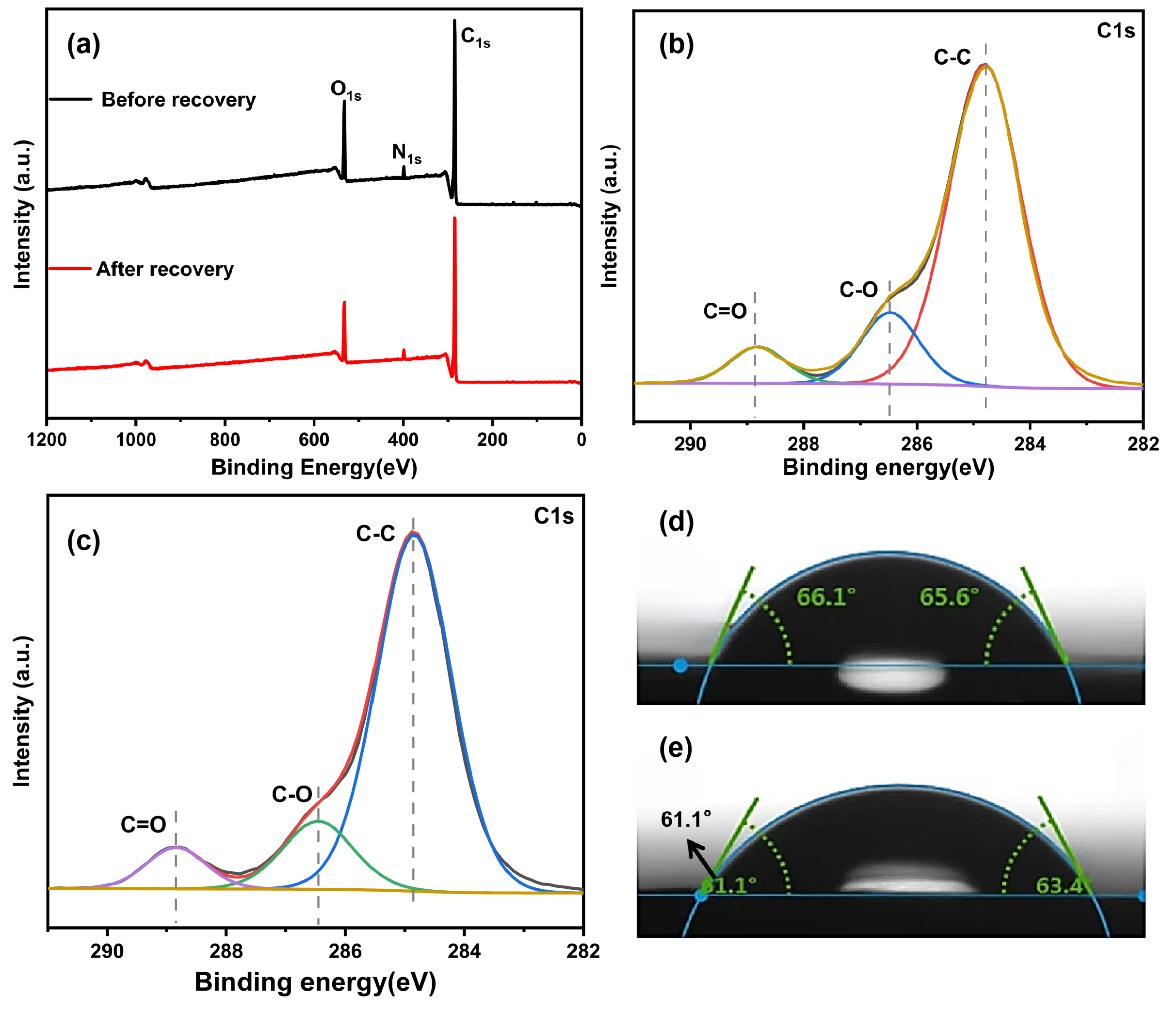

3.1. Properties of Recovered Carbon Fiber

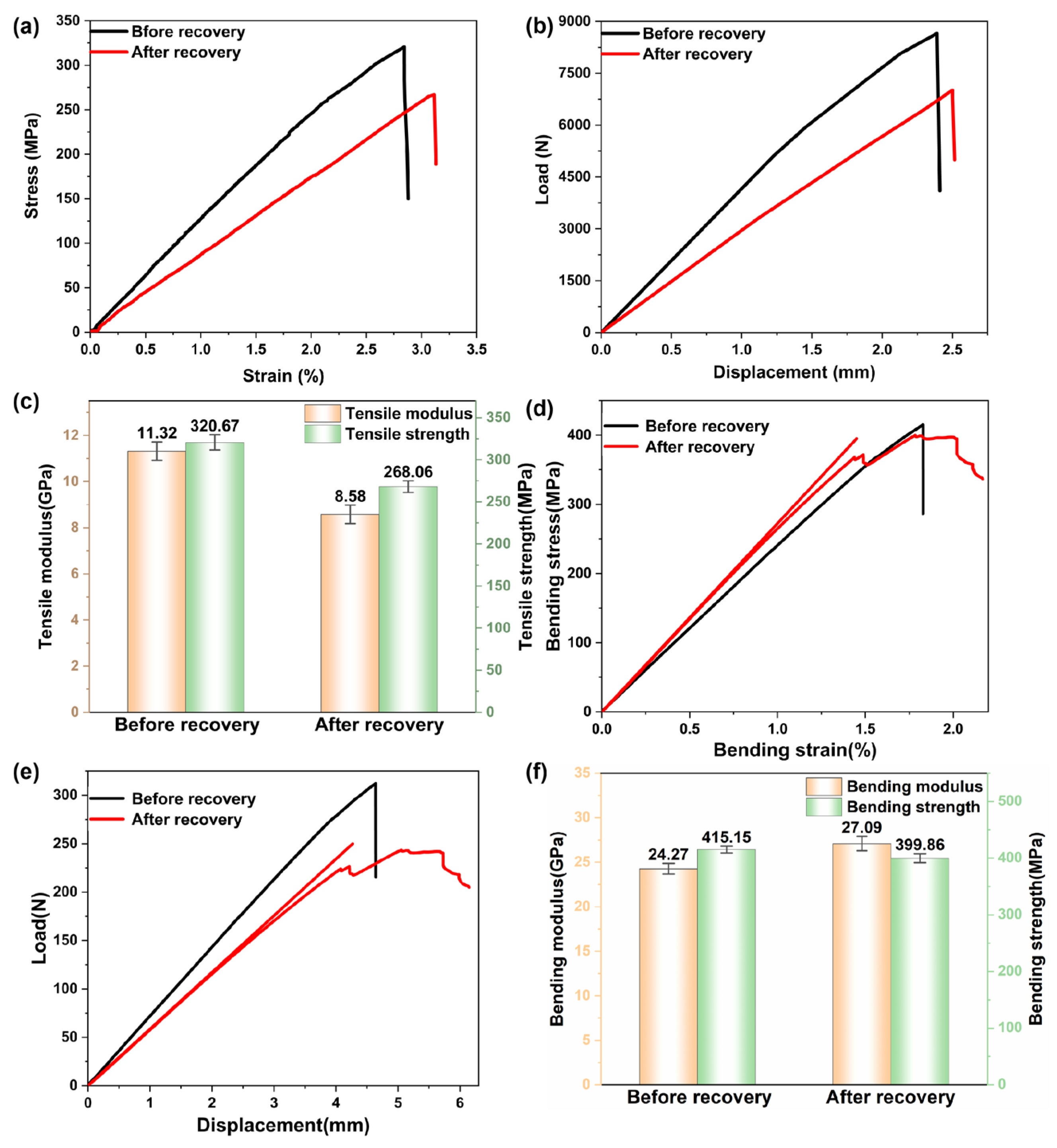

3.2. Mechanical Properties of Composite Plates

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Thalapil, J.; Sawant, S.; Tallur, S.; Banerjee, S. Guided wave based localization and severity assessment of in-plane and out-of-plane fiber waviness in carbon fiber reinforced composites. Compos. Struct. 2022, 297, 115932–115945. [Google Scholar] [CrossRef]

- Liu, D.; Qin, F.J.; Di, J.; Zhang, Z.G. Flexural behavior of reinforced concrete (RC) beams strengthened with carbon fiber reinforced polymer (CFRP) and ECC. Case Stud. Constr. Mater. 2022, 19, e02270–e02286. [Google Scholar] [CrossRef]

- Li, N.; Chen, P.H.; Ling, X. A microscopic elasto-plastic damage model for characterizing transverse responses of unidirectional fiber-reinforced polymer composites. Thin Wall. Struct. 2020, 154, 106828–106846. [Google Scholar] [CrossRef]

- Lee, H.; Jeong, S.; Chung, W. Enhancing bond performance: Carbon fiber reinforced polymer bar interaction with multi-walled carbon nanotubes cementitious composites in chloride-exposed conditions. Constr. Build Mater. 2024, 412, 134763–134777. [Google Scholar] [CrossRef]

- Kumekawa, N.; Mori, Y.; Tanaka, H.; Matsuzaki, R. Experimental evaluation of variable thickness 3d printing of continuous carbon fiber-reinforced composites. Compos. Struct. 2022, 288, 115391–115400. [Google Scholar] [CrossRef]

- Iiba, K.; Takarada, W.; Kikutani, T. Effect of Introducing Long Chain Branching on Fiber Diameter and Fiber Diameter Distribution in Melt Blowing Process of Polypropylene. Int. Polym. Proc. 2021, 36, 403. [Google Scholar] [CrossRef]

- Chen, C.H.; Chiang, C.L.; Wang, J.X.; Shen, M.Y. A circular economy study on the characterization and thermal properties of thermoplastic composite created using regenerated carbon fiber recycled from waste thermoset CFRP bicycle part as reinforcement, Compos. Sci. Technol. 2022, 230, 109761–109774. [Google Scholar] [CrossRef]

- Waller, M.D.; Bakis, C.E.; Koudela, K.L. Fatigue resistance of ultra-high-modulus pitch-based carbon fiber/epoxy composites under tensile loading. J. Compos. Mater. 2021, 56, 167. [Google Scholar] [CrossRef]

- Uludag-Demirer, S.; Smerigan, A.; Hsiao, P.J.; Marks, A.; Smith, M.R.; Liao, W. Enhanced Carbon Dioxide Capture Using a Mixed Amino Acid Salt Solution. Ind. Eng. Chem. Res. 2023, 62, 4064–4073. [Google Scholar] [CrossRef]

- Caltagirone, P.E.; Ginder, R.S.; Ozcan, S.; Li, K.; Gay, A.M.; Stonecash, J.; Steirer, K.X.; Cousins, D.; Kline, S.P.; Maxey, A.T.; et al. Substitution of virgin carbon fiber with low-cost recycled fiber in automotive grade injection molding polyamide 66 for equivalent composite mechanical performance with improved sustainability. Compos. Part. B-Eng. 2021, 221, 109007–109016. [Google Scholar] [CrossRef]

- Han, J.C.; Zhu, Y.K.; Wang, L.F.; Mu, Y.; Feng, G.G.; Liu, K.Q.; Tong, C.H.; Yu, Z.X. Modification of regenerated cellulose ultrafiltration membranes with multi-walled carbon nanotubes for enhanced antifouling ability: Field test and mechanism study. Sci. Total Environ. 2021, 780, 146657–146666. [Google Scholar] [CrossRef] [PubMed]

- Kravtsova, V.; Minchenkov, K.; Gusev, S.; Evlashin, S.; Bondareva, J.; Alajarmeh, O.; Safonov, A. Recyclability of unidirectional reinforced pultruded thermoplastic profiles into composite laminates. Compos. Commun. 2024, 46, 101843. [Google Scholar] [CrossRef]

- Ren, Y.Y.; Xu, L.; Shang, X.B.; Shen, Z.G.; Fu, R.Z.; Li, W.; Guo, L.R. Evaluation of Mechanical Properties and Pyrolysis Products of Carbon Fibers Recycled by Microwave Pyrolysis. ACS Omega 2022, 7, 13529–13537. [Google Scholar] [CrossRef] [PubMed]

- ASTM D 3822/D 3822 M-14; Standard Test Method for Tensile Properties of Single Textile Fibers. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTMD256; Standard Test Method for Determining the Izod Pendulum Impact Resistence of Plastics. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D3039/D 3039M–08Standard Test Method for Tensile Properties of Polymer-Matrix Composite Materials; ASTM: West Conshohocken, PA, USA, 2008.

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM: West Conshohocken, PA, USA, 2017.

- Deng, Z.Y.; Fan, J.M.; Huang, Z.X.; Yang, X.Y. Efficient recycling of carbon fiber from carbon fiber reinforced composite and reuse as high performance electromagnetic shielding materials with superior mechanical strength. Polym. Test. 2023, 125, 108110–108124. [Google Scholar] [CrossRef]

- Dharmasiri, B.; Randall, J.; Yin, Y.; Andersson, G.G.; Doeven, E.H.; Francis, P.S.; Henderson, L.C. Carbon reinforced carbon fibers: Using surface modification as a route to enhanced physical performance. Compos. Sci. Technol. 2022, 218, 109217–109226. [Google Scholar] [CrossRef]

- Liu, J.H.; Zhang, C.; Guo, S.H.; Xu, L.; Xiao, S.J.; Shen, Z.G. Microwave treatment of pre-oxidized fibers for improving their structure and mechanical properties. Ceram. Int. 2019, 45, 1379–1384. [Google Scholar] [CrossRef]

- Yang, X.; Wang, Y.D.; Zhang, X.K.; Jian, Z.W.; Lu, X.L.; Wang, Z.H.; Xia, H.S. Carbon Fiber Reinforced Epoxy Resin Composites with Excellent Recyclable Performance via Dynamic Acylsemicarbazide Moieties. ACS Appl. Polym. Mater. 2023, 5, 5189–5199. [Google Scholar] [CrossRef]

- Salas, A.; Berrio, M.E.; Martel, S.; Díaz-Gomez, A.; Palacio, D.A.; Tuninetti, V.; Medina, C.; Mel’endrez, M.F. Towards recycling of waste carbon fiber: Strength, morphology and structural features of recovered carbon fibers. Waste Manag. 2023, 165, 59–69. [Google Scholar] [CrossRef]

- Wickramasingha, Y.A.; Dharmasiri, B.; Randall, J.D.; Yin, Y.; Andersson, G.G.; Nepal, D.; Newman, B.; Stojcevski, F.; Eyckens, D.J.; Henderson, L.C. Surface modification of carbon fiber as a protective strategy against thermal degradation. Compos. Part A Appl. Sci. Manuf. 2022, 153, 106740–106751. [Google Scholar] [CrossRef]

- Xu, H.F.; Hu, J.R.; Liu, X.; Wu, H.H.; Jiang, Y.; Xu, Z.J.; Chen, S.F.; Li, T.C.; Zhang, J.H.; Zhang, D.H. Interface strengthening and high-value recycling of epoxy resin/carbon fiber fabric composites. Chem. Eng. J. 2023, 465, 142998–143008. [Google Scholar] [CrossRef]

- Zhang, B.Y.; Cui, T.T.; Jiao, X.W.; Ma, Y.; Gao, L.; Hu, J. Reprocessable and recyclable high-performance carbon fiber-reinforced composites enabled by catalyst-free covalent adaptable networks. Chem. Eng. J. 2023, 476, 146625–146634. [Google Scholar] [CrossRef]

- Lebedeva, E.A.; Astaf’eva, S.A.; Istomina, T.S.; Trukhinov, D.K.; Shamsutdinov, A.S.; Strel’nikov, V.N.; Kukharenko, A.I.; Zhidkov, I.S. Novel approach to recycled carbon fiber suitability assessment for additive technologies. Appl. Surf. Sci. 2022, 602, 154251–154260. [Google Scholar] [CrossRef]

- Li, H.Y.; Yang, J.; Wang, L.; Li, L.H.; Xia, Y.; Koberle, T.; Dong, W.K.; Zhang, N.; Yang, B.; Mechtcherine, V. Multiscale assessment of performance of limestone calcined clay cement reinforced with virgin and recycled carbon fibers. Constr. Build. Mater. 2023, 406, 133228–133250. [Google Scholar] [CrossRef]

- Ren, Y.Y.; Xu, L.; Sun, Y.F.; Li, X.; Shen, Z.G.; Li, H.; Liu, J.H. Study on oxidation behavior during process of recycling carbon fibers from CFRP by pyrolysis. Environ. Manag. 2023, 347, 119103. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Zhang, Z.Y.; Pang, J.Y.; Su, L. Preparation of carbon fibre-reinforced composite panels from epoxy resin matrix of nano lignin polyol particles. J. Clean. Prod. 2023, 428, 139170–139185. [Google Scholar] [CrossRef]

- Chen, H.Y.; Hsueh, Y.T.; Hu, Z.K.; Huang, H.H. Fabrication of unibody multifunctional energy storage composites from recycled carbon fiber—An atmospheric activation process. J. Energy Storage 2023, 72, 108223–108234. [Google Scholar] [CrossRef]

- Ma, X.; Wu, Y.; Liang, N.; Xu, H.F.; Xu, Z.J.; Chen, S.F.; Zhang, D.H. High-efficiently renewable hyperbranched epoxy resin/carbon fiber composites with both long service life and high performance. Compos. Commun. 2023, 40, 101630–101635. [Google Scholar] [CrossRef]

- Chen, Q.H.; Zhang, H.; Liu, H.B.; Yuan, J.Y.; Gao, Y.; Wu, C.Y.; Wang, Q.; Zhao, G.Z.; Liu, Y.G. Improved mechanical properties of carbon fiber/epoxy composites via fiber surface grafting of rigid-flexible chain structure. Diam. Relat. Mater. 2024, 142, 110739–110748. [Google Scholar] [CrossRef]

| Element Name | Energy/eV | Wavelength/μm | Wave Number/cm−1 | Cpeak/% | |

|---|---|---|---|---|---|

| Before recovery | C 1s | 285.13 | 3.01 | 1,404,777 | 72.22 ± 0.5 |

| O 1s | 532.75 | 3.28 | 612,550.5 | 13.04 ± 0.2 | |

| N 1s | 399.53 | 1.5 | 67,448.27 | 2.23 ± 0.1 | |

| After recovery | C 1s | 285.12 | 2.97 | 1,444,991 | 73.8 ± 0.3 |

| O 1s | 532.84 | 3.32 | 550,435.6 | 11.63 ± 0.1 | |

| N 1s | 399.43 | 1.72 | 67,526.24 | 2.22 ± 0.05 |

| Carbon Fiber | Before Recovery | After Recovery | |

|---|---|---|---|

| C–C | E/eV | 284.8 | 284.8 |

| Cpeak/% | 78.93 | 78.65 ± 0.4 | |

| C–0 | E/eV | 286.47 | 286.46 |

| Cpeak/% | 14.22 | 14.11 ± 0.3 | |

| C=0 | E/eV | 288.8 | 288.84 |

| Cpeak/% | 6.85 | 7.24 ± 0.05 | |

| Index Name | Before Recovery | After Recovery |

|---|---|---|

| Width/mm | 4.962 | 4.63 |

| Absorbed energy/J | 0.667 ± 0.02 | 0.41 ± 0.01 |

| Impact strength/(kJ/m2) | 48.83 ± 0.5 | 37.05 ± 0.3 |

| Fracture mode | ductile | ductile |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Xu, L.; Ren, Y.; Nan, Z.; Xiao, S.; Shen, Z. Research on Microwave Pyrolysis Recovery and Reuse Performance of Carbon Fiber Composites. Polymers 2024, 16, 1383. https://doi.org/10.3390/polym16101383

Li X, Xu L, Ren Y, Nan Z, Xiao S, Shen Z. Research on Microwave Pyrolysis Recovery and Reuse Performance of Carbon Fiber Composites. Polymers. 2024; 16(10):1383. https://doi.org/10.3390/polym16101383

Chicago/Turabian StyleLi, Xuan, Lei Xu, Yiyao Ren, Zheng Nan, Shijie Xiao, and Zhigang Shen. 2024. "Research on Microwave Pyrolysis Recovery and Reuse Performance of Carbon Fiber Composites" Polymers 16, no. 10: 1383. https://doi.org/10.3390/polym16101383

APA StyleLi, X., Xu, L., Ren, Y., Nan, Z., Xiao, S., & Shen, Z. (2024). Research on Microwave Pyrolysis Recovery and Reuse Performance of Carbon Fiber Composites. Polymers, 16(10), 1383. https://doi.org/10.3390/polym16101383