Improved Electrical Properties of Organic Modified Thermoplastic Insulation Material for Direct Current Cable Application

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Preparation

2.2. Characterization

2.3. Direct Current Electrical Properties

2.4. Density Functional Theory Calculation

2.5. Carrier Transport Simulation

3. Results

3.1. Characterization

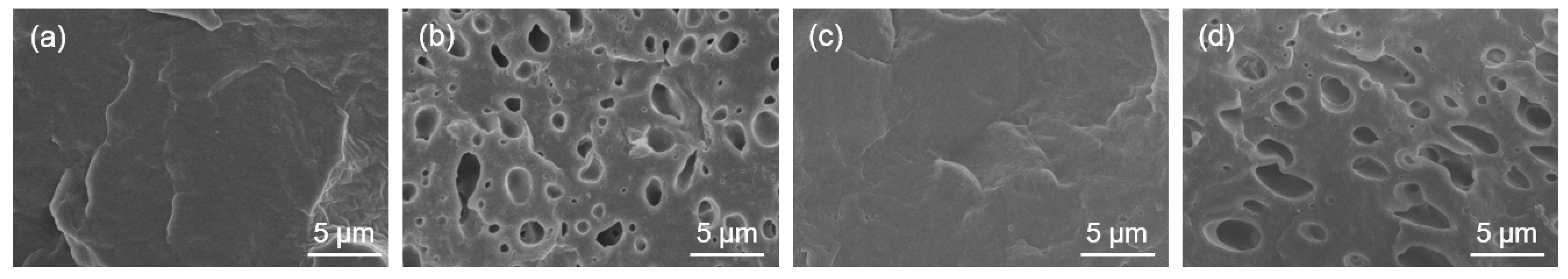

3.1.1. Microscopic Morphology

3.1.2. Crystal Morphology

3.1.3. Molecular Structure

3.2. Direct Current Electrical Properties

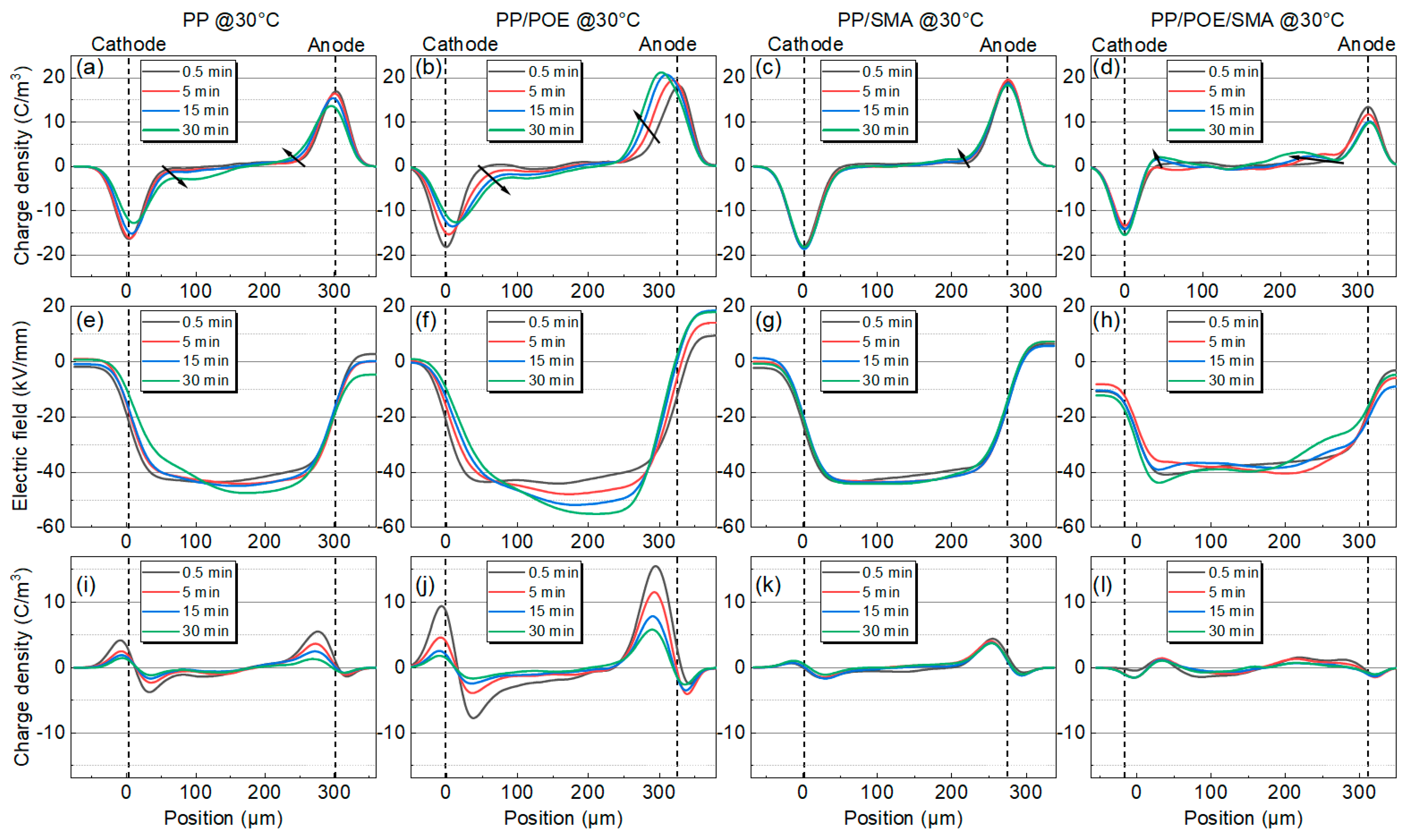

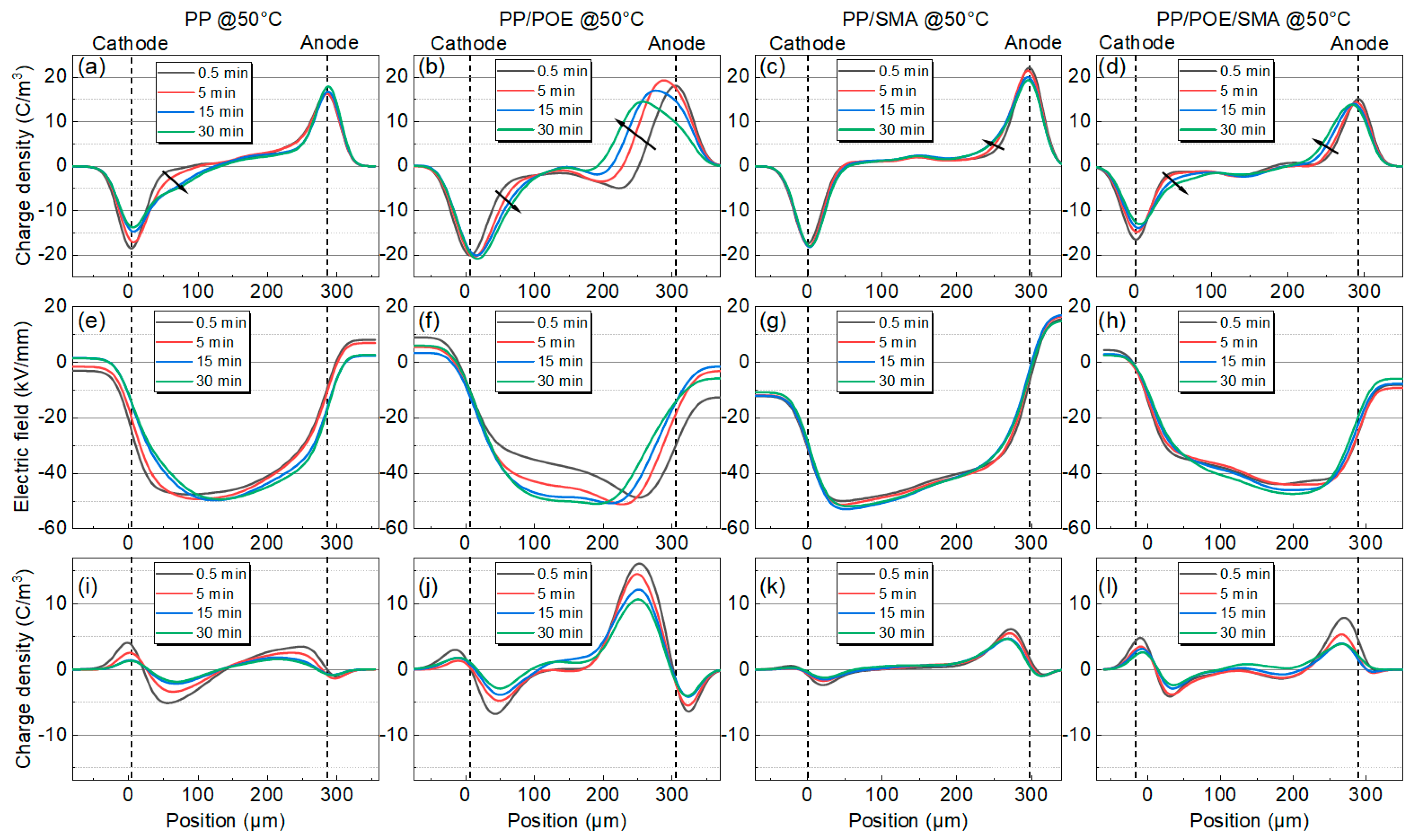

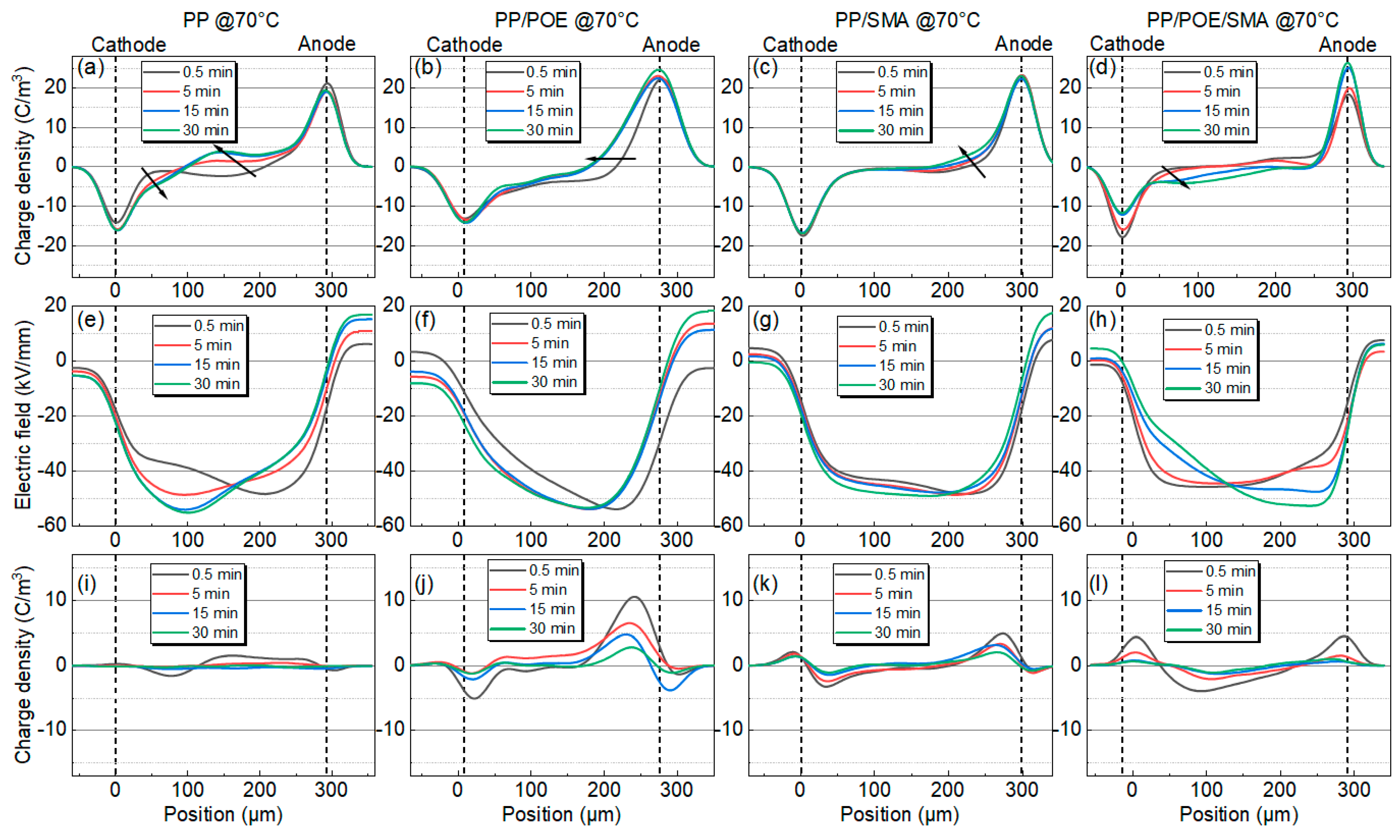

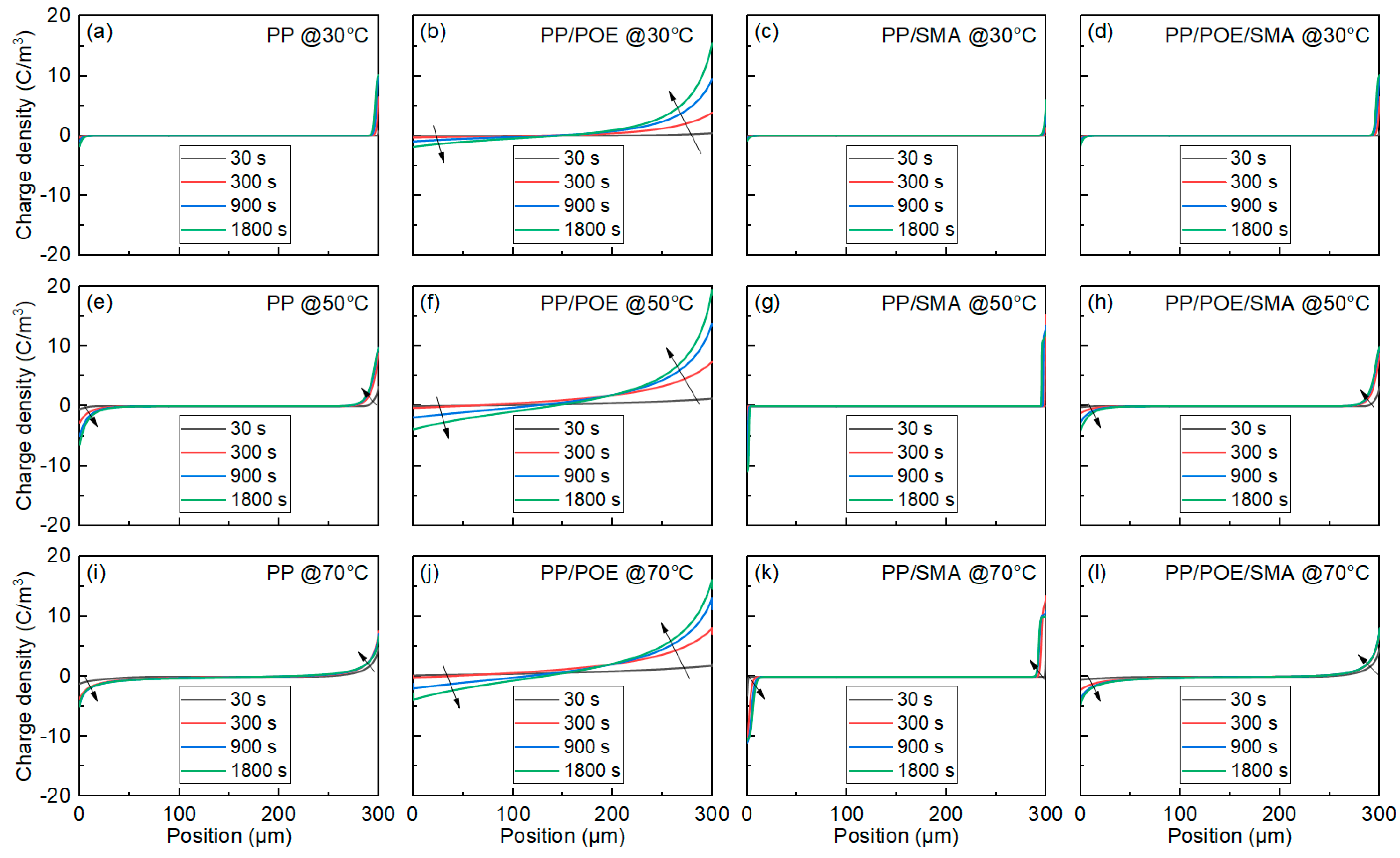

3.2.1. Space Charge Distribution

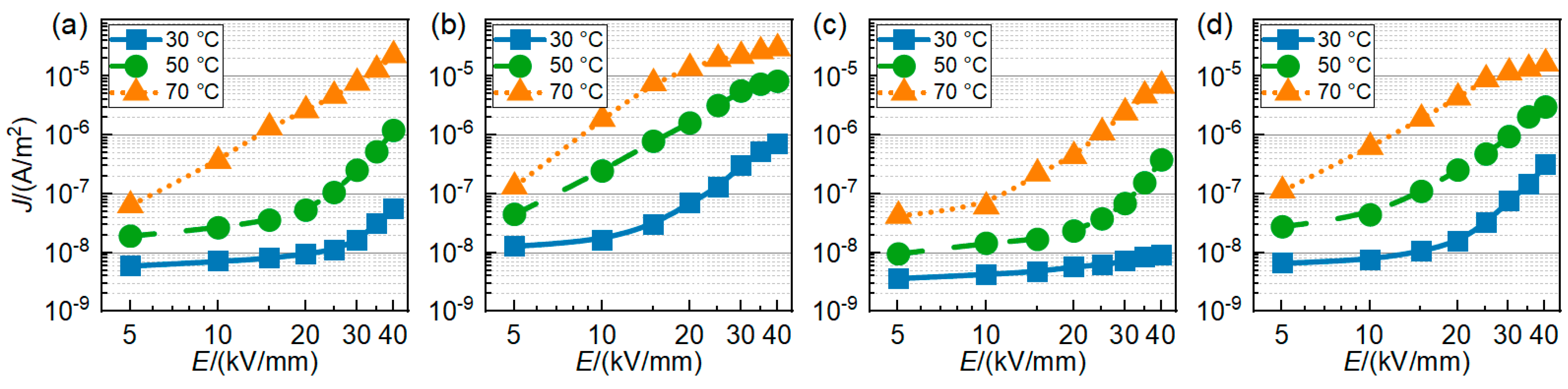

3.2.2. Conductance Current

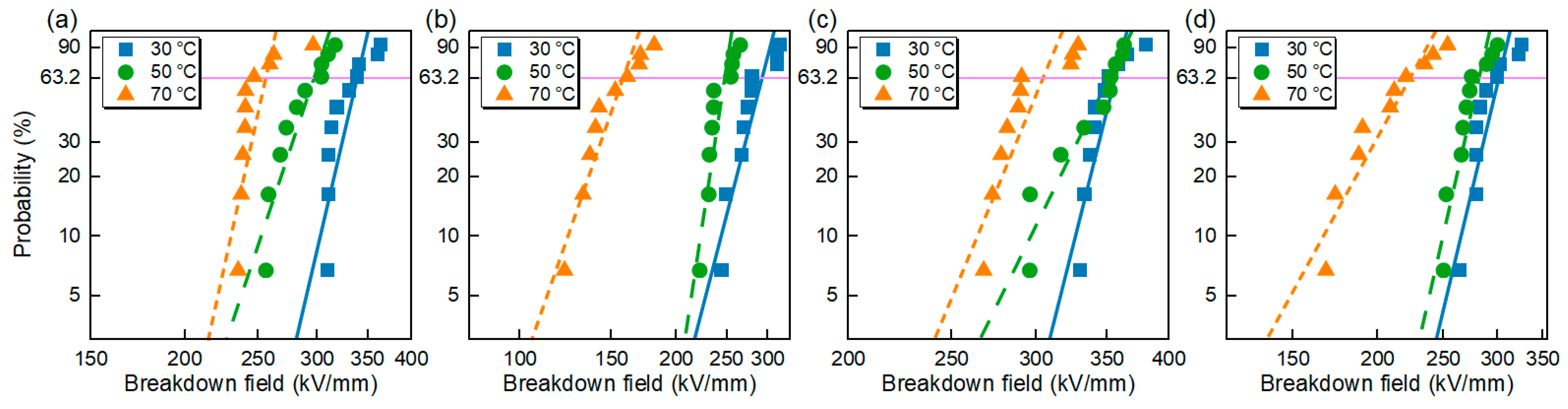

3.2.3. Breakdown Strength

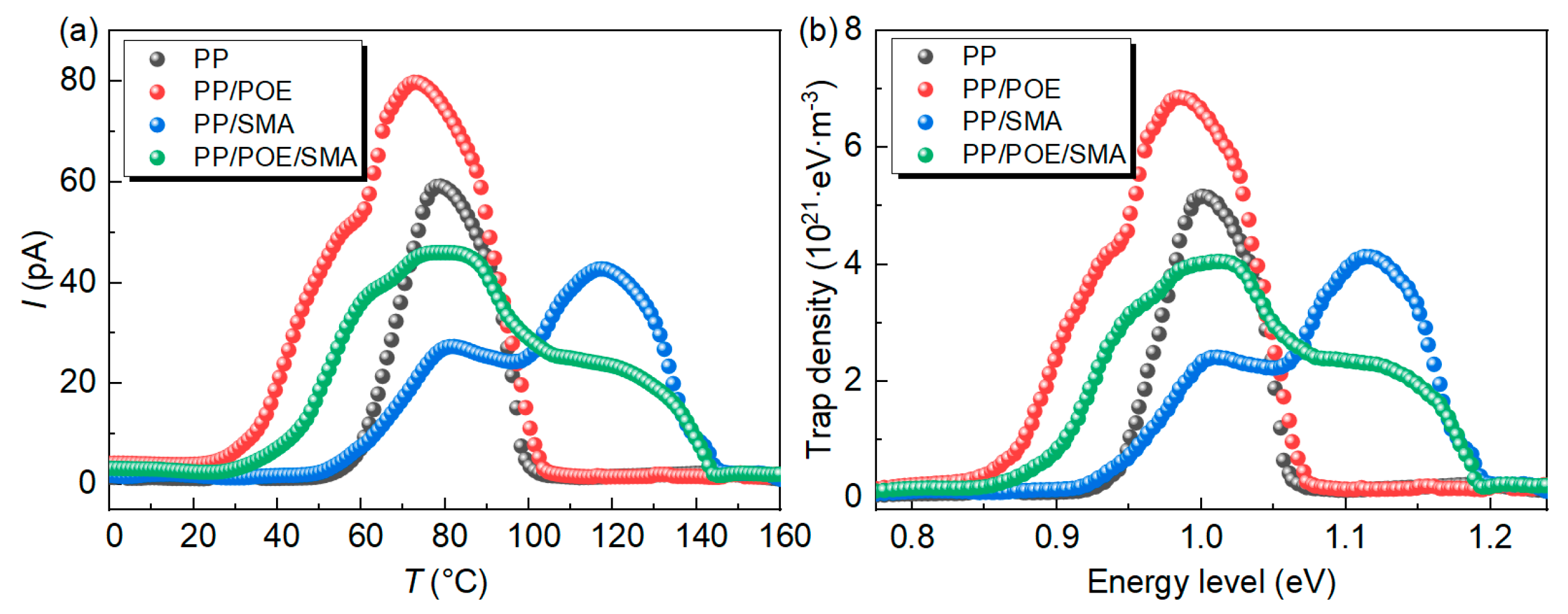

3.2.4. Thermal-Stimulated Depolarization Current

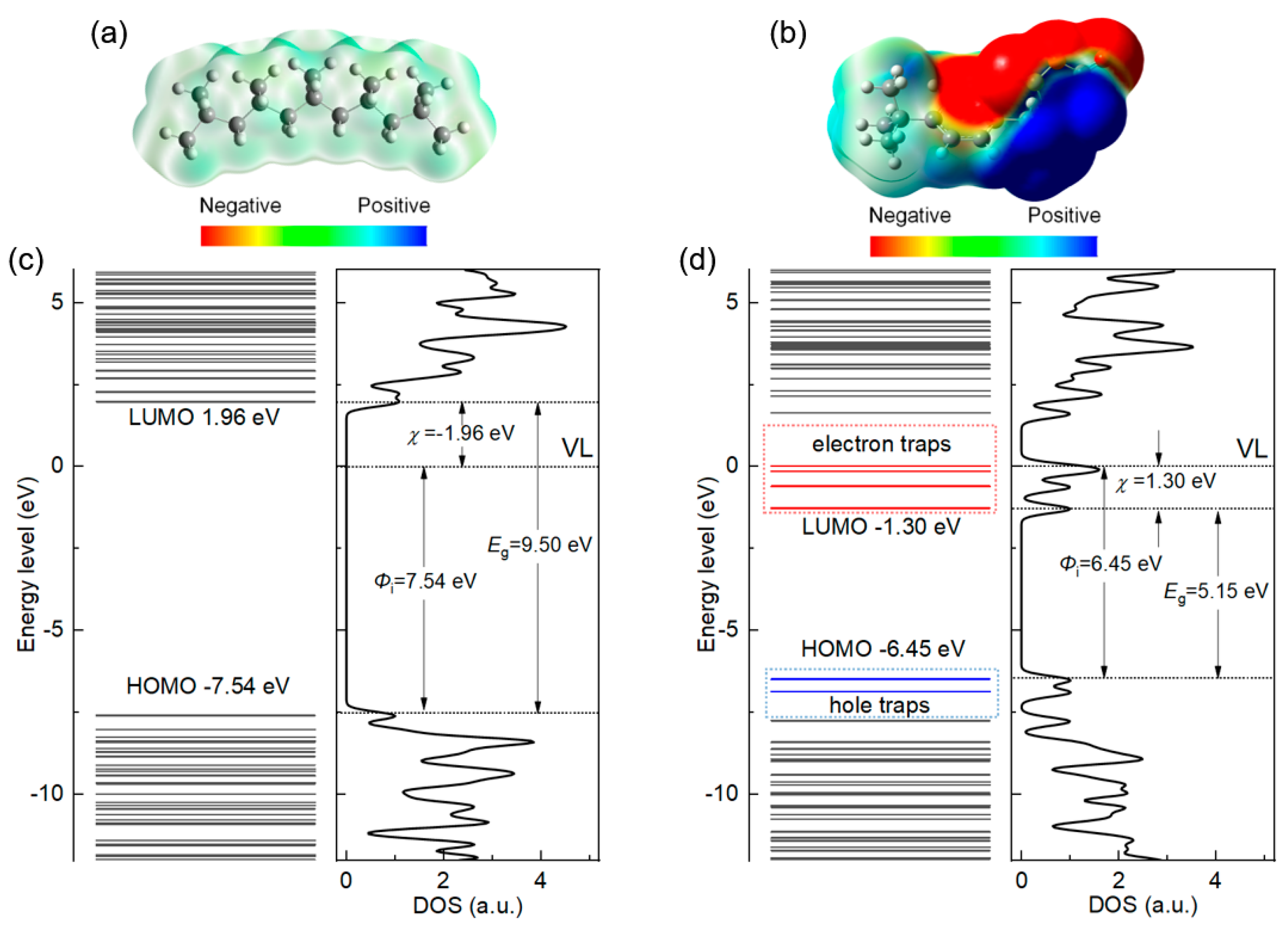

3.3. Density Functional Theory Calculation

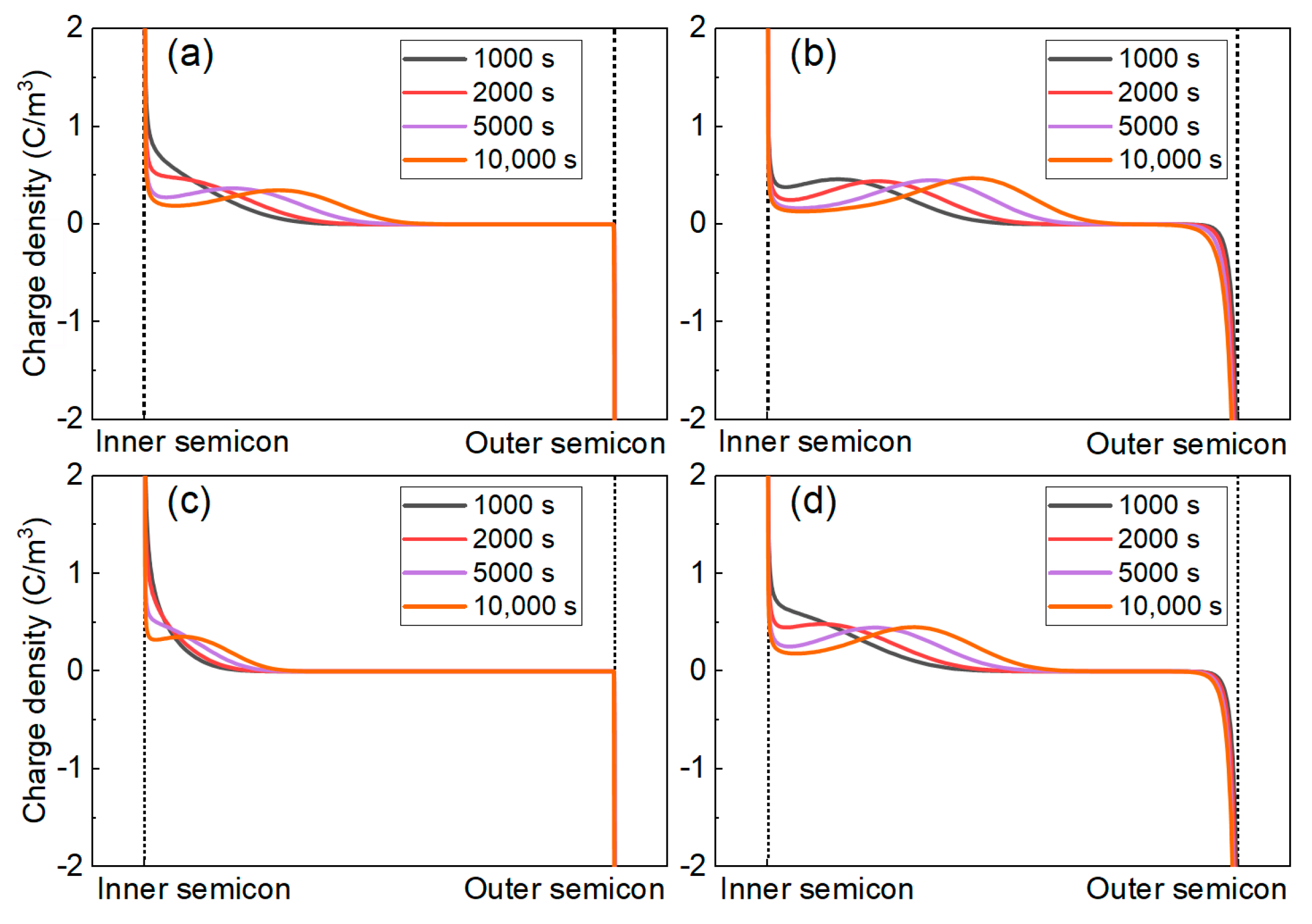

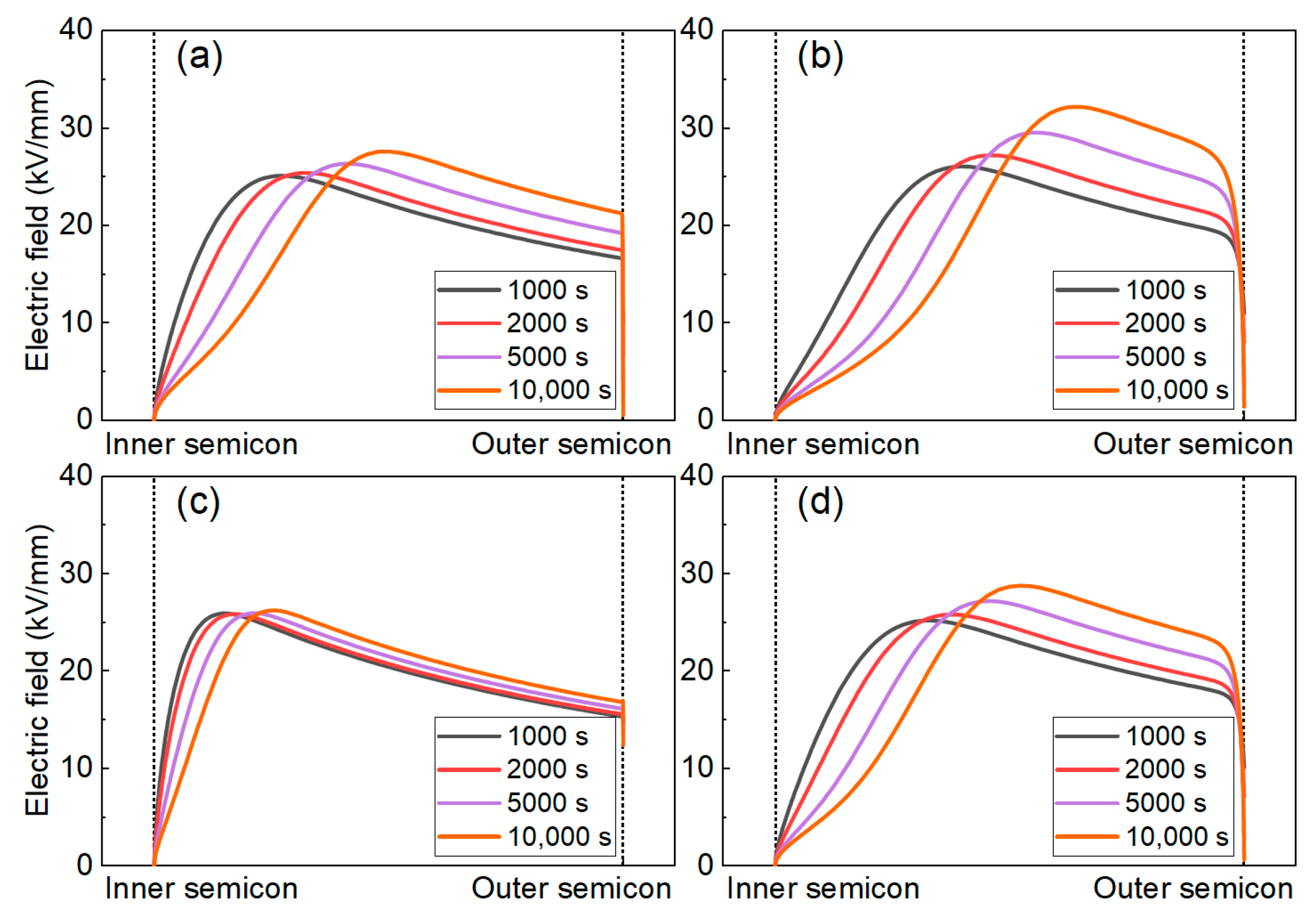

3.4. Carrier Transport Simulation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ji, K.; Tang, G.F.; Pang, H.; Yang, J. Impedance Modeling and Analysis of MMC-HVDC for Offshore Wind Farm Integration. IEEE Trans. Power Deliv. 2020, 35, 1488–1501. [Google Scholar] [CrossRef]

- George, C. Review of high voltage direct current cables. CSEE J. Power Energy Syst. 2015, 1, 9–21. [Google Scholar] [CrossRef]

- Wang, S.H.; Li, J.Y.; Li, S.T. XLPE/h-BN Nanocomposites with Enhanced DC Insulation Properties. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 62–68. [Google Scholar] [CrossRef]

- Zhou, Y.; Peng, S.M.; Hu, J.; He, J.H. Polymeric Insulation Materials for HVDC Cables: Development, Challenges and Future Perspective. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1308–1318. [Google Scholar] [CrossRef]

- Li, Z.L.; Du, B.X. Polymeric insulation for high-voltage dc extruded cables: Challenges and development directions. IEEE Electr. Insul. Mag. 2018, 34, 30–43. [Google Scholar] [CrossRef]

- Huang, X.Y.; Zhang, J.; Jiang, P.K.; Toshikatsu, T. Material progress toward recyclable insulation of power cables part 2: Polypropylene-based thermoplastic materials. IEEE Electr. Insul. Mag. 2019, 36, 8–18. [Google Scholar] [CrossRef]

- Hosier, I.L.; Vaughan, A.S.; Swingler, S.G. An investigation of the potential of polypropylene and its blends for use in recyclable high voltage cable insulation systems. J. Mater. Sci. 2011, 46, 4058–4070. [Google Scholar] [CrossRef]

- Gao, Y.H.; Huang, X.Y.; Min, D.M.; Li, S.T.; Jiang, P.K. Recyclable dielectric polymer nanocomposites with voltage stabilizer interface: Toward new generation of high voltage direct current cable insulation. ACS Sustain. Chem. Eng. 2019, 7, 513–525. [Google Scholar] [CrossRef]

- Zhou, Y.; He, J.L.; Hu, J.; Huang, X.Y.; Jiang, P.K. Evaluation of polypropylene/polyolefin elastomer blends for potential recyclable HVDC cable insulation applications. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 673–681. [Google Scholar] [CrossRef]

- Green, C.; Vaughan, A.; Stevens, G.; Pye, A.; Sutton, S.; Geussens, T.; Fairhurst, M. Thermoplastic cable insulation comprising a blend of isotactic polypropylene and a propylene-ethylene copolymer. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 639–648. [Google Scholar] [CrossRef]

- Wu, J.B.; Dang, B.; Hu, J. Comparison of Effects of Ethylene-Based and Propylene-Based Copolymer on Tailoring the Properties of Polypropylene. IEEE Access 2022, 8, 123507–123513. [Google Scholar] [CrossRef]

- Zhou, M.; Wang, H.; Ren, X.; Chen, G.; Luo, Y.; Yu, F. Investigation on effect of semiconducting screen on space charge behaviour of polypropylene-based polymers for HVDC cables. High Volt. 2022, 7, 968–981. [Google Scholar] [CrossRef]

- Yuan, C.; Zhou, Y.; Zhu, Y.; Hu, S.; Liang, J.; Luo, Z.; Gao, B.; Zeng, T.; Zhang, Y.; Li, J.; et al. Improved High-Temperature Electrical Properties of Polymeric Material by Grafting Modification. ACS Sustain. Chem. Eng. 2022, 10, 8685–8693. [Google Scholar] [CrossRef]

- Fan, L.; Hao, G.; Zhang, W.; Tu, Y.; Chen, B.; Zheng, Z.; Huang, S.; Li, Q.; He, J. An Electron and Hole Trap Energy Distribution Estimation Model and Its Application in Polypropylene Nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 1957–1963. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, R.; Yang, X.; Sun, Z.; Zhao, X.; Zhao, H.; Wang, X.; Li, L.; Liu, H. Optimisation Method for Carbon Black Distribution of Polypropylene-based Semi-conductive Screen Materials and Its Effect on Charge Emission Behaviour at Screen/Insulation Interface. High Volt. 2023, 8, 239–250. [Google Scholar] [CrossRef]

- Zhou, Y.; Dang, B.; Wang, H.; Liu, J.; Li, Q.; Hu, J.; He, J. Polypropylene-Based Ternary Nanocomposites for Recyclable High-Voltage Direct-Current Cable Insulation. Compos. Sci. Technol. 2018, 165, 168–174. [Google Scholar] [CrossRef]

- Meunier, M.; Quirke, N.; Aslanides, A. Molecular Modeling of Electron Traps in Polymer Insulators: Chemical Defects and Impurities. J. Chem. Phys. 2001, 115, 2876–2881. [Google Scholar] [CrossRef]

- Zhou, Y.; Hu, J.; Dang, B.; He, J. Mechanism of Highly Improved Electrical Properties in Polypropylene by Chemical Modification of Grafting Maleic Anhydride. J. Phys. D Appl. Phys. 2016, 49, 415301. [Google Scholar] [CrossRef]

- Gaylord, N.G.; Mishra, M.K. Nondegradative Reaction of Maleic Anhydride and Molten Polypropylene in the Presence of Peroxides. J. Polym. Sci. Polym. Lett. Ed. 1983, 21, 23–30. [Google Scholar] [CrossRef]

- Zhao, X.D.; Zhao, H.; Sun, W.F. Significantly Improved Electrical Properties of Crosslinked Polyethylene Modified by UV-Initiated Grafting MAH. Polymers 2020, 12, 62. [Google Scholar] [CrossRef]

- Yang, X.; Zhao, H.; Li, C.; Zhao, X.; Yang, J.; Wang, X. Improved Wide-Temperature-Range Insulation Properties of Block Polypropylene by UV-Irradiated Cografting of Maleic Anhydride and 4- Tert -Butylstyrene. ACS Appl. Polym. Mater. 2023, 5, 247–258. [Google Scholar] [CrossRef]

- Zhan, Y.; Chen, G.; Hao, M. Space Charge Modelling in HVDC Extruded Cable Insulation. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 43–50. [Google Scholar] [CrossRef]

- Le Roy, S.; Teyssèdre, G.; Laurent, C. Modelling space charge in a cable geometry. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2361–2367. [Google Scholar] [CrossRef]

- Dharmarajan, N.; Datta, S.; Ver Strate, G.; Ban, L. Compatibilized polymer blends of isotactic polypropylene and styrene-maleic anhydride copolymer. Polymer 1995, 36, 3849–3861. [Google Scholar] [CrossRef]

- Gao, M.; Yang, J.; Zhao, H.; He, H.; Hu, M.; Xie, S. Preparation Methods of Polypropylene/Nano-Silica/Styrene-Ethylene-Butylene-Styrene Composite and Its Effect on Electrical Properties. Polymers 2019, 11, 797. [Google Scholar] [CrossRef]

- Lv, Z.P.; Ma, T.T.; Zhang, C.; Peng, J.Y.; Wu, K.; Dissado, L.A. The Simultaneous Evolution of Space Charge and Conduction Current in LDPE. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 614–624. [Google Scholar] [CrossRef]

- Kim, M.; Lee, S.-H. Modified Molecular Chain Displacement Analysis Employing Electro-Mechanical Threshold Energy Condition for Direct Current Breakdown of Low-Density Polyethylene. Polymers 2021, 13, 2746. [Google Scholar] [CrossRef]

- Huang, H.; Liu, Y. Simulation of the Space-Charge-Limited Current Density for Time-Variant Pulsed Injection. IEEE Trans. Dielectr. Electr. Insul. 2019, 47, 3631–3635. [Google Scholar] [CrossRef]

- Lei, Q.; Tian, F.; Yang, C.; He, L.; Wang, Y. Modified Isothermal Discharge Current Theory and its Application in the Determination of Trap Level Distribution in Polyimide films. J. Electrost. 2010, 68, 243–248. [Google Scholar] [CrossRef]

- Dang, B.; He, J.; Hu, J.; Zhou, Y. Large Improvement in Trap Level and Space Charge Distribution of Polypropylene by Enhancing the Crystalline-amorphous Interface Effect in Blends. Polym. Int. 2016, 65, 371–379. [Google Scholar] [CrossRef]

- Yang, X.; Zhao, H.; Zhang, C.; Li, C.; Zhao, H.; Yang, J.; Wang, X. Improved direct current electrical properties of XLPE modified by graftable antioxidant and crosslinking coagent at a wide temperature range. High Volt. 2023, 1–11. [Google Scholar] [CrossRef]

| PP (wt %) | POE (wt %) | SMA (wt %) | |

|---|---|---|---|

| PP | 100 | -- | -- |

| PP/POE | 70 | 30 | -- |

| PP/SMA | 99.5 | -- | 0.5 |

| PP/POE/SMA | 69.5 | 30 | 0.5 |

| Type | Parameter | Value |

|---|---|---|

| Schottky emission | Electron injection barrier | 1.27 eV |

| Hole injection barrier | 1.30 eV | |

| Environment | Permittivity | 2.3 |

| Inner temperature | 70 °C | |

| Outer temperature | 50 °C | |

| Thickness | 31 mm |

| PP | PP/POE | PP/SMA | PP/POE/SMA | |||||

|---|---|---|---|---|---|---|---|---|

| Eb/(kV/mm) | β | Eb/(kV/mm) | β | Eb/(kV/mm) | β | Eb/(kV/mm) | β | |

| 30 °C | 339.2 | 16.9 | 291.5 | 12.6 | 356.3 | 21.6 | 301.5 | 15.7 |

| 50 °C | 295.6 | 15.8 | 248.8 | 18.8 | 348.7 | 19.0 | 281.1 | 18.5 |

| 70 °C | 258.8 | 11.9 | 158.8 | 9.1 | 305.2 | 14.2 | 220.9 | 8.6 |

| Parameter | PP | PP/POE | PP/SMA | PP/POE/SMA |

|---|---|---|---|---|

| Electron mobility barrier (eV) | 0.9 | 0.75 | 0.9 | 0.75 |

| Hole mobility barrier (eV) | 0.9 | 0.75 | 0.9 | 0.75 |

| Electron trap depth (eV) | 1.09 | 1.09 | 1.12 | 1.12 |

| Hole trap depth (eV) | 1.09 | 1.09 | 1.12 | 1.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhan, Y.; Yang, X.; Yang, J.; Hou, S.; Fu, M. Improved Electrical Properties of Organic Modified Thermoplastic Insulation Material for Direct Current Cable Application. Polymers 2024, 16, 46. https://doi.org/10.3390/polym16010046

Zhan Y, Yang X, Yang J, Hou S, Fu M. Improved Electrical Properties of Organic Modified Thermoplastic Insulation Material for Direct Current Cable Application. Polymers. 2024; 16(1):46. https://doi.org/10.3390/polym16010046

Chicago/Turabian StyleZhan, Yunpeng, Xu Yang, Jiaming Yang, Shuai Hou, and Mingli Fu. 2024. "Improved Electrical Properties of Organic Modified Thermoplastic Insulation Material for Direct Current Cable Application" Polymers 16, no. 1: 46. https://doi.org/10.3390/polym16010046

APA StyleZhan, Y., Yang, X., Yang, J., Hou, S., & Fu, M. (2024). Improved Electrical Properties of Organic Modified Thermoplastic Insulation Material for Direct Current Cable Application. Polymers, 16(1), 46. https://doi.org/10.3390/polym16010046