A New Microwave-Assisted Protocol for Cellulose Extraction from Eucalyptus and Pine Tree Wood Waste

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Instrumentation

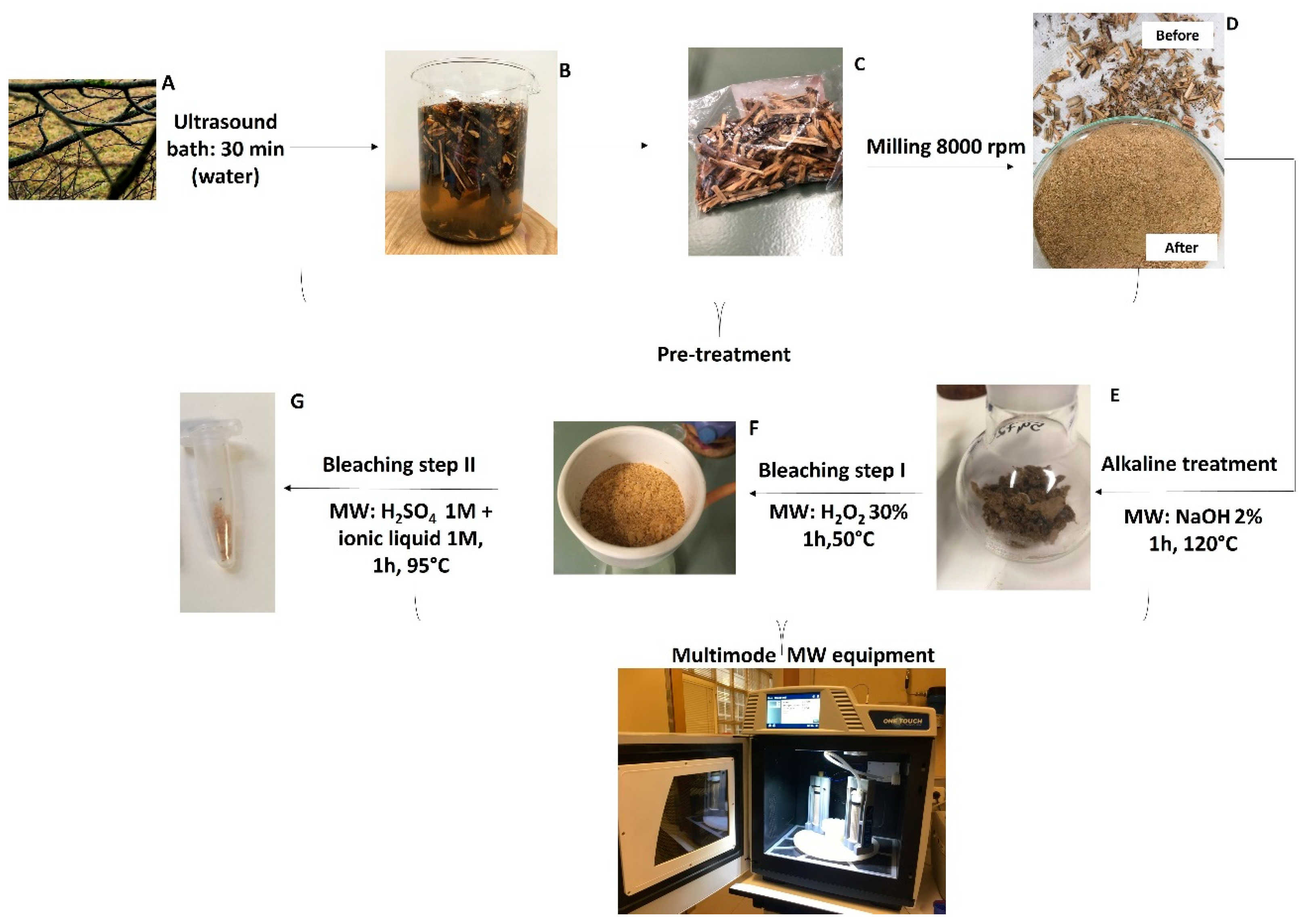

2.2. Wood Samples Pre-Treatment

2.3. Alkaline Treatment

2.4. Bleaching I

2.5. Bleaching II

2.6. Characterization of the Extracted Samples

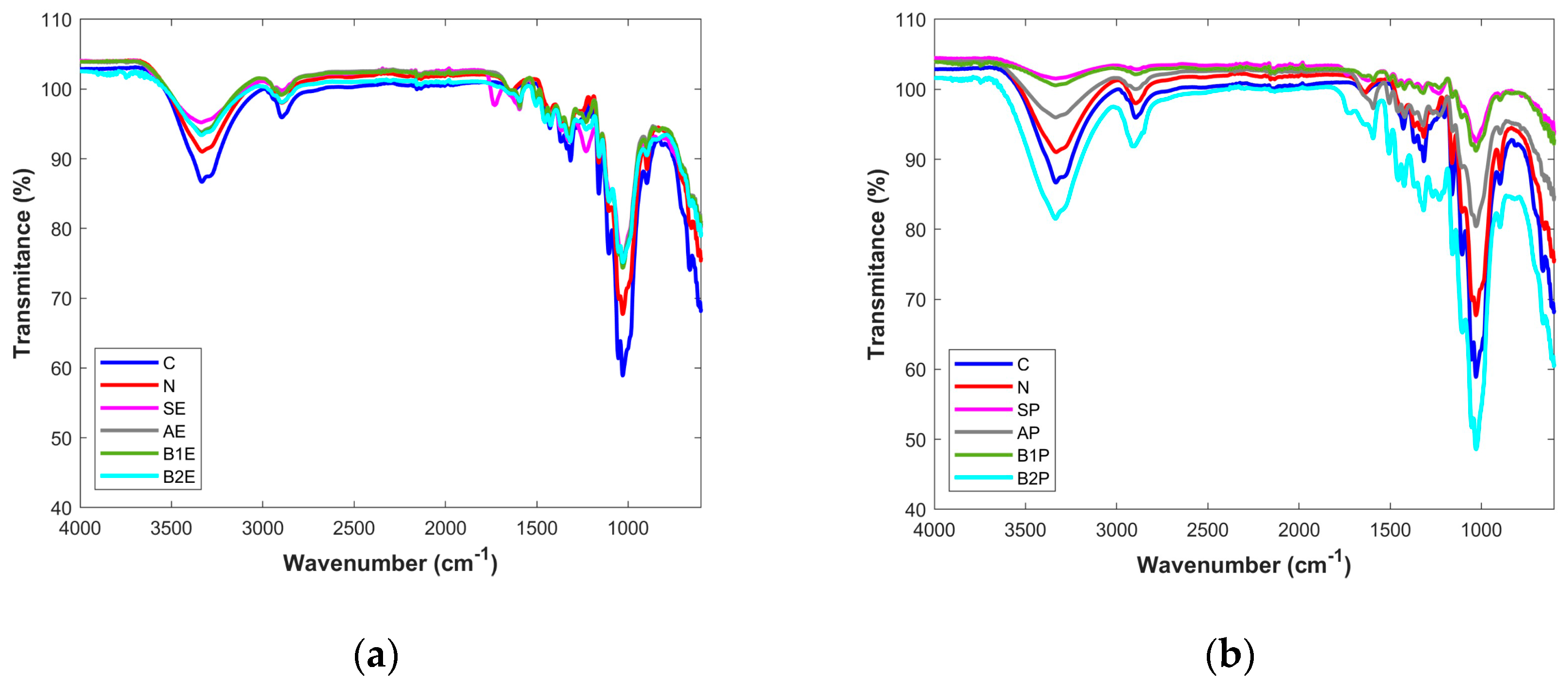

2.6.1. Fourier Transform Infrared Spectroscopy (FTIR)

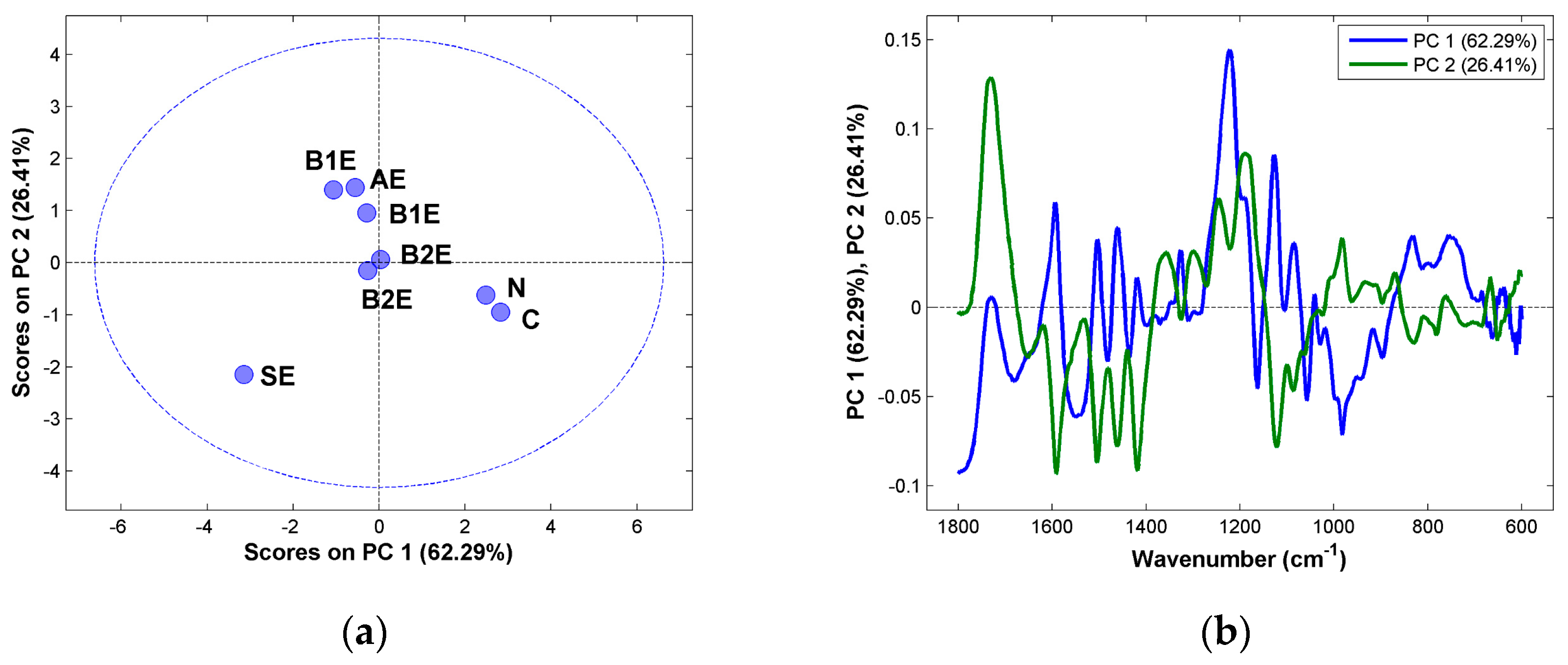

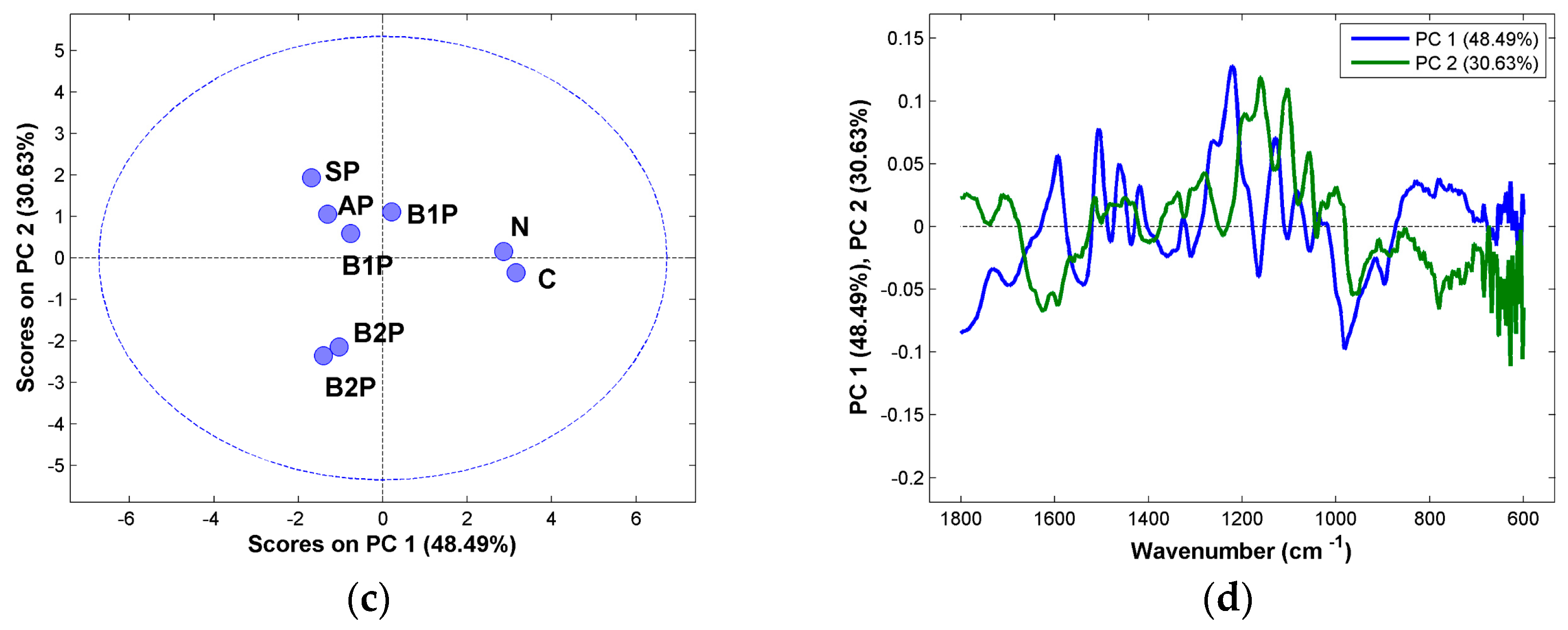

- Principal Component Analysis (PCA)

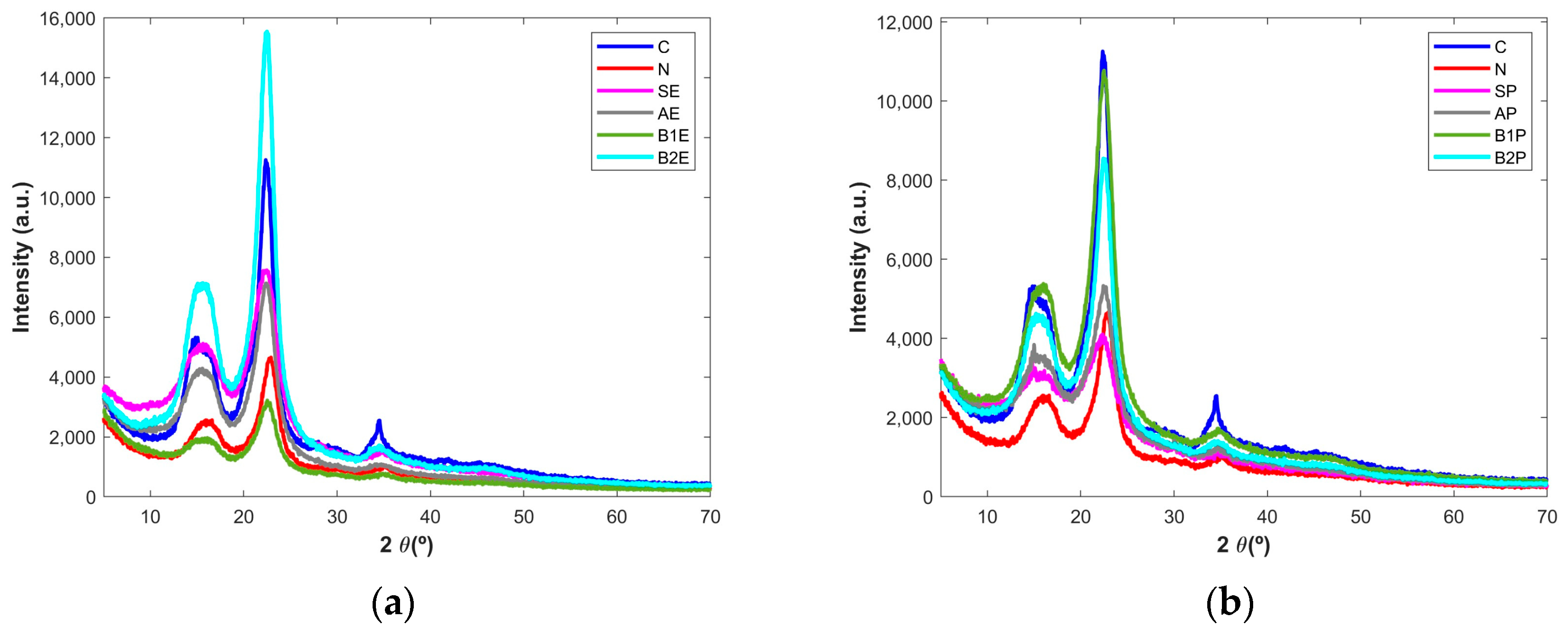

2.6.2. Powder X-ray Diffraction (PXRD)

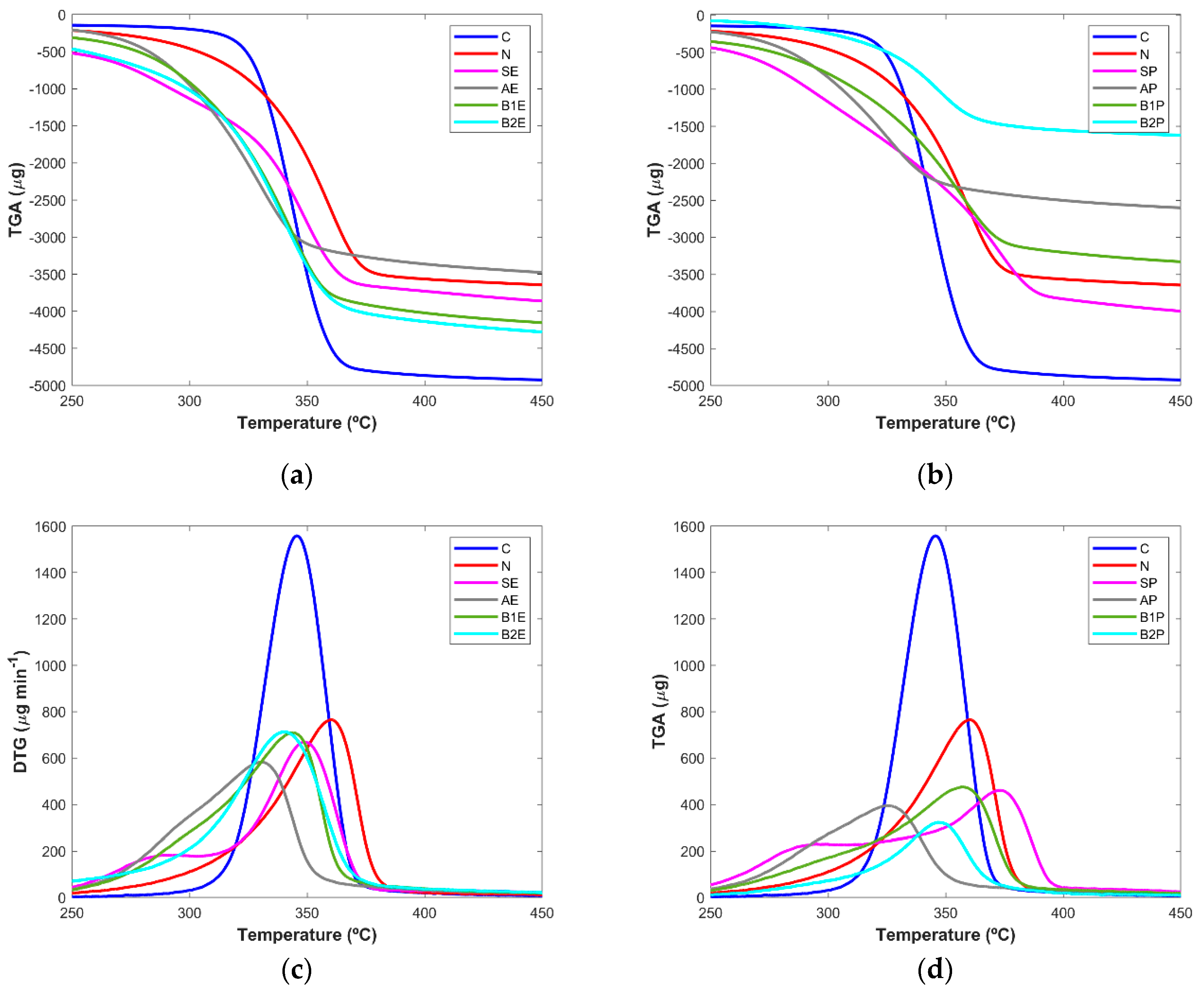

2.6.3. Thermogravimetric Analysis (TGA)

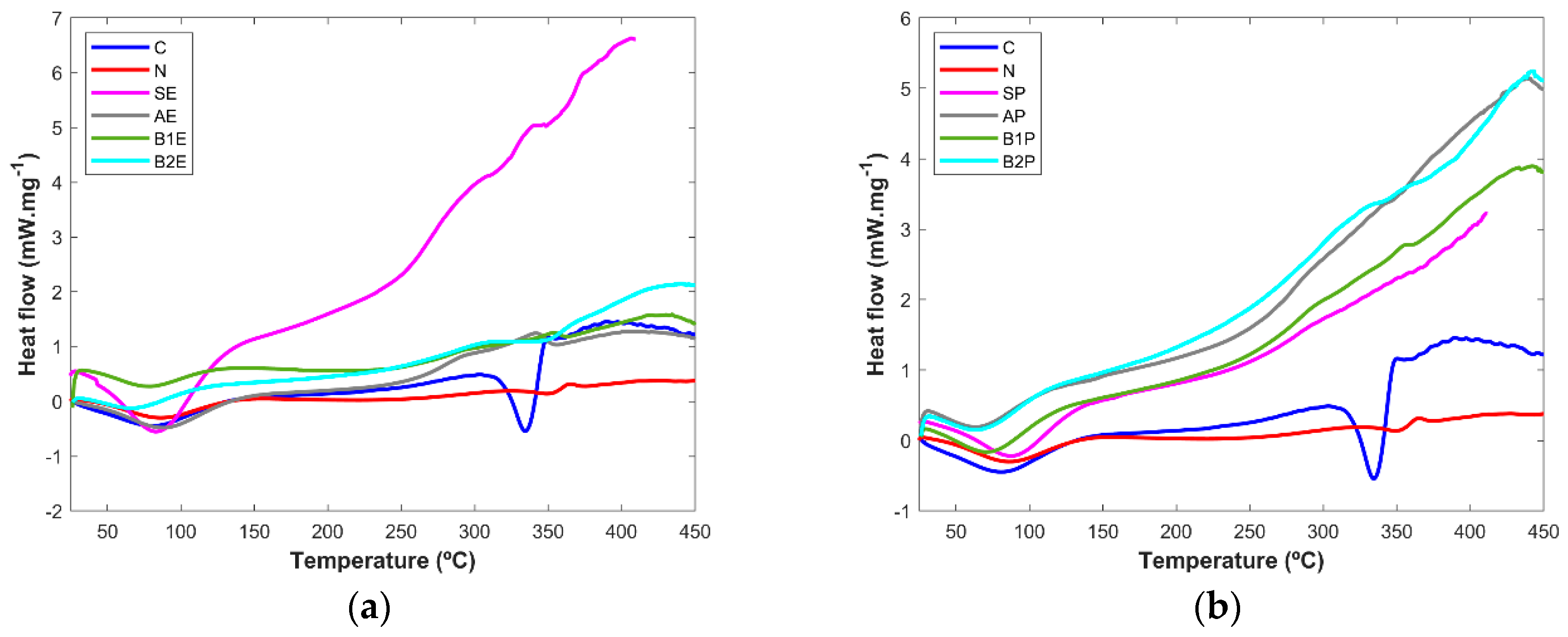

2.6.4. Differential Scanning Calorimetry (DSC)

3. Results and Discussion

3.1. Development of the Protocol for Cellulose Extraction from Wood Samples

3.2. Characterization of the Extracted Products

3.2.1. Fourier Transform Infrared Spectroscopy

3.2.2. Powder X-ray Diffraction

3.2.3. Thermogravimetric Analysis

3.2.4. Differential Scanning Calorimetry

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kadir, N.H.A.; Mohammad, M.; Alam, M.; Torkashvand, M.; Silvaragi, T.G.B.; Gururuloo, S.L. Chapter 19—Utilization of nanocellulose fibers, nanocrystalline cellulose and bacterial cellulose in biomedical and pharmaceutical applications. In Nanotechnology in Paper and Wood Engineering; Bhat, R., Kumar, A., Nguyen, T.A., Sharma, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 409–470. [Google Scholar]

- Rizwan, M.; Gilani, S.R.; Durrani, A.I.; Naseem, S. Low temperature green extraction of Acer platanoides cellulose using nitrogen protected microwave assisted extraction (NPMAE) technique. Carbohydr. Polym. 2021, 272, 118465. [Google Scholar] [CrossRef] [PubMed]

- Azlan, N.S.M.; Yap, C.L.; Gan, S.; Rahman, M.B.A. Effectiveness of various solvents in the microwave-assisted extraction of cellulose from oil palm mesocarp fiber. Mater. Today Proc. 2022, 59, 583–590. [Google Scholar] [CrossRef]

- Hou, X.; Wang, Z.; Sun, J.; Li, M.; Wang, S.; Chen, K.; Gao, Z. A microwave-assisted aqueous ionic liquid pretreatment to enhance enzymatic hydrolysis of Eucalyptus and its mechanism. Bioresour. Technol. 2019, 272, 99–104. [Google Scholar] [CrossRef] [PubMed]

- Yadav, V.; Kumar, A.; Bilal, M.; Nguyen, T.A.; Iqbal, H.M.N. Chapter 12—Lignin removal from pulp and paper industry waste streams and its application. In Nanotechnology in Paper and Wood Engineering; Bhat, R., Kumar, A., Nguyen, T.A., Sharma, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 265–283. [Google Scholar]

- Froschauer, C.; Hummel, M.; Iakovlev, M.; Roselli, A.; Schottenberger, H.; Sixta, H. Separation of hemicellulose and cellulose from wood pulp by means of ionic liquid/cosolvent systems. Biomacromolecules 2013, 14, 1741–1750. [Google Scholar] [CrossRef] [PubMed]

- Watkins, D.; Nuruddin, M.; Hosur, M.; Tcherbi-Narteh, A.; Jeelani, S. Extraction and characterization of lignin from different biomass resources. J. Mater. Res. Technol. 2015, 4, 26–32. [Google Scholar] [CrossRef]

- Barhoum, A.; Jeevanandam, J.; Rastogi, A.; Samyn, P.; Boluk, Y.; Dufresne, A.; Danquah, M.K.; Bechelany, M. Plant celluloses, hemicelluloses, lignins, and volatile oils for the synthesis of nanoparticles and nanostructured materials. Nanoscale 2020, 12, 22845–22890. [Google Scholar] [CrossRef] [PubMed]

- Moret, S.; Conchione, C.; Srbinovska, A.; Lucci, P. Microwave-Based Technique for Fast and Reliable Extraction of Organic Contaminants from Food, with a Special Focus on Hydrocarbon Contaminants. Foods 2019, 8, 503. [Google Scholar] [CrossRef]

- Ruhan Askin, U. Microwave-Assisted Green Extraction Technology for Sustainable Food Processing. In Emerging Microwave Technologies in Industrial, Agricultural, Medical and Food Processing; Kok Yeow, Y., Ed.; IntechOpen: Rijeka, Croatia, 2018; Chapter 9. [Google Scholar]

- Wang, Q.; Xiao, S.; Shi, S.Q.; Cai, L. Microwave-assisted formic acid extraction for high-purity cellulose production. Cellulose 2019, 26, 5913–5924. [Google Scholar] [CrossRef]

- Ndruru, S.T.C.L.; Wahyuningrum, D.; Bundjali, B.; Arcana, I.M. Green simple microwave-assisted extraction (MAE) of cellulose from Theobroma cacao L. (TCL) husk. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019. [Google Scholar]

- Singh, S.; Gaikwad, K.K.; Park, S.-I.; Lee, Y.S. Microwave-assisted step reduced extraction of seaweed (Gelidiella aceroso) cellulose nanocrystals. Int. J. Biol. Macromol. 2017, 99, 506–510. [Google Scholar] [CrossRef]

- Santos, D.M.d.; Bukzem, A.d.L.; Ascheri, D.P.R.; Signini, R.; Aquino, G.L.B.d. Microwave-assisted carboxymethylation of cellulose extracted from brewer’s spent grain. Carbohydr. Polym. 2015, 131, 125–133. [Google Scholar] [CrossRef]

- Antonio De La, H.; Jesús, A.; José, C.; María, A.H.; Juan De, M.M.; Pilar, P.; Abel De, C.; Angel, D.-O. Reproducibility and Scalability of Microwave-Assisted Reactions. In Microwave Heating; Usha, C., Ed.; IntechOpen: Rijeka, Croatia, 2011; Chapter 7. [Google Scholar]

- Kusumattaqiin, F.; Chonkaew, W. Preparation and Characterization of Microcrystalline Cellulose (MCC) by Acid Hydrolysis Using Microwave Assisted Method from Cotton Wool. Macromol. Symp. 2015, 354, 35–41. [Google Scholar] [CrossRef]

- Yan, D.; Ji, Q.; Yu, X.; Li, M.; Abiola Fakayode, O.; Yagoub, A.E.A.; Chen, L.; Zhou, C. Multimode-ultrasound and microwave assisted natural ternary deep eutectic solvent sequential pretreatments for corn straw biomass deconstruction under mild conditions. Ultrason. Sonochem. 2021, 72, 105414. [Google Scholar] [CrossRef] [PubMed]

- Jodeh, S.; Hu, M.; Hamed, O.; Salghi, R.; Abidi, N.; Hattb, R. Extraction and characterization of cellulose from agricultural waste argan press cake. Cellul. Chem. Technol. 2017, 51, 263–272. [Google Scholar]

- Silvy, N.; Reza, S.; Uddin, N.; Akther, M. Comparison between Different Components of Some Available Hardwood and Softwood in Bangladesh. J. Biotechnol. Biochem. 2018, 4, 1–5. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Chen, W.; Wang, Q.; Liu, Y.; Li, J.; Yu, H. Facile extraction of cellulose nanocrystals from wood using ethanol and peroxide solvothermal pretreatment followed by ultrasonic nanofibrillation. Green Chem. 2016, 18, 1010–1018. [Google Scholar] [CrossRef]

- Casas, A.; Alonso, M.V.; Oliet, M.; Santos, T.M.; Rodriguez, F. Characterization of cellulose regenerated from solutions of pine and eucalyptus woods in 1-allyl-3-methilimidazolium chloride. Carbohydr. Polym. 2013, 92, 1946–1952. [Google Scholar] [CrossRef] [PubMed]

- Duarte Urueña, G.; Ribeiro, K.C.; Prestes, E.; Pinheiro, L.A.; Carvalho, B.M. Extraction of Cellulose Nanocrystal from Multilayer Packaging Residues Composed of a Mixture of Eucalyptus and Pine Fibers. Waste Biomass Valorization 2021, 12, 5763–5777. [Google Scholar] [CrossRef]

- Besbes, I.; Vilar, M.R.; Boufi, S. Nanofibrillated cellulose from Alfa, Eucalyptus and Pine fibres: Preparation, characteristics and reinforcing potential. Carbohydr. Polym. 2011, 86, 1198–1206. [Google Scholar] [CrossRef]

- Fall, A.B.; Burman, A.; Wågberg, L. Cellulosic nanofibrils from eucalyptus, acacia and pine fibers. Nord. Pulp Pap. Res. J. 2014, 29, 176–184. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, Y. High energy oxidation and organosolv solubilization for high yield isolation of cellulose nanocrystals (CNC) from Eucalyptus hardwood. Sci. Rep. 2018, 8, 16505. [Google Scholar] [CrossRef]

- Bajpai, P. Chapter Two—General Background. In Environmentally Benign Approaches for Pulp Bleaching, 2nd ed.; Bajpai, P., Ed.; Elsevier: Boston, MA, USA, 2012; pp. 5–18. [Google Scholar]

- Bajpai, P. Chapter One Introduction. In Environmentally Benign Approaches for Pulp Bleaching, 2nd ed.; Bajpai, P., Ed.; Elsevier: Boston, MA, USA, 2012; pp. 1–4. [Google Scholar]

- Morán, J.I.; Alvarez, V.A.; Cyras, V.P.; Vázquez, A. Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose 2008, 15, 149–159. [Google Scholar] [CrossRef]

- Zetty Shafiqa, O.; Nur Hasyareeda, H.; Saiful Irwan, Z. Imidazolium-Based Ionic Liquid Binary Solvent System as an Extraction Medium in Enhancing the Rotenone Yield Extracted from Derris elliptica Roots. In Ionic Liquids; Scott, H., Ed.; IntechOpen: Rijeka, Croatia, 2017; Chapter 21. [Google Scholar]

- Baruah, J.; Nath, B.K.; Sharma, R.; Kumar, S.; Deka, R.C.; Baruah, D.C.; Kalita, E. Recent trends in the pretreatment of lignocellulosic biomass for value-added products. Front. Energy Res. 2018, 6, 141. [Google Scholar] [CrossRef]

- Zhang, Y.-H.P.; Lynd, L.R. Toward an aggregated understanding of enzymatic hydrolysis of cellulose: Noncomplexed cellulase systems. Biotechnol. Bioeng. 2004, 88, 797–824. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vinhas, S.; Sarraguça, M.; Moniz, T.; Reis, S.; Rangel, M. A New Microwave-Assisted Protocol for Cellulose Extraction from Eucalyptus and Pine Tree Wood Waste. Polymers 2024, 16, 20. https://doi.org/10.3390/polym16010020

Vinhas S, Sarraguça M, Moniz T, Reis S, Rangel M. A New Microwave-Assisted Protocol for Cellulose Extraction from Eucalyptus and Pine Tree Wood Waste. Polymers. 2024; 16(1):20. https://doi.org/10.3390/polym16010020

Chicago/Turabian StyleVinhas, Silvia, Mafalda Sarraguça, Tânia Moniz, Salette Reis, and Maria Rangel. 2024. "A New Microwave-Assisted Protocol for Cellulose Extraction from Eucalyptus and Pine Tree Wood Waste" Polymers 16, no. 1: 20. https://doi.org/10.3390/polym16010020

APA StyleVinhas, S., Sarraguça, M., Moniz, T., Reis, S., & Rangel, M. (2024). A New Microwave-Assisted Protocol for Cellulose Extraction from Eucalyptus and Pine Tree Wood Waste. Polymers, 16(1), 20. https://doi.org/10.3390/polym16010020