Influence of Post-Processing on the Properties of Multi-Material Parts Obtained by Material Projection AM

Abstract

1. Introduction

2. Materials and Methodology

2.1. Materials

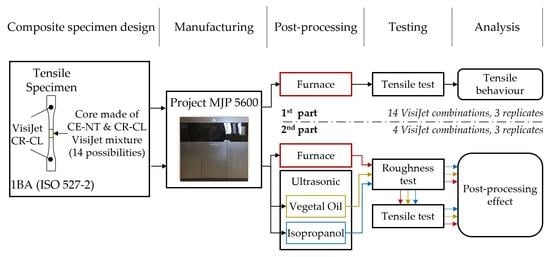

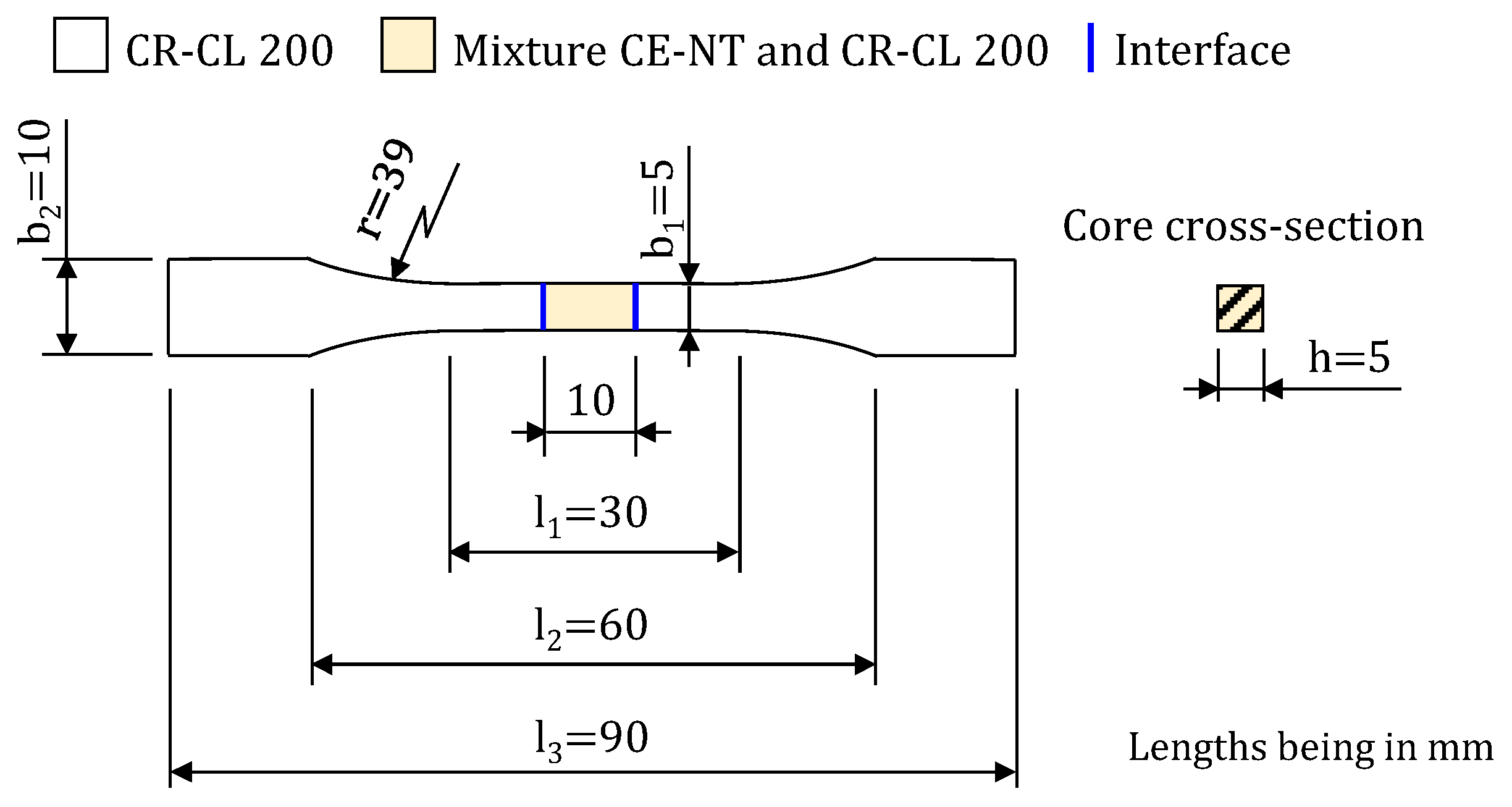

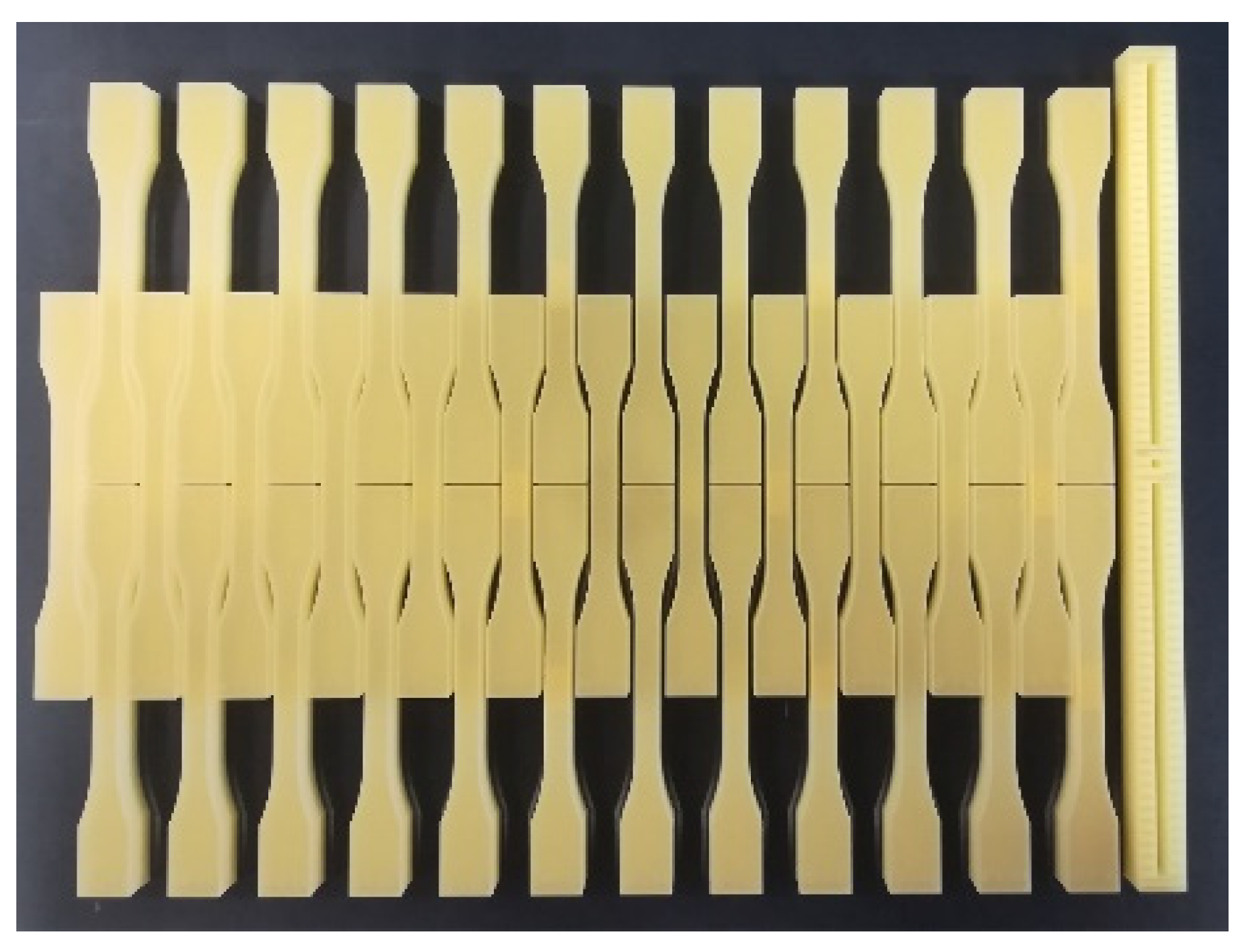

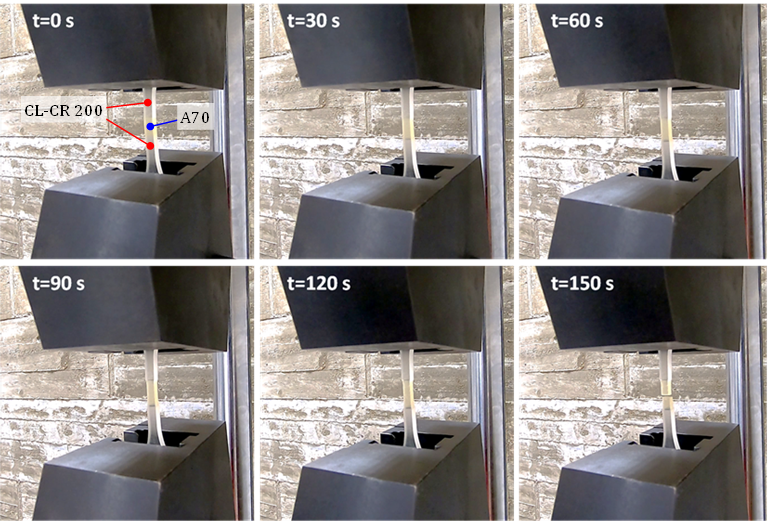

2.2. Methodology

- F: two furnace cycles at 60 °C;

- OU: two ultrasonic cycles with mineral oil at 60 °C;

- IU: two ultrasound cycles with isopropyl alcohol at 60 °C.

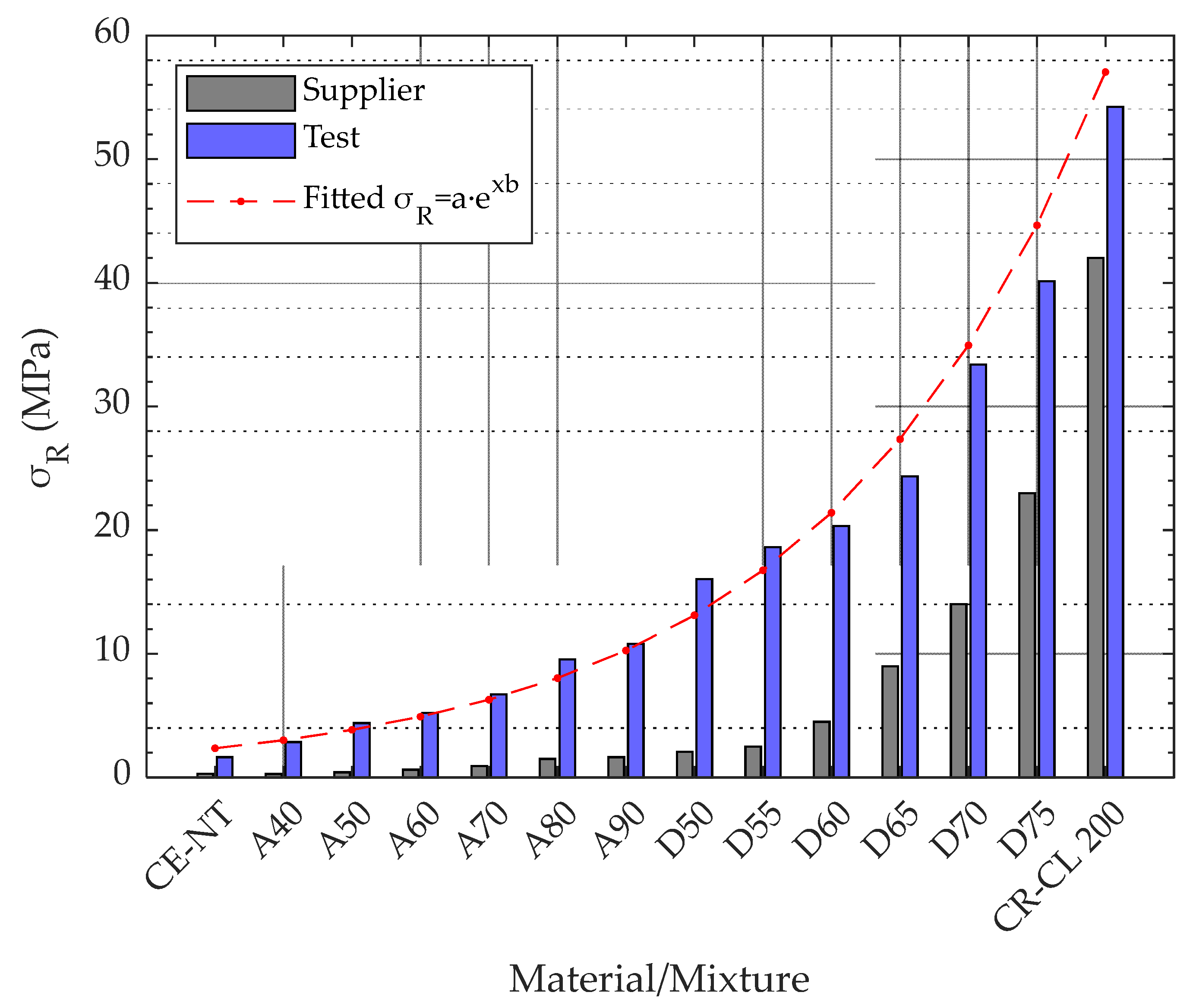

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Javaid, M.; Haleem, A. Additive manufacturing applications in medical cases: A literature based review. Alex. J. Med. 2018, 54, 411–422. [Google Scholar] [CrossRef]

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of additive manufacturing technologies and applications in the aerospace industry. In Additive Manufacturing for the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2019; pp. 7–31. [Google Scholar]

- Nugraha, A.D.; Ruli; Supriyanto, E.; Rasgianti; Prawara, B.; Martides, E.; Junianto, E.; Wibowo, A.; Sentanuhady, J.; Muflikhun, M.A. First-rate manufacturing process of primary air fan (PAF) coal power plant in Indonesia using laser powder bed fusion (LPBF) technology. J. Mater. Res. Technol. 2022, 18, 4075–4088. [Google Scholar] [CrossRef]

- Nugraha, A.D.; Syahril, M.; Muflikhun, M.A. Excellent performance of hybrid model manufactured via additive manufacturing process reinforced with GFRP for sport climbing equipment. Heliyon 2023, 9, e14706. [Google Scholar] [CrossRef] [PubMed]

- Muflikhun, M.A.; Sentanu, D.A. Characteristics and performance of carabiner remodeling using 3D printing with graded filler and different orientation methods. Eng. Fail. Anal. 2021, 130, 105795. [Google Scholar] [CrossRef]

- Patmonoaji, A.; Mahardika, M.A.; Nasir, M.; She, Y.; Wang, W.; Muflikhun, M.A.; Suekane, T. Stereolithography 3D Printer for Micromodel Fabrications with Comprehensive Accuracy Evaluation by Using Microtomography. Geosciences 2022, 12, 183. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2015; Additive Manufacturing General principles—Terminology. International Organization for Standardization: Geneva, Switzerland, 1996.

- Tyagi, S.; Yadav, A.; Deshmukh, S. Review on mechanical characterization of 3D printed parts created using material jetting process. Mater. Today Proc. 2022, 51, 1012–1016. [Google Scholar] [CrossRef]

- VisiJet® Base Materials for the ProJet MJP 5600. Available online: https://es.3dsystems.com/multi-jet-printing (accessed on 16 May 2022).

- Stratasys PolyJet Technology. Available online: https://www.stratasys.com/es/polyjet-technology (accessed on 16 May 2022).

- Akbari, S.; Sakhaei, A.H.; Kowsari, K.; Yang, B.; Serjouei, A.; Yuanfang, Z.; Ge, Q. Enhanced multimaterial 4D printing with active hinges. Smart Mater. Struct. 2018, 27, 065027. [Google Scholar] [CrossRef]

- Ge, Q.; Gu, G.; Wang, D.; Zhang, B.; Zhang, N.; Yuan, C.; Hingorani, H.; Ding, N.; Zhang, Y.-F. Fast-response, stiffness-tunable soft actuator by hybrid multimaterial 3D printing. Adv. Funct. Mater. 2019, 29, 1806698. [Google Scholar]

- Dikshit, V.; Nagalingam, P.A.; Yap, L.Y.; Sing, L.S.; Yeong, Y.W.; Wei, J. Investigation of quasi-static indentation response of inkjet printed sandwich structures under various indenter geometries. Materials 2017, 10, 290. [Google Scholar] [CrossRef]

- MultiJet Printing, Case of Study. Available online: https://es.3dsystems.com/motorsports/performance-wind-tunnel-testing?ind=motorsports (accessed on 16 May 2022).

- Davoudinejad, A.; Khosravani, M.R.; Pedersen, D.B.; Tosello, G. Influence of thermal ageing on the fracture and lifetime of additively manufactured mold inserts. Eng. Fail. Anal. 2020, 115, 104694. [Google Scholar] [CrossRef]

- León-Cabezas, M.A.; Martínez-García, A.; Varela-Gandía, F.J. Innovative advances in additive manufactured moulds for short plastic injection series. Procedia Manuf. 2017, 13, 732–737. [Google Scholar]

- Dämmer, G.; Gablenz, S.; Hildebrandt, A.; Major, Z. Design and shape optimization of PolyJet bellows actuators. In Proceedings of the 2018 IEEE International Conference on Soft Robotics (RoboSoft), Livorno, Italy, 24–28 April 2018. [Google Scholar]

- Kakogawa, A.; Ma, S.A. Differential Elastic Joint for Multi-linked Pipeline Inspection Robots. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018. [Google Scholar]

- Pazhamannil, R.V.; Govindan, P. Current state and future scope of additive manufacturing technologies via vat photopolymerization. Mater. Today Proc. 2021, 43, 130–136. [Google Scholar] [CrossRef]

- Bezek, L.B.; Chatham, C.A.; Dillard, D.A.; Williams, C.B. Mechanical properties of tissue-mimicking composites formed by material jetting additive manufacturing. J. Mech. Behav. Biomed. Mater. 2022, 125, 104938. [Google Scholar] [CrossRef]

- Khalid, G.A.; Bakhtiarydavijani, H.; Whittington, W.R.; Prabhu, R.; Jones, M.D. Material response characterization of three poly jet printed materials used in a high fidelity human infant skull. Mater. Today Proc. 2020, 4, 408–413. [Google Scholar] [CrossRef]

- Wang, Y.C.; Chen, T.; Yeh, Y.L. Advanced 3D printing technologies for the aircraft industry: A fuzzy systematic approach for assessing the critical factors. Int. J. Adv. Manuf. Technol. 2019, 105, 4059–4069. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wange, C.C.L.; Shin, Y.C.; Zhanga, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Yap, Y.L.; Wang, C.; Sing, S.L.; Dikshit, V.; Yeong, W.Y.; Wei, J. Material jetting additive manufacturing: An experimental study using designed metrological benchmarks. Precis. Eng. 2017, 50, 275–285. [Google Scholar] [CrossRef]

- Pugalendhi, A.; Ranganathan, R.; Ganesan, S. Impact of process parameters on mechanical behaviour in multi-material jetting. Mater. Today Proc. 2021, 46, 9139–9144. [Google Scholar] [CrossRef]

- Sagbas, B.; Gümüş, B.E.; Kahraman, Y.; Dowling, D.P. Impact of print bed build location on the dimensional accuracy and surface quality of parts printed by multi jet fusion. J. Manuf. Process. 2021, 70, 290–299. [Google Scholar] [CrossRef]

- Khoshkhoo, A.; Carrano, A.L.; Blersch, D.M. Effect of surface slope and build orientation on surface finish and dimensional accuracy in material jetting processes. Procedia Manuf. 2018, 26, 720–730. [Google Scholar] [CrossRef]

- Chen, T.; Dilag, J.; Bateman, S. Surface topology modification of organic substrates using material jetting technologies. Mater. Des. 2020, 196, 109116. [Google Scholar] [CrossRef]

- Stanković, T.; Mueller, J.; Shea, K. The effect of anisotropy on the optimization of additively manufactured lattice structures. Addit. Manuf. 2017, 17, 67–76. [Google Scholar] [CrossRef]

- Sugavaneswaran, M.; Arumaikkannu, G. Analytical and experimental investigation on elastic modulus of reinforced additive manufactured structure. Mater. Des. 2015, 66, 29–36. [Google Scholar] [CrossRef]

- Abayazid, F.F.; Ghajari, M. Material characterisation of additively manufactured elastomers at different strain rates and build orientations. Addit. Manuf. 2020, 33, 101160. [Google Scholar] [CrossRef]

- Liu, W.; Song, H.; Huang, C. Maximizing mechanical properties and minimizing support material of PolyJet fabricated 3D lattice structures. Addit. Manuf. 2020, 35, 101257. [Google Scholar] [CrossRef]

- Meisel, N.A.; Williams, C.B. Design for Additive Manufacturing: An investigation of key manufacturing considerations in multi-material PolyJet 3D printing. In Proceedings of the 25th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 4–6 August 2014. [Google Scholar]

- Eren, O.; Sezer, H.K.; Yalçın, N. Effect of lattice design on mechanical response of PolyJet additively manufactured cellular structures. J. Manuf. Process. 2022, 75, 1175–1188. [Google Scholar] [CrossRef]

- He, Y.; Zhang, F.; Saleh, E.; Vaithilingam, J.; Aboulkhair, N.; Begines, B.; Tuck, C.J.; Hague, R.J.M.; Ashcroft, I.A.; Wildman, R.D. A tripropylene glycol diacrylate-based polymeric support ink for material jetting. Addit. Manuf. 2017, 16, 153–161. [Google Scholar] [CrossRef]

- Boopathy, V.R.; Sriraman, A.; Arumaikkannu, G. Energy absorbing capability of additive manufactured multi-material honeycomb structure. Rapid Prototyp. J. 2019, 25, 623–629. [Google Scholar] [CrossRef]

- ISO 527:2012; Plastics Determination of Tensile Properties: Test Conditions for Moulding and Extrusion Plastics. International Organization for Standardization: Geneva, Switzerland, 1996.

- Nguyen, C.H.P.; Kim, Y.; Choi, Y. Design for additive manufacturing of functionally graded lattice structures: A design method with process induced anisotropy consideration. Int. J. Precis. Eng. Manuf.–Green. Technol. 2021, 8, 29–45. [Google Scholar] [CrossRef]

- ISO 4288:1996; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Rules and Procedures for the Assessment of Surface Texture. International Organization for Standardization: Geneva, Switzerland, 1996.

- Bass, L.; Meisel, N.A.; Williams, C.B. Exploring variability of orientation and aging effects in material properties of multi-material jetting parts. Rapid Prototyp. J. 2016, 22, 826–834. [Google Scholar] [CrossRef]

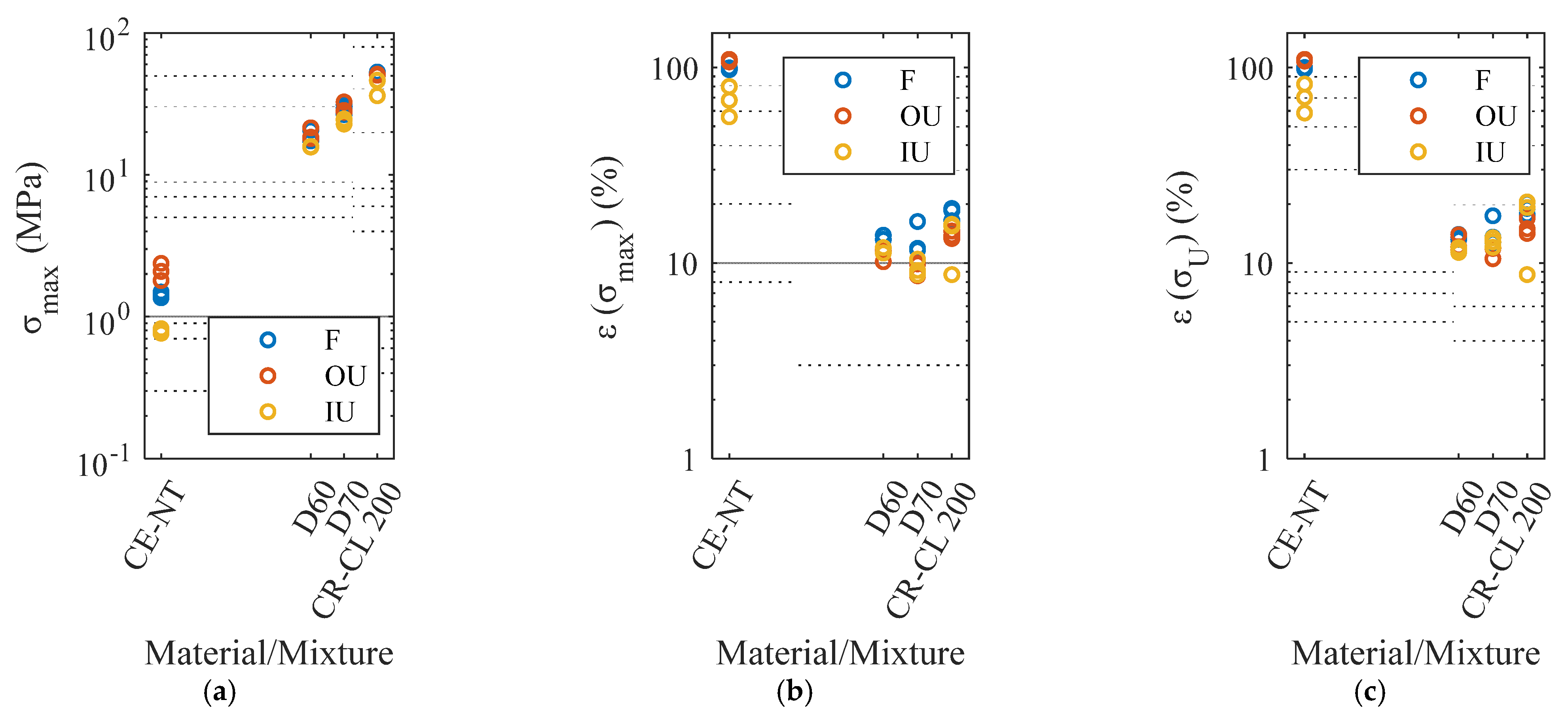

| Material/Mixture | Tensile Strength (MPa) | Material/Mixture | Tensile Strength (MPa) | |

|---|---|---|---|---|

| VisiJet CE-NT | 0.20–0.40 | D50 | 1–3 | |

| A40 | 0.23–0.32 | D55 | 2–3 | |

| A50 | 0.35–0.48 | D60 | 4–5 | |

| A60 | 0.48–0.77 | D65 | 8–10 | |

| A70 | 0.75–1.10 | D70 | 12–16 | |

| A80 | 1.30–1.70 | D75 | 19–27 | |

| A90 | 1.40–1.90 | VisiJet CR-CL 200 | 30–43 |

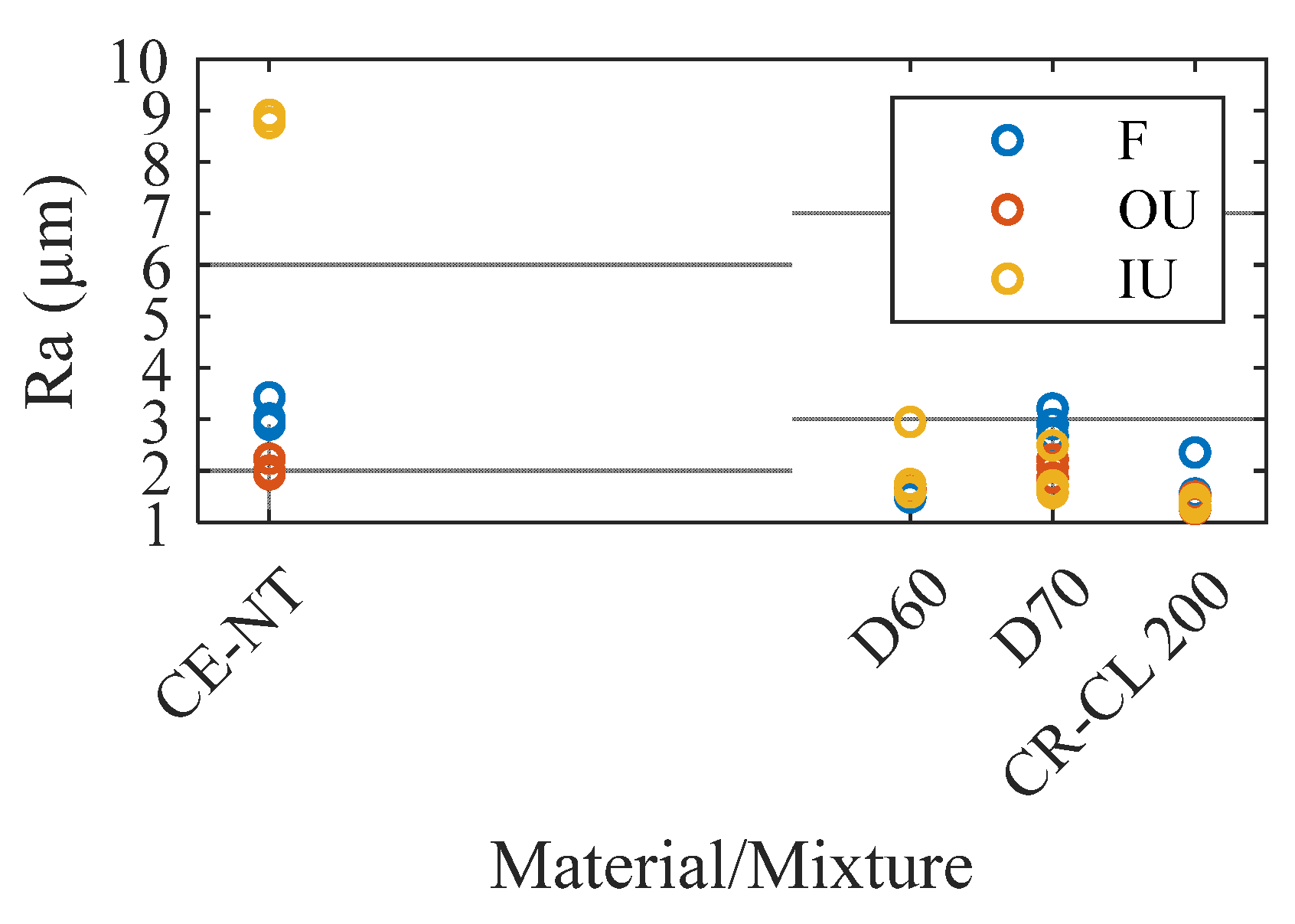

| Ra (µm) | |||||

|---|---|---|---|---|---|

| Post-Process | Material/Mixture | CE-NT | D60 | D70 | CR-CL 200 |

| F | Replica 1 | 2.9 | 0.8 | 2.7 | 2.4 |

| Replica 2 | 3.4 | 1.5 | 2.9 | 1.5 | |

| Replica 3 | 3.0 | 1.6 | 3.2 | 1.6 | |

| Mean | 3.10 | 1.30 | 2.93 | 1.83 | |

| OU | Replica 1 | 1.9 | 1.6 | 2.2 | 1.5 |

| Replica 2 | 2.2 | 1.7 | 1.9 | 1.4 | |

| Replica 3 | 2.0 | 1.6 | 2.1 | 1.3 | |

| Mean | 2.03 | 1.63 | 2.07 | 1.40 | |

| IU | Replica 1 | 8.9 | 1.6 | 1.7 | 1.5 |

| Replica 2 | 8.9 | 1.7 | 2.5 | 1.3 | |

| Replica 3 | 8.8 | 3.0 | 1.6 | 1.3 | |

| Mean | 8.87 | 2.10 | 1.93 | 1.37 | |

| Material/Mixture | |||

|---|---|---|---|

| CE-NT | 0.000 (✓) | 0.001 (✓) | 0.001 (✓) |

| D60 | 0.048 (✓) | 0.010 (✓) | 0.054 (✕) |

| D70 | 0.031 (✓) | 0.047 (✓) | 0.132 (✕) |

| CR-CL 200 | 0.032 (✓) | 0.110 (✕) | 0.520 (✕) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zapico, P.; Rodríguez-González, P.; Robles-Valero, P.; Fernández-Abia, A.I.; Barreiro, J. Influence of Post-Processing on the Properties of Multi-Material Parts Obtained by Material Projection AM. Polymers 2023, 15, 2089. https://doi.org/10.3390/polym15092089

Zapico P, Rodríguez-González P, Robles-Valero P, Fernández-Abia AI, Barreiro J. Influence of Post-Processing on the Properties of Multi-Material Parts Obtained by Material Projection AM. Polymers. 2023; 15(9):2089. https://doi.org/10.3390/polym15092089

Chicago/Turabian StyleZapico, Pablo, Pablo Rodríguez-González, Pablo Robles-Valero, Ana Isabel Fernández-Abia, and Joaquín Barreiro. 2023. "Influence of Post-Processing on the Properties of Multi-Material Parts Obtained by Material Projection AM" Polymers 15, no. 9: 2089. https://doi.org/10.3390/polym15092089

APA StyleZapico, P., Rodríguez-González, P., Robles-Valero, P., Fernández-Abia, A. I., & Barreiro, J. (2023). Influence of Post-Processing on the Properties of Multi-Material Parts Obtained by Material Projection AM. Polymers, 15(9), 2089. https://doi.org/10.3390/polym15092089