Polymerization of Allyltrimethylisilane and 4-Methyl-1-Pentene by Using Metallocene Catalysts

Abstract

1. Introduction

2. Materials and Methods

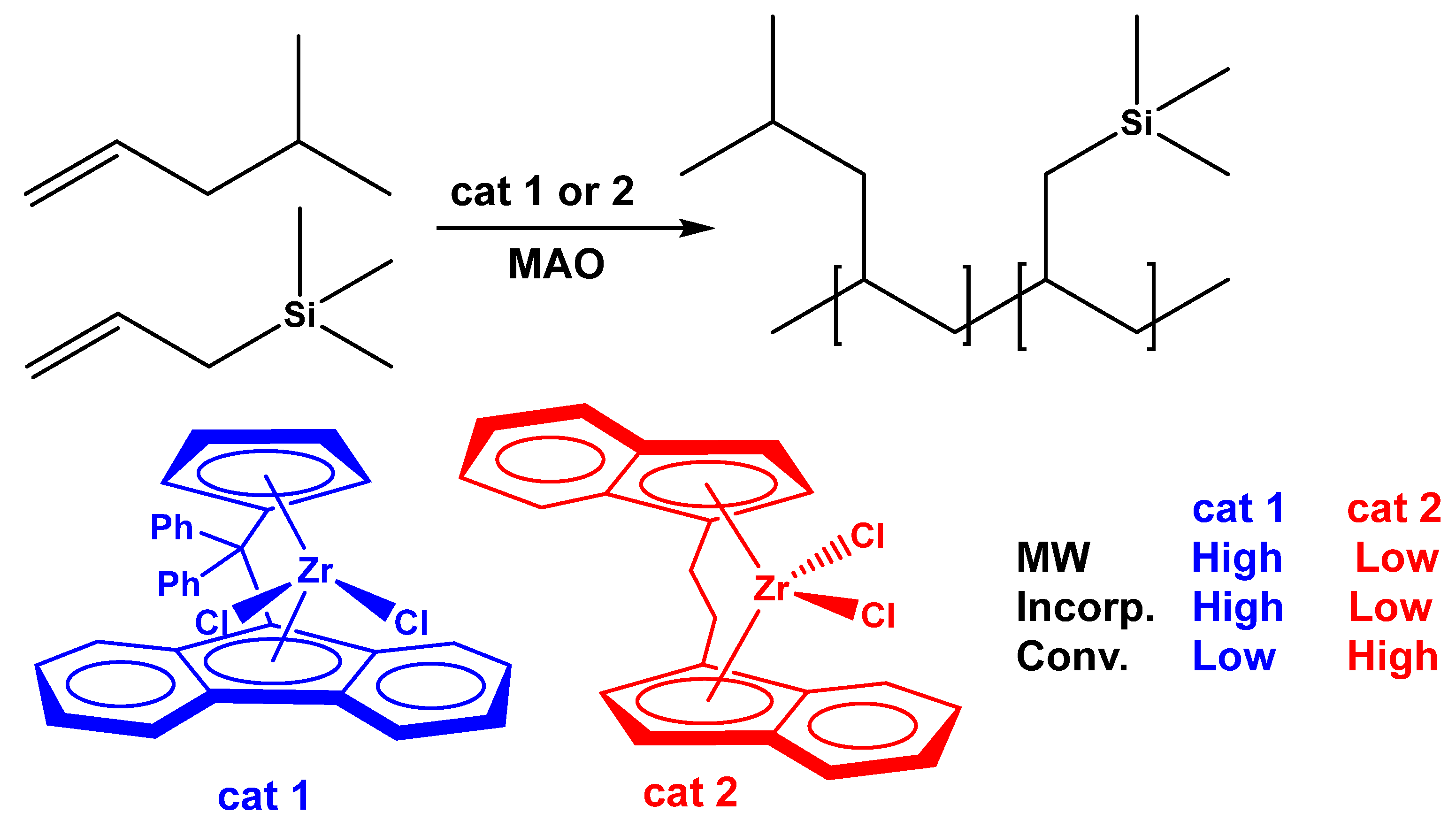

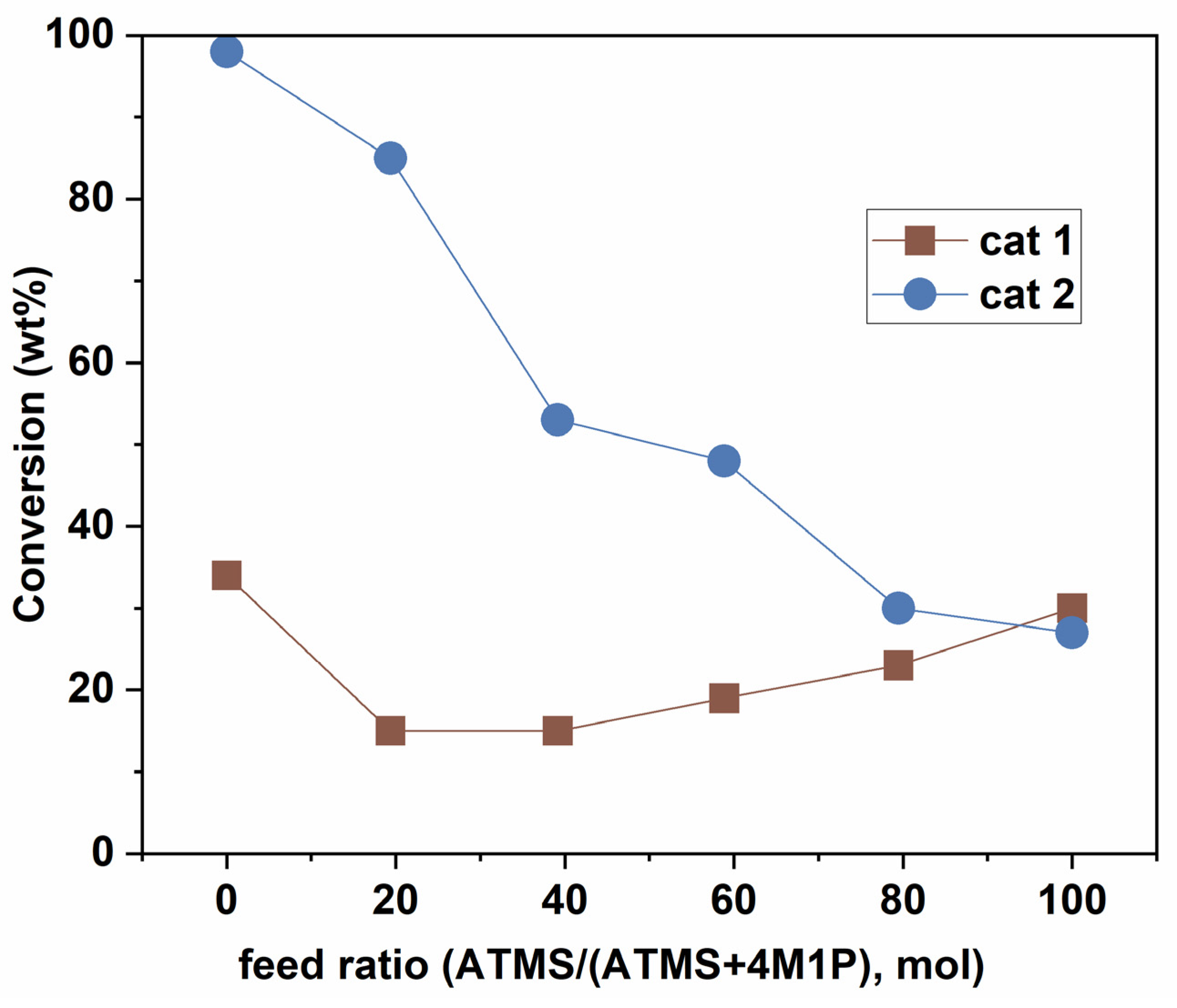

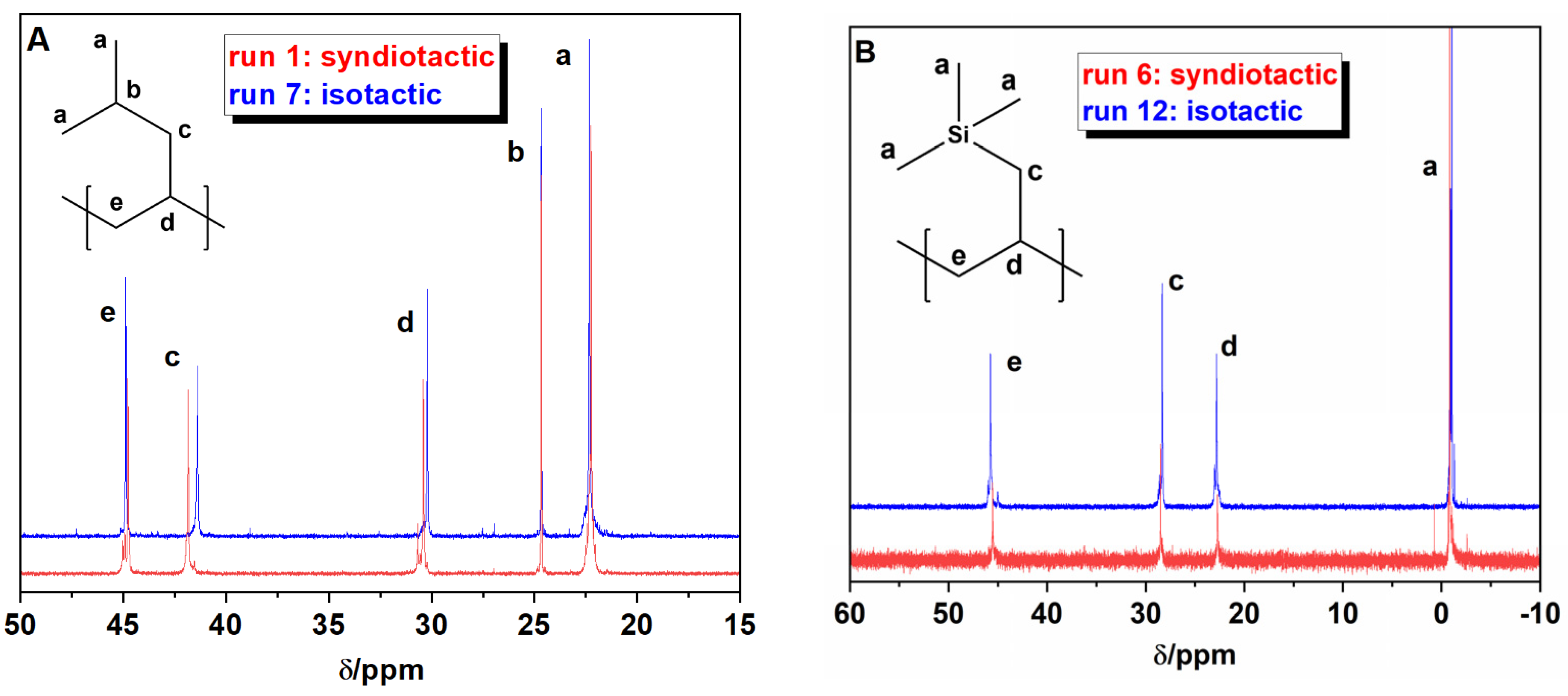

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, J.; Rempel, G.L. Ziegler-Natta catalysts for olefin polymerization: Mechanistic insights from metallocene systems. Prog. Polym. Sci. 1995, 20, 459–526. [Google Scholar] [CrossRef]

- Alt, H.G.; Alexander, K. Effect of the nature of metallocene complexes of Group IV metals on their performance in catalytic ethylene and propylene polymerization. Chem. Rev. 2000, 100, 1205–1221. [Google Scholar] [CrossRef]

- Singh, R.P. Recent developments in the degradation and stabilization of poly(1-butene). Prog. Polym. Sci. 1985, 11, 201–219. [Google Scholar] [CrossRef]

- Day, M.R. “TPX” [4-methyl-1-pentene] methylpentene polymers. Plast. Polym. 1968, 36, 101–108. [Google Scholar]

- Hanifpour, A.; Bahri-Laleh, N.; Nekoomanesh-Haghighi, M.; Poater, A. Coordinative chain transfer polymerization of 1-decene in the presence of a Ti-based diamine bis(phenolate) catalyst: A sustainable approach to produce low viscosity PAOs. Green Chem. 2020, 22, 4617–4626. [Google Scholar] [CrossRef]

- Hu, J.; Li, Z.; Hu, Z.-D.; Wu, J.; Wang, J. Achieving super resolution lithography based on bulk plasmon polaritons of hyperbolic metamaterials. Opt. Mater. 2022, 130, 112536. [Google Scholar] [CrossRef]

- Wang, C.; Cui, Z.; Song, J.; Wang, Z. Molecular simulation study on the separation of CO2 and N2 in poly(4-methyl-1-pentene) membrane. J. Mol. Liq. 2022, 359, 119376. [Google Scholar] [CrossRef]

- Markova, S.Y.; Dukhov, A.V.; Pelzer, M.; Shalygin, M.G.; Vad, T.; Gries, T.; Teplyakov, V.V. Designing 3D Membrane Modules for Gas Separation Based on Hollow Fibers from Poly(4-methyl-1-pentene). Membranes 2022, 12, 36. [Google Scholar] [CrossRef]

- Markova, S.Y.; Pelzer, M.; Shalygin, M.G.; Vad, T.; Gries, T.; Teplyakov, V.V. Gas separating hollow fibres from Poly(4-methyl-1-pentene): A new development. Sep. Purif. Technol. 2022, 278, 119534. [Google Scholar] [CrossRef]

- Tan, X.; Liu, T.-H.; Zhou, W.; Yuan, Q.; Ying, J.; Yan, Q.; Lv, L.; Chen, L.; Wang, X.; Du, S.; et al. Enhanced Electromagnetic Shielding and Thermal Conductive Properties of Polyolefin Composites with a Ti3C2Tx MXene/Graphene Framework Connected by a Hydrogen-Bonded Interface. ACS Nano 2022, 16, 9254–9266. [Google Scholar] [CrossRef]

- Abetz, C.; Georgopanos, P.; Pistidda, C.; Klassen, T.; Abetz, V. Reactive Hydride Composite Confined in a Polymer Matrix: New Insights into the Desorption and Absorption of Hydrogen in a Storage Material with High Cycling Stability. Adv. Mater. Technol. 2022, 7, 2101584. [Google Scholar] [CrossRef]

- Fukuda, M.; Furuya, T.; Sadano, K.; Tokumine, A.; Mori, T.; Saomoto, H.; Sakai, K. Electron Microscopic Confirmation of Anisotropic Pore Characteristics for ECMO Membranes Theoretically Validating the Risk of SARS-CoV-2 Permeation. Membranes 2021, 11, 529. [Google Scholar] [CrossRef] [PubMed]

- Lopez, L.C.; Wilkes, G.L.; Stricklen, P.M.; White, S.A. Synthesis, structure, and properties of poly(4-methyl-1-pentene). J. Macromol. Sci. Rev. Macromol. Chem. Phys. 1992, C32, 301–406. [Google Scholar] [CrossRef]

- Sung, Y.-C.; Huang, P.-S.; Huang, S.-H.; Chiang, Y.-W.; Tsai, J.-C. Syndiotactic Poly(4-methyl-1-pentene)-Based Stereoregular Diblock Copolymers: Synthesis and Self-Assembly Studies. Polymers 2022, 14, 4815. [Google Scholar] [CrossRef] [PubMed]

- Descour, C.; Duchateau, R.; Mosia, M.R.; Gruter, G.M.; Severn, J.R.; Rastogi, S. Catalyst behavior for 1-pentene and 4-methyl-1-pentene polymerization for C2-, Cs- and C1-symmetric zirconocenes. Polym. Chem. 2011, 2, 2261–2272. [Google Scholar] [CrossRef]

- Wang, W.; Hou, L.; Sheng, J.; Ren, M.; Tang, Y. Copolymerization of 4-methyl-1-pentene with α,ω-alkenols. Express Polym. Lett. 2016, 10, 1026–1033. [Google Scholar] [CrossRef]

- Wang, W.; Hou, L.; Sheng, J. Syndiotactic Polymer of Allylcyclopentane by A Metallocene Catalyst. ChemCatChem 2016, 8, 3218–3223. [Google Scholar] [CrossRef]

- Kirshenbaum, I.; Feist, W.C.; Isaacson, R.B. Properties of semicrystalline polyolefins. IV. Crystallization phenomena in poly(3-methyl-1-butene). J. Appl. Polym. Sci. 1965, 9, 3023–3031. [Google Scholar] [CrossRef]

- Hu, W.; Hagihara, H.; Miyoshi, T. Microstructure and Thermal Property of Isotactic Poly(3-methyl-1-butene) Obtained Using the C2-Symmetrical Zirconocene/MAO Catalyst System. Macromolecules 2007, 40, 1763–1766. [Google Scholar] [CrossRef]

- Liu, J.; Nomura, K. Efficient functional group introduction into polyolefins by copolymerization of ethylene with allyltrialkylsilane using nonbridged half-titanocenes. Macromolecules 2008, 41, 1070–1072. [Google Scholar] [CrossRef]

- Kawakami, T.; Ito, S.; Nozaki, K. Iron-catalyzed homo- and copolymerization of propylene: Steric influence of bis(imino)pyridine ligands. Dalton Trans. 2015, 44, 20745–20752. [Google Scholar] [CrossRef] [PubMed]

- Zeigler, R.; Resconi, L.; Balbontin, G.; Guerra, G.; Venditto, V.; De Rosa, C. Allyltrimethylsilane polymers from metallocene catalysts: Tacticity and structural characterization. Polymer 1994, 35, 4648–4655. [Google Scholar] [CrossRef]

- De Rosa, C.; Auriemma, F.; Tarallo, O.; Malafronte, A.; Di Girolamo, R.; Esposito, S.; Piemontesi, F.; Liguori, D.; Morini, G. The “Nodular” α Form of Isotactic Polypropylene: Stiff and Strong Polypropylene with High Deformability. Macromolecules 2017, 50, 5434–5446. [Google Scholar] [CrossRef]

- De Rosa, C.; Auriemma, F.; Tarallo, O.; Di Girolamo, R.; Troisi, E.M.; Esposito, S.; Liguori, D.; Piemontesi, F.; Vitale, G.; Morini, G. Tailoring the properties of polypropylene in the polymerization reactor using polymeric nucleating agents as prepolymers on the Ziegler-Natta catalyst granule. Polym. Chem. 2017, 8, 655–660. [Google Scholar] [CrossRef]

- Habaue, S.; Baraki, H.; Okamoto, Y. Polymerization and asymmetric oligomerization of allylsilanes using chiral ethylenebis(4,5,6,7-tetrahydro-1-indenyl)zirconium and -hafnium complexes. Macromol. Chem. Phys. 1998, 199, 2211–2215. [Google Scholar] [CrossRef]

- Sugie, K.; Yamada, T.; Yamaji, T. Novel silicon-containing copolymer, ultrathin solid membrane composed of said copolymer, use of said solid membrane for concentrating a specified gas in a gaseous mixture, and process for producing said solid membrane. U.S. Patent 4393113A, 12 July 1983. [Google Scholar]

- Kaminsky, W.; Kuelper, K.; Brintzinger, H.H.; Wild, F.R.W.P. Polymerization of propene and butene with a chiral zirconocene and methylaluminoxane as cocatalyst. Angew. Chem. 1985, 97, 507–508. [Google Scholar] [CrossRef]

- Ewen, J.A.; Jones, R.L.; Razavi, A.; Ferrara, J.D. Syndiospecific propylene polymerizations with Group IVB metallocenes. J. Am. Chem. Soc. 1988, 110, 6255–6256. [Google Scholar] [CrossRef] [PubMed]

- Ewen, J.A. Mechanisms of stereochemical control in propylene polymerizations with soluble Group 4B metallocene/methylalumoxane catalysts. J. Am. Chem. Soc. 1984, 106, 6355–6364. [Google Scholar] [CrossRef]

- Wang, W.; Hou, L.; Zhang, T. Integrated Effect of Comonomer and Catalyst on Copolymerization of Ethylene with Allylcyclopentane or Allylcyclohexane by Using Metallocene Catalysts. ChemistrySelect 2020, 5, 7581–7585. [Google Scholar] [CrossRef]

- Razavi, A.; Atwood, J.L. Preparation and crystal structures of the cyclopentadienylfluorenyldiphenylmethane zirconium and hafnium complexes (η5-C5H4CPh2-η5-C13H8)MCl2 (M = Zr, Hf) and the catalytic formation of high molecular weight high tacticity syndiotactic polypropylene. J. Organomet. Chem. 1993, 459, 117–123. [Google Scholar] [CrossRef]

- Piemontesi, F.; Camurati, I.; Resconi, L.; Balboni, D.; Sironi, A.; Moret, M.; Zeigler, R.; Piccolrovazzi, N. Crystal Structures and Solution Conformations of the Meso and Racemic Isomers of Ethylenebis(1-indenyl))zirconium Dichloride. Organometallics 1995, 14, 1256–1266. [Google Scholar] [CrossRef]

- Wang, L.; Li, D.; Ren, H.; Wang, Y.; Wu, W.; Gao, Y.; Wang, X.; Gao, H. Isoselective 4-methylpentene polymerization by pyridylamido hafnium catalysts. Polym. Chem. 2021, 12, 3556–3563. [Google Scholar] [CrossRef]

- Li, Y.; Guo, Z.; Xue, M.; Yan, S. Epitaxial Recrystallization of IPBu in Form II on an Oriented IPS Film Initially Induced by Oriented Form I IPBu. Macromolecules 2019, 52, 4232–4239. [Google Scholar] [CrossRef]

- Diez-Rodriguez, T.M.; Blazquez-Blazquez, E.; Perez, E.; Cerrada, M.L. Influence of Content in D Isomer and Incorporation of SBA-15 Silica on the Crystallization Ability and Mechanical Properties in PLLA Based Materials. Polymers 2022, 14, 1237. [Google Scholar] [CrossRef]

- De Rosa, C.; Venditto, V.; Guerra, G.; Corradini, P. Chain conformation and unit cell in the crystalline phase of syndiotactic poly(4-methyl-1-pentene). Macromolecules 1992, 25, 6938–6942. [Google Scholar] [CrossRef]

- Jeon, K.; Palza, H.; Quijada, R.; Alamo, R.G. Effect of Comonomer Type on the Crystallization Kinetics of Random Isotactic Propylene 1-Alkene Copolymers. Polymer 2009, 50, 832–844. [Google Scholar] [CrossRef]

- Hosier, I.L.; Alamo, R.G.; Esteso, P.; Isasi, J.R.; Mandelkern, L. Formation of the Alpha and Gamma Polymorphs in Random Metallocene Copolymers. Effect of Concentration and Type of Comonomer. Macromolecules 2003, 36, 5623–5636. [Google Scholar] [CrossRef]

- Alamo, R.G.; Ghosal, A.; Chatterjee, J.; Thomson, K.L. Linear Growth Rates of Random Propylene Ethylene Copolymers. The Changeover from γ Dominated Growth to Mix (α + γ) Polymorphic Growth. Polymer 2005, 46, 8774–8789. [Google Scholar] [CrossRef]

- De Rosa, C. Crystal Structure of Form II of Isotactic Poly(4-methyl-1-pentene). Macromolecules 2003, 36, 6087–6094. [Google Scholar] [CrossRef]

- De Rosa, C.; Capitani, D.; Cosco, S. Solid-state 13C nuclear magnetic resonance spectra of four crystalline forms of isotactic poly(4-methyl-1-pentene). Macromolecules 1997, 30, 8322–8331. [Google Scholar] [CrossRef]

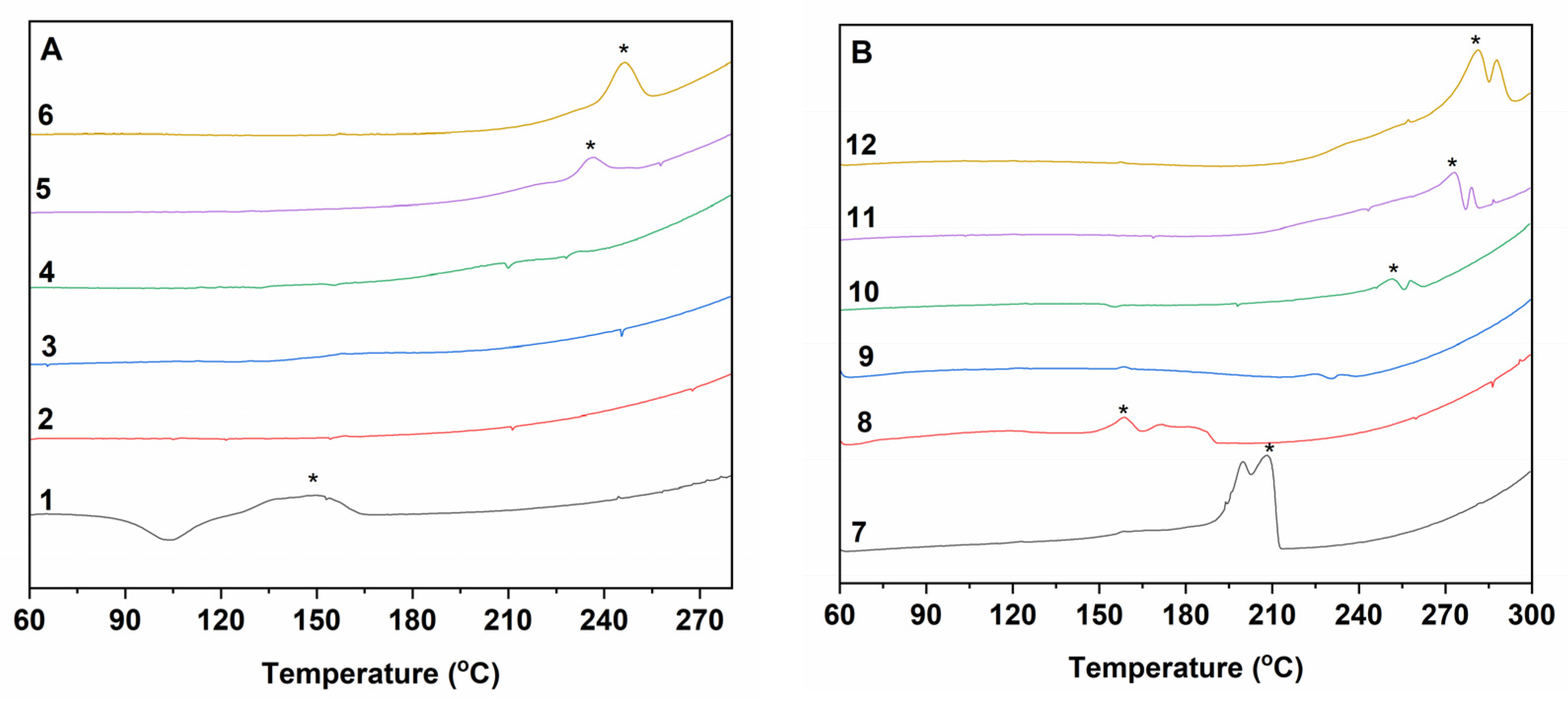

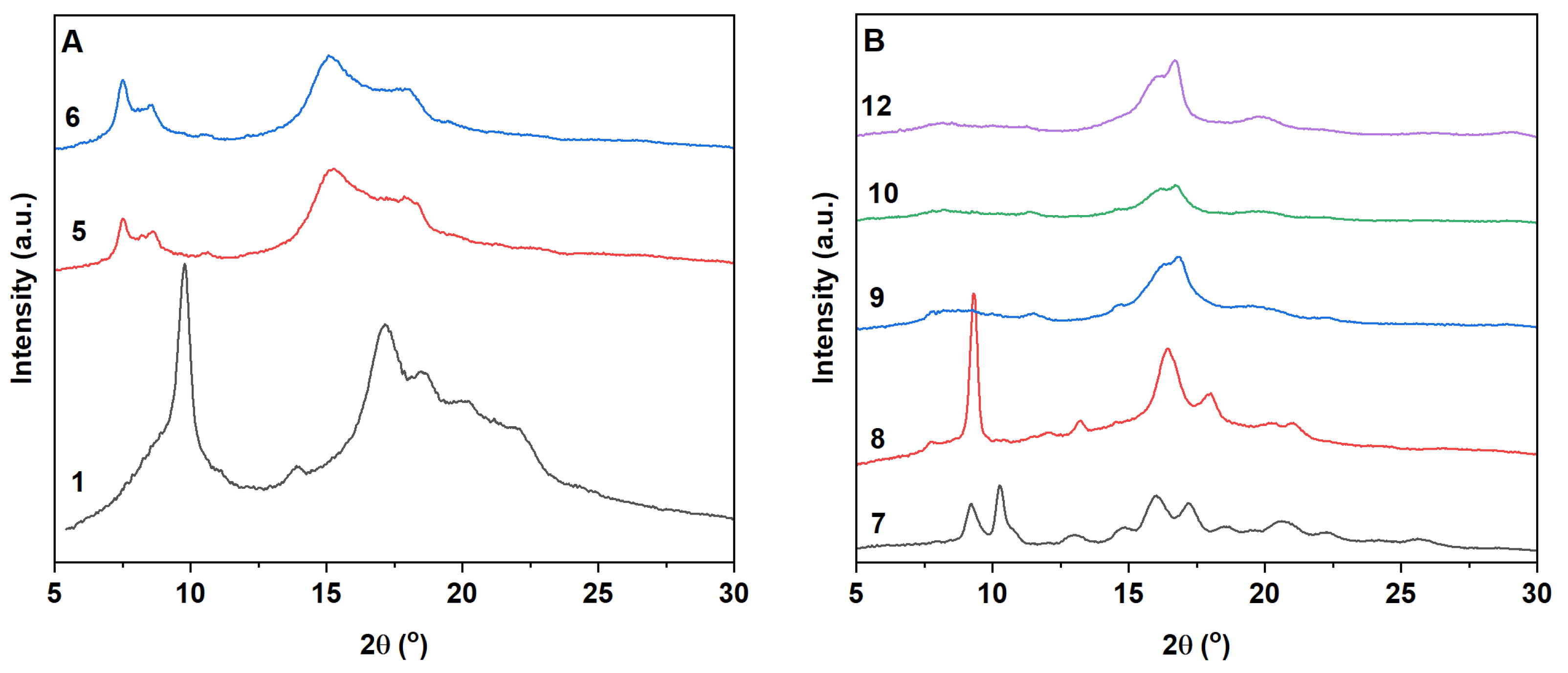

| Run | ATMS (mmol) | 4M1P (mmol) | Polymer (g) | Conv (wt%) | Tm b (°C) | ΔHm b (J/g) | Mw c (k) | pdi c | ATMS Incorp. d (mol%) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0 | 19.7 | 0.56 | 34 | 149 | 8.3 | 26.5 | 1.90 | 0 |

| 2 | 3.8 | 15.8 | 0.28 | 15 | -- e | -- e | 25.4 | 1.85 | -- f |

| 3 | 7.6 | 11.8 | 0.30 | 15 | -- e | -- e | 37.3 | 1.78 | -- f |

| 4 | 11.3 | 7.9 | 0.41 | 19 | -- e | -- e | 28.8 | 1.80 | 89.0 |

| 5 | 15.1 | 3.9 | 0.55 | 23 | 236 | 2.7 | 34.6 | 1.84 | -- f |

| 6 | 18.9 | 0 | 0.77 | 30 | 246 | 6.8 | 46.3 | 1.83 | 100 |

| 7 | 0 | 19.7 | 1.62 | 98 | 208 | 45.1 | 8.5 | 1.94 | 0 |

| 8 | 3.8 | 15.8 | 1.56 | 85 | 159 | 25.2 | 4.7 | 1.69 | -- f |

| 9 | 7.6 | 11.8 | 1.15 | 53 | -- e | -- e | 5.0 | 1.71 | 66.0 |

| 10 | 11.3 | 7.9 | 0.96 | 48 | 251 | 1.7 | 6.2 | 1.85 | 81.5 |

| 11 | 15.1 | 3.9 | 0.71 | 30 | 273 | 16.5 | 7.5 | 1.69 | -- f |

| 12 | 18.9 | 0 | 0.69 | 27 | 281 | 19.4 | 6.1 | 1.75 | 100 |

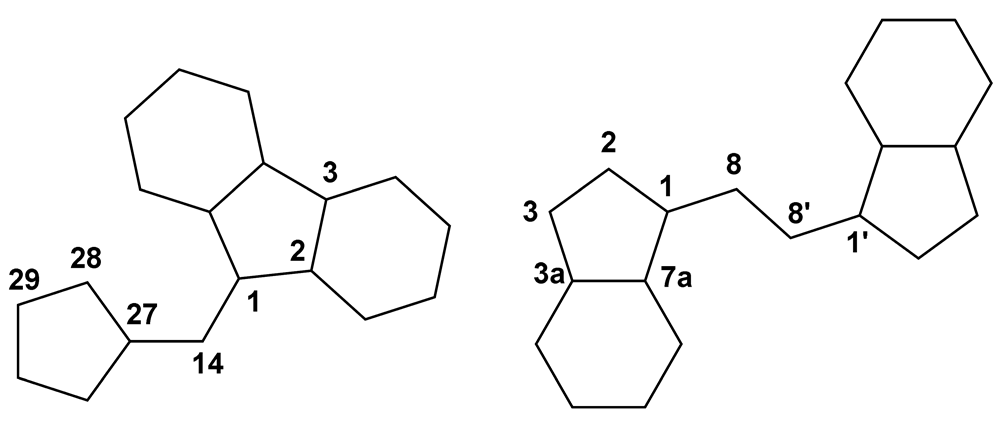

| Ph2(Cp)(Flu)ZrCl2 [31] (cat 1) | rac-EBIZrCl2 [32] (cat 2) | |||

|---|---|---|---|---|

| Bond length (Å) | Zr-Cl | 2.424(2) | Zr-Cl | 2.3884(5) |

| Zr-C(1) | 2.417(8) | Zr-C(1) | 2.438(2) | |

| Zr-C(2) | 2.513(6) | Zr-C(2) | 2.443(2) | |

| Zr-C(3) | 2.680(6) | Zr-C(3) | 2.531(2) | |

| Zr-C(27) | 2.452(8) | Zr-(C3a) | 2.624(2) | |

| Zr-C(28) | 2.450(6) | Zr-(C7a) | 2.553(2) | |

| Zr-C(29) | 2.523(6) | |||

| Bond angles (°) | Flu-Zr-Cp | 118.2 | Ind-Zr-Ind | 125.3(1) |

| Cl-Zr-Cl | 95.6 | Cl-Zr-Cl′ | 99.09(3) | |

| C1-C14-C27 | 99.6 | C(1)-C(8)-C(8′)-C(1′) | 45.6(3) | |

| ||||

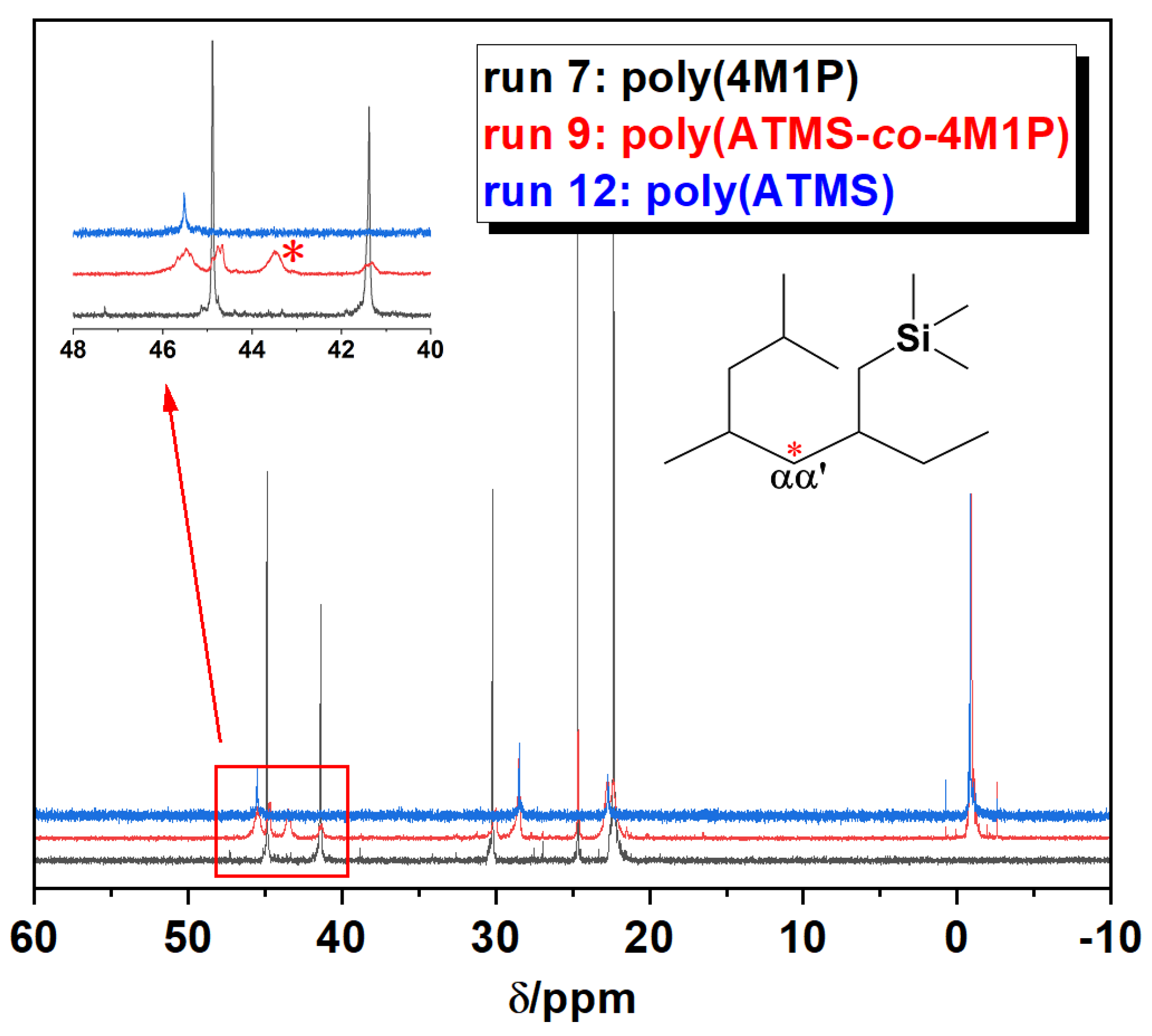

| Polymer | Chemical Shift of Carbon (ppm) | ||||

|---|---|---|---|---|---|

| e | c | d | b | a | |

| iso-PMP | 44.84 | 41.38 | 30.19 | 24.68 | 22.33 |

| syndio-PMP | 44.75 | 41.80 | 30.36 | 24.67 | 22.25 |

| iso-PATMS | 45.47 | 28.48 | 22,72 | -- | -0.89 |

| syndio-PATMS | 45.70 | 28.25 | 22,78 | -- | -1.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Ren, M.; Hou, L.; Qu, S.; Li, X.; Guo, Z. Polymerization of Allyltrimethylisilane and 4-Methyl-1-Pentene by Using Metallocene Catalysts. Polymers 2023, 15, 2038. https://doi.org/10.3390/polym15092038

Wang W, Ren M, Hou L, Qu S, Li X, Guo Z. Polymerization of Allyltrimethylisilane and 4-Methyl-1-Pentene by Using Metallocene Catalysts. Polymers. 2023; 15(9):2038. https://doi.org/10.3390/polym15092038

Chicago/Turabian StyleWang, Wei, Minqiao Ren, Liping Hou, Shuzhang Qu, Xinwei Li, and Zifang Guo. 2023. "Polymerization of Allyltrimethylisilane and 4-Methyl-1-Pentene by Using Metallocene Catalysts" Polymers 15, no. 9: 2038. https://doi.org/10.3390/polym15092038

APA StyleWang, W., Ren, M., Hou, L., Qu, S., Li, X., & Guo, Z. (2023). Polymerization of Allyltrimethylisilane and 4-Methyl-1-Pentene by Using Metallocene Catalysts. Polymers, 15(9), 2038. https://doi.org/10.3390/polym15092038