Magneto-Mechanical and Thermal Properties of Nd-Fe-B-Epoxy-Bonded Composite Materials

Abstract

1. Introduction

2. Materials and Methods

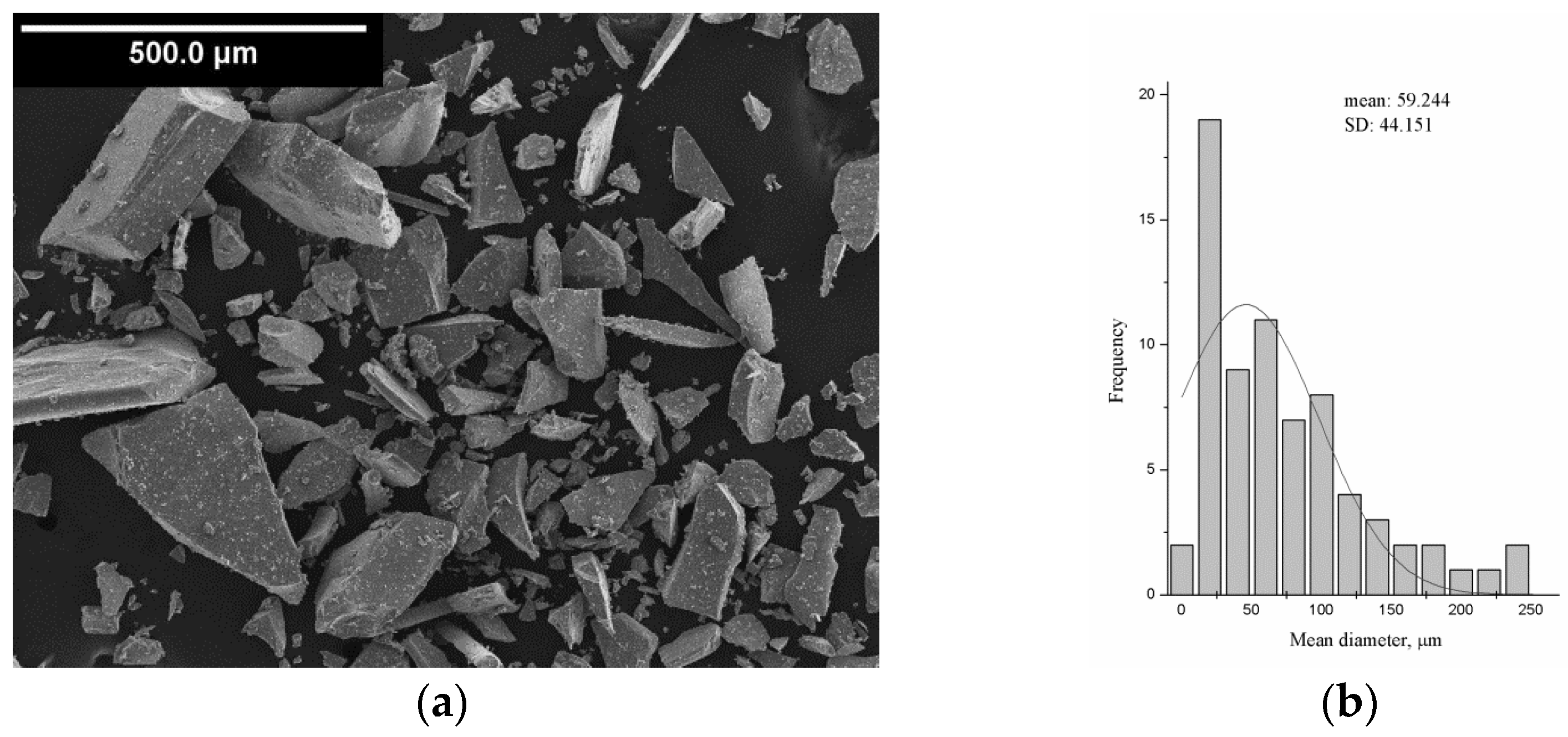

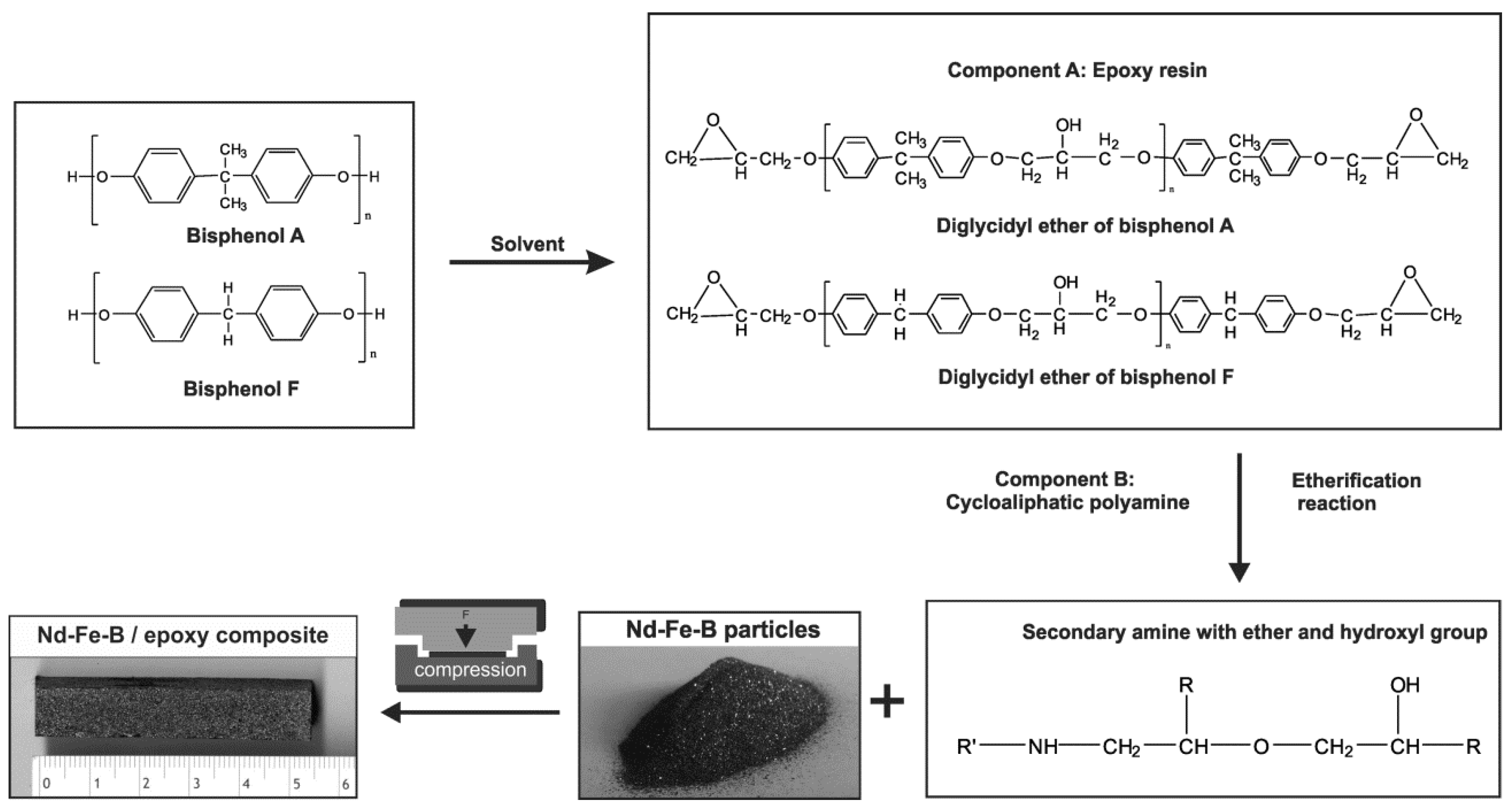

2.1. Materials

2.2. Preparation of Composites

2.3. Characterizing Methods

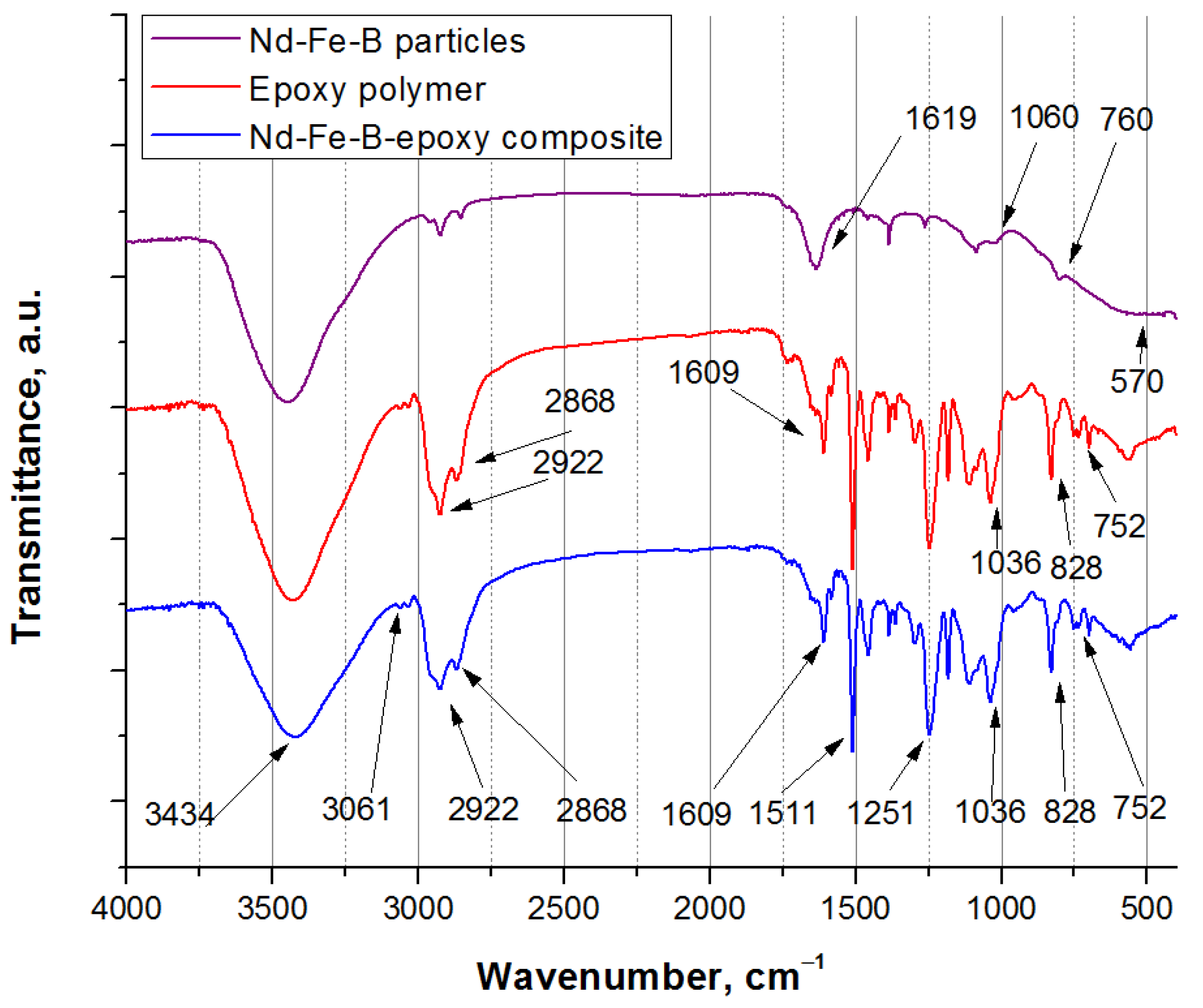

2.3.1. Chemical Characterization

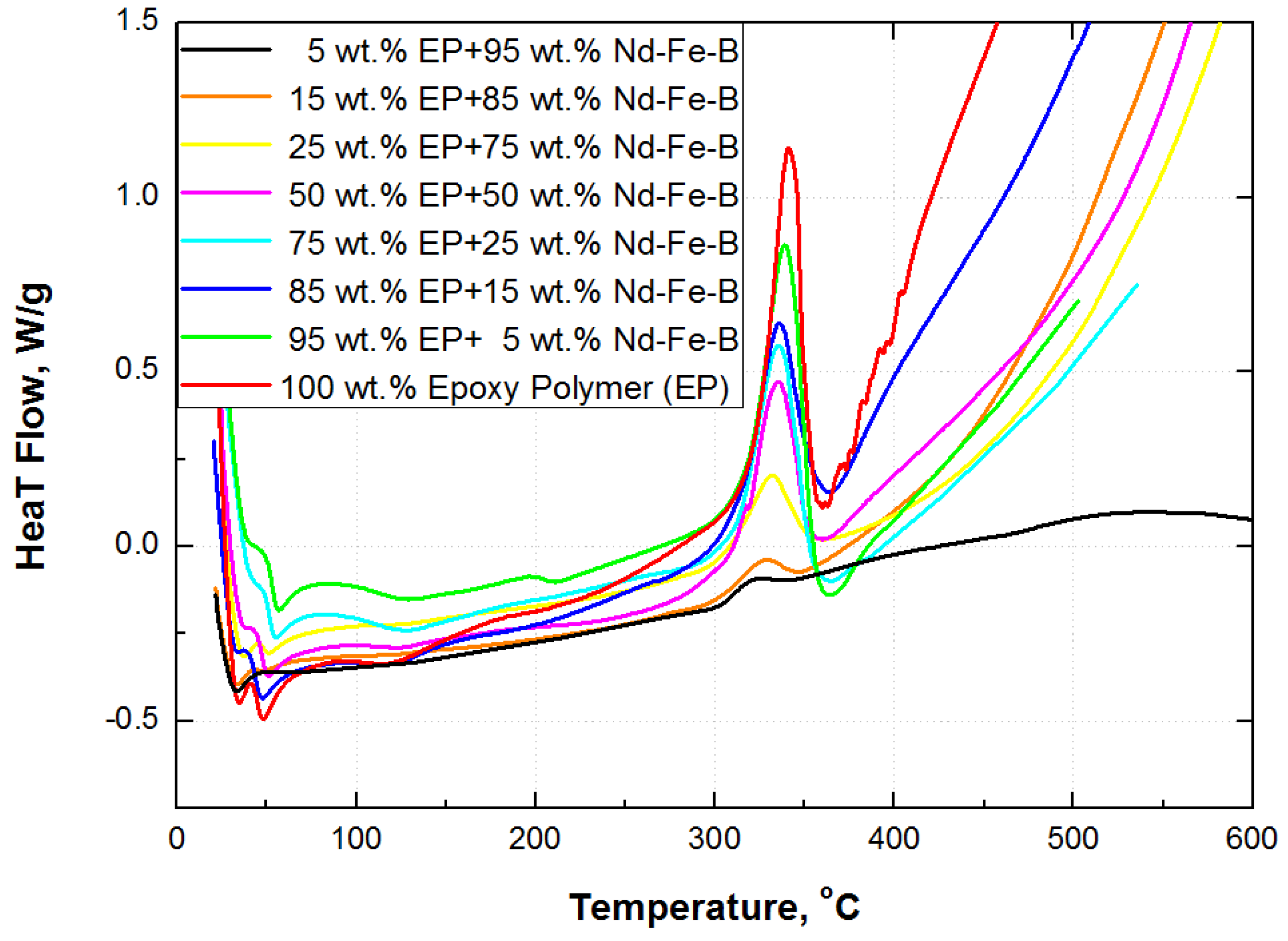

2.3.2. Thermal Analysis

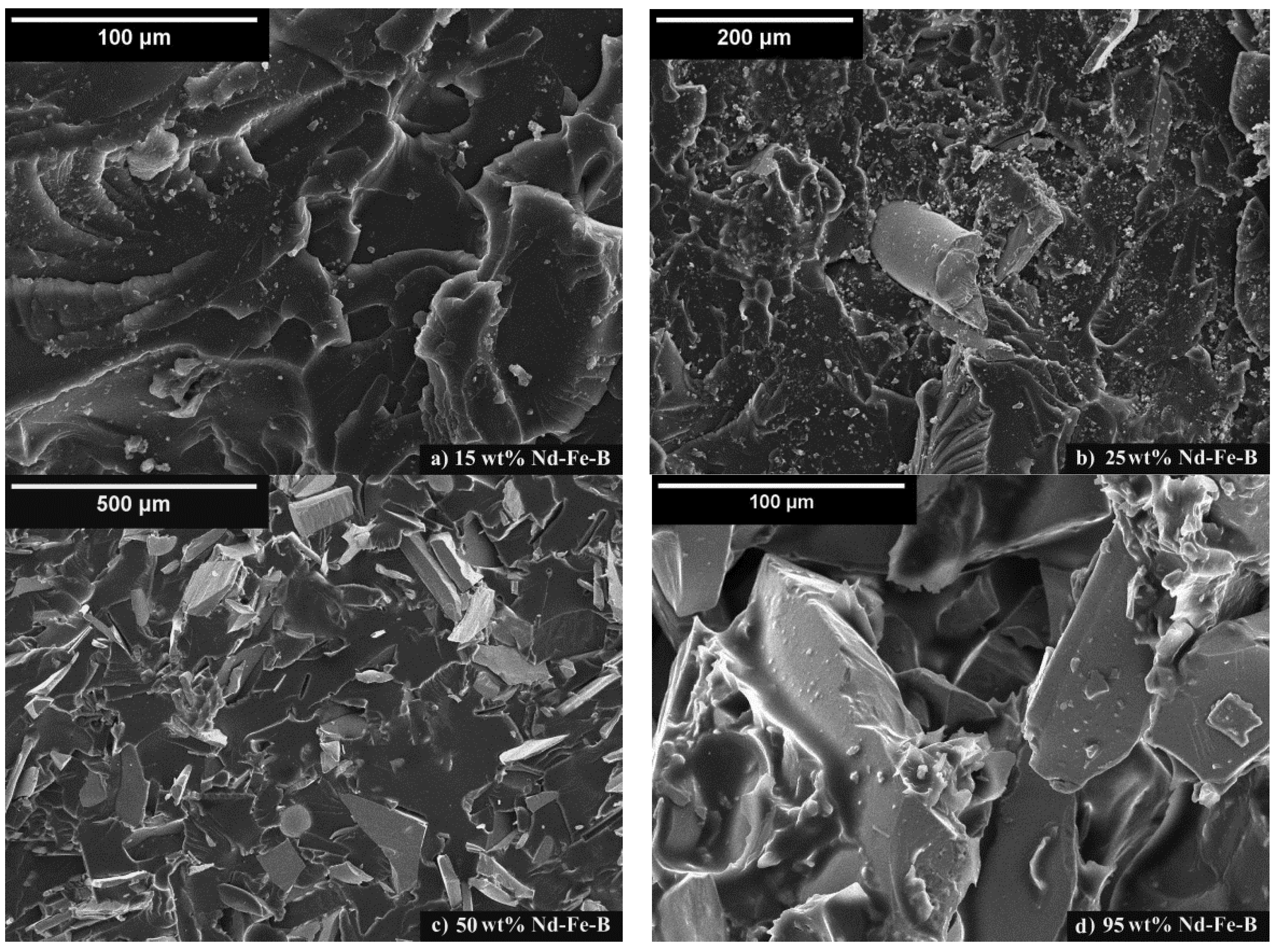

2.3.3. Surface Characterization

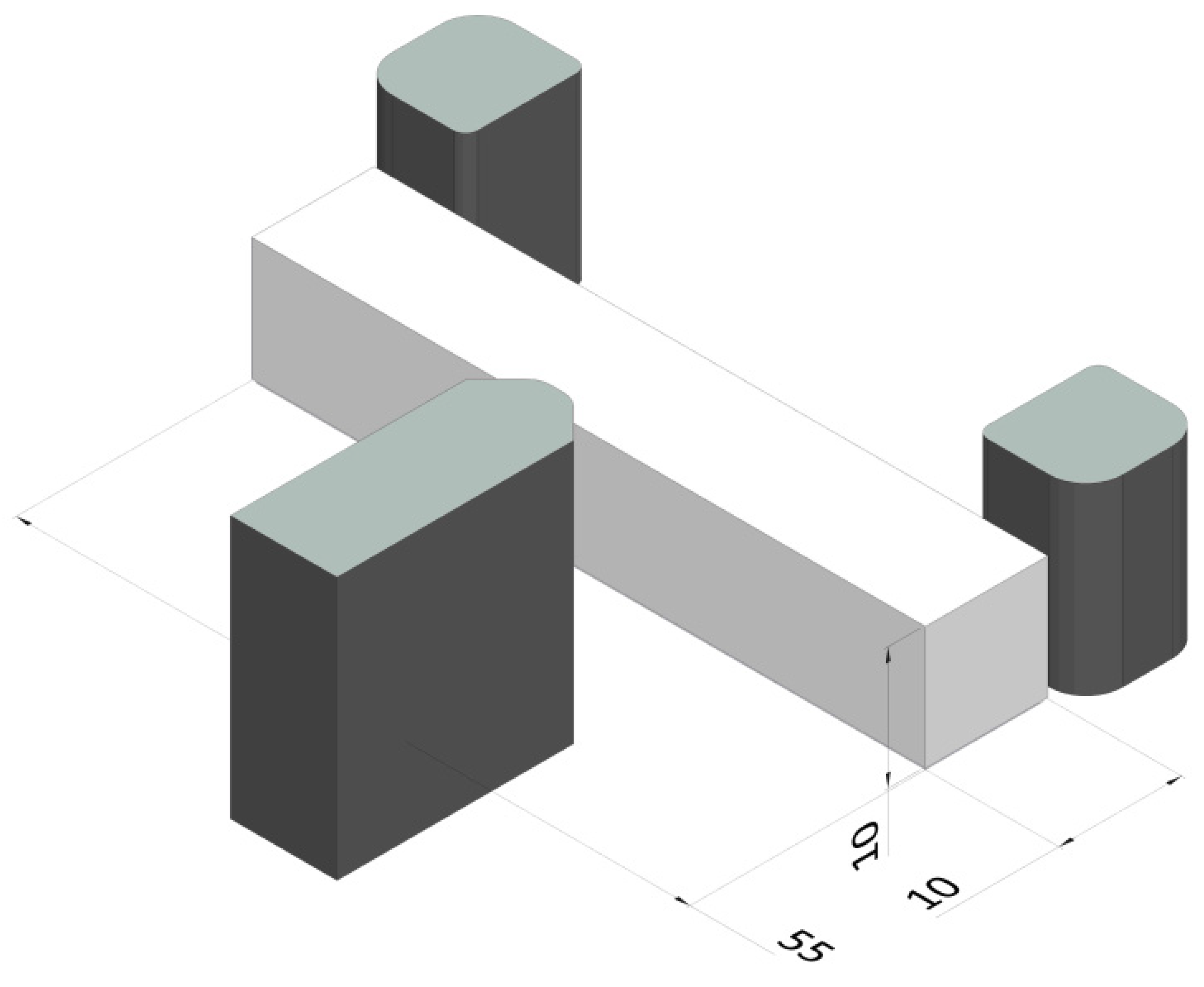

2.3.4. Impact Test

2.3.5. Crack Growth Rate Analysis

2.3.6. Magnetic Measurements

3. Results and Discussion

3.1. Chemical Properties

3.2. Thermal Analysis Results

3.3. Surface Properties

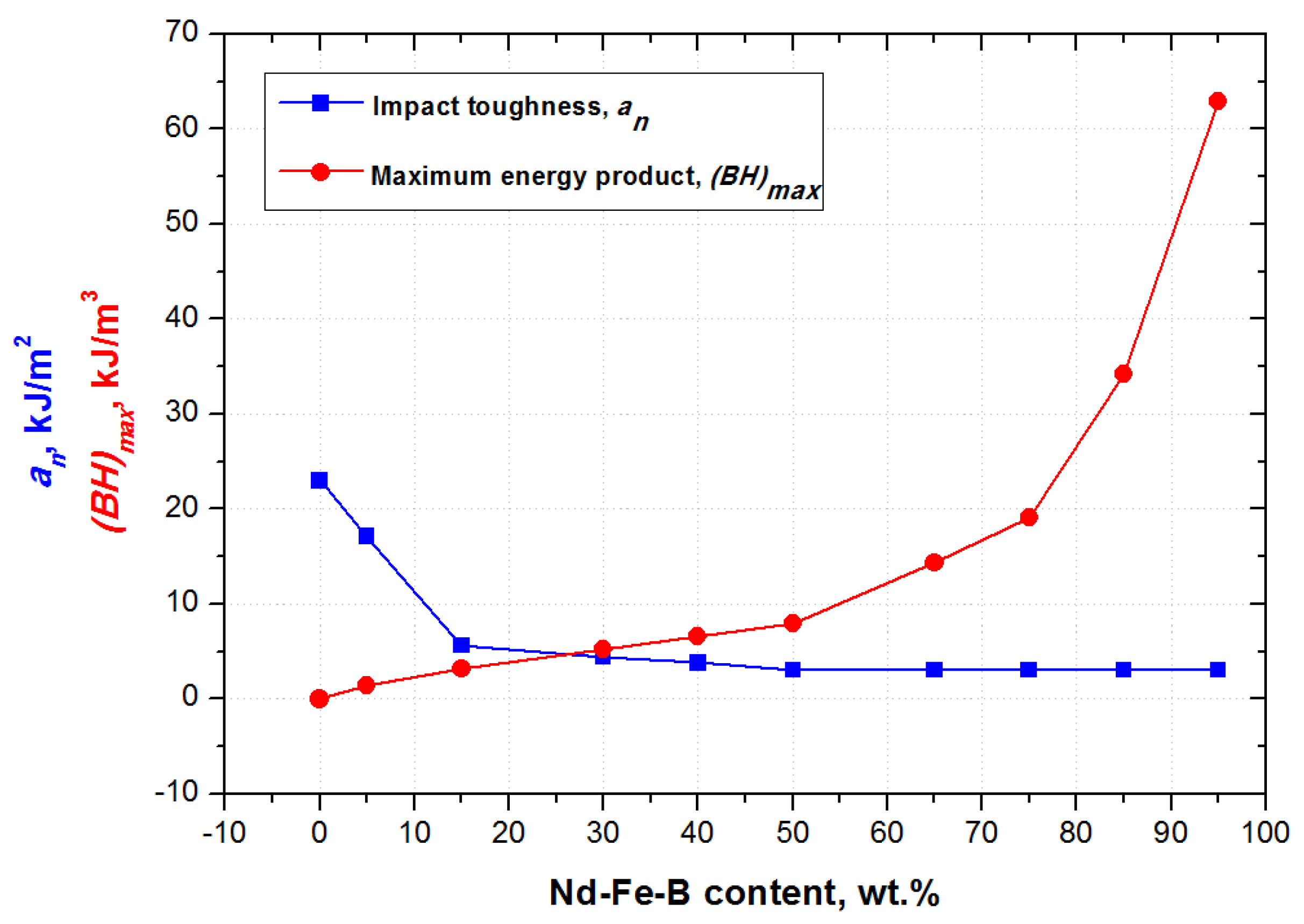

3.4. Magnetic and Mechanical Properties

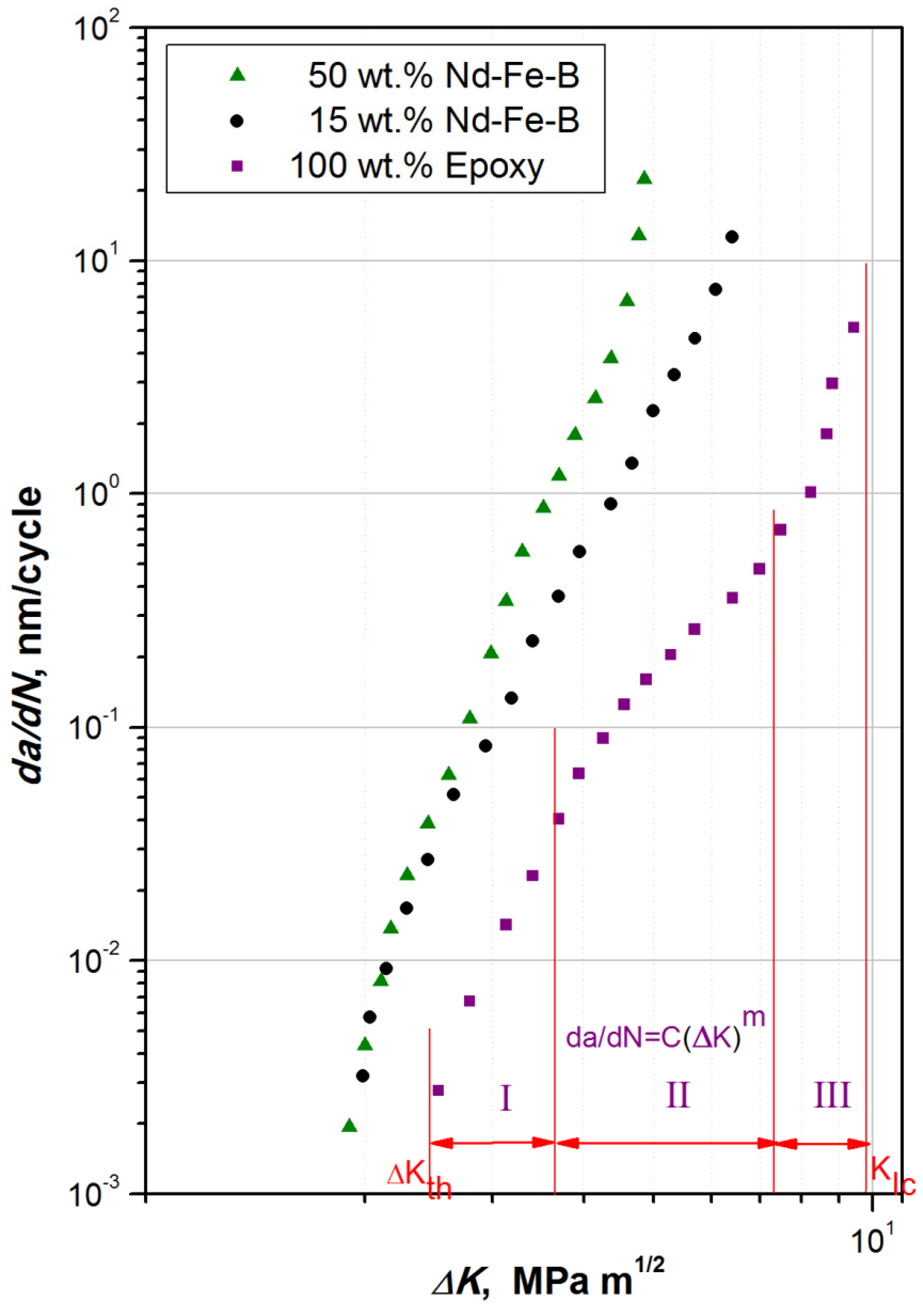

- In the short crack propagation area I, increasing ΔK causes a rapid increase in da/dN. Moreover, the threshold range of the stress intensity factor to fatigue threshold, ΔKth, is the point below which all fatigue cracks behave as cracks without the tendency to rise

- The fatigue life, often referred to as “residual”, is a characteristic of the material, and can be determined from area II, as suggested by Paris and Erdogan [57]. Equation (1) can be used to express the linear relationship between ΔK and da/dN as follows [57]:where the constants C and m are empirically derived material properties that depend on the material, the stress range, and the test environment.

- As for the fast crack propagation area III, there is a sudden crack growth before the final fracture. The critical value of fracture toughness KIc for a given material is directly related to the early phases of a brittle fracture.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Hadjipanayis, G.C. Bonded Magnets; Kluwer Academic Publishers, NATO Science Series: London, UK, 2003. [Google Scholar]

- Kimiabeigi, M.; Sheridan, R.S.; Widmer, J.D.; Walton, A.; Farr, M.; Scholes, B.; Harris, I.R. Production and Application of HPMS Recycled Bonded Permanent Magnets for a Traction Motor Application. IEEE Trans. Ind. Electron. 2018, 65, 3795–3804. [Google Scholar] [CrossRef]

- Rada, M.; Kardelky, S.; Mazilu, I.; Kirchner, A.; Gebert, A.; Gutfleisch, O.; Schultz, L. Corrosion Behavior of Polymer-Bonded NdFeB-Based Nanocrystalline Magnets. IEEE Trans. Magn. 2004, 40, 2864–2866. [Google Scholar] [CrossRef]

- Cui, J.; Ormerod, J.; Parker, D.; Ott, R.; Palasyuk, A.; McCall, S.; Paranthaman, M.P.; Kesler, M.S.; Mcguire, M.A.; Nlebedim, C.; et al. Manufacturing Processes for Permanent Magnets: Part I—Sintering and Casting. JOM 2022, 74, 1279–1295. [Google Scholar] [CrossRef]

- Brown, D.; Ma, B.M.; Chen, Z. Developments in the processing and properties of NdFeB-type permanent magnets. J. Magn. Magn. Mater. 2002, 248, 432–440. [Google Scholar] [CrossRef]

- Cui, J.; Ormerod, J.; Parker, D.S.; Ott, R.; Palasyuk, A.; McCall, S.; Paranthaman, M.P.; Kesler, M.S.; Mcguire, M.A.; Nlebedim, C.; et al. Manufacturing Processes for Permanent Magnets: Part II—Bonding and Emerging Methods. JOM 2022, 74, 2492–2506. [Google Scholar] [CrossRef]

- Constantinides, S. Permanent Magnets in a Changing World Market, Magnetics Business and Technology. 2016. Available online: https://magneticsmag.com/permanent-magnets-in-a-changing-world-market/ (accessed on 14 February 2016).

- Ormerod, J. Bonded Magnets: A Versatile Class of Permanent Magnets. 2015. Available online: https://magneticsmag.com/bonded-magnets-a-versatile-class-of-permanent-magnets/ (accessed on 7 July 2015).

- Grujić, A.; Stijepović, M.; Stajić-Trošić, J.; Stevanović, J.; Aleksić, R. Magnetic and Dynamic Mechanical Properties of Nd-Fe-B Composite Materials with Polymer Matrix, book: Metal, Ceramic and Polymeric Composite for Various Uses edited by John Cuppoletti. In-Tech Open 2011, 25, 505–524. [Google Scholar] [CrossRef]

- Tian, J.; Tang, Z.; Zuo, Z.; Pan, D.; Zhang, S. Architecturing high magnetic properties of NdFeB/SmFeN hybrid magnets. Mater. Lett. 2013, 105, 87–89. [Google Scholar] [CrossRef]

- Horikawa, T.; Yamazaki, M.; Matsuura, M.; Sugimoto, S. Recent progress in the development of high-performance bonded magnets using rare earth–Fe compounds. Sci. Technol. Adv. Mater. 2021, 22, 729–747. [Google Scholar] [CrossRef]

- Bathias, C. An engineering point of view about fatigue of polymer matrix composite materials. Int. J. Fatigue 2006, 28, 1094–1099. [Google Scholar] [CrossRef]

- Otaigbe, J.U.; Kim, H.S.; Xiao, J. Effect of Coupling Agent and Filler Particle Size on Melt Rheology of Polymer-Bonded Nd-Fe-B Magnets. Polym. Compos. 1999, 20, 697–704. [Google Scholar] [CrossRef]

- Grujić, A.; Talijan, N.; Stojanović, D.; Stajić-Trošić, J.; Burzić, Z.; Balanović, L.J.; Aleksić, R. Mechanical and magnetic properties of composite materials with polymer matrix. J. Min. Metall. Sect. B Metall. 2010, 46, 25–32. [Google Scholar] [CrossRef]

- Zhang, X.H.; Xiong, W.H.; Li, Y.F.; Song, N. Effect of process on the magnetic and mechanical properties of Nd–Fe–B bonded magnets. Mater. Des. 2009, 30, 1386–1390. [Google Scholar] [CrossRef]

- Kaidarova, A.; Khan, M.A.; Amara, S.; Geraldi, N.R.; Karimi, M.A.; Shamim, A.; Wilson, R.P.; Duarte, C.M. Tunable, Flexible Composite Magnets for Marine Monitoring Applications. Adv. Eng. Mater. 2018, 20, 1800229. [Google Scholar] [CrossRef]

- Grujić, A.; Stijepović, M.; Stajić-Trošić, J.; Putić, S.; Nedeljković, D.; Stajčić, A.; Aleksić, R. Dynamic Mechanical Behaviour of Polymer Bonded Nd-Fe-B Composite Materials. Mater. Trans. 2012, 53, 395–400. [Google Scholar] [CrossRef]

- Li, L.; Tirado, A.; Nlebedim, I.C.; Rios, O.; Post, B.; Kunc, V.; Lowden, R.R.; Lara-Curzio, e.; Fredette, R.; Ormerod, J.; et al. Big Area Additive Manufacturing of High Performance Bonded NdFeB Magnets. Sci. Rep. 2016, 6, 36212. [Google Scholar] [CrossRef]

- Chen, Y.J.; Lee, Y.I.; Chang, W.C.; Hsiao, P.J.; You, J.S.; Wang, C.C.; Wei, C.M. Modelling of the material flow of Nd-Fe-B magnets under high temperature deformation via finite element simulation method. Sci. Technol. Adv. Mater. 2017, 18, 611–619. [Google Scholar] [CrossRef] [PubMed]

- Nlebedim, I.C.; Ucar, H.; Hatter, C.B.; McCallum, R.W.; McCall, S.K.; Kramer, M.J.; Paranthaman, M.P. Studies on in situ magnetic alignment of bonded anisotropic Nd-Fe-B alloy powders. J. Magn. Magn. Mater. 2017, 422, 168–173. [Google Scholar] [CrossRef]

- Stancu, C.; Notingher, P.V.; Panaitescu, D.M.; Marinescu, V. Electrical Properties of Polyethylene Composites with Low Content of Neodymium. Polym.-Plast. Technol. Eng. 2015, 54, 1135–1143. [Google Scholar] [CrossRef]

- Stancu, C.; Notingher, P.V.; Ionita, V.; Marinescu, V.; Panaitescu, D. Polyethylene-based Magnetic Composites. In Proceedings of the International Conference on Applied and Theoretical Electricity (ICATE), Craiova, Romania, 23–25 October 2014; pp. 1–7. [Google Scholar]

- Gandha, K.; Ouyang, G.; Gupta, S.; Kunc, V.; Paranthaman, M.P.; Nlebedima, I.C. Recycling of additively printed rare-earth bonded magnets. Waste Manag. 2019, 90, 94–99. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.F.; Vora, P.; Walmer, M.H.; Kottcamp, E. Microstructure and magnetic properties of sintered NdFeB magnets with improved impact toughness. J. Appl. Phys. 2005, 97, 1–3. [Google Scholar] [CrossRef]

- Tayefeh, A.; Wiesner, M.; Mousavi, S.A.; Poursalehi, R. Modeling magneto-mechanical behavior of Fe3O4 nanoparticle/polyamide nanocomposite membrane in an external magnetic field. J. Compos. Mater. 2018, 52, 1505–1517. [Google Scholar] [CrossRef]

- Ormerod, J.; Constantinides, S. Bonded permanent magnets: Current status and future opportunities. J. Appl. Phys. 1997, 81, 4816–4820. [Google Scholar] [CrossRef]

- Zheng, J.; Cheng, X.; Chen, H.; Qiao, L.; Lin, M.; Jiang, L.; Che, S. An electrodeposition metal layers method for magnetic powders and warm-pressing preparation of Nd-Fe-B/Sn bonded magnets. J. Adhes. Sci. Technol. 2016, 30, 275–283. [Google Scholar] [CrossRef]

- Huber, C.; Abert, C.; Bruckner, F.; Groenefeld, M.; Schuschnigg, S.; Teliban, I.; Vogler, C.; Wautischer, G.; Windl, R.; Suess, D. 3D Printing of Polymer-Bonded Rare-Earth Magnets With a Variable Magnetic Compound Fraction for a Predefined Stray Field. Sci. Rep. 2017, 7, 9419. [Google Scholar] [CrossRef] [PubMed]

- El Swie, H.; Radojević, V.; Brajović, L.; Stajic-Trosić, J.; Cosović, V.; Grujić, A.; Aleksić, R. Synthesis and Performance of Polymer Based Magnetic Composite Sensing Element. Dig. J. Nanomater. Biostruct. 2015, 10, 1475–1483. [Google Scholar]

- Maeda, T.; Watanabe, A.; Yamada, K. High-Thermostability Nd-Fe-B Magnet Formed by Binderless Net-Shaping. SEI Tech. Rev. 2016, 83, 66–71. [Google Scholar]

- Yunas, J.; Mulyanti, B.; Hamidah, I.; Said, M.M.; Pawinanto, R.E.; Wan Ali, W.A.F.; Subandi, A.; Hamzah, A.A.; Latif, R.; Majlis, B.Y. Polymer-Based MEMS Electromagnetic Actuator for Biomedical Application: A Review. Polymers 2020, 12, 1184. [Google Scholar] [CrossRef] [PubMed]

- Compton, B.G.; Kemp, J.W.; Novikov, T.V.; Pack, R.C.; Nlebedim, I.C.; Duty, C.E.; Rios, O.; Sales, B.C.; Paranthaman, M.P. Direct-Write 3D-Printing of NdFeB Bonded Magnets. Mater. Manuf. Process. 2016, 33, 109–113. [Google Scholar] [CrossRef]

- Naebe, M.; Abolhasani, M.M.; Khayyam, H.; Amini, A.; Fox, B. Crack Damage in Polymers and Composites: A Review. Polym. Rev. 2016, 56, 31–69. [Google Scholar] [CrossRef]

- Klingler, A.; Wetzel, B. Fatigue crack propagation in triblock copolymer toughened epoxy nanocompositesl. Polym. Eng. Sci. 2017, 57, 579–587. [Google Scholar] [CrossRef]

- Begley, M.R.; Hutchinson, J.W. Linear Elastic Fracture Mechanics in: The Mechanics and Reliability of Films, Multilayers and Coatings; Cambridge University Press: Cambridge, UK, 2017; pp. 21–48. [Google Scholar]

- Awaja, F.; Zhang, S.; Tripathi, M.; Nikiforov, A.; Pugno, N. Cracks, microcracks and fracture in polymer structures: Formation, detection, autonomic repair. Prog. Mater. Sci. 2016, 83, 536–573. [Google Scholar] [CrossRef]

- Grujić, A.; Stajić-Trošić, J.; Stijepović, M.Z.; Perišić, S.; Žák, T. Tensile strength properties of hybrid magnetic composite materials. Zast. Mater. 2017, 58, 570–575. [Google Scholar] [CrossRef]

- Grujić, A.; Ćosović, V.; Ćosović, A.; Stajić-Trošić, J. Nanocrystalline Nd-Fe-B Alloys for Polymer-Bonded Magnets Production. ISRN Nanotechnol. 2012, 2012, 438436. [Google Scholar] [CrossRef]

- Achilias, D.S.; Karabela, M.M.; Varkopoulou, E.A.; Sideridou, I.D. Cure Kinetics Study of Two Epoxy Systems with Fourier Tranform Infrared Spectroscopy (FTIR) and Differential Scanning Calorimetry (DSC). J. Macromol. Sci. Part A Pure Appl. Chem. 2012, 49, 630–638. [Google Scholar] [CrossRef]

- Khanam, P.N.; Al Ali AlMaadeed, M. Processing and characterization of polyethylene-based composites. Adv. Manuf. Polym. Compos. Sci. 2015, 1, 63–79. [Google Scholar] [CrossRef]

- ASTM E23-01; Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2001. Available online: www.astm.org (accessed on 7 March 2023).

- ASTM E647-15e1; Standard Test Method for Measurement of Fatigue Crack Growth Rates. ASTM International: West Conshohocken, PA, USA, 2015. Available online: www.astm.org (accessed on 14 March 2023).

- Akiyama, E.; Kawakami, T.; Ito, H.; Yokota, H. Amine-Cured Type Epoxy Resin Electrolyte Having a Sulfonic Acid Group and Method for Preparation Thereof. World Intellectual Property Organization, WO2004078822A1, 16 September 2004. Available online: https://encrypted.google.com/patents/WO2004078822A1?cl=da (accessed on 16 September 2004).

- Deheri, P.K.; Swaminathan, V.; Bhame, S.D.; Liu, Z.; Ramanujan, R.V. Sol−Gel Based Chemical Synthesis of Nd2Fe14B Hard Magnetic Nanoparticles. Chem. Mater. 2010, 22, 6509–6517. [Google Scholar] [CrossRef]

- Coey, J.M.D. Hard Magnetic Materials: A Perspective. IEEE Trans. Magn. 2011, 47, 4671–4681. [Google Scholar] [CrossRef]

- RCarbas, J.C.; Marques, E.A.S.; da Silva, L.F.M.; Lopes, A.M. Effect of Cure Temperature on the Glass Transition Temperature and Mechanical Properties of Epoxy Adhesives. J. Adhes. 2014, 90, 104–119. [Google Scholar] [CrossRef]

- de Azúa, O.R.; Agulló, N.; Arbusà, J.; Borrós, S. Improving Glass Transition Temperature and Toughness of Epoxy Adhesives by a Complex Room-Temperature Curing System by Changing the Stoichiometry. Polymers 2023, 15, 252. [Google Scholar] [CrossRef] [PubMed]

- Menard, K.P. Dynamic Mechanical Analysis: A Practical Introduction; CRC Press LLC: Florida, FL, USA, 1999. [Google Scholar]

- Payne, A.R. Dynamic Properties of Filler-Loaded Rubbers. In Reinforcement of Elastomers; Kraus, G., Ed.; Interscience Publishers, A division of John Wiley & Sons: New York, NY, USA, 1965; pp. 69–123. [Google Scholar]

- Deng, S.; Hou, M.; Ye, L. Temperature-dependent elastic moduli of epoxies measured by DMA and their correlations to mechanical testing data. Polym. Test. 2007, 26, 803–813. [Google Scholar] [CrossRef]

- Atuanya, C.U.; Aigbodion, V.S.; Agbo, C.O.A.; Anene, F.A. Thermo-Mechanical Behaviour of Functional Polymer Nanocomposites. Int. J. Adv. Manuf. Technol. 2019, 103, 4771–4775. [Google Scholar] [CrossRef]

- Chang, L.; Zhang, Z.; Breidt, C. Impact Resistance of Short Fibre/Particle Reinforced Epoxy. Appl. Compos. Mater. 2004, 11, 1–15. [Google Scholar] [CrossRef]

- Launey, M.E.; Ritchie, R.O. On the Fracture Toughness of Advanced Materials. Adv. Mater. 2009, 21, 2103–2110. [Google Scholar] [CrossRef]

- Ritchie, R.O. Mechanisms of fatigue-crack propagation in ductile and brittle solids. Int. J. Fract. 1999, 100, 55–83. [Google Scholar] [CrossRef]

- Li, J.; Sepehri-Amin, H.; Sasaki, T.; Ohkubo, T.; Hono, K. Most frequently asked questions about the coercivity of Nd-Fe-B permanent magnets. Sci. Technol. Adv. Mater. 2021, 22, 386–403. [Google Scholar] [CrossRef]

- Guo, Y.; Zhao, D.; You, J.; Pei, W.; Qu, Y.; Wang, X.; Meng, Q. Evolution of microstructure and formation mechanism of Nd-Fe-B nanoparticles prepared by low energy consumption chemical method. RSC Adv. 2018, 8, 38850–38859. [Google Scholar] [CrossRef]

- Paris, P.; Erdogan, F. A critical analysis of crack propagation laws. J. Basic Eng. 1963, 85, 528–533. [Google Scholar] [CrossRef]

| Sample | Mr, kA/m | Ms, kA/m | Br, T | Hcb, kA/m | (BH)max, kJ/m3 |

|---|---|---|---|---|---|

| 5 wt.% EP + 95 wt.% Nd-Fe-B | 511.2 | 854.7 | 0.64 | 381.8 | 64.5 |

| 15 wt.% EP + 85 wt.% Nd-Fe-B | 358.2 | 591.2 | 0.44 | 295.1 | 33.9 |

| 25 wt.% EP + 75 wt.% Nd-Fe-B | 271.8 | 452.4 | 0.34 | 237.3 | 20.9 |

| 50 wt.% EP + 50 wt.% Nd-Fe-B | 178.2 | 292.4 | 0.22 | 159.3 | 8.73 |

| 70 wt.% EP + 30 wt.% Nd-Fe-B | 136.5 | 226.5 | 0.17 | 125.7 | 5.41 |

| 85 wt.% EP + 15 wt.% Nd-Fe-B | 112.4 | 191.8 | 0.14 | 108.6 | 3.91 |

| Specimens | 0 wt.% Nd-Fe-B 100 wt.% Epoxy | 15 wt.% Nd-Fe-B 85 wt.% Epoxy | 50 wt.% Nd-Fe-B 50 wt.% Epoxy |

| Parameters | |||

| C | 3.66·10−4 | 9.15·10−5 | 6.82·10−5 |

| m | 3.816 | 6.345 | 7.484 |

| ΔKth, MPa·m1/2 | 2.51 | 1.99 | 1.85 |

| ΔKIc, MPa·m1/2 | 9.65 | 6.47 | 5.06 |

| da/dN, nm/cycle (at ΔK = 4 MPa·m1/2) | 0.067 | 0.6 | 2.02 |

| Goodness of fit | |||

| SSE | 0.0001031 | 0.0003918 | 0.0061913 |

| R-Square | 0.9918 | 0.9974 | 0.9929 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grujić, A.; Nedeljković, D.; Stajić-Trošić, J.; Stijepović, M.Z.; Alnouri, S.; Perišić, S. Magneto-Mechanical and Thermal Properties of Nd-Fe-B-Epoxy-Bonded Composite Materials. Polymers 2023, 15, 1894. https://doi.org/10.3390/polym15081894

Grujić A, Nedeljković D, Stajić-Trošić J, Stijepović MZ, Alnouri S, Perišić S. Magneto-Mechanical and Thermal Properties of Nd-Fe-B-Epoxy-Bonded Composite Materials. Polymers. 2023; 15(8):1894. https://doi.org/10.3390/polym15081894

Chicago/Turabian StyleGrujić, Aleksandar, Dragutin Nedeljković, Jasna Stajić-Trošić, Mirko Z. Stijepović, Sabla Alnouri, and Srdjan Perišić. 2023. "Magneto-Mechanical and Thermal Properties of Nd-Fe-B-Epoxy-Bonded Composite Materials" Polymers 15, no. 8: 1894. https://doi.org/10.3390/polym15081894

APA StyleGrujić, A., Nedeljković, D., Stajić-Trošić, J., Stijepović, M. Z., Alnouri, S., & Perišić, S. (2023). Magneto-Mechanical and Thermal Properties of Nd-Fe-B-Epoxy-Bonded Composite Materials. Polymers, 15(8), 1894. https://doi.org/10.3390/polym15081894