Unveiling the Hidden Properties of Tomato Peels: Cutin Ester Derivatives as Bio-Based Plasticizers for Polylactic Acid

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

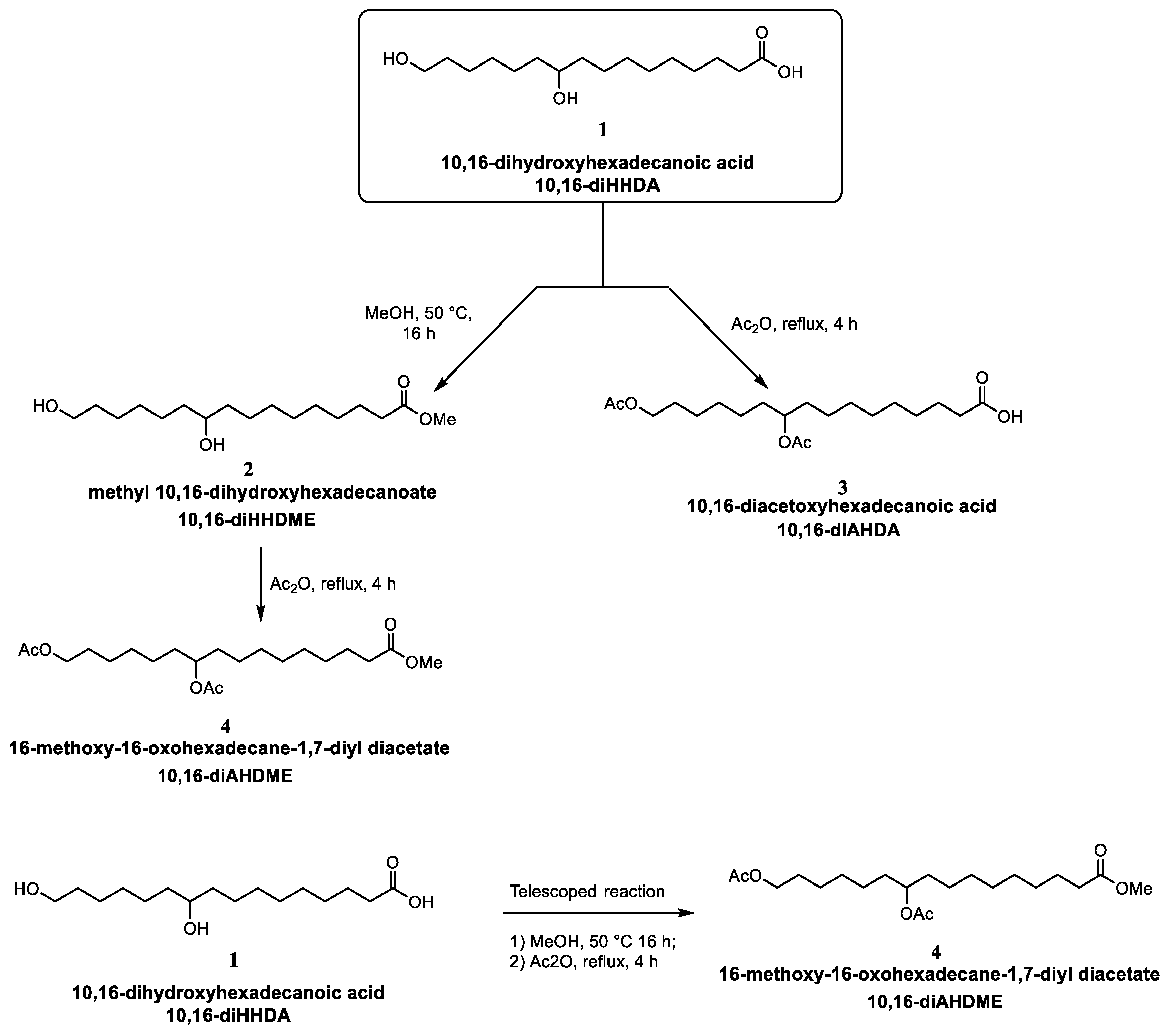

2.2. Synthesis Procedures

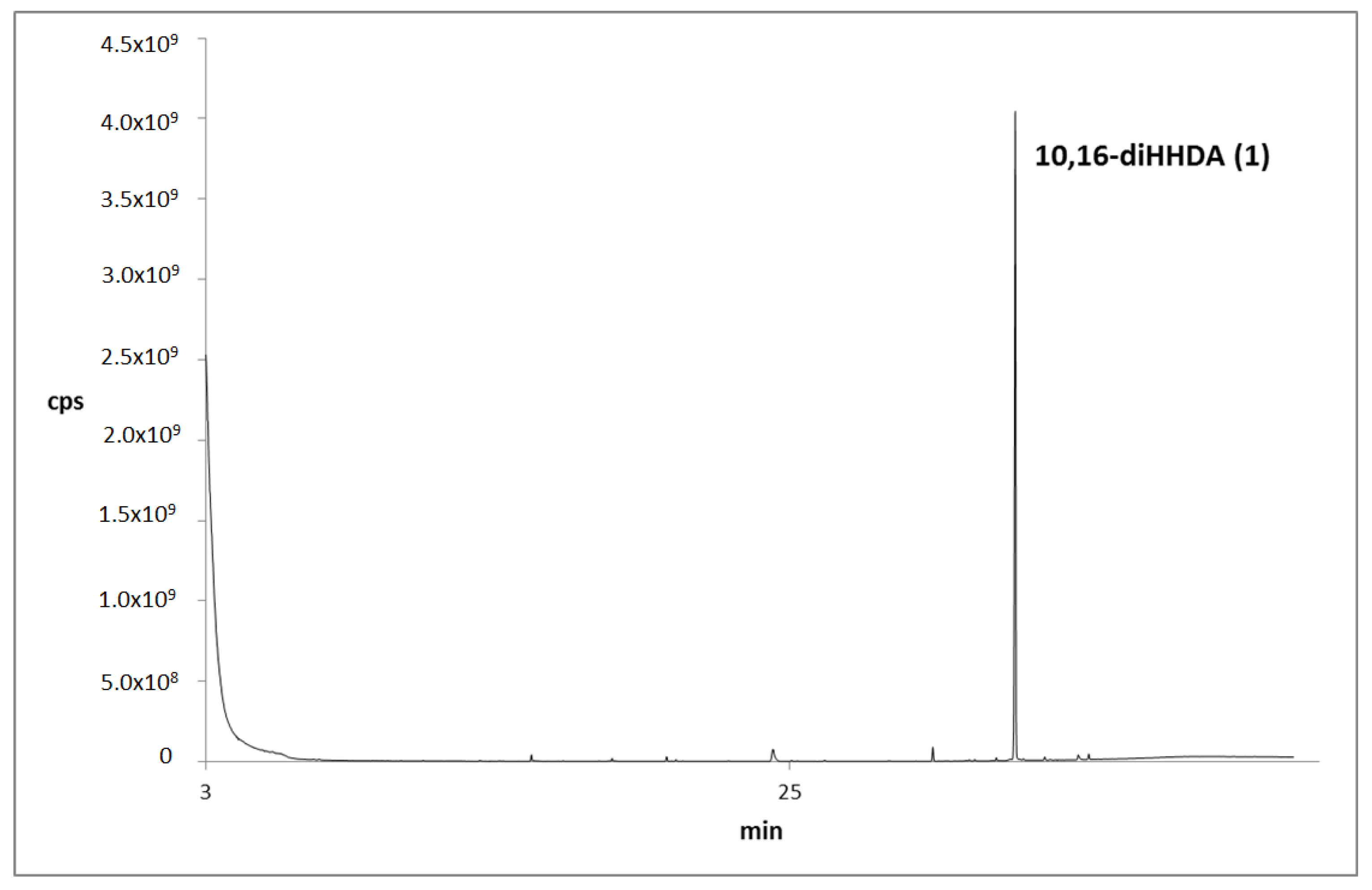

2.2.1. 10,16-Dihydroxy Hexadecanoic Acid Isolation (10,16-diHHDA, 1)

2.2.2. Methyl-10,16-dihydroxy Hexadecanoate Synthesis (10,16-diHHDME, 2)

2.2.3. 10,16-Diacetoxy Hexadecanoic Acid Synthesis (10,16-diAHDA, 3)

2.2.4. 16-Methoxy-16-oxo-hexadecane-1,7-diyl Diacetate Synthesis (10,16-diAHDME, 4)

2.2.5. 16-Methoxy-16-oxo-hexadecane-1,7-diyl Diacetate (4) from 10,16-Dihydroxy Hexadecanoic Acid Synthesis (1)—Telescoped Reaction

2.3. Blend Preparation Procedures

2.3.1. Solution Blending—Procedure for Monomer 1

2.3.2. Solution Blending—General Procedure for 2, 3, and 4

2.3.3. Mechanical Melt Blending—Preparation of PLA + 16-Methoxy-16-oxo-hexadecane-1,7-diyl Diacetate (4)

2.4. Characterization Techniques

3. Results and Discussion

3.1. Hansen Solubility Parameter Analysis

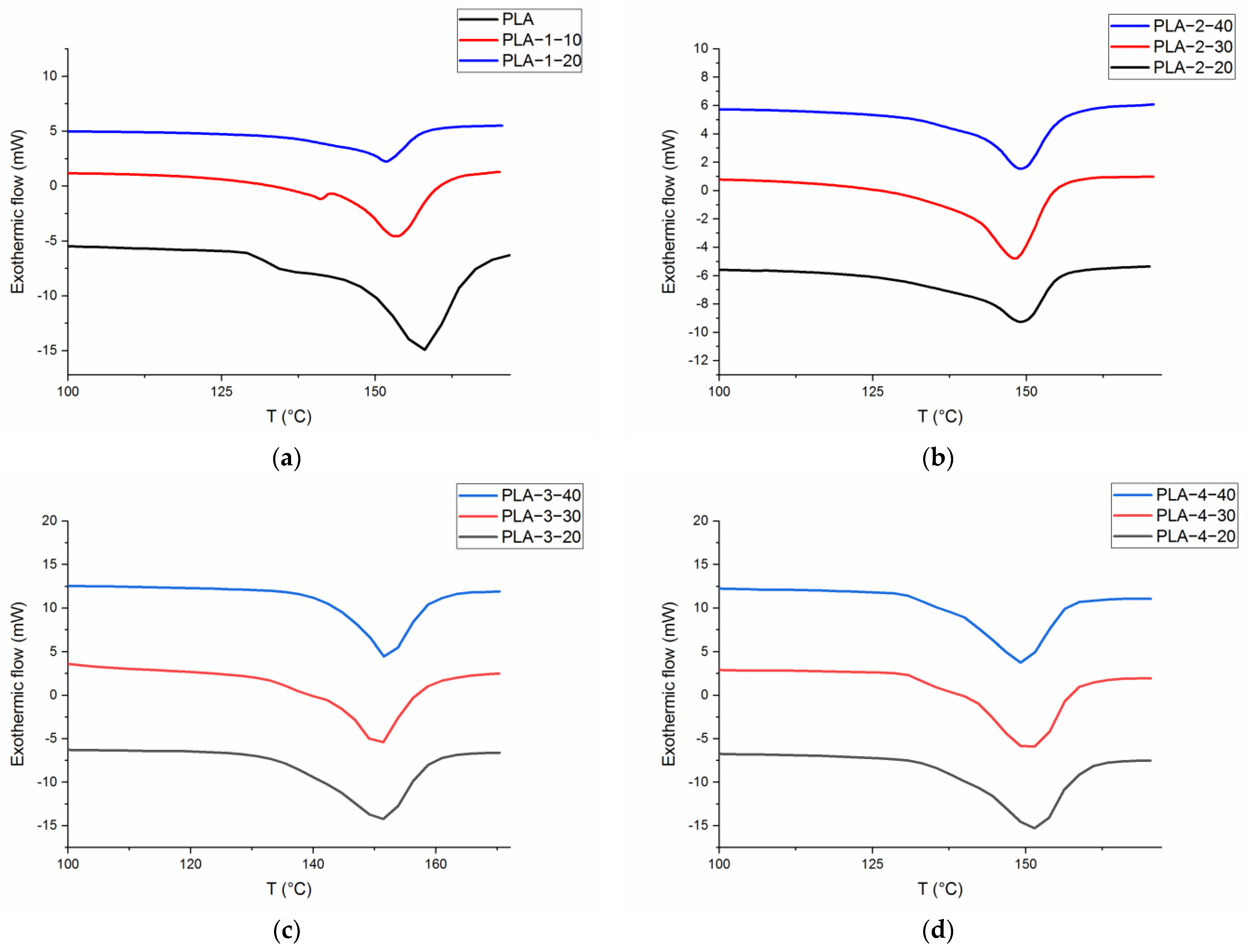

3.2. Solution Blending

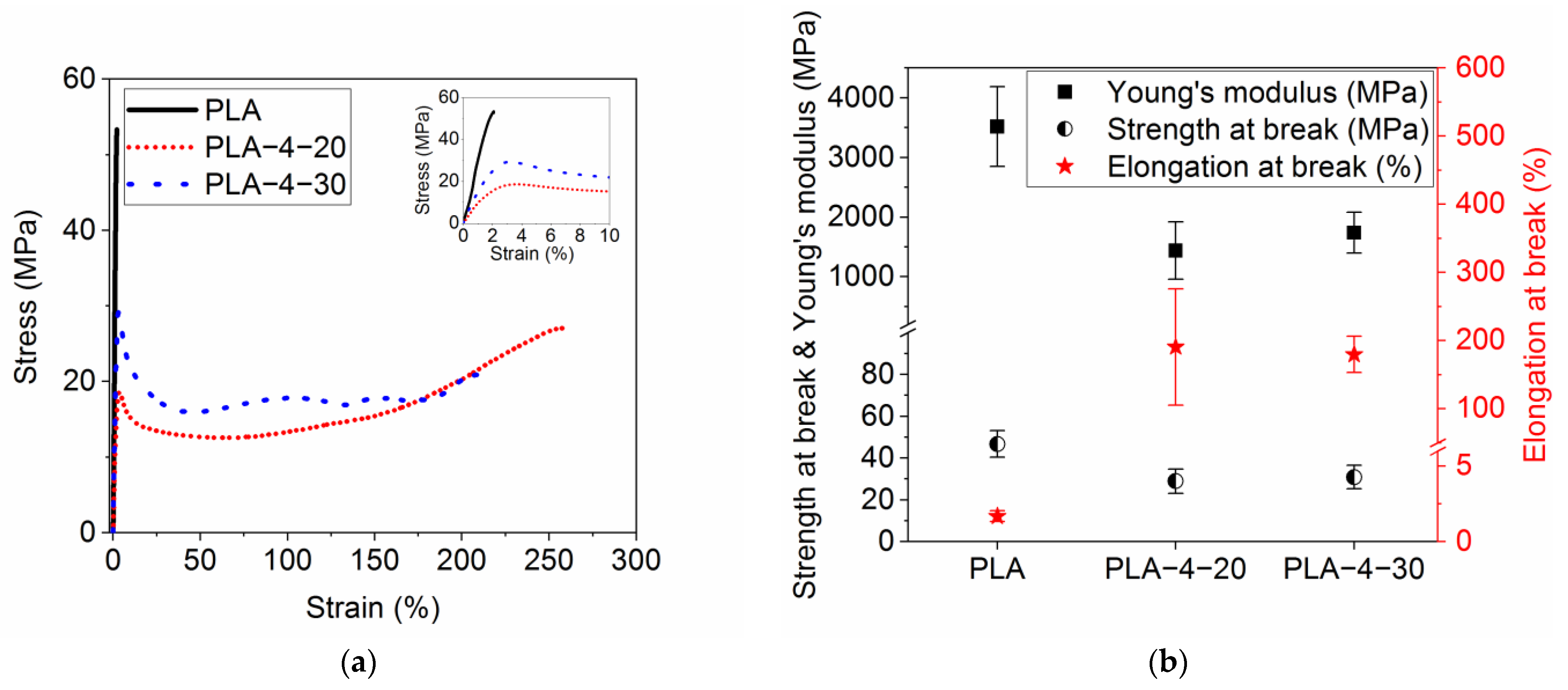

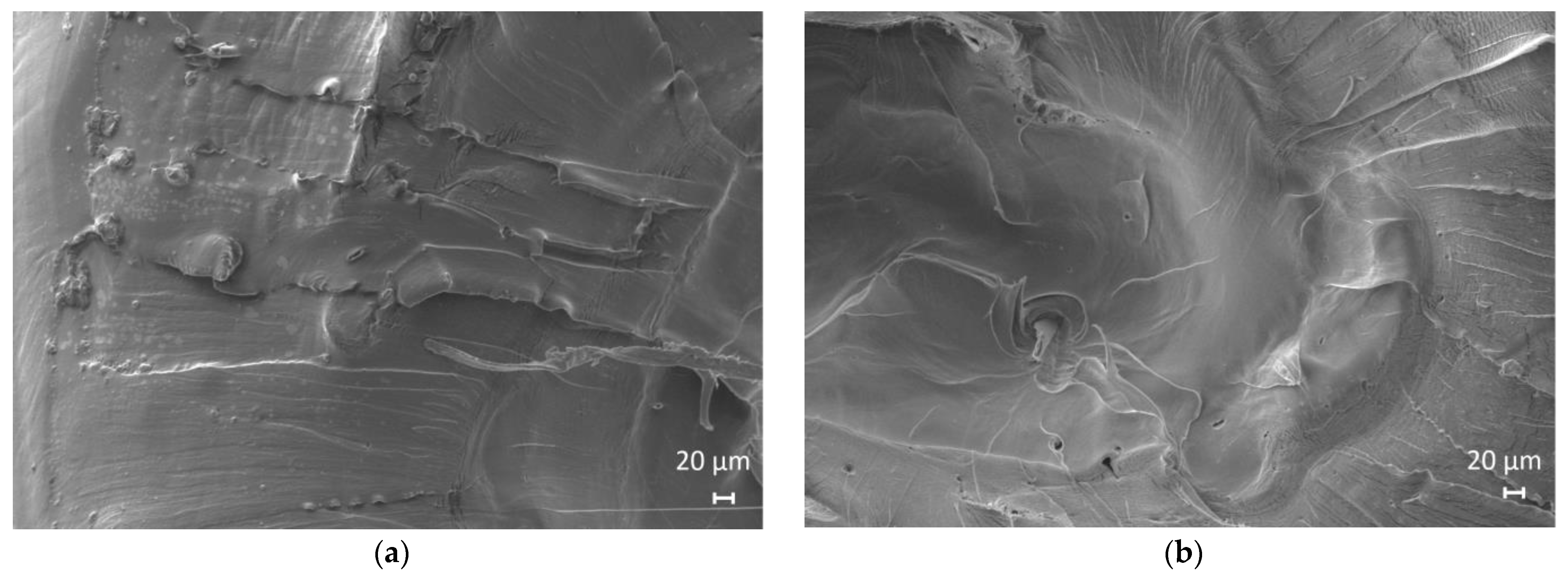

3.3. Mechanical Properties

- The results of the solubility parameter calculations, which highlighted how molecule 4 is the one with and values closest to the ones of PLA;

- When compared to the other monomer derivatives, compound 4 showed a higher plasticizing effect with a greater reduction in Tg.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Entry | [1] (M) | Catalyst (µL) | t (h) | T (°C) | Yield (%) |

|---|---|---|---|---|---|

| 1 | 0.8 | HCl 1 M (50) | 3 | 60 | 65 1 |

| 2 | 0.8 | H2SO4 conc. (50) | 1 | 60 | 58 1,3 |

| 3 | 0.5 | HCl 1 M. (50) | 3 | 80 | 76 1 |

| 4 | 0.5 | HCl conc. (50) | 3 | 80 | 73 1 |

| 5 | 1.5 | HCl conc. (25) | 3 | 90 | 78 1 |

| 6 | 0.3 | HCl conc. (25) | 3 | 90 | 87 1 80 2 |

| 7 | 0.3 | HCl conc. (25) | 3 | 100 | 90 1 88 2 |

| Functional Group | Fdi (J1/2cm3/2/mol) | Fpi (J1/2cm3/2/mol) | Ehi (J/mol) | (cm3/mol) |

|---|---|---|---|---|

| -OH | 210 | 500 | 20,000 | 12.45 |

| -COOH | 530 | 420 | 10,000 | 26.1 |

| -CH2- | 270 | 0 | 0 | 15.55 |

| -CH- | 80 | 0 | 0 | 9.56 |

| -CH3 | 420 | 0 | 0 | 21.55 |

| -COO- | 390 | 490 | 7000 | 23.7 |

References

- Arutyunov, V.S. The Concept of Sustainable Development and Real Challenges of Civilization. Her. Russ. Acad. Sci. 2021, 91, 102–110. [Google Scholar] [CrossRef]

- Unger, N. Global Climate Forcing by Criteria Air Pollutants. Annu. Rev. Environ. Resour. 2012, 37, 1–24. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Sokhansanj, S.; Wright, C.T.; Boardman, R.D.; Yancey, N.A. A Review on Biomass Classification and Composition, Co-Firing Issues and Pretreatment Methods; ASABE: St. Joseph, MI, USA, 2011; Volume 3, pp. 2053–2083. [Google Scholar] [CrossRef]

- Merchan, A.L.; Fischöder, T.; Hee, J.; Lehnertz, M.S.; Osterthun, O.; Pielsticker, S.; Schleier, J.; Tiso, T.; Blank, L.M.; Klankermayer, J.; et al. Chemical Recycling of Bioplastics: Technical Opportunities to Preserve Chemical Functionality as Path towards a Circular Economy. Green Chem. 2022, 24, 9428–9449. [Google Scholar] [CrossRef]

- Heredia-Guerrero, J.A.; Benítez, J.J.; Cataldi, P.; Paul, U.C.; Contardi, M.; Cingolani, R.; Bayer, I.S.; Heredia, A.; Athanassiou, A. All-Natural Sustainable Packaging Materials Inspired by Plant Cuticles. Adv. Sustain. Syst. 2017, 1, 1600024. [Google Scholar] [CrossRef]

- Heredia-Guerrero, J.A.; Athanassiou, A. Editorial: Non-Polysaccharide Plant Polymeric Materials. Front. Mater. 2016, 3, 15. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and Mechanical Properties of PLA, and Their Functions in Widespread Applications—A Comprehensive Review. Adv. Drug. Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Rasal, R.M.; Janorkar, A.V.; Hirt, D.E. Poly(Lactic Acid) Modifications. Prog. Polym. Sci. 2010, 35, 338–356. [Google Scholar] [CrossRef]

- Bocqué, M.; Voirin, C.; Lapinte, V.; Caillol, S.; Robin, J.-J. Petro-Based and Bio-Based Plasticizers: Chemical Structures to Plasticizing Properties. J. Polym. Sci. Part. A Polym. Chem. 2016, 54, 11–33. [Google Scholar] [CrossRef]

- Burgos, N.; Martino, V.P.; Jiménez, A. Characterization and Ageing Study of Poly(Lactic Acid) Films Plasticized with Oligomeric Lactic Acid. Polym. Degrad. Stab. 2013, 98, 651–658. [Google Scholar] [CrossRef]

- Dominguez-Candela, I.; Ferri, J.M.; Cardona, S.C.; Lora, J.; Fombuena, V. Dual Plasticizer/Thermal Stabilizer Effect of Epoxidized Chia Seed Oil (Salvia Hispanica L.) to Improve Ductility and Thermal Properties of Poly(Lactic Acid). Polymers 2021, 13, 1283. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Duart, S.; Montanes, N.; Torres-Giner, S.; Balart, R. Enhancement of the Mechanical and Thermal Properties of Injection-Molded Polylactide Parts by the Addition of Acrylated Epoxidized Soybean Oil. Mater. Des. 2018, 140, 54–63. [Google Scholar] [CrossRef]

- Shirai, M.A.; Grossmann, M.V.E.; Mali, S.; Yamashita, F.; Garcia, P.S.; Müller, C.M.O. Development of Biodegradable Flexible Films of Starch and Poly(Lactic Acid) Plasticized with Adipate or Citrate Esters. Carbohydr. Polym. 2013, 92, 19–22. [Google Scholar] [CrossRef] [PubMed]

- Gzyra-Jagieła, K.; Sulak, K.; Draczyński, Z.; Podzimek, S.; Gałecki, S.; Jagodzińska, S.; Borkowski, D. Modification of Poly(Lactic Acid) by the Plasticization for Application in the Packaging Industry. Polymers 2021, 13, 3651. [Google Scholar] [CrossRef] [PubMed]

- Gu, L.; Nessim, E.E.; Li, T.; Macosko, C.W. Toughening Poly(Lactic Acid) with Poly(Ethylene Oxide)-Poly(Propylene Oxide)-Poly(Ethylene Oxide) Triblock Copolymers. Polymer 2018, 156, 261–269. [Google Scholar] [CrossRef]

- Wadhi, M.M.; Weliam, R. Effect of Epoxidized Sunflower Oil on Polylactic Acid Properties. Res. Chem. Intermed. 2014, 40, 399–406. [Google Scholar] [CrossRef]

- Santos, E.F.; Oliveira, R.V.B.; Reiznautt, Q.B.; Samios, D.; Nachtigall, S.M.B. Sunflower-Oil Biodiesel-Oligoesters/Polylactide Blends: Plasticizing Effect and Ageing. Polym. Test 2014, 39, 23–29. [Google Scholar] [CrossRef]

- Chieng, B.W.; Ibrahim, N.A.; Then, Y.Y.; Loo, Y.Y. Epoxidized Vegetable Oils Plasticized Poly(Lactic Acid) Biocomposites: Mechanical, Thermal and Morphology Properties. Molecules 2014, 19, 16024–16038. [Google Scholar] [CrossRef]

- Azwar, E.; Yin, B.; Hakkarainen, M. Liquefied Biomass Derived Plasticizer for Polylactide. J. Chem. Technol. Biotechnol. 2013, 88, 897–903. [Google Scholar] [CrossRef]

- Reuters Staff, A Third of Food Is Wasted Making It Third-Bigggest Carbon Emitter. Available online: https://www.reuters.com/article/us-food-wastage-idUKBRE98A0E920130911 (accessed on 21 March 2023).

- Food Wastage Footprint. Impacts on Natural Resources. Summary Report FAO 2013. Available online: https://www.fao.org/3/i3347e/i3347e.pdf (accessed on 24 March 2023).

- Boccia, F.; Di Donato, P.; Covino, D.; Poli, A. Food Waste and Bio-Economy: A Scenario for the Italian Tomato Market. J. Clean Prod. 2019, 227, 424–433. [Google Scholar] [CrossRef]

- Heredia-Guerrero, J.A.; Heredia, A.; Domínguez, E.; Cingolani, R.; Bayer, I.S.; Athanassiou, A.; Benítez, J.J. Cutin from Agro-Waste as a Raw Material for the Production of Bioplastics. J. Exp. Bot 2017, 68, 5401–5410. [Google Scholar] [CrossRef]

- Dominguez, E.; Heredia-Guerrero, J.A.; Heredia, A. The Biophysical Design of Plant Cuticles: An Overview. New Phytol. 2011, 189, 938–949. [Google Scholar] [CrossRef] [PubMed]

- Casa, M.; Miccio, M.; De Feo, G.; Paulillo, A.; Chirone, R.; Paulillo, D.; Lettieri, P.; Chirone, R. A Brief Overview on Valorization of Industrial Tomato By-Products Using the Biorefinery Cascade Approach. Detritus 2021, 15, 31–39. [Google Scholar] [CrossRef]

- Benítez, J.J.; Osbild, S.; Guzman-Puyol, S.; Heredia, A.; Heredia-Guerrero, J.A. Bio-Based Coatings for Food Metal Packaging Inspired in Biopolyester Plant Cutin. Polymers 2020, 12, 942. [Google Scholar] [CrossRef]

- Tedeschi, G.; Benitez, J.J.; Ceseracciu, L.; Dastmalchi, K.; Itin, B.; Stark, R.E.; Heredia, A.; Athanassiou, A.; Heredia-Guerrero, J.A. Sustainable Fabrication of Plant Cuticle-Like Packaging Films from Tomato Pomace Agro-Waste, Beeswax, and Alginate. ACS Sustain. Chem. Eng. 2018, 6, 14955–14966. [Google Scholar] [CrossRef]

- Singha, S.; Gowda, V.; Hedenqvist, M.S. Plant Cuticle-Inspired Polyesters as Promising Green and Sustainable Polymer Materials. ACS Appl. Polym. Mater. 2021, 3, 4088–4100. [Google Scholar] [CrossRef]

- Manrich, A.; Moreira, F.K.V.; Otoni, C.G.; Lorevice, M.V.; Martins, M.A.; Mattoso, L.H.C. Hydrophobic Edible Films Made up of Tomato Cutin and Pectin. Carbohydr. Polym. 2017, 164, 83–91. [Google Scholar] [CrossRef]

- Escórcio, R.; Bento, A.; Tomé, A.S.; Correia, V.G.; Rodrigues, R.; Moreira, C.J.S.; Marion, D.; Bakan, B.; Silva Pereira, C. Finding a Needle in a Haystack: Producing Antimicrobial Cutin-Derived Oligomers from Tomato Pomace. ACS Sustain. Chem. Eng. 2022, 10, 11415–11427. [Google Scholar] [CrossRef]

- Cifarelli, A.; Cigognini, I.; Bolzoni, L.; Montanari, A. Cutin Isolated from Tomato Processing by-Products: Extraction Methods and Characterization. CYPRUS 2016 4th International Conference on Sustainable Solid Waste Management, 2016, 1–20. Available online: http://uest.ntua.gr/cyprus2016/proceedings/pdf/Cifarelli_et_al_Cutin_isolated_from_tomato_processing_by-products.pdf (accessed on 24 March 2023).

- Müller, A.J.; ÁVila, M.; Saenz, G.; Salazar, J. Crystallization of PLA-Based Materials, In Poly(lactic acid) Science and Technology: Processing, Properties, Additives and Applications. In RCS Polymer Chemistry Series; Jiménez, A., Peltzer, M., Ruseckaite, R., Eds.; The Royal Society of Chemistry: London, UK, 2015; pp. 66–98. [Google Scholar]

- ASTM International. ASTM International Standard Test Method to Tensile Properties of Plastics; ASTM International: West Conshohocken, PA, USA, 2010; Volume D368-10. [Google Scholar]

- Osman, S.F.; Irwin, P.; Fett, W.F.; O’Conno, J.V.; Parris, N. Preparation, Isolation, and Characterization of Cutin Monomers and Oligomers from Tomato Peels. J. Agric. Food Chem. 1999, 47, 799–802. [Google Scholar] [CrossRef]

- Ahmed, A.; Crawford, T.; Gould, S.; Ha, Y.S.; Hollrah, M.; Noor-E-Ain, F.; Dickman, M.B.; Dussault, P.H. Synthesis of (R)-and (S)-10,16-Dihydroxyhexadecanoic Acid: Cutin Stereochemistry and Fungal Activation. Phytochemistry 2003, 63, 47–52. [Google Scholar] [CrossRef] [PubMed]

- van Krevelen, D.W.; te Nijenhuis, K. Properties of Polymers: Their Correlation with Chemical Structure; Their Numerical Estimation and Prediction from Additive Group Contributions, 4th ed.; Elservier: Amsterdam, The Netherlands, 2009; pp. 201–222. [Google Scholar]

- Adamska, K.; Voelkel, A.; Berlińska, A. The Solubility Parameter for Biomedical Polymers—Application of Inverse Gas Chromatography. J. Pharm. Biomed. Anal. 2016, 127, 202–206. [Google Scholar] [CrossRef]

| Entry | Monomer | Tg (°C) | Tm (°C) |

|---|---|---|---|

| 1 | 1 | −45 | 59 |

| 2 | 2 | −34 | 12 |

| 3 | 3 | −59 | −15 |

| 4 | 4 | −61 | −10 |

| Entry | δ (J/cm3)1/2 | 10,16-diHHDA (1) | 10,16-diHHDME (2) | 10,16-diAHDA (3) | 10,16-diAHDME (4) | PLA * |

|---|---|---|---|---|---|---|

| 1 | 17.3 | 17.1 | 17.5 | 17.3 | 19.8 | |

| 2 | 3.9 | 3.7 | 3.1 | 4.0 | 4.0 | |

| 3 | 13.4 | 12.6 | 8.4 | 7.6 | 6.7 | |

| 4 | 22.2 | 21.6 | 19.7 | 19.3 | 22.0 |

| Entry | Mixture | [Monomer] (% w/w) | Tg (°C) | Tm (°C) | Crystallinity (%) |

|---|---|---|---|---|---|

| 1 | PLA | // | 64 | 158 | 42 |

| 2 | PLA−1−10 | 1, 10 | 61 | 153 | 32 |

| 3 | PLA−1−20 | 1, 20 | 59 | 152 | 30 |

| 4 | PLA−2−20 | 2, 20 | 59 | 149 | 41 |

| 5 | PLA−2−30 | 2, 30 | 57 | 148 | 47 |

| 6 | PLA−2−40 | 2, 40 | 50 | 149 | 44 |

| 7 | PLA−3−20 | 3, 20 | 47 | 151 | 44 |

| 8 | PLA−3−30 | 3, 30 | 39 | 150 | 29 |

| 9 | PLA−3−40 | 3, 40 | 49 | 152 | 49 |

| 10 | PLA−4−20 | 4, 20 | 49 | 151 | 45 |

| 11 | PLA−4−30 | 4, 30 | 36 | 150 | 45 |

| 12 | PLA−4−40 | 4, 40 | 34 | 150 | 48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Righetti, G.I.C.; Nasti, R.; Beretta, G.; Levi, M.; Turri, S.; Suriano, R. Unveiling the Hidden Properties of Tomato Peels: Cutin Ester Derivatives as Bio-Based Plasticizers for Polylactic Acid. Polymers 2023, 15, 1848. https://doi.org/10.3390/polym15081848

Righetti GIC, Nasti R, Beretta G, Levi M, Turri S, Suriano R. Unveiling the Hidden Properties of Tomato Peels: Cutin Ester Derivatives as Bio-Based Plasticizers for Polylactic Acid. Polymers. 2023; 15(8):1848. https://doi.org/10.3390/polym15081848

Chicago/Turabian StyleRighetti, Grazia Isa C., Rita Nasti, Giangiacomo Beretta, Marinella Levi, Stefano Turri, and Raffaella Suriano. 2023. "Unveiling the Hidden Properties of Tomato Peels: Cutin Ester Derivatives as Bio-Based Plasticizers for Polylactic Acid" Polymers 15, no. 8: 1848. https://doi.org/10.3390/polym15081848

APA StyleRighetti, G. I. C., Nasti, R., Beretta, G., Levi, M., Turri, S., & Suriano, R. (2023). Unveiling the Hidden Properties of Tomato Peels: Cutin Ester Derivatives as Bio-Based Plasticizers for Polylactic Acid. Polymers, 15(8), 1848. https://doi.org/10.3390/polym15081848