Mechanical, Thermal, and Fire Retardant Properties of Rice Husk Biochar Reinforced Recycled High-Density Polyethylene Composite Material

Abstract

1. Introduction

2. Materials and Methods

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. A novel approach in organic waste utilization through biochar addition in wood/polypropylene composites. Waste Manag. 2015, 38, 132–140. [Google Scholar] [CrossRef] [PubMed]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. Structure–mechanics property relationship of waste derived biochars. Sci. Total Environ. 2015, 538, 611–620. [Google Scholar] [CrossRef] [PubMed]

- Ho, M.P.; Lau, K.T.; Wang, H.; Hui, D. Improvement on the properties of polylactic acid (PLA) using bamboo charcoal particles. Compos. Part B Eng. 2015, 81, 14–25. [Google Scholar] [CrossRef]

- Nan, N.; DeVallance, D.B.; Xie, X.; Wang, J. The effect of bio-carbon addition on the electrical, mechanical, and thermal properties of polyvinyl alcohol/biochar composites. J. Compos. Mater. 2016, 50, 1161–1168. [Google Scholar] [CrossRef]

- Behazin, E.; Misra, M.; Mohanty, A.K. Sustainable biocarbon from pyrolyzed perennial grasses and their effects on impact modified polypropylene biocomposites. Compos. Part B Eng. 2017, 118, 116–124. [Google Scholar] [CrossRef]

- DeVallance, D.B.; Oporto, G.S.; Quigley, P. Investigation of hardwood biochar as a replacement for wood flour in wood–polypropylene composites. J. Elastomers Plast. 2016, 48, 510–522. [Google Scholar] [CrossRef]

- Ahmetli, G.; Kocaman, S.; Ozaytekin, I.; Bozkurt, P. Epoxy composites based on inexpensive char filler obtained from plastic waste and natural resources. Polym. Compos. 2013, 34, 500–509. [Google Scholar] [CrossRef]

- Bilal, A.; Lin, R.; Jayaraman, K. Analysis of the mechanical properties of rice husk reinforced polyethylene composites using experiments with mixtures. In Advanced Materials Research; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2013; Volume 747, pp. 395–398. [Google Scholar]

- Ashori, A.; Nourbakhsh, A. Bio-based composites from waste agricultural residues. Waste Manag. 2010, 30, 680–684. [Google Scholar] [CrossRef]

- Kim, N.K.; Dutta, S.; Bhattacharyya, D. A review of flammability of natural fibre reinforced polymeric composites. Compos. Sci. Technol. 2018, 162, 64–78. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. Biocomposites from waste derived biochars: Mechanical, thermal, chemical, and morphological properties. Waste Manag. 2016, 49, 560–570. [Google Scholar] [CrossRef]

- Xie, X.; Goodell, B.; Qian, Y.; Peterson, M.; Jellison, J. Significance of the heating rate on the physical properties of carbonized maple wood. Holzforschung 2008, 62, 591–596. [Google Scholar] [CrossRef]

- Marsh, H. CHAPTER 6-activation processes (chemical). In Activated Carbon; Marsh, H., Rodríguez-Reinoso, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2006; pp. 322–365. [Google Scholar] [CrossRef]

- Väisänen, T.; Haapala, A.; Lappalainen, R.; Tomppo, L. Utilization of agricultural and forest industry waste and residues in natural fiber-polymer composites: A review. Waste Manag. 2016, 54, 62–73. [Google Scholar] [CrossRef] [PubMed]

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef] [PubMed]

- Ayrilmis, N.; Kwon, J.H.; Han, T.H.; Durmus, A. Effect of wood-derived charcoal content on properties of wood plastic composites. Mater. Res. 2015, 18, 654–659. [Google Scholar] [CrossRef]

- Das, O.; Kim, N.K.; Hedenqvist, M.S.; Lin, R.J.; Sarmah, A.K.; Bhattacharyya, D. An attempt to find a suitable biomass for biochar-based polypropylene biocomposites. Environ. Manag. 2018, 62, 403–413. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Yi, W.; Li, Z.; Wang, L.; Cai, H. Mechanical properties of rice husk biochar reinforced high density polyethylene composites. Polymers 2018, 10, 286. [Google Scholar] [CrossRef]

- Sundara, K.R.; Arumugaprabu, V.; Poomari Muthukumar, G.; Vigneshwaran, S.; Deepan Saravana Kumar, S.R.; Muneesh Raj, R. Biochar from Sugarcane Waste in Polymer Matrix Composite. Int. J. Innov. Technol. Explor. Eng. 2019, 9, 350–352. [Google Scholar]

- Sundarakannan, R.; Arumugaprabu, V.; Manikandan, V.; Vigneshwaran, S. Mechanical property analysis of biochar derived from cashew nut shell waste reinforced polymer matrix. Mater. Res. Express 2020, 6, 125349. [Google Scholar] [CrossRef]

- Huber, T.; Misra, M.; Mohanty, A.K. The effect of particle size on the rheological properties of polyamide 6/biochar composites. In AIP Conference Proceedings 2015, Proceedings of the 30th International Conference of the Polymer Processing Society (PPS-30), Cleveland, OH, USA, 6–12 June 2014; AIP Publishing: New York, NY, USA, 2015; Volume 1664, p. 150004. [Google Scholar] [CrossRef]

- Khan, A.; Savi, P.; Quaranta, S.; Rovere, M.; Giorcelli, M.; Tagliaferro, A.; Jia, C.Q. Low-cost carbon fillers to improve mechanical properties and conductivity of epoxy composites. Polymers 2017, 9, 642. [Google Scholar] [CrossRef]

- Bartoli, M.; Giorcelli, M.; Rosso, C.; Rovere, M.; Jagdale, P.; Tagliaferro, A. Influence of commercial biochar fillers on brittleness/ductility of epoxy resin composites. Appl. Sci. 2019, 9, 3109. [Google Scholar] [CrossRef]

- Pandey, A.; Telang, A.; Rana, R. Mechanical characterization of bio-char made hybrid composite. Int. J. Eng. Res. Appl. 2016, 6, 26–31. [Google Scholar]

- Ketabchi, M.R.; Khalid, M.; Walvekar, R. Effect of oil palm EFB-biochar on properties of PP/EVA composites. J. Eng. Sci. Technol. 2017, 12, 797–808. [Google Scholar]

- Zhang, Q.; Cai, H.; Ren, X.; Kong, L.; Liu, J.; Jiang, X. The dynamic mechanical analysis of highly filled rice husk biochar/high-density polyethylene composites. Polymers 2017, 9, 628. [Google Scholar] [CrossRef] [PubMed]

- Bajwa, D.S.; Adhikari, S.; Shojaeiarani, J.; Bajwa, S.G.; Pandey, P.; Shanmugam, S.R. Characterization of bio-carbon and ligno-cellulosic fiber reinforced bio-composites with compatibilizer. Constr. Build. Mater. 2019, 204, 193–202. [Google Scholar] [CrossRef]

- Das, O.; Kim, N.K.; Kalamkarov, A.L.; Sarmah, A.K.; Bhattacharyya, D. Biochar to the rescue: Balancing the fire performance and mechanical properties of polypropylene composites. Polym. Degrad. Stab. 2017, 144, 485–496. [Google Scholar] [CrossRef]

- Dahal, R.K.; Acharya, B.; Saha, G.; Bissessur, R.; Dutta, A.; Farooque, A. Biochar as a filler in glassfiber reinforced composites: Experimental study of thermal and mechanical properties. Compos. Part B Eng. 2019, 175, 107169. [Google Scholar] [CrossRef]

- Li, S.; Xu, Y.; Jing, X.; Yilmaz, G.; Li, D.; Turng, L.S. Effect of carbonization temperature on mechanical properties and biocompatibility of biochar/ultra-high molecular weight polyethylene composites. Compos. Part B Eng. 2020, 196, 108120. [Google Scholar] [CrossRef]

- Zhang, Q.; Khan, M.U.; Lin, X.; Cai, H.; Lei, H. Temperature varied biochar as a reinforcing filler for high- density polyethylene composites. Compos. Part B Eng. 2019, 175, 107151. [Google Scholar] [CrossRef]

- Arrigo, R.; Bartoli, M.; Malucelli, G. Poly (lactic acid)–biochar biocomposites: Effect of processing and filler content on rheological, thermal, and mechanical properties. Polymers 2020, 12, 892. [Google Scholar] [CrossRef] [PubMed]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar physicochemical properties: Pyrolysis temperature and feedstock kind effects. Rev. Environ. Sci. Bio/Technol. 2020, 19, 191–215. [Google Scholar] [CrossRef]

- Das, O.; Hedenqvist, M.S.; Johansson, E.; Olsson, R.T.; Loho, T.A.; Capezza, A.J.; Holder, S. An all- gluten biocomposite: Comparisons with carbon black and pine char composites. Compos. Part A Appl. Sci. Manuf. 2019, 120, 42–48. [Google Scholar] [CrossRef]

- Bridgwater, A.V. Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenergy 2012, 38, 68–94. [Google Scholar] [CrossRef]

- Lua, A.C.; Yang, T.; Guo, J. Effects of pyrolysis conditions on the properties of activated carbons prepared from pistachio-nut shells. J. Anal. Appl. Pyrolysis 2004, 72, 279–287. [Google Scholar] [CrossRef]

- Özçimen, D.; Ersoy-Meriçboyu, A. A study on the carbonization of grapeseed and chestnut shell. Fuel Process. Technol. 2008, 89, 1041–1046. [Google Scholar] [CrossRef]

- Hasan, M.M.; Bachmann, R.T.; Loh, S.K.; Manroshan, S.; Ong, S.K. Effect of pyrolysis temperature and time on properties of palm kernel shell-based biochar. IOP Conf. Ser. Mater. Sci. Eng. 2019, 548, 012020. [Google Scholar] [CrossRef]

- Elnour, A.Y.; Alghyamah, A.A.; Shaikh, H.M.; Poulose, A.M.; Al-Zahrani, S.M.; Anis, A.; Al-Wabel, M.I. Effect of pyrolysis temperature on biochar microstructural evolution, physicochemical characteristics, and its influence on biochar/polypropylene composites. Appl. Sci. 2019, 9, 1149. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, D.; Lu, W.; Khan, M.U.; Xu, H.; Yi, W.; Zou, R. Production of high-density polyethylene biocomposites from rice husk biochar: Effects of varying pyrolysis temperature. Sci. Total Environ. 2020, 738, 139910. [Google Scholar] [CrossRef] [PubMed]

- Ayadi, R.; Koubaa, A.; Braghiroli, F.; Migneault, S.; Wang, H.; Bradai, C. Effect of the pyro-gasification temperature of wood on the physical and mechanical properties of biochar-polymer biocomposites. Materials 2020, 13, 1327. [Google Scholar] [CrossRef] [PubMed]

- Hahn, A.; Gerdts, G.; Völker, C.; Niebühr, V. Using FTIRS as pre-screening method for detection of microplastic in bulk sediment samples. Sci. Total Environ. 2019, 689, 341–346. [Google Scholar] [CrossRef]

- Song, B.; Chen, M.; Zhao, L.; Qiu, H.; Cao, X. Physicochemical property and colloidal stability of micron- and nano-particle biochar derived from a variety of feedstock sources. Sci. Total Environ. 2019, 661, 685–695. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, D.; Xu, H.; Lu, W.; Ren, X.; Cai, H.; Mateo, W. Biochar filled high-density polyethylene composites with excellent properties: Towards maximizing the utilization of agricultural wastes. Ind. Crops Prod. 2020, 146, 112185. [Google Scholar] [CrossRef]

- Zhang, Q.; Lei, H.; Cai, H.; Han, X.; Lin, X.; Qian, M.; Zhao, Y.; Huo, E.; Villota, E.M.; Mateo, W. Improvement on the properties of microcrystalline cellulose/polylactic acid composites by using activated biochar. J. Clean. Prod. 2020, 252, 119898. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, H.; Lu, W.; Zhang, D.; Ren, X.; Yu, W.; Lei, H. Properties evaluation of biochar/high- density polyethylene composites: Emphasizing the porous structure of biochar by activation. Sci. Total Environ. 2020, 737, 139770. [Google Scholar] [CrossRef] [PubMed]

- Kai, X.; Li, R.; Yang, T.; Shen, S.; Ji, Q.; Zhang, T. Study on the co-pyrolysis of rice straw and high density polyethylene blends using TG-FTIR-MS. Energy Convers. Manag. 2017, 146, 20–33. [Google Scholar] [CrossRef]

- Jindo, K.; Mizumoto, H.; Sawada, Y.; Sanchez-Monedero, M.A.; Sonoki, T. Physical and chemical characterizations of biochars derived from different agricultural residues. Biogeosci. Discuss. 2014, 11, 6613–6621. [Google Scholar] [CrossRef]

- Wei, L.; Huang, Y.; Li, Y.; Huang, L.; Mar, N.N.; Huang, Q.; Liu, Z. Biochar characteristics produced from rice husks and their sorption properties for the acetanilide herbicide metolachlor. Environ. Sci. Pollut. Res. 2017, 24, 4552–4561. [Google Scholar] [CrossRef] [PubMed]

- Fu, S.Y.; Feng, X.Q.; Lauke, B.; Mai, Y.W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Compos. Part B Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Nasser, J.; Lin, J.; Steinke, K.; Sodano, H.A. Enhanced interfacial strength of aramid fiber reinforced composites through adsorbed aramid nanofiber coatings. Compos. Sci. Technol. 2019, 174, 125–133. [Google Scholar] [CrossRef]

- Siebert, H.M.; Wilker, J.J. Deriving commercial level adhesive performance from a bio-based mussel mimetic polymer. ACS Sustain. Chem. Eng. 2019, 7, 13315–13323. [Google Scholar] [CrossRef]

- Goud, V.; Alagirusamy, R.; Das, A.; Kalyanasundaram, D. Influence of various forms of polypropylene matrix (fiber, powder and film states) on the flexural strength of carbon-polypropylene composites. Compos. Part B Eng. 2019, 166, 56–64. [Google Scholar] [CrossRef]

- Oliveira, L.Á.; Santos, J.C.; Panzera, T.H.; Freire, R.T.; Vieira, L.M.; Scarpa, F. Evaluation of hybrid-short-coir-fibre-reinforced composites via full factorial design. Compos. Struct. 2018, 202, 313–323. [Google Scholar] [CrossRef]

- Kaymakci, A.; Ayrilmis, N. Investigation of correlation between Brinell hardness and tensile strength of wood plastic composites. Compos. Part B Eng. 2014, 58, 582–585. [Google Scholar] [CrossRef]

- Manzello, S.L. (Ed.) Encyclopedia of Wildfires and Wildland-Urban Interface (WUI) Fires; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- De Bhowmick, G.; Sarmah, A.K.; Sen, R. Production and characterization of a value added biochar mix using seaweed, rice husk and pine sawdust: A parametric study. J. Clean. Prod. 2018, 200, 641–656. [Google Scholar] [CrossRef]

- Chen, C.; Yan, X.; Xu, Y.; Yoza, B.A.; Wang, X.; Kou, Y.; Ye, H.; Wang, Q.; Li, Q.X. Activated petroleum waste sludge biochar for efficient catalytic ozonation of refinery wastewater. Sci. Total Environ. 2019, 651, 2631–2640. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Wang, J.; Ni, A.; Chen, H.; Shen, P. Synthesis of a novel phosphorous-nitrogen based charring agent and its application in flame-retardant HDPE/IFR composites. Polymers 2019, 11, 1062. [Google Scholar] [CrossRef] [PubMed]

| Sr. No.# | Recycled Pellets wt. % | Rice Husk Biochar wt. % | Nomenclature |

|---|---|---|---|

| 1 | 100 | 0 | Rec-HDPE |

| 2 | 90 | 10 | C10 |

| 3 | 80 | 20 | C20 |

| 4 | 70 | 30 | C30 |

| 5 | 60 | 40 | C40 |

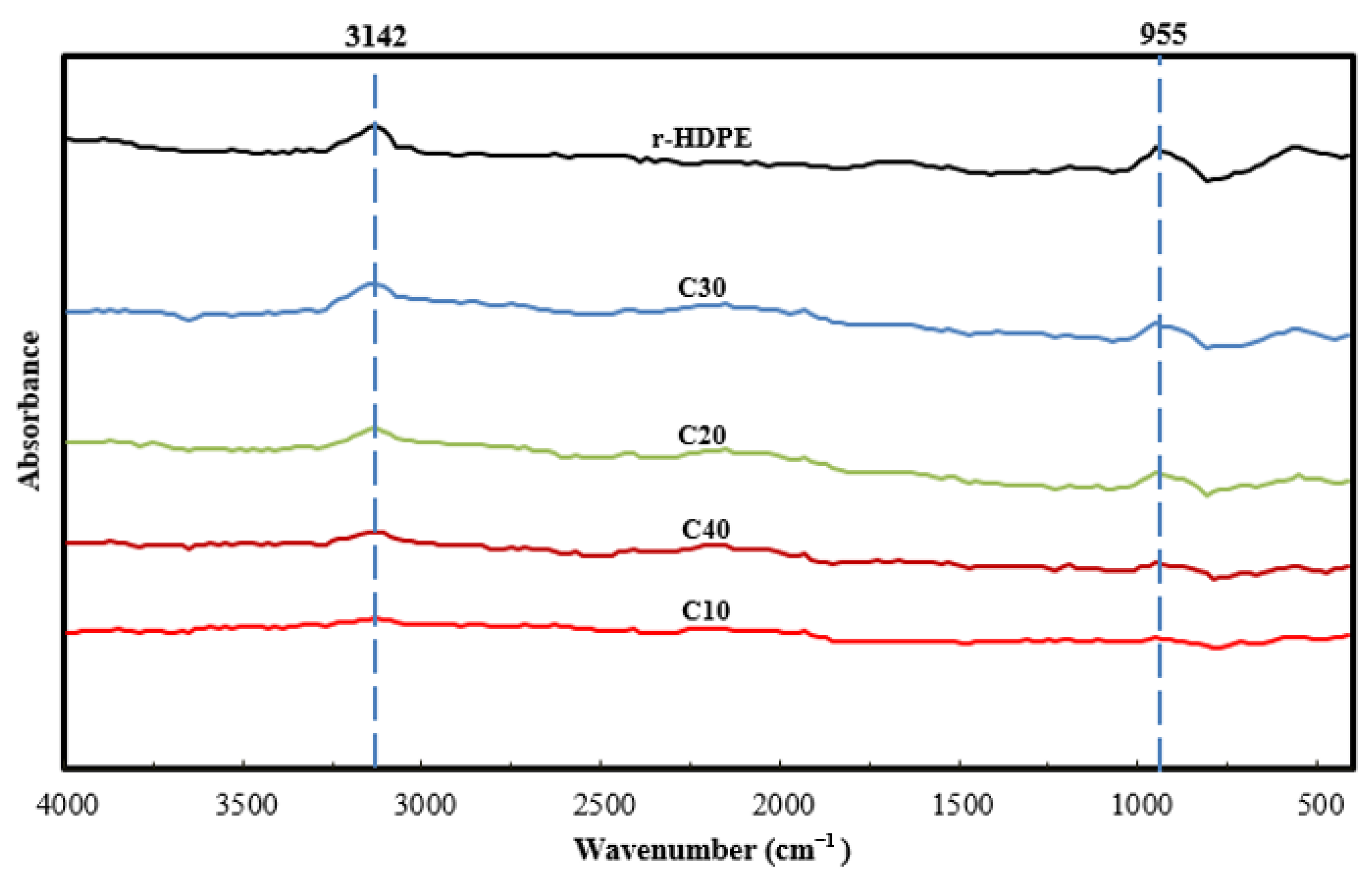

| Material | Wavelength (cm−1) | Bonds |

|---|---|---|

| Recycled HDPE | 2924 | C-H Stretching of Hydrocarbons |

| 1492 | C-H Bending of Alkanes | |

| Rice husk biochar | 3611 | O-H Stretching of Phenolic hydroxyl and Alcohol hydroxyl |

| 1614 | C=C Stretching of Hydroxyl Functional groups | |

| 955 | C-O Stretching of Carbohydrates | |

| 778 | Silicon Hydrogen Single Bond (Si-H) | |

| C10,C20,C30,C40 | 3611 | O-H Stretching of Phenolic hydroxyl and Alcohol hydroxyl |

| 2924 | C-H Stretching of Hydrocarbons | |

| 1614 | C=C Stretching of Hydroxyl Functional groups | |

| 1492 | C-H Bending of Alkanes | |

| 955 | C-O Stretching of Carbohydrates | |

| 778 | Silicon Hydrogen Single Bond (Si-H) |

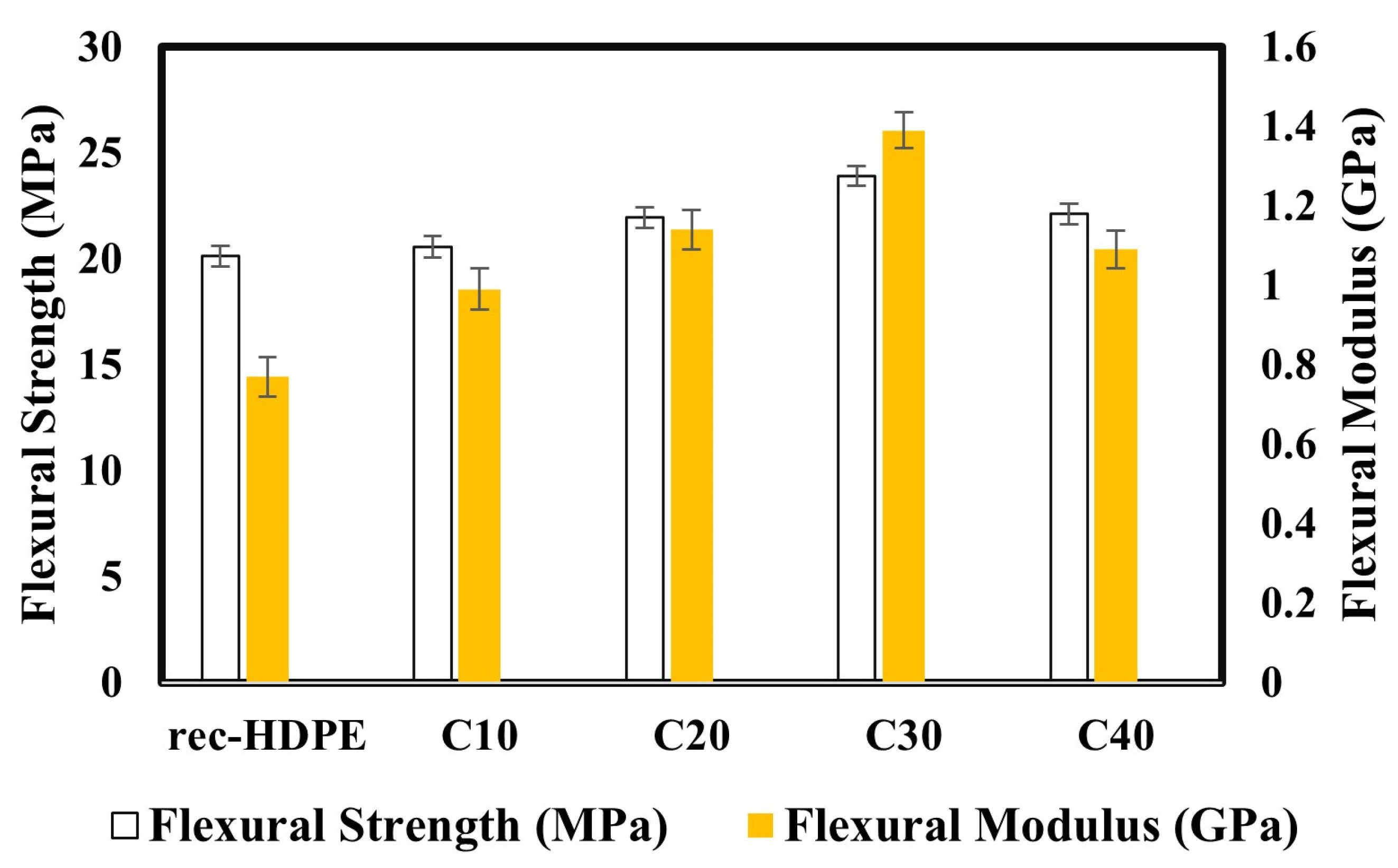

| Samples | Tensile Strength (MPa) | Tensile Modulus (GPa) | Flexural Strength (MPa) | Flexural Modulus (GPa) | Impact Strength (kJ/m2) |

|---|---|---|---|---|---|

| Rec-HDPE | 14.99 | 1.01 | 20.12 | 0.77 | 3.43 |

| C10 | 15.71 | 1.11 | 20.56 | 0.99 | 3.77 |

| C20 | 16.43 | 1.18 | 21.94 | 1.14 | 5.76 |

| C30 | 18.54 | 1.35 | 23.91 | 1.39 | 5.11 |

| C40 | 15.97 | 1.10 | 22.12 | 1.09 | 4.51 |

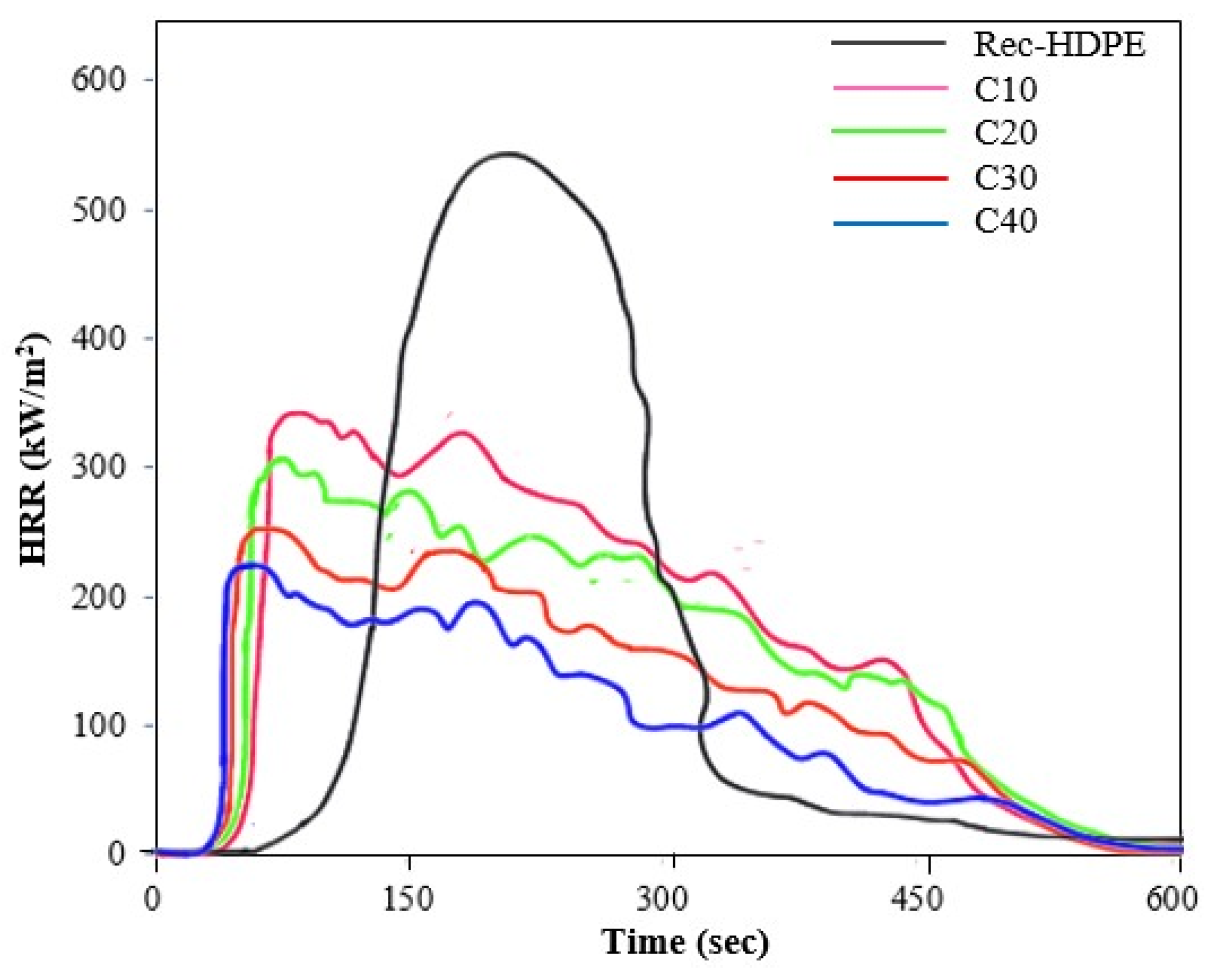

| Material Types | Cone Calorimetric Test | Horizontal Burning Test | Vertical Burning Test | LOI Test | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TTI (s) | TPHRR (s) | PHRR (kW/m2) | THR (MJ/m2) | Avg. Burning Time (min) | Avg. Burning Rate (mm/min) | Rating | Max. After Flame Time (s) | Total After Flame Time (s) | Max After Flame + After Glow Time (s) | Flame up to the Holding Clamp | Cotton Ignited by Flaming Drops | Rating | LOI (%) | |

| Rec-HDPE | 59 | 210 | 633 | 144 | 1.66 | 45.10 | Nil | 61 | 281 | - | Yes | Yes | Nil | 16.97 |

| C10 | 32 | 214 | 434 | 120 | 2.01 | 37.19 | HB | 63 | 304 | - | Yes | Yes | Nil | 18.82 |

| C20 | 28 | 222 | 399 | 103 | 2.30 | 32.66 | HB | 26 | 235 | 34 | No | Yes | V-2 | 20.73 |

| C30 | 30 | 229 | 344 | 83 | 2.64 | 28.38 | HB | 16 | 152 | 22 | No | No | V-1 | 23.01 |

| C40 | 31 | 233 | 301 | 68 | 2.89 | 25.99 | HB | 7 | 59 | 8 | No | No | V-1 | 25.28 |

| Type of Sample | T0 (Onset Degradation Temperature) (°C) | T1 (Start Degradation Temperature) (°C) | T2 (Finish Degradation Temperature) (°C) | Tpeak (Point of Inflection Temperature) (°C) | Residue % at 600 °C |

|---|---|---|---|---|---|

| Rec-HDPE | 425.09 | 402.34 | 522.12 | 459.63 | 0.39% |

| C10 | 435.86 | 406.12 | 528.05 | 466.41 | 10.95% |

| C20 | 440.93 | 410.87 | 535.67 | 471.18 | 21.47% |

| C30 | 438.14 | 416.03 | 541.31 | 477.35 | 32.09% |

| C40 | 442.36 | 421.21 | 548.88 | 481.22 | 43.51% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shah, A.u.R.; Imdad, A.; Sadiq, A.; Malik, R.A.; Alrobei, H.; Badruddin, I.A. Mechanical, Thermal, and Fire Retardant Properties of Rice Husk Biochar Reinforced Recycled High-Density Polyethylene Composite Material. Polymers 2023, 15, 1827. https://doi.org/10.3390/polym15081827

Shah AuR, Imdad A, Sadiq A, Malik RA, Alrobei H, Badruddin IA. Mechanical, Thermal, and Fire Retardant Properties of Rice Husk Biochar Reinforced Recycled High-Density Polyethylene Composite Material. Polymers. 2023; 15(8):1827. https://doi.org/10.3390/polym15081827

Chicago/Turabian StyleShah, Atta ur Rehman, Anas Imdad, Atiya Sadiq, Rizwan Ahmed Malik, Hussein Alrobei, and Irfan Anjum Badruddin. 2023. "Mechanical, Thermal, and Fire Retardant Properties of Rice Husk Biochar Reinforced Recycled High-Density Polyethylene Composite Material" Polymers 15, no. 8: 1827. https://doi.org/10.3390/polym15081827

APA StyleShah, A. u. R., Imdad, A., Sadiq, A., Malik, R. A., Alrobei, H., & Badruddin, I. A. (2023). Mechanical, Thermal, and Fire Retardant Properties of Rice Husk Biochar Reinforced Recycled High-Density Polyethylene Composite Material. Polymers, 15(8), 1827. https://doi.org/10.3390/polym15081827