Examination of Low-Cyclic Fatigue Tests and Poisson’s Ratio Depending on the Different Infill Density of Polylactide (PLA) Produced by the Fused Deposition Modeling Method

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Parameters of 3D Printing

2.3. Method of Testing

- K—degree of crystallinity;

- —melting enthalpy;

- —post-crystalline enthalpy;

- —melting enthalpy of crystalline polymer. For 100% pure polylactide, this is equal to 110 J/g.

3. Results and Discussion

3.1. Bulk Modulus

- E—Young’s modulus [Pa];

- ν—Poisson’s ratio.

3.2. Lame’s Parameter

- E—Young’s modulus;

- ν—Poisson’s ratio.

3.3. Kirchhoff’s Modulus

- E—Young’s modulus;

- ν—Poisson’s ratio.

3.4. Poisson’s Ratio

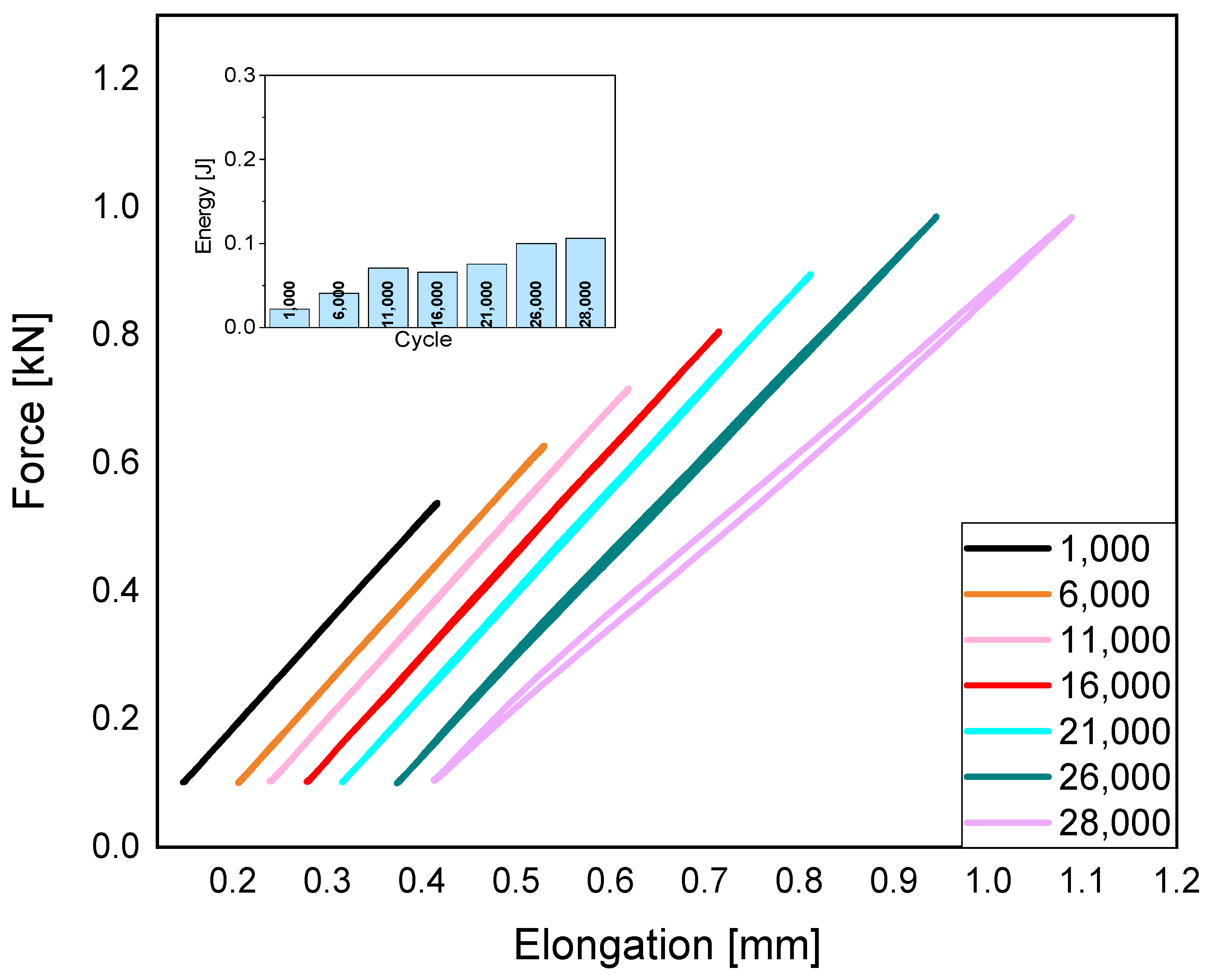

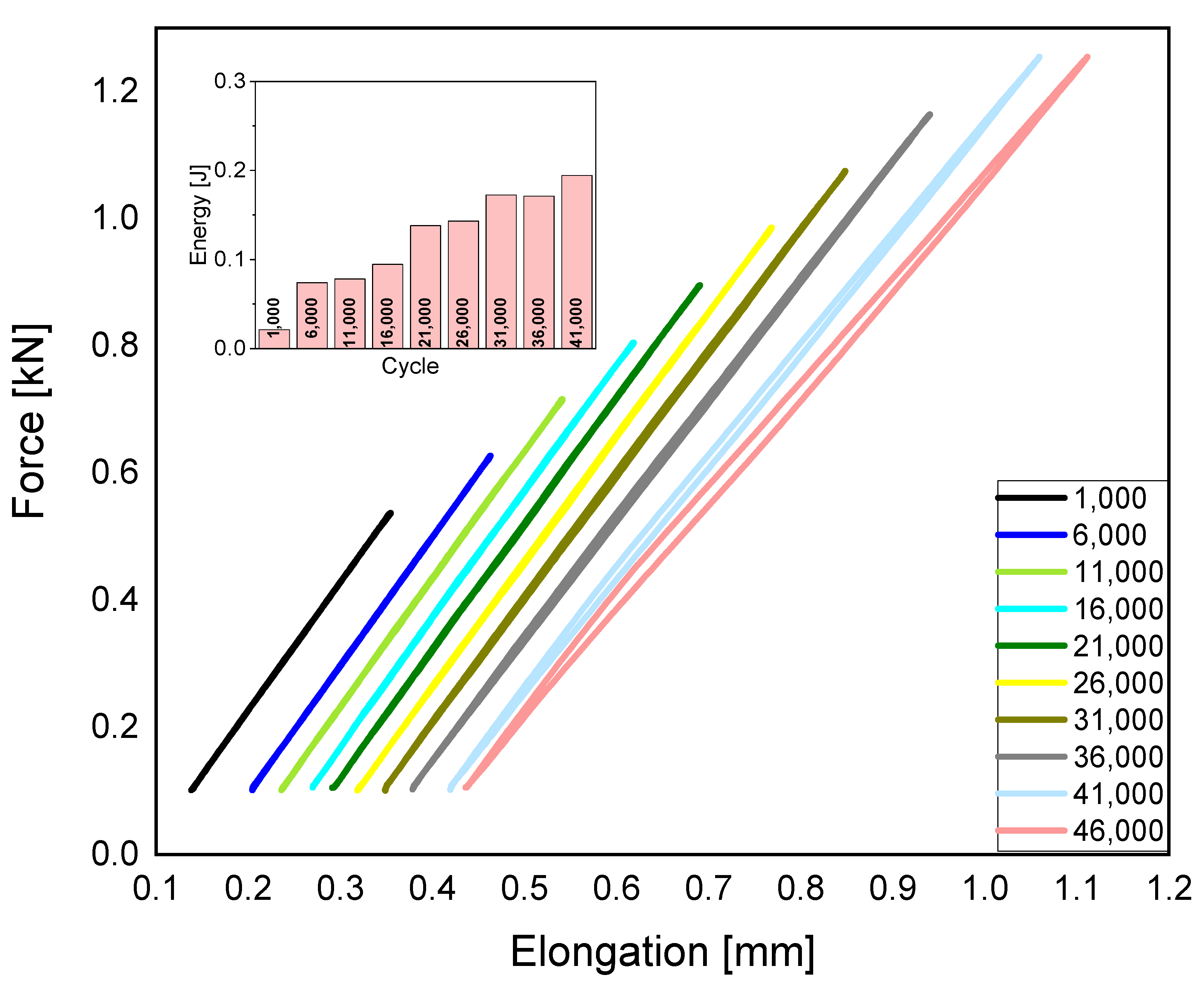

3.5. Fatigue Tests

- PLA with 100 infill density—Fmax = 1950 N;

- PLA with 75 infill density—Fmax = 1850 N;

- PLA with 50 infill density—Fmax = 1625 N.

- The mean value of the force for all samples—Fmax = 1.8 kN

- E—energy [J];

- yn—force value [kN];

- xn—elongation value [mm];

- n—number of points.

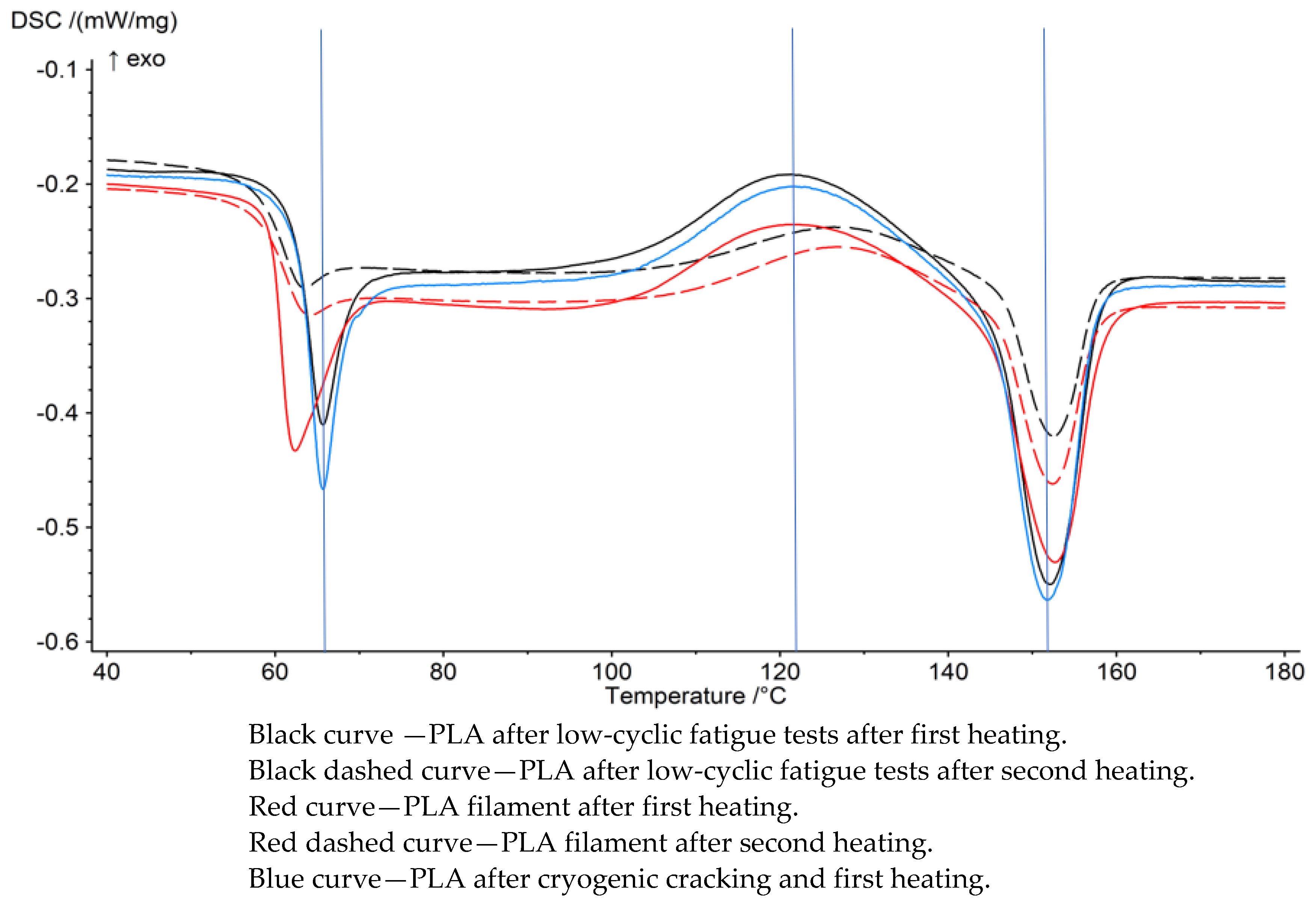

3.6. DSC

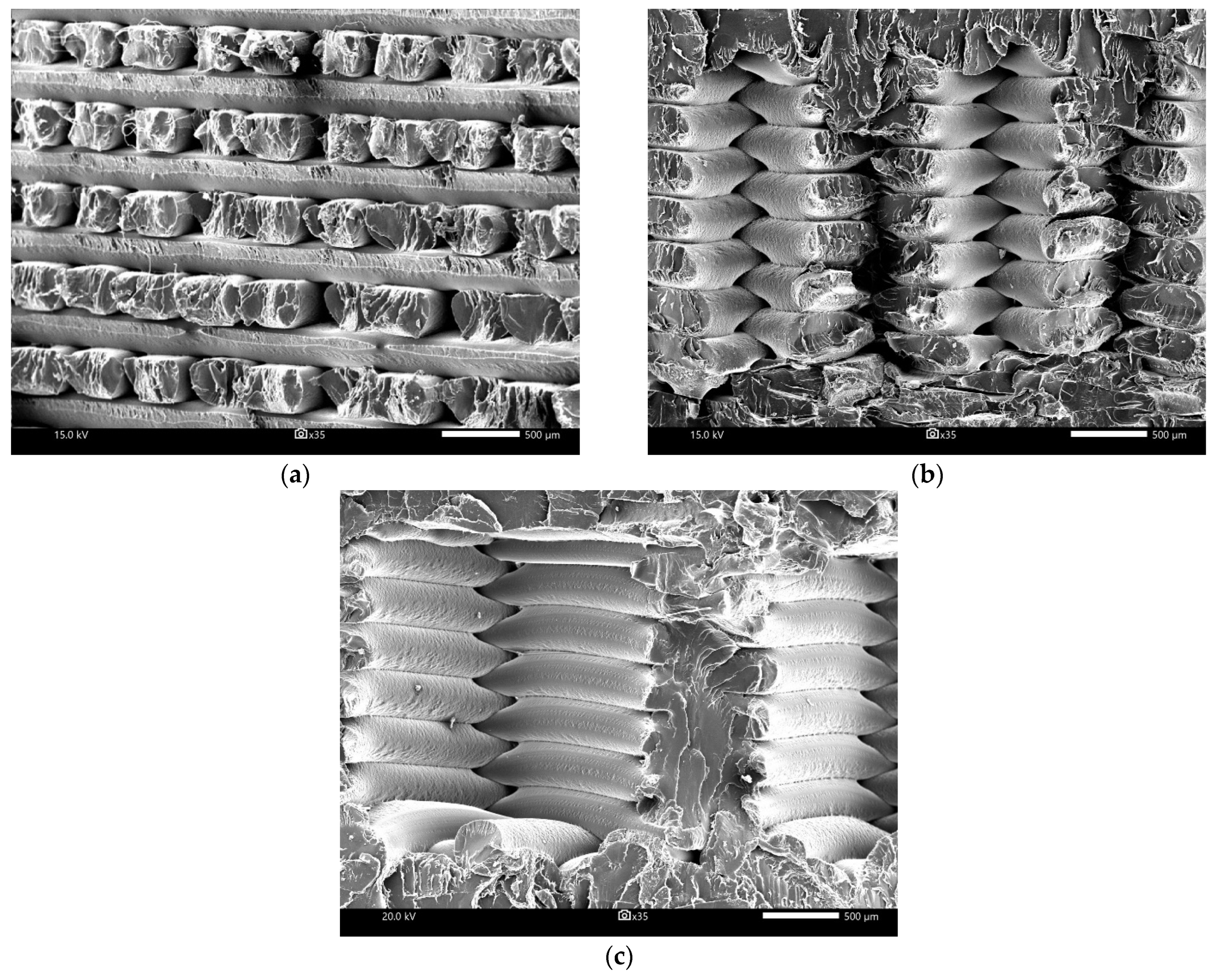

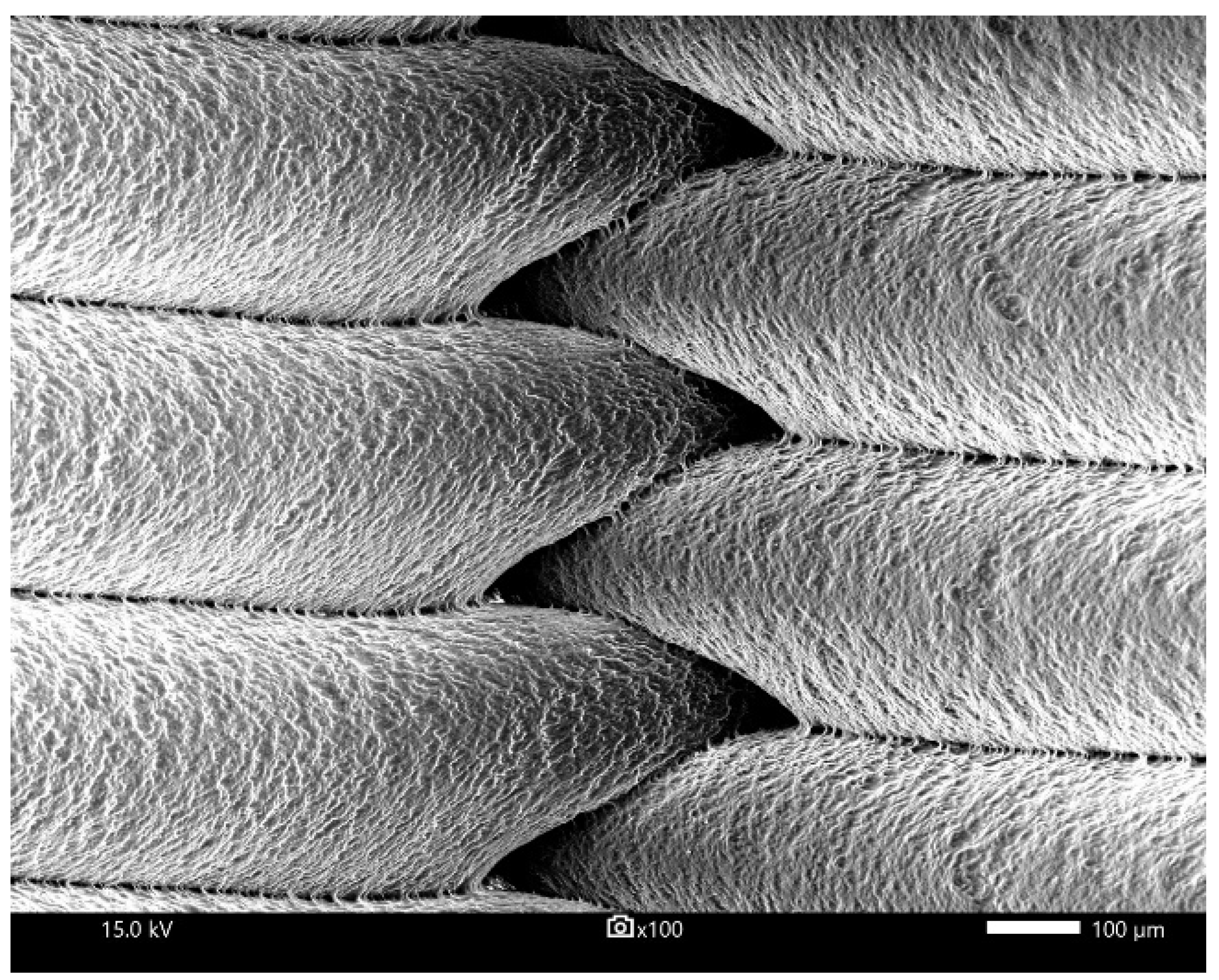

3.7. Scanning Electron Microscope

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Mazurchevici, A.D.; Nedelcu, D.; Popa, R. Additive manufacturing of composite materials by FDM technology: A review. Indian J. Eng. Mater. Sci. 2020, 27, 179–192. [Google Scholar]

- Bryll, K.; Piesowicz, E.; Szymański, P.; Ślączka, W.; Pijanowski, M. Polymer Composite Manufacturing by FDM 3D Printing Technology. MATEC Web Conf. 2018, 237, 02006. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.W.; Gou, J.H.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Garzon-Hernandez, S.; Garcia-Gonzalez, D.; Jérusalem, A.; Arias, A. Design of FDM 3D printed polymers: An experimental-modelling methodology for the prediction of mechanical properties. Mater. Des. 2020, 188, 108414. [Google Scholar] [CrossRef]

- Dou, H.; Cheng, Y.; Ye, W.; Zhang, D.; Li, J.; Miao, Z.; Rudykh, S. Effect of Process Parameters on Tensile Mechanical Properties of 3D Printing Continuous Carbon Fiber-Reinforced PLA Composites. Materials 2020, 13, 3850. [Google Scholar] [CrossRef] [PubMed]

- Gaweł, A.; Kuciel, S. The Study of Physico-Mechanical Properties of Polylactide Composites with Different Level of Infill Produced by the FDM Method. Polymers 2020, 12, 3056. [Google Scholar] [CrossRef]

- Sanatgar, R.H.; Campagne, C.; Nierstrasz, V. Investigation of the adhesion properties of direct 3D printing of polymers and nanocomposites on textiles: Effect of FDM printing process parameters. Appl. Surf. Sci. 2017, 403, 551–563. [Google Scholar] [CrossRef]

- Kiński, W.; Pietkiewicz, P. Influence of the Printing Nozzle Diameter on Tensile Strength of Produced 3D Models in FDM Technology. Agric. Eng. 2020, 24, 31–38. [Google Scholar] [CrossRef]

- Moradi, M.; Aminzadeh, A.; Rahmatabadi, D.; Hakimi, A. Experimental investigation on mechanical characterization of 3D printed PLA produced by fused deposition modeling (FDM). Mater. Res. Express 2021, 8, 035304. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Soltanmohammadi, K.; Aberoumand, M.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. Development of Pure Poly Vinyl Chloride (PVC) with Excellent 3D Printability and Macro- and Micro-Structural Properties. Macromol. Mater. Eng. 2022, 2200568, 1–12. [Google Scholar] [CrossRef]

- Moradi, M.; Aminzadeh, A.; Rahmatabadi, D.; Rasouli, S.A. Statistical and Experimental Analysis of Process Parameters of 3D Nylon Printed Parts by Fused Deposition Modeling: Response Surface Modeling and Optimization. J. Mater. Eng. Perform. 2021, 30, 5441–5454. [Google Scholar] [CrossRef]

- Islam, M.R.; Faisal, H.M.; Tarefder, R.A. Determining temperature and time dependent Poisson’s ratio of asphalt concrete using indirect tension test. Fuel 2015, 146, 119–124. [Google Scholar] [CrossRef]

- Ferreira, R.T.L.; Amatte, I.C.; Dutra, T.A.; Bürger, D. Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers. Compos. Part B Eng. 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Grasso, M.; Azzouz, L.; Ruiz-Hincapie, P.; Zarrelli, M.; Ren, G. Effect of temperature on the mechanical properties of 3D-printed PLA tensile specimens. Rapid Prototyp. J. 2018, 24, 1337–1346. [Google Scholar] [CrossRef]

- Erartsın, O.; van Drongelen, M.; Govaert, L.E. Identification of plasticity-controlled creep and fatigue failure mechanisms in transversely loaded unidirectional thermoplastic composites. J. Compos. Mater. 2021, 55, 1947–1965. [Google Scholar] [CrossRef]

- Shi, X.; Lian, C.; Shang, Y.; Zhang, H. Evolution of the dynamic fatigue failure of the adhesion between rubber and polymer cords. Polym. Test. 2015, 48, 175–182. [Google Scholar] [CrossRef]

- Brown, N. Fundamental Mechanism of Slow Crack Growth in Semi-Crystalline Polymers under a Constant Load. Mater. Sci. Appl. 2019, 10, 721–731. [Google Scholar] [CrossRef]

- Frank, A.; Berger, I.; Messicha, M.; Ek, C.-G.; Schuler, N.; Storheil, J.-M.; Mayrbäurl, E.; Heeley, S.; Krause, F.; Niemöller, L.; et al. Slow Crack Growth Resistance of Non-Virgin Polymers. In Proceedings of the 19th Plastic Pipes Conference PPXIX, Las Vegas, NV, USA, 24–26 November 2018. [Google Scholar]

- Kanters, M.J.; Kurokawa, T.; Govaert, L.E. Competition between plasticity-controlled and crack-growth controlled failure in static and cyclic fatigue of thermoplastic polymer systems. Polym. Test. 2016, 50, 101–110. [Google Scholar] [CrossRef]

- Lin, S.; Ni, J.; Zheng, D.; Zhao, X. Fracture and fatigue of ideal polymer networks. Extreme Mech. Lett. 2021, 48, 101399. [Google Scholar] [CrossRef]

- Rizal, S.; Saharudin, N.; Olaiya, N.; Khalil, H.; Haafiz, M.; Ikramullah, I.; Muksin, U.; Olaiya, F.; Abdullah, C.; Yahya, E. Functional Properties and Molecular Degradation of Schizostachyum Brachycladum Bamboo Cellulose Nanofibre in PLA-Chitosan Bionanocomposites. Molecules 2021, 26, 2008. [Google Scholar] [CrossRef]

- Zhong, K.; Zhang, Q.; Tong, L.; Liu, L.; Zhou, X.; Zhou, S. Molecular weight degradation and rheological properties of schizophyllan under ultrasonic treatment. Ultrason. Sonochemistry 2015, 23, 75–80. [Google Scholar] [CrossRef] [PubMed]

- Rahmatabadi, D.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Baghani, M. 3D printing of PLA-TPU with different component ratios: Fracture toughness, mechanical properties, and morphology. J. Mater. Res. Technol. 2022, 21, 3970–3981. [Google Scholar] [CrossRef]

- Mofokeng, J.; Luyt, A. Morphology and thermal degradation studies of melt-mixed poly(lactic acid) (PLA)/poly(ε-caprolactone) (PCL) biodegradable polymer blend nanocomposites with TiO2 as filler. Polym. Test. 2015, 45, 93–100. [Google Scholar] [CrossRef]

- Le, T.-T.; Le, M.V. Nanoscale Effect Investigation for Effective Bulk Modulus of Particulate Polymer Nanocomposites Using Micromechanical Framework. Adv. Mater. Sci. Eng. 2021, 2021, 1563845. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y. A Core-Shell Structure for Interphase Regions Surrounding Nanoparticles to Predict the Shear, Bulk and Young’s Polymer Moduli of Particulate Nanocomposites. Phys. Mesomech. 2020, 23, 89–96. [Google Scholar] [CrossRef]

- Hong, X.; Daming, W.; Ying, L.; Yajun, Z. Research on Measurement Method for Polymer Melt Bulk Modulus of Elasticity. Procedia Eng. 2011, 16, 72–78. [Google Scholar] [CrossRef]

- ZWu, Z.; Zhao, J.; Wu, W.; Wang, P.; Wang, B.; Li, G.; Zhang, S. Radial Compressive Property and the Proof-of-Concept Study for Realizing Self-expansion of 3D Printing Polylactic Acid Vascular Stents with Negative Poisson’s Ratio Structure. Materials 2018, 11, 1357. [Google Scholar] [CrossRef]

| Infill Density [%] | Young’s Modulus E [MPa] | Poisson’s Ratio v | Bulk Modulus K [MPa] | Shear Modulus G [MPa] |

|---|---|---|---|---|

| 100 | 2553 | 0.35 | −4522 | 801 |

| 75 | 2188 | 0.38 | −1137 | 601 |

| 50 | 2004 | 0.41 | −600 | 478 |

| Materials | Number of Cycles | Maximum Force [kN] | Energy [J] |

|---|---|---|---|

| PLA50 | 28,325 | 0.99 | 0.86 |

| PLA75 | 31,812 | 1.08 | 0.95 |

| PLA100 | 43,406 | 1.26 | 2.19 |

| Specimen | Glass Transition [°C] | Energy [J/g] | DSC mW/mg | Cold Crystallization [°C] | Energy [J/g] | DSC mW/mg | Melting Point [°C] | Energy [J/g] | DSC mW/mg | Calculated Crystallinity [%] |

|---|---|---|---|---|---|---|---|---|---|---|

| PLA_100_A | 65.8 | −3.737 | −0.4403 | 121.7 | 16.2 | −0.2025 | 151.8 | −9.978 | −0.5581 | 16.2 |

| PLA_100_Z | 65.7 | −2.91 | −0.4102 | 121.4 | 16.53 | −0.1915 | 152.1 | −9.112 | −0.5498 | 16.5 |

| PLA_filament | 62.4 | −4.995 | −0.4331 | 122.0 | 14.72 | −0.2353 | 152.6 | −8.272 | −0.5306 | 14.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gaweł, A.; Kuciel, S.; Liber-Kneć, A.; Mierzwiński, D. Examination of Low-Cyclic Fatigue Tests and Poisson’s Ratio Depending on the Different Infill Density of Polylactide (PLA) Produced by the Fused Deposition Modeling Method. Polymers 2023, 15, 1651. https://doi.org/10.3390/polym15071651

Gaweł A, Kuciel S, Liber-Kneć A, Mierzwiński D. Examination of Low-Cyclic Fatigue Tests and Poisson’s Ratio Depending on the Different Infill Density of Polylactide (PLA) Produced by the Fused Deposition Modeling Method. Polymers. 2023; 15(7):1651. https://doi.org/10.3390/polym15071651

Chicago/Turabian StyleGaweł, Anna, Stanisław Kuciel, Aneta Liber-Kneć, and Dariusz Mierzwiński. 2023. "Examination of Low-Cyclic Fatigue Tests and Poisson’s Ratio Depending on the Different Infill Density of Polylactide (PLA) Produced by the Fused Deposition Modeling Method" Polymers 15, no. 7: 1651. https://doi.org/10.3390/polym15071651

APA StyleGaweł, A., Kuciel, S., Liber-Kneć, A., & Mierzwiński, D. (2023). Examination of Low-Cyclic Fatigue Tests and Poisson’s Ratio Depending on the Different Infill Density of Polylactide (PLA) Produced by the Fused Deposition Modeling Method. Polymers, 15(7), 1651. https://doi.org/10.3390/polym15071651