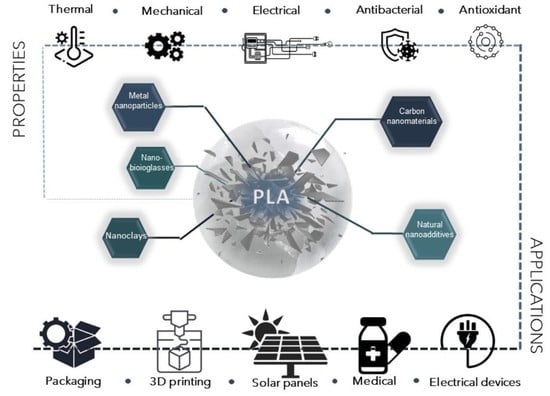

Recent Advances in the Investigation of Poly(lactic acid) (PLA) Nanocomposites: Incorporation of Various Nanofillers and their Properties and Applications

Abstract

1. Introduction

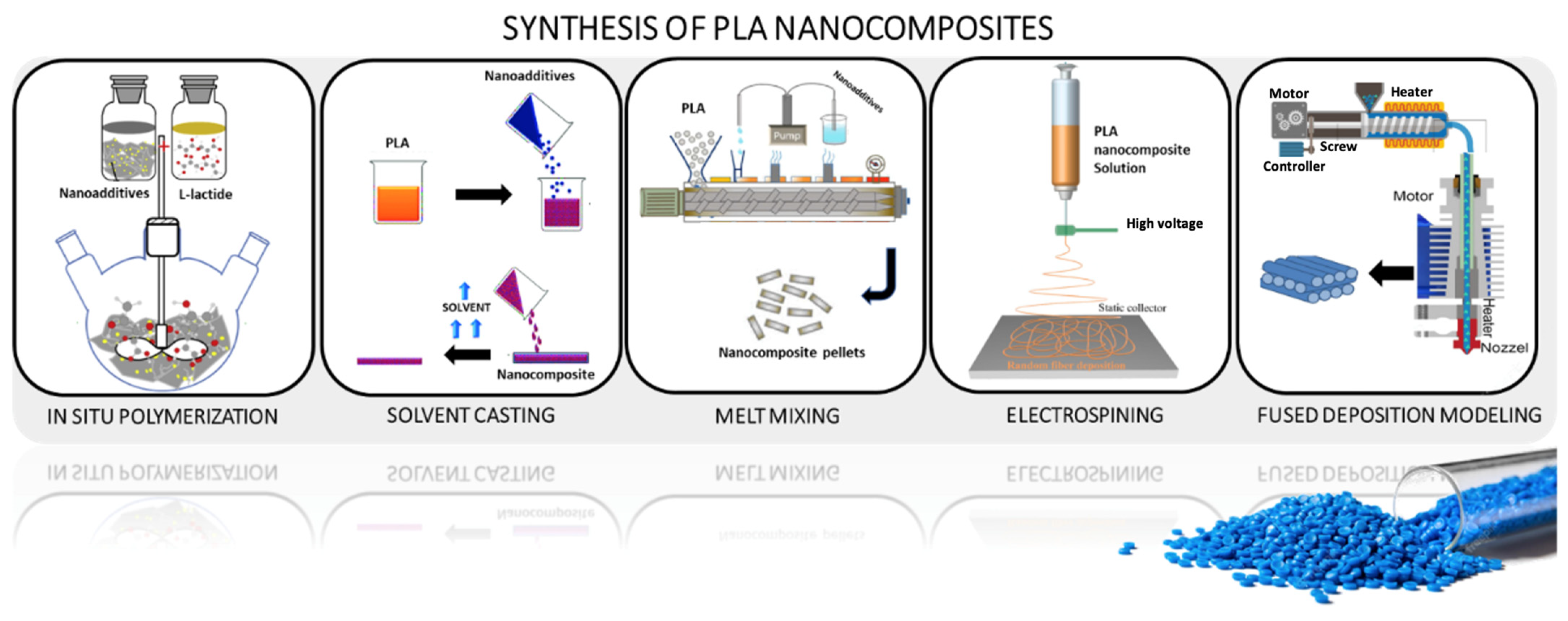

2. Synthesis of Nanocomposites

2.1. In-Situ Polymerization

2.2. Solution Casting

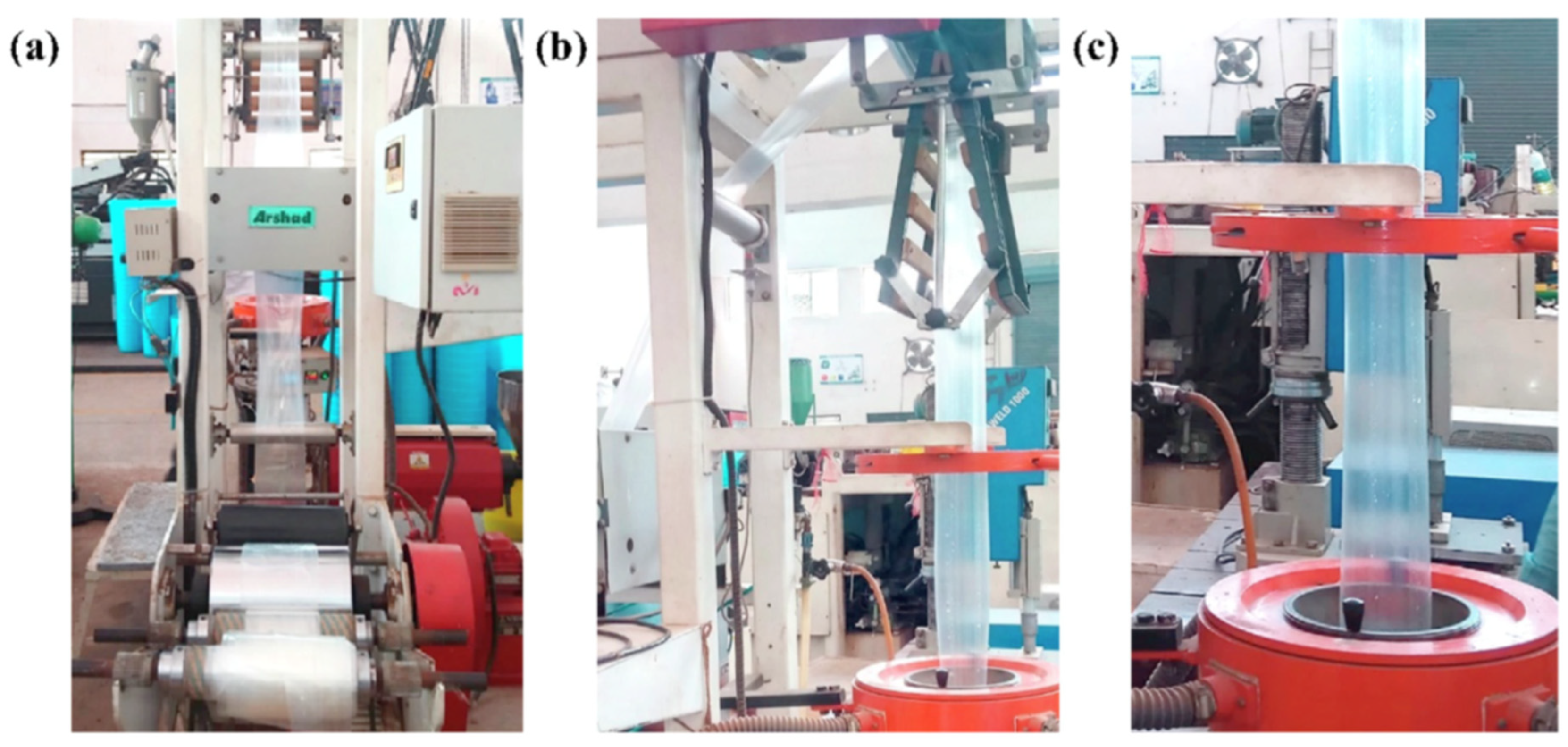

2.3. Melt Mixing

2.4. Electrospinning

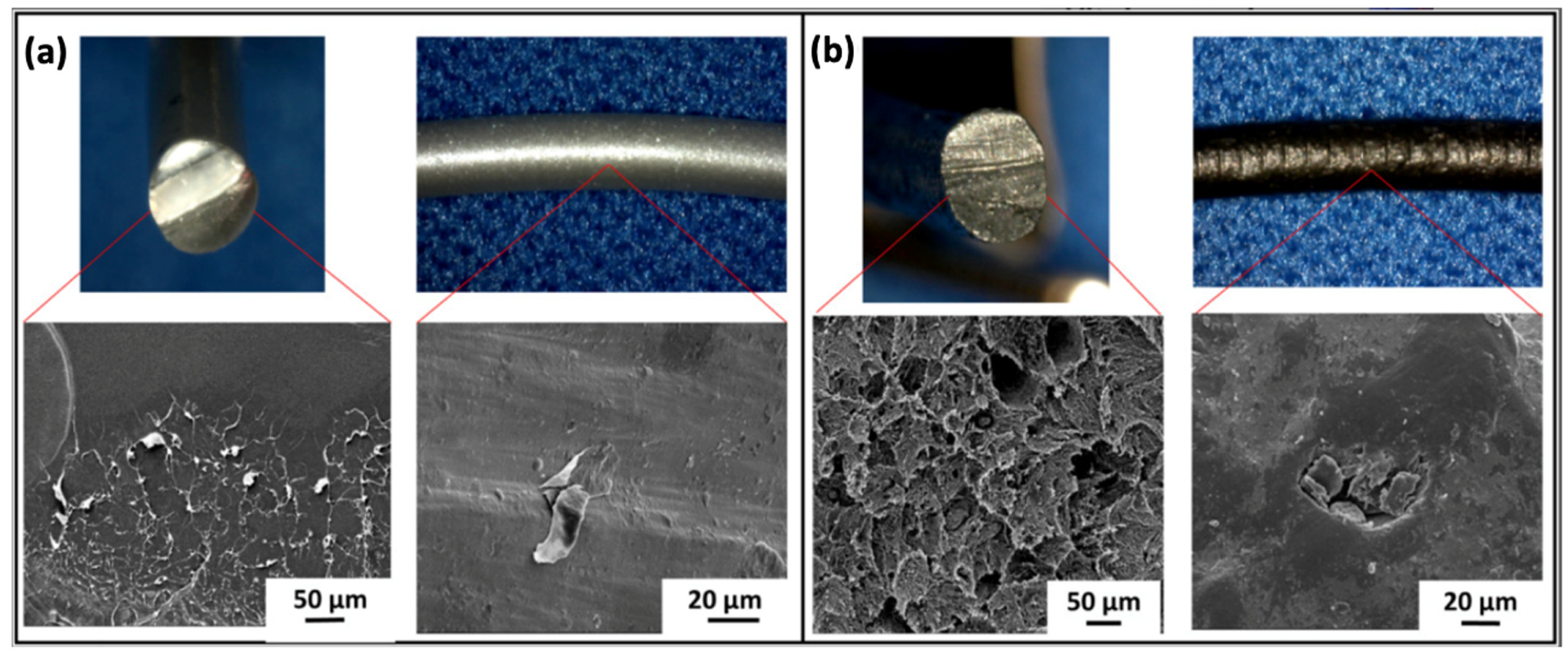

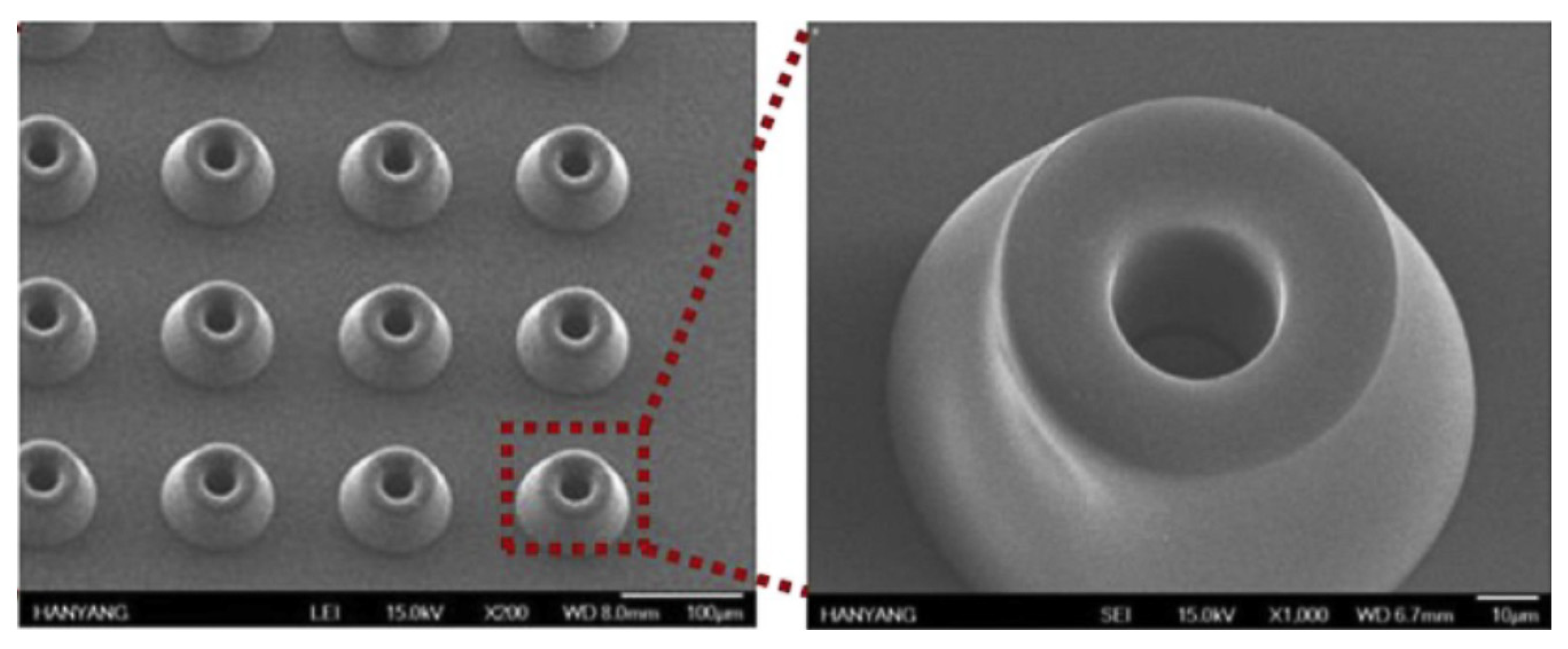

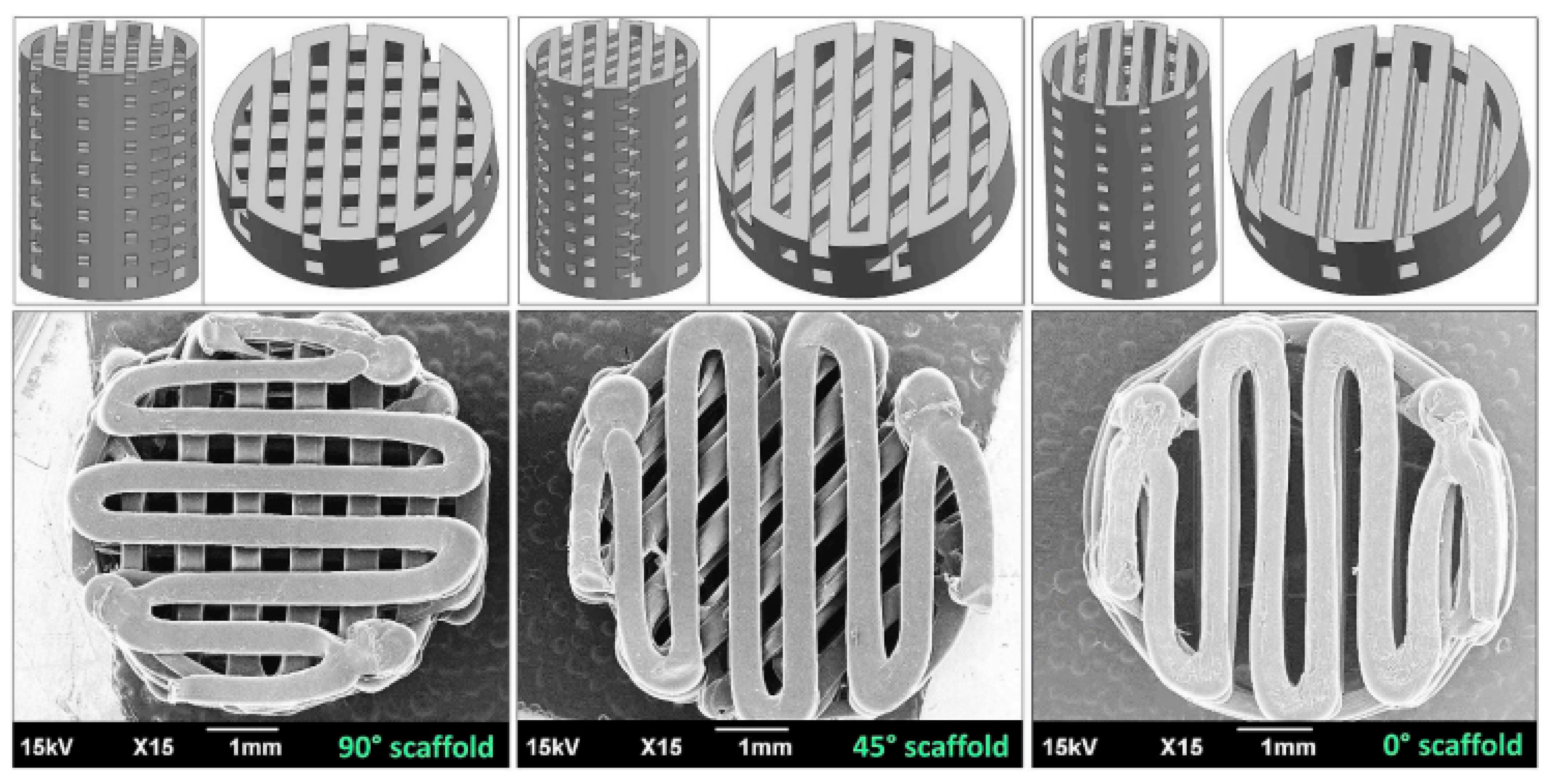

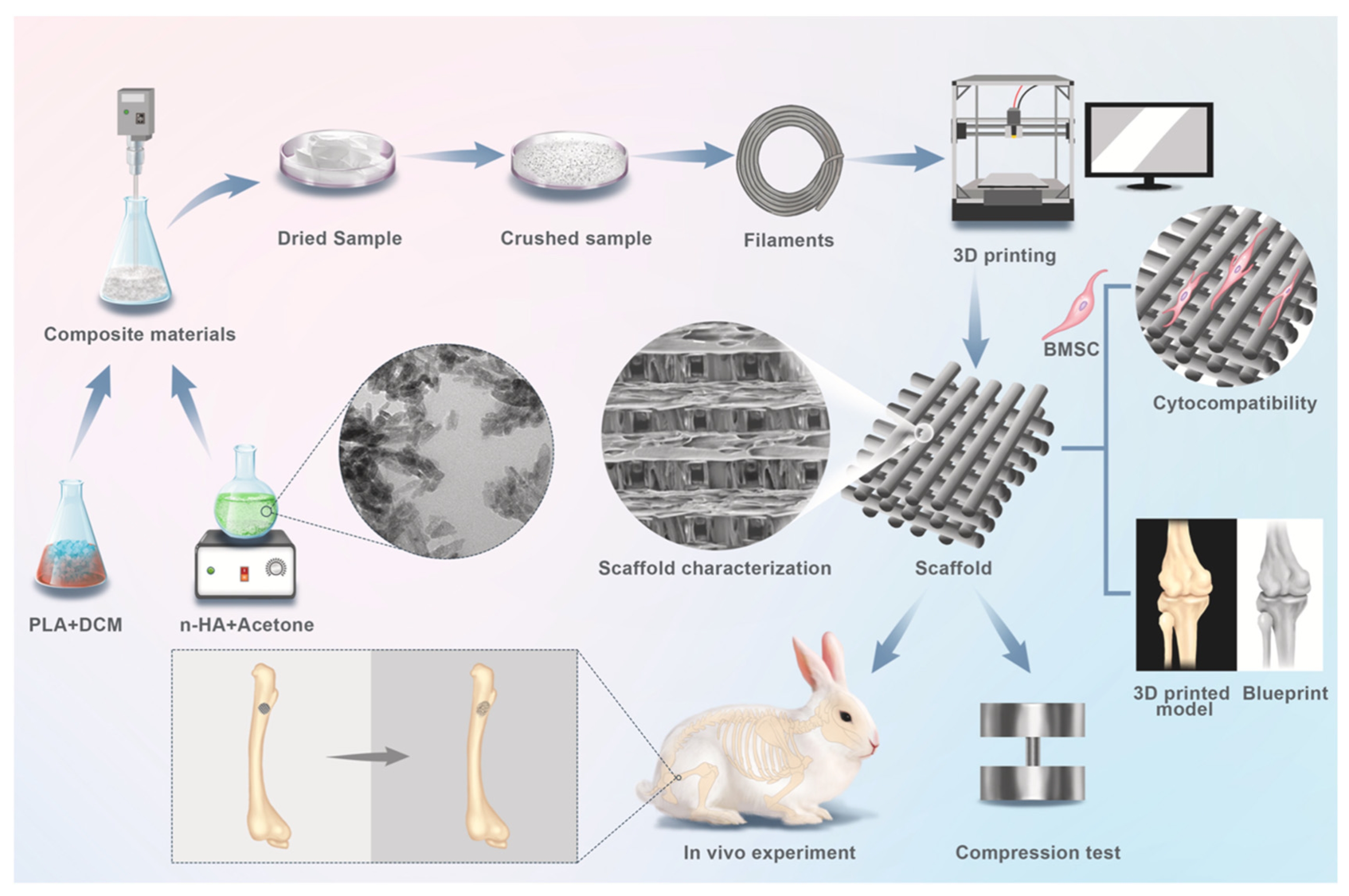

2.5. Additive Manufacturing

3. Effect of Nano-Additives on PLA/Nanocomposite Properties

3.1. PLA/Metal Oxides

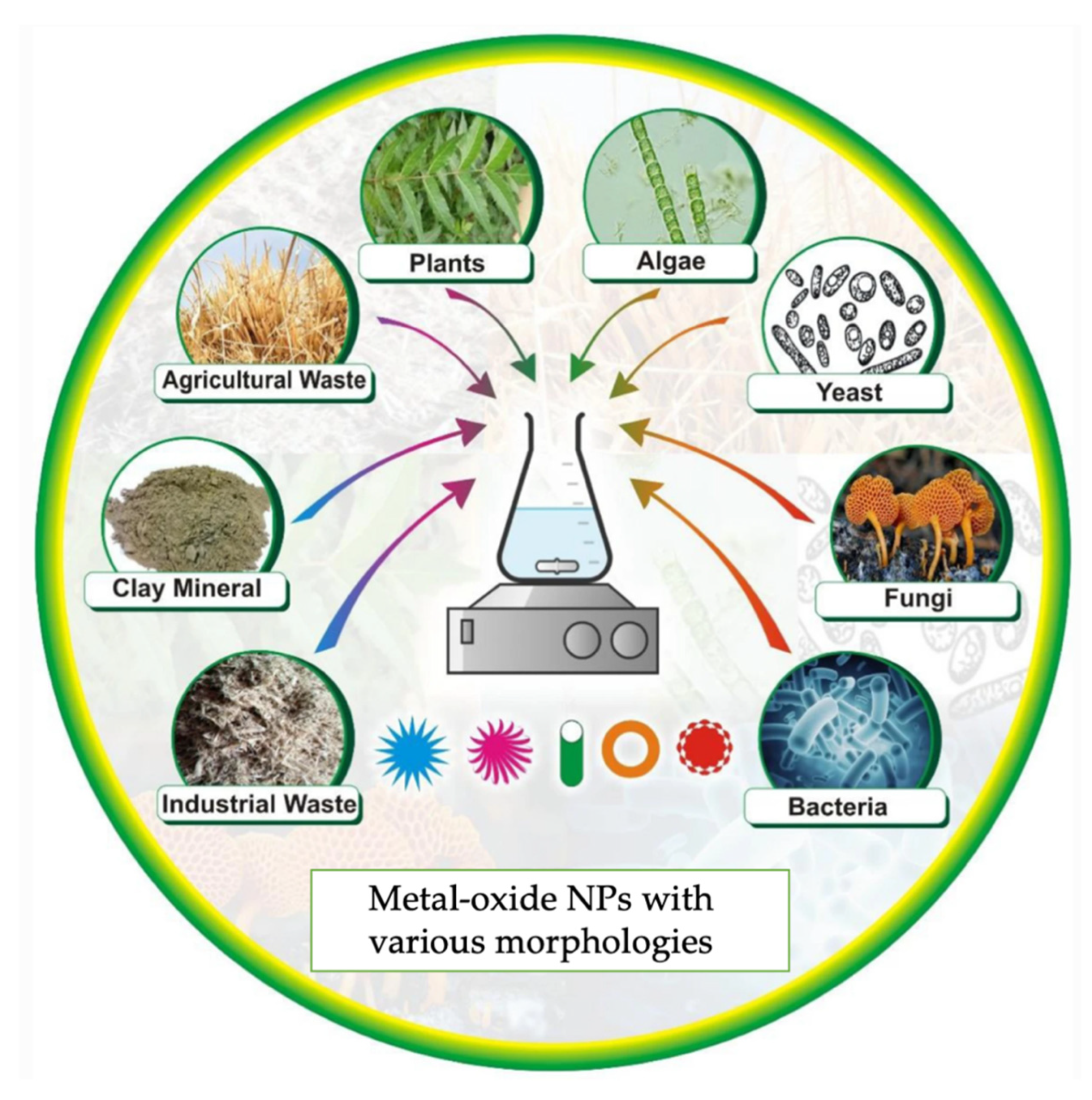

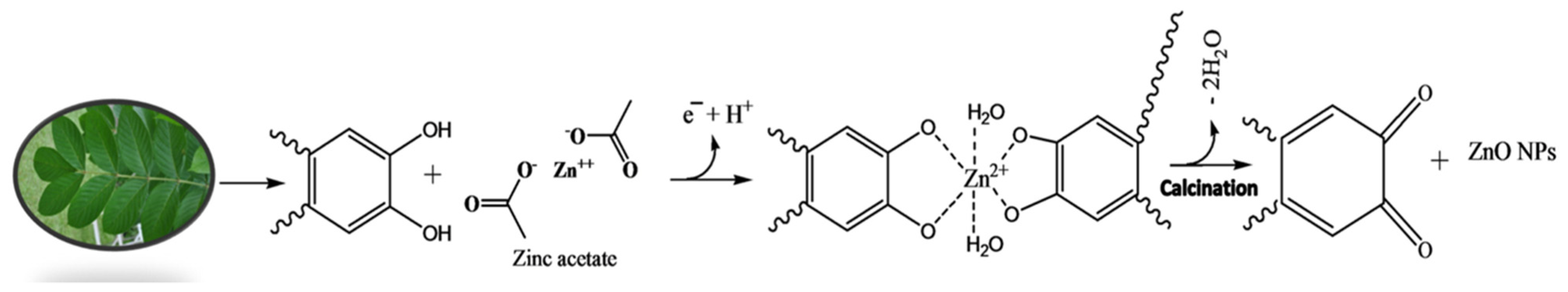

3.1.1. Green Synthesis of Nanosized Metal-Oxides

3.1.2. MgO

3.1.3. ZnO

3.1.4. TiO2

3.1.5. n-SiO2

3.2. Carbon-Based PLA/Nanocomposites

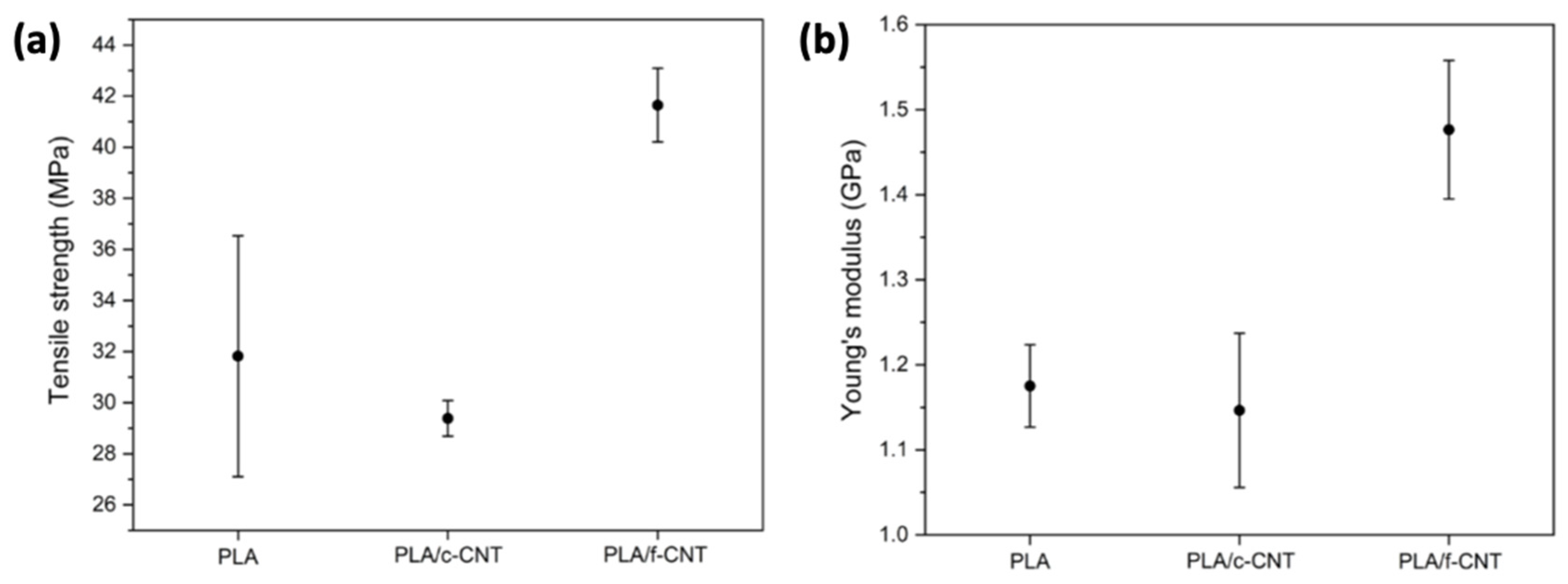

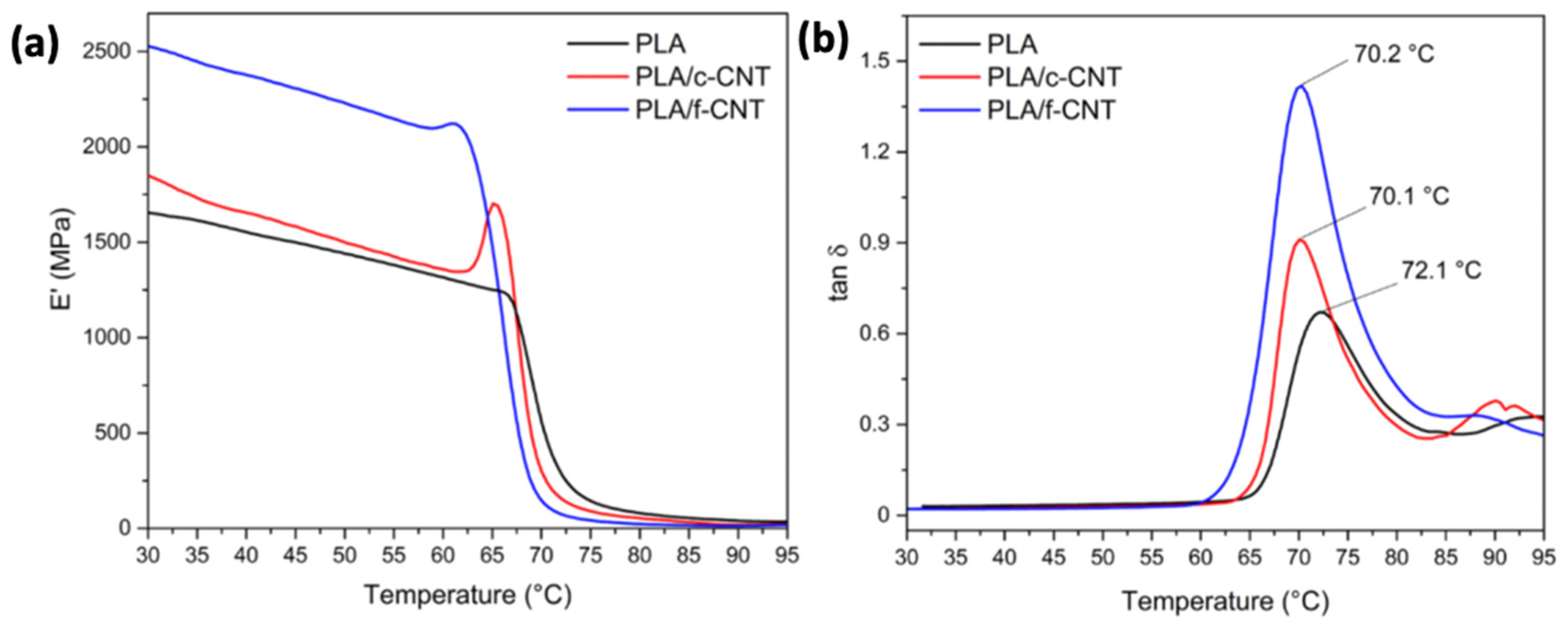

3.2.1. Carbon Nanotubes (CNTs)

3.2.2. Graphene

3.2.3. Carbon Nanofibers (CNFs)

3.2.4. Fullerene

3.3. PLA Nanocomposites with Natural Nano-Additives

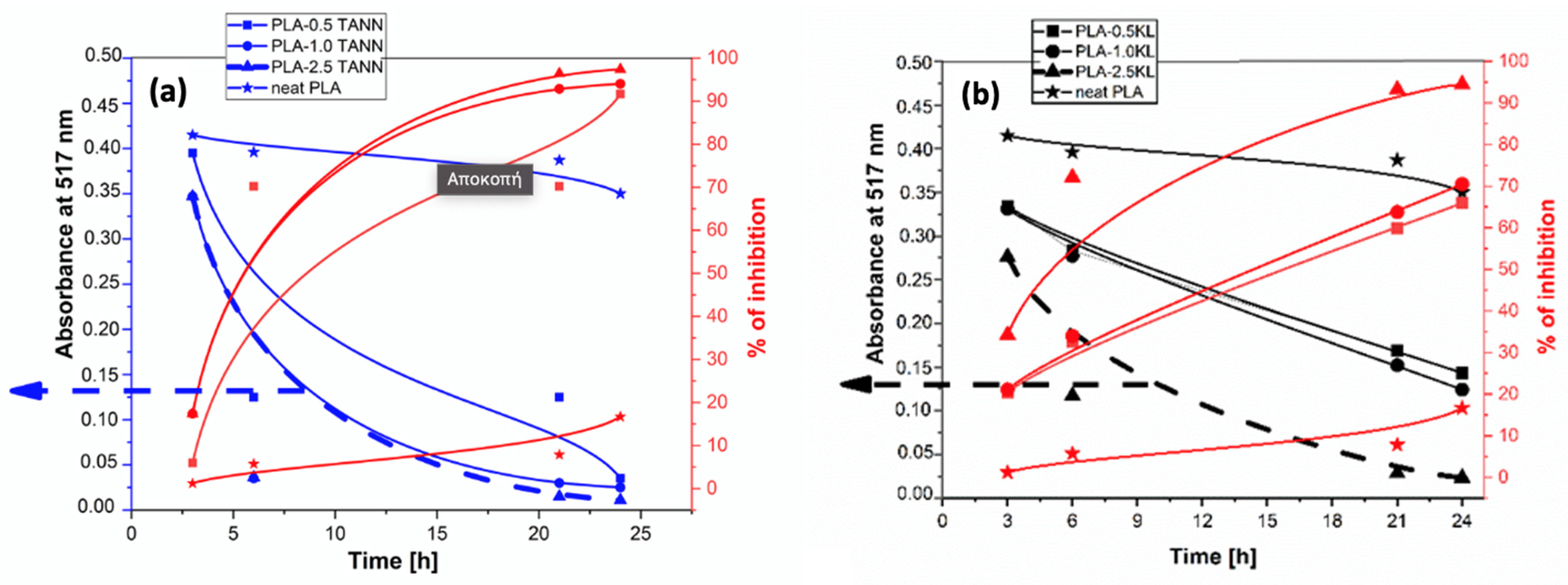

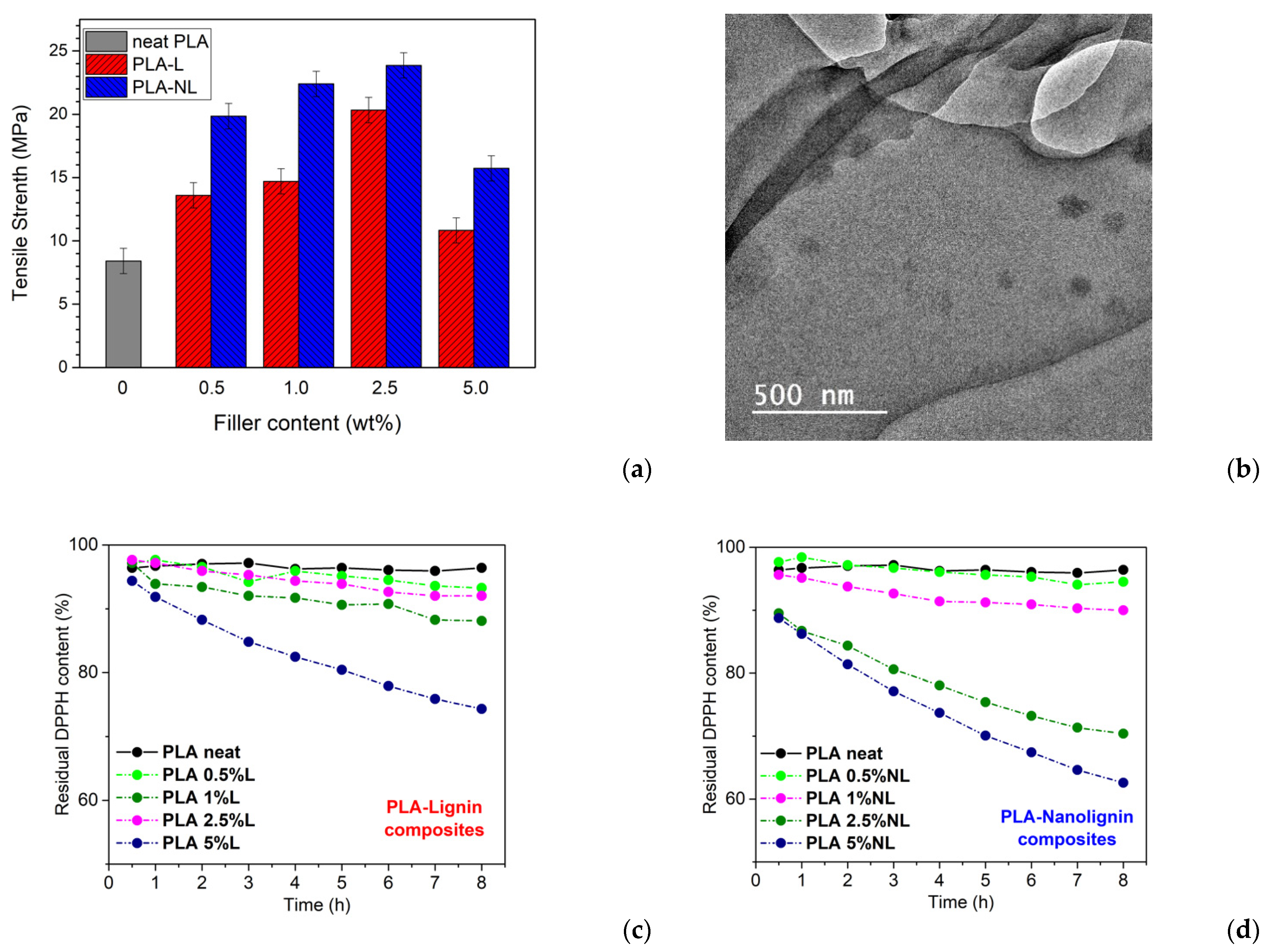

3.3.1. Lignin

3.3.2. Tannin

3.3.3. Nanocellulose (NC)

3.3.4. Nano-Biochar (n-BC)

3.4. PLA/Ceramic Nanocomposites

3.4.1. Bioglass

3.4.2. n-Hydroxyapatite (HAp)

3.5. Nanoclays

4. Applications of PLA Nanocomposites

4.1. Applications of PLA/Metal Oxides

4.1.1. Food Packaging

4.1.2. Medical Applications

4.1.3. Environmental Applications

4.1.4. Other Applications

| Material | Application | Properties | References |

|---|---|---|---|

| PLA-ZnO | Packaging, tissue engineering, wound healing, drug delivery, disposable electronics | Dielectric properties, nti-inflammatory and antibacterial activity, biocompatibility | [195,199,203] |

| PLA-TiO2 | Packaging, air filters, tissue engineering, wound healing, electronics | Total anti-UV protection, optical and antibacterial properties, nanocomposites with higher kinetics of crystallization, photodegradability, etc. | [94,214,215] |

| PLA/Al2O3 and PLA/BO | Electronics, packaging and automotives industries | Anti-inflammatory properties and non-toxicity against fibroblast L929 cells | [210,211] |

4.2. PLA/Carbon-Based Nanocomposites

4.2.1. Thermal and Electrical Applications

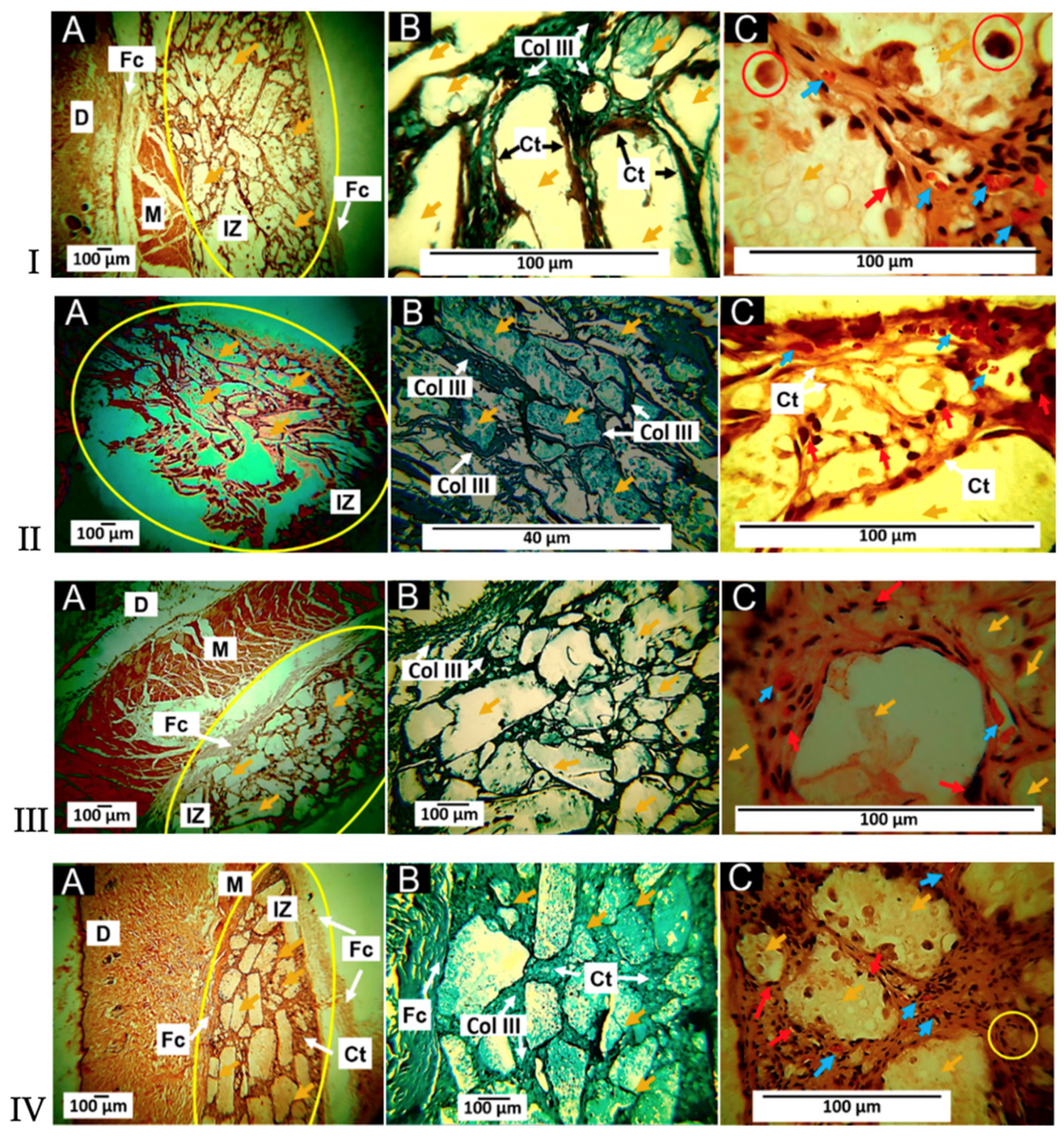

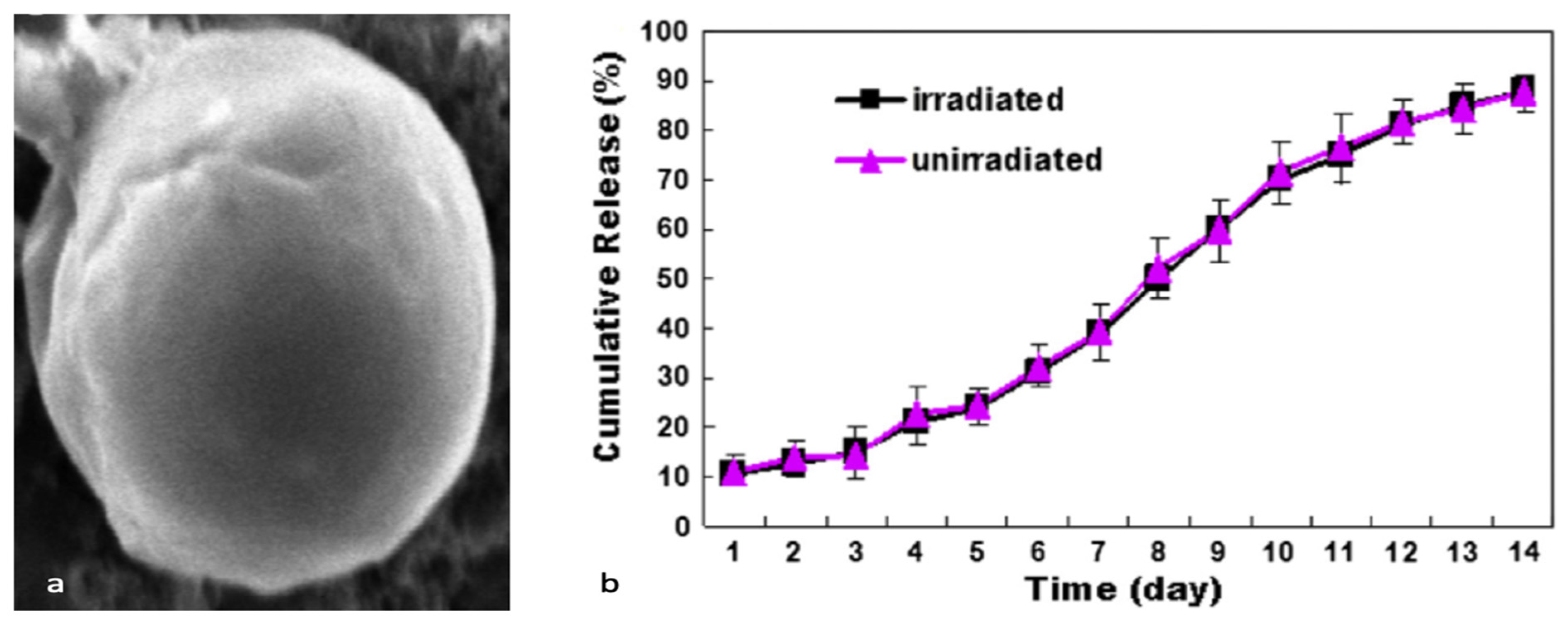

4.2.2. Biomedical Applications

4.2.3. Structural Applications (Mechanical-Thermal Properties Enhancement)

4.3. Applications of PLA/Nanocomposites with Natural Nano-Additives

4.3.1. Food Packaging

4.3.2. Flame Retardants

4.3.3. Pesticides

4.3.4. Implantable Medical Devices

4.3.5. Heavy Metals Removal

4.3.6. Optical Applications

4.3.7. Outdoor Usages

4.4. Nanoceramics

4.4.1. Medical Applications

4.4.2. Agricultural

4.5. PLA/Nanoclays

4.5.1. Food Packaging

4.5.2. Engineering Applications

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pappa, A.; Papadimitriou-Tsantarliotou, A.; Kaloyianni, M.; Kastrinaki, G.; Dailianis, S.; Lambropoulou, D.A.; Christodoulou, E.; Kyzas, G.Z.; Bikiaris, D.N. Insights into the Toxicity of Biomaterials Microparticles with a Combination of Cellular and Oxidative Biomarkers. J. Hazard. Mater. 2021, 413, 125335. [Google Scholar] [CrossRef] [PubMed]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, Use, and Fate of All Plastics Ever Made—Supplementary Information. Sci. Adv. 2017, 3, 19–24. [Google Scholar] [CrossRef] [PubMed]

- Kaloyianni, M.; Bobori, D.C.; Xanthopoulou, D.; Malioufa, G.; Sampsonidis, I.; Kalogiannis, S.; Feidantsis, K.; Kastrinaki, G.; Dimitriadi, A.; Koumoundouros, G.; et al. Toxicity and Functional Tissue Responses of Two Freshwater Fish after Exposure to Polystyrene Microplastics. Toxics 2021, 9, 289. [Google Scholar] [CrossRef] [PubMed]

- Bobori, D.C.; Dimitriadi, A.; Feidantsis, K.; Samiotaki, A.; Fafouti, D.; Sampsonidis, I.; Kalogiannis, S.; Kastrinaki, G.; Lambropoulou, D.A.; Kyzas, G.Z.; et al. Differentiation in the Expression of Toxic Effects of Polyethylene-Microplastics on Two Freshwater Fish Species: Size Matters. Sci. Total Environ. 2022, 830, 154603. [Google Scholar] [CrossRef]

- Bobori, D.C.; Feidantsis, K.; Dimitriadi, A.; Datsi, N.; Ripis, P.; Kalogiannis, S.; Sampsonidis, I.; Kastrinaki, G.; Ainali, N.M.; Lambropoulou, D.A.; et al. Dose-Dependent Cytotoxicity of Polypropylene Microplastics (PP-MPs) in Two Freshwater Fishes. Int. J. Mol. Sci. 2022, 23, 13878. [Google Scholar] [CrossRef]

- Jiang, J.Q. Occurrence of Microplastics and Its Pollution in the Environment: A Review. Sustain. Prod. Consum. 2018, 13, 16–23. [Google Scholar] [CrossRef]

- Huang, D.; Tao, J.; Cheng, M.; Deng, R.; Chen, S.; Yin, L.; Li, R. Microplastics and Nanoplastics in the Environment: Macroscopic Transport and Effects on Creatures. J. Hazard. Mater. 2021, 407, 124399. [Google Scholar] [CrossRef]

- Kian, L.K.; Saba, N.; Jawaid, M.; Sultan, M.T.H. A Review on Processing Techniques of Bast Fibers Nanocellulose and Its Polylactic Acid (PLA) Nanocomposites. Int. J. Biol. Macromol. 2019, 121, 1314–1328. [Google Scholar] [CrossRef]

- Banerjee, R.; Ray, S.S. An Overview of the Recent Advances in Polylactide-Based Sustainable Nanocomposites. Polym. Eng. Sci. 2021, 61, 617–649. [Google Scholar] [CrossRef]

- Balla, E.; Daniilidis, V.; Karlioti, G.; Kalamas, T.; Stefanidou, M.; Bikiaris, N.D.; Vlachopoulos, A.; Koumentakou, I.; Bikiaris, D.N. Poly(Lactic Acid): A Versatile Biobased Polymer for the Future with Multifunctional Properties-from Monomer Synthesis, Polymerization Techniques and Molecular Weight Increase to PLA Applications. Polymers 2021, 13, 1822. [Google Scholar] [CrossRef]

- Raquez, J.M.; Habibi, Y.; Murariu, M.; Dubois, P. Polylactide (PLA)-Based Nanocomposites. Prog. Polym. Sci. 2013, 38, 1504–1542. [Google Scholar] [CrossRef]

- Kervran, M.; Vagner, C.; Cochez, M.; Ponçot, M.; Saeb, M.R.; Vahabi, H. Thermal Degradation of Polylactic Acid (PLA)/Polyhydroxybutyrate (PHB) Blends: A Systematic Review. Polym. Degrad. Stab. 2022, 201, 109995. [Google Scholar] [CrossRef]

- John, A.; Črešnar, K.P.; Bikiaris, D.N.; Zemljič, L.F. Colloidal Solutions as Advanced Coatings for Active Packaging Development: Focus on PLA Systems. Polymers 2023, 15, 273. [Google Scholar] [CrossRef] [PubMed]

- Papageorgiou, G.Z.; Achilias, D.S.; Nanaki, S.; Beslikas, T.; Bikiaris, D. PLA Nanocomposites: Effect of Filler Type on Non-Isothermal Crystallization. Thermochim. Acta 2010, 511, 129–139. [Google Scholar] [CrossRef]

- Sanusi, O.M.; Benelfellah, A.; Bikiaris, D.N.; Aït Hocine, N. Effect of Rigid Nanoparticles and Preparation Techniques on the Performances of Poly(Lactic Acid) Nanocomposites: A Review. Polym. Adv. Technol. 2021, 32, 444–460. [Google Scholar] [CrossRef]

- Klonos, P.A.; Lazaridou, M.; Samiotaki, C.; Kyritsis, A.; Bikiaris, D.N. Dielectric and Calorimetric Study in Renewable Polymer Blends Based on Poly(Ethylene Adipate) and Poly(Lactic Acid) with Microphase Separation. Polymer 2022, 259, 125329. [Google Scholar] [CrossRef]

- Ainali, N.M.; Kalaronis, D.; Evgenidou, E.; Kyzas, G.Z.; Bobori, D.C.; Kaloyianni, M.; Yang, X.; Bikiaris, D.N.; Lambropoulou, D.A. Do Poly(Lactic Acid) Microplastics Instigate a Threat? A Perception for Their Dynamic towards Environmental Pollution and Toxicity. Sci. Total Environ. 2022, 832, 155014. [Google Scholar] [CrossRef]

- Vlachopoulos, A.; Karlioti, G.; Balla, E.; Daniilidis, V.; Kalamas, T.; Stefanidou, M.; Bikiaris, N.D.; Christodoulou, E.; Koumentakou, I.; Karavas, E.; et al. Poly(Lactic Acid)-Based Microparticles for Drug Delivery Applications: An Overview of Recent Advances. Pharmaceutics 2022, 14, 359. [Google Scholar] [CrossRef]

- Beslikas, T.; Gigis, I.; Goulios, V.; Christoforides, J.; Papageorgiou, G.Z.; Bikiaris, D.N. Crystallization Study and Comparative in Vitro-in Vivo Hydrolysis of PLA Reinforcement Ligament. Int. J. Mol. Sci. 2011, 12, 6597–6618. [Google Scholar] [CrossRef]

- Mayekar, P.C.; Castro-Aguirre, E.; Auras, R.; Selke, S.; Narayan, R. Effect of Nano-Clay and Surfactant on the Biodegradation of Poly(Lactic Acid) Films. Polymers 2020, 12, 311. [Google Scholar] [CrossRef]

- Sharif, A.; Mondal, S.; Hoque, M.E. Polylactic Acid (PLA)-Based Nanocomposites: Processing and Properties. Bio-Based Polym. Nanocompos. Prep. Process. Prop. Perform. 2019, 233–254. [Google Scholar] [CrossRef]

- Sha, L.; Chen, Z.; Chen, Z.; Zhang, A.; Yang, Z. Polylactic Acid Based Nanocomposites: Promising Safe and Biodegradable Materials in Biomedical Field. Int. J. Polym. Sci. 2016, 2016, 6869154. [Google Scholar] [CrossRef]

- Najafi, N.; Heuzey, M.C.; Carreau, P.J. Polylactide (PLA)-Clay Nanocomposites Prepared by Melt Compounding in the Presence of a Chain Extender. Compos. Sci. Technol. 2012, 72, 608–615. [Google Scholar] [CrossRef]

- Črešnar, K.P.; Aulova, A.; Bikiaris, D.N.; Lambropoulou, D.; Kuzmič, K.; Zemljič, L.F. Incorporation of Metal-based Nanoadditives into the Pla Matrix: Effect of Surface Properties on Antibacterial Activity and Mechanical Performance of Pla Nanoadditive Films. Molecules 2021, 26, 4161. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.K.; Shih, C.C.; Chen, A.F. Ductile PLA Nanocomposites with Improved Thermal Stability. Compos. Part A Appl. Sci. Manuf. 2012, 43, 2289–2295. [Google Scholar] [CrossRef]

- Alikarami, N.; Abrisham, M.; Huang, X.; Panahi-Sarmad, M.; Zhang, K.; Dong, K.; Xiao, X. Compatibilization of PLA Grafted Maleic Anhydrate through Blending of Thermoplastic Starch (TPS) and Nanoclay Nanocomposites for the Reduction of Gas Permeability. Int. J. Smart Nano Mater. 2022, 13, 130–151. [Google Scholar] [CrossRef]

- Norazlina, H.; Kamal, Y. Graphene Modifications in Polylactic Acid Nanocomposites: A Review. Polym. Bull. 2015, 72, 931–961. [Google Scholar] [CrossRef]

- Vassiliou, A.A.; Bikiaris, D.; El Mabrouk, K.; Kontopoulou, M. Effect of Evolved Interactions in Poly(Butylene Succinate)/Fumed Silica Biodegradable In Situ Prepared Nanocomposites on Molecular Weight, Material Properties, and Biodegradability. J. Appl. Polym. Sci. 2010, 116, 2658–2667. [Google Scholar] [CrossRef]

- Bikiaris, D.; Karavelidis, V.; Karayannidis, G. A New Approach to Prepare Poly(Ethylene Terephthalate)/Silica Nanocomposites with Increased Molecular Weight and Fully Adjustable Branching or Crosslinking by SSP. Macromol. Rapid Commun. 2006, 27, 1199–1205. [Google Scholar] [CrossRef]

- Manju, P.; Krishnan, P.S.G.; Nayak, S.K. In-Situ Polymerised PLA-SEP Bionanocomposites: Effect of Silanol Groups on the Properties of PLA. J. Polym. Res. 2020, 27, 134. [Google Scholar] [CrossRef]

- Yang, J.H.; Lin, S.H.; Lee, Y.D. Preparation and Characterization of Poly(l-Lactide)-Graphene Composites Using the in Situ Ring-Opening Polymerization of PLLA with Graphene as the Initiator. J. Mater. Chem. 2012, 22, 10805–10815. [Google Scholar] [CrossRef]

- Song, W.; Zheng, Z.; Tang, W.; Wang, X. A Facile Approach to Covalently Functionalized Carbon Nanotubes with Biocompatible Polymer. Polymer 2007, 48, 3658–3663. [Google Scholar] [CrossRef]

- Acevedo, J.; Escobar, G.; López, D. Functionalized Multiwalled Carbon Nanotubes for the Improvement of Dispersion Stability in Diesel Fuel-Type for Potential Application as Nano Additives. ChemistrySelect 2022, 7, e202202626. [Google Scholar] [CrossRef]

- Feng, S.; Zhang, F.; Ahmed, S.; Liu, Y. Physico-Mechanical and Antibacterial Properties of PLA/TiO2 Composite Materials Synthesized via Electrospinning and Solution Casting Processes. Coatings 2019, 9, 525. [Google Scholar] [CrossRef]

- Fu, L.; Wu, F.; Xu, C.; Cao, T.; Wang, R.; Guo, S. Anisotropic Shape Memory Behaviors of Polylactic Acid/Citric Acid− Bentonite Composite with a Gradient Filler Concentration in Thickness Direction. Ind. Eng. Chem. Res. 2018, 57, 6265–6274. [Google Scholar] [CrossRef]

- Lawal, A.T. Recent Progress in Graphene Based Polymer Nanocomposites. Cogent Chem. 2020, 6, 1833476. [Google Scholar] [CrossRef]

- Tsioptsias, C.; Leontiadis, K.; Tzimpilis, E.; Tsivintzelis, I. Polypropylene Nanocomposite Fibers: A Review of Current Trends and New Developments. J. Plast. Film Sheeting 2021, 37, 283–311. [Google Scholar] [CrossRef]

- Sinha Ray, S.; Yamada, K.; Okamoto, M.; Ueda, K. Control of Biodegradability of Polylactide via Nanocomposite Technology. Macromol. Mater. Eng. 2003, 288, 203–208. [Google Scholar] [CrossRef]

- Botta, L.; Scaffaro, R.; Sutera, F.; Mistretta, M.C. Reprocessing of PLA/Graphene Nanoplatelets Nanocomposites. Polymers 2018, 10, 18. [Google Scholar] [CrossRef]

- Yu, W.; Sisi, L.; Haiyan, Y.; Jie, L. Progress in the Functional Modification of Graphene/Graphene Oxide: A Review. RSC Adv. 2020, 10, 15328–15345. [Google Scholar] [CrossRef]

- Murariu, M.; Dechief, A.L.; Bonnaud, L.; Paint, Y.; Gallos, A.; Fontaine, G.; Bourbigot, S.; Dubois, P. The Production and Properties of Polylactide Composites Filled with Expanded Graphite. Polym. Degrad. Stab. 2010, 95, 889–900. [Google Scholar] [CrossRef]

- Bikiaris, N.D.; Koumentakou, I.; Michailidou, G.; Kostoglou, M.; Vlachou, M.; Barmpalexis, P.; Karavas, E.; Papageorgiou, G.Z. Investigation of Molecular Weight, Polymer Concentration and Process Parameters Factors on the Sustained Release of the Anti-Multiple-Sclerosis Agent Teriflunomide from Poly(ε-Caprolactone) Electrospun Nanofibrous Matrices. Pharmaceutics 2022, 14, 1693. [Google Scholar] [CrossRef] [PubMed]

- Barkoula, N.M.; Alcock, B.; Cabrera, N.O.; Peijs, T. Flame-Retardancy Properties of Intumescent Ammonium Poly(Phosphate) and Mineral Filler Magnesium Hydroxide in Combination with Graphene. Polym. Polym. Compos. 2008, 16, 101–113. [Google Scholar]

- Kim, G.H.; Cho, Y.S.; Kim, W.D. Stability Analysis for Multi-Jets Electrospinning Process Modified with a Cylindrical Electrode. Eur. Polym. J. 2006, 42, 2031–2038. [Google Scholar] [CrossRef]

- SalehHudin, H.S.; Mohamad, E.N.; Mahadi, W.N.L.; Afifi, A.M. Simulation and Experimental Study of Parameters in Multiple-Nozzle Electrospinning: Effects of Nozzle Arrangement on Jet Paths and Fiber Formation. J. Manuf. Process. 2021, 62, 440–449. [Google Scholar] [CrossRef]

- Touny, A.H.; Lawrence, J.G.; Jones, A.D.; Bhaduri, S.B. Effect of Electrospinning Parameters on the Characterization of PLA/HNT Nanocomposite Fibers. J. Mater. Res. 2010, 25, 857–865. [Google Scholar] [CrossRef]

- Shi, Q.; Zhou, C.; Yue, Y.; Guo, W.; Wu, Y.; Wu, Q. Mechanical Properties and in Vitro Degradation of Electrospun Bio-Nanocomposite Mats from PLA and Cellulose Nanocrystals. Carbohydr. Polym. 2012, 90, 301–308. [Google Scholar] [CrossRef]

- Liu, C.; Wong, H.M.; Yeung, K.W.K.; Tjong, S.C. Novel Electrospun Polylactic Acid Nanocomposite Fiber Mats with Hybrid Graphene Oxide and Nanohydroxyapatite Reinforcements Having Enhanced Biocompatibility. Polymers 2016, 8, 287. [Google Scholar] [CrossRef]

- Li, M.; Mondrinos, M.J.; Chen, X.; Gandhi, M.R.; Ko, F.K.; Lelkes, P.I. Elastin Blends for Tissue Engineering Scaffolds. J. Biomed. Mater. Res. Part A 2006, 79, 963–973. [Google Scholar] [CrossRef]

- Zhang, R.; Lan, W.; Ji, T.; Sameen, D.E.; Ahmed, S.; Qin, W.; Liu, Y. Development of Polylactic Acid/ZnO Composite Membranes Prepared by Ultrasonication and Electrospinning for Food Packaging. Lwt 2021, 135, 110072. [Google Scholar] [CrossRef]

- Xiang, C.; Joo, Y.L.; Frey, M.W. Nanocomposite Fibers Electrospun from Poly(Lactic Acid)/Cellulose Nanocrystals. J. Biobased Mater. Bioenergy 2009, 3, 147–155. [Google Scholar] [CrossRef]

- Alam, F.; Varadarajan, K.M.; Kumar, S. 3D Printed Polylactic Acid Nanocomposite Scaffolds for Tissue Engineering Applications. Polym. Test. 2020, 81, 106203. [Google Scholar] [CrossRef]

- Alam, F.; Shukla, V.R.; Varadarajan, K.M.; Kumar, S. Microarchitected 3D Printed Polylactic Acid (PLA) Nanocomposite Scaffolds for Biomedical Applications. J. Mech. Behav. Biomed. Mater. 2020, 103, 103576. [Google Scholar] [CrossRef] [PubMed]

- Bhagia, S.; Bornani, K.; Agarwal, R.; Satlewal, A.; Ďurkovič, J.; Lagaňa, R.; Bhagia, M.; Yoo, C.G.; Zhao, X.; Kunc, V.; et al. Critical Review of FDM 3D Printing of PLA Biocomposites Filled with Biomass Resources, Characterization, Biodegradability, Upcycling and Opportunities for Biorefineries. Appl. Mater. Today 2021, 24, 101078. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, B.; Li, M.; Li, J.; Zhang, C.; Han, Y.; Wang, L.; Wang, K.; Zhou, C.; Liu, L.; et al. 3D Printing of PLA/n-HA Composite Scaffolds with Customized Mechanical Properties and Biological Functions for Bone Tissue Engineering. Compos. Part B Eng. 2021, 224, 109192. [Google Scholar] [CrossRef]

- Yang, L.; Li, S.; Zhou, X.; Liu, J.; Li, Y.; Yang, M.; Yuan, Q.; Zhang, W. Effects of Carbon Nanotube on the Thermal, Mechanical, and Electrical Properties of PLA/CNT Printed Parts in the FDM Process. Synth. Met. 2019, 253, 122–130. [Google Scholar] [CrossRef]

- Bustillos, J.; Montero, D.; Nautiyal, P.; Loganathan, A.; Boesl, B.; Agarwal, A. Integration of Graphene in Poly(Lactic) Acid by 3D Printing to Develop Creep and Wear-Resistant Hierarchical Nanocomposites. Polym. Polym. Compos. 2008, 16, 101–113. [Google Scholar] [CrossRef]

- Demchenko, V.; Kobylinskyi, S.; Iurzhenko, M.; Riabov, S.; Vashchuk, A.; Rybalchenko, N.; Zahorodnia, S.; Naumenko, K.; Demchenko, O.; Adamus, G.; et al. Nanocomposites Based on Polylactide and Silver Nanoparticles and Their Antimicrobial and Antiviral Applications. React. Funct. Polym. 2022, 170, 105096. [Google Scholar] [CrossRef]

- Shifrina, Z.B.; Matveeva, V.G.; Bronstein, L.M. Role of Polymer Structures in Catalysis by Transition Metal and Metal Oxide Nanoparticle Composites. Chem. Rev. 2020, 120, 1350–1396. [Google Scholar] [CrossRef]

- Prasanna, S.R.V.S.; Pandey, S.; Balaji, K.; Rana, S. Metal Oxide Based Nanomaterials and Their Polymer Nanocomposites. In Nanomaterials and Polymer Nanocomposites; Elsevier Inc.: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Kim, J.S.; Kuk, E.; Yu, K.N.; Kim, J.H.; Park, S.J.; Lee, H.J.; Kim, S.H.; Park, Y.K.; Park, Y.H.; Hwang, C.Y.; et al. Antimicrobial Effects of Silver Nanoparticles. Nanomed. Nanotechnol. Biol. Med. 2007, 3, 95–101. [Google Scholar] [CrossRef]

- Singh, J.; Dutta, T.; Kim, K.H.; Rawat, M.; Samddar, P.; Kumar, P. “Green” Synthesis of Metals and Their Oxide Nanoparticles: Applications for Environmental Remediation. J. Nanobiotechnol. 2018, 16, 84. [Google Scholar] [CrossRef] [PubMed]

- Ramanujam, K.; Sundrarajan, M. Antibacterial Effects of Biosynthesized MgO Nanoparticles Using Ethanolic Fruit Extract of Emblica Officinalis. J. Photochem. Photobiol. B Biol. 2014, 141, 296–300. [Google Scholar] [CrossRef]

- Anantharaman, A.; Sathyabhama, S.; George, M. Green Synthesis of Magnesium Oxide Nanoparticles Using Aloe Vera and Its Applications. Int. J. Sci. Res. Dev. 2016, 4, 2321–2613. [Google Scholar]

- Karande, S.D.; Jadhav, S.A.; Garud, H.B.; Kalantre, V.A.; Burungale, S.H.; Patil, P.S. Green and Sustainable Synthesis of Silica Nanoparticles. Nanotechnol. Environ. Eng. 2021, 6, 29. [Google Scholar] [CrossRef]

- Sankar, R.; Rizwana, K.; Shivashangari, K.S.; Ravikumar, V. Ultra-Rapid Photocatalytic Activity of Azadirachta Indica Engineered Colloidal Titanium Dioxide Nanoparticles. Appl. Nanosci. 2015, 5, 731–736. [Google Scholar] [CrossRef]

- Dobrucka, R. Synthesis of Titanium Dioxide Nanoparticles Using Echinacea Purpurea Herba. Iran. J. Pharm. Res. 2017, 16, 753–759. [Google Scholar]

- Jayaseelan, C.; Rahuman, A.A.; Roopan, S.M.; Kirthi, A.V.; Venkatesan, J.; Kim, S.K.; Iyappan, M.; Siva, C. Biological Approach to Synthesize TiO2 Nanoparticles Using Aeromonas Hydrophila and Its Antibacterial Activity. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2013, 107, 82–89. [Google Scholar] [CrossRef]

- Roopan, S.M.; Bharathi, A.; Prabhakarn, A.; Abdul Rahuman, A.; Velayutham, K.; Rajakumar, G.; Padmaja, R.D.; Lekshmi, M.; Madhumitha, G. Efficient Phyto-Synthesis and Structural Characterization of Rutile TiO2 Nanoparticles Using Annona Squamosa Peel Extract. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2012, 98, 86–90. [Google Scholar] [CrossRef]

- Khan, R.; Fulekar, M.H. Biosynthesis of Titanium Dioxide Nanoparticles Using Bacillus Amyloliquefaciens Culture and Enhancement of Its Photocatalytic Activity for the Degradation of a Sulfonated Textile Dye Reactive Red 31. J. Colloid Interface Sci. 2016, 475, 184–191. [Google Scholar] [CrossRef]

- Zahir, A.A.; Chauhan, I.S.; Bagavan, A.; Kamaraj, C.; Elango, G.; Shankar, J.; Arjaria, N.; Roopan, S.M.; Rahuman, A.A.; Singh, N. Green Synthesis of Silver and Titanium Dioxide Nanoparticles Using Euphorbia Prostrata Extract Shows Shift from Apoptosis to G0/G1 Arrest Followed by Necrotic Cell Death in Leishmania Donovani. Antimicrob. Agents Chemother. 2015, 59, 4782–4799. [Google Scholar] [CrossRef]

- Sai Saraswathi, V.; Tatsugi, J.; Shin, P.K.; Santhakumar, K. Facile Biosynthesis, Characterization, and Solar Assisted Photocatalytic Effect of ZnO Nanoparticles Mediated by Leaves of L. speciosa. J. Photochem. Photobiol. B Biol. 2017, 167, 89–98. [Google Scholar] [CrossRef] [PubMed]

- Yuvakkumar, R.; Suresh, J.; Nathanael, A.J.; Sundrarajan, M.; Hong, S.I. Novel Green Synthetic Strategy to Prepare ZnO Nanocrystals Using Rambutan (Nephelium lappaceum L.) Peel Extract and Its Antibacterial Applications. Mater. Sci. Eng. C 2014, 41, 17–27. [Google Scholar] [CrossRef] [PubMed]

- Sharma, D.; Sabela, M.I.; Kanchi, S.; Mdluli, P.S.; Singh, G.; Stenström, T.A.; Bisetty, K. Biosynthesis of ZnO Nanoparticles Using Jacaranda Mimosifolia Flowers Extract: Synergistic Antibacterial Activity and Molecular Simulated Facet Specific Adsorption Studies. J. Photochem. Photobiol. B Biol. 2016, 162, 199–207. [Google Scholar] [CrossRef] [PubMed]

- Lingaraju, K.; Raja Naika, H.; Manjunath, K.; Basavaraj, R.B.; Nagabhushana, H.; Nagaraju, G.; Suresh, D. Biogenic Synthesis of Zinc Oxide Nanoparticles Using Ruta graveolens (L.) and Their Antibacterial and Antioxidant Activities. Appl. Nanosci. 2016, 6, 703–710. [Google Scholar] [CrossRef]

- Matinise, N.; Fuku, X.G.; Kaviyarasu, K.; Mayedwa, N.; Maaza, M. ZnO Nanoparticles via Moringa Oleifera Green Synthesis: Physical Properties & Mechanism of Formation. Appl. Surf. Sci. 2017, 406, 339–347. [Google Scholar] [CrossRef]

- Nagajyothi, P.C.; Cha, S.J.; Yang, I.J.; Sreekanth, T.V.M.; Kim, K.J.; Shin, H.M. Antioxidant and Anti-Inflammatory Activities of Zinc Oxide Nanoparticles Synthesized Using Polygala Tenuifolia Root Extract. J. Photochem. Photobiol. B Biol. 2015, 146, 10–17. [Google Scholar] [CrossRef] [PubMed]

- Elavarasan, N.; Kokila, K.; Inbasekar, G.; Sujatha, V. Evaluation of Photocatalytic Activity, Antibacterial and Cytotoxic Effects of Green Synthesized ZnO Nanoparticles by Sechium Edule Leaf Extract. Res. Chem. Intermed. 2017, 43, 3361–3376. [Google Scholar] [CrossRef]

- Rahimzadeh, C.Y.; Barzinjy, A.A.; Mohammed, A.S.; Hamad, S.M. Green Synthesis of SiO2 Nanoparticles from Rhus Coriaria L. Extract: Comparison with Chemically Synthesized SiO2 Nanoparticles. PLoS ONE 2022, 17, e0268184. [Google Scholar] [CrossRef]

- Rezaeian, M.; Afjoul, H.; Shamloo, A.; Maleki, A.; Afjoul, N. Green Synthesis of Silica Nanoparticles from Olive Residue and Investigation of Their Anticancer Potential. Nanomedicine 2021, 16, 1581–1593. [Google Scholar] [CrossRef]

- Arshad, A.N.; Wahid, M.H.M.; Rusop, M.; Majid, W.H.A.; Subban, R.H.Y.; Rozana, M.D. Dielectric and Structural Properties of Poly(Vinylidene Fluoride) (PVDF) and Poly(Vinylidene Fluoride-Trifluoroethylene) (PVDF-TrFE) Filled with Magnesium Oxide Nanofillers. J. Nanomater. 2019, 2019, 5961563. [Google Scholar] [CrossRef]

- Das, B.; Moumita, S.; Ghosh, S.; Khan, M.I.; Indira, D.; Jayabalan, R.; Tripathy, S.K.; Mishra, A.; Balasubramanian, P. Biosynthesis of Magnesium Oxide (MgO) Nanoflakes by Using Leaf Extract of Bauhinia Purpurea and Evaluation of Its Antibacterial Property against Staphylococcus Aureus. Mater. Sci. Eng. C 2018, 91, 436–444. [Google Scholar] [CrossRef] [PubMed]

- Leung, Y.H.; Ng, A.M.C.; Xu, X.; Shen, Z.; Gethings, L.A.; Wong, M.T.; Chan, C.M.N.; Guo, M.Y.; Ng, Y.H.; Djurišić, A.B.; et al. Mechanisms of Antibacterial Activity of Mgo: Non-Ros Mediated Toxicity of Mgo Nanoparticles towards Escherichia coli. Small 2014, 10, 1171–1183. [Google Scholar] [CrossRef] [PubMed]

- Nassar, M.Y.; Mohamed, T.Y.; Ahmed, I.S.; Samir, I. MgO Nanostructure via a Sol-Gel Combustion Synthesis Method Using Different Fuels: An Efficient Nano-Adsorbent for the Removal of Some Anionic Textile Dyes. J. Mol. Liq. 2017, 225, 730–740. [Google Scholar] [CrossRef]

- Halder, R.; Bandyopadhyay, S. Synthesis and Optical Properties of Anion Deficient Nano MgO. J. Alloys Compd. 2017, 693, 534–542. [Google Scholar] [CrossRef]

- Look, D.C. Recent Advances in ZnO Materials and Devices. Mater. Sci. Eng. 2001, 80, 383–387. [Google Scholar] [CrossRef]

- Sharma, P.; Hasan, M.R.; Mehto, N.K.; Deepak; Bishoyi, A.; Narang, J. 92 Years of Zinc Oxide: Has Been Studied by the Scientific Community since the 1930s- An Overview. Sensors Int. 2022, 3, 100182. [Google Scholar] [CrossRef]

- Talam, S.; Karumuri, S.R.; Gunnam, N. Synthesis, Characterization, and Spectroscopic Properties of ZnO Nanoparticles. ISRN Nanotechnol. 2012, 2012, 372505. [Google Scholar] [CrossRef]

- Arya, S.; Mahajan, P.; Mahajan, S.; Khosla, A.; Datt, R.; Gupta, V.; Young, S.-J.; Oruganti, S.K. Review—Influence of Processing Parameters to Control Morphology and Optical Properties of Sol-Gel Synthesized ZnO Nanoparticles. ECS J. Solid State Sci. Technol. 2021, 10, 023002. [Google Scholar] [CrossRef]

- Gudkov, S.V.; Burmistrov, D.E.; Serov, D.A.; Rebezov, M.B.; Semenova, A.A.; Lisitsyn, A.B. A Mini Review of Antibacterial Properties of ZnO Nanoparticles. Front. Phys. 2021, 9, 641481. [Google Scholar] [CrossRef]

- Li, S.; Chen, G.; Qiang, S.; Yin, Z.; Zhang, Z.; Chen, Y. Synthesis and Evaluation of Highly Dispersible and Efficient Photocatalytic TiO2/Poly Lactic Acid Nanocomposite Films via Sol-Gel and Casting Processes. Int. J. Food Microbiol. 2020, 331, 108763. [Google Scholar] [CrossRef]

- Zorah, M.; Mustapa, I.R.; Daud, N.; Nahida, J.H.; Sudin, N.A.S.; Majhool, A.A.; Mahmoudi, E. Improvement Thermomechanical Properties of Polylactic Acid via Titania Nanofillers Reinforcement. J. Adv. Res. Fluid Mech. Therm. Sci. 2020, 70, 97–111. [Google Scholar] [CrossRef]

- González, E.A.S.; Olmos, D.; Lorente, M.A.; Vélaz, I.; González-Benito, J. Preparation and Characterization of Polymer Composite Materials Based on PLA/TiO2 for Antibacterial Packaging. Polymers 2018, 10, 1365. [Google Scholar] [CrossRef] [PubMed]

- Buzarovska, A.; Dinescu, S.; Chitoiu, L.; Costache, M. Porous Poly(l-Lactic Acid) Nanocomposite Scaffolds with Functionalized TiO2 Nanoparticles: Properties, Cytocompatibility and Drug Release Capability. J. Mater. Sci. 2018, 53, 11151–11166. [Google Scholar] [CrossRef]

- Mallick, S.; Ahmad, Z.; Touati, F.; Bhadra, J.; Shakoor, R.A.; Al-Thani, N.J. PLA-TiO2 Nanocomposites: Thermal, Morphological, Structural, and Humidity Sensing Properties. Ceram. Int. 2018, 44, 16507–16513. [Google Scholar] [CrossRef]

- Luo, Y.; Lin, Z.; Guo, G. Biodegradation Assessment of Poly (Lactic Acid) Filled with Functionalized Titania Nanoparticles (PLA/TiO2) under Compost Conditions. Nanoscale Res. Lett. 2019, 14, 56. [Google Scholar] [CrossRef] [PubMed]

- Shebi, A.; Lisa, S. Evaluation of Biocompatibility and Bactericidal Activity of Hierarchically Porous PLA-TiO2 Nanocomposite Films Fabricated by Breath-Figure Method. Mater. Chem. Phys. 2019, 230, 308–318. [Google Scholar] [CrossRef]

- Xie, J.; Hung, Y.C. UV-A Activated TiO2 Embedded Biodegradable Polymer Film for Antimicrobial Food Packaging Application. Lwt 2018, 96, 307–314. [Google Scholar] [CrossRef]

- Ismael, M. Latest Progress on the Key Operating Parameters Affecting the Photocatalytic Activity of TiO2-Based Photocatalysts for Hydrogen Fuel Production: A Comprehensive Review. Fuel 2021, 303, 121207. [Google Scholar] [CrossRef]

- Foster, H.A.; Ditta, I.B.; Varghese, S.; Steele, A. Photocatalytic Disinfection Using Titanium Dioxide: Spectrum and Mechanism of Antimicrobial Activity. Appl. Microbiol. Biotechnol. 2011, 90, 1847–1868. [Google Scholar] [CrossRef]

- Ling, Y.; Zhang, P.; Wang, J.; Chen, Y. Effect of PVA Fiber on Mechanical Properties of Cementitious Composite with and without Nano-SiO2. Constr. Build. Mater. 2019, 229, 117068. [Google Scholar] [CrossRef]

- Papadopoulos, L.; Klonos, P.A.; Terzopoulou, Z.; Psochia, E.; Sanusi, O.M.; Hocine, N.A.; Benelfellah, A.; Giliopoulos, D.; Triantafyllidis, K.; Kyritsis, A.; et al. Comparative Study of Crystallization, Semicrystalline Morphology, and Molecular Mobility in Nanocomposites Based on Polylactide and Various Inclusions at Low Filler Loadings. Polymer 2021, 217, 123457. [Google Scholar] [CrossRef]

- Charitos, I.; Klonos, P.A.; Kyritsis, A.; Koralli, P.; Kontos, A.G.; Kontou, E. Thermomechanical Performance of Biodegradable Poly (Lactic Acid)/Carbonaceous Hybrid Nanocomposites: Comparative Study. Polym. Compos. 2022, 43, 1900–1915. [Google Scholar] [CrossRef]

- Klonos, P.; Terzopoulou, Z.; Koutsoumpis, S.; Zidropoulos, S.; Kripotou, S.; Papageorgiou, G.Z.; Bikiaris, D.N.; Kyritsis, A.; Pissis, P. Rigid Amorphous Fraction and Segmental Dynamics in Nanocomposites Based on Poly(L–Lactic Acid) and Nano-Inclusions of 1–3D Geometry Studied by Thermal and Dielectric Techniques. Eur. Polym. J. 2016, 82, 16–34. [Google Scholar] [CrossRef]

- Bhattacharya, M. Polymer Nanocomposites-A Comparison between Carbon Nanotubes, Graphene, and Clay as Nanofillers. Materials 2016, 9, 262. [Google Scholar] [CrossRef] [PubMed]

- Scaffaro, R.; Maio, A. Integrated Ternary Bionanocomposites with Superior Mechanical Performance via the Synergistic Role of Graphene and Plasma Treated Carbon Nanotubes. Compos. Part B Eng. 2019, 168, 550–559. [Google Scholar] [CrossRef]

- Valdes, A.; Qu, Z.W.; Kroes, G.J.; Rossmeisl, J.; Nørskov, J.K. Oxidation and Photo-Oxidation of Water on TiO2 Surface. J. Phys. Chem. C 2008, 112, 9872–9879. [Google Scholar] [CrossRef]

- Ivanov, E.; Kotsilkova, R.; Xia, H.; Chen, Y.; Donato, R.K.; Donato, K.; Godoy, A.P.; Di Maio, R.; Silvestre, C.; Cimmino, S.; et al. PLA/Graphene/MWCNT Composites with Improved Electrical and Thermal Properties Suitable for FDM 3D Printing Applications. Appl. Sci. 2019, 9, 1209. [Google Scholar] [CrossRef]

- Norizan, M.N.; Moklis, M.H.; Ngah Demon, S.Z.; Halim, N.A.; Samsuri, A.; Mohamad, I.S.; Knight, V.F.; Abdullah, N. Carbon Nanotubes: Functionalisation and Their Application in Chemical Sensors. RSC Adv. 2020, 10, 43704–43732. [Google Scholar] [CrossRef]

- Tang, R.; Shi, Y.; Hou, Z.; Wei, L. Carbon Nanotube-Based Chemiresistive Sensors. Sensors 2017, 17, 882. [Google Scholar] [CrossRef]

- Clemons, C.B.; Roberts, M.W.; Wilber, J.P.; Young, G.W.; Buldum, A.; Quinn, D.D. Continuum Plate Theory and Atomistic Modeling to Find the Flexural Rigidity of a Graphene Sheet Interacting with a Substrate. J. Nanotechnol. 2010, 2010, 868492. [Google Scholar] [CrossRef]

- Porto, L.S.; Silva, D.N.; de Oliveira, A.E.F.; Pereira, A.C.; Borges, K.B. Carbon Nanomaterials: Synthesis and Applications to Development of Electrochemical Sensors in Determination of Drugs and Compounds of Clinical Interest. Rev. Anal. Chem. 2020, 38, 1–16. [Google Scholar] [CrossRef]

- Milani, M.A.; Quijada, R.; Basso, N.R.S.; Graebin, A.P.; Galland, G.B. Influence of the Graphite Type on the Synthesis of Polypropylene/Graphene Nanocomposites. J. Polym. Sci. Part A Polym. Chem. 2012, 50, 3598–3605. [Google Scholar] [CrossRef]

- Papageorgiou, G.Z.; Terzopoulou, Z.; Bikiaris, D.; Triantafyllidis, K.S.; Diamanti, E.; Gournis, D.; Klonos, P.; Giannoulidis, E.; Pissis, P. Evaluation of the Formed Interface in Biodegradable Poly(l-Lactic Acid)/Graphene Oxide Nanocomposites and the Effect of Nanofillers on Mechanical and Thermal Properties. Thermochim. Acta 2014, 597, 48–57. [Google Scholar] [CrossRef]

- Klonos, P.; Kripotou, S.; Kyritsis, A.; Papageorgiou, G.Z.; Bikiaris, D.; Gournis, D.; Pissis, P. Glass Transition and Segmental Dynamics in Poly(l-Lactic Acid)/Graphene Oxide Nanocomposites. Thermochim. Acta 2015, 617, 44–53. [Google Scholar] [CrossRef]

- Klonos, P.A.; Peoglos, V.; Bikiaris, D.N.; Kyritsis, A. Rigid Amorphous Fraction and Thermal Diffusivity in Nanocomposites Based on Poly(l -Lactic Acid) Filled with Carbon Nanotubes and Graphene Oxide. J. Phys. Chem. C 2020, 124, 5469–5479. [Google Scholar] [CrossRef]

- Trivedi, D.N.; Rachchh, N.V. Graphene and Its Application in Thermoplastic Polymers as Nano-Filler- A Review. Polymer 2022, 240, 124486. [Google Scholar] [CrossRef]

- Angelova, P. Mechanical and Thermal Properties of PLA Based Nanocomposites with Graphene and Carbon Nanotubes. J. Theor. Appl. Mech. 2019, 49, 241–256. [Google Scholar] [CrossRef]

- Msibi, M.; Mashamba, A.; Mashinini, P.M.; Hashe, V.T. 3D Printing of Carbon Nanofiber-PLA Composite. In Proceedings of the 11th South African Conference Computational and Applied Mechanics, SACAM 2018, Vanderbijlpark, South Africa, 17–19 September 2018; pp. 670–679. [Google Scholar]

- Díez-Pascual, A.M. State of the Art in the Antibacterial and Antiviral Applications of Carbon-Based Polymeric Nanocomposites. Int. J. Mol. Sci. 2021, 22, 10511. [Google Scholar] [CrossRef]

- Giannopoulos, G.I. Linking MD and FEM to Predict the Mechanical Behaviour of Fullerene Reinforced Nylon-12. Compos. Part B Eng. 2019, 161, 455–463. [Google Scholar] [CrossRef]

- Kausar, A. Polymer/Fullerene Nanocomposite Coatings—Front Line Potential. Emergent Mater. 2022, 5, 29–40. [Google Scholar] [CrossRef]

- Pan, Y.; Guo, Z.; Ran, S.; Fang, Z. Influence of Fullerenes on the Thermal and Flame-Retardant Properties of Polymeric Materials. J. Appl. Polym. Sci. 2020, 137, 47538. [Google Scholar] [CrossRef]

- Dhanaraj, A.; Das, K.; Keller, J.M. A Study of the Optical Band Gap Energy and Urbach Energy of Fullerene (C60) Doped PMMA Nanocomposites. In AIP Conference Proceedings; AIP Publishing LLC: Woodbury, NY, USA, 2020; p. 110040. [Google Scholar] [CrossRef]

- Fraga-Corral, M.; García-Oliveira, P.; Pereira, A.G.; Lourenço-Lopes, C.; Jimenez-Lopez, C.; Prieto, M.A.; Simal-Gandara, J. Technological Application of Tannin-Based Extracts. Molecules 2020, 25, 614. [Google Scholar] [CrossRef] [PubMed]

- Chinaglia, S.; Tosin, M.; Degli-Innocenti, F. Biodegradation Rate of Biodegradable Plastics at Molecular Level. Polym. Degrad. Stab. 2018, 147, 237–244. [Google Scholar] [CrossRef]

- Haslam, E. Vegetable Tannins. In Biochemistry of Plant Phenolics; Plenum Press: New York, NY, USA, 1979. [Google Scholar]

- Smeriglio, A.; Barreca, D.; Bellocco, E.; Trombetta, D. Proanthocyanidins and Hydrolysable Tannins: Occurrence, Dietary Intake and Pharmacological Effects. Br. J. Pharmacol. 2017, 174, 1244–1262. [Google Scholar] [CrossRef]

- Cerro, D.; Bustos, G.; Villegas, C.; Buendia, N.; Truffa, G.; Godoy, M.P.; Rodríguez, F.; Rojas, A.; Galotto, M.J.; Constandil, L.; et al. Effect of Supercritical Incorporation of Cinnamaldehyde on Physical-Chemical Properties, Disintegration and Toxicity Studies of PLA/Lignin Nanocomposites. Int. J. Biol. Macromol. 2021, 167, 255–266. [Google Scholar] [CrossRef]

- Cavallo, E.; He, X.; Luzi, F.; Dominici, F.; Cerrutti, P.; Bernal, C.; Foresti, M.L.; Torre, L.; Puglia, D. UV Protective, Antioxidant, Antibacterial and Compostable Polylactic Acid Composites Containing Pristine and Chemically Modified Lignin Nanoparticles. Molecules 2021, 26, 126. [Google Scholar] [CrossRef]

- Patanair, B.; Saiter-Fourcin, A.; Thomas, S.; Thomas, M.G.; Pundarikashan, P.P.; Nair, K.G.; Kumar, V.K.; Maria, H.J.; Delpouve, N. Promoting Interfacial Interactions with the Addition of Lignin in Poly(Lactic Acid) Hybrid Nanocomposites. Polymers 2021, 13, 272. [Google Scholar] [CrossRef]

- Bikiaris, N.D.; Koumentakou, I.; Lykidou, S.; Nikolaidis, N. Innovative Skin Product O/W Emulsions Containing Lignin, Multiwall Carbon Nanotubes and Graphene Oxide Nanoadditives with Enhanced Sun Protection Factor and UV Stability Properties. Appl. Nano 2022, 3, 1–15. [Google Scholar] [CrossRef]

- Groh, K.J.; Backhaus, T.; Carney-Almroth, B.; Geueke, B.; Inostroza, P.A.; Lennquist, A.; Leslie, H.A.; Maffini, M.; Slunge, D.; Trasande, L.; et al. Overview of Known Plastic Packaging-Associated Chemicals and Their Hazards. Sci. Total Environ. 2019, 651, 3253–3268. [Google Scholar] [CrossRef]

- Suppakul, P.; Miltz, J.; Sonneveld, K.; Bigger, S.W. Active Packaging Technologies with an Emphasis on Antimicrobial Packaging and Its Applications. J. Food Sci. 2003, 68, 408–420. [Google Scholar] [CrossRef]

- Karunarathna, M.S.; Smith, R.C. Valorization of Lignin as a Sustainable Component of Structural Materials and Composites: Advances from 2011 to 2019. Sustainability 2020, 12, 734. [Google Scholar] [CrossRef]

- Das, A.K.; Islam, M.N.; Faruk, M.O.; Ashaduzzaman, M.; Dungani, R. Review on Tannins: Extraction Processes, Applications and Possibilities. S. Afr. J. Bot. 2020, 135, 58–70. [Google Scholar] [CrossRef]

- Chang, Z.; Zhang, Q.; Liang, W.; Zhou, K.; Jian, P.; She, G.; Zhang, L. A Comprehensive Review of the Structure Elucidation of Tannins from Terminalia Linn. Evid. Based Complement. Altern. Med. 2019, 2019, 8623909. [Google Scholar] [CrossRef] [PubMed]

- Pizzi, A. Tannins: Prospectives and Actual Industrial Applications. Biomolecules 2019, 9, 344. [Google Scholar] [CrossRef] [PubMed]

- Liao, J.; Brosse, N.; Hoppe, S.; Du, G.; Zhou, X.; Pizzi, A. One-Step Compatibilization of Poly(Lactic Acid) and Tannin via Reactive Extrusion. Mater. Des. 2020, 191, 108603. [Google Scholar] [CrossRef]

- Bridson, J.H.; Kaur, J.; Zhang, Z.; Donaldson, L.; Fernyhough, A. Polymeric Flavonoids Processed with Co-Polymers as UV and Thermal Stabilisers for Polyethylene Films. Polym. Degrad. Stab. 2015, 122, 18–24. [Google Scholar] [CrossRef]

- Shnawa, H.A.; Khaleel, M.I.; Muhamed, F.J. Oxidation of HDPE in the Presence of PVC Grafted with Natural Polyphenols (Tannins) as Antioxidant. Open J. Polym. Chem. 2015, 05, 9–16. [Google Scholar] [CrossRef]

- Liao, J.; Brosse, N.; Pizzi, A.; Hoppe, S. Dynamically Cross-Linked Tannin as a Reinforcement of Polypropylene and UV Protection Properties. Polymers 2019, 11, 102. [Google Scholar] [CrossRef]

- Zhai, Y.; Wang, J.; Wang, H.; Song, T.; Hu, W.; Li, S. Preparation and Characterization of Antioxidative and UV-Protective Larch Bark Tannin/PVA Composite Membranes. Molecules 2018, 23, 2073. [Google Scholar] [CrossRef]

- Cresnar, K.P.; Zamboulis, A.; Bikiaris, D.N.; Aulova, A.; Zemljic, L.F. Kraft Lignin/Tannin as a Potential Accelerator of Antioxidant and Antibacterial Properties in an Active Thermoplastic Polyester-Based Multifunctional Material. Polymers 2022, 14, 1532. [Google Scholar] [CrossRef]

- Ainali, N.M.; Tarani, E.; Zamboulis, A.; Črešnar, K.P.; Zemljič, L.F.; Chrissafis, K.; Lambropoulou, D.A.; Bikiaris, D.N. Thermal Stability and Decomposition Mechanism of Pla Nanocomposites with Kraft Lignin and Tannin. Polymers 2021, 13, 2818. [Google Scholar] [CrossRef] [PubMed]

- Črešnar, K.P.; Klonos, P.A.; Zamboulis, A.; Terzopoulou, Z.; Xanthopoulou, E.; Papadopoulos, L.; Kyritsis, A.; Kuzmič, K.; Zemljič, L.F.; Bikiaris, D.N. Structure-Properties Relationships in Renewable Composites Based on Polylactide Filled with Tannin and Kraft Lignin—Crystallization and Molecular Mobility. Thermochim. Acta 2021, 703, 178998. [Google Scholar] [CrossRef]

- Li, T.; Chen, C.; Brozena, A.H.; Zhu, J.Y.; Xu, L.; Driemeier, C.; Dai, J.; Rojas, O.J.; Isogai, A.; Wågberg, L.; et al. Developing Fibrillated Cellulose as a Sustainable Technological Material. Nature 2021, 590, 47–56. [Google Scholar] [CrossRef] [PubMed]

- Trache, D.; Tarchoun, A.F.; Derradji, M.; Hamidon, T.S.; Masruchin, N.; Brosse, N.; Hussin, M.H. Nanocellulose: From Fundamentals to Advanced Applications. Front. Chem. 2020, 8, 392. [Google Scholar] [CrossRef]

- Xu, T.; Du, H.; Liu, H.; Liu, W.; Zhang, X.; Si, C.; Liu, P.; Zhang, K. Advanced Nanocellulose-Based Composites for Flexible Functional Energy Storage Devices. Adv. Mater. 2021, 33, 2101368. [Google Scholar] [CrossRef]

- Rigotti, D.; Checchetto, R.; Tarter, S.; Caretti, D.; Rizzuto, M.; Fambri, L.; Pegoretti, A. Polylactic Acid-Lauryl Functionalized Nanocellulose Nanocomposites: Microstructural, Thermo-Mechanical and Gas Transport Properties. Express Polym. Lett. 2019, 13, 858–876. [Google Scholar] [CrossRef]

- Shanmugam, K.; Doosthosseini, H.; Varanasi, S.; Garnier, G.; Batchelor, W. Nanocellulose Films as Air and Water Vapour Barriers: A Recyclable and Biodegradable Alternative to Polyolefin Packaging. Sustain. Mater. Technol. 2019, 22, e00115. [Google Scholar] [CrossRef]

- Ahankari, S.S.; Subhedar, A.R.; Bhadauria, S.S.; Dufresne, A. Nanocellulose in Food Packaging: A Review. Carbohydr. Polym. 2021, 255, 117479. [Google Scholar] [CrossRef]

- Wang, J.; Wang, S. Preparation, Modification and Environmental Application of Biochar: A Review. J. Clean. Prod. 2019, 227, 1002–1022. [Google Scholar] [CrossRef]

- Weber, K.; Quicker, P. Properties of Biochar. Fuel 2018, 217, 240–261. [Google Scholar] [CrossRef]

- Zhang, M.; Song, G.; Gelardi, D.L.; Huang, L.; Khan, E.; Mašek, O.; Parikh, S.J.; Ok, Y.S. Evaluating Biochar and Its Modifications for the Removal of Ammonium, Nitrate, and Phosphate in Water. Water Res. 2020, 186, 116303. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Ok, Y.S.; Tsang, D.C.W.; Alessi, D.S.; Rinklebe, J.; Mašek, O.; Bolan, N.S.; Hou, D. Biochar Composites: Emerging Trends, Field Successes and Sustainability Implications. Soil Use Manag. 2022, 38, 14–38. [Google Scholar] [CrossRef]

- Lehmann, J.; Cowie, A.; Masiello, C.A.; Kammann, C.; Woolf, D.; Amonette, J.E.; Cazuela, M.L.; Camprs-Arbestain, M.; Whitman, T. Biochar in Climate Change Mitigation. Nat. Geosci. 2021, 13, 883–892. [Google Scholar] [CrossRef]

- Naghdi, M.; Taheran, M.; Brar, S.K.; Rouissi, T.; Verma, M.; Surampalli, R.Y.; Valero, J.R. A Green Method for Production of Nanobiochar by Ball Milling- Optimization and Characterization. J. Clean. Prod. 2017, 164, 1394–1405. [Google Scholar] [CrossRef]

- Song, B.; Cao, X.; Gao, W.; Aziz, S.; Gao, S.; Lam, C.H.; Lin, R. Preparation of Nano-Biochar from Conventional Biorefineries for High-Value Applications. Renew. Sustain. Energy Rev. 2022, 157, 112057. [Google Scholar] [CrossRef]

- Lian, F.; Yu, W.; Zhou, Q.; Gu, S.; Wang, Z.; Xing, B.; Xing, B. Size Matters: Nano-Biochar Triggers Decomposition and Transformation Inhibition of Antibiotic Resistance Genes in Aqueous Environments. Environ. Sci. Technol. 2020, 54, 8821–8829. [Google Scholar] [CrossRef]

- Anupama; Khare, P. A Comprehensive Evaluation of Inherent Properties and Applications of Nano-Biochar Prepared from Different Methods and Feedstocks. J. Clean. Prod. 2021, 320, 128759. [Google Scholar] [CrossRef]

- Liu, G.; Zheng, H.; Jiang, Z.; Zhao, J.; Wang, Z.; Pan, B.; Xing, B. Formation and Physicochemical Characteristics of Nano Biochar: Insight into Chemical and Colloidal Stability. Environ. Sci. Technol. 2018, 52, 10369–10379. [Google Scholar] [CrossRef]

- Barsoum, M. Fundamental of Ceramics; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D Printing of Ceramics: A Review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Gupta, N.; Singh, A.; Dey, N.; Chattopadhyay, S.; Joseph, J.P.; Gupta, D.; Ganguli, M.; Pal, A. Pathway-Driven Peptide-Bioglass Nanocomposites as the Dynamic and Self-Healable Matrix. Chem. Mater. 2021, 33, 589–599. [Google Scholar] [CrossRef]

- Dehnavi, N.; Parivar, K.; Goodarzi, V.; Salimi, A.; Nourani, M.R. Systematically Engineered Electrospun Conduit Based on PGA/Collagen/Bioglass Nanocomposites: The Evaluation of Morphological, Mechanical, and Bio-Properties. Polym. Adv. Technol. 2019, 30, 2192–2206. [Google Scholar] [CrossRef]

- Canales, D.; Saavedra, M.; Flores, M.T.; Bejarano, J.; Ortiz, J.A.; Orihuela, P.; Alfaro, A.; Pabón, E.; Palza, H.; Zapata, P.A. Effect of Bioglass Nanoparticles on the Properties and Bioactivity of Poly(Lactic Acid) Films. J. Biomed. Mater. Res. Part A 2020, 108, 2032–2043. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Hu, H.; Liu, Y.; Tan, J.; Chen, W.; Ying, C.; Liu, Q.; Fu, X.; Hu, S.; Wong, C.P. Homogeneously Dispersed Composites of Hydroxyapatite Nanorods and Poly(Lactic Acid) and Their Mechanical Properties and Crystallization Behavior. Compos. Part A Appl. Sci. Manuf. 2020, 132, 105841. [Google Scholar] [CrossRef]

- Michael, F.M.; Ratnam, C.T.; Khalid, M.; Ramarad, S.; Walvekar, R. Surface Modification of Nanohydroxyapatite and Its Loading Effect on Polylactic Acid Properties for Load Bearing Implants. Polym. Polym. Compos. 2017, 16, 101–113. [Google Scholar] [CrossRef]

- Szcześ, A.; Hołysz, L.; Chibowski, E. Synthesis of Hydroxyapatite for Biomedical Applications. Adv. Colloid Interface Sci. 2017, 249, 321–330. [Google Scholar] [CrossRef] [PubMed]

- Du, M.; Chen, J.; Liu, K.; Xing, H.; Song, C. Recent Advances in Biomedical Engineering of Nano-Hydroxyapatite Including Dentistry, Cancer Treatment and Bone Repair. Compos. Part B Eng. 2021, 215, 108790. [Google Scholar] [CrossRef]

- Wetteland, C.L.; Liu, H. Optical and Biological Properties of Polymer-Based Nanocomposites with Improved Dispersion of Ceramic Nanoparticles. J. Biomed. Mater. Res. Part A 2018, 106, 2692–2707. [Google Scholar] [CrossRef]

- Ray, S.S. Recent Trends and Future Outlooks in the Field of Clay-Containing Polymer Nanocomposites. Macromol. Chem. Phys. 2014, 215, 1162–1179. [Google Scholar] [CrossRef]

- Guo, F.; Aryana, S.; Han, Y.; Jiao, Y. A Review of the Synthesis and Applications of Polymer-Nanoclay Composites. Appl. Sci. 2018, 8, 1696. [Google Scholar] [CrossRef]

- Rafiee, R.; Shahzadi, R. Mechanical Properties of Nanoclay and Nanoclay Reinforced Polymers: A Review. Polym. Compos. 2019, 40, 431–445. [Google Scholar] [CrossRef]

- Jawaid, M.; Qaiss, A.E.K.; Bouhfi, R. Nanoclay Reinforced Polymer Composites Natural Fibre/Nanoclay Hybrid Composites; Springer: Singapore, 2016. [Google Scholar] [CrossRef]

- Rhim, J.W.; Hong, S.I.; Ha, C.S. Tensile, Water Vapor Barrier and Antimicrobial Properties of PLA/Nanoclay Composite Films. Lwt 2009, 42, 612–617. [Google Scholar] [CrossRef]

- Pluta, M.; Galeski, A.; Alexandre, M.; Paul, M.A.; Dubois, P. Polylactide/Montmorillonite Nanocomposites and Microcomposites Prepared by Melt Blending: Structure and Some Physical Properties. J. Appl. Polym. Sci. 2002, 86, 1497–1506. [Google Scholar] [CrossRef]

- Re, G.L.; Benali, S.; Habibi, Y.; Raquez, J.M.; Dubois, P. Stereocomplexed PLA Nanocomposites: From in Situ Polymerization to Materials Properties. Eur. Polym. J. 2014, 54, 138–150. [Google Scholar] [CrossRef]

- Othman, S.H.; Ling, H.N.; Talib, R.A.; Naim, M.N.; Risyon, N.P.; Saifullah, M. PLA/MMT and PLA/Halloysite Bio-Nanocomposite Films: Mechanical, Barrier, and Transparency. J. Nano Res. 2019, 59, 77–93. [Google Scholar] [CrossRef]

- Morais, D.D.S.; Barbosa, R.; Medeiros, K.M.; Araújo, E.M.; Melo, T.J.A. Preparation of Poly(Lactic Acid)/Bentonite Clay Bionanocomposite. Mater. Sci. Forum 2014, 775–776, 233–237. [Google Scholar] [CrossRef]

- Guo, F.; Liao, X.; Li, S.; Yan, Z.; Tang, W.; Li, G. Heat Insulating PLA/HNTs Foams with Enhanced Compression Performance Fabricated by Supercritical Carbon Dioxide. J. Supercrit. Fluids 2021, 177, 105344. [Google Scholar] [CrossRef]

- Moazeni, N.; Mohamad, Z.; Dehbari, N. Study of Silane Treatment on Poly-Lactic Acid(PLA)/Sepiolite Nanocomposite Thin Films. J. Appl. Polym. Sci. 2015, 132, 1–8. [Google Scholar] [CrossRef]

- Kasprzhitskii, A.; Lazorenko, G.; Kruglikov, A.; Kuchkina, I.; Gorodov, V. Effect of Silane Functionalization on Properties of Poly(Lactic Acid)/Palygorskite Nanocomposites. Inorganics 2021, 9, 3. [Google Scholar] [CrossRef]

- Cardoso, R.S.; Aguiar, V.O.; Marques, M.D.F.V. Masterbatches of Polypropylene/Clay Obtained by in Situ Polymerization and Melt-Blended with Commercial Polypropylene. J. Compos. Mater. 2017, 51, 3547–3556. [Google Scholar] [CrossRef]

- Ramesh, P.; Prasad, B.D.; Narayana, K.L. Effect of MMT Clay on Mechanical, Thermal and Barrier Properties of Treated Aloevera Fiber/PLA-Hybrid Biocomposites. Silicon 2020, 12, 1751–1760. [Google Scholar] [CrossRef]

- Ramesh, P.; Prasad, B.D.; Narayana, K.L. Effect of Fiber Hybridization and Montmorillonite Clay on Properties of Treated Kenaf/Aloe Vera Fiber Reinforced PLA Hybrid Nanobiocomposite. Cellulose 2020, 27, 6977–6993. [Google Scholar] [CrossRef]

- Othman, S.H.; Hassan, N.; Talib, R.A.; Kadir Basha, R.; Risyon, N.P. Mechanical and Thermal Properties of PLA/Halloysite Bio-Nanocomposite Films: Effect of Halloysite Nanoclay Concentration and Addition of Glycerol. J. Polym. Eng. 2017, 37, 381–389. [Google Scholar] [CrossRef]

- Risyon, N.P.; Othman, S.H.; Basha, R.K.; Talib, R.A. Effect of Halloysite Nanoclay Concentration and Addition of Glycerol on Mechanical Properties of Bionanocomposite Films. Polym. Polym. Compos. 2016, 24, 795–802. [Google Scholar] [CrossRef]

- Ramesh, P.; Prasad, B.D.; Narayana, K.L. Influence of Montmorillonite Clay Content on Thermal, Mechanical, Water Absorption and Biodegradability Properties of Treated Kenaf Fiber/PLA-Hybrid Biocomposites. Silicon 2021, 13, 109–118. [Google Scholar] [CrossRef]

- Rao, R.U.; Venkatanarayana, B.; Suman, K.N.S. Enhancement of Mechanical Properties of PLA/PCL (80/20) Blend by Reinforcing with MMT Nanoclay. Mater. Today Proc. 2019, 18, 85–97. [Google Scholar] [CrossRef]

- Montava-Jorda, S.; Chacon, V.; Lascano, D.; Sanchez-Nacher, L.; Montanes, N. Manufacturing and Characterization of Functionalized Aliphatic Polyester from Poly(Lactic Acid) with Halloysite Nanotubes. Polymers 2019, 11, 1314. [Google Scholar] [CrossRef]

- Swaroop, C.; Shukla, M. Nano-Magnesium Oxide Reinforced Polylactic Acid Biofilms for Food Packaging Applications. Int. J. Biol. Macromol. 2018, 113, 729–736. [Google Scholar] [CrossRef]

- Swaroop, C.; Shukla, M. Development of Blown Polylactic Acid-MgO Nanocomposite Films for Food Packaging. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105482. [Google Scholar] [CrossRef]

- Chong, W.J.; Shen, S.; Li, Y.; Trinchi, A.; Pejak, D.; (Louis) Kyratzis, I.; Sola, A.; Wen, C. Additive Manufacturing of Antibacterial PLA-ZnO Nanocomposites: Benefits, Limitations and Open Challenges. J. Mater. Sci. Technol. 2022, 111, 120–151. [Google Scholar] [CrossRef]

- Dash, K.K.; Ali, N.A.; Das, D.; Mohanta, D. Thorough Evaluation of Sweet Potato Starch and Lemon-Waste Pectin Based-Edible Films with Nano-Titania Inclusions for Food Packaging Applications. Int. J. Biol. Macromol. 2019, 139, 449–458. [Google Scholar] [CrossRef]

- Baek, N.; Kim, Y.T.; Marcy, J.E.; Duncan, S.E.; O’Keefe, S.F. Physical Properties of Nanocomposite Polylactic Acid Films Prepared with Oleic Acid Modified Titanium Dioxide. Food Packag. Shelf Life 2018, 17, 30–38. [Google Scholar] [CrossRef]

- Batool, M.; Abid, A.; Khurshid, S.; Bashir, T.; Ismail, M.A.; Razaq, M.A.; Jamil, M. Quality Control of Nano-Food Packing Material for Grapes (Vitis Vinifera) Based on ZnO and Polylactic Acid (PLA) Biofilm. Arab. J. Sci. Eng. 2022, 47, 319–331. [Google Scholar] [CrossRef]

- Grande-Tovar, C.D.; Castro, J.I.; Valencia Llano, C.H.; Tenorio, D.L.; Saavedra, M.; Zapata, P.A.; Chaur, M.N. Polycaprolactone (PCL)-Polylactic Acid (PLA)-Glycerol (Gly) Composites Incorporated with Zinc Oxide Nanoparticles (ZnO-NPs) and Tea Tree Essential Oil (TTEO) for Tissue Engineering Applications. Pharmaceutics 2022, 15, 43. [Google Scholar] [CrossRef] [PubMed]

- Roeinfard, M.; Bahari, A. Nanostructural Characterization of the Fe3O4/ZnO Magnetic Nanocomposite as an Application in Medicine. J. Supercond. Nov. Magn. 2017, 30, 3541–3548. [Google Scholar] [CrossRef]

- Kim, I.; Viswanathan, K.; Kasi, G.; Thanakkasaranee, S.; Sadeghi, K.; Seo, J. ZnO Nanostructures in Active Antibacterial Food Packaging: Preparation Methods, Antimicrobial Mechanisms, Safety Issues, Future Prospects, and Challenges. Food Rev. Int. 2022, 38, 537–565. [Google Scholar] [CrossRef]

- Nonato, R.C.; Mei, L.H.I.; Bonse, B.C.; Leal, C.V.; Levy, C.E.; Oliveira, F.A.; Delarmelina, C.; Duarte, M.C.T.; Morales, A.R. Nanocomposites of PLA/ZnO Nanofibers for Medical Applications: Antimicrobial Effect, Thermal, and Mechanical Behavior under Cyclic Stress. Polym. Eng. Sci. 2022, 62, 1147–1155. [Google Scholar] [CrossRef]

- Rashedi, S.M.; Khajavi, R.; Rashidi, A.; Rahimi, M.K.; Bahador, A. Novel PLA/ZnO Nanofibrous Nanocomposite Loaded with Tranexamic Acid as an Effective Wound Dressing: In Vitro and in Vivo Assessment. Iran. J. Biotechnol. 2021, 19, 38–47. [Google Scholar] [CrossRef]

- Sefidan, A.M. Novel Silicon Dioxide -Based Nanocomposites as an Antimicrobial in Poly (Lactic Acid) Nanocomposites Films. Nanomed. Res. J. 2018, 3, 65–70. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, X.; Zhang, L.; Feng, Y.; Liu, C.; Shen, C. Simultaneously Reinforcing and Toughening Poly(Lactic Acid) by Incorporating Reactive Melt-Functionalized Silica Nanoparticles. J. Appl. Polym. Sci. 2020, 137, 48834. [Google Scholar] [CrossRef]

- Nerantzaki, M.; Prokopiou, L.; Bikiaris, D.N.; Patsiaoura, D.; Chrissafis, K.; Klonos, P.; Kyritsis, A.; Pissis, P. In Situ Prepared Poly(DL-Lactic Acid)/Silica Nanocomposites: Study of Molecular Composition, Thermal Stability, Glass Transition and Molecular Dynamics. Thermochim. Acta 2018, 669, 16–29. [Google Scholar] [CrossRef]

- Ainali, N.M.; Kalaronis, D.; Evgenidou, E.; Bikiaris, D.N.; Lambropoulou, D.A. Insights into Biodegradable Polymer-Supported Titanium Dioxide Photocatalysts for Environmental Remediation. Macromol 2021, 1, 201–233. [Google Scholar] [CrossRef]

- Bobirică, C.; Bobirică, L.; Râpă, M.; Matei, E.; Predescu, A.M.; Orbeci, C. Photocatalytic Degradation of Ampicillin Using PLA/TiO2 Hybrid Nanofibers Coated on Different Types of Fiberglass. Water 2020, 12, 176. [Google Scholar] [CrossRef]

- Gupta, N.; Kozlovskaya, V.; Dolmat, M.; Yancey, B.; Oh, J.; Lungu, C.T.; Kharlampieva, E. Photocatalytic Nanocomposite Microsponges of Polylactide-Titania for Chemical Remediation in Water. ACS Appl. Polym. Mater. 2020, 2, 5188–5197. [Google Scholar] [CrossRef]

- Petousis, M.; Vidakis, N.; Mountakis, N.; Papadakis, V.; Tzounis, L. Three-Dimensional Printed Polyamide 12 (PA12) and Polylactic Acid (PLA) Alumina (Al2O3) Nanocomposites with Significantly Enhanced Tensile, Flexural, and Impact Properties. Nanomaterials 2022, 12, 4292. [Google Scholar] [CrossRef]

- Sukhanova, A.; Boyandin, A.; Ertiletskaya, N.; Simunin, M.; Shalygina, T.; Voronin, A.; Vasiliev, A.; Nemtsev, I.; Volochaev, M.; Pyatina, S. Study of the Effect of Modified Aluminum Oxide Nanofibers on the Properties of PLA-Based Films. Materials 2022, 15, 6097. [Google Scholar] [CrossRef]

- Kangallı, E.; Bayraktar, E. Preparation and Characterization of Poly(Lactic Acid)/Boron Oxide Nanocomposites: Thermal, Mechanical, Crystallization, and Flammability Properties. J. Appl. Polym. Sci. 2022, 139, e52521. [Google Scholar] [CrossRef]

- Wang, Z.; Pan, Z.; Wang, J.; Zhao, R. A Novel Hierarchical Structured Poly(Lactic Acid)/Titania Fibrous Membrane with Excellent Antibacterial Activity and Air Filtration Performance. J. Nanomater. 2016, 2016, 39. [Google Scholar] [CrossRef]

- Salahuddin, N.; Abdelwahab, M.; Gaber, M.; Elneanaey, S. Synthesis and Design of Norfloxacin Drug Delivery System Based on PLA/TiO2 Nanocomposites: Antibacterial and Antitumor Activities. Mater. Sci. Eng. C 2020, 108, 110337. [Google Scholar] [CrossRef]

- Marsi, T.C.O.; Ricci, R.; Toniato, T.V.; Vasconcellos, L.M.R.; Elias, C.D.M.V.; Silva, A.D.R.; Furtado, A.S.A.; Magalhães, L.S.S.M.; Silva-Filho, E.C.; Marciano, F.R.; et al. Electrospun Nanofibrous Poly (Lactic Acid)/Titanium Dioxide Nanocomposite Membranes for Cutaneous Scar Minimization. Front. Bioeng. Biotechnol. 2019, 7, 421. [Google Scholar] [CrossRef]

- Wang, G.; Wang, L.; Mark, L.H.; Shaayegan, V.; Wang, G.; Li, H.; Zhao, G.; Park, C.B. Ultralow-Threshold and Lightweight Biodegradable Porous PLA/MWCNT with Segregated Conductive Networks for High-Performance Thermal Insulation and Electromagnetic Interference Shielding Applications. ACS Appl. Mater. Interfaces 2018, 10, 1195–1203. [Google Scholar] [CrossRef]

- Li, Y.; Yin, D.; Liu, W.; Zhou, H.; Zhang, Y.; Wang, X. Fabrication of Biodegradable Poly (Lactic Acid)/Carbon Nanotube Nanocomposite Foams: Significant Improvement on Rheological Property and Foamability. Int. J. Biol. Macromol. 2020, 163, 1175–1186. [Google Scholar] [CrossRef] [PubMed]

- Sanusi, O.M.; Benelfellah, A.; Papadopoulos, L.; Terzopoulou, Z.; Malletzidou, L.; Vasileiadis, I.G.; Chrissafis, K.; Bikiaris, D.N.; Aït Hocine, N. Influence of Montmorillonite/Carbon Nanotube Hybrid Nanofillers on the Properties of Poly(Lactic Acid). Appl. Clay Sci. 2021, 201, 105925. [Google Scholar] [CrossRef]

- Sanusi, O.M.; Benelfellah, A.; Terzopoulou, Z.; Bikiaris, D.N.; Aït Hocine, N. Properties of Polylactide Reinforced with Montmorillonite/Multiwalled Carbon Nanotube Hybrid. Mater. Today Proc. 2021, 47, 3247–3250. [Google Scholar] [CrossRef]

- Sanusi, O.M.; Benelfellah, A.; Papadopoulos, L.; Terzopoulou, Z.; Bikiaris, D.N.; Aït Hocine, N. Properties of Poly(Lactic Acid)/Montmorillonite/Carbon Nanotubes Nanocomposites: Determination of Percolation Threshold. J. Mater. Sci. 2021, 56, 16887–16901. [Google Scholar] [CrossRef]

- Kalinke, C.; Neumsteir, N.V.; Aparecido, G.D.O.; Ferraz, T.V.D.B.; Dos Santos, P.L.; Janegitz, B.C.; Bonacin, J.A. Comparison of Activation Processes for 3D Printed PLA-Graphene Electrodes: Electrochemical Properties and Application for Sensing of Dopamine. Analyst 2020, 145, 1207–1218. [Google Scholar] [CrossRef]

- Chakraborty, G.; Pugazhenthi, G.; Katiyar, V. Exfoliated Graphene-Dispersed Poly (Lactic Acid)-Based Nanocomposite Sensors for Ethanol Detection. Polym. Bull. 2019, 76, 2367–2386. [Google Scholar] [CrossRef]

- Spinelli, G.; Guarini, R.; Kotsilkova, R.; Batakliev, T.; Ivanov, E.; Romano, V. Experimental and Simulation Studies of Temperature Effect on Thermophysical Properties of Graphene-Based Polylactic Acid. Materials 2022, 15, 2340. [Google Scholar] [CrossRef]

- Masarra, N.A.; Batistella, M.; Quantin, J.C.; Regazzi, A.; Pucci, M.F.; El Hage, R.; Lopez-Cuesta, J.M. Fabrication of PLA/PCL/Graphene Nanoplatelet (GNP) Electrically Conductive Circuit Using the Fused Filament Fabrication (FFF) 3D Printing Technique. Materials 2022, 15, 762. [Google Scholar] [CrossRef]

- Paydayesh, A.; Pashaei Soorbaghi, F.; Aref Azar, A.; Jalali-Arani, A. Electrical Conductivity of Graphene Filled PLA/PMMA Blends: Experimental Investigation and Modeling. Polym. Compos. 2019, 40, 704–715. [Google Scholar] [CrossRef]

- Silva, A.P.B.; Montagna, L.S.; Passador, F.R.; Rezende, M.C.; Lemes, A.P. Biodegradable Nanocomposites Based on PLA/PHBV Blend Reinforced with Carbon Nanotubes with Potential for Electrical and Electromagnetic Applications. Express Polym. Lett. 2021, 15, 987–1003. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y. Following the Morphological and Thermal Properties of PLA/PEO Blends Containing Carbon Nanotubes (CNTs) during Hydrolytic Degradation. Compos. Part B Eng. 2019, 175, 107132. [Google Scholar] [CrossRef]

- Cataldo, F. On the Interaction of C60 Fullerene with Poly(L-Lactic Acid) or Poly(Lactide). Fullerenes Nanotub. Carbon Nanostruct. 2020, 28, 621–626. [Google Scholar] [CrossRef]

- Shi, S.; Chen, Y.; Jing, J.; Yang, L. Preparation and 3D-Printing of Highly Conductive Polylactic Acid/Carbon Nanotube Nanocomposites: Via Local Enrichment Strategy. RSC Adv. 2019, 9, 29980–29986. [Google Scholar] [CrossRef] [PubMed]

- Magiera, A.; Markowski, J.; Pilch, J.; Blazewicz, S. Degradation Behavior of Electrospun PLA and PLA/CNT Nanofibres in Aqueous Environment. J. Nanomater. 2018, 2018, 8796583. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, S.; Xiong, H.; Jing, X.; Xie, Z.; Chen, X.; Huang, Y. Electrospun PLA/MWCNTs Composite Nanofibers for Combined Chemo- and Photothermal Therapy. Acta Biomater. 2015, 26, 115–123. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Park, S.H.; Kim, S.H.; Ito, H. Replication and Surface Properties of Micro Injection Molded PLA/MWCNT Nanocomposites. Polym. Test. 2020, 83, 106321. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Kourinou, M.; Velidakis, E.; Mountakis, N.; Fischer-Griffiths, P.E.; Grammatikos, S.; Tzounis, L. Additive Manufacturing of Multifunctional Polylactic Acid (PLA)—Multiwalled Carbon Nanotubes (MWCNTs) Nanocomposites. Nanocomposites 2021, 7, 184–199. [Google Scholar] [CrossRef]

- Thummarungsan, N.; Pattavarakorn, D.; Sirivat, A. Electrically Responsive Materials Based on Dibutyl Phathalate Plasticized Poly(Lactic Acid) and Spherical Fullerene. Smart Mater. Struct. 2022, 31, 035029. [Google Scholar] [CrossRef]

- Chen, L.; Pang, X.; Zhao, J.; Piao, G. Facile Method to Fabricate Poly(L-Lactic Acid)/C60 Tetragonal Single Crystal Composites with Enhanced Thermal Stability. Chem. Phys. Lett. 2019, 723, 16–21. [Google Scholar] [CrossRef]

- Naffakh, M. Biopolymer Nanocomposite Materials Based on Poly(L-lactic Acid) and Inorganic Fullerene-like Ws2 Nanoparticles. Polymers 2021, 13, 2947. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, F.L.; Pan, L.L.; Zhu, X.L.; Zhang, Z.Z. Preparation and Characterization of Injectable Mitoxantrone Poly (Lactic Acid)/Fullerene Implants for in Vivo Chemo-Photodynamic Therapy. J. Photochem. Photobiol. B Biol. 2015, 149, 51–57. [Google Scholar] [CrossRef] [PubMed]

- De Bortoli, L.S.; de Farias, R.; Mezalira, D.Z.; Schabbach, L.M.; Fredel, M.C. Functionalized Carbon Nanotubes for 3D-Printed PLA-Nanocomposites: Effects on Thermal and Mechanical Properties. Mater. Today Commun. 2022, 31, 103402. [Google Scholar] [CrossRef]

- Camargo, J.C.; Machado, Á.R.; Almeida, E.C.; Silva, E.F.M.S. Mechanical Properties of PLA-Graphene Filament for FDM 3D Printing. Int. J. Adv. Manuf. Technol. 2019, 103, 2423–2443. [Google Scholar] [CrossRef]

- Caminero, M.Á.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J.; Reverte, J.M.; Becar, J.P. Additive Manufacturing of PLA-Based Composites Using Fused Filament Fabrication: Effect of Graphene Nanoplatelet Reinforcement on Mechanical Properties, Dimensional Accuracy and Texture. Polymers 2019, 11, 799. [Google Scholar] [CrossRef]

- Garc, E.; Jos, P.; Miguel, Á.; Torija, C. Analysis of PLA Geometric Properties Processed by FFF Additive Manufacturing: E Ff Ects of Process Parameters and Plate-Extruder Precision Motion. Polymers 2019, 11, 1581. [Google Scholar]

- El Magri, A.; Vanaei, S.; Shirinbayan, M.; Vaudreuil, S.; Tcharkhtchi, A. An Investigation to Study the Effect of Process Parameters on the Strength and Fatigue Behavior of 3d-Printed Pla-Graphene. Polymers 2021, 13, 3218. [Google Scholar] [CrossRef]

- García, E.; Núñez, P.J.; Chacón, J.M.; Caminero, M.A.; Kamarthi, S. Comparative Study of Geometric Properties of Unreinforced PLA and PLA-Graphene Composite Materials Applied to Additive Manufacturing Using FFF Technology. Polym. Test. 2020, 91, 106860. [Google Scholar] [CrossRef]

- Ab Ghani, N.F.; Mat Desa, M.S.Z.; Bijarimi, M. The Evaluation of Mechanical Properties Graphene Nanoplatelets Reinforced Polylactic Acid Nanocomposites. Mater. Today Proc. 2019, 42, 283–287. [Google Scholar] [CrossRef]

- Davoodi, A.H.; Mazinani, S.; Sharif, F.; Ranaei-Siadat, S.O. GO Nanosheets Localization by Morphological Study on PLA-GO Electrospun Nanocomposite Nanofibers. J. Polym. Res. 2018, 25, 16–19. [Google Scholar] [CrossRef]

- Papon, E.A.; Haque, A. Tensile Properties, Void Contents, Dispersion and Fracture Behaviour of 3D Printed Carbon Nanofiber Reinforced Composites. J. Reinf. Plast. Compos. 2018, 37, 381–395. [Google Scholar] [CrossRef]

- Malafeev, K.; Ivankova, E.M.; Kamalov, A.; Yudin, V.; Popova, E.N.; Moskalyuk, O. Influence of VGCF Concentration on Properties of Biodegradable Fibers Based on Poly (Lactide Acid). In Proceedings of the 2021 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (ElConRus), St. Petersburg, Moscow, Russia, 26–29 January 2021; pp. 1786–1789. [Google Scholar] [CrossRef]

- Dave, K.; Mahmud, Z.; Gomes, V.G. Superhydrophilic 3D-Printed Scaffolds Using Conjugated Bioresorbable Nanocomposites for Enhanced Bone Regeneration. Chem. Eng. J. 2022, 445, 136639. [Google Scholar] [CrossRef]

- Segun, A.; Adewuyi, B.O.; Ojo, D.O.; Gideon, O.N. Mechanical and Structural Properties of Nanocarbon Particles Reinforced in Plasticised Polylactic Acid for High Strength Application. J. Phys. Sci. 2021, 32, 41–56. [Google Scholar] [CrossRef]

- Potnuru, A.; Tadesse, Y. Investigation of Polylactide and Carbon Nanocomposite Filament for 3D Printing. Prog. Addit. Manuf. 2019, 4, 23–41. [Google Scholar] [CrossRef]

- Jain, S.K.; Tadesse, Y. Fabrication of Polylactide/Carbon Nanopowder Filament Using Melt Extrusion and Filament Characterization for 3D Printing. Int. J. Nanosci. 2019, 18, 1850026. [Google Scholar] [CrossRef]

- Amran, N.A.M.; Ahmad, S.; Chen, R.S.; Shahdan, D. Tensile Properties and Thermal Stability of Nanocomposite Poly-Lactic Acid/Liquid Natural Rubber Filled Graphene Nanoplates. In AIP Conference Proceedings; AIP Publishing LLC: Woodbury, NY, USA, 2019; p. 030006. [Google Scholar] [CrossRef]

- Mohd Amran, N.A.; Ahmad, S.; Chen, R.S.; Shahdan, D.; Flaifel, M.H.; Omar, A. Assessment of Mechanical and Electrical Performances of Polylactic Acid/Liquid Natural Rubber/Graphene Platelets Nanocomposites in the Light of Different Graphene Platelets Functionalization Routes. Macromol. Chem. Phys. 2021, 222, 2100185. [Google Scholar] [CrossRef]

- Wang, B.; Ye, X.; Wang, B.; Li, X.; Xiao, S.; Liu, H. Reactive Graphene as Highly Efficient Compatibilizer for Cocontinuous Poly(Lactic Acid)/Poly(ε-Caprolactone) Blends toward Robust Biodegradable Nanocomposites. Compos. Sci. Technol. 2022, 221, 109326. [Google Scholar] [CrossRef]

- Paydayesh, A.; Mousavi, S.R.; Estaji, S.; Khonakdar, H.A.; Nozarinya, M.A. Functionalized Graphene Nanoplatelets/Poly (Lactic Acid)/Chitosan Nanocomposites: Mechanical, Biodegradability, and Electrical Conductivity Properties. Polym. Compos. 2022, 43, 411–421. [Google Scholar] [CrossRef]

- Wang, D.; Lu, X.; Qu, J. Role of In Situ Thermal-Reduced Graphene Oxide on the Morphology and Properties of Biodegradable Poly(Lactic Acid)/Poly(Butylene Succinate) Blends. Polym. Compos. 2017, 16, 101–113. [Google Scholar] [CrossRef]

- Iglesias Montes, M.L.; Luzi, F.; Dominici, F.; Torre, L.; Cyras, V.P.; Manfredi, L.B.; Puglia, D. Design and Characterization of PLA Bilayer Films Containing Lignin and Cellulose Nanostructures in Combination with Umbelliferone as Active Ingredient. Front. Chem. 2019, 7, 157. [Google Scholar] [CrossRef]

- Yang, W.; Fortunati, E.; Bertoglio, F.; Owczarek, J.S.; Bruni, G.; Kozanecki, M.; Kenny, J.M.; Torre, L.; Visai, L.; Puglia, D. Polyvinyl Alcohol/Chitosan Hydrogels with Enhanced Antioxidant and Antibacterial Properties Induced by Lignin Nanoparticles. Carbohydr. Polym. 2018, 181, 275–284. [Google Scholar] [CrossRef]

- Li, J.H.; Miao, J.; Wu, J.L.; Chen, S.F.; Zhang, Q.Q. Preparation and Characterization of Active Gelatin-Based Films Incorporated with Natural Antioxidants. Food Hydrocoll. 2014, 37, 166–173. [Google Scholar] [CrossRef]

- Makri, S.P.; Xanthopoulou, E.; Klonos, P.A.; Grigoropoulos, A.; Kyritsis, A.; Tsachouridis, K.; Anastasiou, A.; Deligkiozi, I.; Nikolaidis, N.; Bikiaris, D.N. Effect of Micro- and Nano-Lignin on the Thermal, Mechanical, and Antioxidant Properties of Biobased PLA–Lignin Composite Films. Polymers 2022, 14, 5274. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Fortunati, E.; Dominici, F.; Kenny, J.M.; Puglia, D. Effect of Processing Conditions and Lignin Content on Thermal, Mechanical and Degradative Behavior of Lignin Nanoparticles/Polylactic (Acid) Bionanocomposites Prepared by Melt Extrusion and Solvent Casting. Eur. Polym. J. 2015, 71, 126–139. [Google Scholar] [CrossRef]

- Yang, W.; Zhu, Y.; He, Y.; Xiao, L.; Xu, P.; Puglia, D.; Ma, P. Preparation of Toughened Poly(Lactic Acid)-Poly(ε-Caprolactone)-Lignin Nanocomposites with Good Heat- and UV-Resistance. Ind. Crops Prod. 2022, 183, 114965. [Google Scholar] [CrossRef]

- Chihaoui, B.; Tarrés, Q.; Delgado-Aguilar, M.; Mutjé, P.; Boufi, S. Lignin-Containing Cellulose Fibrils as Reinforcement of Plasticized PLA Biocomposites Produced by Melt Processing Using PEG as a Carrier. Ind. Crops Prod. 2022, 175, 114287. [Google Scholar] [CrossRef]

- Gulzar, S.; Tagrida, M.; Nilsuwan, K.; Prodpran, T.; Benjakul, S. Electrospinning of Gelatin/Chitosan Nanofibers Incorporated with Tannic Acid and Chitooligosaccharides on Polylactic Acid Film: Characteristics and Bioactivities. Food Hydrocoll. 2022, 133, 107916. [Google Scholar] [CrossRef]

- Ng, W.K.; Chow, W.S.; Ismail, H. Tensile, Thermal and Optical Properties of Poly(Lactic Acid)/Poly(2-Ethyl-2-Oxazoline)/Corn Cob Nanocellulose Nanocomposite Film. Polym. Technol. Mater. 2022, 61, 207–219. [Google Scholar] [CrossRef]

- Sangeetha, V.H.; Varghese, T.O.; Nayak, S.K. Value Addition of Waste Cotton: Effect of Nanofibrillated Cellulose on EVA/EVOH Toughened Polylactic Acid System. Waste Biomass Valorization 2020, 11, 4119–4128. [Google Scholar] [CrossRef]

- Rasheed, M.; Jawaid, M.; Parveez, B. Bamboo Fiber Based Cellulose Nanocrystals/Poly(Lactic Acid)/Poly(Butylene Succinate) Nanocomposites: Morphological, Mechanical and Thermal Properties. Polymers 2021, 13, 1076. [Google Scholar] [CrossRef]

- Jin, K.; Tang, Y.; Zhu, X.; Zhou, Y. Polylactic Acid Based Biocomposite Films Reinforced with Silanized Nanocrystalline Cellulose. Int. J. Biol. Macromol. 2020, 162, 1109–1117. [Google Scholar] [CrossRef]

- Li, L.; Chen, Y.; Yu, T.; Wang, N.; Wang, C.; Wang, H. Preparation of Polylactic Acid/TEMPO-Oxidized Bacterial Cellulose Nanocomposites for 3D Printing via Pickering Emulsion Approach. Compos. Commun. 2019, 16, 162–167. [Google Scholar] [CrossRef]

- Somphol, W.; Lampang, T.N.; Prapainainar, P.; Sae-Oui, P.; Loykulnant, S.; Suebsai, A.; Dittanet, P. Effect of Polyethylene Glycol in Nanocellulose/PLA Composites. Key Eng. Mater. 2019, 821, 89–95. [Google Scholar] [CrossRef]

- Sobhan, A.; Muthukumarappan, K.; Wei, L. Development of Bio-Nanocomposite Films by Combination of PLA and Biochar for Smart Food Packaging. In Proceedings of the 2020 ASABE Annual International Virtual Meeting, Online, 13–15 July 2020; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA; pp. 1–9. [Google Scholar] [CrossRef]

- Jasim, S.M.; Ali, N.A. Properties Characterization of Plasticized Polylactic Acid/Biochar (Bio Carbon) Nano-Composites for Antistatic Packaging. Iraqi J. Phys. 2019, 17, 13–26. [Google Scholar] [CrossRef]

- Chollet, B.; Lopez-Cuesta, J.M.; Laoutid, F.; Ferry, L. Lignin Nanoparticles as a Promising Way for Enhancing Lignin Flame Retardant Effect in Polylactide. Materials 2019, 12, 2132. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.; Sun, C.; Xue, Y.; Liu, C.; Qiu, D.; Cui, B.; Zhang, Y.; Cui, H.; Zeng, Z. Tannic Acid-Based Nanopesticides Coating with Highly Improved Foliage Adhesion to Enhance Foliar Retention. RSC Adv. 2019, 9, 27096–27104. [Google Scholar] [CrossRef] [PubMed]

- Liao, J.; Brosse, N.; Pizzi, A.; Hoppe, S.; Zhou, X.; Du, G. Characterization and 3D Printability of Poly (Lactic Acid)/Acetylated Tannin Composites. Ind. Crops Prod. 2020, 149, 112320. [Google Scholar] [CrossRef]

- Liao, J.; Brosse, N.; Hoppe, S.; Zhou, X.; Xi, X.; Du, G.; Pizzi, A. Interfacial Improvement of Poly (Lactic Acid)/Tannin Acetate Composites via Radical Initiated Polymerization. Ind. Crops Prod. 2021, 159, 113068. [Google Scholar] [CrossRef]

- Kian, L.K.; Jawaid, M.; Nasef, M.M.; Fouad, H.; Karim, Z. Poly(Lactic Acid)/Poly(Butylene Succinate) Dual-Layer Membranes with Cellulose Nanowhisker for Heavy Metal Ion Separation. Int. J. Biol. Macromol. 2021, 192, 654–664. [Google Scholar] [CrossRef]

- Geng, S.; Yao, K.; Zhou, Q.; Oksman, K. High-Strength, High-Toughness Aligned Polymer-Based Nanocomposite Reinforced with Ultralow Weight Fraction of Functionalized Nanocellulos. Biomacromolecules 2018, 19, 4075–4083. [Google Scholar] [CrossRef]

- Ghasemi, S.; Behrooz, R.; Ghasemi, I.; Yassar, R.S.; Long, F. Development of Nanocellulose-Reinforced PLA Nanocomposite by Using Maleated PLA (PLA-g-MA). J. Thermoplast. Compos. Mater. 2018, 31, 1090–1101. [Google Scholar] [CrossRef]

- Shazleen, S.S.; Foong Ng, L.Y.; Ibrahim, N.A.; Hassan, M.A.; Ariffin, H. Combined Effects of Cellulose Nanofiber Nucleation and Maleated Polylactic Acid Compatibilization on the Crystallization Kinetic and Mechanical Properties of Polylactic Acid Nanocomposite. Polymers 2021, 13, 3226. [Google Scholar] [CrossRef] [PubMed]

- Castro, J.I.; Valencia Llano, C.H.; Tenorio, D.L.; Saavedra, M.; Zapata, P.; Navia-Porras, D.P.; Delgado-Ospina, J.; Chaur, M.N.; Hernández, J.H.M.; Grande-Tovar, C.D. Biocompatibility Assessment of Polylactic Acid (PLA) and Nanobioglass (n-BG) Nanocomposites for Biomedical Applications. Molecules 2022, 27, 3640. [Google Scholar] [CrossRef]

- Esmaeilzadeh, J. In Vivo Assessments of the Poly (d/l) Lactide/Polycaprolactone/Bioactive Glass Nanocomposites for Bioscrews Application. Adv. Ceram. Prog. 2021, 7, 17–22. [Google Scholar]

- Macha, I.J.; Ben-Nissan, B.; Santos, J.; Cazalbou, S.; Stamboulis, A.; Grossin, D.; Giordano, G. Biocompatibility of a New Biodegradable Polymer-Hydroxyapatite Composite. J. Drug Deliv. Sci. Technol. 2017, 38, 72–77. [Google Scholar] [CrossRef]

- Morsi, M.A.; Hezma, A.E.M. Effect of Iron Doped Hydroxyapatite Nanoparticles on the Structural, Morphological, Mechanical and Magnetic Properties of Polylactic Acid Polymer. J. Mater. Res. Technol. 2019, 8, 2098–2106. [Google Scholar] [CrossRef]

- Toong, D.W.Y.; Ng, J.C.K.; Cui, F.; Leo, H.L.; Zhong, L.; Lian, S.S.; Venkatraman, S.; Tan, L.P.; Huang, Y.Y.; Ang, H.Y. Nanoparticles-Reinforced Poly-l-Lactic Acid Composite Materials as Bioresorbable Scaffold Candidates for Coronary Stents: Insights from Mechanical and Finite Element Analysis. J. Mech. Behav. Biomed. Mater. 2022, 125, 104977. [Google Scholar] [CrossRef] [PubMed]

- Ziaee, F.; Zebarjad, S.M.; Javadpour, S. Compressive and Flexural Properties of Novel Polylactic Acid/Hydroxyapatite/Yttria-Stabilized Zirconia Hybrid Nanocomposite Scaffold. Int. J. Polym. Mater. Polym. Biomater. 2018, 67, 229–238. [Google Scholar] [CrossRef]

- Ghassemi, B.; Estaji, S.; Mousavi, S.R.; Nemati Mahand, S.; Shojaei, S.; Mostafaiyan, M.; Arjmand, M.; Khonakdar, H.A. In-Depth Study of Mechanical Properties of Poly(Lactic Acid)/Thermoplastic Polyurethane/Hydroxyapatite Blend Nanocomposites. J. Mater. Sci. 2022, 57, 7250–7264. [Google Scholar] [CrossRef]

- Rahman, M.M.; Shahruzzaman, M.; Islam, M.S.; Khan, M.N.; Haque, P. Preparation and Properties of Biodegradable Polymer/Nano-Hydroxyapatite Bioceramic Scaffold for Spongy Bone Regeneration. J. Polym. Eng. 2019, 39, 134–142. [Google Scholar] [CrossRef]

- Yan, D.; Wang, Z.; Guo, Z.; Ma, Y.; Wang, C.; Tan, H.; Zhang, Y. Study on the Properties of PLA/PBAT Composite Modified by Nanohydroxyapatite. J. Mater. Res. Technol. 2020, 9, 11895–11904. [Google Scholar] [CrossRef]

- Peponi, L.; Sessini, V.; Arrieta, M.P.; Navarro-Baena, I.; Sonseca, A.; Dominici, F.; Gimenez, E.; Torre, L.; Tercjak, A.; López, D.; et al. Thermally-Activated Shape Memory Effect on Biodegradable Nanocomposites Based on PLA/PCL Blend Reinforced with Hydroxyapatite. Polym. Degrad. Stab. 2018, 151, 36–51. [Google Scholar] [CrossRef]

- Mondal, S.; Nguyen, T.P.; Pham, V.H.; Hoang, G.; Manivasagan, P.; Kim, M.H.; Nam, S.Y.; Oh, J. Hydroxyapatite Nano Bioceramics Optimized 3D Printed Poly Lactic Acid Scaffold for Bone Tissue Engineering Application. Ceram. Int. 2020, 46, 3443–3455. [Google Scholar] [CrossRef]

- Swetha, S.; Balagangadharan, K.; Lavanya, K.; Selvamurugan, N. Three-Dimensional-Poly(Lactic Acid) Scaffolds Coated with Gelatin/Magnesium-Doped Nano-Hydroxyapatite for Bone Tissue Engineering. Biotechnol. J. 2021, 16, 2100282. [Google Scholar] [CrossRef] [PubMed]

- Hajibeygi, M.; Shafiei-Navid, S. Design and Preparation of Poly(Lactic Acid) Hydroxyapatite Nanocomposites Reinforced with Phosphorus-Based Organic Additive: Thermal, Combustion, and Mechanical Properties Studies. Polym. Adv. Technol. 2019, 30, 2233–2249. [Google Scholar] [CrossRef]

- Salehi, A.; Jafari, S.H.; Khonakdar, H.A.; Ebadi-Dehaghani, H. Temperature Dependency of Gas Barrier Properties of Biodegradable PP/PLA/Nanoclay Films: Experimental Analyses with a Molecular Dynamics Simulation Approach. J. Appl. Polym. Sci. 2018, 135, 46665. [Google Scholar] [CrossRef]

- Alakrach, A.M.; Noriman, N.Z.; Dahham, O.S.; Hamzah, R.; Alsaadi, M.A.; Shayfull, Z.; Idrus, S.S. The Effects of Tensile Properties of PLA/HNTs-ZrO2 Bionanocomposites. J. Phys. Conf. Ser. 2018, 1019, 012066. [Google Scholar] [CrossRef]

- Li, Y.; Li, P.; Wu, M.; Yu, X.; Naito, K.; Zhang, Q. Halloysite Nanotubes Grafted Polylactic Acid and Its Composites with Enhanced Interfacial Compatibility. J. Appl. Polym. Sci. 2021, 138, 49668. [Google Scholar] [CrossRef]

- Mohd Nizar, M.; Hamzah, M.S.A.; Abd Razak, S.I.; Mat Nayan, N.H. Thermal Stability and Surface Wettability Studies of Polylactic Acid/Halloysite Nanotube Nanocomposite Scaffold for Tissue Engineering Studies. IOP Conf. Ser. Mater. Sci. Eng. 2018, 318, 012006. [Google Scholar] [CrossRef]

- Chaiwutthinan, P.; Phutfak, N.; Larpkasemsuk, A. Effects of Thermoplastic Poly(Ether-Ester) Elastomer and Bentonite Nanoclay on Properties of Poly(Lactic Acid). J. Appl. Polym. Sci. 2021, 138, 8–11. [Google Scholar] [CrossRef]

| Biological Source | Size of NPs | References |

|---|---|---|

| Azadirachta indica, leaf extract | 124 (average) nm | [66] |

| Aeromonas hydrophila, bacterium | 28–54 nm | [68] |

| Annona squamosal, fruit peel extract | 23 nm | [69] |

| Bacillus amyloliquefaciens, bacterium | 15–86 nm | [70] |

| Euphorbia prostrata, leaf extract | 83.22 nm | [71] |

| Biological Source | Size | References |

|---|---|---|

| Jacarandamimosifolia, flow erextract | 2–4 nm | [74] |