Abstract

The depletion of fossil resources and the growing demand for plastic waste reduction has put industries and academic researchers under pressure to develop increasingly sustainable packaging solutions that are both functional and circularly designed. In this review, we provide an overview of the fundamentals and recent advances in biobased packaging materials, including new materials and techniques for their modification as well as their end-of-life scenarios. We also discuss the composition and modification of biobased films and multilayer structures, with particular attention to readily available drop-in solutions, as well as coating techniques. Moreover, we discuss end-of-life factors, including sorting systems, detection methods, composting options, and recycling and upcycling possibilities. Finally, regulatory aspects are pointed out for each application scenario and end-of-life option. Moreover, we discuss the human factor in terms of consumer perception and acceptance of upcycling.

1. Introduction

Despite the overall growth in the worldwide production of plastics, European plastic production in 2020 saw a slight decrease from 58 million tonnes in 2019 to 55 million tonnes in 2020 due to the coronavirus pandemic, but is expected to show an even stronger recovery forecasted at +8.5% by the end of 2021, due to global economic upswing (PlasticsEurope, 2021). Currently, the share of bioplastics in the global plastics market remains low at between 1 and 2% of overall plastics production. Yet, the global production capacities of bioplastics are reported to have had a steady growth from 1.9 million tonnes in 2019 to 2.1 million tonnes in 2020 and 2.4 million tonnes in 2021. By 2026, the global production of bioplastics is even forecasted to triple (more than a 200% growth rate in the next five years) and pass the 2% mark for its share of global plastics production [1]. This is an important trend considering the depletion of fossil resources that are needed for the production of conventional non-biobased plastics, which requires more sustainable alternative solutions. Being the largest market for plastics, the packaging sector particularly requires improved circularity from origin to subsequent life cycles as well as increases in bioplastics and other renewably sourced materials in order to contribute to a more responsible use of resources.

In fact, packaging manufacturers are committed to sustainability in terms of reducing the use of raw materials, focusing on the use of materials derived from renewable sources, and re-designing packaging, leading to (a) lower amounts of used packaging material (e.g., lightweighting) and (b) enhanced recyclability, subsequently contributing to and facilitating the circular economy [2,3]. By using multilayer packaging, the reduction in packaging material is accompanied by enhanced barrier properties, since this approach enables the product contained inside to be protected by several layers that are able to provide distinct barrier properties.

Although the approaches mentioned have potential, they are currently limited and not capable of producing a packaging material that is fully sustainable and meets the requirements of a circular bioeconomy. Multi-layered plastic packaging material, for example, is oftenchallenging to recycle. Thus, this kind of packaging material needs to be incinerated or even landfilled [4]. In case of coated fibre-based packaging, depending on the selection of the barrier material, the impact on recyclability may be limited, benefitting from the already high recycling rate for this category of packaging. Therefore, innovative approaches towards a circular bioeconomy and sustainability are needed, and the demand for materials derived from renewable sources is rising.

Bioplastics are plastics that are biobased, biodegradable, or both. They can be used as the main packaging matrix material or as a coating for different substrates, including paper or cardboard, that can also contribute to fully biobased packaging concepts. Bioplastics exhibit numerous advantages, such as replacing fossil-based plastics, renewable feedstocks, and an increased end-of-life (EoL) modularity. Moreover, recent trends in consumer behaviour aiming for waste reduction, greener packaging, and greater sustainability also increase the demand for bioplastics [5]. The human factor, i.e., consumer preferences, is decisive for establishing new and sustainable packaging strategies, and, therefore, it must not be neglected. Innovative packaging solutions suitable for improving sustainability aspects have to not only provide a lower carbon footprint and sustainable EoL options but also maintain barrier properties and subsequently the shelf life of the products contained in order to achieve consumer acceptance [6].

The objective of this review is to present the most recent state of the art of biobased packaging, including their modification strategies and potential applications. In order to provide an expedient and comprehensive overview, this review article focuses on polylactic acid (PLA), polyhydroxyalkanoates (PHA), biobased polyethylene (bioPE), biobased polyethylene terephthalate (bioPET), and fibre-based packaging materials. These materials are the main focus of this research study as it was carried out within the PRESERVE Project: “High performance sustainable bio-based packaging with tailored end of life and upcycled secondary use”, funded by the European Union (EU) Horizon 2020 Research and Innovation Programme under Grant Agreement No. 952983. In order to comprehensively evaluate the sustainability and circularity of these biobased packaging materials, this review outlines and discusses assessment of different EoL options, such as home composting and industrial composting as well as material recycling and upcycling. Examples of recent advances in the development of biobased packaging materials for specific applications are also covered.

2. Types of Biobased Packaging Material

According to the European standard EN 16575 (“Biobased Products—Vocabulary”), the term “biobased” means that a material or product is wholly or partly derived from biomass, which can be sourced from carbohydrate-rich plants, such as corn or sugarcane, from ligno-cellulosic feedstock, or from waste. Whereas “biobased” only refers to the type of feedstock source and origin, the term “biodegradable” refers to the EoL of a material. Biodegradation is a biochemical process during which microorganisms that are present in the environment metabolise materials into water, carbon dioxide, and biomass, and artificial additives facilitating the biodegradation process are not needed [7]. The biodegradation process is highly influenced by various environmental factors, as for example temperature, humidity, inoculum, the material to be biodegraded and the specific application may affect the biodegradation rate. Therefore, especially for certification purposes, the term “biodegradability” should only be used when the specific environmental conditions and time frame in which biodegradation can occur are clearly specified, in order to avoid ambiguity.

As both terms describe a different part of the lifecycle of a material, “biobased” does not equal “biodegradable” and vice versa. Therefore, bioplastic packaging materials can be assigned to one of three groups: they can be either biobased, or biodegradable, or both.

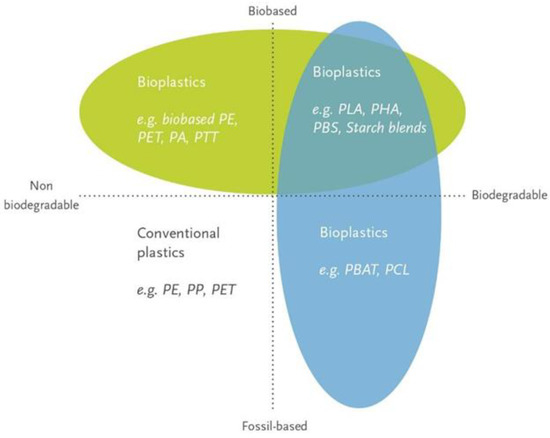

Specifically looking at PLA, PHA, bioPE, and bioPET, they are defined by their source of feedstock and possible EoL options. Referring to Figure 1, PLA and PHA are biobased and biodegradable plastics and can be located in the upper right corner of the matrix, whereas bioPE and bioPET can be located in the upper left corner as biobased but non-biodegradable polyolefins or polyester, respectively. The latter are commodity plastics with the same properties as their fossil-based counterparts (conventional PE and PET) but are made from renewable resources; hence, they are also called drop-in solutions (See Section 2.3 and Section 2.4).

Figure 1.

Material coordinate system of bioplastics [8].

As summarized by European Bioplastics (2016) [9] and Rosenboom et al. (2022) [10], different international standards and labels exist for determining and identifying the biobased content of a certain product or sample. These different labels are awarded by different certification institutes. Consequently, the precise certification strategies may differ, but in any case, they rely on accredited international standards. The same holds true for biodegradability certification and labelling. Different certification schemes and corresponding labels are accredited for the European market. For the certification and labelling of biodegradability, however, it needs to first be specified in which environment and according to which standard a material is biodegradable. The requirements for the biodegradability of packaging material in different possible environments, such as industrial composting plants, home and garden composting, marine environments, and soil, are defined for the corresponding standard, if available. More detailed information on certification and labelling are provided by European Bioplastics (2016) [9] and Rosenboom et al. (2022) [10].

Paper and cardboard can also be used to develop high-performance biobased packaging. Fibre in paper and cardboard is generally biodegradable by nature [11]. Nevertheless, in some cases, there is a maximum thickness at which it actually reaches the maximum time period allowed by specific industrial and/or home composting standards. Likewise, the selection of the appropriate additives and coating to meet the requirements set in the respective standards is important.

2.1. Polylactic Acid (PLA)

Polylactic acid (PLA) is a versatile material that is already being used successfully in various different packaging applications. It is currently the biobased plastic material with the highest market share, due to its versatility and processability [12]. PLA is synthesised by either the ring-opening polymerisation of lactide (made from lactic acid (LA)) or a direct condensation reaction of LA. Lactic acid can be obtained by the fermentation of glucose, which is derived from hydrolysed corn starch from corn, or sucrose, which is derived from sugarcane. [13] The properties of PLA can vary by the ratio of the stereoisomers used in the synthesis, i.e., D- or L-LA, and by molecular weight. PLA made from either isomer is crystalline. However, high crystallinity increases the brittleness of the material. Most PLA used for packaging applications is poly(L-lactic acid) (PLLA) modified with D-isomer to less than 15% to maintain the necessary crystallinity [14]. PLA has a good oxygen barrier but a poor water vapour barrier and shows high transparency [15]. Typical applications made with PLA currently on the market are mainly rigid packaging, including trays, blisters, containers for fresh produce, or bottles for non-carbonated drinks. PLA is industrial compostable in line with EN 13432 but shows more or less no degradation behaviour in environments with lower temperatures [16]. PLA can also be easily mechanically recycled, and recycled PLA (r-PLA) from post-industrial waste could already be used in the market [17]. Even options for chemical recycling routes for PLA are possible and have been tested [18].

2.2. Polyhydroxyalkanoate (PHA)

Polyhydroxyalkanoate (PHA) comprises a family of biopolymers that occur in nature but can also be produced by the fermentation processes of sugar-containing feedstock—in most cases, the glucose obtained from corn starch—in industrial settings using a wide range of microorganisms, such as bacteria, yeast, or fungi. To obtain a plastic material from these processes, the polymer needs to be extracted from the bacterial cells, purified, and finally compounded [6]. Some PHA types are already produced on an industrial scale, for example poly-3-hydroxybutyrate (PHB), poly-hydroxybutyrate-co-hydroxyvalerate (PHBV), or polyhydroxy-butylhexanoate [19]. The properties of PHA depend on the distance between the ester groups in the molecule, the molecular weight, and the functional groups in the side chains [20,21]. PHAs are used in pharmaceutical and medical applications, but are increasingly applied in agriculture, i.e., mulch films, and packaging [22]. In packaging, PHAs are rarely used as pure materials but are blended with other biodegradable plastics, such as PLA or polycaprolactone (PCL), or act as an additive to improve biodegradation properties. PHAs have been the subject of special interest because some of them provide outstanding biodegradability properties and have been shown to biodegrade even in marine environments. [23] However, marine biodegradability is not necessarily a property that is desirable to be communicated to consumers, as it might easily lead to unwanted littering behaviour. Therefore, recyclability and industrial or home compostability should be considered preferable EoL options for packaging made of PHAs.

2.3. Biobased Polyethylene (bioPE)

Biobased polyethylene (bioPE) is made by polymerising ethylene that has been obtained through the dehydration of bioethanol. BioPE has been on the market for several years now and is predominately sourced from Brazilian sugarcane and bagasse. However, any source containing sugar- or polysaccharide could potentially be used as feedstock, as route to produce bioethanol from, e.g., corn or sugar beet, and even bioPE from cellulosic feedstocks, are already well known [24,25,26]. Recently, PE made from bio-naphtha, which is produced by the hydrotreatment of plant oil waste, has gained commercial interest. Tall oil, a residue from paper pulp production and also palm oil waste, for example, is currently used as feedstock for bio-naphtha [27,28,29]. The share of biobased content of this kind of bioPE does not necessarily reach 100% and is therefore currently often marketed as “bio-attributed”. A third option to produce bioPE is to produce the PE directly using certain microorganisms, but this technology is still at the research and development level. BioPE has the same chemical and physical properties as conventionally sourced, fossil-based PE and is, similar to its fossil-based counterpart, available as HDPE, LDPE, and LLDPE. Providing a much better carbon footprint, it can be used in the same applications, for example in various packaging, carrier bags, or shrink films, and can, at the end of its material life cycle, be recycled together with conventional PE in the respective recycling streams without any problems [26].

2.4. Biobased Polyethylene Terephthalate (bioPET)

Another drop-in bioplastic that has gained a lot of commercial interest in the past years is biobased polyethylene terephthalate (bioPET). The bioPET currently on the market has, in most cases, a biobased content of only up to 30%, as only one building block of the polymer, monoethylene glycol (MEG), can be produced from renewable sources, such as sugarcane [30]. The process route for bio-MEG is quite costly, starting from bioethanol, over ethylene, ethylene oxide, and ethylene carbonate. However, there have been developments to decrease costs by producing MEG directly from sugars [31,32]. The second PET building block, terephthalic acid (TPA), has proven to be more difficult to obtain, as is the case for most renewable aromatics, which is why 100% biobased PET is found to a lesser extent on the market. Nevertheless, there has been ongoing research and development to produce biobased TPA from different sources, such as limonene, bio-paratoluic acid, or bio-paraxylene obtained from glucose using cornstarch as feedstock [33,34,35,36,37]. Consequently, the first bioPET bottles with 100% biobased content have been introduced to the market [38,39].

Similar to its conventional counterpart, biobased PET is used for both technical applications, i.e., fibres and packaging, and mainly for beverage bottles. Like other drop-in bioplastics, bioPET can be recycled easily in the corresponding recycling stream, as its chemical and physical properties are exactly the same as those of fossil-based PET.

2.5. Paperboard

Paper is a very traditional renewably sourced material with a long history; there have been many efficiency and sustainability improvements over the years as well as recent innovations especially in terms of barrier coatings that can be applied on paper [40,41]. Some of these are discussed later in this paper and can support the replacement of conventional plastic packaging by fibre-based solutions.

The principal materials used in paper and paperboard packaging include kraft, cardboard, and paperboard, but also specialty papers, such as greaseproof, glassine, cellophane, and moulded pulp. Cardboard has a grammage generally above 200 or 225 g/m2, whereas paper has a grammage below 200 g/m2. Moreover, most generally speaking, cardboard is multi-ply, whereas paper is single-ply [42].

In general, the pulp obtained is differentiated according to the pulping processes used [43]. In addition, a classification can be made according to the raw material used. If the pulp comes from softwoods, such as pine, larch, or spruce, it is called long-fibre pulp and has average fibre lengths between 2.5 and 4.5 mm. If, on the other hand, the raw material used is hardwood, such as eucalyptus, birch, beech, and poplar, it is referred to as short-fibre pulp, as the cellulose chains are arranged in fibres of average lengths between 0.7 and 1.6 mm [44].

The type of used fibres, the pulping process, type of paper machine, and number of plies distinguish paperboard grades. Different performances can thus be created by combining these material and process variables. Whereas kraft is strong and keeps its dark colour, bleaching or the application of a clay coating is used to obtain a lighter colour and improve the printing properties of the top plies [42].

The main grades are among those using (i) virgin fibres, such as CUK (coated unbleached kraft), SUS (solid unbleached sulphate), SBS (solid bleached sulphate), and FBB (folding boxboard GC); and (ii) secondary fibres, such as WLC (white lined chipboard) or CRB (coated recycled board). SBS and FBB are the most premium grades. They are bleached and have a white surface that may be coated with mineral pigments but differ by the internal combination of pulp types in the successive plies, leading to different yields and weights. SUS is a strong and lightweight kraft board with its main applications in beverage carriers, packaging for frozen foods, detergent boxes, and filter frame structures requiring high strength. WLC as recycled board with shorter fibres may to some extent not meet the mechanical performance standards of the most demanding applications and has been subject to some legal limits in its use for direct food contact depending on the packed product [11,45].

Worldwide, more than 187 million tonnes of pulp were produced in 2018, of which about 62% came from the densely forested areas of North America and Europe. The largest net consumers were China and the European Union (EU) [46]. Fibre-based packaging represents ~38% of total packaging in Europe, followed by plastics (~35%), and has a CAGR of ca 2.5%. Paperboard is the most circular packaging material, as, on the one hand, it is sourced from virgin fibers that derive from sustainably managed forests and are typically obtained as a by-product of the construction industry. On the other hand, it is also made from secondary fibers and currently has a recycling rate of 82% in Europe [47]. There are well-established applications for recycled fibres from consumer packaging and a large fraction is used to produce corrugated board.

2.6. Moulded Pulp

Moulded pulp was traditionally produced from recycled paperboard or paper, for example to make egg cartons. Such moulded pulp is recyclable in the paper stream but also compostable and biodegradable. Generally lacking gas barrier properties, it has been for a long time mainly used as protective packaging. However, there have been new developments both in terms of its process and in terms of materials, e.g., applying thin polymer films or barrier coatings that expand the fields of applications of moulded pulp to include ready-meal trays, punnets, clamshells, jars, or even bottles. The high growth of the market for moulded fibre products is also related to the substitution of plastic with fibre-based packaging which has a greater eco-friendly appearance; however, its pricing can sometimes hinder this transition. Recent studies have also investigated how such innovative moulded pulp solutions can reduce the carbon footprint of packaging versus conventional plastic counterparts [48,49].

Moulded fibre products nowadays range from low-value products to premium high-value products. The selection between virgin fibre, which may be needed in terms of safety for new food contact applications, and recycled fibre, as well as the ability to add functionality and/or further treatments to products adds variability. There are several different end-uses for moulded fibre packaging. Protective and industrial packaging is the largest end-use in terms of volume but food service and food packaging are also significant applications, accounting for 40% of the total [50]. Other end-uses include consumer electronics packaging, home appliances, medical applications, and other non-food packaging.

As opposed to other formed packaging, such as pressed trays, moulded fibre or moulded pulp packaging generally starts from a non-flat slurry of fibres that is then formed into its 3D shape. New categories of processes have emerged generating different wall thicknesses and properties.

Figure 2 shows the main categories of moulded fibre products depending on the wet production technology [50]. Dry production technologies are also emerging and are claimed to have improved productivity and a better environmental profile.

Figure 2.

Four different types of fibre moulded products.

3. Biobased Coatings and Adhesives for Multilayer Packaging

Multilayer packaging structures are widely used in the packaging industry, as these structures are able to achieve low oxygen permeability. The protection against oxygen is essential not only for sensitive and fresh food but also for cosmetic and pharmaceutical items, in order to ensure a sufficient shelf life. Insufficient oxygen protection can lead to various issues, such as colour or taste deviation, the oxidation of fats, the undesired growth of microorganisms, or the degradation of nutrients. To address this, the most widely used oxygen barrier materials are ethylene vinyl alcohol co-polymer (EVOH) or polyvinylidene dichloride, which are derived from petrochemicals [51,52]. However, these polymers have the downside of neither being biodegradable nor being biobased. Moreover, conventional multilayer structures are difficult to delaminate and, therefore, difficult to recycle. Consequently, research on sustainable packaging materials, which show appropriate barrier properties while still being able to be removed, is in progress. A selection of these advances is summarised in the following chapters.

3.1. Whey-Protein-Based Films and Coatings

Due to current efforts to develop more sustainable packaging materials for the production of packaging materials, proteins from the residual products or by-products of the food industry are becoming increasingly important. The growing interest of the public and thus also of politicians in packaging materials based on renewable raw materials and biodegradable packaging materials is also leading to increased research activities on proteins such as wheat gluten, soy protein, casein, and whey protein for their use as possible resources for packaging materials.

Protein-based films and coatings can serve several functions. They can be applied by different techniques to improve the packaging-relevant properties of packaging materials, such as barrier properties, or they can be used as an adhesive to allow the lamination of different materials [53].

A very extensively studied protein in terms of its potential in packaging applications is whey protein, a by-product of cheese production. Whey-protein-based formulations have already been shown to be suitable for the production of edible coatings and films. Although these films exhibit only a medium water vapour barrier due to their hydrophilic character, they have excellent oxygen barrier properties [54]. Another advantage of whey protein is its availability. As a by-product of cheese production, whey protein is produced in large quantities [55].

Purified whey protein concentrates (WPC) or even highly purified whey protein isolates (WPI) can be used to form whey protein-based films. In order to form coherent and non-brittle coatings, different plasticizers are incorporated into an aqueous film-forming solution. The final properties of the resulting films and coatings vary with the proteins and additives used. In particular, the concentration of plasticizers, chemical agents, or the addition of lipids or salts affects the resulting properties [40].

Whey-protein-coated film can be laminated to other packaging films to create recyclable multilayer structures as developed in the European funded projects Wheylayer, Wheylayer2, and Thermowhey. These multilayer structures can be used in additional conversion processes, such as thermoforming or form-fill-seal processes, in order to create different packaging items with tailored properties. The application of whey-protein-based coating formulations has been proven to work in pilot scale in roll-to-roll coating and lamination lines. The films produced were found to possess exceptional mechanical properties, as well as effective barrier properties against gases and ultraviolet (UV) light [56]. Whey-protein-based coatings in multilayer structures have the potential to replace synthetic oxygen-barrier layersincluding EVOH. This bio-based and biodegradable coating provides an alternative to organic fossil-based barrier materials [56]. A recent study has shown that whey protein-based multilayer packaging films can provide similar functionalities as those of multilayer packaging films with inorganic barrier coatings [57]. The combination of protein-based films and coating with inorganic coatings could be an interesting approach to further improving the functionality, such as the barrier properties, of novel sustainable multilayer packaging films.

The application of whey protein coating on paperboard has also been the research subject of several studies. These studies demonstrated that whey proteins decrease water vapour and oxygen permeability and increase the oil resistance of paper(board), whereas the grease resistance of the coatings depends on the plasticiser used [58,59,60,61]. A more recent study aimed to further improve the barrier properties of whey-protein-coated paperboard by applying a new WPC–beeswax–sucrose coating [62]. This combination resulted in decreased water absorption and decreased water vapour permeability compared to WPC-coated paper without beeswax. Combining protein coating with lipids or lipophilic compounds seems to be an interesting strategy to achieve further improvements. A different technology allowing the combination of proteins and lipophilic components is described in Section 3.1.1.

3.1.1. Chemical Modifications of Proteins

The chemical modification of proteins for edible films and coatings can involve reactions with different chemical agents [63]. Alkylation, acylation, acetylation, and succinylation are some selected chemical reactions that can take place in protein-based film-forming solutions. However, in case of food packaging materials with direct food contact, the recent legal situation regarding food contact compliance needs to be considered very carefully; therefore, several modification pathways are not suitable, as the potential chemicals are lacking food contact compliance. Chemical grafting, meaning the application of fatty acid chlorides by an acylation reaction, could potentially gain importance for whey protein modification. Here, alkyl chains covalently bond to protein chains and can act as internal plasticizers. Comparable to the effect of external plasticizers, the intermolecular interactions between the protein sides chains are reduced, resulting in changed properties of the protein films and coatings [63,64].

A highly material-efficient method to increase the water vapour barrier and repellence properties of biobased films and coatings is chemical grafting technology using fatty acid chlorides, e.g., palmitoyl chloride, to monomolecularly graft a hydrophobic nanoscale layer on hydroxyl-group-containing surfaces [65]. Experiments at Albstadt-Sigmaringen University first showed that the water vapour barrier properties of protein-based films could be altered by this grafting process (data not published). Fatty acid chlorides can be applied by a transfer method that was developed for the surface grafting of polyvinyl-alcohol-based films [66,67,68]. The fatty acid chlorides react with the hydroxyl groups of the substrate surface. The main advantage of this grafting process is its material efficiency. In addition, the fatty acid nanoscale grafting provides hydrophobic surface properties [66], leading to an improved easy emptying behaviour of several packed goods, such as high-viscosity food products. These repellence properties are comparable to those of emerging non-biobased and non-biodegradable solutions on the market.

3.2. Polyhydroxyalkanoate (PHA)-Based Coatings

PHAs constitute the carbon and energy storage material of certain bacterial species produced under carbon excess and nutrient limitation conditions [69,70]. They are aliphatic polyesters that can be classified according to their monomer size as short-length PHAs, consisting of three to five carbon monomers, and medium-chain-length (mcl) PHAs with six to fourteen carbon monomers in the 3-hydroxyalkanoate units [71].

The ability to manipulate and modify the cellular system through metabolic and genetic engineering tools has paved the way for the creation of PHAs that are rationally designed [72,73]. This has been demonstrated by controlling the carbon flow through the beta-oxidation pathway, which results in obtaining a higher percentage of shorter monomers in the PHA when the repressor PsrA (PsrA: Pseudomonas sigma regulator) is deleted [74] or longer monomers when the beta-oxidation pathway is slowed down [75].

Depending on the monomer composition and the length of the side chain, different PHA properties are obtained in regards to hydrophobicity, melting point, glass transition temperature, and degree of crystallinity, as well as a wide variety of mechanical properties from rigid and highly crystalline to flexible, amorphous, or elastic [20,21]. Structural diversity is critical to defining potential applications, as the biological, thermal, and mechanical properties of the resulting polymer depend on the monomer composition and molecular structure of the polymer. Long-chain PHAs are generally water-insoluble and resistant to hydrolytic degradation due to their high hydrophobicity [76]. They possess excellent film-forming properties, a higher water vapour barrier than other biopolymers, good UV resistance, and poor resistance to acids and bases [77]. Yeo et al. (2018) [78] summarized that adjusting the ratio between hydroxyvalerate (HV) and hydroxybutyrate (HB), which can be achieved by the manipulation of the growth media, can alter the properties of the film A high proportion of polyhydroxybutyrate (PHB) lead to a strong and rigid material, while polyhydroxyvalerate (PHV) increases flexibility and toughness.

Medium-chain-length (mcl) PHAs are considered promising candidates for packaging applications due to their high elasticity, hydrophobicity, low oxygen permeability, water resistance, and biodegradability [79]. Using mcl-PHA in blends with poly(3-hydroxybutyrate-co-3-hydroxyvalerate) PHBV or PHB results in an improved elongation at break and decreased tensile strength compared to those of neat PHBV or PHB films [80,81]. In the case of PHB, the O2 permeability is decreased by 38% upon blending with mcl-PHA. Comparing the aforementioned PHB/mcl-PHA blended films with neat mcl-PHA films, the reduction in O2 permeation is even more prominent [81]. PHA coated on cellulose nanopaper significantly improved the surface hydrophobicity [82]. In another study published by Pérez-Arauz et al. (2019) [83], cast films of blended PHA, which were rich in PHB with low amounts of PHBV and mcl-PHA, showed an increase in the elongation at break in comparison with that of homopolymer PHB, and a decrease in melting temperature. Moreover, regarding water vapour permeability, the blended cast films had the same order of magnitude as the value reported for PET. These properties further indicate their application potential in the food packaging sector [83]. Nevertheless, the properties of the polymers need to be diversified to be applied in different fields [84].

PHAs have been processed using different techniques, such as extrusion and injection [85,86], compression moulding [77], thermoforming [86], solvent and spin casting [87], and extrusion coating [88,89,90]. The exploitation of PHA as a coating is still hampered by difficulties in processing mainly due to its crystallization behaviour and its narrow thermal processing window [91]. In general, these issues can be solved by adding additives or blending with other polymers. Blending PHB with natural raw materials or other biodegradable polymers, including starch, cellulose derivatives, lignin, or PLA, can improve ihts poor mechanical and thermal properties, thereby extending its as a coating material for food packaging applications on paper or cardboard [92,93,94,95].

Noda et al. [96] reported that 10% of PHA to PLA improved the toughness and elongation at break. Moreover, the tensile strength of a PHB–starch blend at a ratio of 30:70% significantly increased compared with that of the virgin PHB, leading to a substantial reduction in costs [71]. Nevertheless, blending can be complicated by the interfacial interactions between the polymers, so modification by grafting or copolymerization is needed. Willett et al. [97] used a grafted starch/glycidyl methacrylate copolymer leading to improved mechanical properties of PHBV.

To further enhance its barrier and mechanical properties and overcome the difficulties regarding its processing properties, PHA could be combined with additives and fillers, as their addition affects the crystallization behaviour. The critical point in this case is to achieve a homogeneous dispersion of these fillers. Furthermore, these fillers can act as nucleating agents to promote crystallization in order to improve barrier properties and reduce the brittleness of the coatings. Nanofillers with different morphologies and chemical natures, such as natural clays, micro- and nanofibrillated cellulose, and cellulose nanocrystals, can be considered [98]. El-Hadi [99] has shown that the integration of clays in PHB improves the barrier properties against water vapour and oxygen. The integration of nanocellulose led to a significant improvement of 70% in the water vapour barrier properties with 15% of CNC in PHBV according to Yu et al. (2014) [100]. Simultaneously, the mechanical and thermal properties were also enhanced [100]. Coatings consisting of plasticized PHB and cellulose nanocrystals were found to enhance the performance of paperboard not only in terms of the water vapour barrier but also regarding its tensile properties [101]. In conclusion, blending and incorporating additives provide the opportunity to obtain favourable barrier properties and improve mechanical properties.

Nevertheless, the dispersion and solvent casting processes continue to be a challenge for PHB. This process involves dissolving the polymer in a suitable solvent to obtain ultra-thin films with a high optical clarity. Chloroform is one of the most compatible solvents for PHB [102,103]. Thus, PHB has been coated on paper by solvent casting using chloroform as a solvent, resulting in a reduction in moisture and water absorption along with improved tensile properties [104]. However, as chloroform is one of the chemicals that is the most damaging to the environment and human health [105], there is a need to find risk-free solvents. Anbukarasu et al. [106] demonstrated the possibility of using acetic acid as an alternative to chloroform, obtaining films with comparable properties. PHB coatings can also be obtained by aqueous polymer dispersion processes, but PHA continues to pose a challenge due to unsatisfactory performances and relatively high costs [107,108]. Future developments are necessary in this area mainly for paper coating in order to pave the way for a sustainable and green future.

Besides solvent-based coatings, PHAs can also be applied as waterborne coatings using the patented plastisol method [109]. This plastisol consists of PHA powder, plasticizer, and water, which are mixed into a homogeneous, coatable paste. This paste can then be coated via knife coating, rod coating, or screen-printing on a range of substrates, such as textiles, paper, or foils [109]. After the application of the plastisol, the coating is heated above the melting point of the used PHA to evaporate the water and fuse the PHA and plasticizer into a homogeneous coating. Visually, the coatings are colourless and transparent. The coatings show excellent abrasion resistance, good flexibility, and promising barrier properties [109].

Using a combination of β-oxidation pathway-modified strains and growth on selected carbon sources, PHA can be produced with a tailored monomer content, yielding PHA with desired properties for specific applications. PHAs with more or less similar structures, but different physical properties due to their lower glass transition temperature compared with PLAs, are referred to as second-generation bio-polyesters. Overall, we highlight here that PHAs might be a better candidate for thin film manufacturing not only due to their synthesis by microorganisms and the biodegradability of unmodified PHAs in several environments, but also because of the significant variability in their microstructure that in turn provides a wide range of properties. PHA has found many potential applications in a wide variety of fields thanks to its biocompatibility, biodegradability, and low permeability against H2O, CO2, and O2. The present barrier to its bulk use is its cost. This is partially connected with the manufacturing route and partly the production scale. Consequently, a key factor in the spreading of biobased polymers in food packaging is the development of analogous continuous processes for manufacturing at a reduced cost and to a pre-defined quality. Another key factor is the production of polymer resins that can readily be processed into film using existing industrial machinery, only necessitating a minor modification of the production plant. The potential of this polymer type in the packaging sector is excellent.

3.3. Biobased Adhesives

Multilayer materials for packaging applications are structured by bonding two or more substrates through an adhesive. Substrates in flexible multilayer packaging are typically fossil-based polymers, such as PE; PP; PET; polyamides (PA); biobased polymers, including PLA, PHA, bioPE, and bioPET; fibre-based materials, i.e., cardboard, paper, barrier coatings, such as EVOH; or inorganic barrier materials, e.g., aluminium [110]. The multilayer materials can be distinguished between laminates, i.e., adhesives applied on the full area of the packaging, and seams, i.e., adhesives applied over a partial area of the packaging for sealing. The area of adhesive application has a big impact on the adhesive forces that can be developed [111].

Adhesives in general are classified according to their intended function, their chemical composition, method of curing, physical form, and their applications [112,113]. In terms of sustainability, a distinction between synthetic or natural adhesives has become more and more common.

3.3.1. Adhesive Types and Potential of Biobased Adhesives

Synthetic adhesives include a broad spectrum of adhesives and can be sub-classified according to their method of curing, which comprises mainly the following three mechanisms: (1) a loss of solvent or loss of water, i.e., solutions or dispersions; (2) cooling from a melt, i.e., hotmelt adhesives (HMAs); and (3) curing by a chemical reaction, i.e., polyaddition or radical polymerisation.

For the first type, the solvent subsequently evaporates to give the final joint. In terms of environmental safety, using water instead of organic solvents has become more popular recently. Solvent-based adhesives can be based on polyvinyl acetates, polyvinyl alcohol, ethylene vinyl acetate copolymers (EVA), polyurethanes (PU), acrylates, and natural and synthetic rubber [110,114,115,116]. HMAs, on the other hand, are polymers or polymer mixtures that join two substrates by cooling from a melt. The joint formation is achieved very fast. Therefore, HMAs are usually chosen for processes that require a high throughput. HMAs are thermoplastic polymers, such as PA, saturated polyesters, and EVA [117]. The third type of adhesives are those cured by a chemical reaction. They can be separated into one-component reactive adhesives, in which the crosslinking reaction is triggered by an external impulse; and two-component reactive adhesives, in which the two reactants are mixed shortly prior to their application [118]. One-component adhesives can be PU, silane adhesives, and cyanoacrylates, which are cured by water; condensation resins, such as phenol-, urea- or melamine formaldehyde adhesives, which are cured by high temperatures; or acrylates, which are cured through UV light. Two-component reactive adhesives can be epoxides, PU (addition reaction), or methacrylates (a radical polymerisation reaction started by an initiator compound) [119]. A separate class of adhesives are pressure-sensitive adhesives (PSAs). They do not harden, but retain their tackiness, which is caused by non-covalent interactions with the substrate, throughout their service life. Therefore, they are used in adhesive tapes and labels. PSAs are mainly based on acrylates, rubbers, and UV-curable polymers [120].

The adhesive has to address many technical needs, such as the bonding strength between substrates, including printed ones, heat resistance, and chemical resistance [121]. It is a key factor in maintaining the packaging clear and shiny, preserving the marketing design given by the printed film. Above everything, the adhesive must be safe for consumers and respect all food legislation applied at a country or regional level [121]. Reactive PU adhesives that form a cured PU network as the adhesive layer may fulfil these requirements. These adhesive systems are applied by a roller process with or without a drying step depending on the solvent contents [122]. A PU adhesive is generally formed by the polyaddition reaction of a hydroxylated component with an isocyanate component. The hydroxylated component can vary widely, ranging from straight polyesters and PU pre-polymers to polyether polyols. The same goes for the isocyanate component, which ranges from PU pre-polymers based on either polyester or polyether to aliphatic or aromatic isocyanates [122]. These systems with many variables give a high degree of freedom for the formulation, customisation, and optimisation of performance and efficiency. The properties of PU could be tuned by the appropriate selection of these starting materials. Some biobased polyols, including polyester polyols [123,124], estolide polyols [125,126,127,128], polylactic polyols [129,130], and natural oil polyols [129,130,131,132,133,134], have been attracting interest lately; thus, biobased dicarboxylic acids and diols/triols have already been developed and are commercially available as potential substitutes for their petroleum-based counterparts. However, the choice is limited by regulations and current industrial potential.

Except for some aliphatic isocyanates, such as pentamethylene diisocyanate [135,136] and derivatives, the number of biobased isocyanates is extremely limited. The PU adhesive could be supplied either as a solvent-based product or as a solvent-free one. Solvent-based PU adhesives can cover all the needs of the market from general purpose applications, such as packaging for snacks, to highly demanding applications in the retort and packaging of chemically aggressive products. Solvent-free adhesive systems, 100% solids in this case, are generally not efficient enough for highly demanding end-use when compared to solvent-based ones [137,138].

Natural adhesives are manufactured from naturally occurring materials, such as animal or agricultural products, including starch, casein, animal glue, fish glue, blood glues, and natural rubber. However, besides originating from renewable resources, they have further advantages compared to fossil-based synthetic adhesives [133]. By using natural building blocks with different functionalities, e.g., unsaturated or epoxidized oils, peroxidized starch, itaconic and cinnamic acid derivatives, and terpenes, the molecular architecture of biobased adhesives can be different to that of petroleum-based adhesives, resulting in new interesting properties, as summarized by Heinrich (2019) [133]. For example, the introduction of lignins with high chemical functionality can increase the curing speed and strengthen the adhesive bond. Furthermore, water resistance can be promoted by the introduction of long alkyl chains from vegetable oils. New functionalities such as those deriving from nanocellulose, which can act both as a binder and as a structural reinforcement, can be introduced into biobased adhesives [133].

The use of renewable feedstock for the development of novel adhesives is an incentive for the circular economy. Furthermore, next to natural building blocks, waste feedstock can be an alternative to reduce the carbon footprint and to promote the circular use of plastics [133]. Thus, oligomers and monomers obtained from the degradation of biobased polymers, such as PLA, can be used to develop novel adhesives. Commercial PLA cannot be used as an adhesive because of its high molecular weight and its high transition glass temperature. However, the presence of hydrolysable ester bonds and the ability to be degraded by enzymes make its degradation products interesting for the development of biobased adhesives. Recently, lactic acid oligomers (OLAs) have been used in different adhesive formulations. Wendels et al. (2022) [139] prepared biobased polyurethane sealants for tissue adhesive applications, based on an isocyanate-terminated pre-polymer and a chain extender. In order to bring controlled variations on the final macromolecular architectures, they prepared different prepolymers based on poly(3-hydroxybutyrate) diol oligomers and poly(lactic acid) diol oligomers, obtaining different physico-chemical and mechanical properties. Moreover, the final adhesives exhibited good biocompatibility, with limited cytotoxicity [139]. OLAs were also used in the synthesis of renewable pressure-sensitive adhesives, by their copolymerisation with epoxidized soybean oil [140]. The carboxyl and hydroxyl end-groups of OLAs are in fact able to open the epoxy rings of the oil and to form polymer networks with good adhesion properties.

3.3.2. Protein-Based Adhesives

Adhesives derived from proteins offer several advantages, such as a wide applicability in terms of their processes and substrates, non-toxicity, safety for indirect food contact, biodegradability, easy clean up with water, and cost effectiveness [141]. The drawbacks of protein-based adhesives are their poor water resistance, the low adhesion with non-polar-based substrates, such as polyolefins, and their limitations regarding direct food contact or exposure to low temperatures, i.e., freezers.

These macroscopic properties can be related to the chemical structure of proteins. They have a primary, secondary, tertiary, and quaternary structure, which depends on the outer conditions and can be modified to change the protein’s properties. As a natural biopolymer, proteins have a high degree of free functional groups resulting from the natural amino acid profile, such as the carboxy, amino, thiol or hydroxyl groups. These functional groups, unlike other biopolymers, are relatively easy to chemically modify, and, therefore, the properties of the protein can be adjusted for the target application.

Casein, obtained from cow’s milk, precipitated by acid and solubilized again by alkali, is the main protein for adhesives. Adhesives based on casein were traditionally used for laminating timber, since the wooden pieces could easily be reassembled and repaired by releasing the brittle joint. Casein has been also used ever since to attach labels to glass bottles due to its good adhesion on glass in cold or wet environments and the ease of removing it under hot water prior to recycling or refilling [121,142]. Further crosslinking can be achieved by metal salts containing bi- or trivalent metals, for example calcium or aluminium. To influence the setting time, casein glues contain urea. All formulations need a preservative and a defoamer [122].

To improve its resistance against water, various strategies of protein modification have been reported. Chemical crosslinking involves the modification of the tertiary and quaternary structure, for example, creating denser networks, which are less prone to water [143]. Another strategy, in which soy protein is self-crosslinked with pre-hydrolysed carbohydrates from soy flour, has been shown to increase moisture resistance and improve shear strength by almost 100% [144,145].

The interfacial adhesion of soy protein can be improved by inorganic fillers, such as calcium carbonate, which interact with the functional groups of the protein [146]. The formed nanocomposite has been used to bond plywood samples. The shear strength increased from 1.7 MPa to above 5 MPa [146].

The hydroxyl- and amine functional groups of soy proteins have been covalently bonded to traditional crosslinking agents, such as poly-methylenediphenylisocyanates for obtaining a similar shear strength to that of commercial adhesives [147], a bisphenol-A-based epoxy resin to increase the shear strength by 55% when hydrolysed [148], or urea-formaldehyde resin to increase the shear strength by 150% [149]. Blending proteins with commercial adhesives can also improve their performance, as demonstrated in a formulation of urea formaldehyde resin with soy protein [150]. Using 25% soy protein increased the internal bond strength of glued cardboards by a factor of two to three.

Non-polymeric crosslinkers for proteins have also been reported. These non-polymeric crosslinkers include epoxy-silane coupling agents that have double the shear strength of unmodified soy-protein adhesives [151]; glutaraldehyde, which increases the molecular weight of bacteria protein by a factor of six [152]; and L-3,4-Dihydroxyphenylalanine, which increases the shear strength of soy protein by a factor of three [153]. Crosslinking soybean protein with soybean-derived daidzein results in a nearly 100% biobased adhesive with an improved shear strength and increased mildew resistance [154].

The modification of the tertiary structure of soy protein by disrupting intramolecular crosslinks through guanidine hydrochloride, sodium dodecyl sulphate, sodium hydroxide, or urea increased the shear strength of soy protein slightly, but showed the reverse effect for cottonseed protein [155]. Likewise, enzymatic hydrolysis, followed by heating to 50–90 °C, improved the bond strength and water resistance of a wheat gluten adhesive [156]. Changing the pH value can either increase or decrease the adhesive strength [157]. In general, the highest shear strength of protein adhesives is near their isoelectric point. The solubility in water also is lowered by increasing the hydrophobicity caused by the stronger interaction between protein chains [158,159]. The susceptibility of proteins to hydrolysis and their degradation upon exposure to a high humidity during service needs to be addressed, but can at the same time advance the recyclability of the blended products such as adhesive tapes, which can potentially be made fully biodegradable [160].

As an example for a HMA, a mixture of coconut oil, PCL, and soy protein isolate was prepared and its mechanical and thermal properties were analysed [161]. The addition of 40% soy protein increased the softening point from 60 °C to above 75 °C, while the tensile strength decreased from 11 MPa to 2.9 MPa.

3.4. Further Biobased Multilayer Approaches

Besides the intensively studied whey protein and PHA-based coatings described in Section 3.1 and Section 3.2, respectively, several other biobased coatings are under investigation for applications in multilayer structures. Besides animal-derived materials, such as fish gelatine, casein, chitosan, and others, plant-based proteins and coatings, including soy protein and zein, also have shown great potential for application in laminates [40,162,163]. Besides terrestrial plants, macrophytes (aquatic plants) can be considered a potential protein source for packaging applications [164].

Another approach for gas-barrier coatings has been patented for combining natural proteins and natural polysaccharides with synthetic polymers as structuring agents and metal oxides as reinforcement agents. The applicable proteins comprise gelatine, wheat gluten, casein, zein, or whey proteins, whereas pectin, cellulose, chitosan, alginates, carrageenan, guar gum, or xanthan gum can be used as polysaccharidic materials [165].

Side stream products, for instance from food processing, are of high value as raw materials. For instance, a moulded and fluff pulp material was recently patented to be useful as a biodegradable packaging material. The applicants for the patent filed a method to use the aliphatic polyesters present in the moulded or fluff pulp and a cellulose-based laminate layer to produce a compostable food packaging unit [166,167]. Another recently published patent describes a method for obtaining concentrated protein-rich phases from residues of bioethanol production [168]. The obtained by-products can then be used for the production of self-compostable films, coatings, and rigid plastic after further modification and purification [169].

Outside Europe, several patents have recently been filed in the field of food packaging. These innovations include biodegradable packaging solutions, such as composites consisting of more than five components [170,171,172,173]; multilayers combining nanocellulose with guar gum or chitosan [174,175]; and mixed—biobased and fossil-based—biodegradable multilayer structures consisting of polybutylene adipate terephthalate (PBAT), polypropylene carbonate (PPC), PLA, and PHA [176]. Moreover, a recently published patent describes biobased barrier coatings using prolamins, such as zein, hordein, gliadin, and kafirin, together with oilseed-derived polyol fatty acid esters [177]. A broader approach combines biobased plastic—mainly drop-in solutions—with recycled materials and conventional, fossil-based plastics to achieve polymer compositions with a lower CO2 footprint [178].

Besides the aforementioned multilayer approaches, another approach, which is not included in this review article, is the use of biocomposites. A variety of biocomposites have been and are still being extensively studied regarding their potential application in (food) packaging [179,180,181,182].

4. Recycling, Biodegradation, and Upcycling

The destiny of post-consumer bio-plastics is a subject of paramount importance in designing new industrially viable and sustainable products. The chemical complexity of new biobased and biodegradable materials on the market substantially widens the possibilities for their EoL, requiring new definitions and new strategic planning [183]. A recyclable material can be collected and subsequently physically or chemically treated to obtain a second-generation material presenting the same chemical composition and, in the best-case scenario, restored performances. This method can be performed under the premise that the polymer does not undergo degradation during the recycling process. Biodegradation was previously introduced and refers to the microbial degradation of the material with the production of water, CO2, and biomass. Such an approach sees the complete destruction of the macromolecule and should be preferred when an application prevents a suitable recycling method. The upcycling approach is a relatively new concept and regards the combination of controlled chemical/enzymatic degradation along with a modification step to create a second-generation material presenting brand-new performances, aiming at higher-value applications. However, such a variety of scenarios can be concretely performed only after the proper recovery and sorting of postconsumer plastic.

4.1. Identification and Sorting

Within the circular economy paradigm, there is increasing interest in pushing the EoL of plastics towards more recycling to avoid resource depletion and leakages in terrestrial, freshwater, and marine environments. Only 31% of plastic packaging is currently recycled, mainly limited to rigid packaging, such as PET bottles or other pure PP or PE items. However, an excessive amount, about 30–40%, is still landfilled due to the lack of adequate technologies or to economical unviability [184]. Although the share of bioplastics in the global plastics market remains low at around 1–2% of overall plastics production, as mentioned in the introduction, the global production of bioplastics is reported to have steadily grown and is even forecasted to triple in the upcoming years [1]. With the increasing market share of bioplastics, processing materials at EoL need to be considered [185].

Most post-consumer bioplastics will end in the waste flow together with conventional plastics. Although some biobased plastics are biodegradable and could be biologically decomposed, degradation is not the optimal treatment method for biodegradable plastic waste. Instead, recycling achieves the highest environmental benefits according to life cycle analyses [186]. In addition, with the exception of drop-in solutions, biobased plastics differ from fossil-based plastics and could interfere with the current recycling of conventional plastics, thus hindering the closure of plastic cycles. This is undesirable in view of the current focus on the transition to a circular economy. [187] Hence, a successful identification and sorting of the new biobased materials becomes fundamental for the whole plastic waste recycling process. Despite the fact that biobased plastics as group were not found to pose an overall contamination risk for current recycling practices, each of the biobased plastics must be considered as a potential separate source of contamination. In the case of PLA, its presence, even at low levels, can provably cause a deterioration in the quality of recycled PET. Therefore, in order to said deterioration, contamination of the feed for mechanical recycling should be kept well below 0.1%. [185,187] Hence, it seems necessary to evaluate the impact of biobased plastics on the current recycling of plastics, ensuring that the compatibility with the already established recycling processes for conventional plastics is evaluated and striving for during the development of new biobased packaging solutions.

Most biobased and biodegradable plastics can be processed with conventional waste management options and thus have the potential to be recycled into new products [186,188]. Existing sorting and recycling industrial technologies for conventional plastics are mainly focussed on the separation and recovery of single materials, such as PP or PE, from plastic items containing a unique type of material [189]. On the contrary, the sorting and recycling of multilayers is still under research and development with limited industrial applications [190]. This will also be the case for biobased multilayer materials.

Current waste management technologies for the characterization and analysis of EoL plastics are mainly based on optical spectroscopies. These techniques use different physical phenomena but can be grouped into molecular and atomic spectroscopies according to the information that can be obtained from them. The group of molecular spectroscopies includes Fourier transform infrared (FTIR) spectroscopy, mid-infrared hyperspectral imaging, Raman spectroscopy, near-infrared (NIR) spectroscopy and NIR-hyperspectral imaging, and Terahertz imaging. Laser-induced breakdown spectroscopy and x-ray fluorescence spectroscopy belong to atomic spectroscopies [191].

When it comes to identifying and sorting biobased plastics, it is worth mentioning that some of them—particularly biodegradable ones—can suffer from degradation processes. Theses degradation processes can affect their fingerprints. The influence of bioplastics on the sorting processes of conventional plastics by means of near-infrared (NIR) spectroscopy has also been studied. Using hyperspectral imaging (HSI) technology, Chen et al. (2021) [192] reported that the presence of non-degraded and degraded PLA in lightweight packaging waste in Germany does not influence the sorting process of the main sorted conventional plastics: PP, HDPE, PET, and PS.

4.1.1. Near-Infrared Spectroscopy (NIRS)

Over the past 30 years, on/in-line near-infrared spectroscopy (NIRS) has proven to be one of the most efficient and advanced tools for the continuous monitoring and control of process and product quality in a wide variety of industries. Among the diversity of applications for NIRS, the recycling of plastics has received a lot of attention from industrial communities and also from the governments of different countries [193].

NIRS is a vibrational spectroscopic technique that consists of the interaction between electromagnetic radiation and a material within the wavelength range of 780–2500 nm. The absorption bands seen in this spectral range result from harmonics and combination bands of O-H, N-H, C-H, and S-H stretching and bending vibrations. These bands allow the qualitative and quantitative assessment of chemical and physical characteristics. Therefore, NIRS can be applied to all organic compounds that are rich in a) O-H bonds, e.g., moisture, carbohydrates, and fats, b) C-H bonds, e.g., petroleum derivatives, and c) N–H bonds, e.g., proteins [194].

A basic NIRS setup includes a light source, which is commonly a quartz–tungsten–halogen lamp, beam splitter system, i.e., wavelength selector, sample detector, and optical detector. Additionally, extracting relevant information from spectral data requires requires the application of mathematical and statistical procedures. This processing is known as chemometrics. [195] The possibility to use intact samples, which are directly presented to the instrument without any pre-treatment, is one of the main advantages of NIRS. Depending on the type of sample to be analysed, NIRS spectrometers can work in transmittance and/or reflectance modes [196].

In general, plastic waste products can be separated into two main fractions. Domestic wastes contain only five relevant polymers in large quantities (PE, PP, PS, PET, and polyvinyl chloride). Technical plastics use a broad variety of polymers containing fillers and additives. The plastics from domestic wastes can be reliably identified by the first overtone of the C-H bands between 1600 and 1800 nm. Extending this wavelength range up to 1000 nm, technical non-black plastics can also be identified. In the case of black plastics, the mid-infrared (MIR) spectral range has to be applied as well, due to the reduced penetration depth of radiation into these materials. Additionally, larger amounts of additives, such as plasticizers and flame retardants, can be analysed [197].

NIRS is a successfully technique to identify and thus to classify a number of commonly used plastics, such as PE, PP, PET, and PS, and also biobased polymers, such as PHA and PLA [197,198]. In addition, NIRS has been shown to be a suitable analytical tool for the monitoring of waste recycling [199,200,201].

The identification of plastics from waste in recycling plants requires fast scanning techniques in the millisecond range, especially if many samples are taken for identification of movement. This movement excludes the FTIR system [197], which is an effective tool in identifying plastics off-line, but not on-line.

4.1.2. Hyperspectral Imaging (HSI)

Although punctual measurements with NIR can be useful for the off-line identification of small amounts of plastic waste, in the plastic recycling industry there is usually a large amount of plastic waste to be identified and sorted, thus a NIR-based technology combining spectral fingerprints with spatial information seems more appropriate for recycling processes.

HSI in the NIR region has been widely used for in-line monitoring applications, due to its capability to provide information regarding composition and its spatial distribution [202]. These characteristics have reinforced its use in the solid waste recycling industry.

A basic HSI system consists of a sensitive NIR sensor, which usually is a CCD camera, a broadband illumination source, which often is a tungsten lamp, a spectrometer, which separates the backscattered/transmitted light into its different wavelengths, a computer, and a conveyor belt for sampling when required. In addition, the system requires software support for image acquisition and control, the multivariate analysis of the spectra, and final image processing [194].

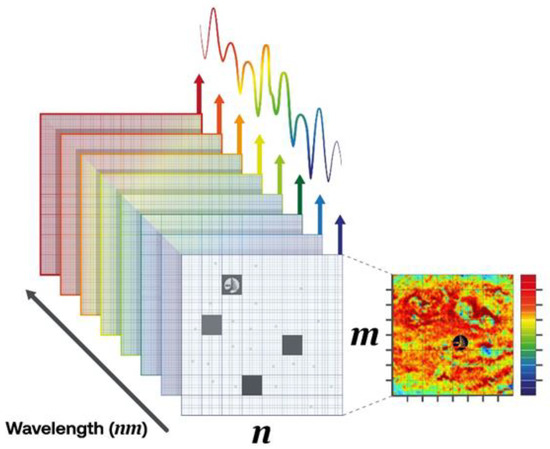

The output of a HSI system is a multispectral image of the sample tested, containing the spatial localization of its interesting features and chemical composition. This data set is generally organised into a hyperspectral data cube (Figure 3). A hypercube is a set of data ordered in three dimensions, two spatial (a plane MN) and one spectral (λ, wavelength). Such a set of data has to be processed using advanced mathematical tools, also known as chemometric techniques, including a multivariate analysis and statistical methods, to extract the most relevant and significant information from the spectral dataset. In this regard, chemometric methods allow the analysis of a large amount of data, identifying the most significant spectral features for discrimination, classification, or prediction purposes.

Figure 3.

Graphic representation of a hyperspectral cube acquired with the industrial hyperspectral system VISUM® HSITM. Each hyperplane (slide) of the cube corresponds to a spectral channel or wavelength band.

The use of HSI technology in the plastic recycling industry has been described in a number of publications [202,203,204,205,206,207,208]. In addition, a few studies have been performed regarding the use of hyperspectral imaging for the identification of bioplastics. Ulrici et al. (2013) [204] demonstrated the effectiveness of HSI in the NIR range (1000–1700 nm) coupled with chemometrics to discriminate PET from PLA. Hollstein et al. [198] concluded that novel bio-plastics made of PLA, potato starch, or corn starch were distinguishable from the established, conventional ones by means of HIS-NIR-SWIR (1200–2200 nm). Moroni and Mei [209] developed an effective methodology based on HSI on the NIR region (900–1700 nm) for the separation of two different conventional plastic polymers (PET and PS) and PLA, which is a biobased and biodegradable plastic material, at different phases of their life cycle—in particular, as primary raw materials and urban waste—and with different morphological and dimensional characteristics.

4.2. Recycling

Framed in the pivotal fields of sustainable development and the circular economy, the recycling of plastic materials represents one of the most relevant aspects for the development of new products. The possibility of re-using materials for multiple life cycles and a pool of different applications allow us to save a substantial amount of primary material resources as well as energy, while positively reducing our carbon footprint [210]. Today, the main challenge resides in designing EoL options in advance for multiple applications [211].

Several technologies have been developed for the recycling of polymers and plastics, including mechanical processes, i.e., shredding, grinding, and melting [212]; chemical processes, i.e., hydrolysis, alcoholysis, and thermal depolymerisation with catalysts [213,214]; and the depolymerisation of (bio)polymers using enzymes [215].

The recycling of biobased polymers allows for different scenarios. While industrially compostable plastics in post-consumer (bio)waste enable organic recycling, i.e., composting, for certain dedicated applications, many non-biodegradable bioplastics, especially drop-in solutions, can be seamlessly integrated into the circular economy to extend their lifetime through additional life cycles. In this perspective, the recycling of biopolymers is crucial to reducing the consumption of renewable resources needed for the synthesis of the corresponding monomers [216].

Four possible recycling pathways are available after bioplastic waste has been collected, sorted, and cleaned:

- Primary recycling allows us to recover polymers by mechanically recycling plastic waste, which has been pre-sorted by type and additionally by colour, application, etc., to obtain polymers of their original chemical structure and for similar applications [217]. However, this procedure currently only applies for PET (bottles).

- Secondary recycling is available for collected plastic waste fractions that cannot be ideally pre-sorted; however, this still allows the reuse of polymers in less demanding product applications in terms of their (thermo-)mechanical properties (downcycling) [218]. Currently, this procedure applies for most mechanically recycled materials.

- Tertiary recycling is performed through chemical and/or biological methods, depolymerising macromolecules into monomers or oligomers. The advantage of this method is its versatility and the possibility of delivering a pool of building block chemicals suitable for various applications [215,219].

- Quaternary recycling is the incineration of low-grade plastic waste for energy recovery.

In the context of a circular economy, priority should be given to the first three recycling methods whenever possible [217]. Still, the thermal recovery of biobased plastics contributes to a closed carbon loop by releasing the sequestered carbon dioxide back to the atmosphere from which it was taken up by the feedstock used in the beginning of the production process.

4.2.1. Recycling and Repulping of Fibre-Based Packaging

Fibre-based packaging is currently recycled at a rate of 82% in Europe [47]. This is made via so-called repulping which allows the wastepaper to be converted back into pulp, which can be converted back into new items made from recycled paper. The potential for the defibrillation of paper- and paperboard-based packaging may be affected by the different coatings or additives used, and the recovered paper quality also depends on defects that can result from impurities in the pulp [220]. As such, there are different country-specific tests to assess the repulpability of fibre-based packaging. These country-realted specificities are due to differences in collection systems in the paper and board stream, among other factors. There are also different infrastructures (standard, deinking, specialized) throughout Europe [221].

In 4evergreen, a cross-industry alliance in which more than 85 entities of different sectors are collaborating to reach a 90% recycling rate by 2030, there is the endeavour to develop an assessment protocol for each main mill type to be endorsed in the value chain throughout Europe. However, every recycling mill technology somewhat differs. Standard mills are by far the most common type in Europe. Consequently, a draft of a harmonised testing method for these mills is already available [222].

In general, the recycling of paperboard involves several steps, such as pulping with detrashing, high-density cleaning, coarse screening with subsequent coarse reject handling, fine forward cleaning, fine slot screening with subsequent fine reject handling, light-weight cleaning, thickening with subsequent water clarification, and storage. Pulping with detrashing means to defibre the paper into its constituent fibres. While doing so, it is important to avoid significant degrading while the contaminants are being removed [223]. During these processes, less than 90% of the fed waste material can be recovered [224].

The recycling of beverage cartons is accomplished by specialized mills. In these mills, the plastic or polymer–aluminum fraction generally ends up in the mixed coarse rejects, if this fraction can be easily separated at the beginning of the repulping step. The mixed coarse rejects in turn are currently not further recycled for economic reasons [225]. These so-called repulping rejects are mainly valorised for energy or used in cements kilns as alternative fuels and bauxite substitutes [226]. Due to innovations in this field, the recyclability of beverage cartons has increased from 75% to at least 90%. In the course of this improvement, there have also been increasing non-food (packaging) applications in which the polymer–aluminum fraction is recycled into injected items [220,227].

4.2.2. Recycling of Polymeric Monomaterials Using PLA as Example

With the exception of drop-in solutions, PLA is one of the most technologically advanced commercially available bio-based plastic materials. Therefore, the following subchapter will elaborate on the recycling of monomaterials using PLA as an example. Further information and literature on the recycling of the main conventional packaging plastics are provided by Schyns and Shaver (2020) [212], Thiounn and Smith (2020) [213], and Antonopoulos et al. (2021) [228].

The main recycling strategies exploited for PLA beyond industrial composting include mechanical and chemical routes, while enzymatic recycling is currently being considered as an additional EoL option.

Mechanical recycling allows the recovery of PLA, making use of well-handled and economically feasible industrial processes [229]. On the other hand, the thermo-mechanical processing of polymers in general causes a decrease in their chain lengths, and in the case of PLA, even its crystallinity can be affected, therefore making it necessary to monitor the number of possible recycling steps and the resulting quality of r-PLA [230]. Chain extenders are often introduced to restore molecular weight and improve mechanical properties [231].

Chemical recycling concerns the controlled degradation of the macromolecular structure of PLA to obtain high-purity products [232]. One approach consists of fully depolymerising the material to recover monomers by hydrolysis or alcoholysis. Hydrolysis at 160–180 °C for 2 h enables a 95% conversion of PLA to LA [233]. This method not only allows us to valorise post-consumer materials but also to produce LA in a more energy-efficient way than fermentation [234]. Similarly, alcoholysis can be applied for depolymerisation of PLA to obtain LA esters as value-added products [235]. In turn, lactide can be generated from these alkyl lactates, and can then be converted into PLA again, matching circular economy processes [236]. A different approach aims at partially degrading the macromolecular structure, obtaining oligomers for specific applications. A remarkable example is the fabrication of biobased adhesives deriving from partially depolymerised PLA [140].

Enzymatic recycling is developed as a new, promising, and sustainable approach for the treatment and re-utilization of polymers. Recycling polyesters by using hydrolytic enzymes can overcome the difficulties encountered with both chemical and mechanical recycling processes [237]. For example, the pyrolysis of PLLA requires high temperatures (approximately 250 °C), leading to the formation of DL-lactide monomers [238]. Conversely, recycling PLA by using enzymes occurs under mild conditions and does not determine the formation of undesirable by-products as racemic mixtures of PLA [239].

Several enzymes are used in a wide range of processes. Lipases, esterases, cutinases, and proteases families can catalyse the hydrolysis of different aliphatic polyesters, such as polybutylene succinate (PBS), PLA, PCL, PHA, and PPC [240,241]. Enzymes exhibit differences in substrate specificity and/or interfacial activation, as various types of hydrolases show remarkable differences in their three-dimensional conformation and their active site surrounding [242]. Furthermore, enzymes can hydrolyse polymers into monomers and/or low-molecular-weight oligomers from the chain-end (exo-type degradation), or along the main chain in a non-selective manner (endo-type degradation), resulting in high-molecular-weight oligomers as main degradation products [243,244].

The degradation of PLLA using commercial proteinase K from Tritirachium album was first reported by Williams (1981) [245]. Later, other serine proteases, such as α-chymotrypsin, trypsin, elastase, and subtilisin, have been shown to be capable of efficiently hydrolysing PLLA [246]. Kawai et al. (2011) [247] proposed two types of PLA-degrading enzymes with different enantioselectivities toward PLLA and PDLA: protease-type and lipase-type (including a cutinase-like enzyme), which preferentially hydrolyse PLLA and PDLA, respectively.

For over 10 years, studies of the enzymatic degradation of polymers into oligomers have been conducted with the main objective of reusing the products generated after enzymatic depolymerisation [248]. Kaihara et al. [249] found that lipase B from Candida antarctica was able not only to efficiently degrade PHAs but also to readily re-polymerise the obtained cyclic oligomers to produce the corresponding polyester. The biological recycling process of PLA was first reported by Youngpreda et al. [250] in which PLA powder was degraded by the protease produced by the Actinomadura keratinilytica strain T16-1 (approximately an 82% conversion) and the degradation products were then re-polymerised repeatedly by a commercial lipase.