Numerical Investigation into GFRP Composite Pipes under Hydrostatic Internal Pressure

Abstract

:1. Introduction

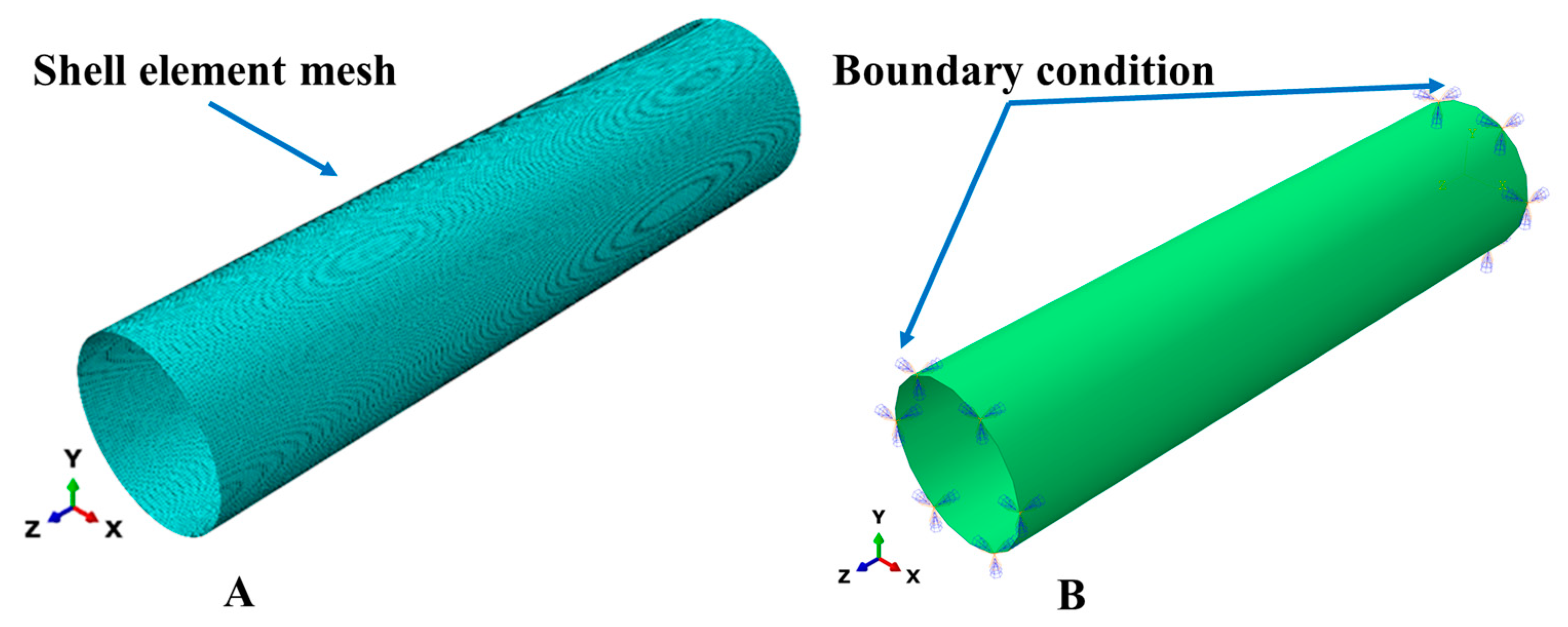

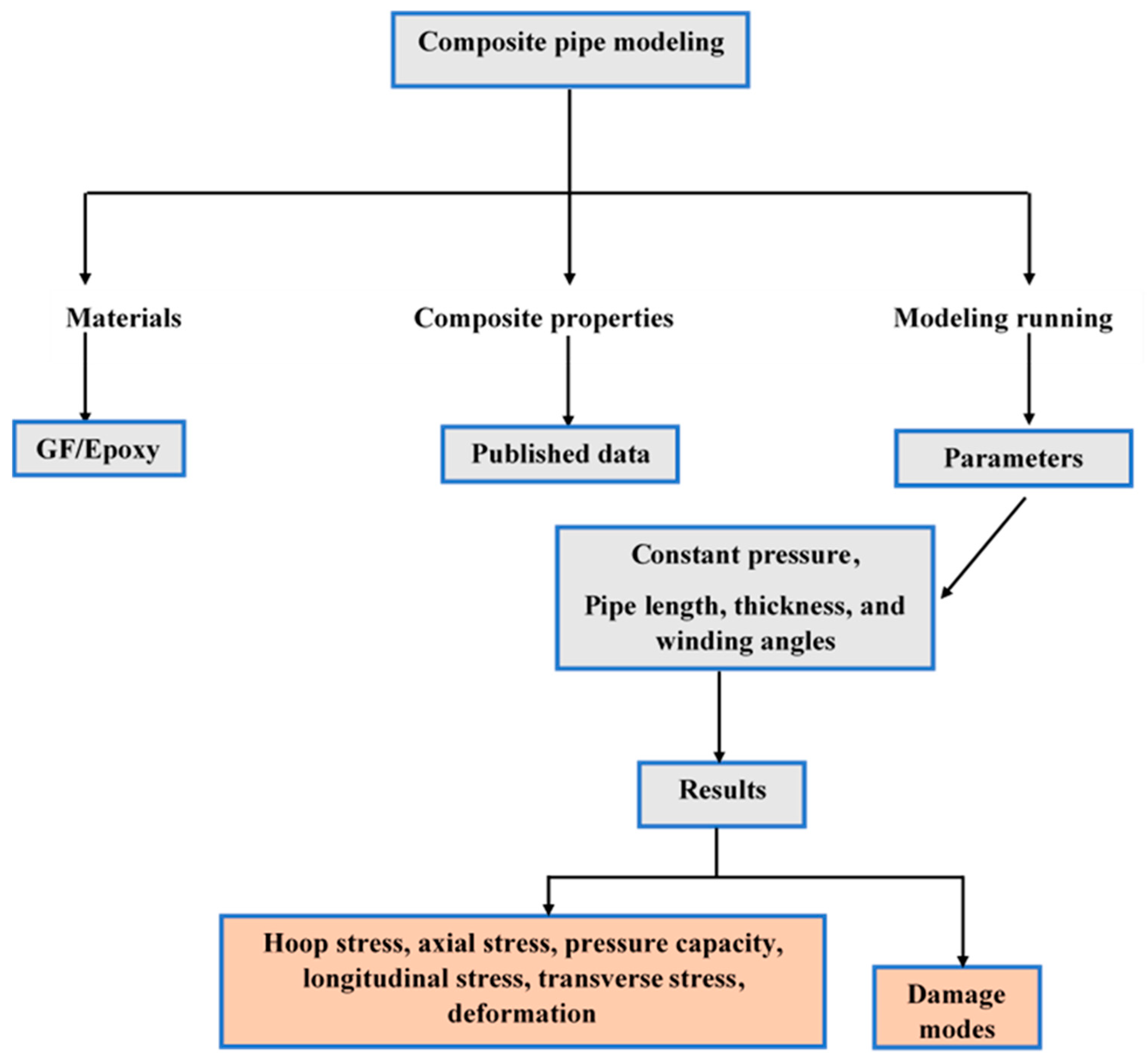

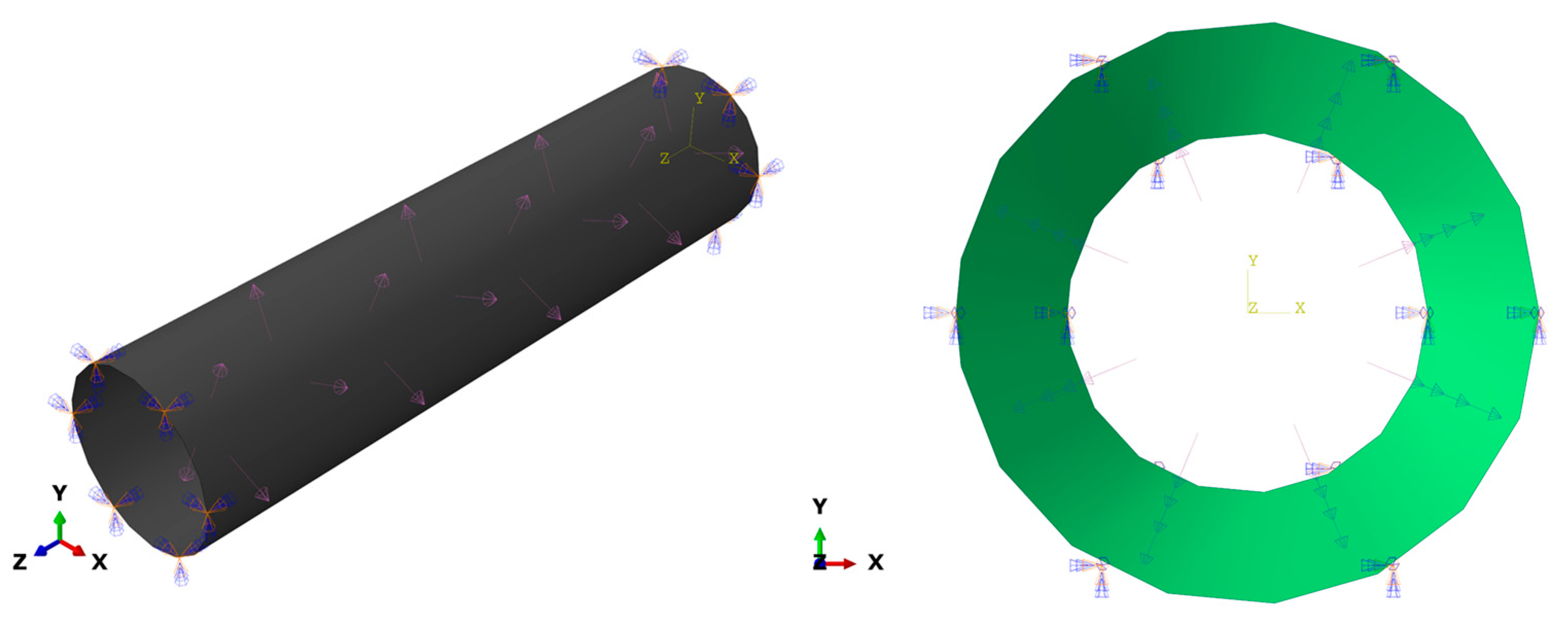

2. Problem Statement

3. Composite Pipe Modeling

4. Failure Inspection

5. Results and Discussion

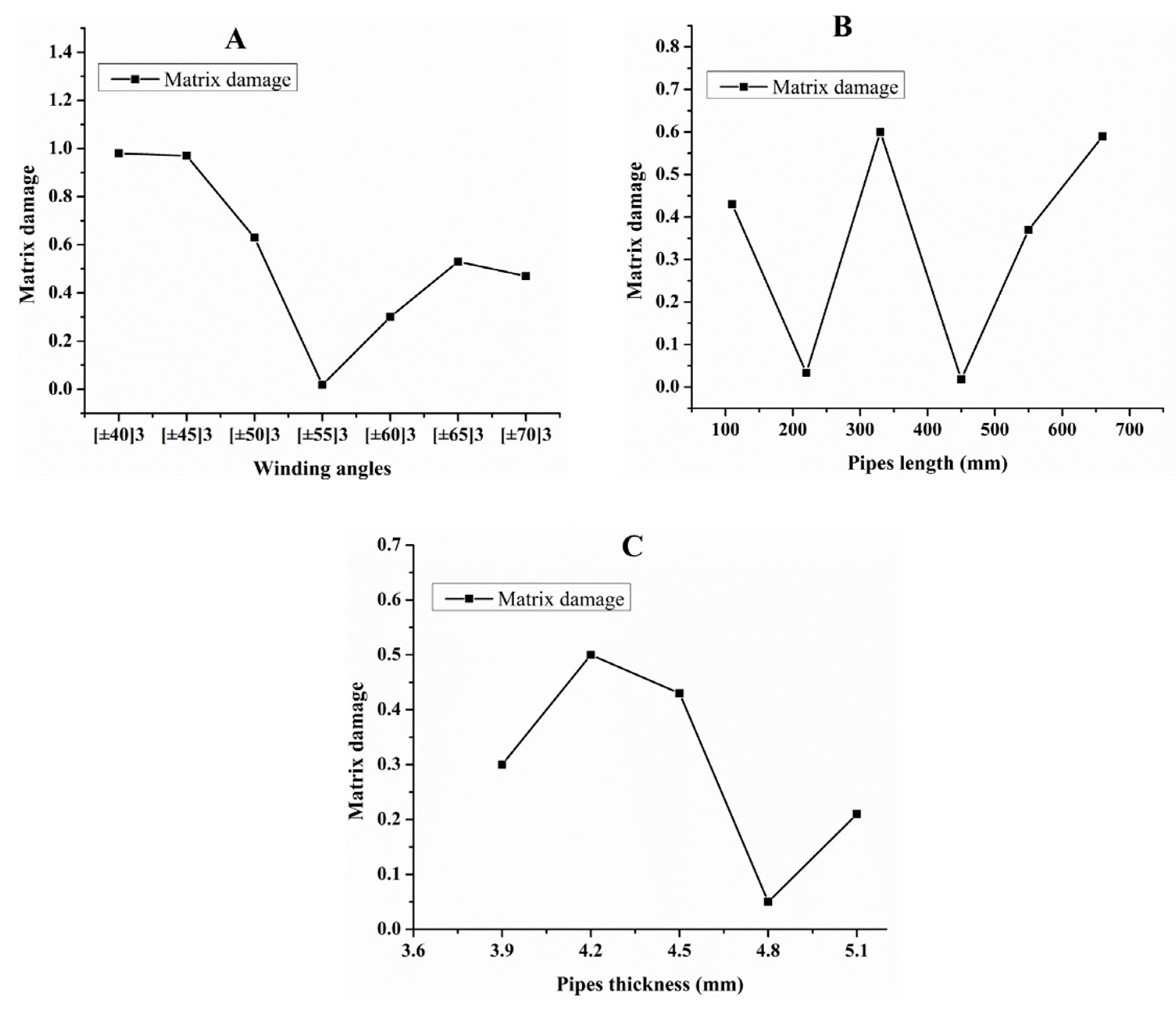

5.1. Effects of Winding Angles

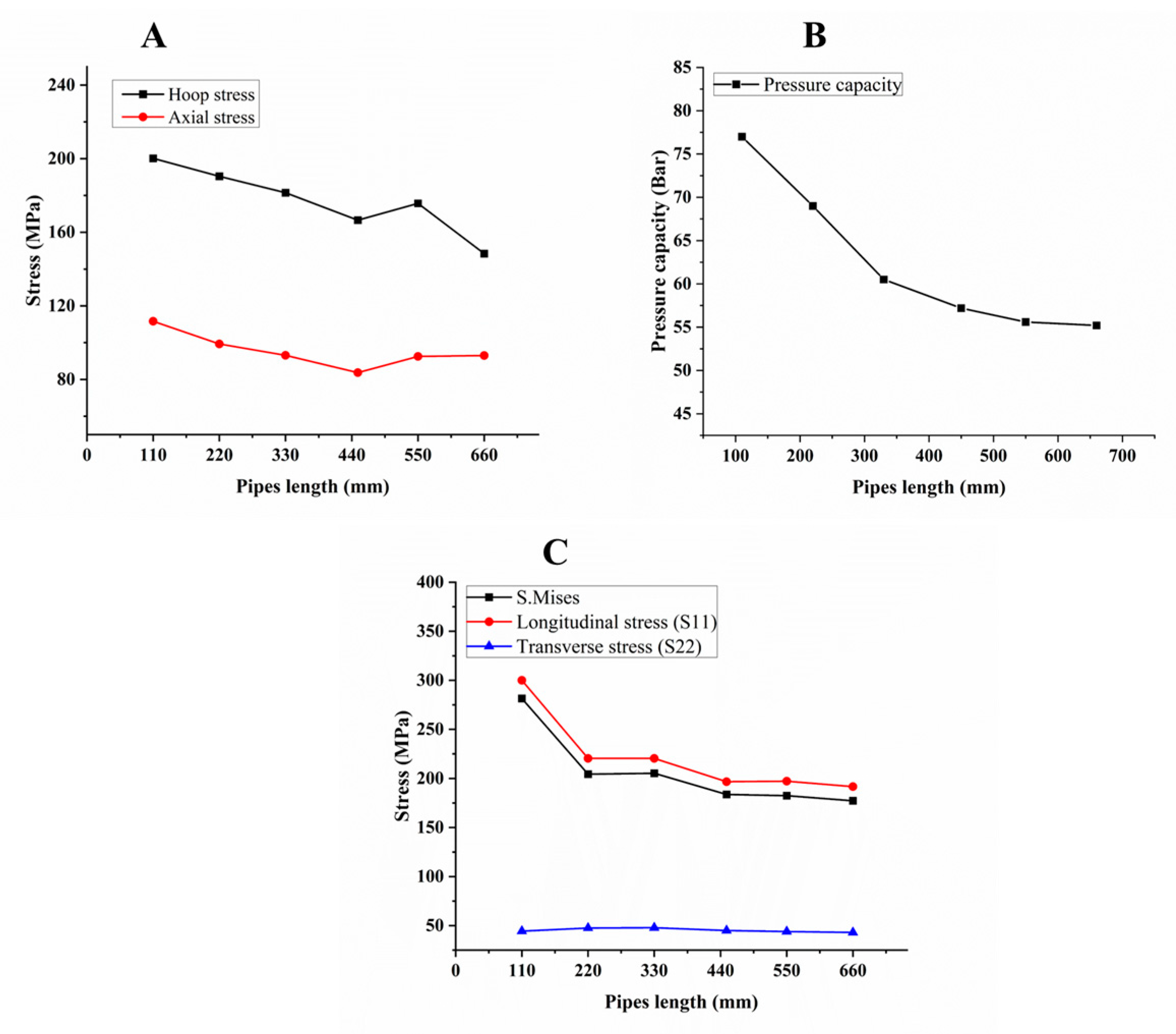

5.2. Effect of Pipe Length to Diameter (L/D)

5.3. Effect of the Pipe Diameter to Thickness (D/T)

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bakaiyan, H.; Hosseini, H.; Ameri, E. Analysis of multi-layered filament-wound composite pipes under combined internal pressure and thermomechanical loading with thermal variations. Compos. Struct. 2009, 88, 532–541. [Google Scholar] [CrossRef]

- Xia, M.; Takayanagi, H.; Kemmochi, K. Analysis of multi-layered filament-wound composite pipes under internal pressure. Compos. Struct. 2001, 53, 483–491. [Google Scholar] [CrossRef]

- Thirumavalavan, K.; Sarukasan, D. Experimental investigation on multi-layered filament wound basalt/E-glass hybrid fiber composite tubes. Mater. Res. Express 2022, 9, 045301. [Google Scholar] [CrossRef]

- Prabhakar, M.M.; Rajini, N.; Ayrilmis, N.; Mayandi, K.; Siengchin, S.; Senthilkumar, K.; Karthikeyan, S.; Ismail, S.O. An overview of burst, buckling, durability and corrosion analysis of lightweight FRP composite pipes and their applicability. Compos. Struct. 2019, 230, 111419. [Google Scholar] [CrossRef]

- Majid, M.S.A.; Afendi, M.; Daud, R.; Amin, N.; Mohamad, A.; Cheng, E.; Gibson, A.; Hekman, M. General lifetime damage model for glass fibre reinforced epoxy (GRE) composite pipes under multiaxial loading. Key Eng. Mater. 2014, 594–595, 624–628. [Google Scholar] [CrossRef]

- Abdellah, M.; Alfattani, R.; Alnaser, I.; Abdel-Jaber, G. Stress Distribution and Fracture Toughness of Underground Reinforced Plastic Pipe Composite. Polymers 2021, 13, 2194. [Google Scholar] [CrossRef] [PubMed]

- Gao, D.; Yang, H.; Yu, W.; Wu, X.; Wu, A.; Lu, G.; Zheng, Q. Research on the Mechanical Behavior of Buried Double-Wall Corrugated Pipes. Polymers 2022, 14, 4000. [Google Scholar] [CrossRef]

- Fekete, J.R.; Sowards, J.W.; Amaro, R.L. Amaro, Economic impact of applying high strength steels in hydrogen gas pipelines. Int. J. Hydrog. Energy 2015, 40, 10547–10558. [Google Scholar] [CrossRef] [Green Version]

- Alamri, A.H. Localized corrosion and mitigation approach of steel materials used in oil and gas pipelines–An overview. Eng. Fail. Anal. 2020, 116, 104735. [Google Scholar] [CrossRef]

- Taheri, F. Advanced fiber-reinforced polymer (FRP) composites for the manufacture and rehabilitation of pipes and tanks in the oil and gas industry. In Advanced Fibre-Reinforced Polymer (FRP) Composites for Structural Applications; Elsevier: Amsterdam, The Netherlands, 2013; pp. 662–704. [Google Scholar]

- Sebaey, T.A. Design of oil and gas composite pipes for energy production. Energy Procedia 2019, 162, 146–155. [Google Scholar] [CrossRef]

- Alabtah, F.G.; Mahdi, E.; Eliyan, F.F. The use of fiber reinforced polymeric composites in pipelines: A review. Compos. Struct. 2021, 276, 114595. [Google Scholar] [CrossRef]

- Aljuboury, M.; Rizvi, J.; Grove, S.; Cullen, R. Manufacturing and development of a bolted GFRP flange joint for oil and gas applications. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 1507–1517. [Google Scholar] [CrossRef]

- Kim, Y.J. State of the practice of FRP composites in highway bridges. Eng. Struct. 2019, 179, 1–8. [Google Scholar] [CrossRef]

- Siwowski, T.; Rajchel, M.; Kaleta, D.; Własak, L. The first Polish road bridge made of FRP composites. Struct. Eng. Int. 2017, 27, 308–314. [Google Scholar] [CrossRef]

- Motlagh, B.; Gholipour, Y.; Ebrahimi, G. Experimental investigation on mechanical properties of old wood members reinforced with frp composite. Wood Res. 2012, 57, 285–296. [Google Scholar]

- Selvaraju, S.; Ilaiyavel, S. Applications of composites in marine industry. J. Eng. Res. Stud. 2011, 2, 89–91. [Google Scholar]

- Vizentin, G.; Glujić, D.; Špada, V. Effect of Time-Real Marine Environment Exposure on the Mechanical Behavior of FRP Composites. Sustainability 2021, 13, 9934. [Google Scholar] [CrossRef]

- Bergan, P.G.; Buene, L.; Echtermeyer, A.T.; Hayman, B. Assessment of FRP sandwich structures for marine applications. Mar. Struct. 1994, 7, 457–473. [Google Scholar] [CrossRef]

- Garcia-Espinel, J.; Castro-Fresno, D.; Gayo, P.P.; Ballester-Muñoz, F. Effects of sea water environment on glass fiber reinforced plastic materials used for marine civil engineering constructions. Mater. Des. 2015, 66, 46–50. [Google Scholar] [CrossRef]

- Velázquez, J.C.; Hernández-Sánchez, E.; Terán, G.; Capula-Colindres, S.; Diaz-Cruz, M.; Cervantes-Tobón, A. Probabilistic and Statistical Techniques to Study the Impact of Localized Corrosion Defects in Oil and Gas Pipelines: A Review. Metals 2022, 12, 576. [Google Scholar] [CrossRef]

- Mokhtari, M.; Melchers, R.E. A new approach to assess the remaining strength of corroded steel pipes. Eng. Fail. Anal. 2018, 93, 144–156. [Google Scholar] [CrossRef]

- Dong, Z.; Wu, G. Research progress on durability of FRP bars reinforced concrete structures. Tumu Gongcheng Xuebao/China Civ. Eng. J. 2019, 52, 1–29. (In Chinese) [Google Scholar] [CrossRef]

- Bhatt, A.T.; Gohil, P.P.; Chaudhary, V. Primary manufacturing processes for fiber reinforced composites: History, development & future research trends. IOP Conf. Ser. Mater. Sci. Eng. 2018, 330, 012107. [Google Scholar]

- Fred Nilson. What is composite pipe and how is it made? Available online: https://www.linkedin.com/pulse/what-composite-pipe-how-made-fred-nilson/ (accessed on 18 February 2023).

- Wang, S.; Wang, W.; Huang, Y.; Li, S. The glass coated composite pipe applied in nuclear power plants. E-J. Adv. Maint. 2017, 9, 185–190. [Google Scholar]

- Zubail, A.; Traidia, A.; Masulli, M.; Vatopoulos, K.; Villette, T.; Taie, I. Carbon and energy footprint of nonmetallic composite pipes in onshore oil and gas flowlines. J. Clean. Prod. 2021, 305, 127150. [Google Scholar] [CrossRef]

- Krishnan, P.; Majid, M.S.A.; Afendi, M.; Gibson, A.; Marzuki, H. Effects of winding angle on the behaviour of glass/epoxy pipes under multiaxial cyclic loading. Mater. Des. 2015, 88, 196–206. [Google Scholar] [CrossRef]

- Pavlopoulou, S.; Roy, S.S.; Gautam, M.; Bradshaw, L.; Potluri, P. Numerical and experimental investigation of the hydrostatic performance of fibre reinforced tubes. Appl. Compos. Mater. 2017, 24, 417–448. [Google Scholar] [CrossRef] [Green Version]

- Rafiee, R.; Amini, A. Modeling and experimental evaluation of functional failure pressures in glass fiber reinforced polyester pipes. Comput. Mater. Sci. 2015, 96, 579–588. [Google Scholar] [CrossRef]

- Pranesh, K.; Majid, M.A.; Afendi, M.; Marzuki, H.; Kazim, M.N.F.M. Short-Term Test of±55° Filament Wound GRE Composite Pipes under Multiaxial Stress Ratios. Appl. Mech. Mater. 2014, 554, 371–375. [Google Scholar] [CrossRef]

- Fyrileiv, O.; Venås, A. Finite element simulation of pipe-in-pipe systems installed on an uneven seabed. In Proceedings of the 34thInternational Conference on Ocean, Offshore and Arctic Engineering, St. John’s, NL, Canada, 31 May–5 June 2015. [Google Scholar]

- Rafiee, R.; Reshadi, F. Simulation of functional failure in GRP mortar pipes. Compos. Struct. 2014, 113, 155–163. [Google Scholar] [CrossRef]

- Liu, R.; Xiong, H.; Wu, X.; Yan, S. Numerical studies on global buckling of subsea pipelines. Ocean. Eng. 2014, 78, 62–72. [Google Scholar] [CrossRef]

- Assaleh, T.A.; Almagguz, L.A. Ultimate Elastic Wall Stress (UEWS) Test under Biaxial Loading for Glass-Fibre Reinforced Epoxy (GRE) Pipes. Adv. Mater. Res. 2014, 974, 188–194. [Google Scholar] [CrossRef]

- Mattos, H.D.C.; Reis, J.; Amorim, F.; Brandao, J.; Lana, L.; Perrut, V. Long-term field performance of a composite pipe repair under constant hydrostatic pressure. Eng. Fail. Anal. 2021, 130, 105765. [Google Scholar] [CrossRef]

- Perillo, G.; Vedivik, N.; Echtermeyer, A. Numerical and experimental investigation of impact on filament wound glass reinforced epoxy pipe. J. Compos. Mater. 2015, 49, 723–738. [Google Scholar] [CrossRef]

- Mistry, J. Theoretical investigation into the effect of the winding angle of the fibres on the strength of filament wound GRP pipes subjected to combined external pressure and axial compression. Compos. Struct. 1992, 20, 83–90. [Google Scholar] [CrossRef]

- Azeem, M.; Ya, H.H.; Alam, M.A.; Kumar, M.; Stabla, P.; Smolnicki, M.; Gemi, L.; Khan, R.; Ahmed, T.; Ma, Q.; et al. Application of filament winding technology in composite pressure vessels and challenges: A review. J. Energy Storage 2022, 49, 103468. [Google Scholar] [CrossRef]

- Guz, I.A.; Menshykova, M.; Paik, J. Thick-walled composite tubes for offshore applications: An example of stress and failure analysis for filament-wound multi-layered pipes. Ships Offshore Struct. 2017, 12, 304–322. [Google Scholar] [CrossRef] [Green Version]

- Huang, Z.; Qian, X.; Su, Z.; Pham, D.C.; Sridhar, N. Experimental investigation and damage simulation of large-scaled filament wound composite pipes. Compos. Part B Eng. 2020, 184, 107639. [Google Scholar] [CrossRef]

- Perillo, G.; Vacher, R.; Grytten, F.; Sørbø, S.; Delhaye, V. Material characterisation and failure envelope evaluation of filament wound GFRP and CFRP composite tubes. Polym. Test. 2014, 40, 54–62. [Google Scholar] [CrossRef]

- Rafiee, R. On the mechanical performance of glass-fibre-reinforced thermosetting-resin pipes: A review. Compos. Struct. 2016, 143, 151–164. [Google Scholar] [CrossRef]

- GÜNÖZ, A.; Kepir, Y.; Memduh, K. The investigation of hardness and density properties of GFRP composite pipes under seawater conditions. Turk. J. Eng. 2022, 6, 34–39. [Google Scholar]

- Rafiee, R.; Habibagahi, M. Evaluating mechanical performance of GFRP pipes subjected to transverse loading. Thin-Walled Struct. 2018, 131, 347–359. [Google Scholar] [CrossRef]

- Gunoz, A.; Kepir, Y.; Kara, M. Tensile strength alteration of GFRP composite pipes under seawater-dominated conditions. J. Fail. Anal. Prev. 2020, 20, 1426–1430. [Google Scholar] [CrossRef]

- Saghir, F.; Gohari, S.; Mozafari, F.; Moslemi, N.; Burvill, C.; Smith, A.; Lucas, S. Mechanical characterization of particulated FRP composite pipes: A comprehensive experimental study. Polym. Test. 2021, 93, 107001. [Google Scholar] [CrossRef]

- Hawa, A.; Majid, M.A.; Afendi, M.; Haslan, M.; Pranesh, K.; Amin, N. Burst strength of glass fibre/epoxy composite pipes subjected to impact loading. Appl. Mech. Mater. 2015, 786, 121–125. [Google Scholar] [CrossRef]

- Krishnan, P.; Majid, M.A.; Afendi, M.; Yaacob, S.; Gibson, A. Effects of hydrothermal ageing on the behaviour of composite tubes under multiaxial stress ratios. Compos. Struct. 2016, 148, 1–11. [Google Scholar] [CrossRef]

- Rafiee, R.; Torabi, M.; Maleki, S. Investigating structural failure of a filament-wound composite tube subjected to internal pressure: Experimental and theoretical evaluation. Polym. Test. 2018, 67, 322–330. [Google Scholar] [CrossRef]

- Maziz, A.; Rechak, S.; Tarfaoui, M. Comparative study of tubular composite structure subjected to internal pressure loading: Analytical and numerical investigation. J. Compos. Mater. 2021, 55, 1517–1533. [Google Scholar] [CrossRef]

- Firouzsalari, S.E.; Dizhur, D.; Jayaraman, K.; Ingham, J. Experimental study of flax fabric-reinforced epoxy pipes subjected to internal pressure. Compos. Part A Appl. Sci. Manuf. 2021, 147, 106445. [Google Scholar] [CrossRef]

- Gemi, L. Investigation of the effect of stacking sequence on low velocity impact response and damage formation in hybrid composite pipes under internal pressure. A comparative study. Compos. Part B Eng. 2018, 153, 217–232. [Google Scholar] [CrossRef]

- Zeng, W.; Zhao, H.; Wang, Y.; Li, Y.; Huo, S. Hydrostatic Test and Simulation Verification of Pipeline with Carbon Fiber Repair. IOP Conf. Series Earth Environ. Sci. 2020, 565, 012082. [Google Scholar] [CrossRef]

- Sohn, J.M.; Hirdaris, S.; Romanoff, J.; Kim, S.J. Development of Numerical Modelling Techniques for Composite Cylindrical Structures under External Pressure. J. Mar. Sci. Eng. 2022, 10, 466. [Google Scholar] [CrossRef]

- Khashaba, U.; Sebaey, T.; Mahmoud, F.; Selmy, A.; Hamouda, R.; Sebaey, T. Experimental and numerical analysis of pinned-joints composite laminates: Effects of stacking sequences. J. Compos. Mater. 2013, 47, 3353–3366. [Google Scholar] [CrossRef]

- Pavlou, D.G. Composite Materials in Piping Applications: Design, Analysis and Optimization of Subsea and Onshore Pipelines from FRP Materials; DEStech Publications, Inc: Lancaster, PA, USA, 2013. [Google Scholar]

- Grove, S. Optimum fiber orientation in filament wound structures. J. Mater. Sci. Lett. 1999, 18, 1203. [Google Scholar] [CrossRef]

- Sülü, İ.Y. Stress analysis of multi-layered hybrid composite pipes subjected to internal pressure. Int. J. Eng. Appl. Sci. 2016, 8, 87–98. [Google Scholar] [CrossRef] [Green Version]

- Velázquez, J.C.; González-Arévalo, N.E.; Díaz-Cruz, M.; Cervantes-Tobón, A.; Herrera-Hernández, H.; Hernández-Sánchez, E. Failure pressure estimation for an aged and corroded oil and gas pipeline: A finite element study. J. Nat. Gas Sci. Eng. 2022, 101, 104532. [Google Scholar] [CrossRef]

| Material Type | Density (g/cm3) | Longitudinal Coefficient of Linear Expansion (10–6/°C) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Ultimate Elongation % |

|---|---|---|---|---|---|

| GFRP | 1.25–2.10 | 6.0–10.0 | 483–1600 | 35–51 | 1.2–3.1 |

| CFRP | 1.50–1.60 | −9.0–0.0 | 600–3690 | 120–580 | 0.5–1.7 |

| AFRP | 1.25–1.40 | −6.0–2.0 | 1720–2540 | 41–125 | 1.9–4.4 |

| * BFRP | 1.90–2.10 | 9.0–12.0 | 600–1500 | 50–65 | 1.2–2.6 |

| Steel | 7.85 | 11.7 | 483–690 | 200 | 6.0–12.0 |

| Composite Pipe | Type of Hydrostatic Pressure | Stacking Sequences | Pressure Capacity (bar) | Failure Modes | Ref. |

|---|---|---|---|---|---|

| GRE pipe | Exp. Internal | [±55]3 | 56 | Initial leakage and matrix cracking | [11] |

| GRE pipe | Exp. Internal | [±542/908] | 150 | Matrix cracking, fiber breakage, | [50] |

| GRE pipe CF/epoxy (Carbon fiber/epoxy) | Exp. Internal Exp. Internal | [±55/±55] [±50/±50] | 80 62 | Delamination, fiber, and matrix crack | [51] |

| FFRE (flax fabric-reinforced epoxy) | Exp. Internal | [0/90]3 [0/90]4 | 58 75 | Fiber breakage, leakage, and a burst of pipe structures | [52] |

| Hybrid pipes Carbon/Glass/Glass (CGG) | Exp. Internal | [±55]3 | 32 | Matrix cracking, radial cracks, delamination, splitting, and leakage | [53] |

| Steel and carbon fiber pipe | EXP. and FE. Internal | [0/90]4 | 152 | Bulging and rupture | [54] |

| CF/epoxy | EXP. and FE. Internal | [±75/0] and [±15/0] | 63 | Fiber and matrix crack | [55] |

| Property | Value | Property | Value |

|---|---|---|---|

| Longitudinal Young’s moduli, E11 (MPa) | 66,400 | Longitudinal tensile strength, Xt (MPa) | 700 |

| Transverse Young’s moduli, E22 (MPa) | 12,500 | Longitudinal compressive strength, Xc (MPa) | 79 |

| Out-of-plane Young’s moduli, E33 (MPa) | 12,500 | Transverse tensile strength, Yt (MPa) | 79 |

| Poisson’s ratio, ν12 | 0.31 | Transverse compressive strength, Yc (MPa) | 65 |

| Poisson’s ratio, ν13 | 0.38 | Longitudinal shear strength, S12 (MPa) | 50 |

| Poisson’s ratio, ν23 | 0.38 | Transverse shear strength, S23 (MPa) | 50 |

| Shear modulus, G12 (MPa) | 4520 | Density, ρ (kg/m3) | 1724 |

| Shear modulus, G13 (MPa) | 4550 | Thickness, h (mm) | 0.63 |

| Shear modulus, G23 (GPa) | 4550 | Fiber volume fraction (%) | 49.8 |

| No | Stacking Sequences of Composite Pipe | Winding Angle Degree | Number of Layers |

|---|---|---|---|

| 1 | [±40]3 = [+40, −40, +40, −40, +40, −40] | 40 | 6 |

| 2 | [±45]3= [+45, −45, +45, −45, +45, −45] | 45 | 6 |

| 3 | [±50]3= [+50, −50, +50, −50, +50, −50] | 50 | 6 |

| 4 | [±55]3= [+55, −55, +55, −55, +55, −55] | 55 | 6 |

| 5 | [±60]3= [+60, −60, +60, −60, +60, −60] | 60 | 6 |

| 6 | [±65]3= [+65, −65, +65, −65, +65, −65] | 65 | 6 |

| 7 | [±70]3= [+70, −70, +70, −70, +70, −70] | 70 | 6 |

| Specimen Type | Wall Thickness mm | Pipe Length | Hoop Stress MPa | Axial Stress MPa | Hoop to Axial Ratio | Internal Pressure MPa | Pressure Capacity (Bar) | Number of Elements | Study Effect |

|---|---|---|---|---|---|---|---|---|---|

| [±40]3 | 3.78 | 450 | 30.2 | 14.9 | 2:1 | 10 | 17 | 4408 | Effect of winding angles (θ) |

| [±45]3 | 3.78 | 450 | 58.6 | 28.5 | 2:1 | 10 | 26 | ||

| [±50]3 | 3.78 | 450 | 90.3 | 46.2 | 1.96:1 | 10 | 38.2 | ||

| [±55]3 | 3.78 | 450 | 164.6 | 82.7 | 2:1 | 10 | 57.2 | ||

| [±60]3 | 3.78 | 450 | 154.5 | 77.5 | 2:1 | 10 | 49 | ||

| [±65]3 | 3.78 | 450 | 144.4 | 71.9 | 2:1 | 10 | 44.2 | ||

| [±70]3 | 3.78 | 450 | 132.7 | 66.6 | 2:1 | 10 | 41.4 | ||

| [±55]3 | 3.78 | 110 | 200.2 | 111.6 | 1.8:1 | 10 | 77 | 1044 | Effect of pipe length to diameter (L/D) |

| 220 | 190.4 | 99.3 | 1.9:1 | 10 | 69 | 2146 | |||

| 330 | 181.5 | 93.1 | 1.95:1 | 10 | 60.5 | 3190 | |||

| 450 | 164.6 | 82.7 | 2:1 | 10 | 57.2 | 4408 | |||

| 550 | 175.7 | 92.5 | 2:1 | 10 | 55.6 | 5336 | |||

| 660 | 148.4 | 93 | 2:1 | 10 | 55.2 | 6438 | |||

| [±55]3 | 3.9 | 450 | 155.2 | 77.6 | 2:1 | 10 | 59.2 | 4408 | Effect of the pipe diameter to thickness (D/T) |

| 4.2 | 450 | 145.18 | 72.6 | 2:1 | 10 | 64.7 | |||

| 4.5 | 450 | 136.38 | 68.19 | 2:1 | 10 | 71.2 | |||

| 4.8 | 450 | 128.68 | 64.34 | 2:1 | 10 | 76.5 | |||

| 5.1 | 450 | 118.98 | 59.49 | 2:1 | 10 | 83.1 |

| Specimen Type | Wall Thickness mm | Pipe Length | S. Mises Stress MPa | Longitudinal Stress (S11) MPa | Transverse Stress (S22) MPa | Study Effect |

|---|---|---|---|---|---|---|

| [±40]3 | 3.78 | 450 | 32.2 | 35.4 | 11.2 | Effect of winding angles |

| [±45]3 | 3.78 | 450 | 58.3 | 62.9 | 13.3 | |

| [±50]3 | 3.78 | 450 | 99.5 | 107.5 | 23.8 | |

| [±55]3 | 3.78 | 450 | 183.7 | 196.7 | 45 | |

| [±60]3 | 3.78 | 450 | 150.3 | 160.2 | 43.5 | |

| [±65]3 | 3.78 | 450 | 167.9 | 181.5 | 40.1 | |

| [±70]3 | 3.78 | 450 | 136.1 | 143.6 | 48.5 | |

| [±55]3 | 3.78 | 110 | 281.5 | 300 | 44.4 | Effect of pipe length to diameter (L/D) |

| 220 | 204.4 | 220.4 | 47.5 | |||

| 330 | 205.3 | 220.4 | 47.8 | |||

| 450 | 183.7 | 196.7 | 45 | |||

| 550 | 182.4 | 197.2 | 44 | |||

| 660 | 177.2 | 191.7 | 43 | |||

| [±55]3 | 3.9 | 450 | 189.2 | 204.3 | 45.2 | Effect of diameter to thickness (D/T) |

| 4.2 | 450 | 193.7 | 209 | 46 | ||

| 4.5 | 450 | 197.2 | 212.7 | 46.8 | ||

| 4.8 | 450 | 192.5 | 207.7 | 45.7 | ||

| 5.1 | 450 | 192.6 | 207.9 | 45.7 |

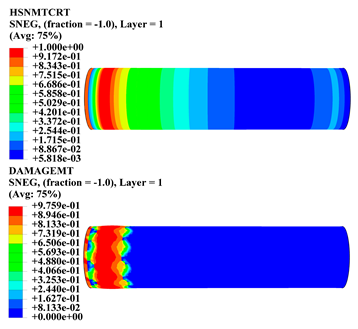

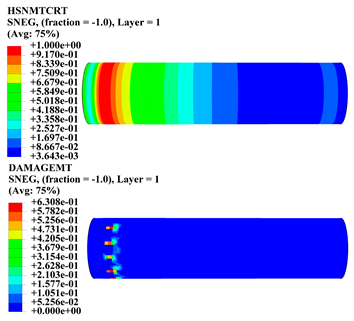

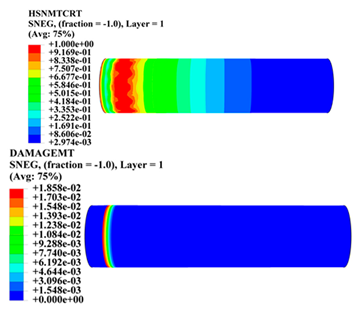

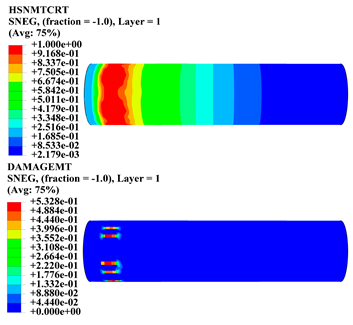

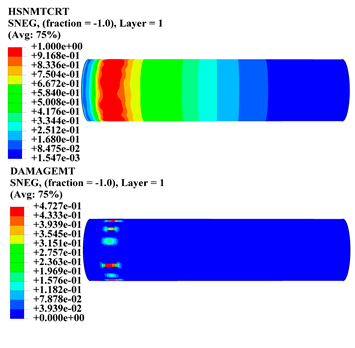

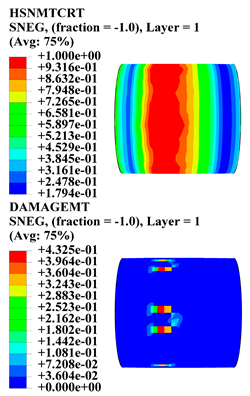

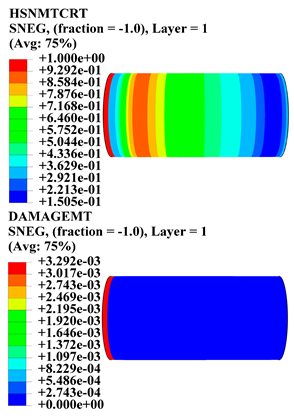

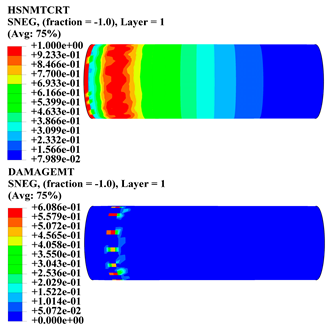

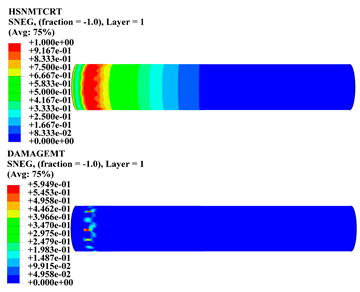

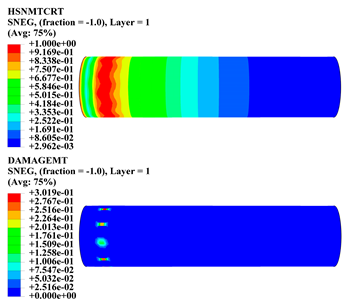

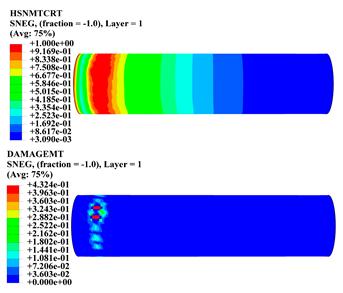

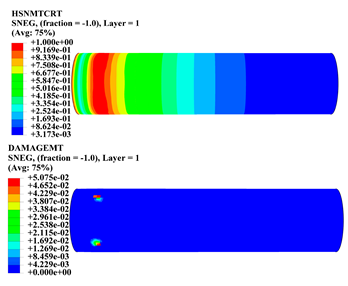

| Specimen Type | Wall Thickness mm | Pipe Length | Matrix Tension Failure (HSNMTCRT) and DAMAGEMT | Deformation (mm) |

|---|---|---|---|---|

| [±40]3 | 3.78 | 450 |  | 0.38 |

| [±45]3 | 3.78 | 450 |  | 0.38 |

| [±50]3 | 3.78 | 450 |  | 0.37 |

| [±55]3 | 3.78 | 450 |  | 0.39 |

| [±60]3 | 3.78 | 450 |  | 0.39 |

| [±65]3 | 3.78 | 450 |  | 0.42 |

| [±70]3 | 3.78 | 450 |  | 0.40 |

| [±55]3 | 3.78 | 110 |  | 0.39 |

| 220 |  | 0.31 | ||

| 330 |  | 0.37 | ||

| 450 |  | 0.39 | ||

| 550 |  | 0.37 | ||

| 660 |  | 0.38 | ||

| [±55]3 | 3.9 | 450 |  | 0.35 |

| 4.2 | 450 |  | 0.36 | |

| 4.5 | 450 |  | 0.38 | |

| 4.8 | 450 |  | 0.35 | |

| 5.1 | 450 |  | 0.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sebeay, T.A.; Ahmed, A. Numerical Investigation into GFRP Composite Pipes under Hydrostatic Internal Pressure. Polymers 2023, 15, 1110. https://doi.org/10.3390/polym15051110

Sebeay TA, Ahmed A. Numerical Investigation into GFRP Composite Pipes under Hydrostatic Internal Pressure. Polymers. 2023; 15(5):1110. https://doi.org/10.3390/polym15051110

Chicago/Turabian StyleSebeay, Tamer Ali, and Azzam Ahmed. 2023. "Numerical Investigation into GFRP Composite Pipes under Hydrostatic Internal Pressure" Polymers 15, no. 5: 1110. https://doi.org/10.3390/polym15051110

APA StyleSebeay, T. A., & Ahmed, A. (2023). Numerical Investigation into GFRP Composite Pipes under Hydrostatic Internal Pressure. Polymers, 15(5), 1110. https://doi.org/10.3390/polym15051110