Effects of Heat Treatment on Color, Dimensional Stability, Hygroscopicity and Chemical Structure of Afrormosia and Newtonia Wood: A Comparative Study of Air and Palm Oil Medium

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Heat Treatment

2.3. Color Change

2.4. Weight Change

2.5. Swelling Coefficients and Anti-Swelling Efficiency

2.6. Moisture Absorption (MA)

2.7. FTIR

2.8. Statistical Analyses

3. Results and Discussion

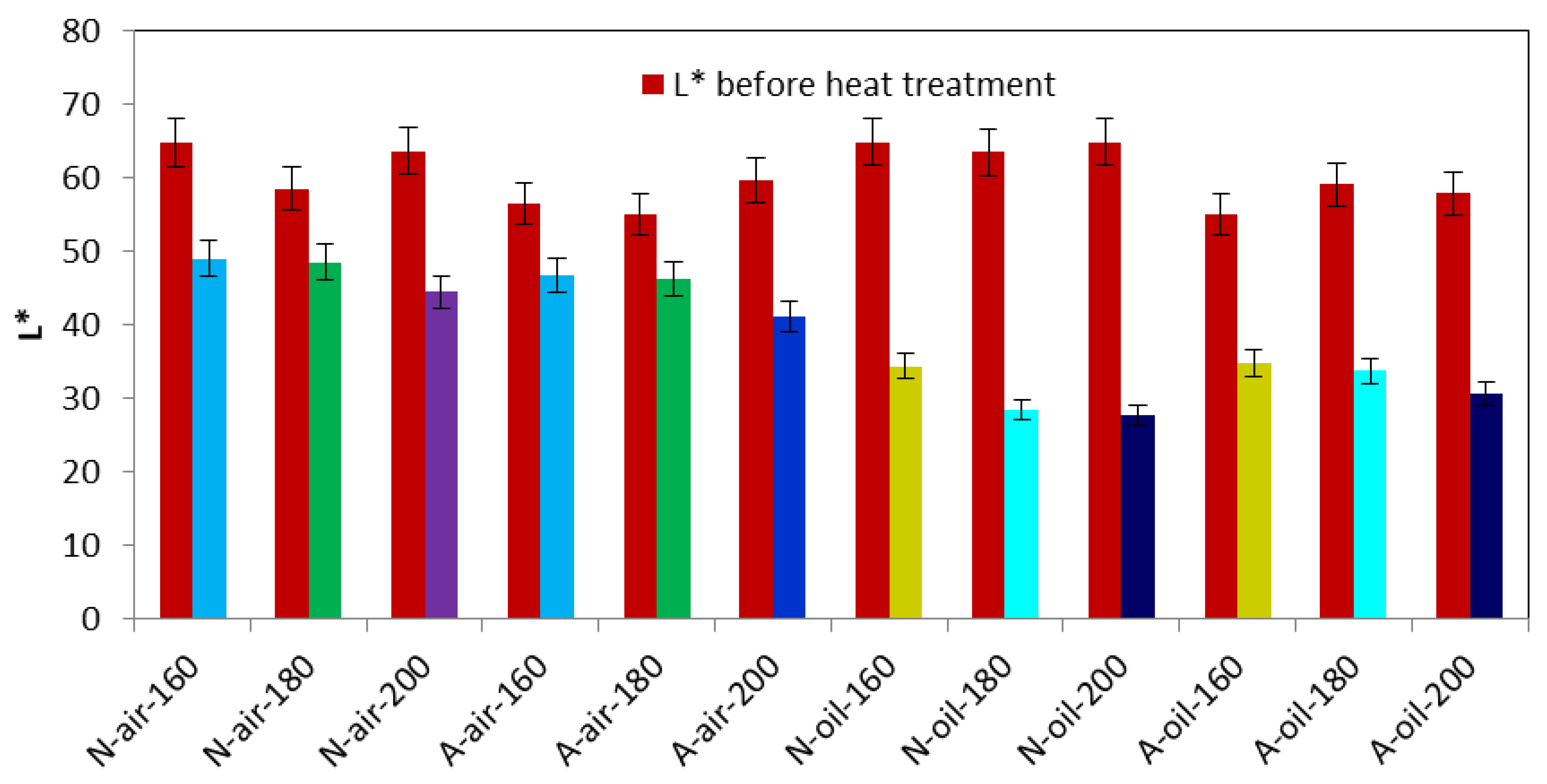

3.1. Color Change

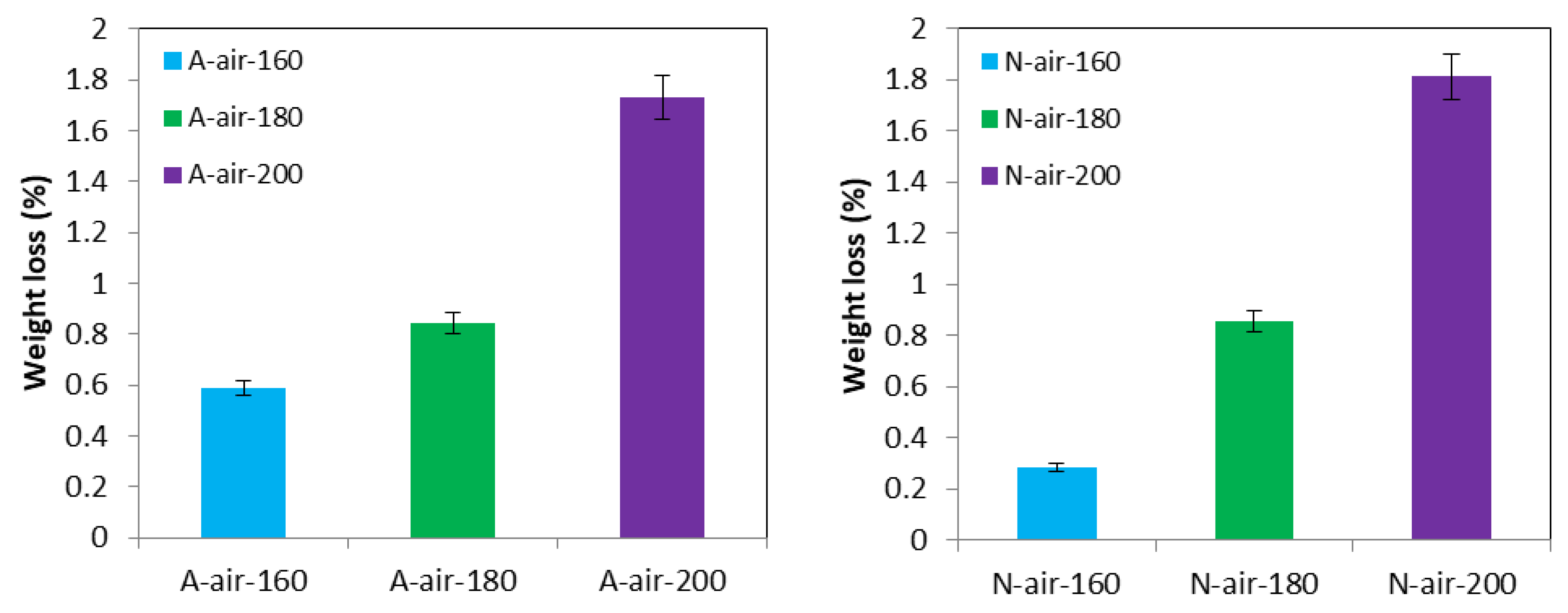

3.2. Weight Change

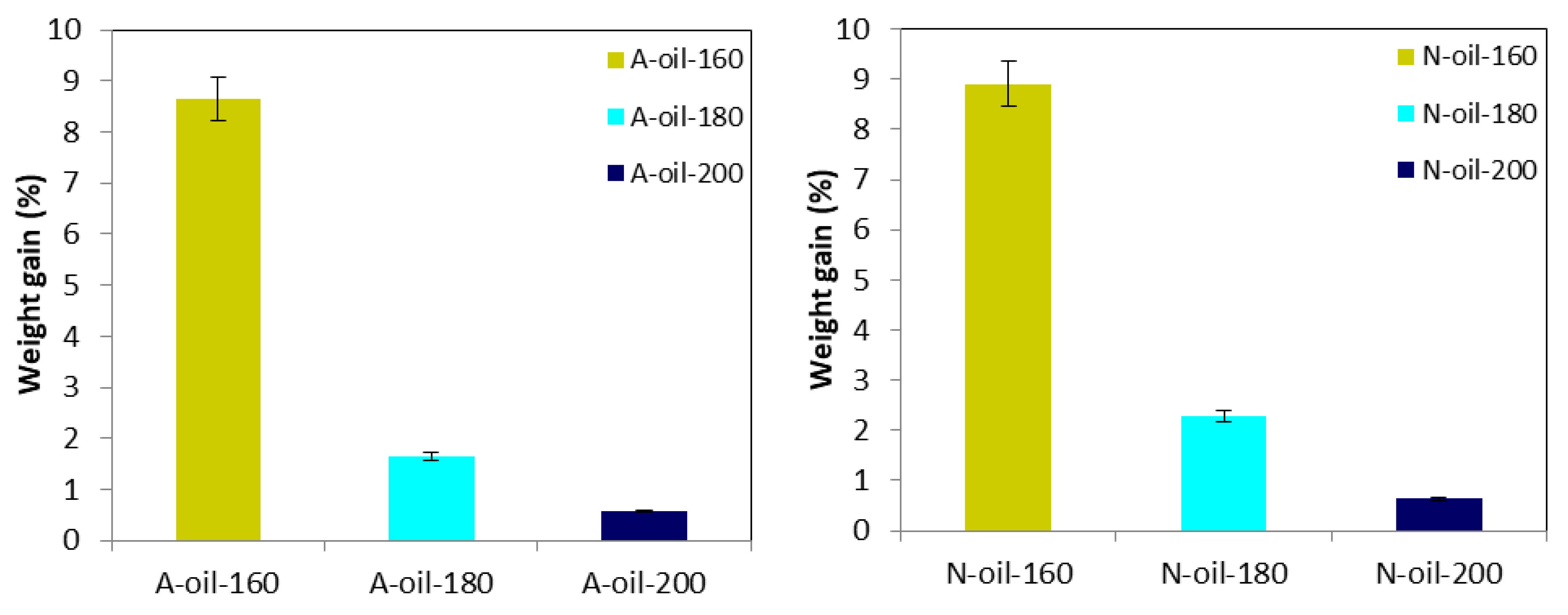

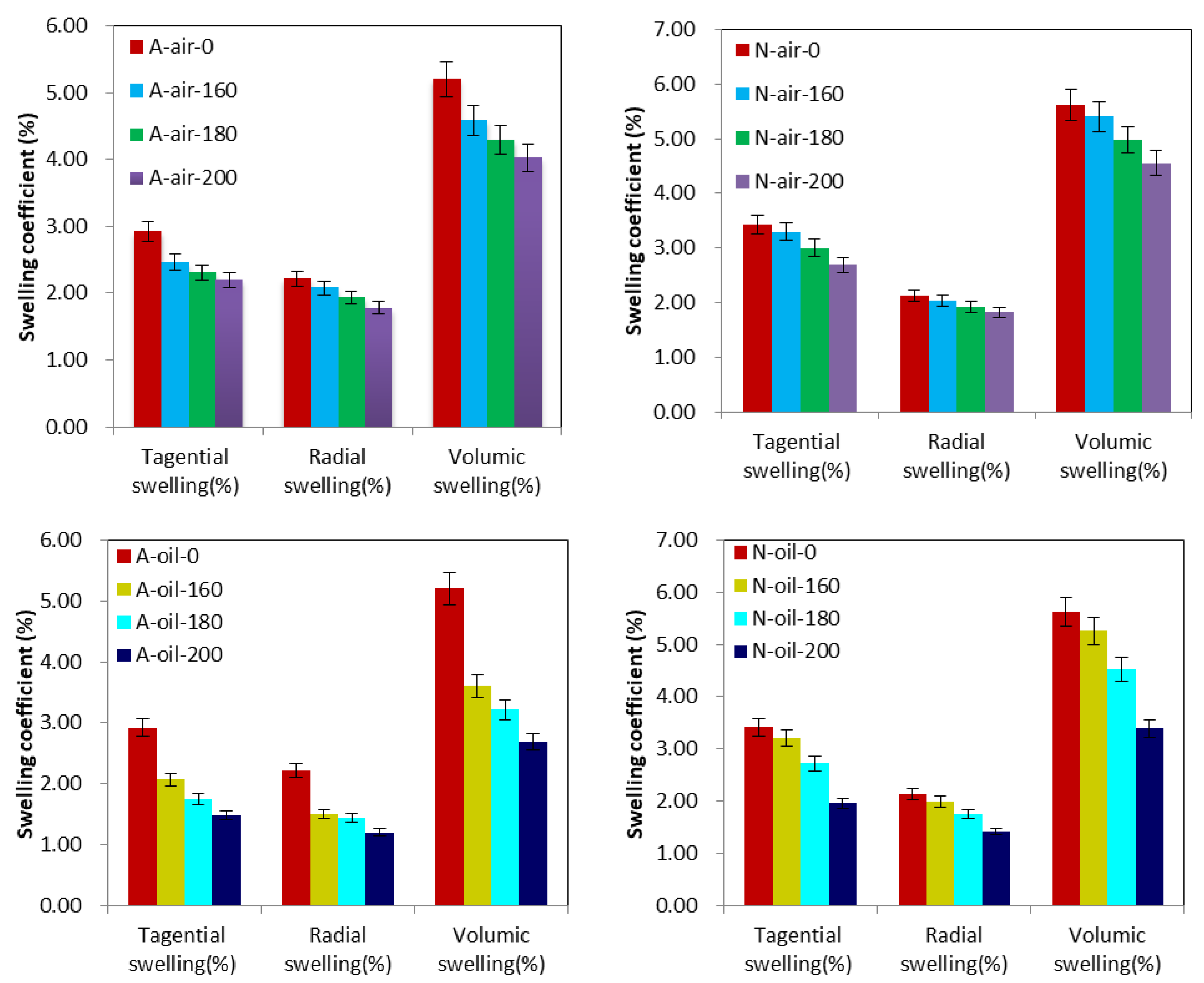

3.3. Swelling

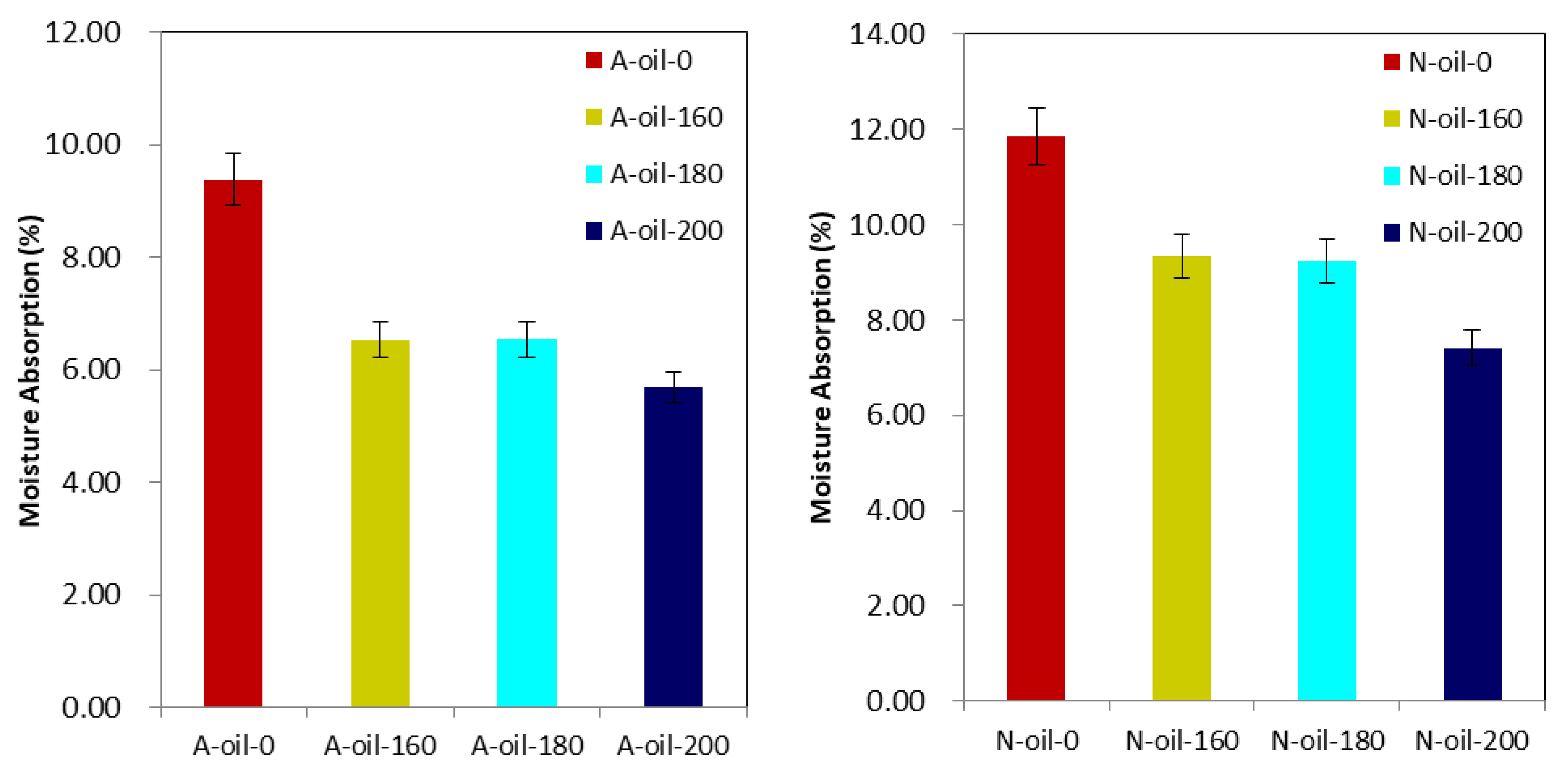

3.4. Moisture Absorption (MA)

3.5. FTIR Analysis

3.6. Comparison on the Efficiency (%) of Heat Treatment under Air and Heat Treatment under Palm Oil

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cirad. Tropix 7.0. Available online: https://tropix.cirad.fr/FichiersComplementaires/EN/Africa/AFRORMOSIA.pdf (accessed on 12 November 2022).

- Fern, K. Useful Tropical Plants. Available online: https://tropical.theferns.info/viewtropical.php?id=Newtonia%20paucijuga (accessed on 12 November 2022).

- Chang, H.-T.; Chang, S.-T. Moisture excluding efficiency and dimensional stability of wood improved by acylation. Bioresour. Technol. 2002, 85, 201–204. [Google Scholar] [CrossRef]

- Chang, H.-T.; Chang, S.-T. Improvements in dimensional stability and lightfastness of wood by butyrylation using microwave heating. J. Wood Sci. 2003, 49, 455–460. [Google Scholar] [CrossRef]

- Charani, P.R.; Rovshandeh, J.; Mohebby, B.; Ramezani, O. Influence of hydrothermal treatment on the dimensional stability of beech wood. Casp. J. Environ. Sci. 2007, 5, 125–131. [Google Scholar]

- Fejfer, M.; Majka, J.; Zborowska, M. Dimensional Stability ofWaterlogged Scots Pine Wood Treated with PEG and Dried Using an Alternative Approach. Forests 2020, 11, 1254. [Google Scholar] [CrossRef]

- Sefc, B.; Trajkovic, J.; Hasan, M.; Katovic, D.; Vukusic, S.B.; Martina, F. Dimensional stability of wood modified by citric acid using different catalysts. Drv. Ind. 2009, 60, 23–26. [Google Scholar]

- Rowell, R.M.; Ibach, R.; McSweeny, J.; Nilsson, T. Understanding decay resistance, dimensional stability and strength changes in heat-treated and acetylated wood. Wood Mater. Sci. Eng. 2009, 4, 14–22. [Google Scholar] [CrossRef]

- Liu, M.; Xu, G.; Wang, J.; Tu, X.; Liu, X.; Wu, Z.; Lv, J.; Xu, W. Effects of Shellac Treatment on Wood Hygroscopicity, Dimensional Stability and Thermostability. Coatings 2020, 10, 881. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, W.; Cao, J. Improvement of Hydrophobicity and dimensional stability of thermally Modified Southern Pine Wood Pretreated with Oleic Acid. BioResources 2014, 9, 2431–2445. [Google Scholar] [CrossRef]

- Sun, B.; Wang, X.; Liu, J. Changes in dimensional stability and mechanical properties of Eucalyptus pellita by melamine–urea–formaldehyde resin impregnation and heat treatment. Eur. J. Wood Prod. 2013, 71, 557–562. [Google Scholar] [CrossRef]

- Schorr, D.; Blanchet, P. Improvement of White Spruce Wood Dimensional stability by Organosilanes Sol-Gel Impregnation and Heat Treatment. Materials 2020, 13, 973. [Google Scholar] [CrossRef]

- Jiang, J.; Zhou, Y.; Mei, C.; Cao, J. Polyethylene glycol and silica sol penetration improves hydrophobicity and dimensional stability of wood after a short time treatment. Eur. J. Wood Wood Prod. 2021, 79, 1395–1404. [Google Scholar] [CrossRef]

- Yang, L.; Liu, H.-H. Effect of a Combination of Moderate-Temperature Heat Treatment and Subsequent Wax Impregnation on Wood Hygroscopicity, Dimensional Stability Mechanical Properties. Forests 2022, 11, 920. [Google Scholar] [CrossRef]

- Kúdela, J.; Rousek, R.; Rademacher, P.; Rešetka, M.; Dejmal, A. Influence of pressing parameters on dimensional stability and density. Eur. J. Wood Wood Prod. 2018, 76, 1241–1252. [Google Scholar] [CrossRef]

- Edvardsen, K.; Sandland, K. Increased drying temperature ± Its influence on the dimensional stability of wood. Holz Als Roh- Und Werkst. 1999, 57, 207. [Google Scholar] [CrossRef]

- Čermák, P.; Rautkari, L.; Horáček, P.; Saake, B.; Rademacher, P.; Sablík, P. Analysis of Dimensional Stability of Thermally Modified Wood Affected by Re-Wetting Cycles. BioResources 2015, 10, 3242–3253. [Google Scholar] [CrossRef]

- Cao, S.; Cheng, S.; Cai, J. Research Progress and Prospects of Wood High-temperature Heat Treatment Technology. BioResources 2022, 17, 3702–3717. [Google Scholar] [CrossRef]

- Navickas, P.; Albrektas, D. Effect of Heat Treatment on Sorption Properties. Mater. Sci. (Medžiagotyra) 2013, 19, 291–294. [Google Scholar]

- Aydemir, D.; Gunduz, G.; Altunta, E.R.; Ertas, M.; Ahin, H.; Alma, M. Investigating changes in the chemical constituents and dimensional stability of heat-treated hornbeam and uludag fir wood. BioResources 2011, 6, 1308–1321. [Google Scholar]

- Aytin, A.; Korkut, S.; Ünsa, Ö.; Çakicier, N. The Effect of Heat Treatment with the Thermowood Method on the Equilibrium Moisture Content and Dimensional Stability of Wild Cherry Wood. BioResources 2015, 10, 2083–2093. [Google Scholar] [CrossRef]

- Bekhta, P.; Niemz, P. Effect of High Temperature on the Change in Color, Dimensional Stability and Mechanical Properties of Spruce Wood. Holzforschung 2003, 57, 539–546. [Google Scholar] [CrossRef]

- Dubey, M.K.; Pang, S.; Walker, J. Changes in chemistry, color, dimensional stability and fungal resistance of Pinus radiata D. Don wood with oil heat-treatment. Holzforschung 2011, 65, 49–57. [Google Scholar] [CrossRef]

- Dubey, M.K.; Pang, S.; Walker, J. Oil uptake by wood during heat-treatment and post-treatment cooling, and effects on wood dimensional stability. Eur. J. Wood Prod. 2012, 70, 183–190. [Google Scholar] [CrossRef]

- Dubey, M.; Pang, S.; Walker, J. Effect of oil heating age on colour and dimensional stability of heat treated Pinus radiata. Eur. J. Wood Prod. 2011, 69, 255–262. [Google Scholar] [CrossRef]

- Lee, S.H.; Ashaari, Z.; Lum, W.; Halip, J.; Ang, A.; Tan, L.; Chin, K.L.; Tahir, P.M. Thermal treatment of wood using vegetable oils: A review. Constr. Build. Mater. 2018, 181, 408–419. [Google Scholar] [CrossRef]

- Wang, J.; Cooper, P.A. Effect of oil type, temperature and time on moisture. Holz Roh Werkst. 2005, 63, 417–422. [Google Scholar] [CrossRef]

- Priadi, T.; Sholihah, M.; Karlinasari, L. Water Absorption and Dimensional Stability of Heat-treated Fast-growing Hardwoods. J. Korean Wood Sci. Technol. 2019, 45, 567–578. [Google Scholar] [CrossRef]

- Cheng, D.; Chen, L.; Jiang, S.; Zhang, Q. Oil uptake percentage in oil-heat-treated wood, its determination by soxhlet extraction, and its effects on wood compression strength parallel to the grain. BioResources 2014, 9, 120–131. [Google Scholar] [CrossRef]

- Court, M. Lefigaro. Available online: https://www.lefigaro.fr/sciences/2018/06/26/01008-20180626ARTFIG00182-l-huile-de-palme-est-une-catastrophe-ecologique-mais-l-interdire-serait-pire-encore.php (accessed on 12 December 2022).

- WWF. Available online: https://www.wwf.fr/champs-daction/alimentation/deforestation/huilepalme#:~:text=Il%20s’agit%20de%20l,de%2073%20millions%20de%20tonnes (accessed on 20 December 2022).

- Patentreger, B.; Fauvelle, E.; Moluçon, C. Huile de Palme de la Déforestation à la Nécessaire Durabilité; WWF France: Paris, France, 2011. [Google Scholar]

- Esteves, B.M.; Pereira, H. Wood modification by heat treatment: A revew. BioResources 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Mitani, A.; Barboutis, I. Changes Caused by Heat Treatment in Color and Dimensional Stability of Beech (Fagus sylvatica L.) Wood. Drv. Ind. 2014, 65, 225–232. [Google Scholar] [CrossRef]

- Srinivas, K.; Pandey, K. Effect of Heat Treatment on Color Changes, Dimensional Stability, and Mechanical Properties of Wood. J. Wood Chem. Technol. 2012, 32, 304–316. [Google Scholar] [CrossRef]

- Torniainen, P.; Jones, D.; Sandberg, D. Colour as a quality indicator for industrially manufactured ThermoWood (R). Wood Mater. Sci. Eng. 2021, 16, 287–289. [Google Scholar] [CrossRef]

- Salca, E.; Kobori, H.; Inagaki, T.; Kojima, Y.; Suzuki, S. Effect of heat treatment on colour changes of black alder and beech veneers. J. Wood Sci. 2016, 62, 297–304. [Google Scholar] [CrossRef]

- Sikora, A.; Kacik, F.; Gaff, M.; Vondrova, V.; Bubenikova, T.; Kubovsky, I. Impact of thermal modification on color and chemical changes of spruce and oak wood. J. Wood Sci. 2018, 64, 406–416. [Google Scholar] [CrossRef]

- Zhan, T.; Zhu, J.; Liu, Z.; Li, T.; Peng, H.; Jiang, J.; Lyu, J. Meta analysis of chromatic properties of heat treated wood. Eur. J. Wood Wood Prod. 2022, 80, 851–858. [Google Scholar] [CrossRef]

- Ayata, U.; Gurleyen, L.; Esteves, B. Effect of heat treatment on the surface of selected exotic wood species. Drewno 2017, 60, 105–116. [Google Scholar]

- Ayata, U.; Gurleyen, T.; Gurleyen, L. Effect of heat treatment on colour and glossiness properties of zebrano sapelli and merbau woods. Furnit. Wooden Mater. Res. J. 2018, 1, 11–20. [Google Scholar]

- Sargent, R. Evaluating dimensional stability in solid wood: A review of current practice. J. Wood Sci. 2019, 65, 36. [Google Scholar] [CrossRef]

- He, Z.; Qian, J.; Qu, L.; Yan, N.; Yi, S. Effects of Tung oil treatment on wood hygroscopicity, dimensional stability. Ind. Crops Prod. 2019, 140, 111647. [Google Scholar] [CrossRef]

- Čabalová, I.; Kačík, F.; Lagaňa, R.; Výbohová, E.; Bubeníková, T.; Čaňová, I.; Ďurkovič, J. Effect of Thermal Treatment on the Chemical, Physical and Mechanical Properties of Pedunculate Oak (Quercus robur L.) Wood. BioResources 2018, 13, 157–170. [Google Scholar] [CrossRef]

- Toker, H.; Baysal, E.; Turkoglu, T.; Kart, S.; Sen, F.; Peker, H. Surface characteristicsof oriental beech and scots pine woods heat-treated above 200 °C. Wood Res. 2016, 61, 43–54. [Google Scholar]

- Hill, C.; Altgen, M.; Rautkari, L. Thermal modification of wood—A review: Chemical changes and hygroscopicity. J. Mater. Sci. 2021, 56, 6581–6614. [Google Scholar] [CrossRef]

- Thybring, E.E.; Fredriksson, M.; Zelinka, S.L.; Glass, S.V. Water in wood: A review of current understanding and knowledge gaps. Forests 2022, 13, 2051. [Google Scholar]

- Čermák, P.; Baar, J.; Dömény, J.; Výbohová, E.; Rousek, R.; Pařil, P.; Oberle, A.; Čabalová, I.; Hess, D.; Vodák, M.; et al. Wood-water interactions of thermally modified, acetylated and melamine formaldehyde resin impregnated beech wood. Holzforschung 2022, 76, 437–450. [Google Scholar] [CrossRef]

- Guller, B. Effects of heat treatment on density, dimensional stability and color of Pinus nigra wood. Afr. J. Biotechnol. 2012, 11, 2204–2209. [Google Scholar]

- Chen, J.; Wang, Y.; Cao, J.; Wang, W. Improved Water Repellency and Dimensional Stability of Wood via Impregnation with an Epoxidized Linseed Oil and CarnaubaWax Complex Emulsion. Forests 2020, 11, 271. [Google Scholar] [CrossRef]

- Salehi, A.M.; Henriksson, G.; Johansson, M. Effect of wood carbohydrates on the oxidation of unsaturated fatty acids. Prog. Org. Coat. 2013, 76, 1068–1074. [Google Scholar] [CrossRef]

- Čabalová, I.; Výbohová, E.; Igaz, R.; Kristak, L.; Kačík, F.; Antov, P.; Papadopoulos, A. Effect of oxidizing thermal modification on the chemical properties and thermal conductivity of Norway spruce (Picea abies L.) wood. Wood Mater. Sci. Eng. 2022, 17, 366–375. [Google Scholar] [CrossRef]

- Suri, I.; Purusatama, B.; Lee, S.; Kim, N.; Hidayat, W.; Ma’ruf, S. Characteristic features of the oil-heat treated woods from tropical fast growing wood species. Wood Res. 2021, 66, 365–378. [Google Scholar] [CrossRef]

| Wood Species | Heat Treatment Medium | Control Samples | 160 °C | 180 °C | 200 °C |

|---|---|---|---|---|---|

| Afrormosia | air | A-air-0 | A-air-160 | A-air-180 | A-air-200 |

| Afrormosia | Palm oil | A-oil-0 | A-oil-160 | A-oil-180 | A-oil-200 |

| Newtonia | air | N-air-0 | N-air-160 | N-air-180 | N-air-200 |

| Newtonia | Palm oil | N-oil-0 | N-oil-160 | N-oil-180 | N-oil-200 |

| Samples | Before Treatment | After Treatment | ΔL* | Δa* | Δb* | ΔE* | ||||

| A-air-160 | 56.45 | 12.98 p | 24.2 p | 46.80 | 13.19 p | 19.77 p | −9.65 | 0.21 | −4.43 | 10.62 |

| A-air-180 | 55.11 | 11.52 p | 22.72 p | 46.23 | 12.29 p | 21.29 p | −8.88 | 0.77 | −1.43 | 9.03 |

| A-air-200 | 59.69 | 11.72 p | 23.69 p | 41.2 | 12.18 p | 18.76 p | −18.49 | 0.46 | −4.93 | 19.14 |

| N-air-160 | 64.74 | 9.29 p | 16.42 p | 49.01 | 10.12 p | 15.34 p | −15.73 | 0.83 | −1.08 | 15.79 |

| N-air-180 | 58.53 | 10.09 p | 17.47 p | 48.52 | 10.58 p | 16.33 p | −10.01 | 0.49 | −1.14 | 10.09 |

| N-air-200 | 63.62 | 8.80 p | 17.78 p | 44.45 | 7.57 p | 10.59 p | −19.17 | −1.23 | −7.19 | 20.51 |

| A-oil-160 | 55.03 | 12.54 | 24.82 | 34.77 | 15.35 | 16.11 | −20.26 | 2.81 | −8.71 | 22.23 |

| A-oil-180 | 59.12 | 11.92 | 24.39 | 33.75 | 13.21 | 14.57 | −25.37 | 1.29 | −9.82 | 27.23 |

| A-oil-200 | 57.93 | 11.65 | 22.77 | 30.66 | 8.64 | 8.71 | −27.27 | −3.01 | −14.06 | 30.83 |

| N-oil-160 | 64.89 | 9.65 p | 17.15 | 34.33 | 11.94 p | 13.36 | −30.56 | 2.29 | −3.79 | 30.88 |

| N-oil-180 | 63.50 | 10.19 p | 18.46 | 28.45 | 7.24 p | 6.55 | −35.05 | −2.95 | −11.91 | 37.14 |

| N-oil-200 | 64.89 | 8.44 | 15.65 | 27.78 | 6.83 | 4.80 | −37.11 | −1.61 | −10.85 | 38.70 |

| Sample Handling | Density | Density Change (%) Percentage (%) |

|---|---|---|

| N-air-0 | 0.719 | - |

| N-air-160 | 0.700 | −2.59 |

| N-air-180 | 0.690 | −3.98 |

| N-air-200 | 0.676 | −6.00 |

| A-air-0 | 0.786 | - |

| A-air-160 | 0.780 | −0.70 |

| A-air-180 | 0.764 | −2.81 |

| A-air-200 | 0.759 | −3.43 |

| N-oil-0 | 0.719 | - |

| N-oil-160 | 0.747 | 3.94 |

| N-oil-180 | 0.742 | 3.22 |

| N-oil-200 | 0.733 | 1.98 |

| A-oil-0 | 0.777 | - |

| A-oil-160 | 0.874 | 12.46 |

| A-oil-180 | 0.819 | 5.46 |

| A-oil-200 | 0.810 | 4.30 |

| Sample Handling * | Tangential Swelling (%) | Radial Swelling (%) | Volumic Swelling (%) | Anti-Swelling Efficacy (%) |

|---|---|---|---|---|

| A-air-0 | 2.92 | 2.22 | 5.2 | - |

| A-air-160 | 2.46 | 2.07 | 4.58 | 11.87 |

| A-air-180 | 2.30 | 1.94 | 4.28 | 17.65 |

| A-air-200 | 2.20 | 1.78 | 4.02 | 22.64 |

| N-air-0 | 3.42 | 2.13 | 5.62 | - |

| N-air-160 | 3.30 | 2.04 | 5.41 | 3.84 |

| N-air-180 | 3.00 | 1.92 | 4.98 | 11.44 |

| N-air-200 | 2.69 | 1.82 | 4.56 | 18.97 |

| A-oil-160 | 2.07 | 1.50 | 3.60 | 30.76 |

| A-oil-180 | 1.75 | 1.44 | 3.22 | 38.13 |

| A-oil-200 | 1.48 | 1.20 | 2.70 | 48.15 |

| N-oil-160 | 3.21 | 1.99 | 5.26 | 6.39 |

| N-oil-180 | 2.72 | 1.75 | 4.52 | 19.57 |

| N-oil-200 | 1.95 | 1.42 | 3.40 | 39.59 |

| Heat Treatment Medium | Samples | Efficiency (%) Based on Control Samples | |||||

|---|---|---|---|---|---|---|---|

| a* | b* | L* | Radial Swelling | Tangential Swelling | Moisture Absorption | ||

| Heat treatment under air | A-air-160 | 1.62 | −18.31 | −17.09 | −6.44 | −15.79 | −13.80 |

| A-air-180 | 6.68 | −6.29 | −16.11 | −12.62 | −21.17 | −18.19 | |

| A-air-200 | 3.92 | −20.81 | −30.98 | −19.58 | −24.59 | −21.67 | |

| N-air-160 | 8.93 | −6.58 | −24.30 | −4.13 | −3.58 | −9.36 | |

| N-air-180 | 4.86 | −6.53 | −17.10 | −9.97 | −12.16 | −14.92 | |

| N-air-200 | −13.98 | −40.44 | −30.13 | −14.77 | −21.32 | −22.12 | |

| Heat treatment under palm oil | A-oil-160 | 22.41 | −35.09 | −36.82 | −32.43 | −29.03 | −30.34 |

| A-oil-180 | 10.82 | −40.26 | −42.91 | −34.97 | −40.03 | −30.75 | |

| A-oil-200 | −25.84 | −61.75 | −47.07 | −45.88 | −49.34 | −39.39 | |

| N-oil-160 | 23.73 | −22.10 | −47.10 | −6.79 | −6.05 | −21.32 | |

| N-oil-180 | −28.95 | −64.52 | −55.20 | −17.82 | −20.37 | −22.14 | |

| N-oil-200 | −19.08 | −69.33 | −57.19 | −33.63 | −42.85 | −37.49 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bessala, L.F.B.; Gao, J.; He, Z.; Wang, Z.; Yi, S. Effects of Heat Treatment on Color, Dimensional Stability, Hygroscopicity and Chemical Structure of Afrormosia and Newtonia Wood: A Comparative Study of Air and Palm Oil Medium. Polymers 2023, 15, 774. https://doi.org/10.3390/polym15030774

Bessala LFB, Gao J, He Z, Wang Z, Yi S. Effects of Heat Treatment on Color, Dimensional Stability, Hygroscopicity and Chemical Structure of Afrormosia and Newtonia Wood: A Comparative Study of Air and Palm Oil Medium. Polymers. 2023; 15(3):774. https://doi.org/10.3390/polym15030774

Chicago/Turabian StyleBessala, Lionnel Frederique Bidzanga, Jingjing Gao, Zhengbin He, Zhenyu Wang, and Songlin Yi. 2023. "Effects of Heat Treatment on Color, Dimensional Stability, Hygroscopicity and Chemical Structure of Afrormosia and Newtonia Wood: A Comparative Study of Air and Palm Oil Medium" Polymers 15, no. 3: 774. https://doi.org/10.3390/polym15030774

APA StyleBessala, L. F. B., Gao, J., He, Z., Wang, Z., & Yi, S. (2023). Effects of Heat Treatment on Color, Dimensional Stability, Hygroscopicity and Chemical Structure of Afrormosia and Newtonia Wood: A Comparative Study of Air and Palm Oil Medium. Polymers, 15(3), 774. https://doi.org/10.3390/polym15030774