Wood Surface Finishing with Transparent Lacquers Intended for Indoor Use, and the Colour Resistance of These Surfaces during Accelerated Aging

Abstract

:1. Introduction

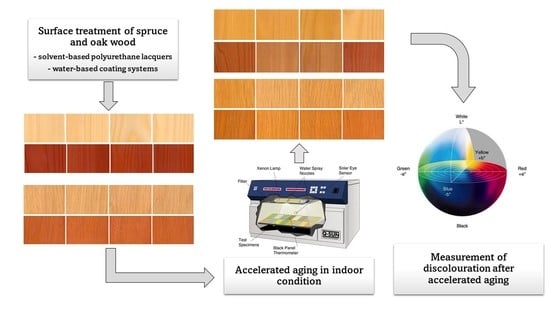

2. Materials and Methods

2.1. Experimental Materials

2.2. Accelerated Aging

2.3. Statistical Evaluation

3. Results and Discussion

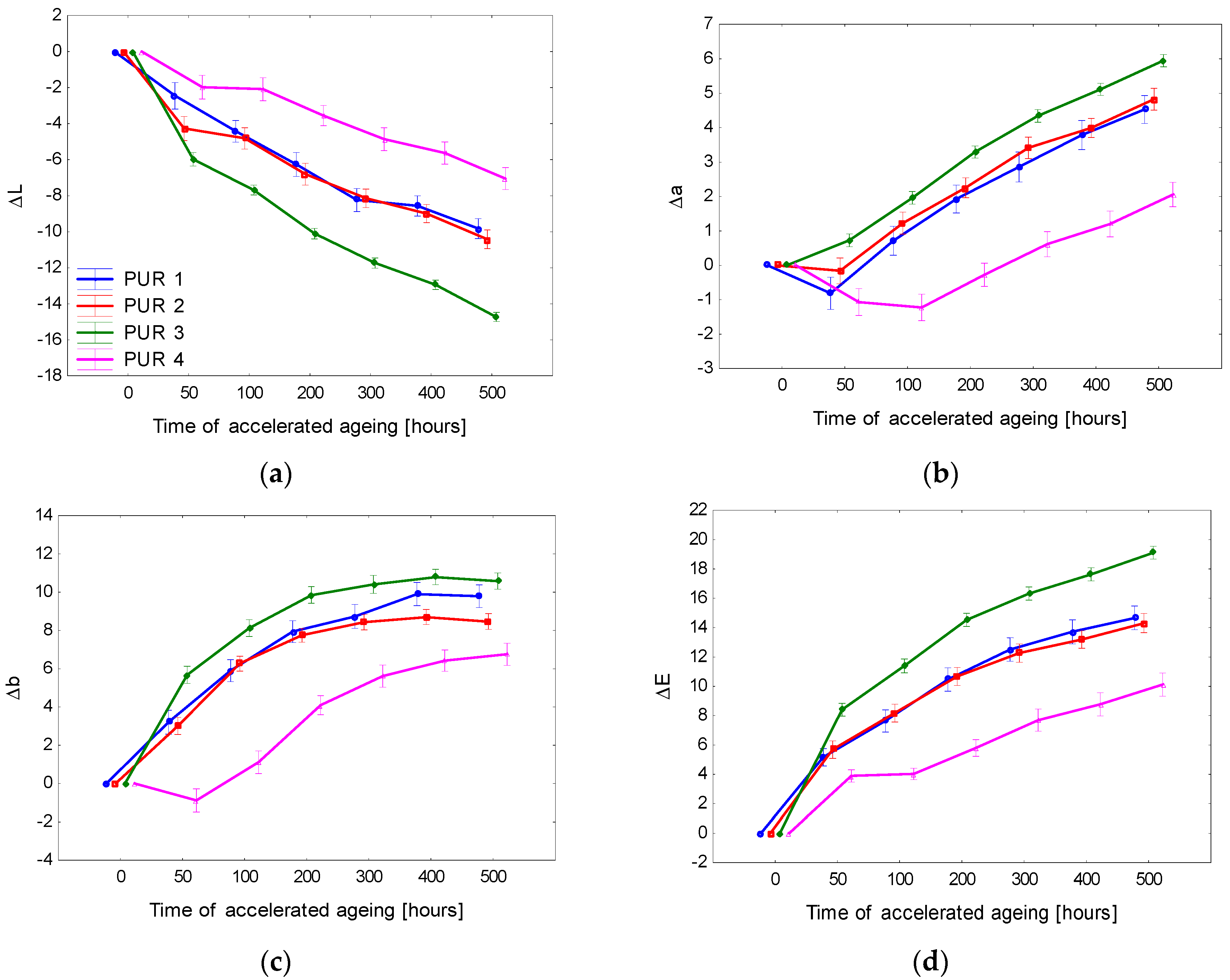

3.1. Discolouration of Spruce Wood Surface Coated with Solvent-Based Polyurethane Lacquers

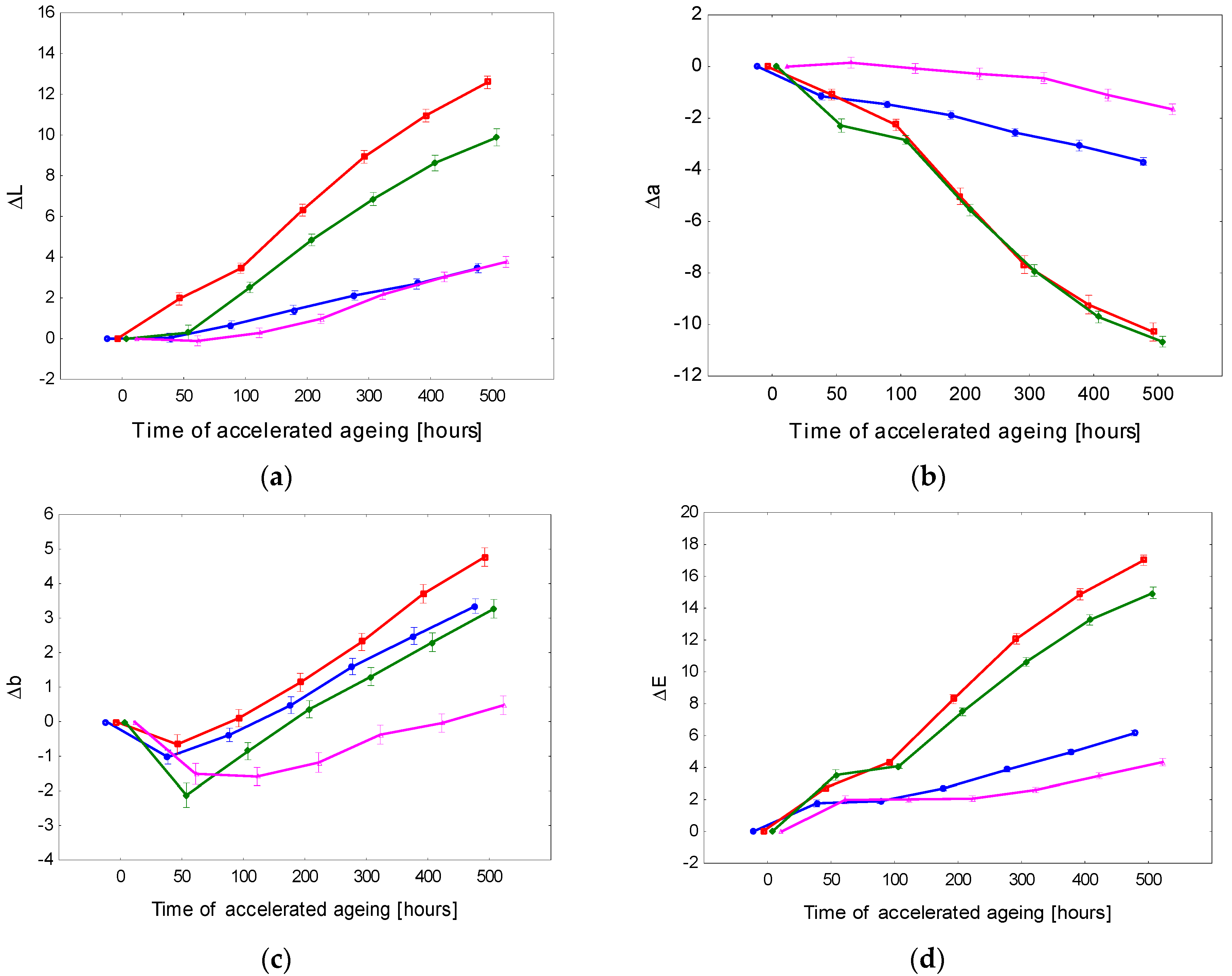

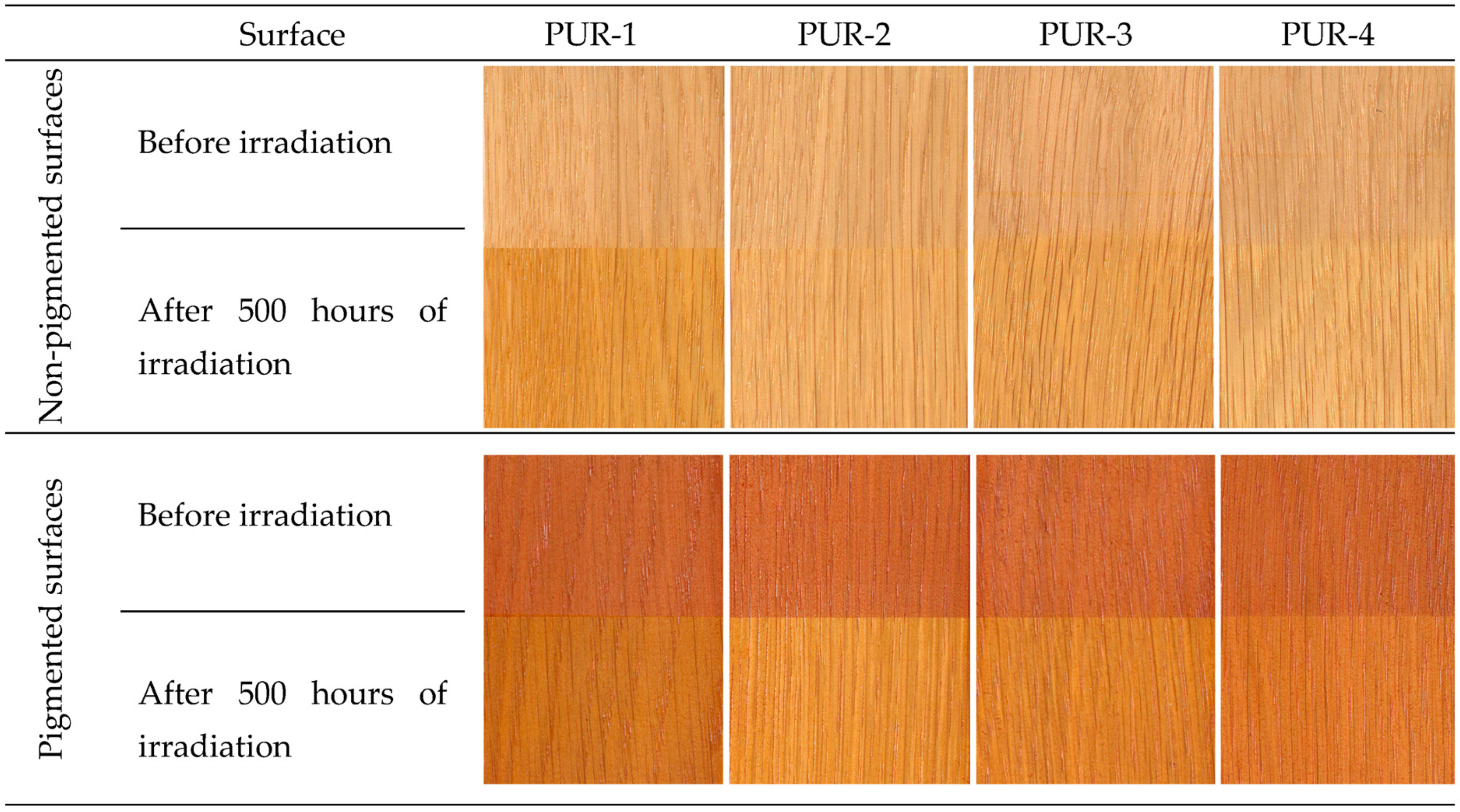

3.2. Discolouration of Oak Wood Surface Coated with Solvent-Based Polyurethane Lacquers

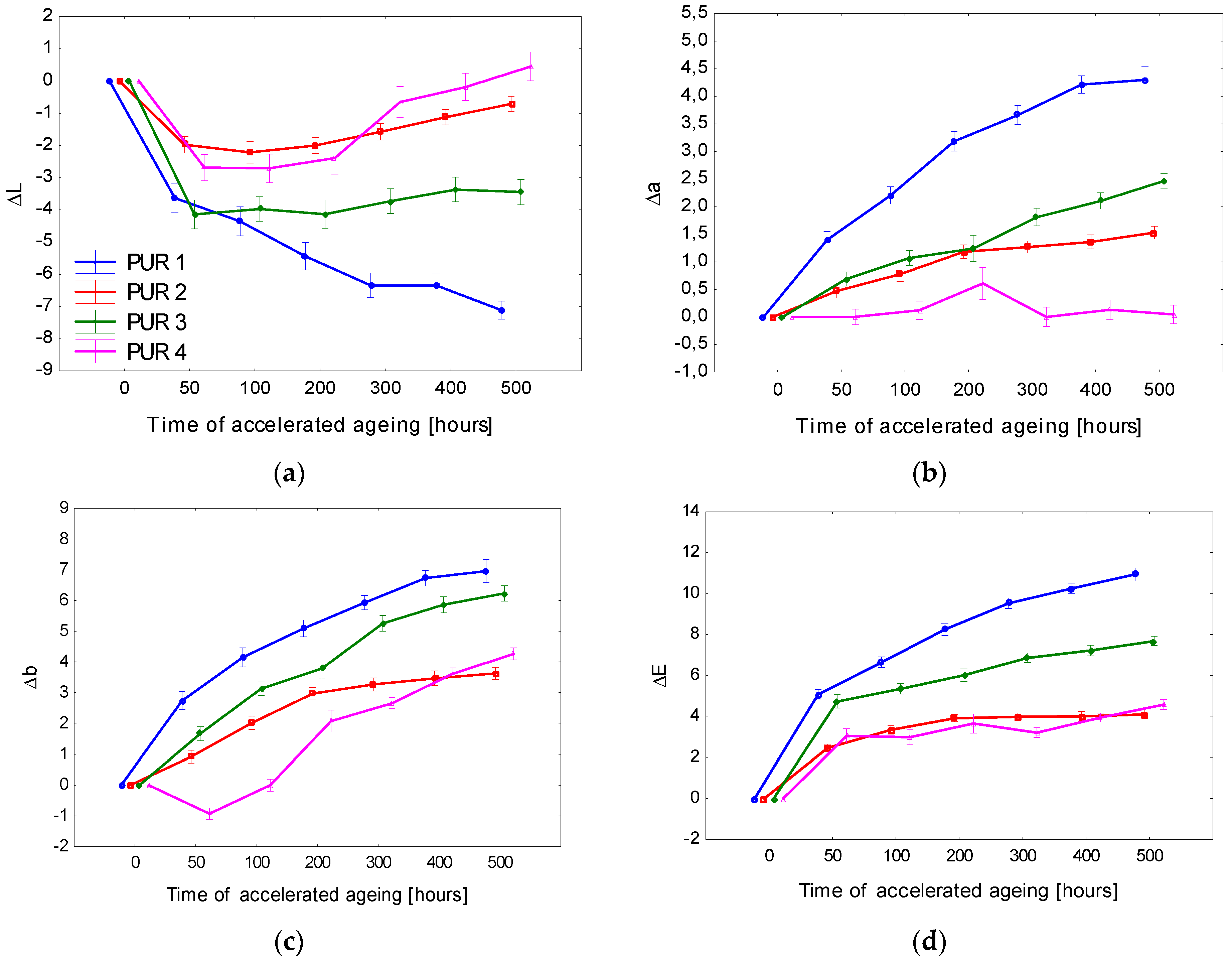

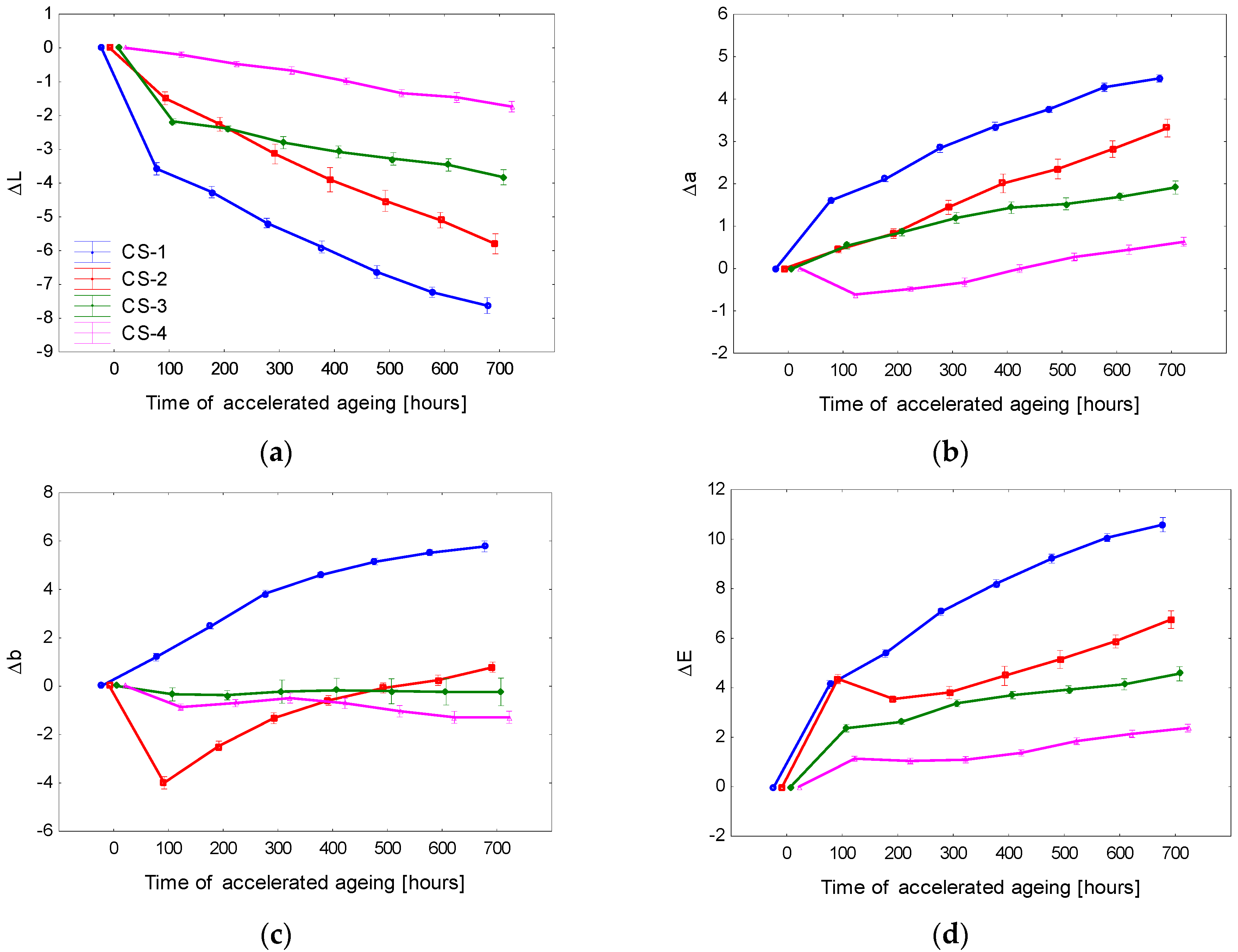

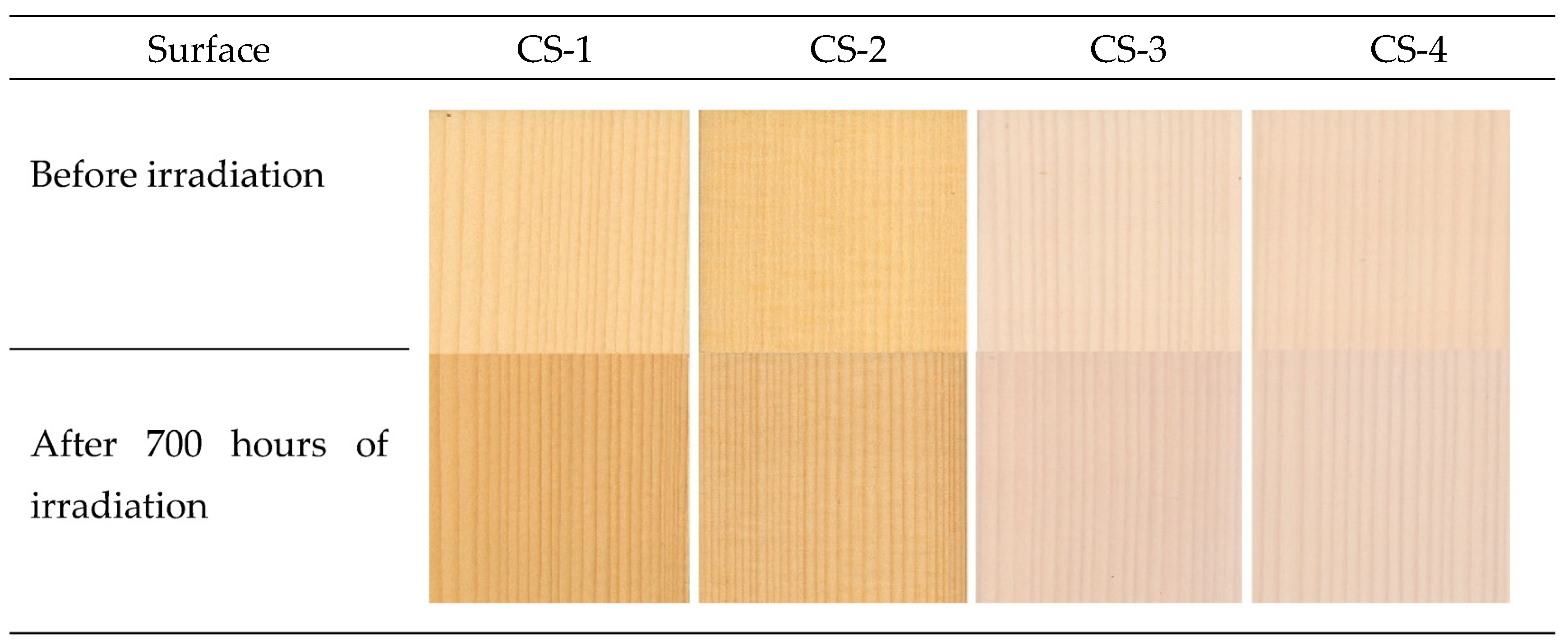

3.3. Discolouration of Oak Wood Surface Coated with Solvent-Based Polyurethane Lacquers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- De Meijer, M. Review on the durability of exterior wood coatings with reduced VOC-content. Prog. Org. Coat. 2001, 43, 217–225. [Google Scholar] [CrossRef]

- Cogulet, A.; Blanchet, P.; Landry, V. The multifactorial aspect of wood eathering: A review based on a Holistic approach of wood degradation protected by clear coating. BioResources 2018, 13, 2116–2138. [Google Scholar] [CrossRef]

- Tolvaj, L.; Faix, O. Modification of colour by steaming. In Proceedings of the 2nd International Conference on the Development of Wood Science/Technology and Forestry; University of Sopron: Sopron, Hungary,, 1996. [Google Scholar]

- Williams, R.S.; Knaebe, M.T.; Evans, J.; Feist, W.C. Erosion rates of wood during natural weathering: Part III. Effect of exposure angle on erosion rate. Wood Fiber Sci. 2001, 33, 50–57. [Google Scholar]

- Kishino, M.; Nakano, T. Artificial weathering of tropical woods. Part 1: Changes in wettability. Holzforschung 2004, 58, 552–557. [Google Scholar] [CrossRef]

- Pandey, K.K.; Vuorinen, T. Comparative study of photodegradation of wood by a UV laser and a xenon light source. Polym. Degrad. Stab. 2008, 93, 2138–2146. [Google Scholar] [CrossRef]

- Fan, Y.; Gao, J.; Chen, Y. Colour responses of black locust (Robinia pseudoacacia L.) to solvent extraction and heat treatment. Wood Sci. Technol. 2010, 44, 667–678. [Google Scholar] [CrossRef]

- Chang, T.C.; Chang, H.T.; Wu, C.L.; Chang, S.T. Influences of extractives on the photodegradation of wood. Polym. Degrad. Stab. 2010, 95, 516–521. [Google Scholar] [CrossRef]

- Chen, Y.; Gao, J.; Fan, Y.; Tschabalala, M.A.; Stark, N.M. Heat–induced chemical and color changes of extractive–free black locust (Robinia pseudoacacia) wood. BioResources 2012, 7, 2236–2248. [Google Scholar] [CrossRef]

- Persze, L.; Tolvaj, L. Photodegradation of wood at elevated temperature: Colour change. J. Photochem. Photobiol. B Biol. 2012, 108, 44–47. [Google Scholar] [CrossRef]

- Huang, X.; Kocoege, D.; Kocaefe, Y.; Boluk, Y.; Pichette, A. A spectrocolorimetric and chemical study on color modification of heat–treated wood during artificial weathering. Appl. Surf. Sci. 2012, 258, 5360–5369. [Google Scholar] [CrossRef]

- Liu, Y.; Shao, L.; Gao, J.; Guo, H.; Chen, Y.; Cheng, Q.; Via, B.K. Surface photo-discoloration and degradation of dyed wood veneer exposed to different wavelengths of artificial light. Appl. Surf. Sci. 2015, 331, 353–361. [Google Scholar] [CrossRef]

- Liu, R.; Zhu, H.W.; Li, K.; Yang, Z. Comparison on the aging of woods exposed to natural sunlight and artificial xenon light. Polymers 2019, 11, 709. [Google Scholar] [CrossRef] [PubMed]

- Reinprecht, L.; Mamoňová, M.; Pánek, M.; Kačik, F. The impact of natural and artificial weathering on the visual, colour and structural changes of seven tropical woods. Eur. J. Wood Wood Prod. 2018, 76, 175–190. [Google Scholar] [CrossRef]

- Kropat, M.; Hubbe, M.A.; Laleicke, F. Natural, accelerated and simulated weathering of wood: A review. BioResources 2020, 15, 9998–10062. [Google Scholar] [CrossRef]

- Landry, V.; Blanchett, P. Weathering resistance of opaque PVDF-acrylic coatings applied on wood substrates. Prog. Org. Coat. 2012, 75, 494–501. [Google Scholar] [CrossRef]

- Kocaefe, D.; Saha, S. Comparison of the protection effectiveness of acrylic polyurethane coatings containing bark extracts on three heat-treated North American wood species: Surface degradation. Appl. Surf. Sci. 2012, 258, 5283–5290. [Google Scholar] [CrossRef]

- Saha, S.; Kocaefe, D.; Boluk, Y.; Pichette, A. Surface degradation of CeO2 stabilized acrylic polyurethane coated thermally treated jack pine during accelerated weathering. Appl. Surf. Sci. 2013, 276, 86–94. [Google Scholar] [CrossRef]

- Saha, S.; Kocaefe, D.; Krause, C.; Krause, C.; Boluk, Y.; Pichette, A. Enhancing exterior durability of heat-treated jack pine by photo-stabilization by acrylic polyurethane coating using bark extract. Part 2: Wetting characteristics and fluorescence microscopy analysis. Prog. Org. Coat. 2013, 76, 504–512. [Google Scholar] [CrossRef]

- Wan, C.; Lu, Y.; Sun, Q.; Li, J. Hydrothermal synthesis of zirconium dioxide coating on the surface of wood with improved UV resistance. Appl. Surf. Sci. 2014, 321, 38–42. [Google Scholar] [CrossRef]

- Girardi, F.; Cappellettoa, E.; Sandak, J.; Bochichio, G.; Tessadri, B.; Palanti, S.; Feci, E.; Di Maggio, R. Hybrid organic–inorganic materials as coatings for protecting wood. Prog. Org. Coat. 2014, 77, 449–457. [Google Scholar] [CrossRef]

- Reinprecht, L.; Šomšák, M. Effect of plasma and UV-additives in transparent coatings on the colour stability of spruce (Picea abies) wood at its weathering in xenotest. Acta Fac. Xylologiae Zvolen 2015, 57, 49–59. [Google Scholar] [CrossRef]

- Liu, X.Y.; Liu, M.; Lv, M.Q.; Lv, J.F. Photodegradation of Three Hardwood Species by Sunlight and Xenon Light Sources. BioResources 2019, 14, 6909–6922. [Google Scholar] [CrossRef]

- Novák, I.; Sedliačik, J.; Krystofiak, T.; Lis, B.; Popelka, A.; Kleinová, A.; Myatyašovský, J.; Jurkovič, P.; Bekhta, P. Study of wood surface pre-treatment by radio-frequency discharge plasma. Drewno 2019, 62, 81–91. [Google Scholar] [CrossRef]

- Kržišnik, D.; Lesar, B.; Thaler, N.; Planinšič, J.; Humar, M. A study on the moisture performance of wood determined in laboratory and field trials. Eur. J. Wood Wood Prod. 2020, 78, 219–235. [Google Scholar] [CrossRef]

- Slabejová, G.; Šmidriaková, M.; Svocák, J. Interlayer with microcapsules and its influence on the surface finish quality of wood. Acta Fac. Xylologiae Zvolen 2020, 62, 61–74. [Google Scholar] [CrossRef]

- Nowrouzi, Z.; Mohebby, B.; Petrič, M.; Ebrahimi, M. Influence of nanoparticles and olive leaf extract in polyacrylate coating on the weathering performance of thermally modified wood. Eur. J. Wood Wood Prod. 2021, 80, 301–311. [Google Scholar] [CrossRef]

- Kúdela, J.; Gondáš, L. Stability testing of coating materials proposed for renovation of surface finish windows. Acta Fac. Xylologiae Zvolen 2022, 64, 25–37. [Google Scholar] [CrossRef]

- Forsthuber, B.; Schaller, C.; Grull, G. Evaluation of the photo stabilizing efficiency of acrylic clear topcoats and wooden surfaces. Polym. Degrad. Stab. 2013, 95, 746–755. [Google Scholar] [CrossRef]

- Olsson, S.K.; Johansson, M.; Westin, M.; Östmark, E. Reactive UV-absorber and epoxy functionalized soybean oil for enhanced UV-protection of clear coated wood. Polym. Degrad. Stab. 2014, 110, 405–414. [Google Scholar] [CrossRef]

- Reinprecht, L.; Pánek, M. Effect of pigments in paints on the natural and accelerated ageing of spruce wood surfaces. Acta Fac. Xylologiae Zvolen 2013, 55, 71–84. [Google Scholar]

- Reinprecht, L.; Tino, R. Effect of plasma and UV-absorbers in transparent acrylic coatings on photostability of spruce wood in exterior. Acta Fac. Xylologiae Zvolen 2015, 57, 63–73. [Google Scholar]

- Kúdela, J.; Štrbová, M.; Jaš, F. Influence of accelerated ageing on colour and gloss changes in tree of heaven surface treated with an iruxil coating system. Acta Fac. Xylologiae Zvolen 2016, 58, 25–34. [Google Scholar] [CrossRef]

- Oberhofnerová, E.; Panek, M.; Böhm, M. Effect of surface pretreatment with natural essential oils on the weathering performance of spruce wood. BioResources 2018, 13, 7053–7070. [Google Scholar] [CrossRef]

- Lagaňa, R.; Svocák, J.; Kúdela, J. A study of the surface properties of a solid wood coating system with self-healing microcapsules. In Proceedings of the 9th Hardwood Proceedings Pt. II. An Underutilized Resource: Hardwood Oriented Research, Sopron 2021; University of Sopron Press: Sopron, Hungary, 2021; pp. 61–67. [Google Scholar]

- Huang, N.; Yan, X.; Han, Y. Preparation of Melamine-Formaldehyde Resin/Rice Husk Powder Coated Epoxy Resin Microcapsules and Effects of Different Microcapsule Contents on the Properties of Waterborne Coatings on Tilia europaea Surface. Coatings 2022, 12, 1213. [Google Scholar] [CrossRef]

- Kúdela, J.; Kubovský, I. Accelerated-ageing-induced photodegradation of beech wood surface treated with selected coating materials. Acta Fac. Xylologiae Zvolen 2016, 58, 27–36. [Google Scholar] [CrossRef]

- Salca, E.A.; Krystofiak, T.; Lis, B.; Hiziroglu, S. Glossiness evaluation of coated wood surfaces as function of varnish type and exposure to different conditions. Coatings 2021, 11, 558. [Google Scholar] [CrossRef]

- Bekhta, P.; Krystofiak, T.; Lis, B.; Bekhta, N. The Impact of Sanding and Thermal Compression of Wood, Varnish Type and Artificial Aging in Indoor Conditions on the Varnished Surface Color. Forests 2022, 13, 300. [Google Scholar] [CrossRef]

- Žigon, J.; Petrič, M.; Dahle, S. Artificially aged spruce and beech wood surfaces reactivated using FE-DBD atmospheric plasma. Holzforschung 2019, 73, 1069–1081. [Google Scholar] [CrossRef]

- Žigon, J.; Zaplotnik, R.; Ayata, Ü.; Petrič, M.; Dahle, S. The influence of artificial weathering and treatment with FE–DBD plasma in atmospheric conditions on wettability of wood surfaces. Niedersächsisches Symp. Mater. Clausthal 2019, 14, 559. [Google Scholar]

- ASTM G155-05; Standard Practice for Operating Xenon Arc Light Exposure of Non-Metallic Materials. American Society of testing and Materials: West Conshohocken, PA, USA, 2005.

- Allegretti, O.; Travan, L.; Cividini, R. Drying techniques to obtain white Beech. In Proceedings of the EDG Conference, Bled, Slovenia, 21–23 April 2009; pp. 7–13. [Google Scholar]

- Pánek, M.; Oberhofnerová, E.; Hýsek, Š.; Šedivka, P.; Zeidler, A. Colour Stabilization of Oak, Spruce, Larch and Douglas Fir Heartwood Treated with Mixtures of Nanoparticle Dispersions and UV-Stabilizers after Exposure to UV and VIS-Radiation. Materials 2018, 11, 1653. [Google Scholar] [CrossRef]

- Machová, D.; Baar, J.; Paschová, Z.; Pařil, P.; Křenková, J.; Kúdela, J. Color changes and accelerated ageing in oak wood treated by ammonia gas and iron nanoparticles. Eur. J. Wood Wood Prod. 2019, 77, 705–716. [Google Scholar] [CrossRef]

- Reinprecht, L.; Pánek, M. Effects of Wood Roughness, Light Pigments, and Water Repellent on the Color Stability of Painted Spruce Subjected to Natural and Accelerated Weathering. BioResources 2015, 10, 7203–7219. [Google Scholar] [CrossRef] [Green Version]

| CS | SCS Structure | Explanations |

|---|---|---|

| 1 | P1 + ML + F1 | P1—colourless primer without lignin stabilizer P2—colourless primer with lignin stabilizer ML—colourless middle layer F1—upper finishing layer colourless F2—upper finishing layer, soft pigmented with a white pigment |

| 2 | P2 + ML + F1 | |

| 3 | P1 + ML + F1 | |

| 4 | P2 + ML + F2 |

| Step | Mode | Radiation Intensity (W/m²) | Black Panel Temperature (°C) | Air Temperature (°C) | Relative Air Humidity (%) | Time (min.) |

|---|---|---|---|---|---|---|

| 1 | Radiation | 0.35 | 63 | 48 | 30 | 102 |

| 2 | Radiation-free | - | - | 38 | – | 18 |

| Lacquer Type | Colour Coordinates | Basic Statistical Characteristics | Aging Time (hours) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 50 | 100 | 200 | 300 | 400 | 500 | |||

| PUR-1 | L* | 73.66 | 71.21 | 69.24 | 67.40 | 65.42 | 65.09 | 63.83 | |

| s | 1.96 | 1.86 | 1.06 | 1.30 | 1.50 | 0.85 | 0.91 | ||

| a* | 8.45 | 7.63 | 9.16 | 10.37 | 11.30 | 12.23 | 12.97 | ||

| s | 1.44 | 0.98 | 0.75 | 0.70 | 0.78 | 0.58 | 0.57 | ||

| b* | 29.21 | 32.42 | 35.11 | 37.15 | 37.94 | 39.11 | 39.00 | ||

| s | 2.07 | 0.90 | 0.65 | 0.59 | 1.16 | 0.50 | 0.54 | ||

| PUR-2 | L* | 73.81 | 69.54 | 68.99 | 67.01 | 65.67 | 64.82 | 63.39 | |

| s | 1.62 | 1.82 | 1.05 | 1.07 | 0.70 | 0.64 | 0.61 | ||

| a* | 8.28 | 8.13 | 9.51 | 10.54 | 11.70 | 12.28 | 13.11 | ||

| s | 0.95 | 0.91 | 0.53 | 0.41 | 0.45 | 0.30 | 0.41 | ||

| b* | 30.45 | 33.47 | 36.73 | 38.21 | 38.89 | 39.15 | 38.92 | ||

| s | 1.25 | 0.79 | 0.50 | 0.53 | 0.49 | 0.48 | 0.45 | ||

| PUR-3 | L* | 78.32 | 72.35 | 70.64 | 68.22 | 66.59 | 65.38 | 63.60 | |

| s | 0.82 | 1.05 | 0.46 | 0.62 | 0.49 | 0.29 | 0.29 | ||

| a* | 6.23 | 6.96 | 8.20 | 9.53 | 10.58 | 11.35 | 12.18 | ||

| s | 0.61 | 0.28 | 0.21 | 0.25 | 0.26 | 0.14 | 0.14 | ||

| b* | 27.10 | 32.78 | 35.22 | 36.95 | 37.51 | 37.89 | 37.68 | ||

| s | 1.49 | 0.61 | 0.55 | 0.47 | 0.63 | 0.30 | 0.33 | ||

| PUR-4 | L* | 76.49 | 74.52 | 74.41 | 72.94 | 71.63 | 70.86 | 69.45 | |

| s | 2.08 | 1.49 | 1.15 | 0.75 | 0.87 | 0.59 | 0.78 | ||

| a* | 7.08 | 6.02 | 5.86 | 6.81 | 7.70 | 8.29 | 9.14 | ||

| s | 1.35 | 0.83 | 0.66 | 0.58 | 0.62 | 0.51 | 0.58 | ||

| b* | 28.41 | 27.53 | 29.53 | 32.50 | 34.03 | 34.84 | 35.17 | ||

| s | 1.88 | 1.44 | 1.05 | 1.09 | 1.23 | 0.97 | 1.61 | ||

| Lacquer Type | Colour Coordinates | Basic Statistical Characteristics | Aging Time (hours) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 50 | 100 | 200 | 300 | 400 | 500 | |||

| PUR-1 | L* | 40.44 | 40.48 | 41.11 | 41.86 | 42.56 | 43.13 | 43.90 | |

| s | 0.73 | 0.64 | 0.62 | 0.56 | 0.61 | 0.59 | 0.63 | ||

| a* | 24.12 | 22.96 | 22.66 | 22.23 | 21.57 | 21.06 | 20.44 | ||

| s | 0.53 | 0.40 | 0.38 | 0.24 | 0.36 | 0.45 | 0.25 | ||

| b* | 19.42 | 18.40 | 19.04 | 19.90 | 21.02 | 21.90 | 22.77 | ||

| s | 0.77 | 0.55 | 0.71 | 0.61 | 0.91 | 0.78 | 0.90 | ||

| PUR-2 | L* | 39.90 | 41.86 | 43.36 | 46.22 | 48.83 | 50.86 | 52.49 | |

| s | 1.11 | 0.69 | 0.80 | 1.09 | 1.18 | 1.22 | 1.04 | ||

| a* | 24.16 | 23.07 | 21.90 | 19.13 | 16.49 | 14.93 | 13.87 | ||

| s | 0.70 | 0.36 | 0.27 | 0.58 | 0.70 | 0.77 | 0.73 | ||

| b* | 21.22 | 20.56 | 21.32 | 22.35 | 23.53 | 24.92 | 25.99 | ||

| s | 0.93 | 0.53 | 0.48 | 0.49 | 0.48 | 0.49 | 0.45 | ||

| PUR-3 | L* | 40.08 | 40.37 | 42.59 | 44.92 | 46.94 | 48.70 | 49.96 | |

| s | 0.89 | 0.89 | 0.61 | 0.64 | 0.65 | 0.85 | 1.02 | ||

| a* | 25.21 | 22.92 | 22.37 | 19.65 | 17.31 | 15.50 | 14.55 | ||

| s | 0.60 | 0.67 | 0.28 | 0.59 | 0.63 | 0.65 | 0.56 | ||

| b* | 22.54 | 20.42 | 21.68 | 22.90 | 23.85 | 24.84 | 25.81 | ||

| s | 0.93 | 0.80 | 0.44 | 0.41 | 0.27 | 0.42 | 0.38 | ||

| PUR-4 | L* | 39.82 | 39.71 | 40.10 | 40.79 | 41.98 | 42.84 | 43.59 | |

| s | 0.86 | 0.81 | 0.69 | 0.75 | 0.80 | 0.80 | 0.97 | ||

| a* | 25.20 | 25.35 | 25.13 | 24.92 | 24.75 | 24.10 | 23.55 | ||

| s | 0.58 | 0.50 | 0.36 | 0.54 | 0.37 | 0.44 | 0.37 | ||

| b* | 22.44 | 20.93 | 20.85 | 21.26 | 22.07 | 22.40 | 22.92 | ||

| s | 0.85 | 0.73 | 0.56 | 0.67 | 0.52 | 0.41 | 0.59 | ||

| Lacquer Type | Colour Coordinates | Basic Statistical Characteristics | Aging Time (hours) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 50 | 100 | 200 | 300 | 400 | 500 | |||

| PUR-1 | L* | 63.11 | 59.48 | 58.75 | 57.67 | 56.77 | 56.77 | 56.00 | |

| s | 1.45 | 0.81 | 0.70 | 0.77 | 0.65 | 0.61 | 1.16 | ||

| a* | 9.56 | 10.96 | 11.76 | 12.74 | 13.22 | 13.77 | 13.86 | ||

| s | 0.36 | 0.37 | 0.40 | 0.51 | 0.48 | 0.44 | 0.71 | ||

| b* | 26.97 | 29.71 | 31.12 | 32.07 | 32.91 | 33.70 | 33.93 | ||

| s | 0.78 | 0.45 | 0.58 | 0.47 | 0.60 | 0.63 | 1.28 | ||

| PUR-2 | L* | 63.20 | 61.22 | 60.98 | 61.20 | 61.62 | 62.08 | 62.49 | |

| s | 1.01 | 0.76 | 1.02 | 0.85 | 0.72 | 0.67 | 0.57 | ||

| a* | 8.98 | 9.45 | 9.75 | 10.16 | 10.24 | 10.34 | 10.51 | ||

| s | 0.32 | 0.52 | 0.45 | 0.48 | 0.30 | 0.39 | 0.36 | ||

| b* | 28.49 | 29.41 | 30.51 | 31.47 | 31.76 | 31.96 | 32.12 | ||

| s | 0.54 | 0.41 | 0.50 | 0.43 | 0.43 | 0.58 | 0.45 | ||

| PUR-3 | L* | 62.86 | 58.72 | 58.89 | 58.73 | 59.13 | 59.49 | 59.41 | |

| s | 1.34 | 1.09 | 0.80 | 1.09 | 0.88 | 0.84 | 0.78 | ||

| a* | 9.87 | 10.56 | 10.94 | 11.11 | 11.68 | 11.97 | 12.34 | ||

| s | 0.28 | 0.56 | 0.55 | 0.87 | 0.62 | 0.59 | 0.52 | ||

| b* | 27.66 | 29.32 | 30.79 | 31.44 | 32.91 | 33.52 | 33.89 | ||

| s | 0.61 | 0.63 | 0.49 | 1.36 | 0.65 | 0.69 | 0.60 | ||

| PUR-4 | L* | 62.25 | 59.56 | 59.54 | 59.86 | 61.60 | 62.07 | 62.70 | |

| s | 1.72 | 1.72 | 1.84 | 1.52 | 1.63 | 1.63 | 1.64 | ||

| a* | 9.79 | 9.79 | 9.91 | 10.40 | 9.79 | 9.92 | 9.84 | ||

| s | 0.50 | 0.46 | 0.52 | 0.72 | 0.51 | 0.52 | 0.38 | ||

| b* | 28.10 | 27.17 | 28.10 | 30.17 | 30.75 | 31.72 | 32.36 | ||

| s | 0.56 | 0.44 | 0.51 | 1.24 | 0.51 | 0.48 | 0.60 | ||

| Lacquer Type | Colour Coordinates | Basic Statistical Characteristics | Aging Time (hours) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 50 | 100 | 200 | 300 | 400 | 500 | |||

| PUR-1 | L* | 49.75 | 47.95 | 48.14 | 48.33 | 48.71 | 48.90 | 49.35 | |

| s | 0.61 | 0.54 | 0.66 | 0.71 | 0.73 | 0.87 | 0.62 | ||

| a* | 20.24 | 17.84 | 17.78 | 17.51 | 17.41 | 17.58 | 17.72 | ||

| s | 0.30 | 0.27 | 0.25 | 0.27 | 0.30 | 0.32 | 0.23 | ||

| b* | 25.69 | 25.48 | 26.61 | 27.19 | 28.13 | 29.22 | 30.47 | ||

| s | 0.59 | 0.42 | 0.65 | 0.62 | 0.58 | 0.87 | 0.68 | ||

| PUR-2 | L* | 49.14 | 49.12 | 50.43 | 52.70 | 54.50 | 56.06 | 57.05 | |

| s | 1.03 | 0.68 | 0.63 | 0.71 | 0.69 | 0.62 | 0.73 | ||

| a* | 21.73 | 20.29 | 20.00 | 19.39 | 18.64 | 17.98 | 17.39 | ||

| s | 0.37 | 0.32 | 0.32 | 0.37 | 0.32 | 0.22 | 0.26 | ||

| b* | 27.50 | 28.88 | 30.85 | 33.31 | 35.01 | 36.22 | 36.88 | ||

| s | 0.65 | 0.58 | 0.55 | 0.64 | 0.65 | 0.67 | 0.63 | ||

| PUR-3 | L* | 49.41 | 48.27 | 49.04 | 50.56 | 51.61 | 52.62 | 53.67 | |

| s | 0.73 | 0.49 | 0.61 | 0.52 | 0.45 | 0.49 | 0.54 | ||

| a* | 21.59 | 20.25 | 20.11 | 19.86 | 19.49 | 19.24 | 18.80 | ||

| s | 0.56 | 0.32 | 0.35 | 0.29 | 0.33 | 0.33 | 0.31 | ||

| b* | 28.02 | 28.90 | 30.09 | 31.88 | 33.23 | 34.30 | 35.10 | ||

| s | 0.76 | 0.30 | 0.41 | 0.38 | 0.43 | 0.48 | 0.49 | ||

| PUR-4 | L* | 46.62 | 46.63 | 47.11 | 48.66 | 49.79 | 50.95 | 51.87 | |

| s | 1.03 | 0.57 | 0.46 | 0.74 | 0.80 | 0.78 | 0.64 | ||

| a* | 21.25 | 20.68 | 20.64 | 21.04 | 21.16 | 21.33 | 21.27 | ||

| s | 0.53 | 0.28 | 0.44 | 0.32 | 0.38 | 0.27 | 0.28 | ||

| b* | 26.30 | 26.65 | 27.36 | 29.24 | 30.72 | 32.10 | 33.22 | ||

| s | 0.97 | 0.43 | 0.37 | 0.55 | 0.58 | 0.63 | 0.53 | ||

| Coating System | Colour Coordinates | Basic Statistical Characteristics | Aging Time (hours) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | |||

| CS-1 | L* | 82.67 | 79.09 | 78.40 | 77.49 | 76.77 | 76.04 | 75.44 | 75.04 | |

| s | 0.28 | 0.63 | 0.60 | 0.61 | 0.62 | 0.66 | 0.53 | 0.42 | ||

| a* | 2.80 | 4.40 | 4.91 | 5.64 | 6.15 | 6.56 | 7.07 | 7.29 | ||

| s | 0.16 | 0.14 | 0.12 | 0.20 | 0.19 | 0.14 | 0.22 | 0.30 | ||

| b* | 26.39 | 27.59 | 28.87 | 30.23 | 30.99 | 31.54 | 31.91 | 32.17 | ||

| s | 0.27 | 0.46 | 0.26 | 0.30 | 0.33 | 0.46 | 0.43 | 0.45 | ||

| CS-2 | L* | 81.54 | 80.05 | 79.29 | 78.40 | 77.64 | 77.02 | 76.44 | 75.74 | |

| s | 0.34 | 0.30 | 0.33 | 0.54 | 0.70 | 0.93 | 0.72 | 0.70 | ||

| a* | 3.66 | 4.11 | 4.49 | 5.11 | 5.67 | 6.02 | 6.49 | 6.98 | ||

| s | 0.12 | 0.17 | 0.26 | 0.43 | 0.56 | 0.66 | 0.57 | 0.53 | ||

| b* | 28.69 | 24.70 | 26.22 | 27.37 | 28.10 | 28.61 | 28.94 | 29.48 | ||

| s | 0.48 | 0.51 | 0.31 | 0.32 | 0.22 | 0.28 | 0.27 | 0.18 | ||

| CS-3 | L* | 85.72 | 83.54 | 83.33 | 82.91 | 82.64 | 82.44 | 82.25 | 81.89 | |

| s | 0.79 | 0.71 | 0.80 | 0.94 | 0.99 | 0.76 | 0.97 | 1.25 | ||

| a* | 2.23 | 2.77 | 3.08 | 3.43 | 3.66 | 3.75 | 3.92 | 4.14 | ||

| s | 0.33 | 0.29 | 0.31 | 0.41 | 0.46 | 0.30 | 0.40 | 0.65 | ||

| b* | 13.57 | 13.24 | 13.20 | 13.35 | 13.40 | 13.37 | 13.34 | 13.34 | ||

| s | 2.77 | 2.12 | 2.49 | 2.76 | 2.84 | 2.97 | 3.04 | 3.12 | ||

| CS-4 | L* | 85.60 | 85.39 | 85.13 | 84.93 | 84.61 | 84.26 | 84.14 | 83.86 | |

| s | 0.12 | 0.20 | 0.19 | 0.25 | 0.22 | 0.24 | 0.34 | 0.39 | ||

| a* | 2.54 | 1.93 | 2.05 | 2.21 | 2.53 | 2.81 | 2.98 | 3.17 | ||

| s | 0.09 | 0.12 | 0.19 | 0.26 | 0.23 | 0.22 | 0.26 | 0.25 | ||

| b* | 13.72 | 12.86 | 13.02 | 13.23 | 13.01 | 12.69 | 12.43 | 12.44 | ||

| s | 0.49 | 0.47 | 0.36 | 0.25 | 0.30 | 0.36 | 0.46 | 0.47 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kúdela, J.; Sikora, A.; Gondáš, L. Wood Surface Finishing with Transparent Lacquers Intended for Indoor Use, and the Colour Resistance of These Surfaces during Accelerated Aging. Polymers 2023, 15, 747. https://doi.org/10.3390/polym15030747

Kúdela J, Sikora A, Gondáš L. Wood Surface Finishing with Transparent Lacquers Intended for Indoor Use, and the Colour Resistance of These Surfaces during Accelerated Aging. Polymers. 2023; 15(3):747. https://doi.org/10.3390/polym15030747

Chicago/Turabian StyleKúdela, Jozef, Adam Sikora, and Lukáš Gondáš. 2023. "Wood Surface Finishing with Transparent Lacquers Intended for Indoor Use, and the Colour Resistance of These Surfaces during Accelerated Aging" Polymers 15, no. 3: 747. https://doi.org/10.3390/polym15030747

APA StyleKúdela, J., Sikora, A., & Gondáš, L. (2023). Wood Surface Finishing with Transparent Lacquers Intended for Indoor Use, and the Colour Resistance of These Surfaces during Accelerated Aging. Polymers, 15(3), 747. https://doi.org/10.3390/polym15030747