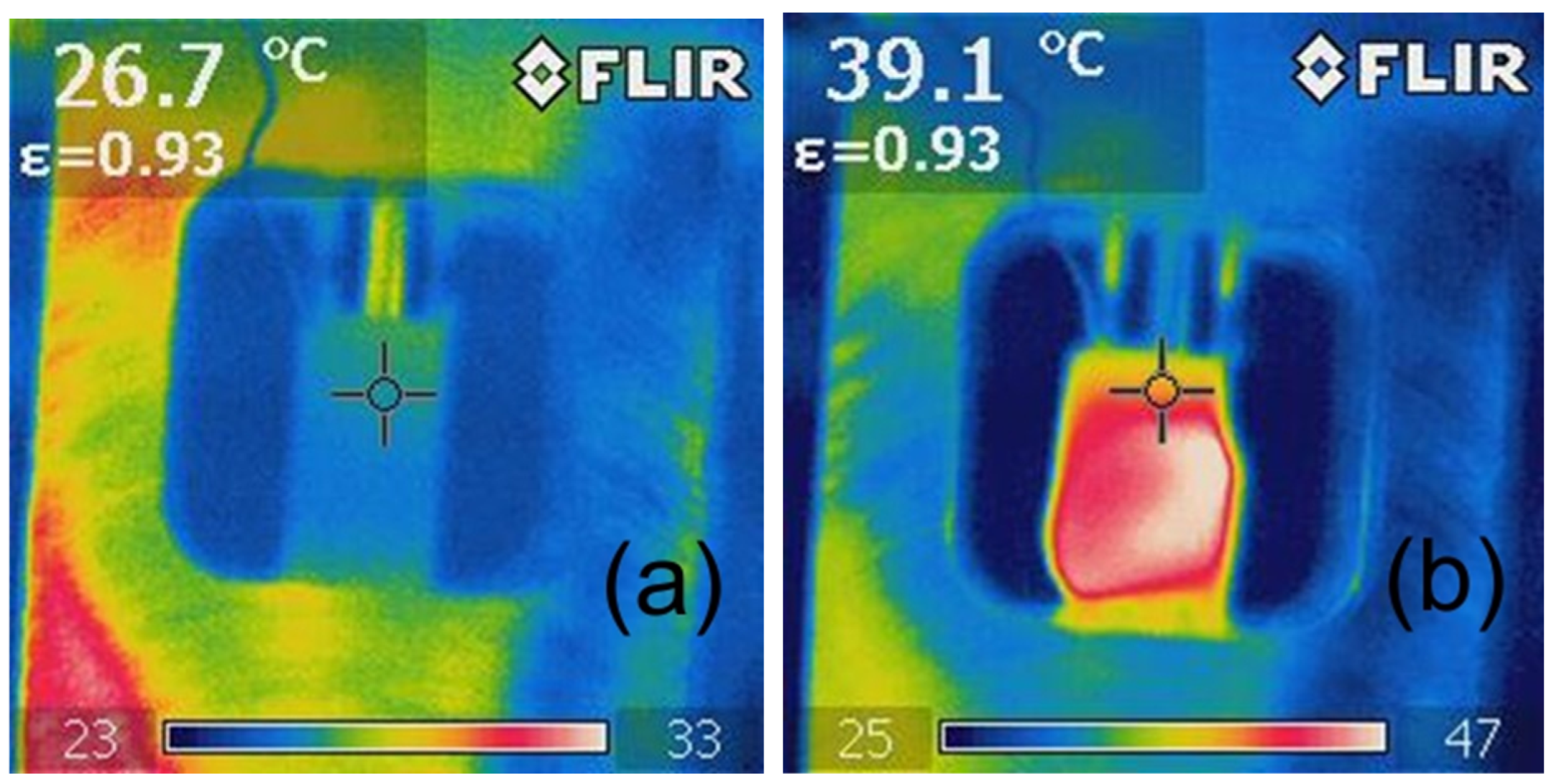

Temperature Rise of an Adhesive Particle-Reinforced Polymer during Fatigue Testing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Methods for Preliminary Research

- 10% tungsten (T) powder,

- Expancel microballoons (microspheres) in a quantity of 1%,

- layered silicate montmorillonite (MMT) in an amount of 10%,

- Micronal DS5038X PCM in an amount of 5%,

- silicon carbide (SiC) with a grit size of 220 in an amount of 10%.

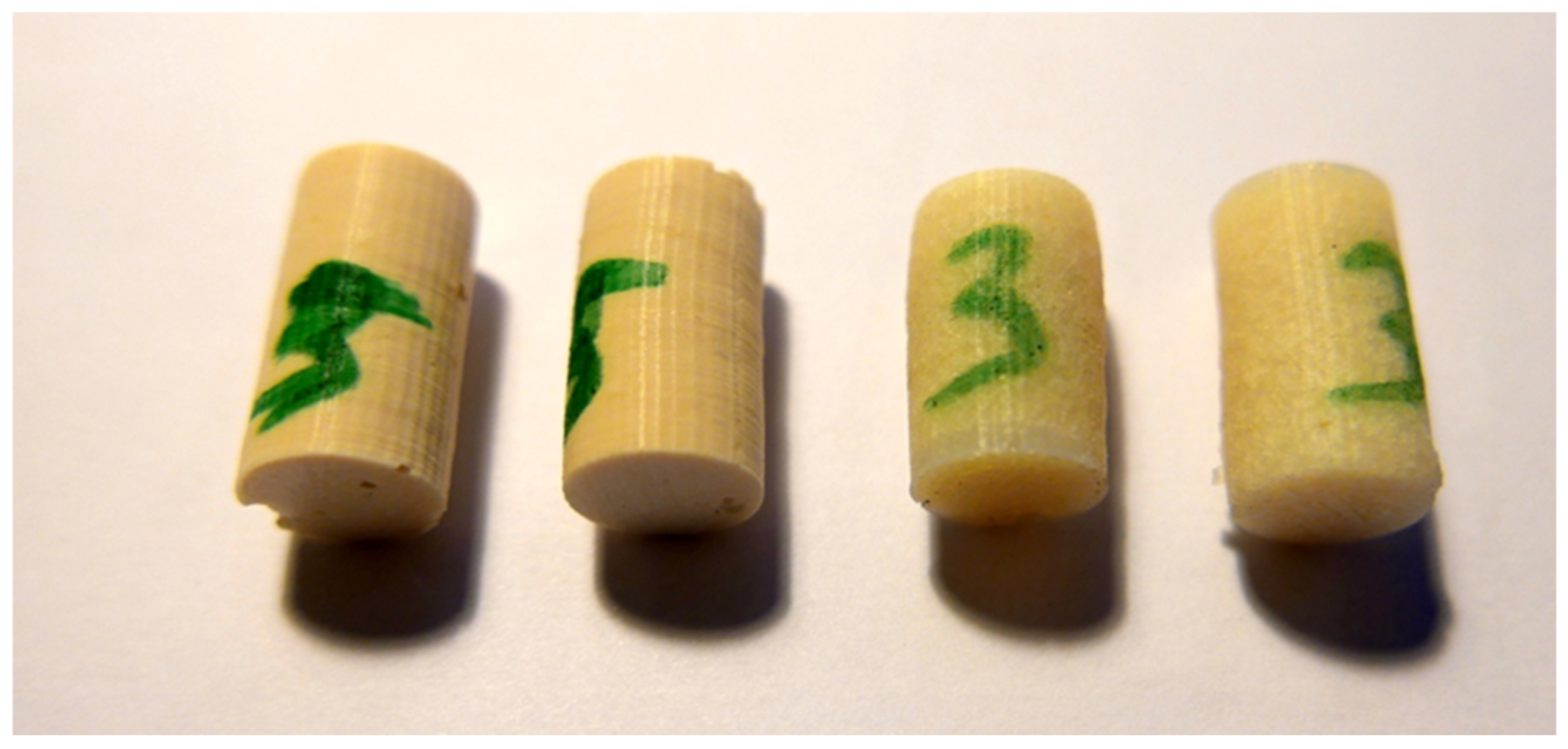

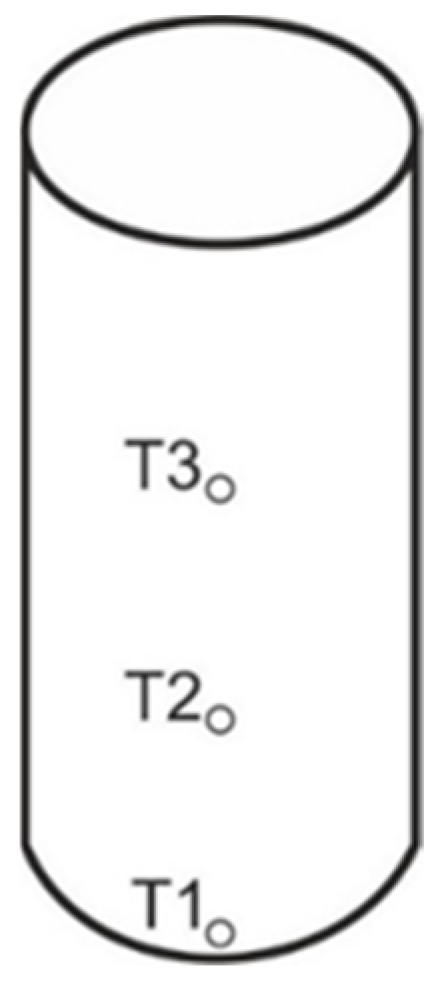

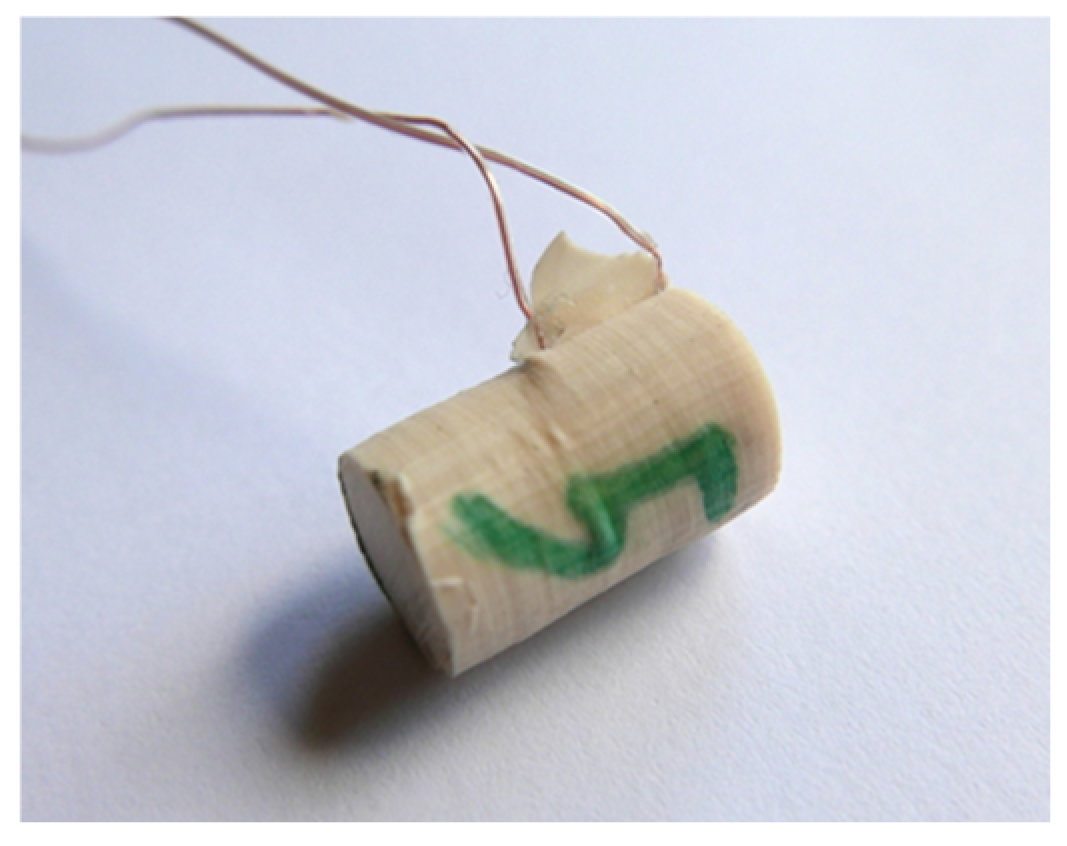

2.2. Preparation of Specimens for Fatigue Testing

3. Research and Discussion

3.1. Density Testing

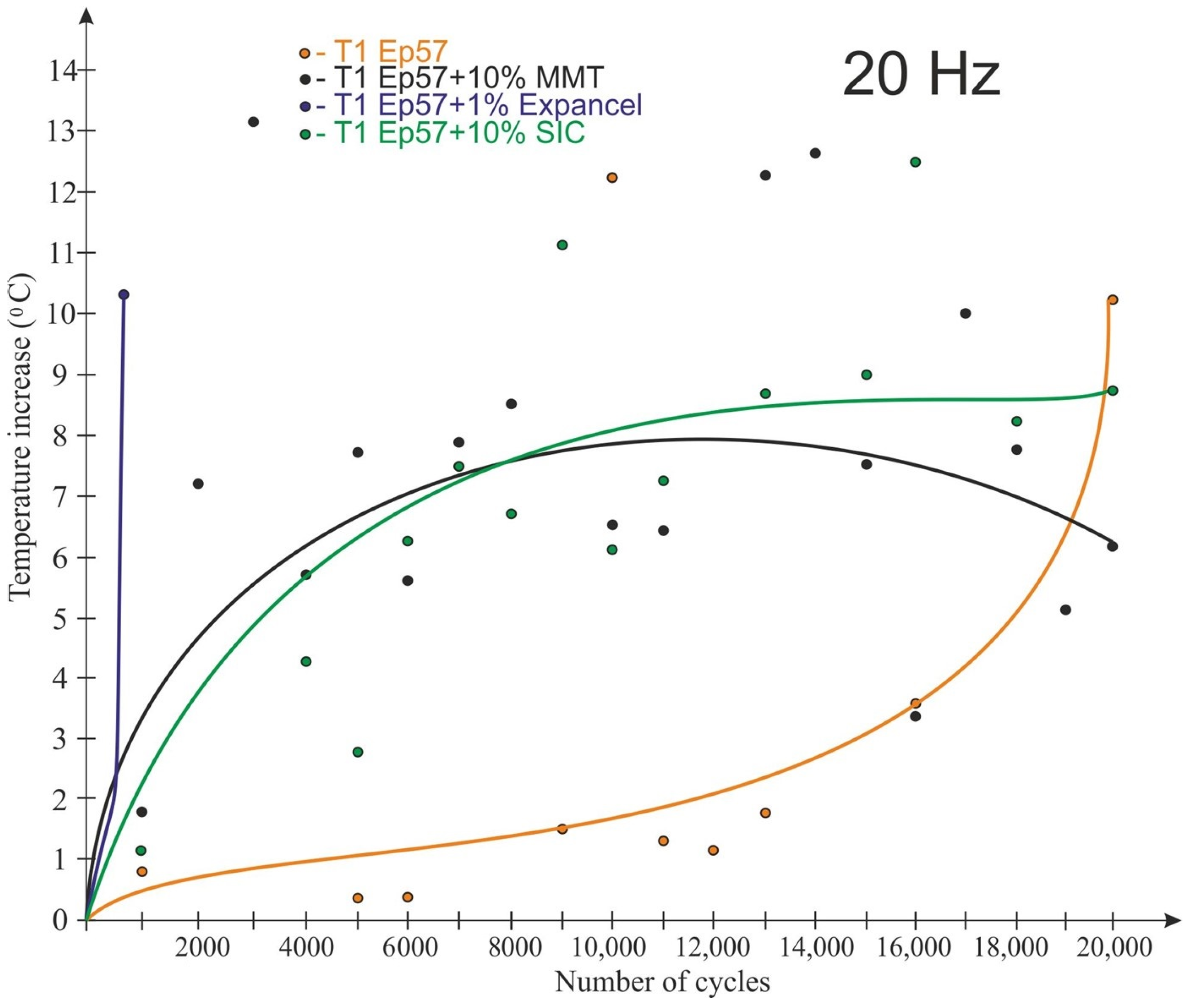

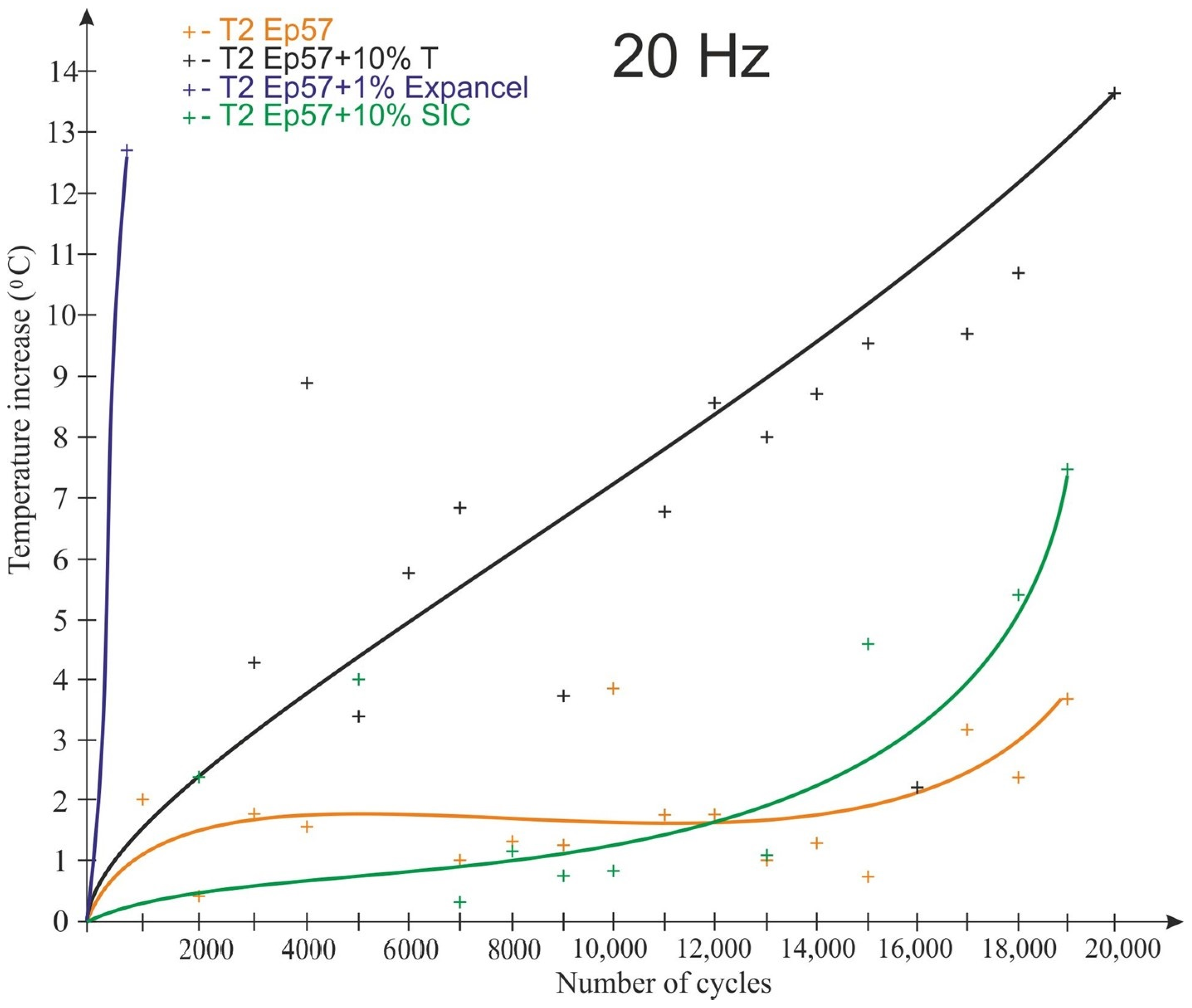

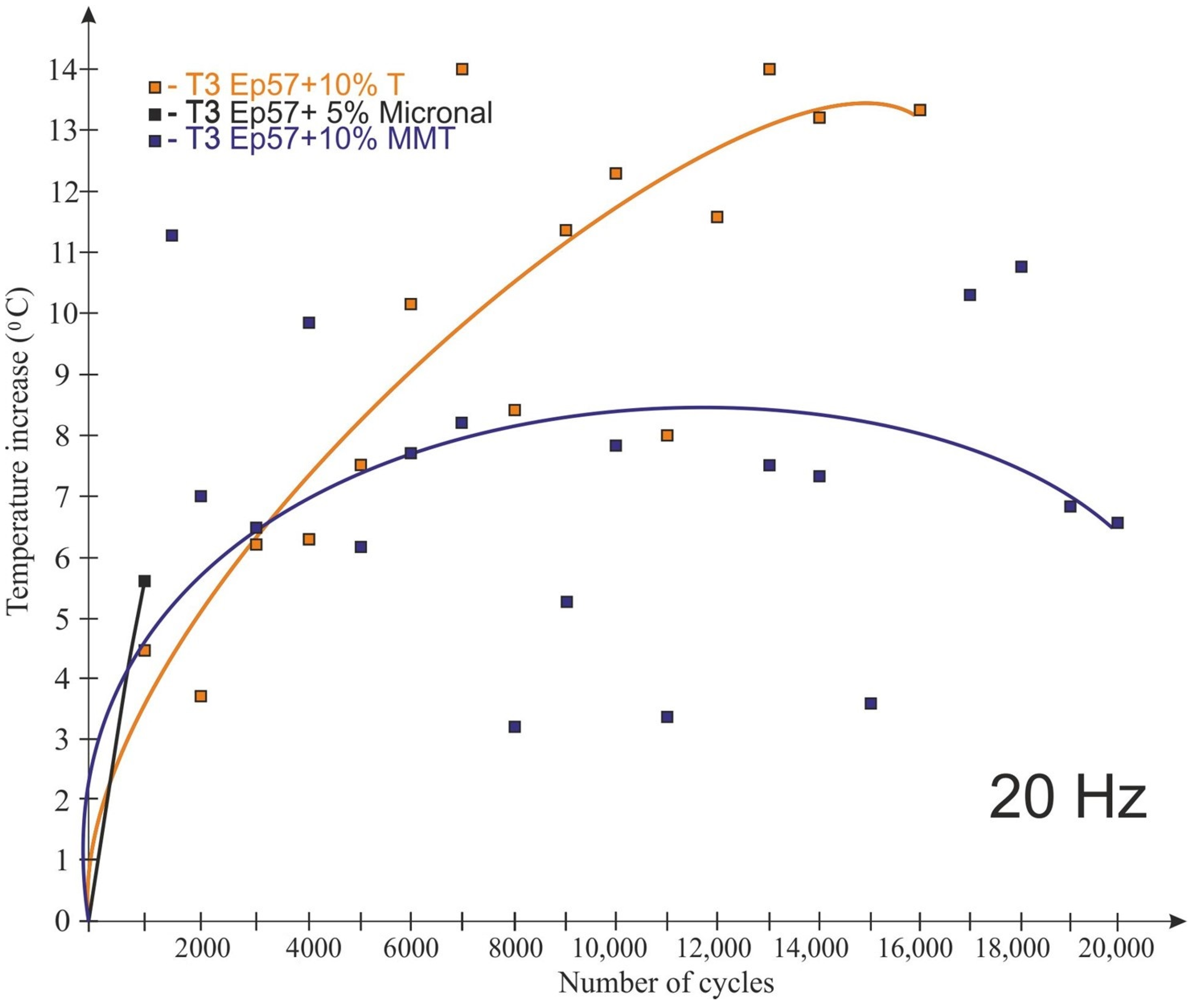

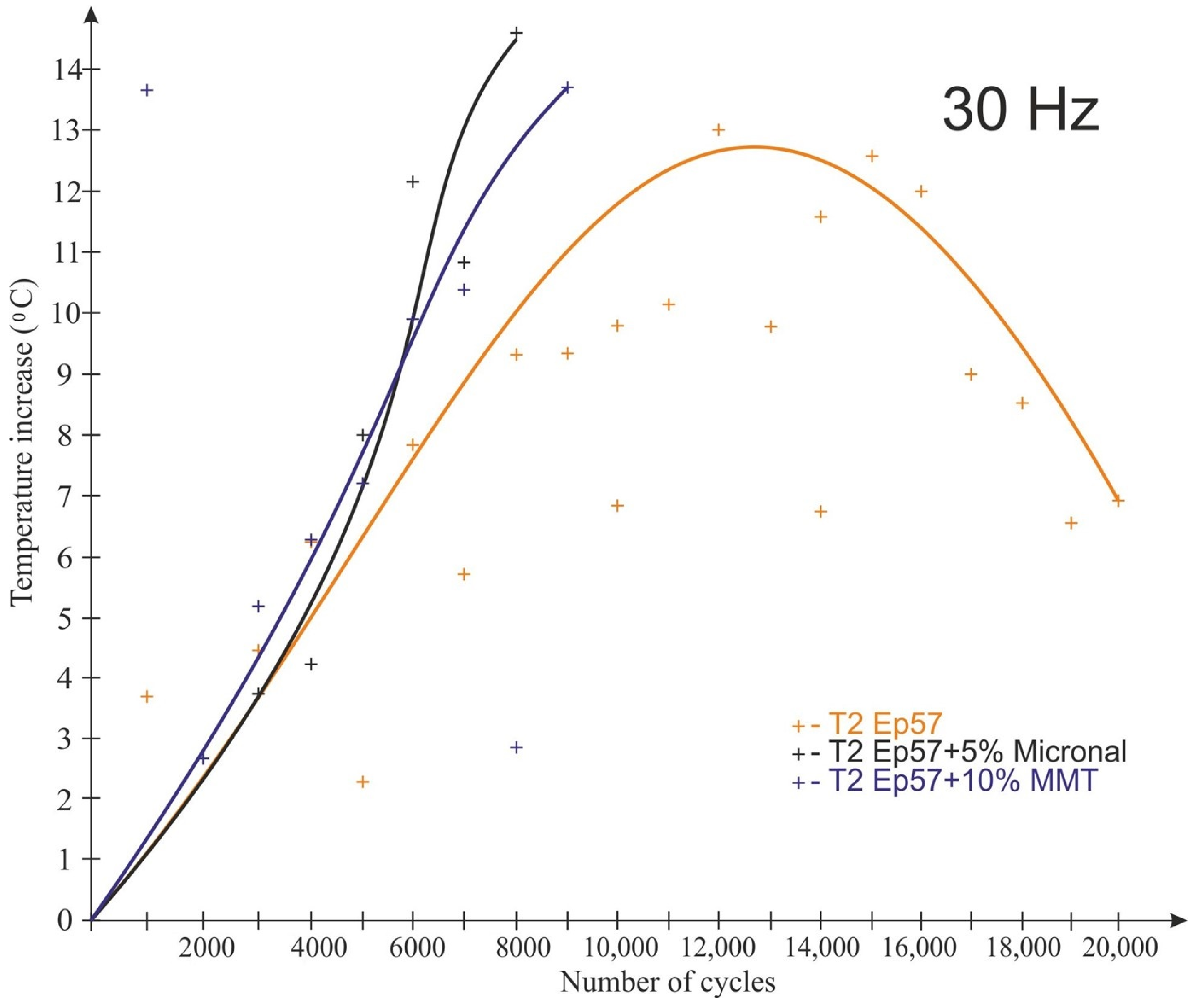

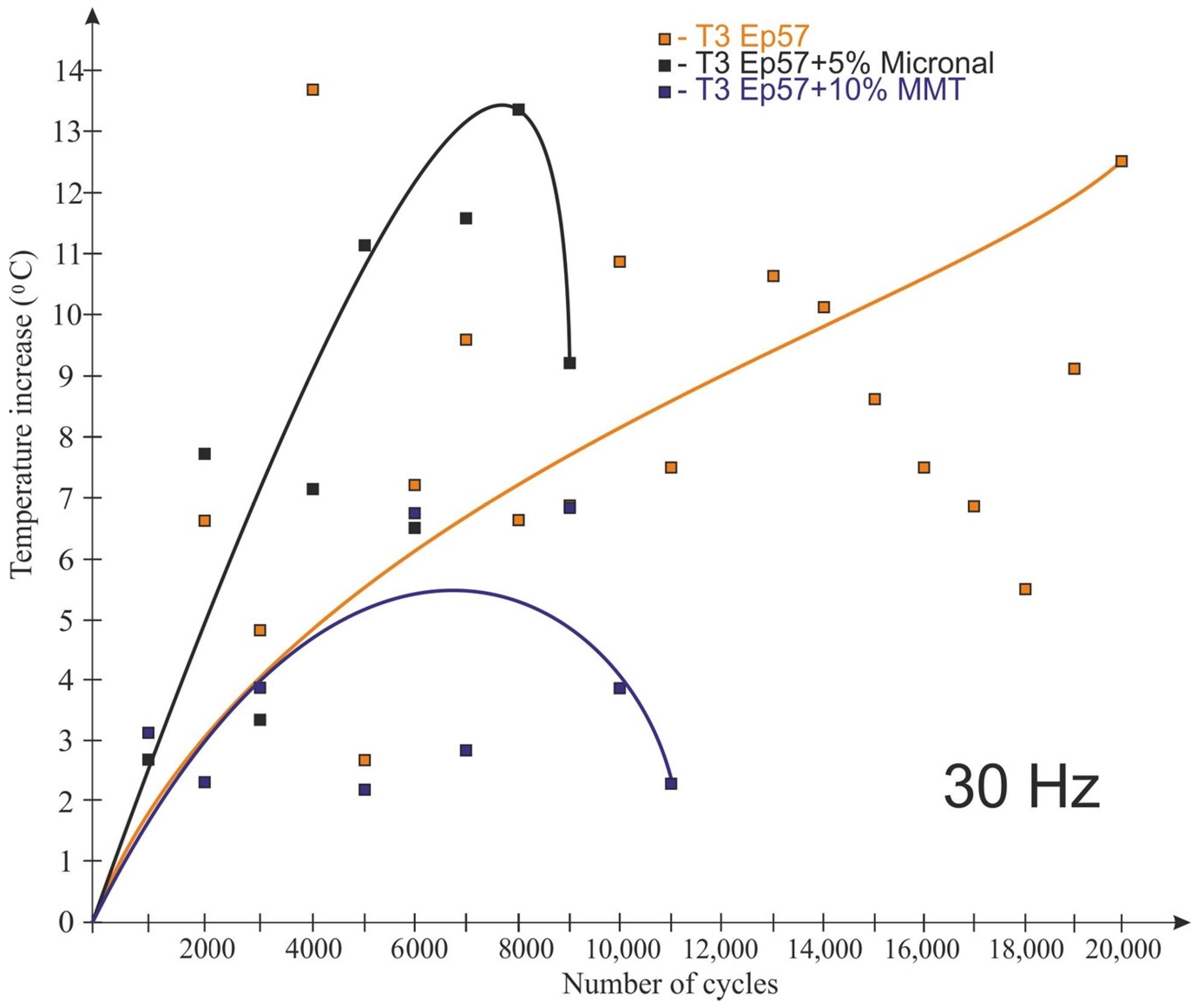

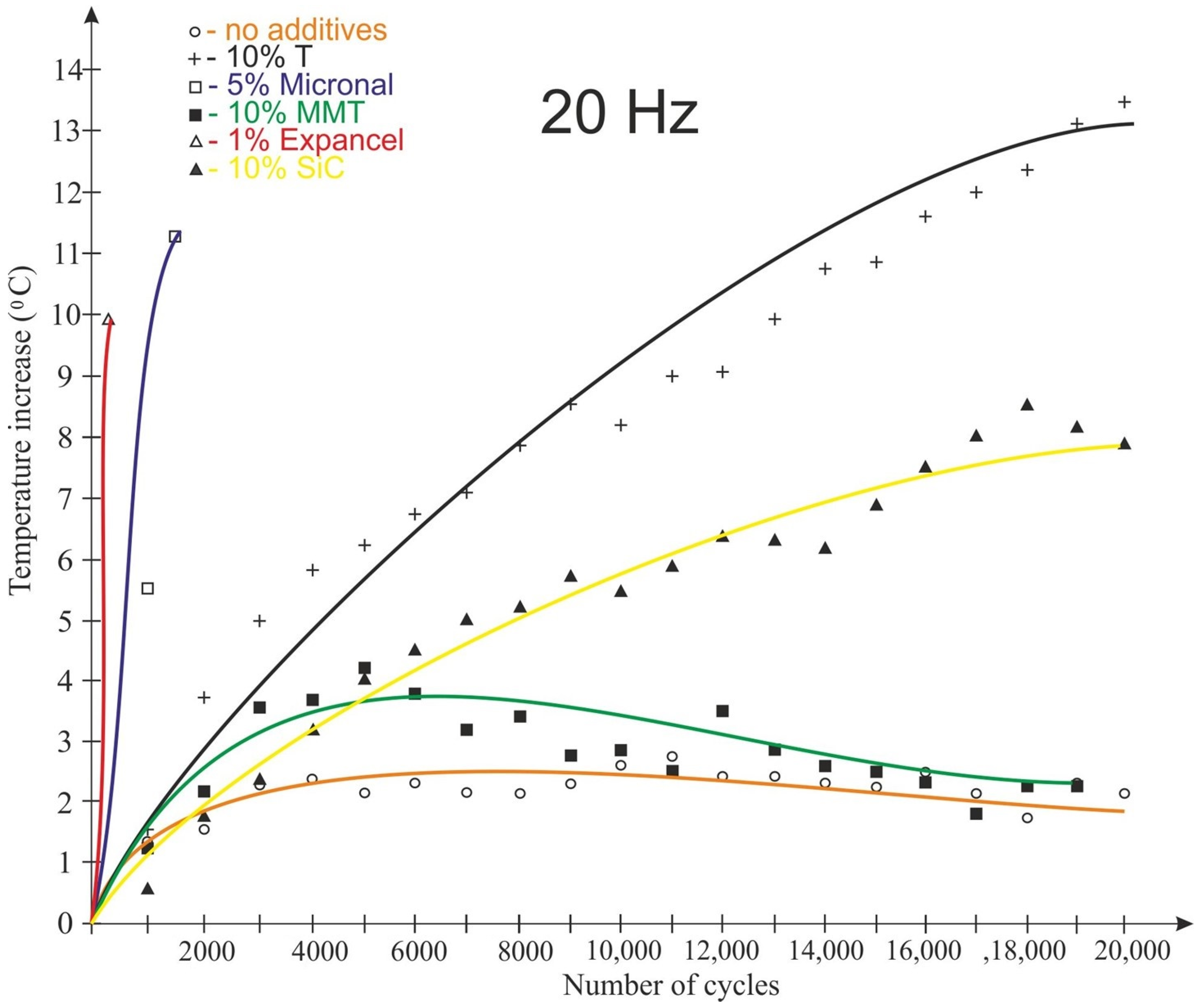

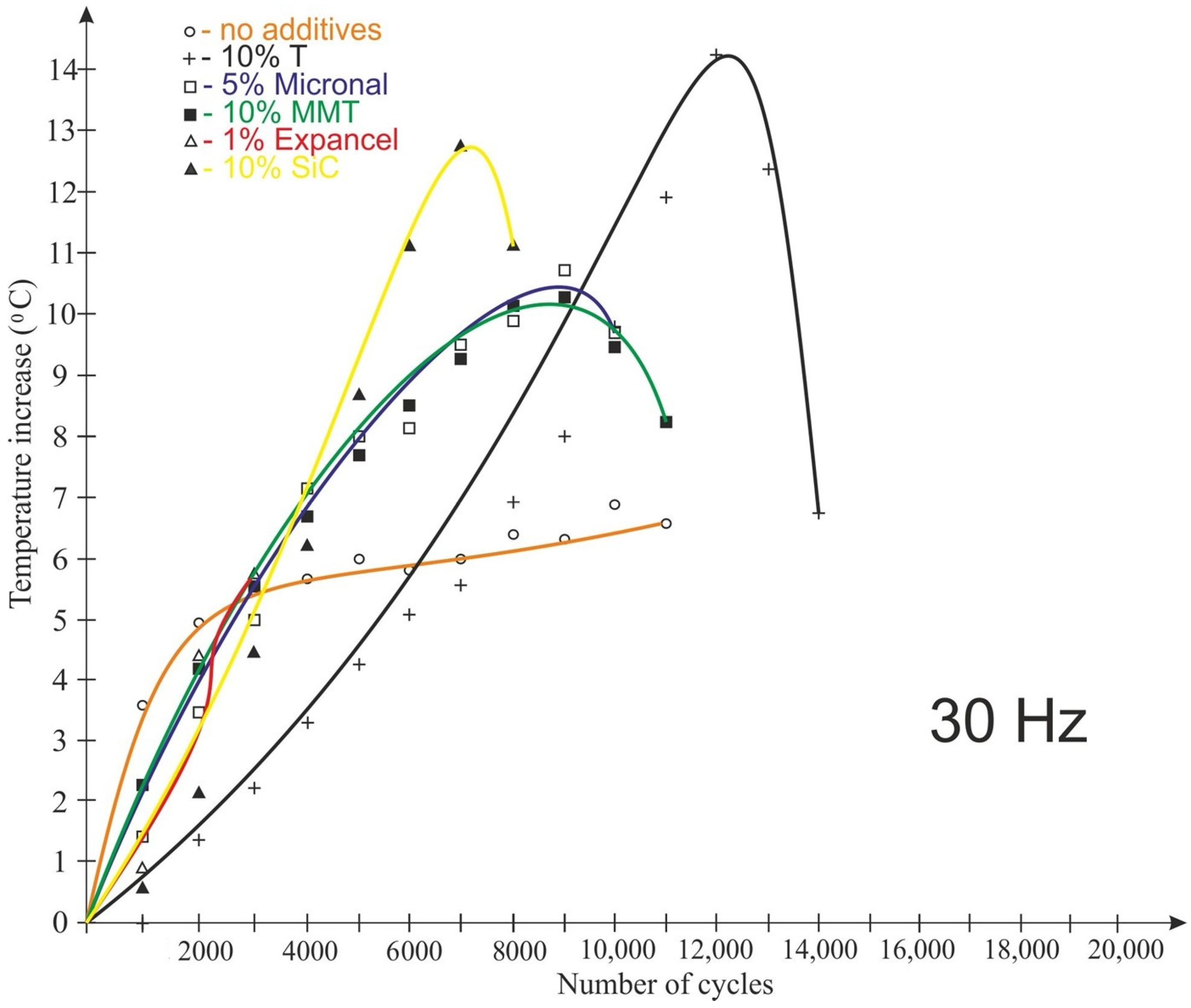

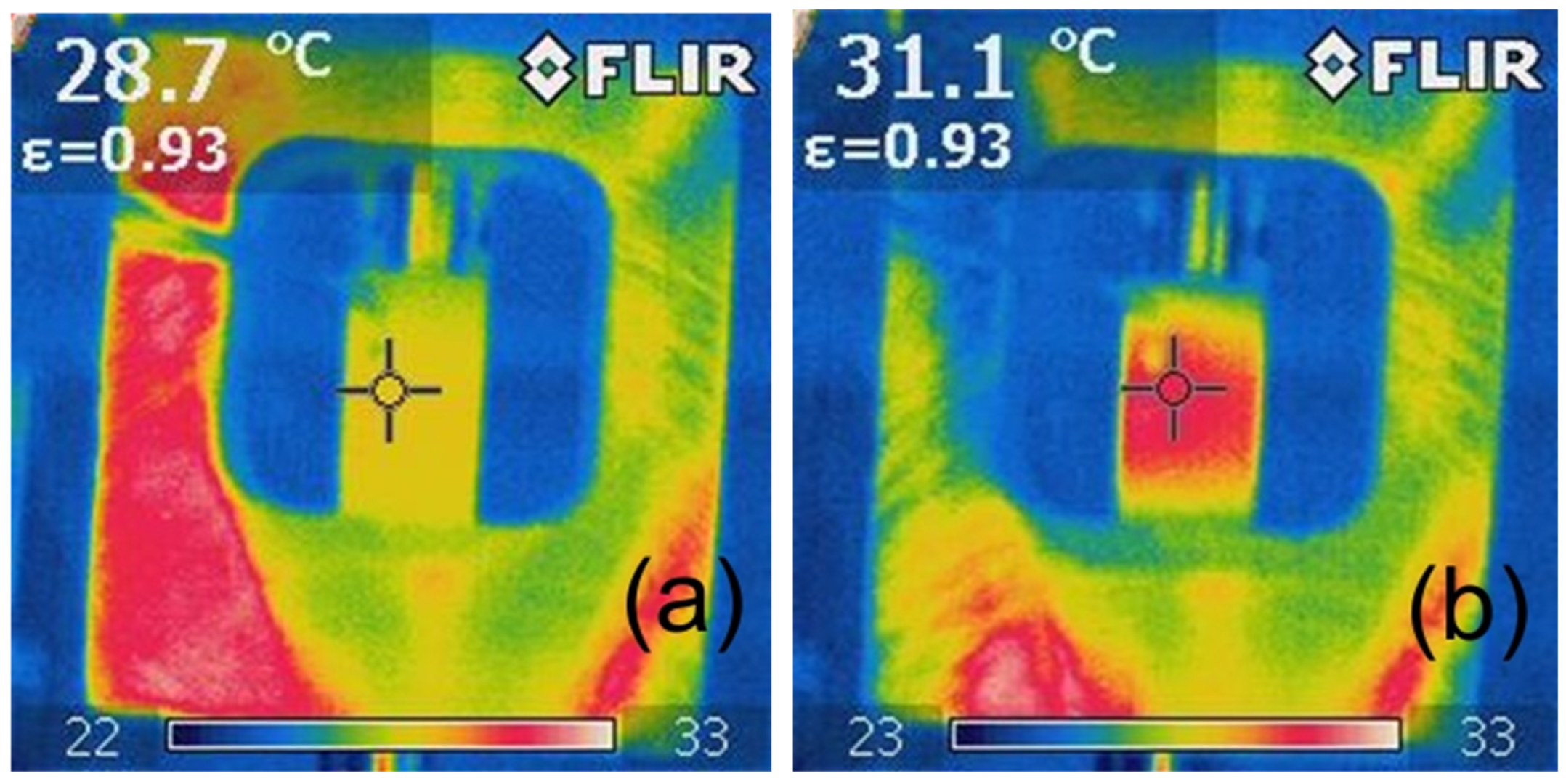

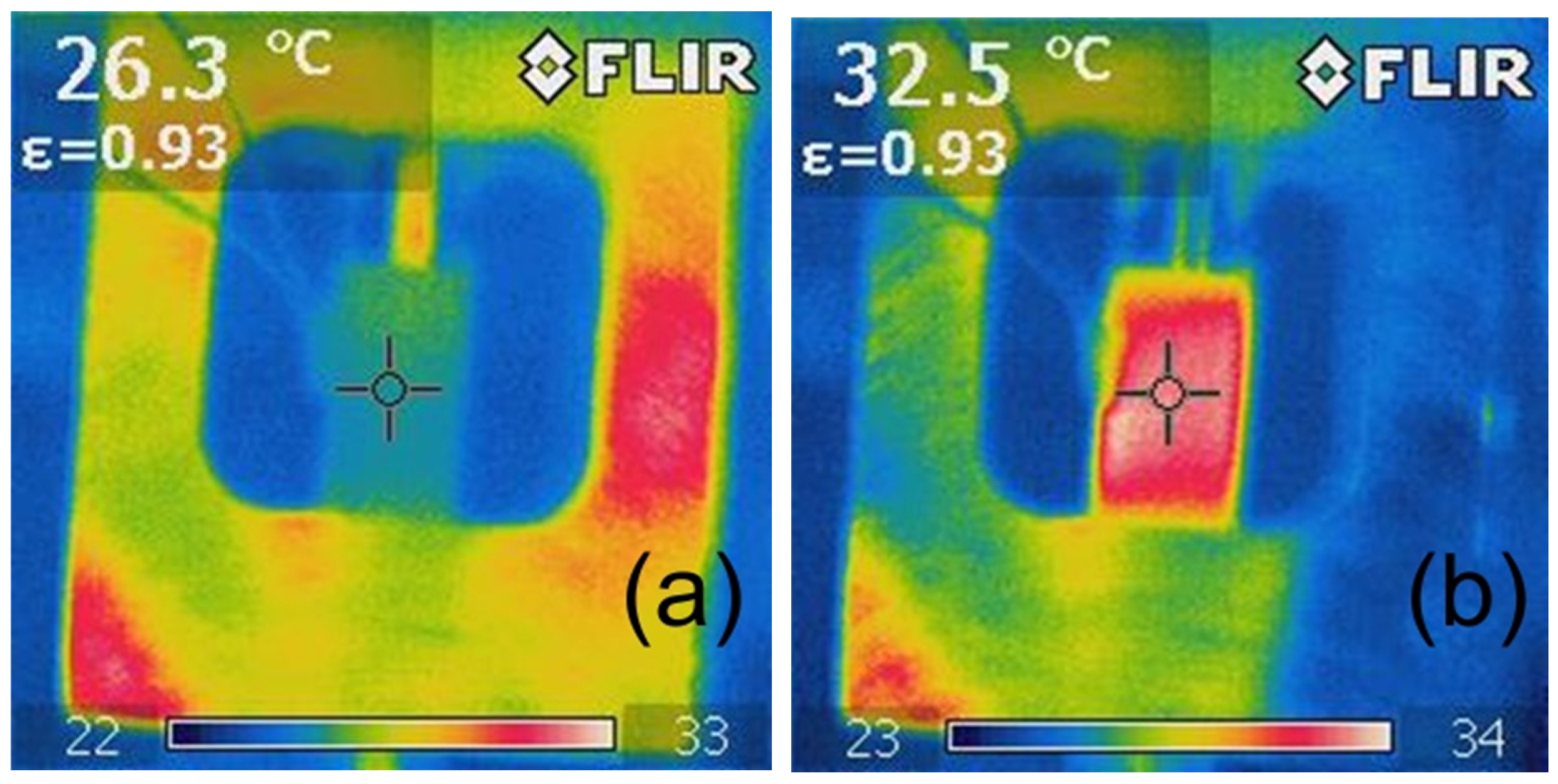

3.2. Fatigue Studies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Cagle, C.V. Adhesive and Adhesive Bonding; McGraw Hill: New York, NY, USA, 1973. [Google Scholar]

- Rośkowicz, M.; Smal, T. Research on durability of composite materials used in repairing aircraft components. Maint. Reliab. 2013, 15, 349–355. [Google Scholar]

- da Silva, L.F.M.; Öchsner, A.; Adams, R.D. Handbook of Adhesion Technology; Springer: New York, NY, USA, 2011. [Google Scholar]

- Petrova, A.P.; Lukina, N.F. Adhesive technologies in aircraft construction. Polym. Sci. D 2008, 1, 83–90. [Google Scholar] [CrossRef]

- Belnoue, J.P.H.; Hallett, S.R. Cohesive/adhesive failure interaction in ductile adhesive joints Part I: A smeared-crack model for cohesive failure. Int. J. Adhes. 2016, 68, 359–368. [Google Scholar] [CrossRef]

- von Fraunhofer, J. Adhesion and Cohesion. Int. J. Dent. 2012, 2012, 951324. [Google Scholar] [CrossRef] [PubMed]

- da Silva, L.F.M.; Dillard, D.A.; Blackman, B.; Adams, R.D. Testing Adhesive Joints: Best Practices; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Komorek, A.; Godzimirski, J.; Pietras, A. Numerical Analysis of Impact Loading of Adhesive Joints. Adv. Mater. Sci. Eng. 2017, 2017, 5941086. [Google Scholar] [CrossRef]

- Silberschmidt, V.V.; Casas Rodriguez, J.P.; Ashcroft, I.A. Impact fatigue in adhesive joints. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2008, 222, 1981–1994. [Google Scholar] [CrossRef]

- Costa, M.; Viana, G.; da Silva, L.F.M.; Campilho, R.D.S.G. Environmental effect on the fatigue degradation of adhesive joints: A review. J. Adhes. 2016, 93, 127–146. [Google Scholar] [CrossRef]

- Wahab, M.M.A. Fatigue in Adhesively Bonded Joints: A Review. Int. Sch. Res. Not. 2012, 2012, 746308. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Q.; Jiang, X.; Liu, H.; Yuan, X.; Zhu, Z. The Effect of Material Static Mechanical Properties on the Fatigue Crack Initiation Life of Rail Fastening Clips. Adv. Civ. Eng. 2021, 2021, 1366007. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M.; Campilho, R.D.S.G.; Sat, C. Smart adhesive joints: An overview of recent developments. J. Adhes. 2014, 90, 16–40. [Google Scholar] [CrossRef]

- Jeandrau, J.P.; Peyrac, C.; Lefebvre, F.; Renard, J.; Gantchenko, V.; Patamaprohm, B.; Guinault, C. Fatigue Behaviour of Adhesive Joints. Procedia Eng. 2015, 133, 508–517. [Google Scholar] [CrossRef]

- Higgins, A. Adhesive bonding of aircraft structures. Int. J. Adhes. Adhes. 2000, 20, 367–376. [Google Scholar] [CrossRef]

- Tant, M.R.; Connell, J.W.; McManus, H.L. High-Temperature Properties and Applications of Polymeric Materials; American Chemical Society: Washington, DC, USA, 1995. [Google Scholar]

- Haque, S.M.; Ardila-Rey, J.A.; Umar, Y.; Mas’ud, A.A.; Muhammad-Sukki, F.; Jume, B.H.; Rahman, H.; Bani, N.A. Application and Suitability of Polymeric Materials as Insulators in Electrical Equipment. Energies 2021, 14, 2758. [Google Scholar] [CrossRef]

- Balani, K.; Verma, V.; Agarwal, A.; Narayan, R. (Eds.) Physical, Thermal, and Mechanical Properties of Polymers. In Biosurfaces; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015. [Google Scholar]

- Rośkowicz, M.; Godzimirski, J.; Komorek, A.; Gąsior, J.; Jasztal, M. Influence of the Arrangement of Mechanical Fasteners on the Static Strength and Fatigue Life of Hybrid Joints. Materials 2020, 13, 5308. [Google Scholar] [CrossRef]

- Godzimirski, J.; Komorek, A.; Komorek, Z. Fatigue life of adhesive joints under shear load. Biul. WAT 2009, 3, 17–27. [Google Scholar]

- Godzimirski, J. (Ed.) Adhesive Materials. Application in the Repair of Technical Equipment; WNT: Warszawa, Poland, 2010. [Google Scholar]

- da Silva, L.F.M.; Adams, R.D. Adhesive joints at high and low temperatures using similar and dissimilar adherends and dual adhesives. Int. J. Adhes. Adhes. 2007, 27, 216–226. [Google Scholar] [CrossRef]

- Al-Mosawe, A.; Al-Mahaidi, R. Temperature Effects on the Fatigue Life and Tensile Strength of Structural Adhesives. In Proceedings of the IOP Conference Series. Materials Science and Engineering, Kerbala, Iraq, 4–6 November 2019; IOP Publishing: Bristol, UK, 2020; Volume 71. [Google Scholar] [CrossRef]

- Rośkowicz, M.; Godzimirski, J.; Komorek, A.; Jasztal, M. The Effect of Adhesive Layer Thickness on Joint Static Strength. Materials 2021, 18, 1499. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M.; Campilho, R.D.S.G. The Effect of Adhesive Thickness on the Mechanical Behavior of a Structural Polyurethane Adhesive. J. Adhes 2015, 91, 331–346. [Google Scholar] [CrossRef]

- Chang, L.; Zhang, Y.; Liu, Y.; Fang, J.; Luan, W.; Yang, X.; Zhang, W. Preparation and characterization of tungsten/epoxy composites for γ-rays radiation shielding. Nucl. Instrum. Methods. Phys. Res. B 2015, 356–357, 88–93. [Google Scholar] [CrossRef]

- Matykiewicz, D. Hybrid Epoxy Composites with Both Powder and Fiber Filler: A Review of Mechanical and Thermomechanical Properties. Materials 2020, 13, 1802. [Google Scholar] [CrossRef]

- Dębska, B.; Lichołai, L.; Szyszka, J. Innovative composite on the basis of an aerogel mat with an epoxy resin modified with PET waste and PCM. E3S Web Conf. 2018, 44, 00031. [Google Scholar] [CrossRef]

- Martin-Gallego, M.; Lopez-Hernandez, E.; Pinto, J.; Rodriguez-Perez, M.A.; Lopez-Manchado, M.A.; Verdejo, R. Transport Properties of One-Step Compression Molded Epoxy Nanocomposite Foams. Polymers 2019, 11, 756. [Google Scholar] [CrossRef] [PubMed]

- Pagacz, J.; Pielichowski, K. Modification of phyllosilicates for applications in nanotechnology. Chemia 2007, 133–147. [Google Scholar]

- Godzimirski, J.; Rośkowicz, M.; Komorek, A. Fatigue durability of Epidian 57. Polimery 2008, 10, 737–742. [Google Scholar] [CrossRef]

- Xue, H.; Wagner, D.; Ranc, N.; Bayraktar, E. Thermographic Analysis in Ultrasonic Fatigue Tests. In Fatigue & Fracture of Engineering Materials & Structures; Wiley-Blackwell: Hoboken, NJ, USA, 2006; Volume 29, pp. 573–580. [Google Scholar]

| Polymer | Epidian 57 + Z1 | |||||

|---|---|---|---|---|---|---|

| Additive | - | Tungsten | Micronal | Montmorillonite | Mcroballons | SiC |

| Density (g/cm3) | 1.157 | 1.281 | 1.012 | 1.218 | 0.887 | 1.236 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Komorek, A.; Szczepaniak, R.; Przybyłek, P.; Komorek, K.; Komorek, Z.; Godzimirski, J.; Zbrowski, A. Temperature Rise of an Adhesive Particle-Reinforced Polymer during Fatigue Testing. Polymers 2023, 15, 742. https://doi.org/10.3390/polym15030742

Komorek A, Szczepaniak R, Przybyłek P, Komorek K, Komorek Z, Godzimirski J, Zbrowski A. Temperature Rise of an Adhesive Particle-Reinforced Polymer during Fatigue Testing. Polymers. 2023; 15(3):742. https://doi.org/10.3390/polym15030742

Chicago/Turabian StyleKomorek, Andrzej, Robert Szczepaniak, Paweł Przybyłek, Kacper Komorek, Zenon Komorek, Jan Godzimirski, and Andrzej Zbrowski. 2023. "Temperature Rise of an Adhesive Particle-Reinforced Polymer during Fatigue Testing" Polymers 15, no. 3: 742. https://doi.org/10.3390/polym15030742

APA StyleKomorek, A., Szczepaniak, R., Przybyłek, P., Komorek, K., Komorek, Z., Godzimirski, J., & Zbrowski, A. (2023). Temperature Rise of an Adhesive Particle-Reinforced Polymer during Fatigue Testing. Polymers, 15(3), 742. https://doi.org/10.3390/polym15030742