Simulated Environmental Conditioning of PHB Composites Reinforced with Barley Fibres to Determine the Viability of Their Use as Plastics for the Agriculture Sector

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Composite Compounding

2.2.2. Sample Processing

2.2.3. Sample Conditioning Prior Characterisation

2.2.4. Simulated Environmental Conditioning

2.2.5. Optical Observation of the Samples

2.2.6. Mechanical Characterisation

2.2.7. Water Contact Angle Measurements

2.2.8. Water Uptake Behaviour

2.2.9. Morphological Study of the Fracture of Tensile Specimens

2.2.10. Statistic Test

3. Results and Discussion

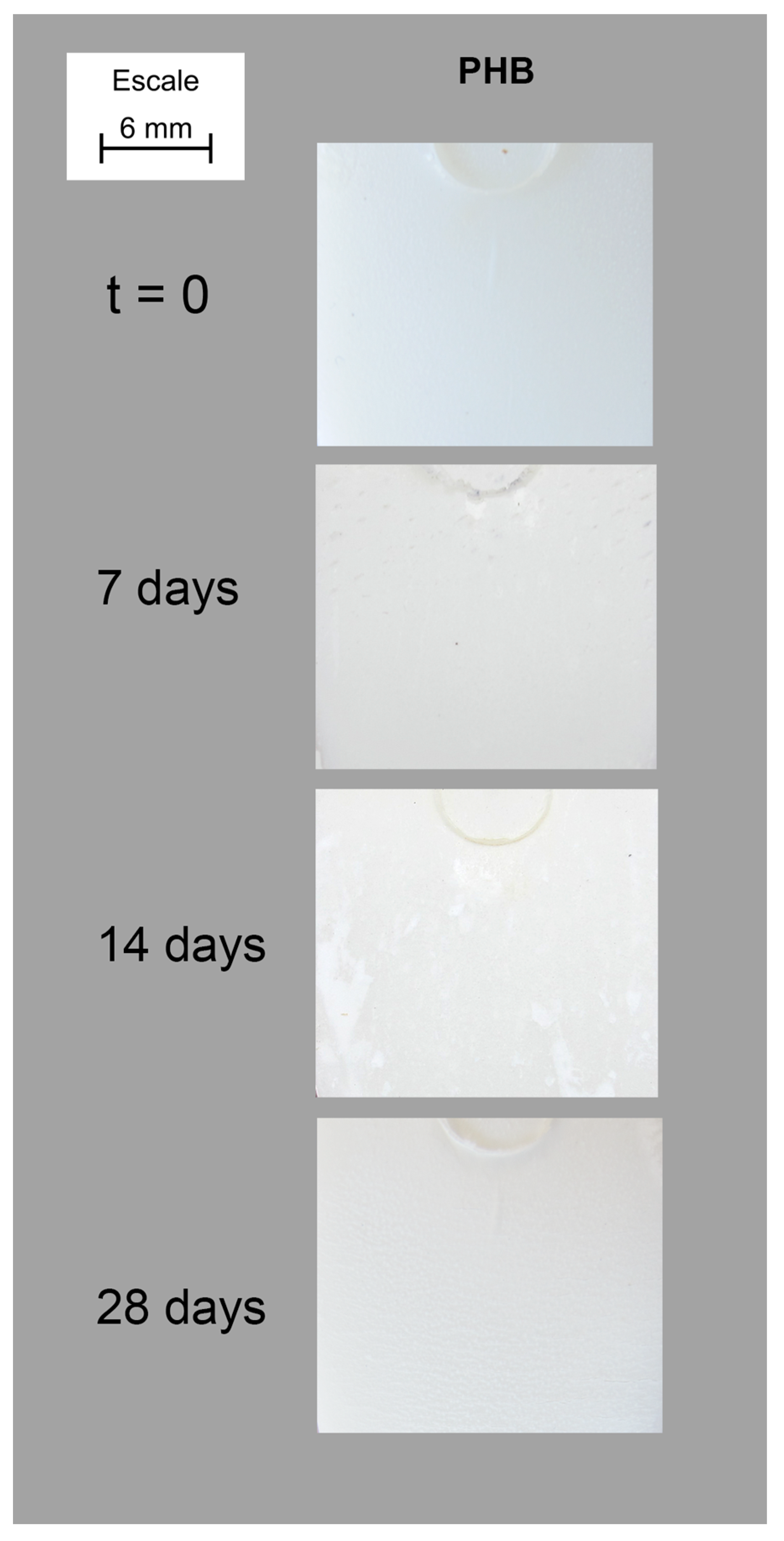

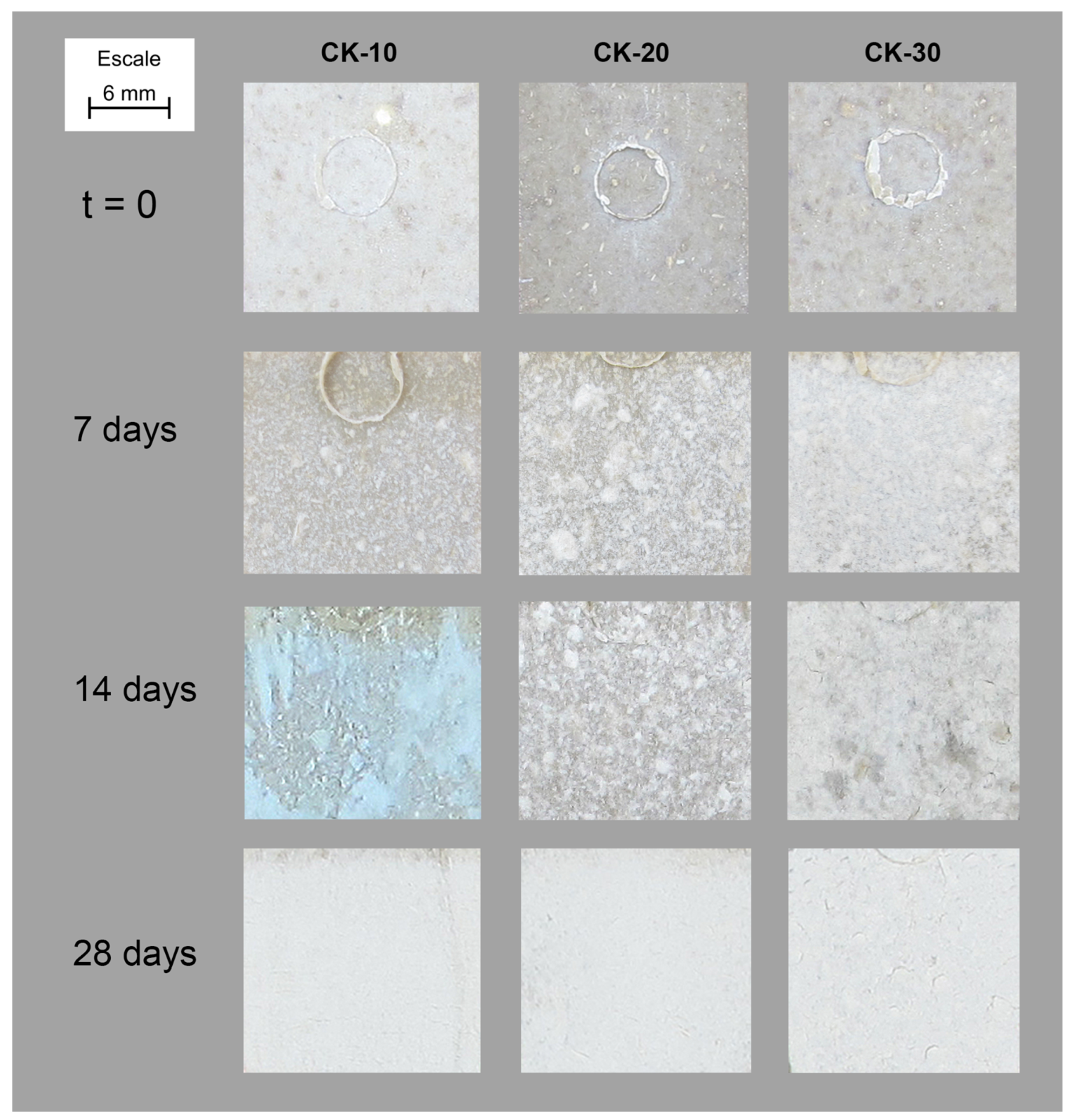

3.1. Surface Observation

3.2. Water Contact Angle

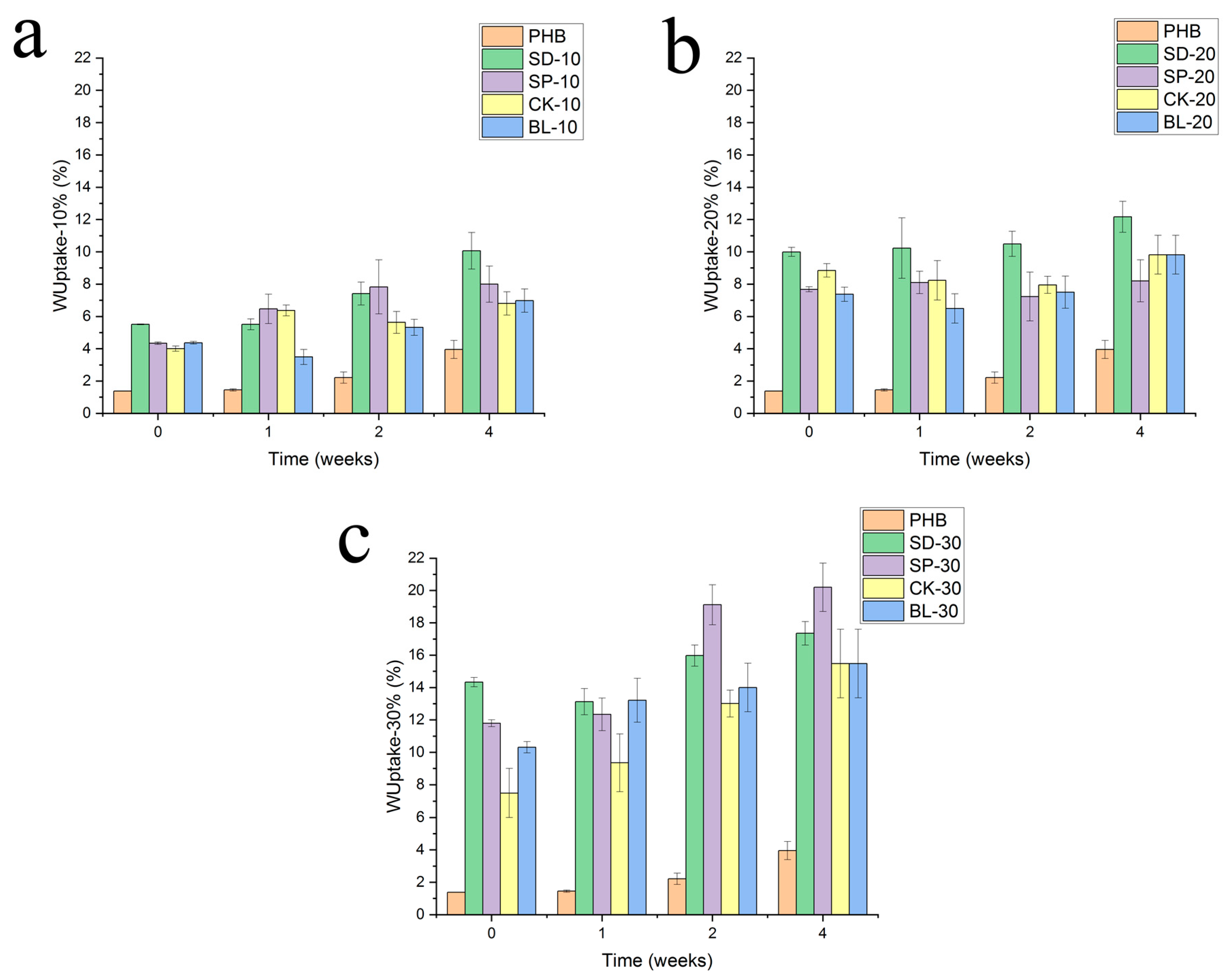

3.3. Water Uptake Behaviour

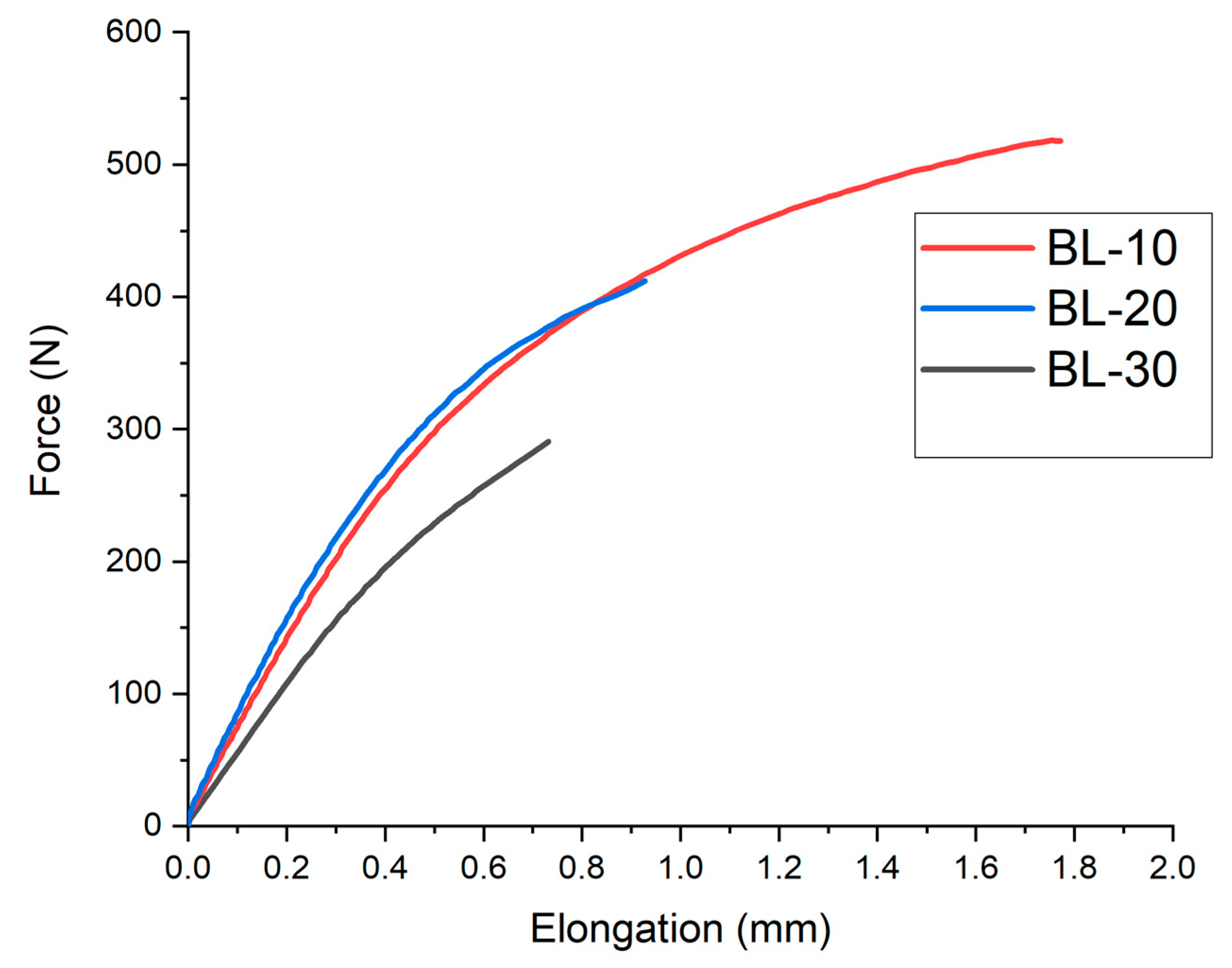

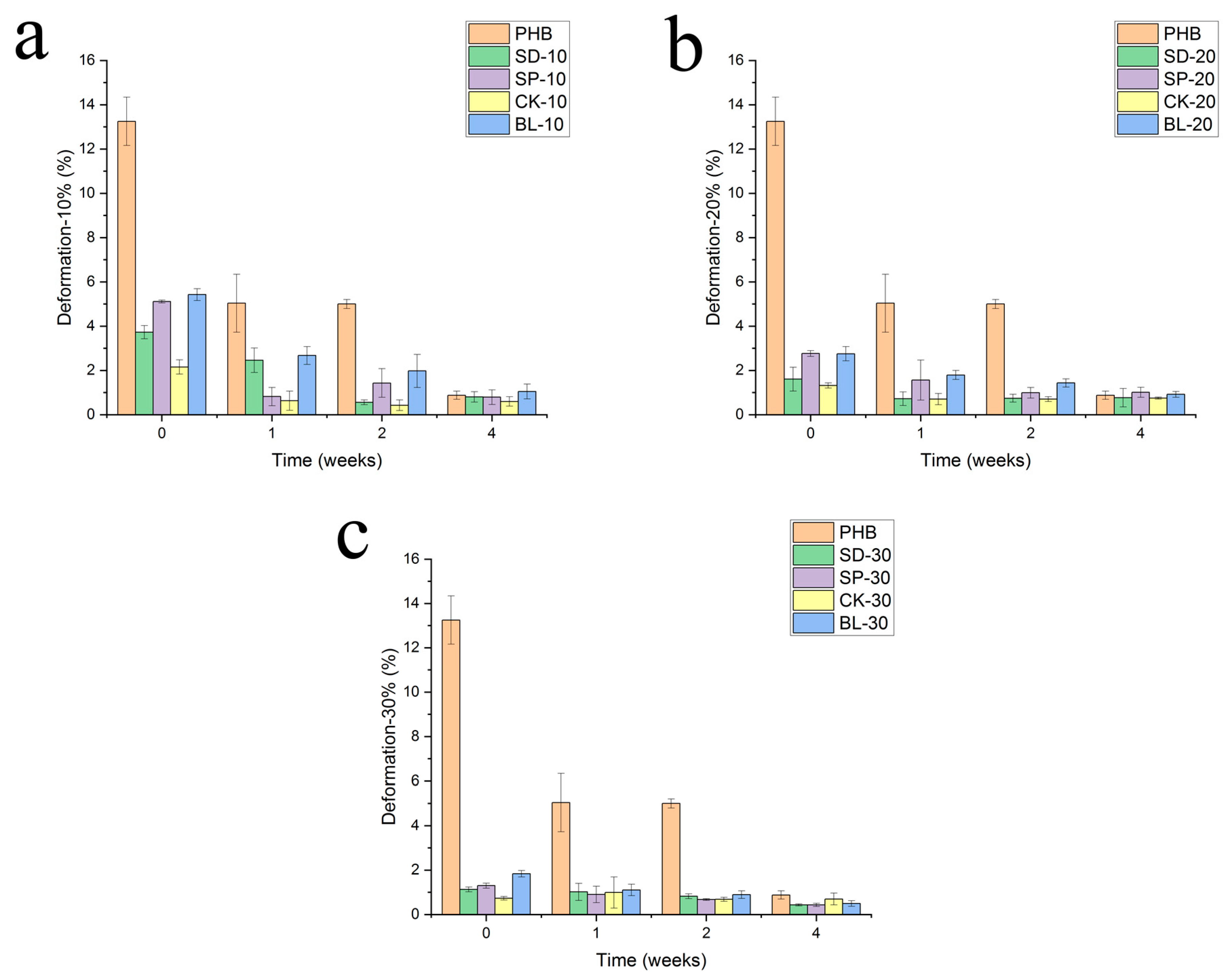

3.4. Mechanical Performance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Garlotta, D. A Literature Review of Poly(Lactic Acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Kumar, R.; Yakubu, M.K.; Anandjiwala, R.D. Biodegradation of flax fiber reinforced poly lactic acid. Express Polym. Lett. 2010, 4, 423–430. [Google Scholar] [CrossRef]

- McKeown, P.; Jones, M.D. The Chemical Recycling of PLA: A Review. Sustain. Chem. 2020, 1, 1. [Google Scholar] [CrossRef]

- Thunwall, M.; Kuthanová, V.; Boldizar, A.; Rigdahl, M. Film blowing of thermoplastic starch. Carbohydr. Polym. 2008, 71, 583–590. [Google Scholar] [CrossRef]

- Basiak, E.; Lenart, A.; Debeaufort, F. How Glycerol and Water Contents Affect the Structural and Functional Properties of Starch-Based Edible Films. Polymers 2018, 10, 412. [Google Scholar] [CrossRef] [PubMed]

- McAdam, B.; Fournet, M.B.; McDonald, P.; Mojicevic, M. Production of Polyhydroxybutyrate (PHB) and Factors Impacting Its Chemical and Mechanical Characteristics. Polymers 2020, 12, 2908. [Google Scholar] [CrossRef]

- Holmes, P.A. Applications of PHB—A microbially produced biodegradable thermoplastic. Phys. Technol. 1985, 16, 32–36. [Google Scholar] [CrossRef]

- Nygård, P.; Tanem, B.; Karlsen, T.; Brachet, P.; Leinsvang, B. Extrusion-based wood fibre–PP composites: Wood powder and pelletized wood fibres—A comparative study. Compos. Sci. Technol. 2008, 68, 3418–3424. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Yang, H.-S.; Kim, H.-J.; Jeong, C.-S.; Lim, B.-S.; Lee, J.-N. Creep behavior and manufacturing parameters of wood flour filled polypropylene composites. Compos. Struct. 2004, 65, 459–469. [Google Scholar] [CrossRef]

- Cobut, A.; Sehaqui, H.; Berglund, L.A. Cellulose Nanocomposites by Melt Compounding of TEMPO-Treated Wood Fibres in Thermoplastic Starch Matrix. Bioresources 2014, 9, 3276–3289. [Google Scholar] [CrossRef]

- Liu, W.; Xie, T.; Qiu, R. Improvement of properties for biobased composites from modified soybean oil and hemp fibers: Dual role of diisocyanate. Compos. Part A Appl. Sci. Manuf. 2016, 90, 278–285. [Google Scholar] [CrossRef]

- Vallejos, M.E.; Gironès, J.; Vilaseca, F.; Méndez, J.A.; López, A.; Mutjé, P. Polypropylene Reinforced with Hemp Strands: Study of the Influence of Propylene Modified with Maleic Anhydride as Coupling Agent. Afinidad 2006, 63(522), 94–105. [Google Scholar]

- Serrano, A.; Espinach, F.; Julian, F.; DEL Rey, R.; Mendez, J.; Mutje, P. Estimation of the interfacial shears strength, orientation factor and mean equivalent intrinsic tensile strength in old newspaper fiber/polypropylene composites. Compos. Part B Eng. 2013, 50, 232–238. [Google Scholar] [CrossRef]

- López, J.; Mutjé, P.; Carvalho, A.; Curvelo, A.; Gironès, J. Newspaper fiber-reinforced thermoplastic starch biocomposites obtained by melt processing: Evaluation of the mechanical, thermal and water sorption properties. Ind. Crops Prod. 2013, 44, 300–305. [Google Scholar] [CrossRef]

- Baroulaki, I.; Karakasi, O.; Pappa, G.; Tarantili, P.; Economides, D.; Magoulas, K. Preparation and study of plastic compounds containing polyolefins and post used newspaper fibers. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1613–1625. [Google Scholar] [CrossRef]

- Freitas, P.A.; González-Martínez, C.; Chiralt, A. Antioxidant starch composite films containing rice straw extract and cellulose fibres. Food Chem. 2023, 400, 134073. [Google Scholar] [CrossRef]

- Reixach, R.; Puig, J.; Méndez, J.A.; Gironès, J.; Espinach, F.X.; Arbat, G.; Mutjé, P. Orange Wood Fiber Reinforced Polypropylene Composites: Thermal Properties. Bioresources 2015, 10, 2156–2166. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Nicolae, C.A.; Gabor, A.R.; Trusca, R. Thermal and mechanical properties of poly(3-hydroxybutyrate) reinforced with cellulose fibers from wood waste. Ind. Crops Prod. 2020, 145, 112071. [Google Scholar] [CrossRef]

- Fiorentini, C.; Bassani, A.; Garrido, G.D.; Merino, D.; Perotto, G.; Athanassiou, A.; Peräntie, J.; Halonen, N.; Spigno, G. High-pressure autohydrolysis process of wheat straw for cellulose recovery and subsequent use in PBAT composites preparation. Biocatal. Agric. Biotechnol. 2022, 39, 102282. [Google Scholar] [CrossRef]

- Somseemee, O.; Sae-Oui, P.; Siriwong, C. Reinforcement of surface-modified cellulose nanofibrils extracted from Napier grass stem in natural rubber composites. Ind. Crops Prod. 2021, 171, 113881. [Google Scholar] [CrossRef]

- Shahril, S.; Ridzuan, M.; Majid, M.A.; Bariah, A.; Rahman, M.; Narayanasamy, P. Alkali treatment influence on cellulosic fiber from Furcraea foetida leaves as potential reinforcement of polymeric composites. J. Mater. Res. Technol. 2022, 19, 2567–2583. [Google Scholar] [CrossRef]

- Mehrez, I.; Hachem, H.; Jemni, A. Thermal insulation potential of wood-cereal straws/plaster composite. Case Stud. Constr. Mater. 2022, 17, e01353. [Google Scholar] [CrossRef]

- Fortunati, E.; Benincasa, P.; Balestra, G.; Luzi, F.; Mazzaglia, A.; Del Buono, D.; Puglia, D.; Torre, L. Revalorization of barley straw and husk as precursors for cellulose nanocrystals extraction and their effect on PVA_CH nanocomposites. Ind. Crops Prod. 2016, 92, 201–217. [Google Scholar] [CrossRef]

- Puglia, D.; Luzi, F.; Lilli, M.; Sbardella, F.; Pauselli, M.; Torre, L.; Benincasa, P. Straw fibres from barley hybrid lines and their reinforcement effect in polypropylene based composites. Ind. Crops Prod. 2020, 154, 112736. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, S.; Wang, Q.; Ji, X.; Yang, G.; Chen, J.; Fatehi, P. Strong, ductile and biodegradable polylactic acid/lignin-containing cellulose nanofibril composites with improved thermal and barrier properties. Ind. Crops Prod. 2021, 171, 113898. [Google Scholar] [CrossRef]

- Feldman, D. Polyer Weathering: Photo-Oxidation. J. Polym. Environ. 2002, 10, 163–173. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Tarrés, Q.; Mutjé, P.; Delgado-Aguilar, M.; Méndez, J.A.; Espinach, F.X. Impact Strength and Water Uptake Behavior of Bleached Kraft Softwood-Reinforced PLA Composites as Alternative to PP-Based Materials. Polymers 2020, 12, 2144. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Méndez, J.A.; Espinach, F.X.; Tarrés, Q.; Ardanuy, M.; Mutjé, P. Impact Strength and Water Uptake Behaviors of Fully Bio-Based PA11-SGW Composites. Polymers 2018, 10, 717. [Google Scholar] [CrossRef]

- Cheung, H.-Y.; Lau, K.-T.; Lu, T.-P.; Hui, D. A critical review on polymer-based bio-engineered materials for scaffold development. Compos. Part B Eng. 2006, 38, 291–300. [Google Scholar] [CrossRef]

- Delgado-Aguilar, M.; Julián, F.; Tarrés, Q.; Méndez, J.; Mutjé, P.; Espinach, F. Bio composite from bleached pine fibers reinforced polylactic acid as a replacement of glass fiber reinforced polypropylene, macro and micro-mechanics of the Young’s modulus. Compos. Part B Eng. 2017, 125, 203–210. [Google Scholar] [CrossRef]

- Granda, L.; Espinach, F.; Méndez, J.A.; Tresserras, J.; Delgado-Aguilar, M.; Mutjé, P. Semichemical fibres of Leucaena collinsii reinforced polypropylene composites: Young’s modulus analysis and fibre diameter effect on the stiffness. Compos. Part B Eng. 2016, 92, 332–337. [Google Scholar] [CrossRef]

| Phase | Starting Time (min) | Ending Time (min) | Radiation Power (W·m−2) | Temperature (°C) | Relative Humidity (%) | Rain (Yes/No) |

|---|---|---|---|---|---|---|

| 1 | 0 | 101 | 42 | 63 | 50 | no |

| 2 | 102 | 119 | 42 | --* | 50 | yes |

| 3 | 120 | 159 | 0 | --** | 95 | no |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliver-Ortega, H.; Julián, F.; Espinach, F.X.; Méndez, J.A. Simulated Environmental Conditioning of PHB Composites Reinforced with Barley Fibres to Determine the Viability of Their Use as Plastics for the Agriculture Sector. Polymers 2023, 15, 579. https://doi.org/10.3390/polym15030579

Oliver-Ortega H, Julián F, Espinach FX, Méndez JA. Simulated Environmental Conditioning of PHB Composites Reinforced with Barley Fibres to Determine the Viability of Their Use as Plastics for the Agriculture Sector. Polymers. 2023; 15(3):579. https://doi.org/10.3390/polym15030579

Chicago/Turabian StyleOliver-Ortega, Helena, Fernando Julián, Francesc Xavier Espinach, and José Alberto Méndez. 2023. "Simulated Environmental Conditioning of PHB Composites Reinforced with Barley Fibres to Determine the Viability of Their Use as Plastics for the Agriculture Sector" Polymers 15, no. 3: 579. https://doi.org/10.3390/polym15030579

APA StyleOliver-Ortega, H., Julián, F., Espinach, F. X., & Méndez, J. A. (2023). Simulated Environmental Conditioning of PHB Composites Reinforced with Barley Fibres to Determine the Viability of Their Use as Plastics for the Agriculture Sector. Polymers, 15(3), 579. https://doi.org/10.3390/polym15030579