Preparation and Performance Investigation of Epoxy Resin-Based Permeable Concrete Containing Ceramsite

Abstract

:1. Introduction

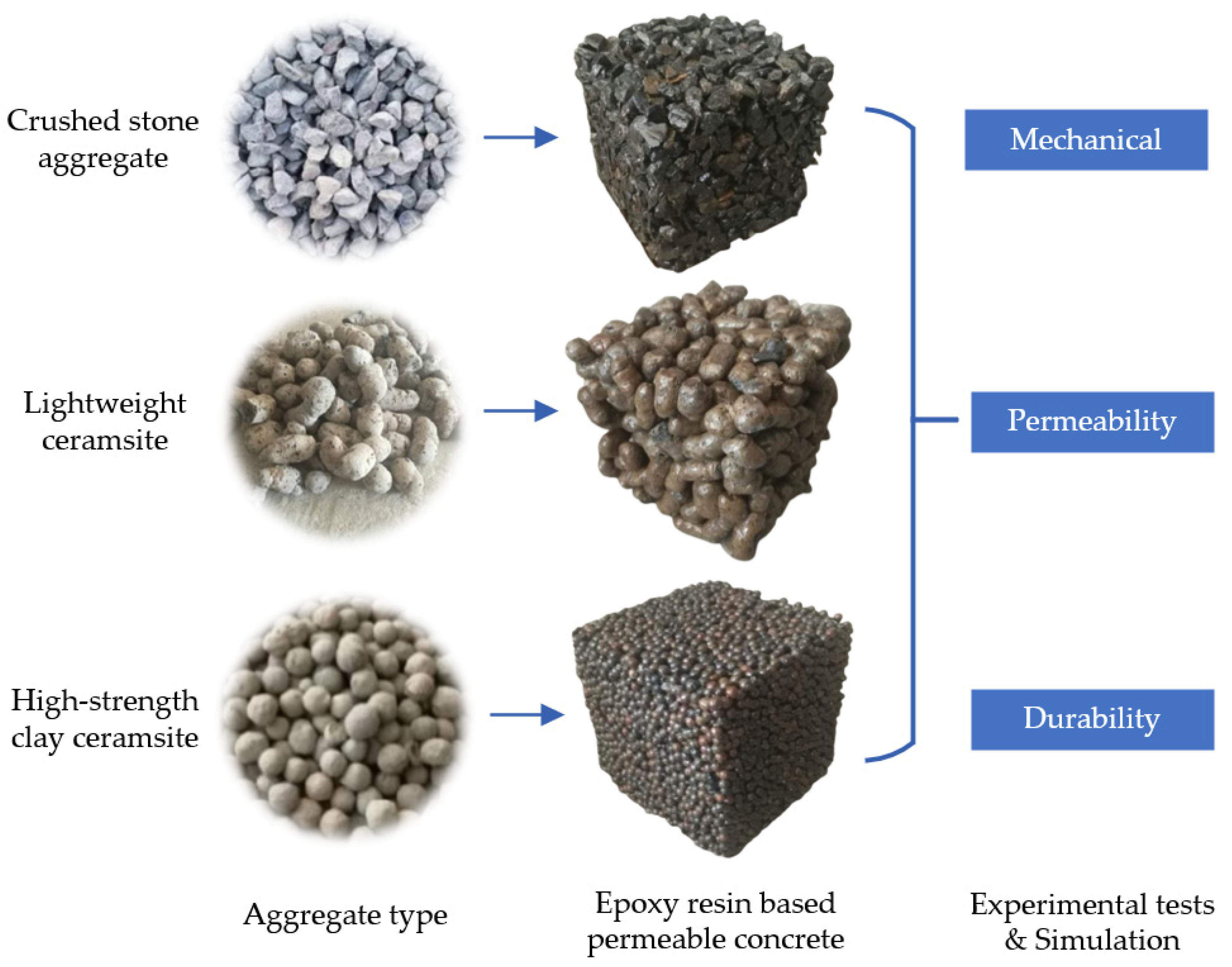

2. Materials and Methods

2.1. Raw Materials

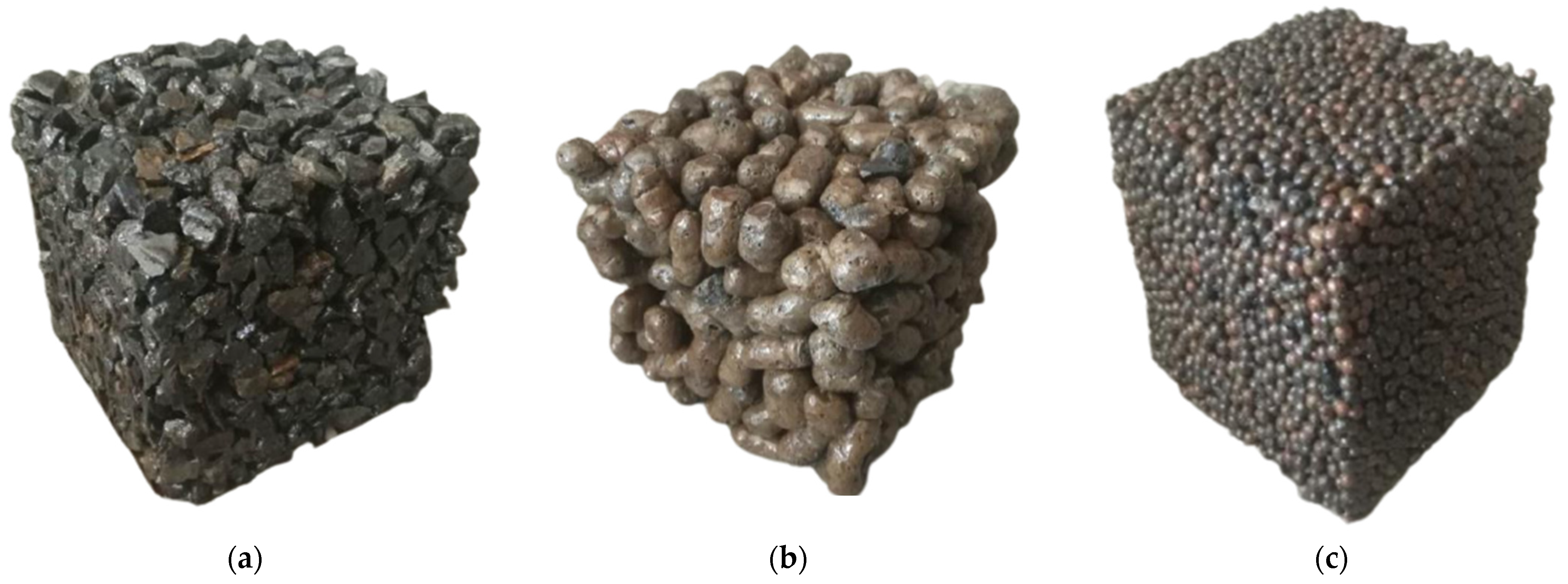

2.2. Mix Design and Specimen Preparation of Epoxy Resin-Based Permeable Concrete

2.3. Experimental Tests

3. Results and Discussion

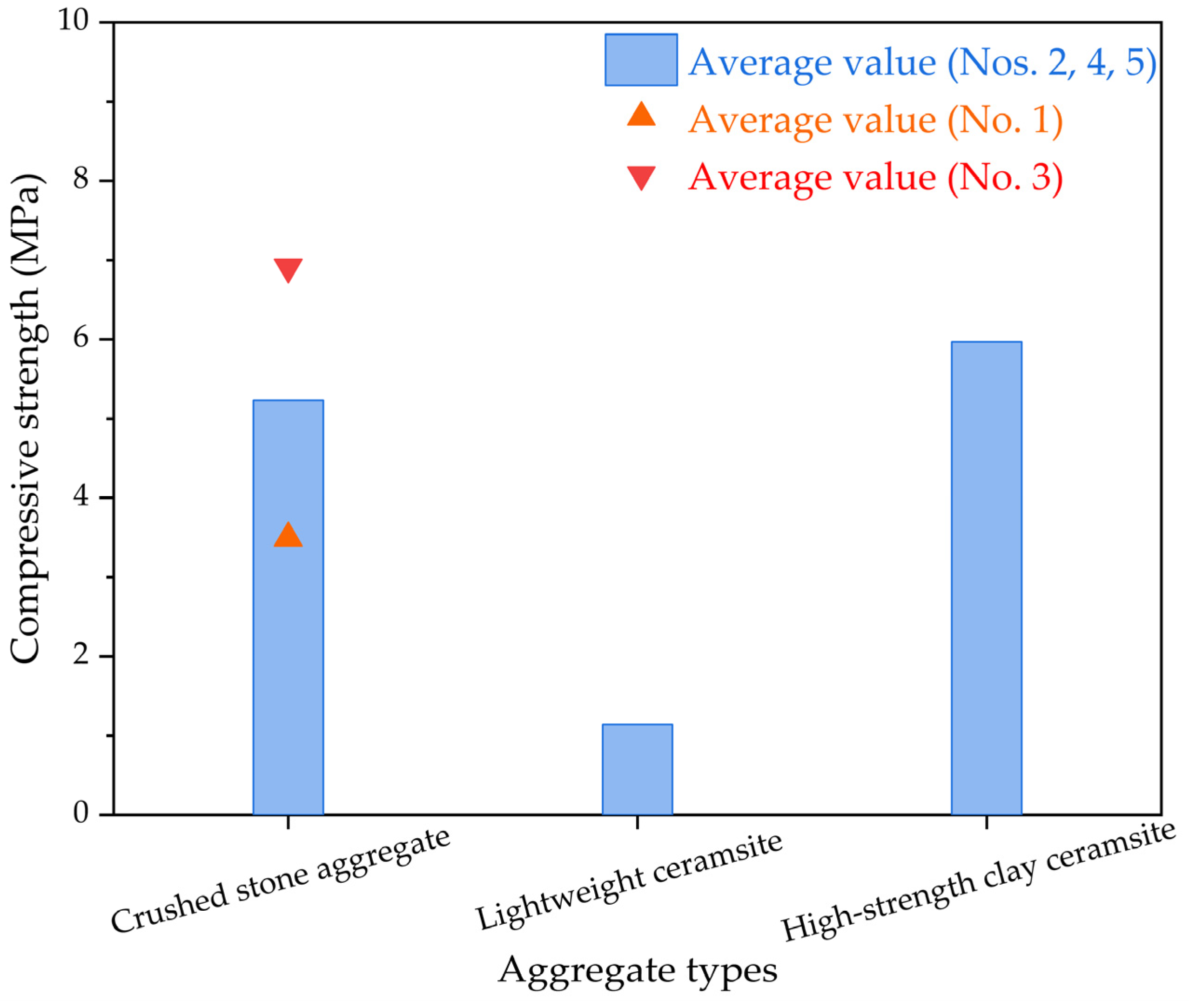

3.1. Compression Stress Analysis of Epoxy Resin-Based Permeable Concrete Considering Aggregate Type

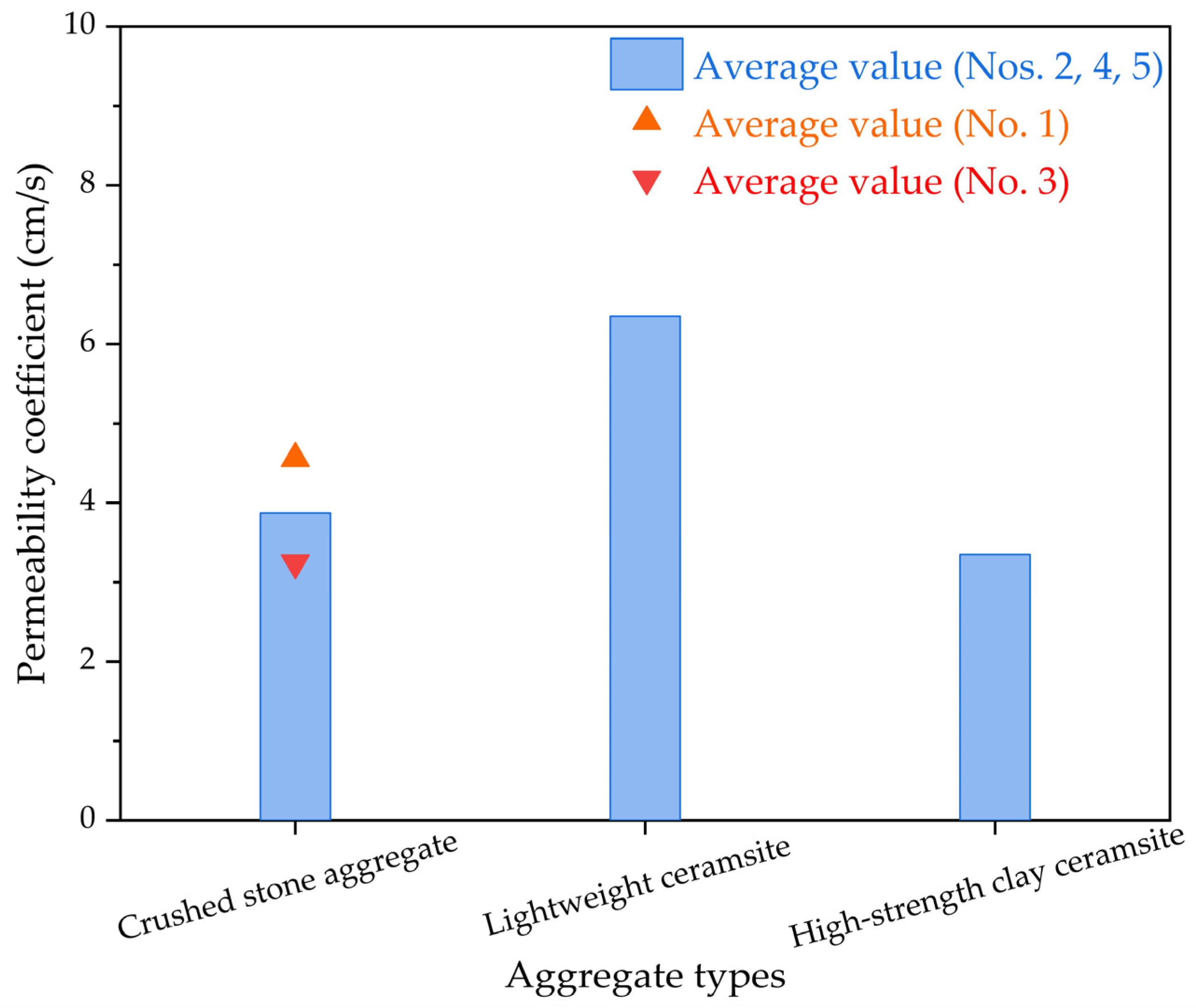

3.2. Permeability Coefficient Analysis of Epoxy Resin-Based Permeable Concrete Considering Aggregate Type

3.3. Exploration on Compressive Strength Simulation of Epoxy Resin-Based Permeable Concrete with Ceramsite Based on Discrete Element Method

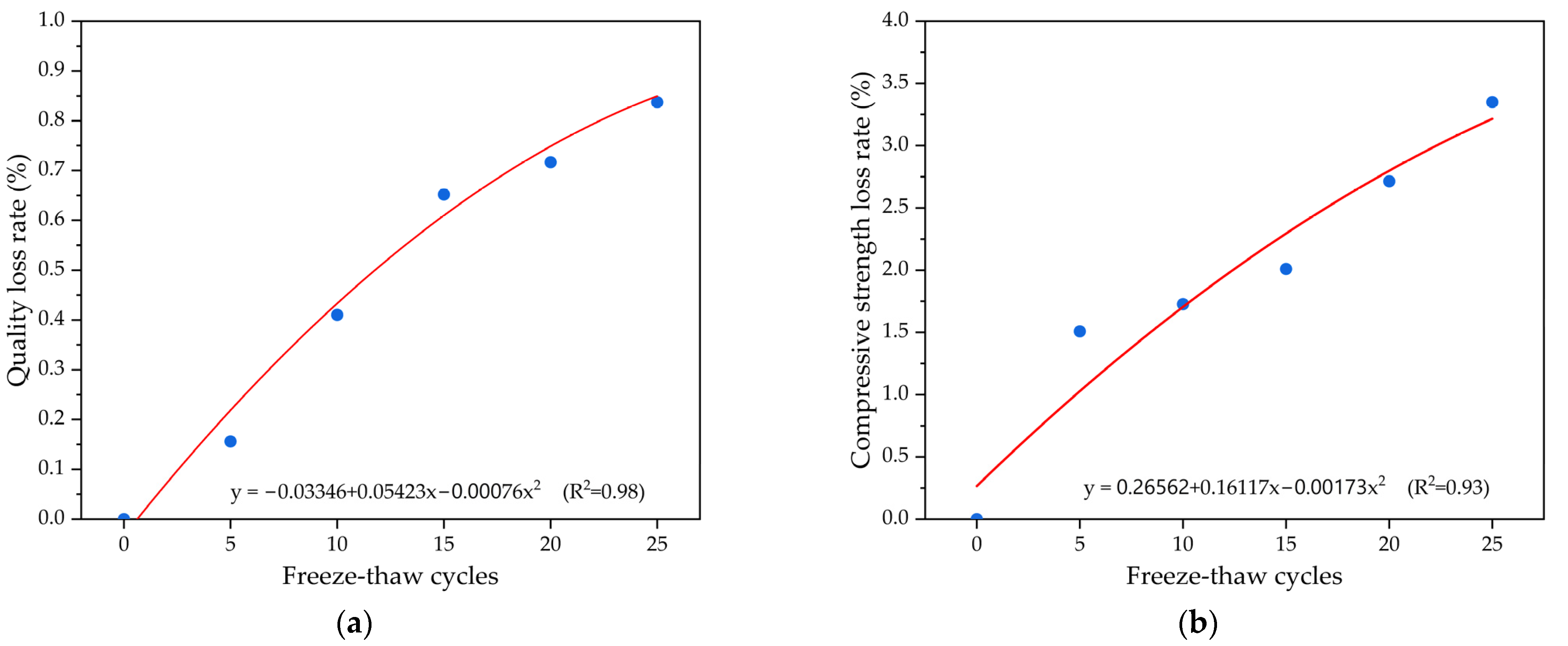

3.4. Freeze-Thaw Durability Analysis of Epoxy Resin-Based Permeable Concrete with Ceramsite

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, H.T.; Wen, C.C.; Wang, Z.Q.; Li, L. Study on the Permeability of Recycled Aggregate Pervious Concrete with Fibers. Materials 2020, 13, 321. [Google Scholar] [CrossRef] [PubMed]

- Xie, H.Z.; Li, L.G.; Liu, F.; Kwan, A.K.H. Recycling Old Concrete as Waste Concrete Powder for Use in Pervious Concrete: Effects on Permeability, Strength and Eco-Friendliness. Buildings 2022, 12, 2172. [Google Scholar] [CrossRef]

- Li, H.; Yang, J.; Yu, X.Q.; Zhang, Y.; Zhang, L. Permeability prediction of pervious concrete based on mix proportions and pore characteristics. Constr. Build. Mater. 2023, 395, 132247. [Google Scholar] [CrossRef]

- Zhang, Y. Review of Influencing Factors for Porous Cement Concrete Strength. J. Munic. Technol. 2022, 40, 82–92. [Google Scholar] [CrossRef]

- Yang, Q.X.; Gao, Z.Q.; Beecham, S. A Sustainable Approach to Cleaning Porous and Permeable Pavements. Sustainability 2022, 14, 14583. [Google Scholar] [CrossRef]

- Wu, Z.G.; Xu, J.Q.; Zhang, Z.Y.; Liu, X.X.; Wang, J.Z. Research on Properties of Color Permeable Asphalt Binder and Mixture. J. Munic. Technol. 2022, 40, 50–54. [Google Scholar] [CrossRef]

- Chen, J.Q.; Chu, R.X.; Wang, H.; Zhang, L.C.; Chen, X.D.; Du, Y.F. Alleviating urban heat island effect using high-conductivity permeable concrete pavement. J. Clean. Prod. 2019, 237, 117722. [Google Scholar] [CrossRef]

- Li, L.; Wang, M.X.; Xiao, L.L.; He, A.Z.; Yan, C.Q. Experimental Study on Improving Anti-clogging Performance of SEAL-80 Permeable Concrete. J. Munic. Technol. 2022, 40, 71–75. [Google Scholar] [CrossRef]

- Zhu, H.B.; Chen, H.Z.; Fu, Z.H.; Guo, Z.F.; Liu, P.; Chen, Y. Experimental Study on Axial Compressive Load-Bearing Performance of RC Short Columns Strengthened by All-Light Ceramsite Concrete. Appl. Sci. 2022, 12, 11206. [Google Scholar] [CrossRef]

- Liao, Y.X.; Lv, Y.R.; Yuan, S.J.; Li, Q.L. Research on Application of Calcined Phyllite Ceramsite in Thermal Resistance Asphalt Pavement. J. Munic. Technol. 2022, 40, 208–212. [Google Scholar] [CrossRef]

- Bu, C.M.; Yang, H.Y.; Liu, L.; Zhu, D.X.; Sun, Y.; Yu, L.W.; Ouyang, Y.H.; Cao, X.M.; Wei, Q.K. Quantification of Ceramsite Granules in Lightweight Concrete Panels through an Image Analysis Technique. Materials 2022, 15, 1063. [Google Scholar] [CrossRef]

- Zhu, H.B.; Fu, Z.H.; Wang, Y.; Zhang, N. Study on splitting tensile strength of interface between the full lightweight ceramsite concrete and ordinary concrete. Case Stud. Constr. Mat. 2023, 18, 01829. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, F.Z.; Liu, P.; Yang, L.; Hu, S.G.; Zhang, W.Q. Preparation, Physicochemical Properties, and Long-Term Performance of Photocatalytic Ceramsite Sand in Cementitious Materials. Appl. Sci. 2017, 7, 828. [Google Scholar] [CrossRef]

- Ma, Q.Y.; Shi, Y.H.; Ma, D.D.; Huang, K.; Yang, X. Effect of sludge ceramsite particle grade on static and dynamic mechanical properties of alkali-activated slag lightweight concrete at early age. J. Build. Eng. 2023, 69, 106330. [Google Scholar] [CrossRef]

- Shang, S.; Fan, H.H.; Li, Y.X.; Li, L.; Li, Z. Preparation of Lightweight Ceramsite from Solid Waste Using SiC as a Foaming Agent. Materials 2022, 15, 325. [Google Scholar] [CrossRef]

- Zang, J.W.; Pan, C.G.; Hu, Y.; Qu, S.Y. Preparation of Ceramsite Using Dehydrated Silt Soil and Its Performance on Compressive Strength of Ceramsite Concrete Block. Sustainability 2023, 15, 9134. [Google Scholar] [CrossRef]

- Wang, Y.S.; Liu, J.T.; Dong, B.Q.; Ren, J.; Fang, G.H. Stabilization/solidification of sand-washing slurry used for porous cold-bonded ceramsite. Cem. Concr. Comp. 2022, 134, 104771. [Google Scholar] [CrossRef]

- Gao, S.; Huang, K.N.; Chu, W.C.; Wang, W.S. Feasibility Study of Pervious Concrete with Ceramsite as Aggregate Considering Mechanical Properties, Permeability, and Durability. Materials 2023, 16, 5127. [Google Scholar] [CrossRef]

- Zhang, Y.T.; Sun, X.W. Synergistic effects of nano-silica and fly ash on the mechanical properties and durability of internal-cured concrete incorporating artificial shale ceramsite. J. Build. Eng. 2023, 66, 105905. [Google Scholar] [CrossRef]

- Kong, L.J.; Zhang, B.S.; Ge, Y.; Yuan, J. Effect of ceramsite structure on microstructure of interfacial zone and durability of combined aggregate concrete. J. Wuhan Univ. Technol. 2009, 24, 145–149. [Google Scholar] [CrossRef]

- Hong, X.J.; Lee, J.C.; Ng, J.L.; Yusof, Z.M.; He, Q.; Li, Q.S. Effect of Graphene Oxide on the Mechanical Properties and Durability of High-Strength Lightweight Concrete Containing Shale Ceramsite. Materials 2023, 16, 2756. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, Q.; Teng, J.H.; Deng, P.; Sun, Y. Bond Performance of Anti-Corrosion Bar Embedded in Ceramsite Concrete in Freeze-Thaw Cycles and Corrosive Environments. Buildings 2023, 13, 884. [Google Scholar] [CrossRef]

- Nan, D.; Li, X.; Li, D.S.; Liu, Q.; Wang, B.; Gao, X.; Ma, T.; He, N.; Xu, Y.; Dong, J.H. Preparation and Anticorrosive Performance of Waterborne Epoxy Resin Composite Coating with Amino-Modified Graphene Oxide. Polymers 2023, 15, 27. [Google Scholar] [CrossRef]

- Qian, L.J.; Ye, L.J.; Qiu, Y.; Qu, S.R. Thermal degradation behavior of the compound containing phosphaphenanthrene and phosphazene groups and its flame retardant mechanism on epoxy resin. Polymer 2011, 52, 5486–5493. [Google Scholar] [CrossRef]

- Yu, L.; Chen, H.; Wang, H.Z. Tracking and Analysis of Anti-slip Performance Evolutionary of Epoxy Asphalt Pavement on Steel Bridge Decks. J. Munic. Technol. 2022, 40, 29–34. [Google Scholar] [CrossRef]

- Mishnev, M.; Korolev, A.; Ulrikh, D.; Gorechneva, A.; Sadretdinov, D.; Grinkevich, D. Solid Particle Erosion of Filled and Unfilled Epoxy Resin at Room and Elevated Temperatures. Polymers 2023, 15, 1. [Google Scholar] [CrossRef]

- Szewczak, A.; Lagod, G. Adhesion of Modified Epoxy Resin to a Concrete Surface. Materials 2022, 15, 8961. [Google Scholar] [CrossRef]

- Michels, J.; Widmann, R.; Czaderski, C.; Allahvirdizadeh, R.; Motavalli, M. Glass transition evaluation of commercially available epoxy resins used for civil engineering applications. Compos. Part B Eng. 2015, 77, 484–493. [Google Scholar] [CrossRef]

- Dai, L.H.; Li, Y.; Wang, Z.H.; Zheng, Y.Y.; Chen, M. Research on the Application of Ceramic Particles in Epoxy Anti-skid Cover. J. Munic. Technol. 2022, 40, 79–83. [Google Scholar] [CrossRef]

- Irshidat, M.R.; Al-Saleh, M.H. Effect of using carbon nanotube modified epoxy on bond-slip behavior between concrete and FRP sheets. Constr. Build. Mater. 2016, 105, 511–518. [Google Scholar] [CrossRef]

- Irshidat, M.R.; Al-Saleh, M.H.; Al-Shoubaki, M. Using carbon nanotubes to improve strengthening efficiency of carbon fiber/epoxy composites confined RC columns. Compos. Struct. 2015, 134, 523–532. [Google Scholar] [CrossRef]

- Sadowski, L.; Czarnecki, S.; Hola, J. Evaluation of the height 3D roughness parameters of concrete substrate and the adhesion to epoxy resin. Int. J. Adhes. Adhes. 2016, 67, 3–13. [Google Scholar] [CrossRef]

- Pang, B.; Zhang, Y.S.; Liu, G.J. Study on the effect of waterborne epoxy resins on the performance and microstructure of cement paste. Constr. Build. Mater. 2018, 167, 831–845. [Google Scholar] [CrossRef]

- Li, Y.Y.; Li, J.; Li, C.; Chen, A.Q.; Bai, T.; Tang, S.M.; Wu, S.P.; Gao, Y.M.; Zhu, H.B.; Feng, J.L. Strength formation mechanism and performance of steel slag self-compacting epoxy resin concrete. Constr. Build. Mater. 2022, 359, 129525. [Google Scholar] [CrossRef]

- Cao, B.J.; Zhu, S.Y.; Huang, H.F.; Zheng, X.Y.; Shen, Y.S. Development and experiment of similar materials of epoxy curing agent for tunnel structure in liquefied formation. Highw. Eng. J. 2021, 46, 15–22. [Google Scholar] [CrossRef]

- GB/T 50081-2002; Standard for Test Method of Mechanical Properties on Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2002.

- CJJ/T 135-2009; Technical Specification for Pervious Cement Concrete Pavement. China Architecture & Building Press: Beijing, China, 2009.

- GB/T 50082-2009; Standard for Test Methods of Long-term Performance and Durability of Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2009.

- Tang, H.Y.; Yan, S.M. Research on the influence of different aggregate particle size on the performance of permeable concrete. Highw. Eng. J. 2020, 45, 193–196. [Google Scholar] [CrossRef]

- Zhou, S.L.; Wang, H.; Wang, Q.S.; Wang, W.S.; Zhang, W. Mechanical properties and freeze thaw durability of low sand replacement rate pervious concrete. Highw. Eng. J. 2022, 47, 135–141. [Google Scholar] [CrossRef]

- Zhou, Y.F.; Li, W.W.; Peng, Y.X.; Tang, S.W.; Wang, L.; Shi, Y.; Li, Y.; Wang, Y.; Geng, Z.C.; Wu, K. Hydration and Fractal Analysis on Low-Heat Portland Cement Pastes Using Thermodynamics-Based Methods. Fractal Fract. 2023, 7, 606. [Google Scholar] [CrossRef]

- Peng, Y.X.; Tang, S.W.; Huang, J.S.; Tang, C.; Wang, L.; Liu, Y.F. Fractal Analysis on Pore Structure and Modeling of Hydration of Magnesium Phosphate Cement Paste. Fractal Fract. 2022, 6, 337. [Google Scholar] [CrossRef]

- Huang, J.S.; Li, W.W.; Huang, D.S.; Wang, L.; Chen, E.; Wu, C.Y.; Wang, B.S.; Deng, H.Y.; Tang, S.W.; Shi, Y.; et al. Fractal Analysis on Pore Structure and Hydration of Magnesium Oxysulfate Cements by First Principle, Thermodynamic and Microstructure-Based Methods. Fractal Fract. 2021, 5, 164. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H.; Huang, M.H.; Yin, H.B.; Jiang, K.; Xiao, K.T.; Tang, S.W. Influence of Different Alkali Sulfates on the Shrinkage, Hydration, Pore Structure, Fractal Dimension and Microstructure of Low-Heat Portland Cement, Medium-Heat Portland Cement and Ordinary Portland Cement. Fractal Fract. 2021, 5, 79. [Google Scholar] [CrossRef]

- Ma, J.C. Construction Technology Analysis and Compaction Numerical Simulation of Cement Stabilized Macadam Base. Master’s Thesis, Jilin University, Changchun, China, 2021. [Google Scholar]

- Zhao, C.H.; Li, H.L.; Peng, Y.; Jia, X.Y.; Rahman, A. Toughness Behavior of SBR Acrylate Copolymer-Modified Pervious Concrete with Single-Sized Aggregates. Materials 2021, 14, 5089. [Google Scholar] [CrossRef] [PubMed]

| Properties | Density (g/cm3) | Setting Time (h) | Tensile Strength (MPa) | Shear Strength (MPa) | |

|---|---|---|---|---|---|

| Initial | Final | ||||

| Test | 1.5 | 0.5 | 1.5 | 70.5 | 41.3 |

| Type | Density (g/cm3) | Bulk Density (g/cm3) | Crushing Value (%) | Strength (MPa) |

|---|---|---|---|---|

| Normal | 2.32 | 1.44 | 11.3 | 4.8 |

| Low-weight ceramsite | 0.37 | 0.22 | 86.4 | 0.12 |

| High-strength clay ceramsite | 1.80 | 1.10 | 10.8 | 5.2 |

| Aggregate Type | Epoxy Resin Binder/ Aggregate Ratio | Epoxy Resin Binder (kg) | Aggregate (kg) | Porosity (%) | |

|---|---|---|---|---|---|

| Ordinary crushed stone | No. 1 | 3% | 43.2 | 1440 | 32.6 |

| No. 2 | 4% | 57.6 | 1440 | 31.9 | |

| No. 3 | 5% | 72 | 1440 | 30.7 | |

| Lightweight ceramsite | No. 4 | 4% | 57.6 | 220 | 33.7 |

| High-strength clay ceramsite | No. 5 | 4% | 57.6 | 1100 | 31.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Cui, H.; Wang, H.; Wang, W.; Sui, Y.; Dong, L.; Wang, J. Preparation and Performance Investigation of Epoxy Resin-Based Permeable Concrete Containing Ceramsite. Polymers 2023, 15, 4704. https://doi.org/10.3390/polym15244704

Li S, Cui H, Wang H, Wang W, Sui Y, Dong L, Wang J. Preparation and Performance Investigation of Epoxy Resin-Based Permeable Concrete Containing Ceramsite. Polymers. 2023; 15(24):4704. https://doi.org/10.3390/polym15244704

Chicago/Turabian StyleLi, Shengjia, Honghai Cui, Haihua Wang, Wensheng Wang, Yi Sui, Liangyu Dong, and Jiaxing Wang. 2023. "Preparation and Performance Investigation of Epoxy Resin-Based Permeable Concrete Containing Ceramsite" Polymers 15, no. 24: 4704. https://doi.org/10.3390/polym15244704

APA StyleLi, S., Cui, H., Wang, H., Wang, W., Sui, Y., Dong, L., & Wang, J. (2023). Preparation and Performance Investigation of Epoxy Resin-Based Permeable Concrete Containing Ceramsite. Polymers, 15(24), 4704. https://doi.org/10.3390/polym15244704