Investigating Mechanical Properties of Fabricated Carbon-Fiber-Reinforced Composites via LCD Additive Manufacturing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fiber Preparation

2.2. Surface Modification

2.3. Fabrication via SLA-AM

2.4. Testing and Characterization

3. Results

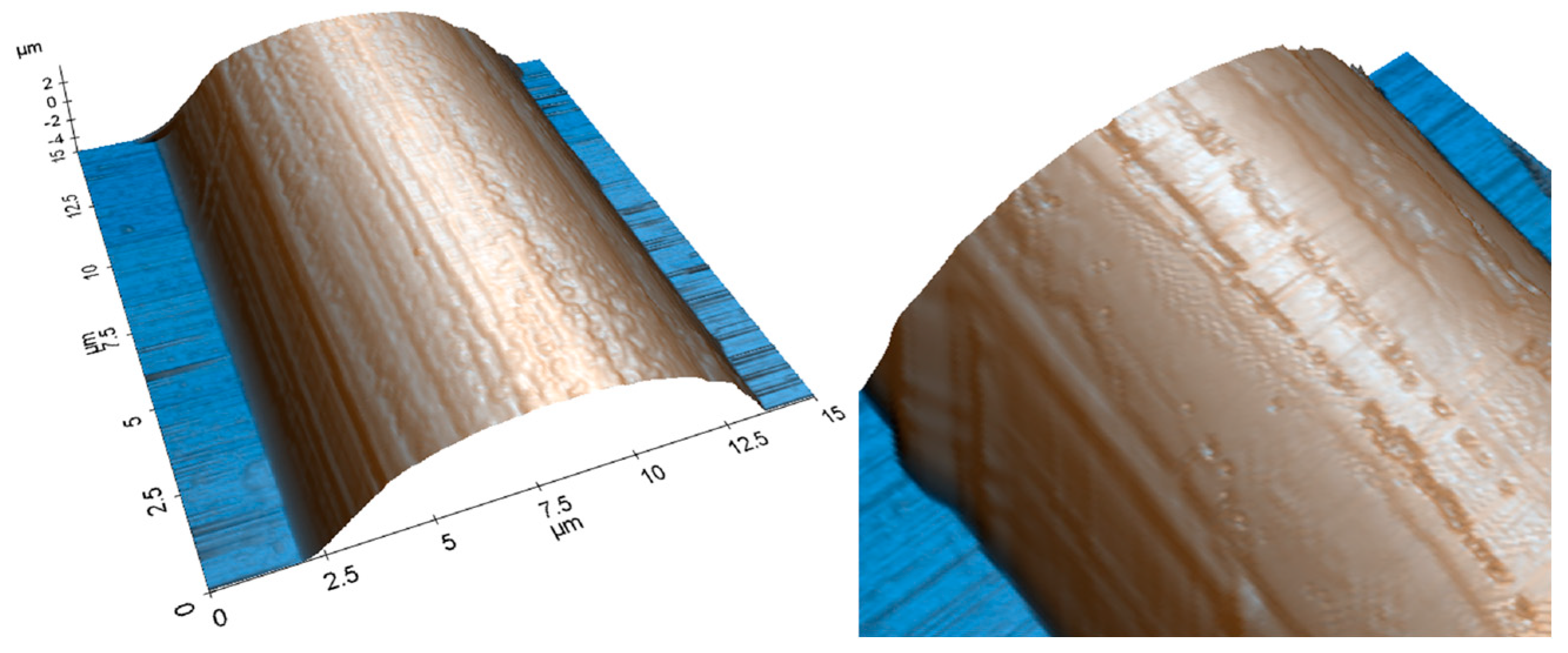

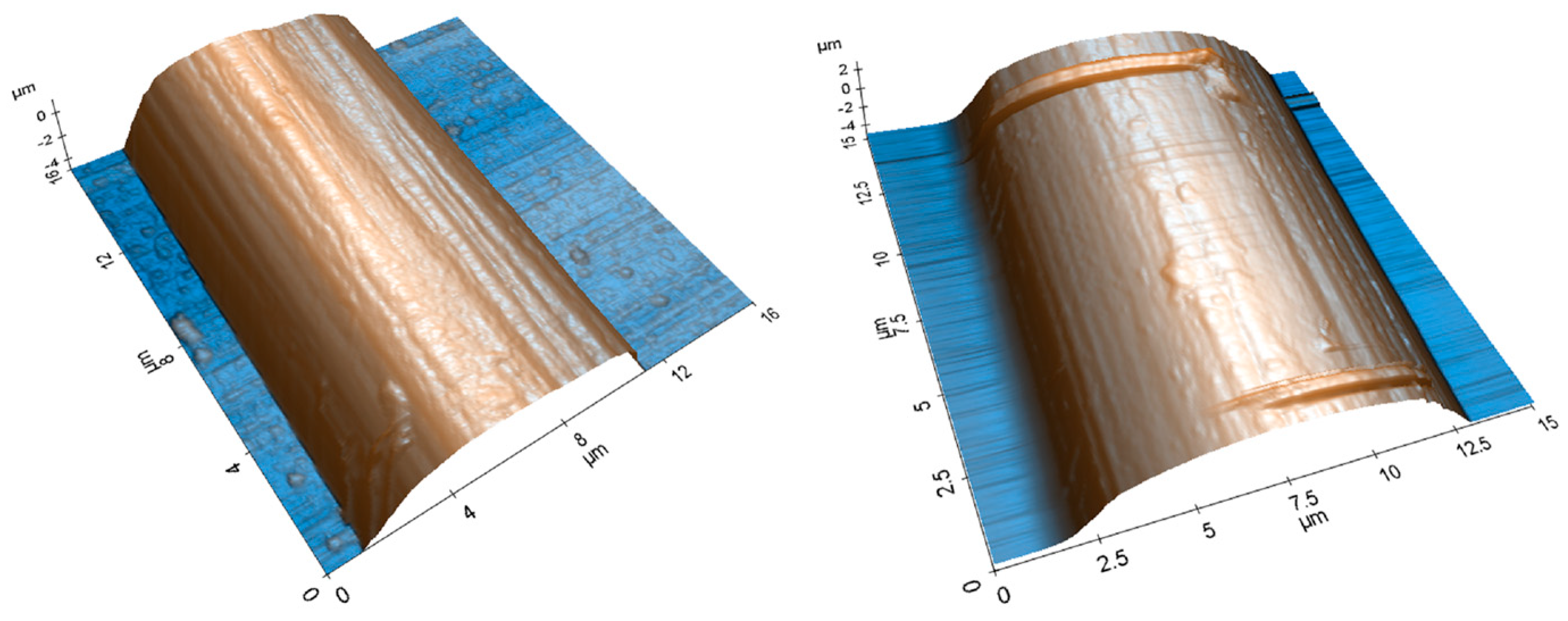

3.1. Atomic Force Microscopy

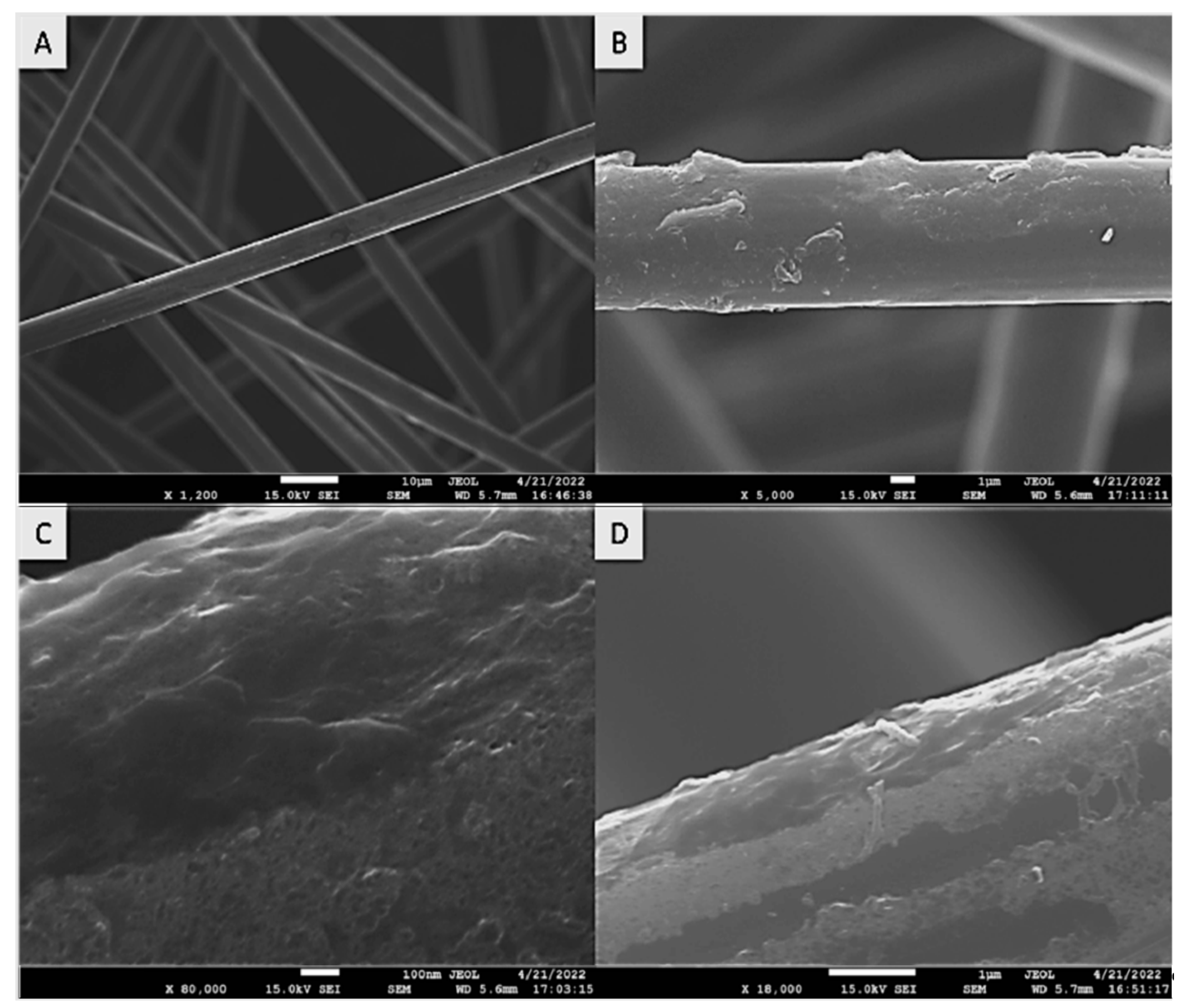

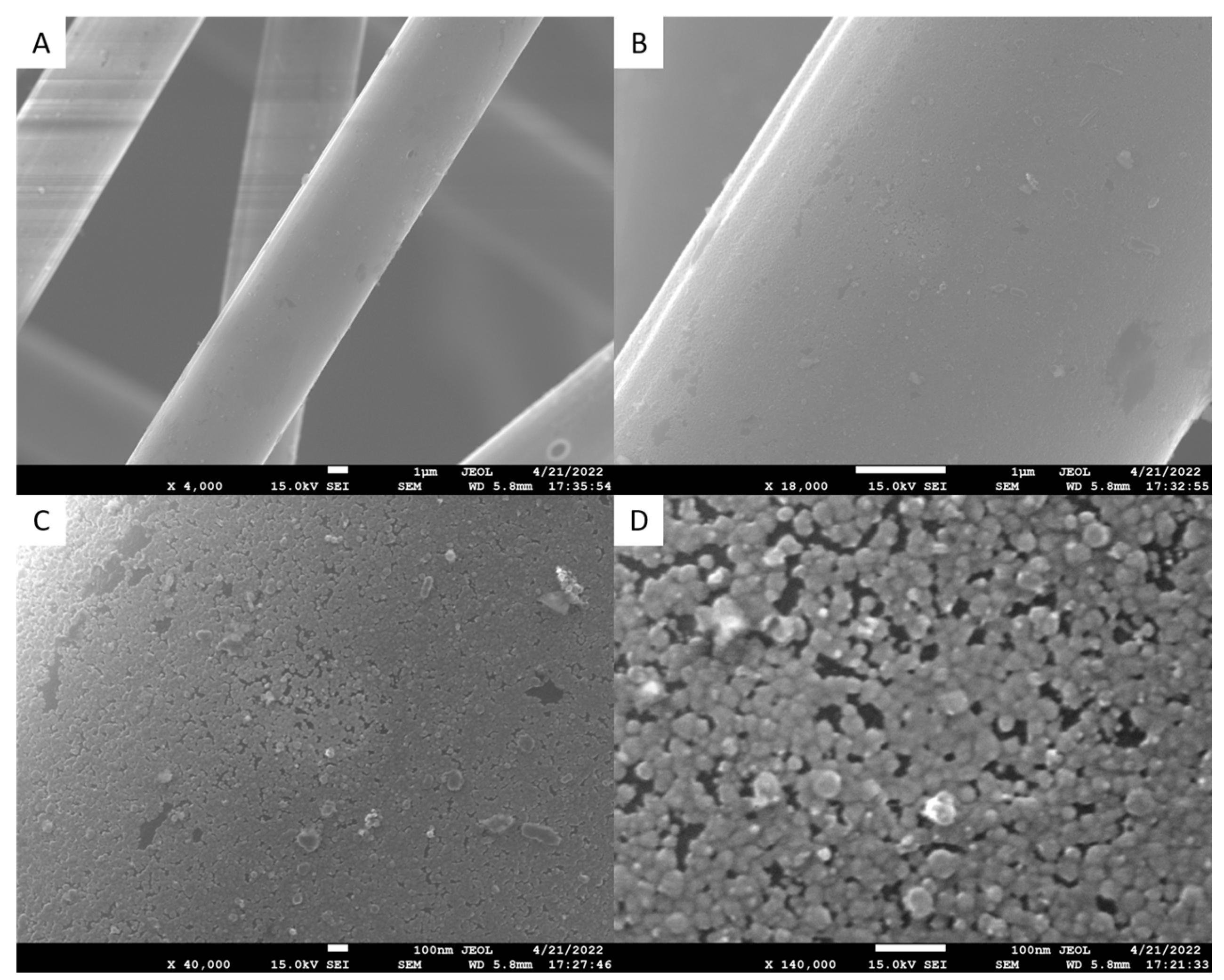

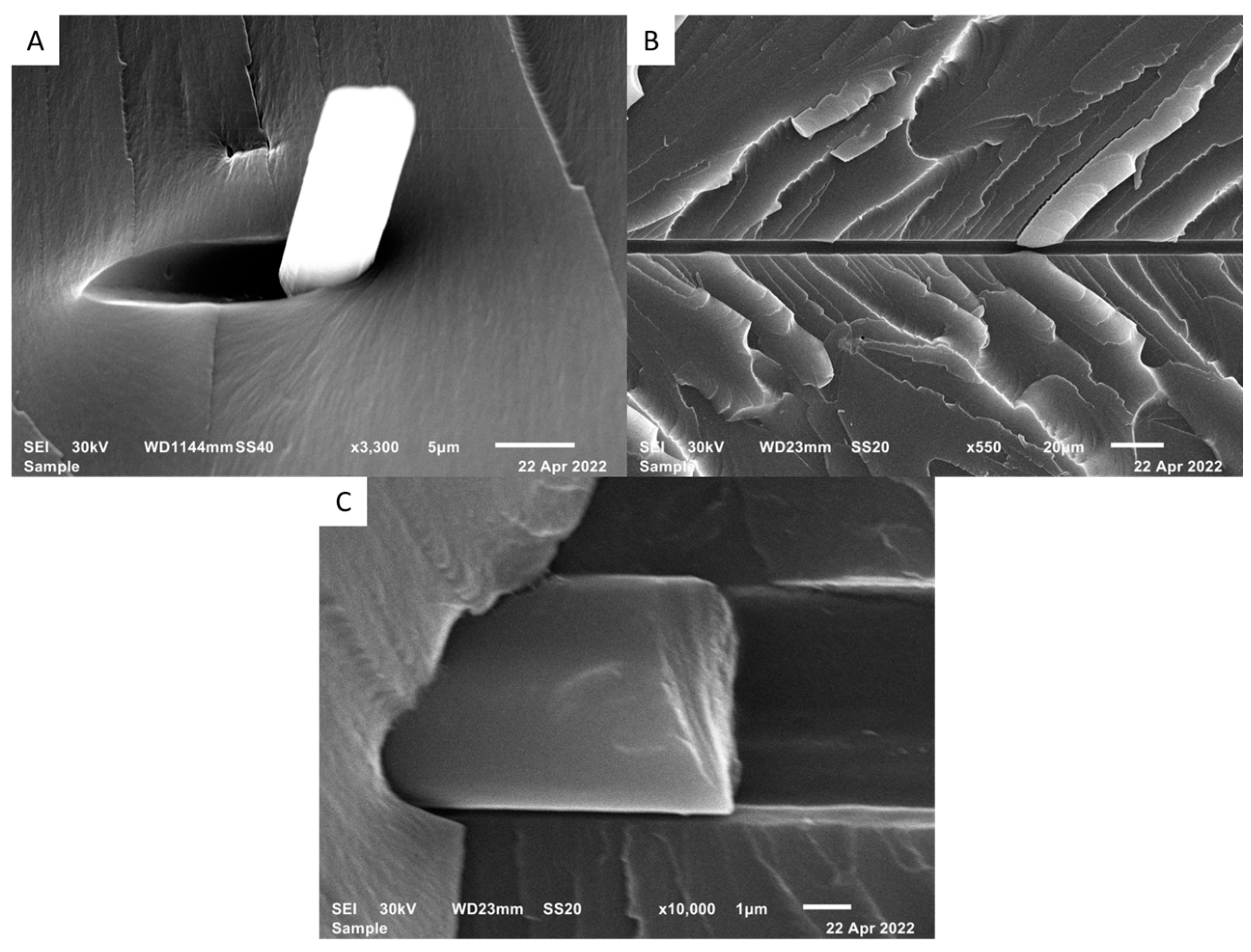

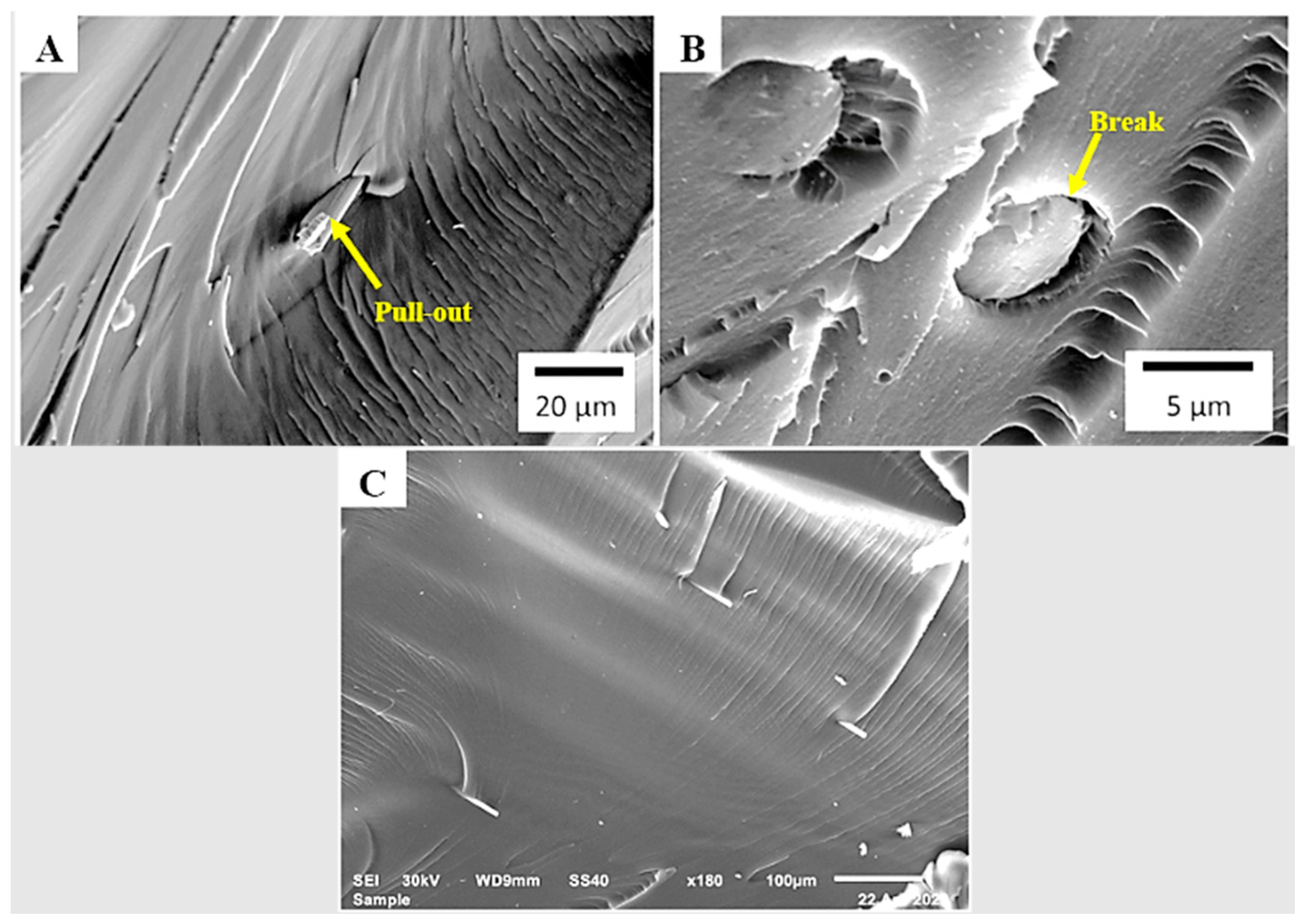

3.2. Scanning Electron Microscopy

3.3. Contact Angle Measurement

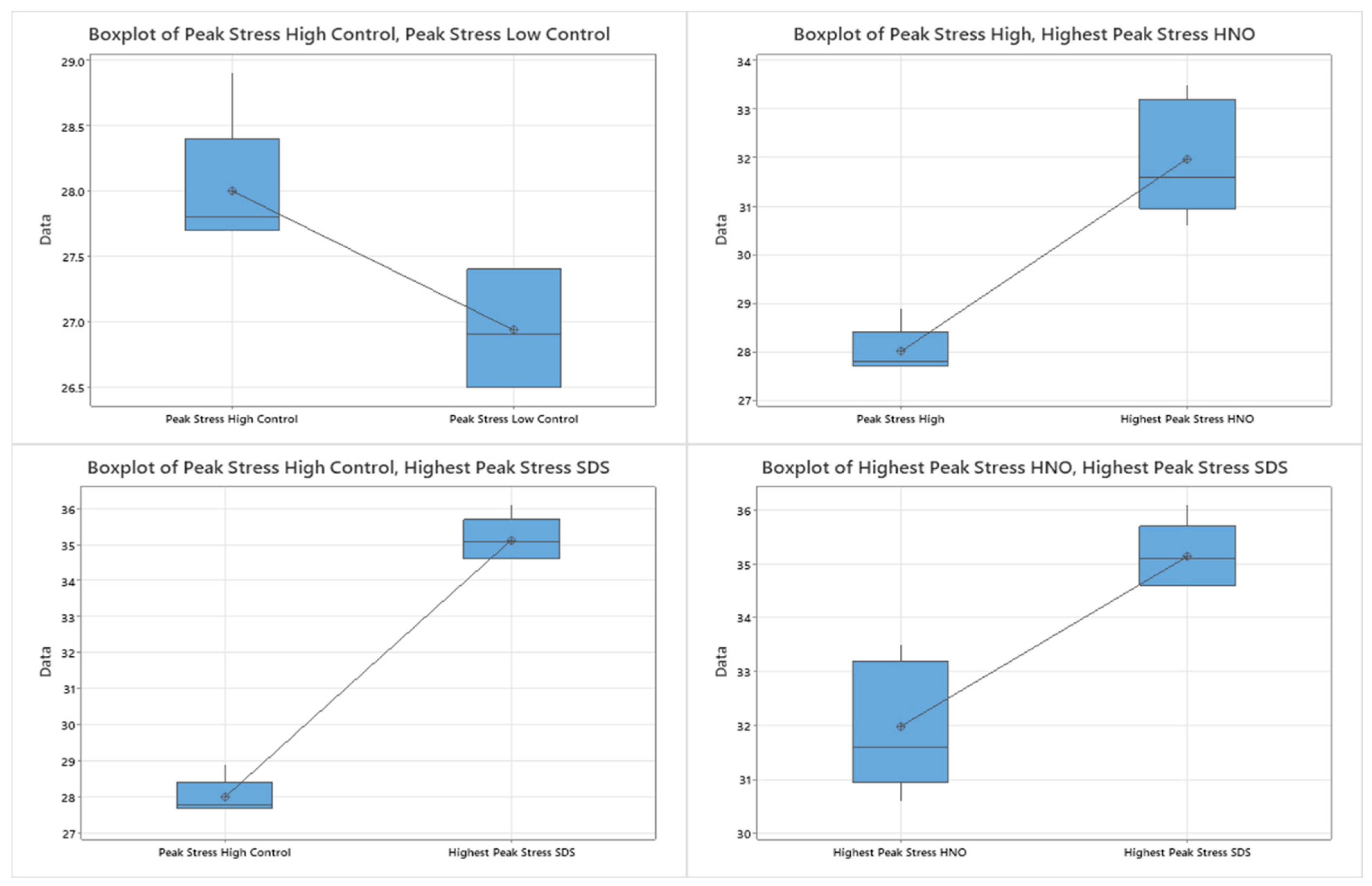

3.4. Tensile Testing

4. Discussion

4.1. SLA Printing

4.2. Control Group

4.3. HNO3 Etching

4.4. Multiscale Nanoparticle Modification: SDS

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Morgan, P. Carbon Fibers and Their Composites; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Xian, G.; Guo, R.; Li, C. Combined effects of sustained bending loading, water immersion and fiber hybrid mode on the mechanical properties of carbon/glass fiber reinforced polymer composite. Compos. Struct. 2022, 281, 115060. [Google Scholar] [CrossRef]

- Wu, J.; Zhu, Y.; Li, C. Experimental Investigation of Fatigue Capacity of Bending-Anchored CFRP Cables. Polymers 2023, 15, 2483. [Google Scholar] [CrossRef] [PubMed]

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. Int. Sch. Res. Not. 2012, 2012, e208760. [Google Scholar] [CrossRef]

- Hull, C.W. Apparatus for Production of Three-Dimensional Objects by Stereolithography. U.S. Patent US4575330, 11 March 1986. [Google Scholar]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing; Springer: New York, NY, USA, 2015. [Google Scholar]

- Chockalingam, K.; Jawahar, N.; Chandrasekhar, U. Influence of layer thickness on mechanical properties in stereolithography. Rapid Prototyp. J. 2006, 12, 106–113. [Google Scholar] [CrossRef]

- Karalekas, D.; Rapti, D.; Gdoutos, E.E.; Aggelopoulos, A. Investigation of Shrinkage-Induced Stresses in Stereolithography Photo-Curable Resins. Exp. Mech. 2002, 42, 439–444. [Google Scholar] [CrossRef]

- Palanikumar, K.; Mudhukrishnan, M. Technologies in Additive Manufacturing for Fiber Reinforced Composite Materials: A Review. Curr. Opin. Chem. Eng. 2020, 28, 51–59. [Google Scholar]

- Sano, Y.; Matsuzaki, R.; Ueda, M.; Todoroki, A.; Hirano, Y. 3D printing of discontinuous and continuous fibre composites using stereolithography. Addit. Manuf. 2018, 24, 521–527. [Google Scholar] [CrossRef]

- Johnston, J.P.; Koo, B.; Subramanian, N.; Chattopadhyay, A. Modeling the molecular structure of the carbon fiber/polymer interphase for multiscale analysis of composites. Compos. Part B Eng. 2017, 111, 27–36. [Google Scholar] [CrossRef]

- Srivastava, V.K.; Zamperlin, N.; Fox, B.; Pegoretti, A. Effect of carbonization and multi-walled carbon nanotubes on polyacrylonitrile short carbon fiber—Epoxy composites. Polym. Compos. 2018, 39, E817–E825. [Google Scholar] [CrossRef]

- Yuan, X.; Zhu, B.; Cai, X.; Liu, J.; Qiao, K.; Yu, J. Optimization of interfacial properties of carbon fiber/epoxy composites via a modified polyacrylate emulsion sizing. Appl. Surf. Sci. 2017, 401, 414–423. [Google Scholar] [CrossRef]

- Kainourgios, P.; Kartsonakis, I.A.; Dragatogiannis, D.A.; Koumoulos, E.P.; Goulis, P.; Charitidis, C.A. Electrochemical surface functionalization of carbon fibers for chemical affinity improvement with epoxy resins. Appl. Surf. Sci. 2017, 416, 593–604. [Google Scholar] [CrossRef]

- Yuan, X.; Zhu, B.; Cai, X.; Zhao, S.; Qiao, K.; Zhang, M. Effects of particle size and distribution of the sizing agent on carbon fiber/epoxy composites interfacial adhesion. Polym. Compos. 2018, 39, E2036–E2045. [Google Scholar] [CrossRef]

- Yuan, H.; Zhang, S.; Lu, C. Surface modification of carbon fibers by a polyether sulfone emulsion sizing for increased interfacial adhesion with polyether sulfone. Appl. Surf. Sci. 2014, 317, 737–744. [Google Scholar] [CrossRef]

- Liu, F.; Shi, Z.; Dong, Y. Improved wettability and interfacial adhesion in carbon fibre/epoxy composites via an aqueous epoxy sizing agent. Compos. Part A Appl. Sci. Manuf. 2018, 112, 337–345. [Google Scholar] [CrossRef]

- Sharma, M.; Gao, S.; Mäder, E.; Sharma, H.; Wei, L.Y.; Bijwe, J. Carbon fiber surfaces and composite interphases. Compos. Sci. Technol. 2014, 102, 35–50. [Google Scholar] [CrossRef]

- Tiwari, S.; Bijwe, J. Surface Treatment of Carbon Fibers—A Review. Procedia Technol. 2014, 14, 505–512. [Google Scholar] [CrossRef]

- Tiwari, S.; Bijwe, J.; Panier, S. Tribological studies on polyetherimide composites based on carbon fabric with optimized oxidation treatment. Wear 2011, 271, 2252–2260. [Google Scholar] [CrossRef]

- Li, J.; Cheng, X. Effect of surface treatment on the tribological performance of carbon fiber reinforced thermoplastic polyimide composites. Polym. Compos. 2009, 30, 59–65. [Google Scholar] [CrossRef]

- Pozegic, T.R.; Huntley, S.; Longana, M.L.; He, S.; Bandara, R.M.I.; King, S.G.; Hamerton, I. Improving Dispersion of Recycled Discontinuous Carbon Fibres to Increase Fibre Throughput in the HiPerDiF Process. Materials 2020, 13, 1544. [Google Scholar] [CrossRef]

- Zhang, X.; Pei, X.; Jia, Q.; Wang, Q. Effects of carbon fiber surface treatment on the tribological properties of 2D woven carbon fabric/polyimide composites. Appl. Phys. A 2009, 95, 793–799. [Google Scholar] [CrossRef]

- King, S.G.; Castaldelli, E.; McCaffterty, L.; Silva, S.R.P.; Stolojan, V. Micro-Centrifugal Technique for Improved Assessment and Optimization of Nanomaterial Dispersions: The Case for Carbon Nanotubes. ACS Appl. Nano Mater. 2018, 1, 6217–6225. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics, iTeh Standards. Available online: https://standards.iteh.ai/catalog/standards/astm/bc99fb25-38c3-49db-9dbc-b9338bbd4c07/astm-d638-14. (accessed on 13 November 2023).

- Carroll, B. The accurate measurement of contact angle, phase contact areas, drop volume, and Laplace excess pressure in drop-on-fiber systems. J. Colloid Interface Sci. 1976, 57, 488–495. [Google Scholar] [CrossRef]

- Yamaki, J.-I.; Katayama, Y. New method of determining contact angle between monofilament and liquid. J. Appl. Polym. Sci. 1975, 19, 2897–2909. [Google Scholar] [CrossRef]

| Modification Technique | Fiber Ratio (g/150 mL) | Fiber Length (mm) | Exposure Time (s) | Samples Printed |

|---|---|---|---|---|

| Acid Etching: Nitric Acid (HNO3) | 30 | 6 | 4 | 5 |

| 6 | 5 | |||

| 12 | 4 | 5 | ||

| 6 | 5 | |||

| 60 | 6 | 4 | 5 | |

| 6 | 5 | |||

| 12 | 4 | 5 | ||

| 6 | 5 | |||

| Multiscale Nanoparticle: Sodium Dodecyl Sulfate (SDS) | 30 | 6 | 4 | 5 |

| 6 | 5 | |||

| 12 | 4 | 5 | ||

| 6 | 5 | |||

| 60 | 6 | 4 | 5 | |

| 6 | 5 | |||

| 12 | 4 | 5 | ||

| 6 | 5 | |||

| None (Control) | N/A | N/A | 4 | 5 |

| 6 | 5 | |||

| Total Samples | 90 |

| Raw | HNO3 | SDS | |

|---|---|---|---|

| Height | 50.41 | 51.19 | 52.92 |

| Length | 65.16 | 71.40 | 73.36 |

| Contact Angle | 59.07 | 49.56 | 50.88 |

| Control H | HNO3 LHH | SDS HLH | |

|---|---|---|---|

| Peak Stress Average (MPa) | 28.00 | 31.98 | 35.14 |

| Variance | 0.26 | 1.417 | 0.38 |

| Modulus Average (MPa) | 1122.39 | 1315.07 | 1405.96 |

| Variance | 596.88 | 211.76 | 470.58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palacio, A.; Baniasadi, M.; Kardel, K. Investigating Mechanical Properties of Fabricated Carbon-Fiber-Reinforced Composites via LCD Additive Manufacturing. Polymers 2023, 15, 4556. https://doi.org/10.3390/polym15234556

Palacio A, Baniasadi M, Kardel K. Investigating Mechanical Properties of Fabricated Carbon-Fiber-Reinforced Composites via LCD Additive Manufacturing. Polymers. 2023; 15(23):4556. https://doi.org/10.3390/polym15234556

Chicago/Turabian StylePalacio, Anthony, Mahmoud Baniasadi, and Kamran Kardel. 2023. "Investigating Mechanical Properties of Fabricated Carbon-Fiber-Reinforced Composites via LCD Additive Manufacturing" Polymers 15, no. 23: 4556. https://doi.org/10.3390/polym15234556

APA StylePalacio, A., Baniasadi, M., & Kardel, K. (2023). Investigating Mechanical Properties of Fabricated Carbon-Fiber-Reinforced Composites via LCD Additive Manufacturing. Polymers, 15(23), 4556. https://doi.org/10.3390/polym15234556