Development of Electromagnetic Shielding Composites Reinforced with Nonwovens Produced from Recycled Fibers

Abstract

:1. Introduction

2. Materials and Methods

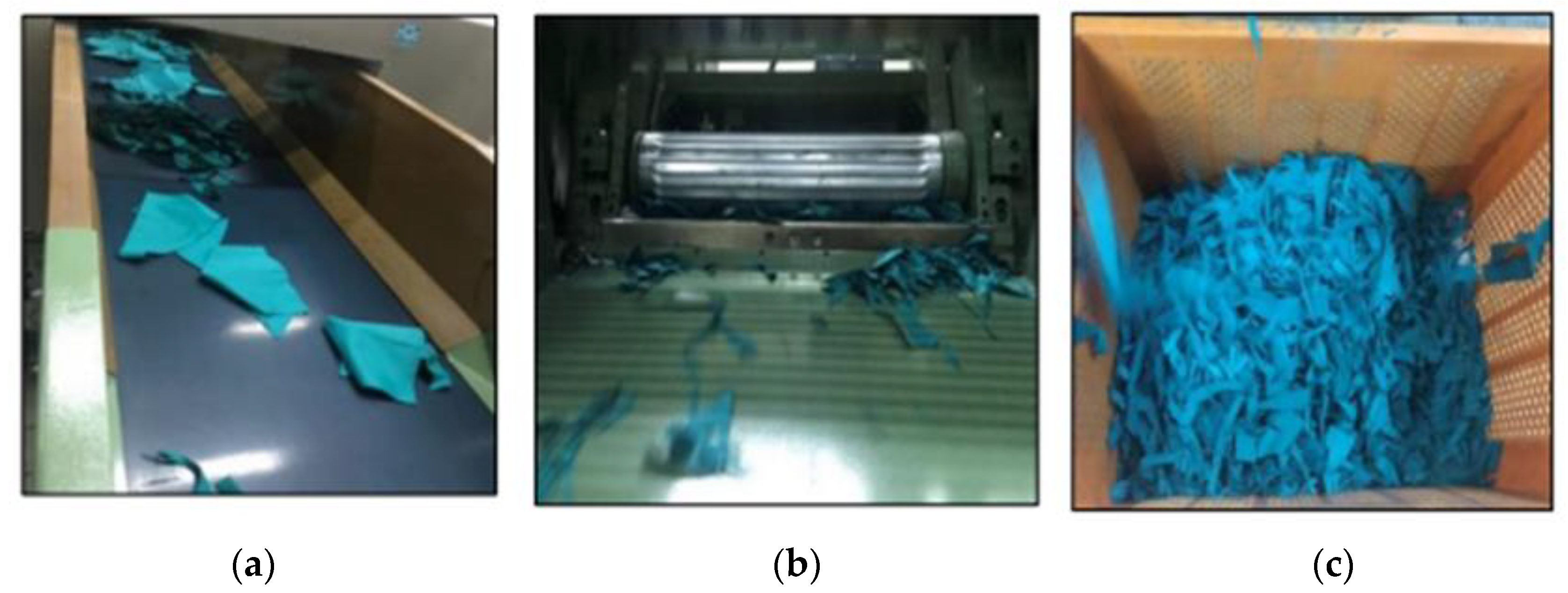

2.1. Recycling Process

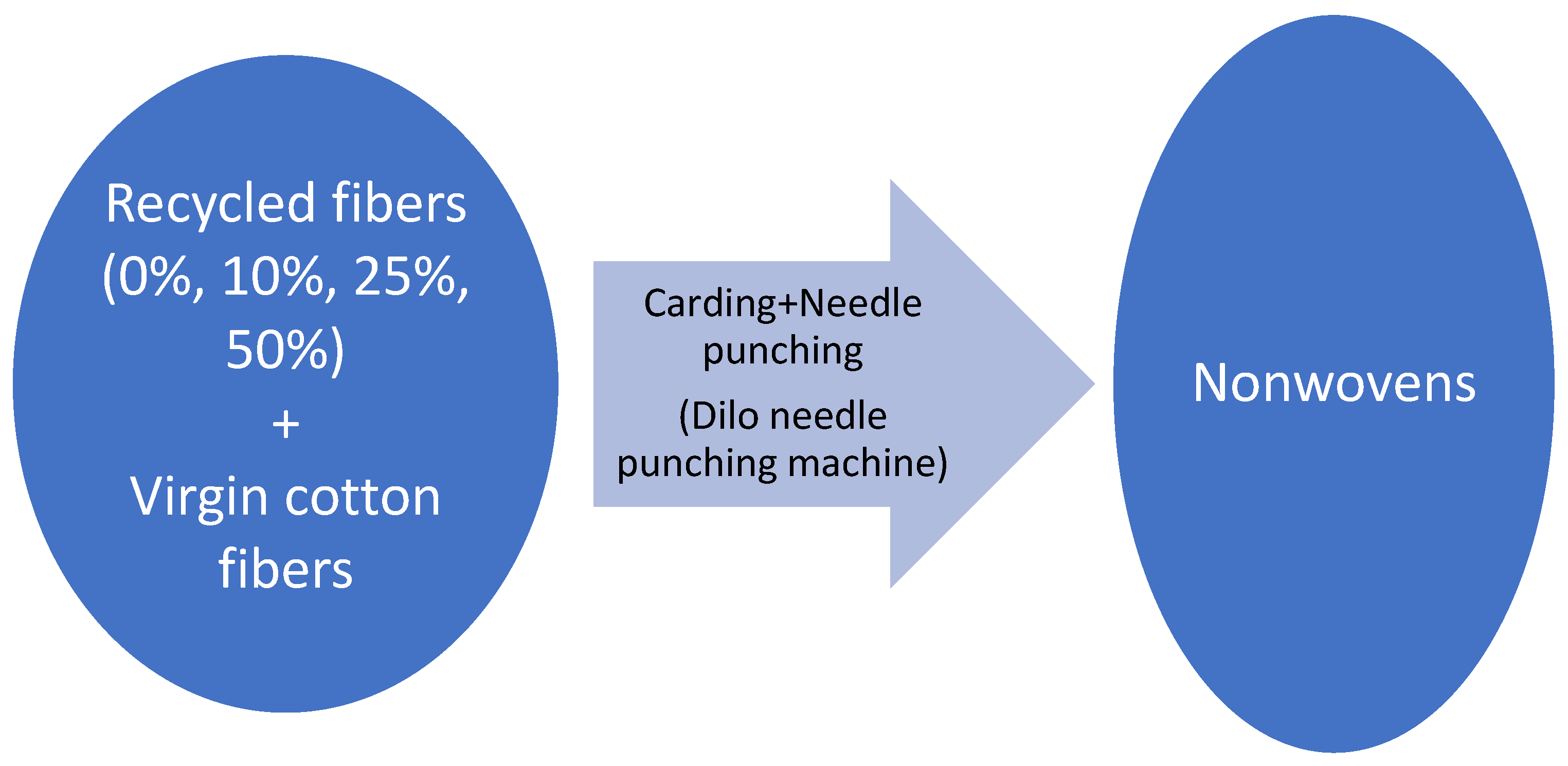

2.2. Nonwoven Production

2.3. Composite Production

2.4. Testing

2.4.1. Electromagnetic Shielding Tests

2.4.2. Electrical Resistivity Tests

2.4.3. Tensile Tests

2.4.4. Flexural Tests

3. Results and Discussion

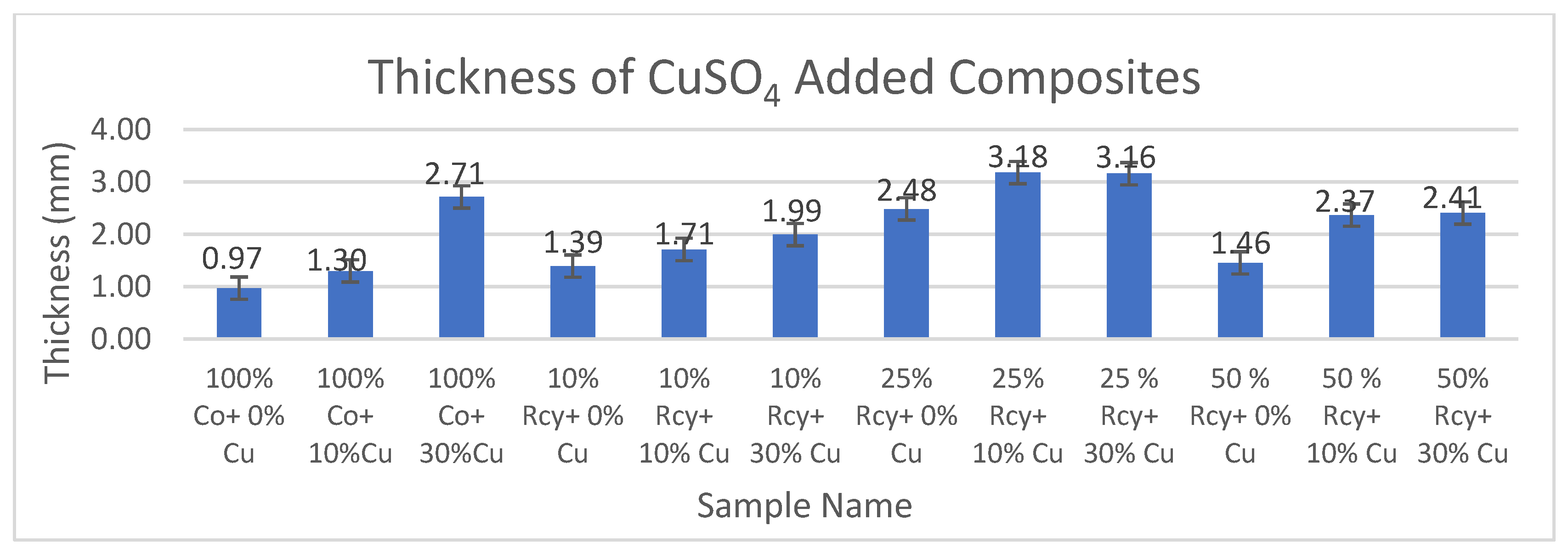

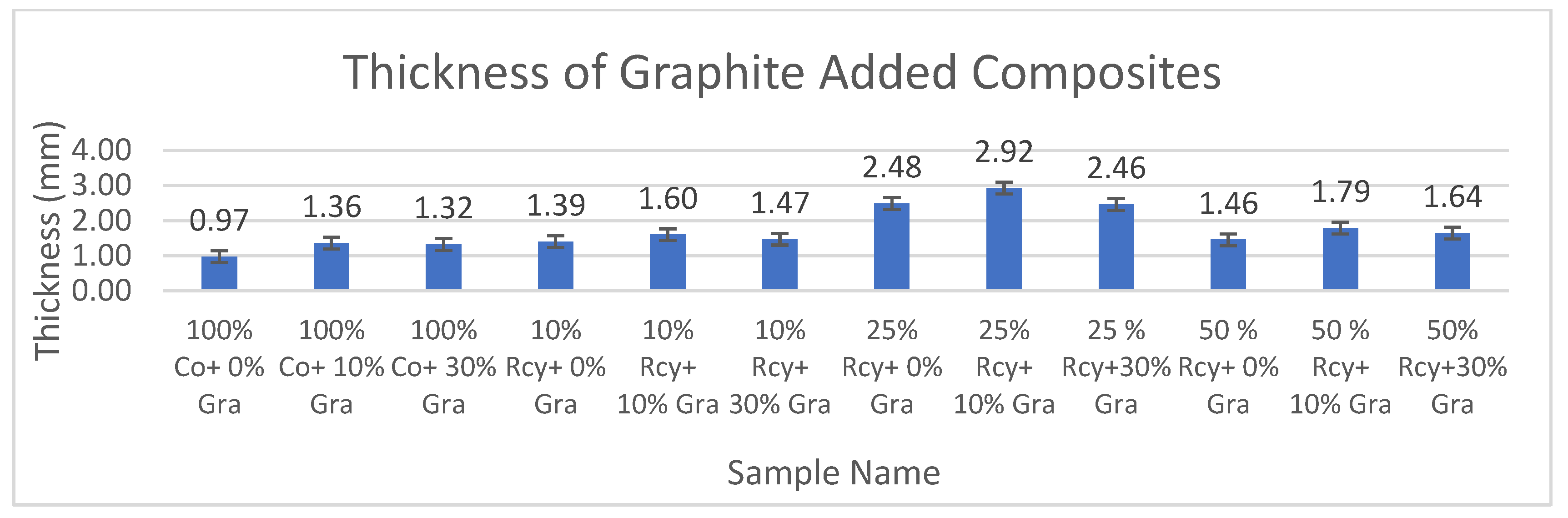

3.1. Results of Thickness Measurements

3.2. Results of Basis Weight Measurements

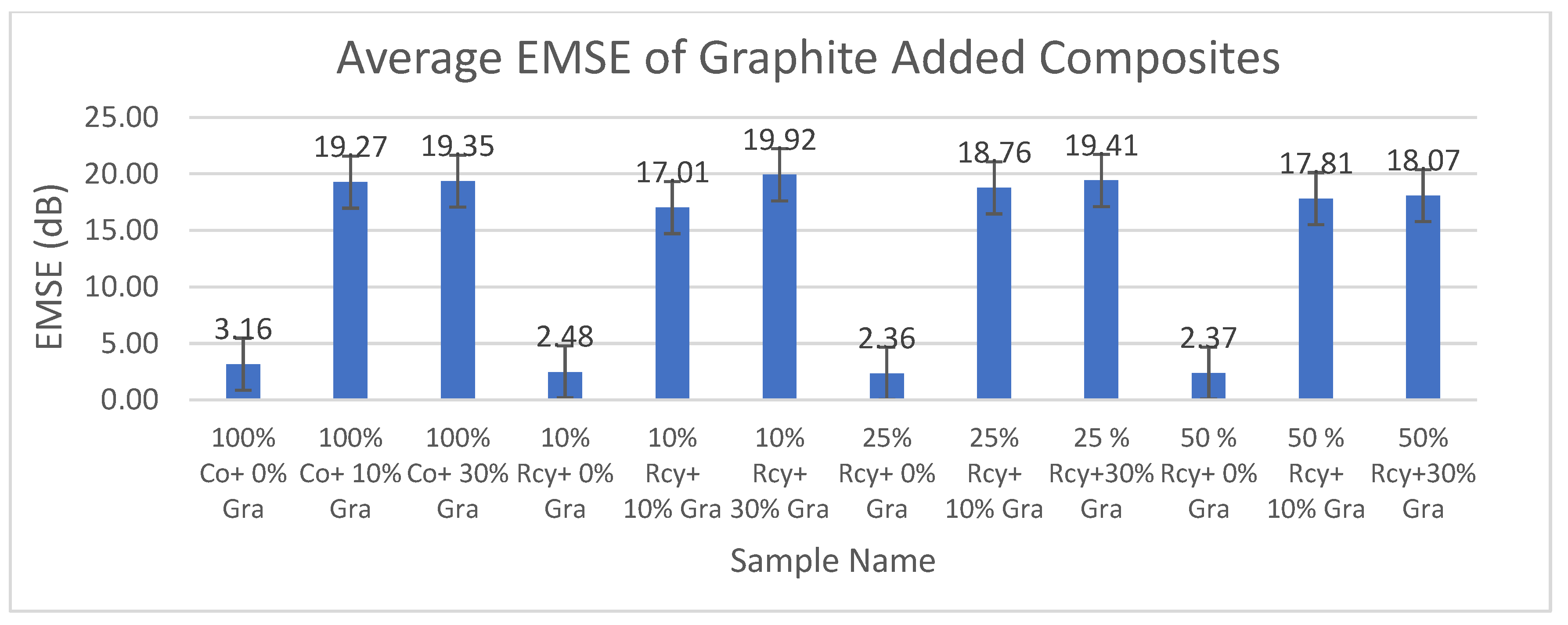

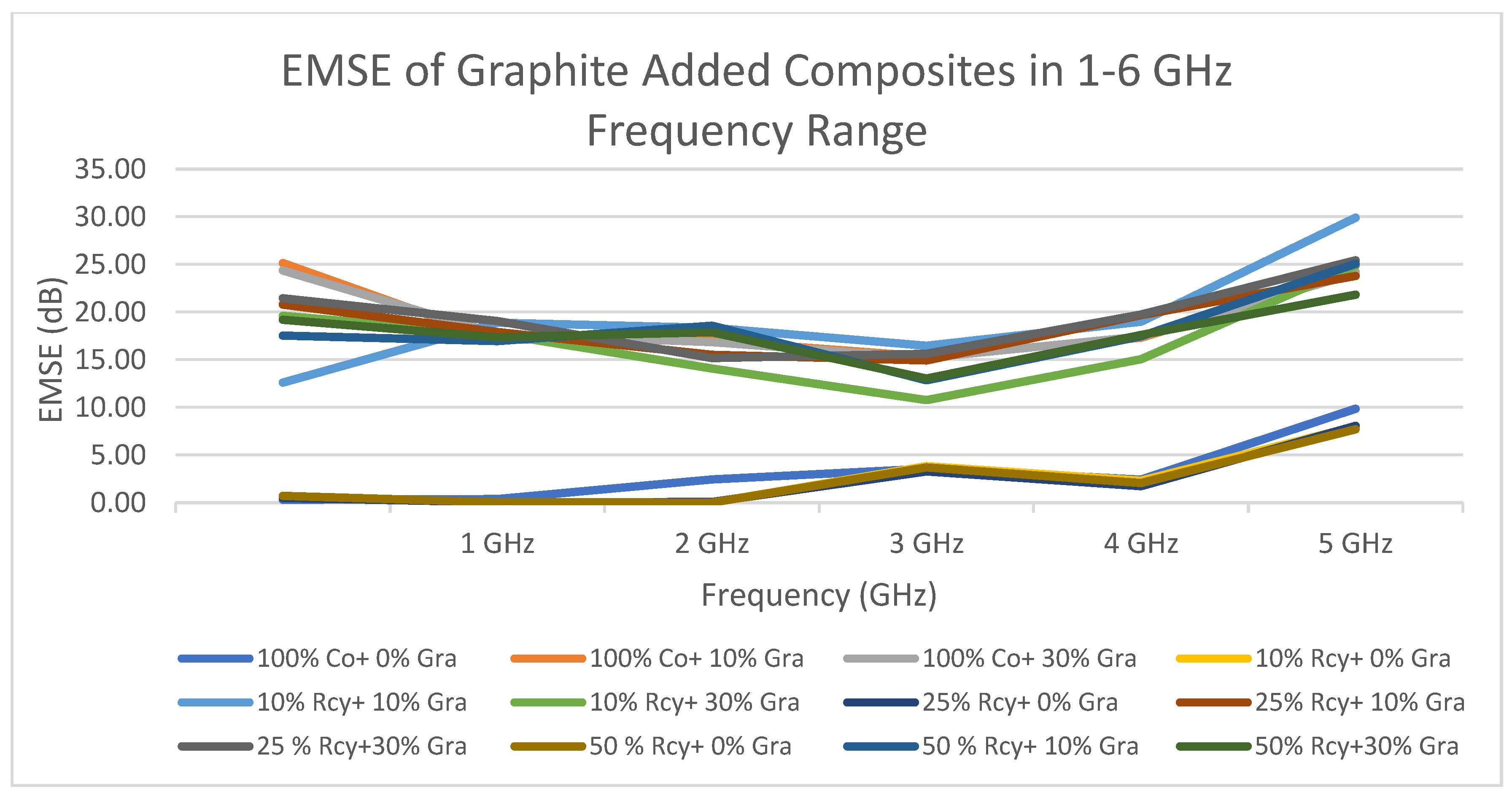

3.3. Results of Electromagnetic Shielding Measurements

3.4. Results of Electrical Resistivity Measurements

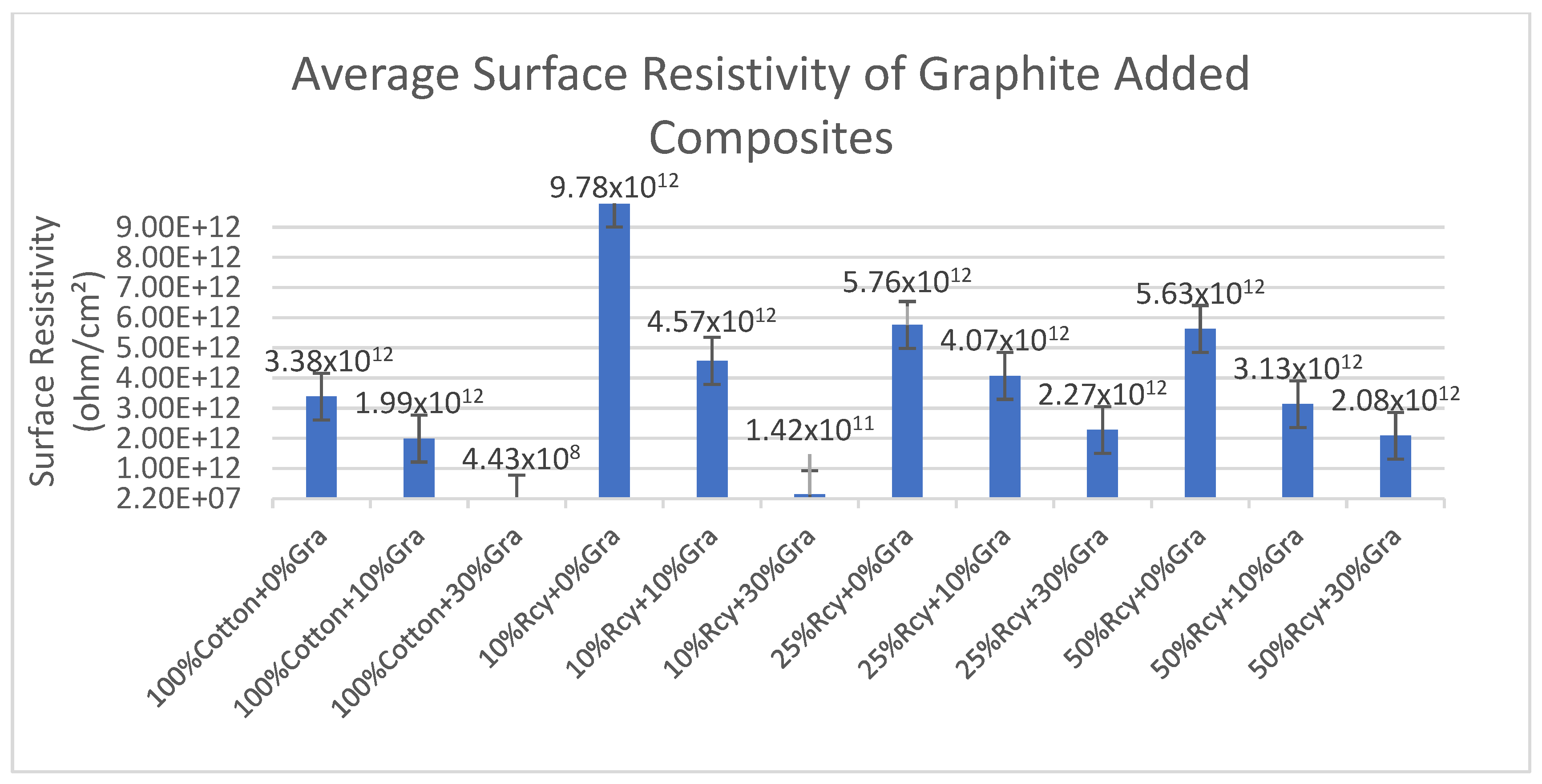

3.4.1. Surface Resistivity

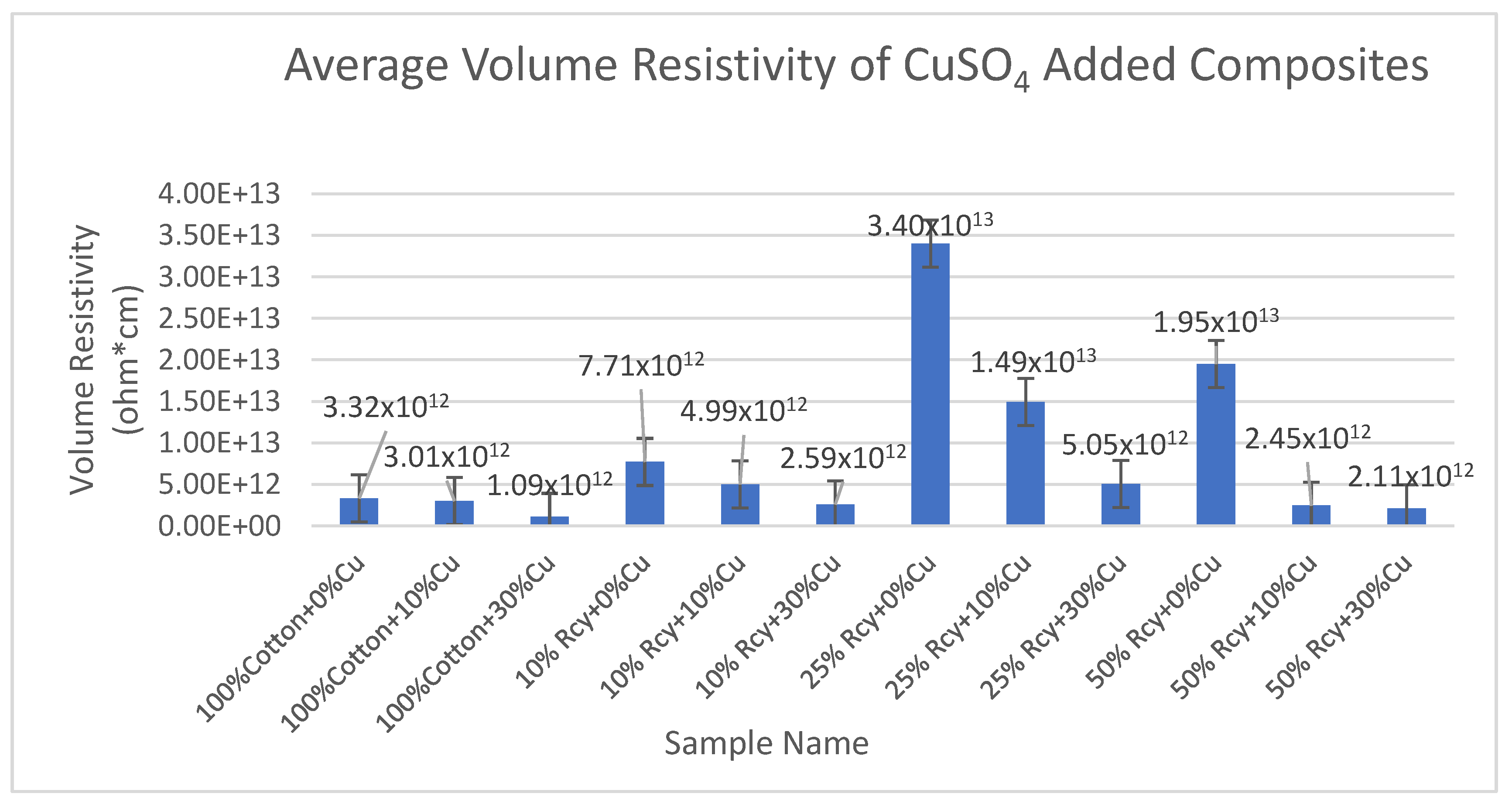

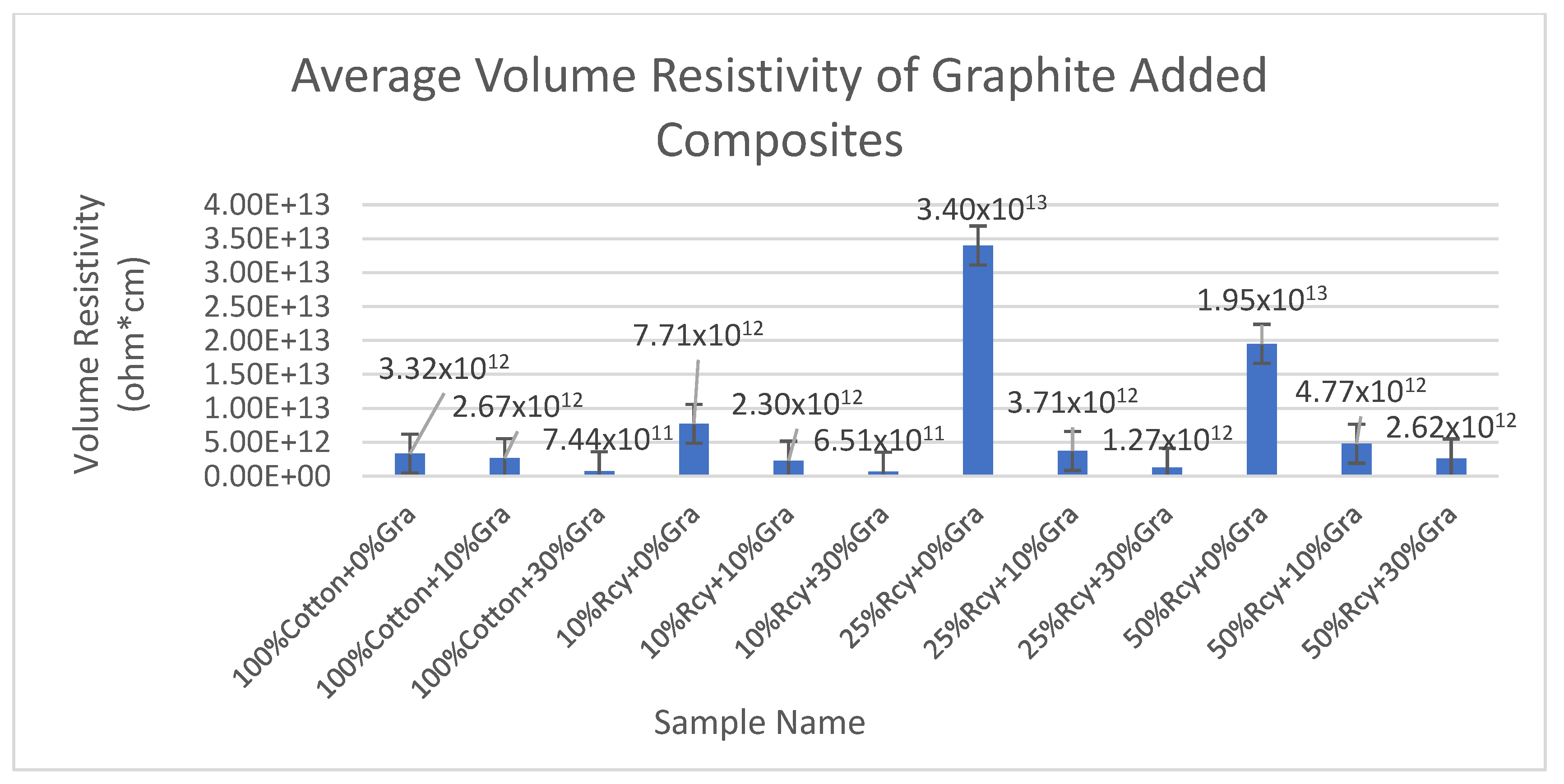

3.4.2. Volume Resistivity

3.5. Results of Tensile Tests

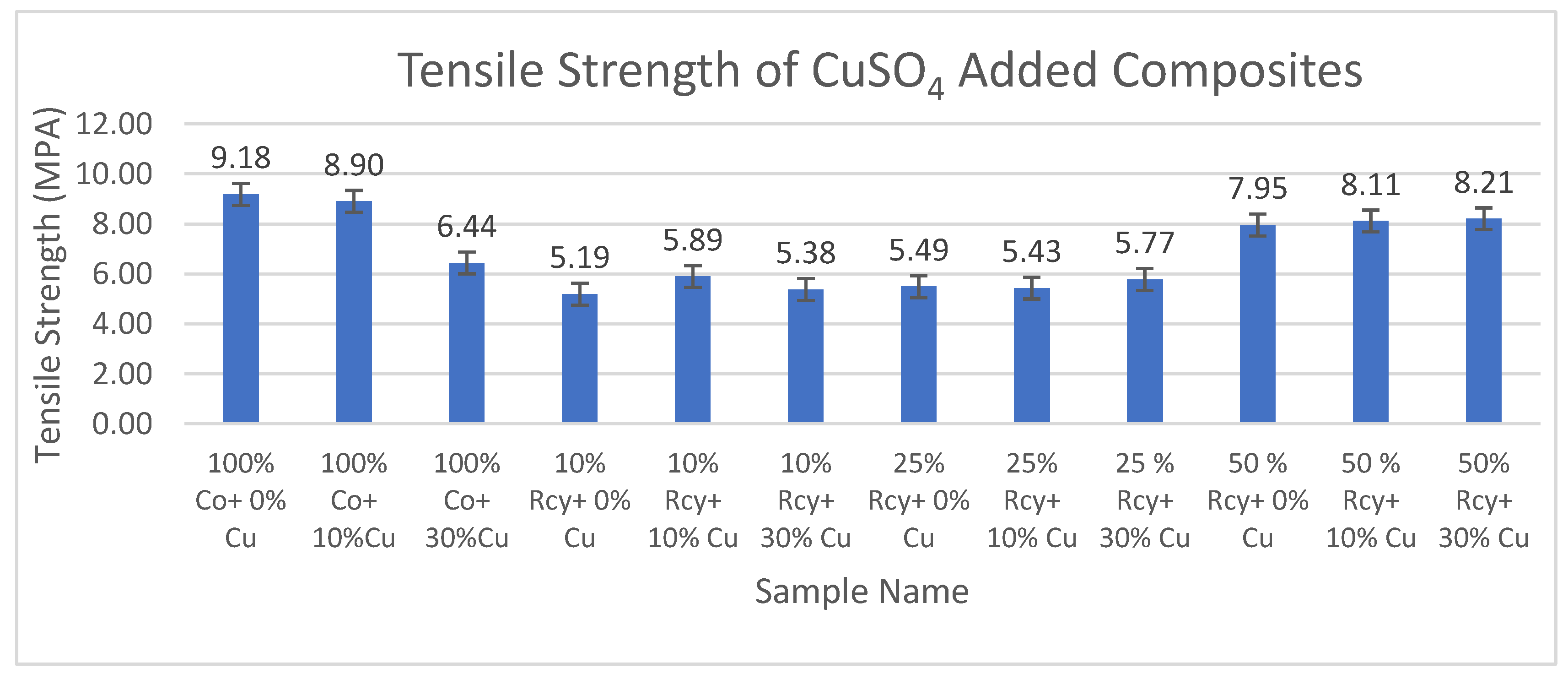

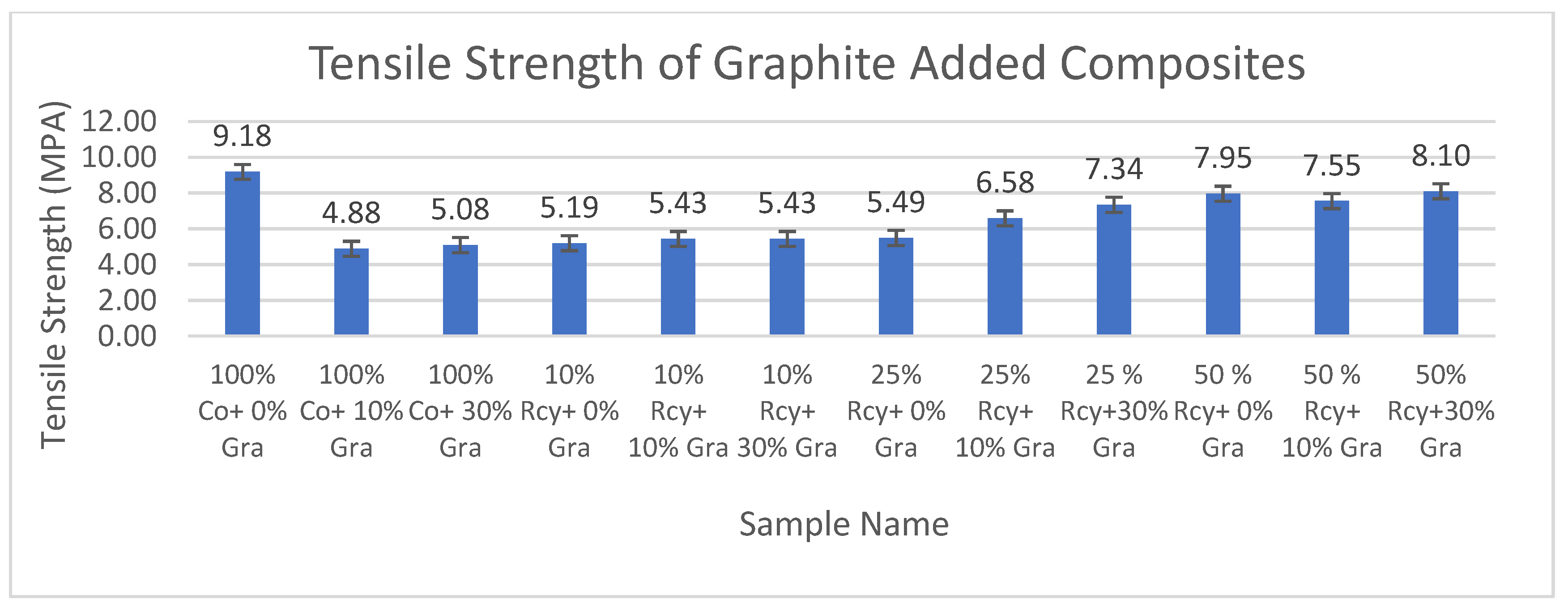

3.5.1. Tensile Strength

3.5.2. Tensile Max. Elongation

3.6. Results of Bending Tests

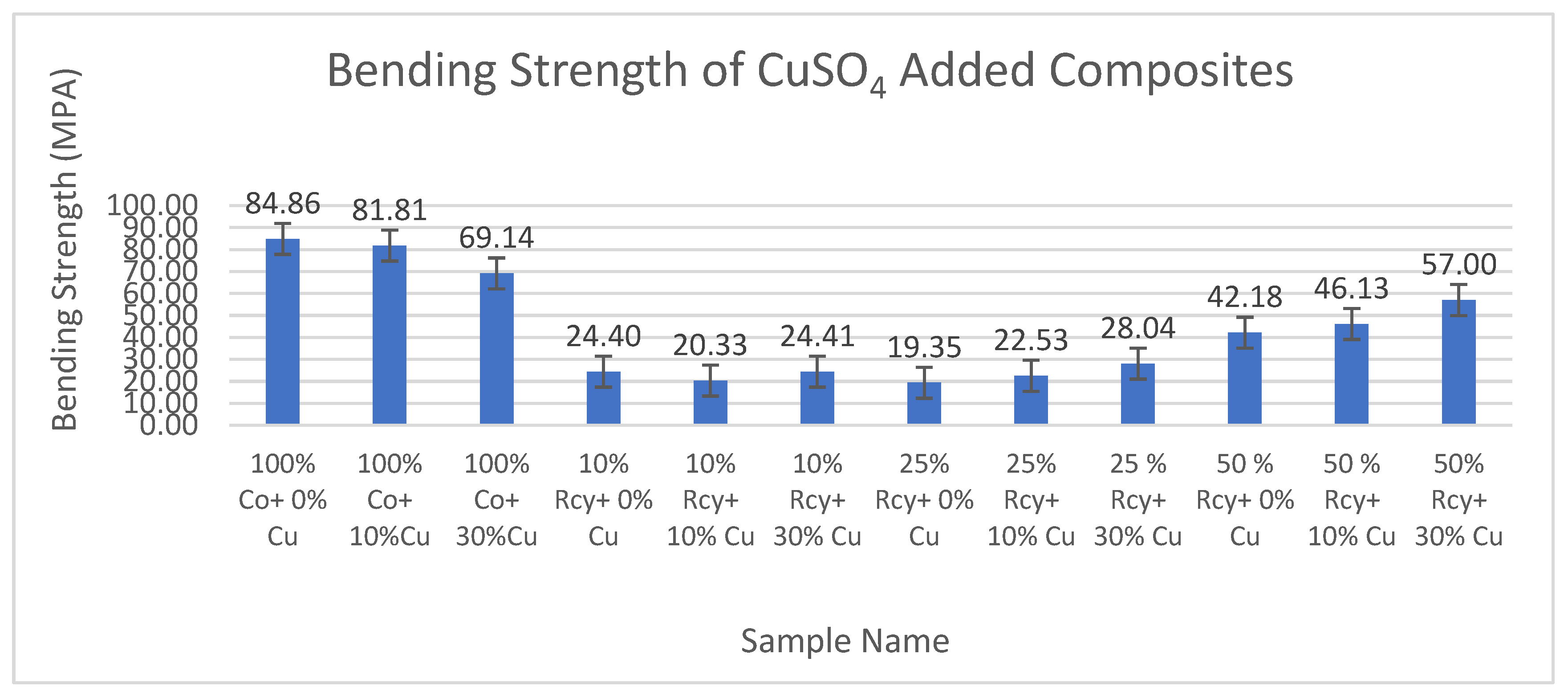

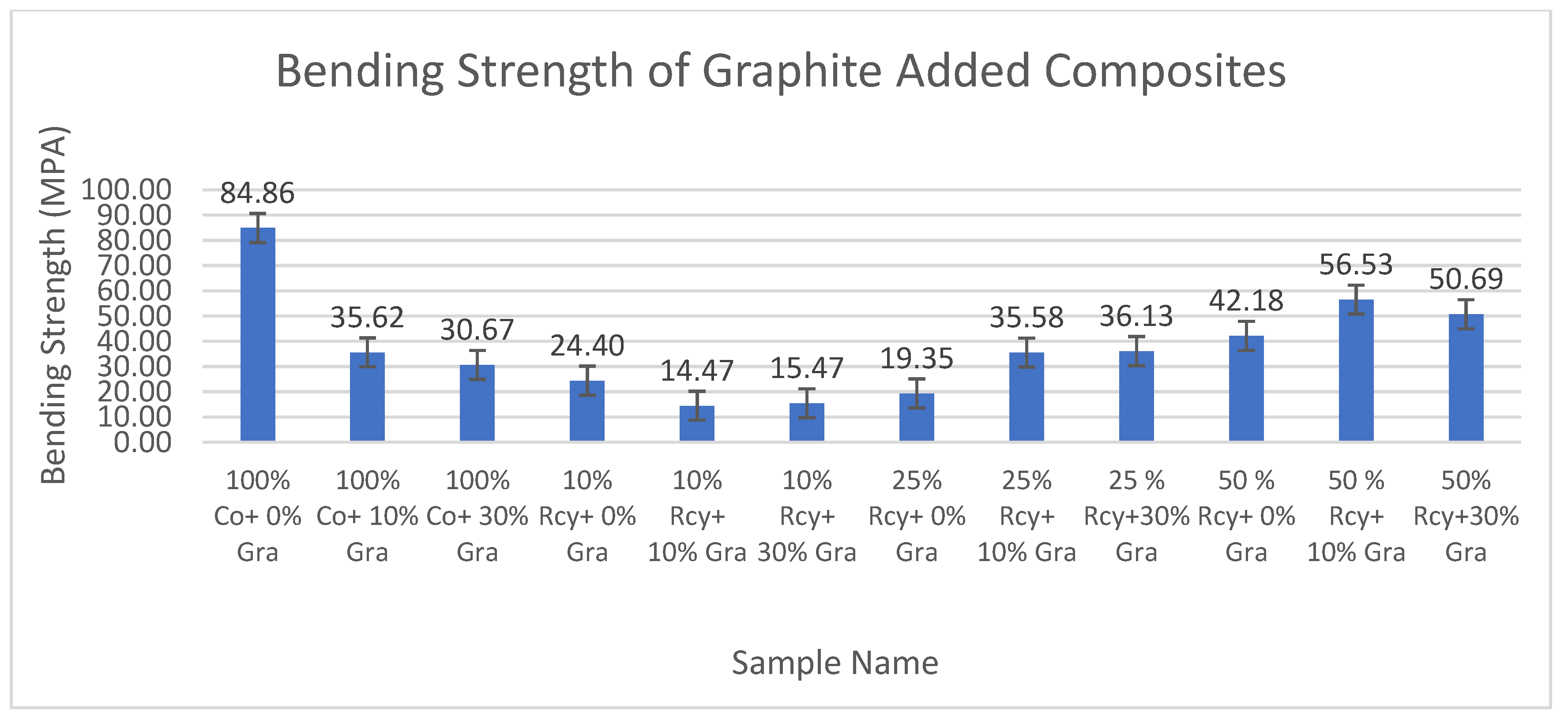

3.6.1. Bending Strength

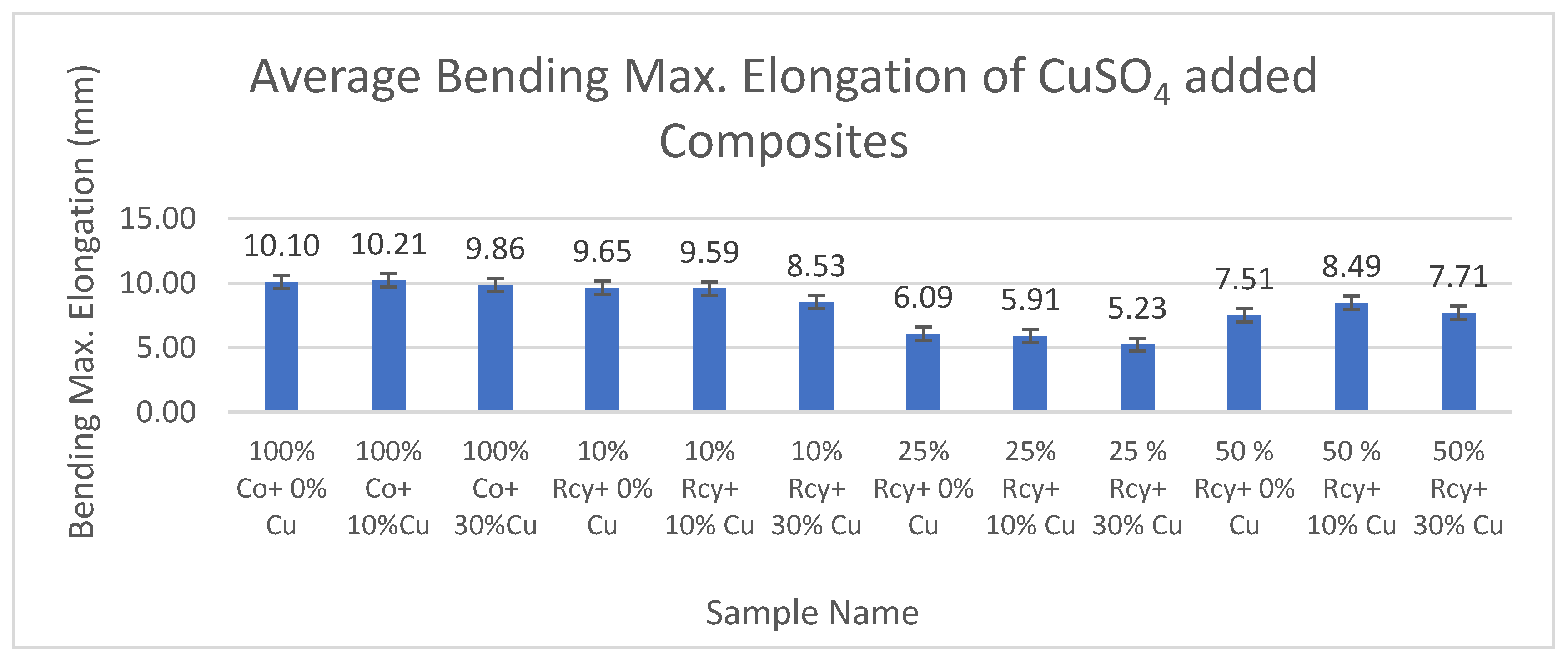

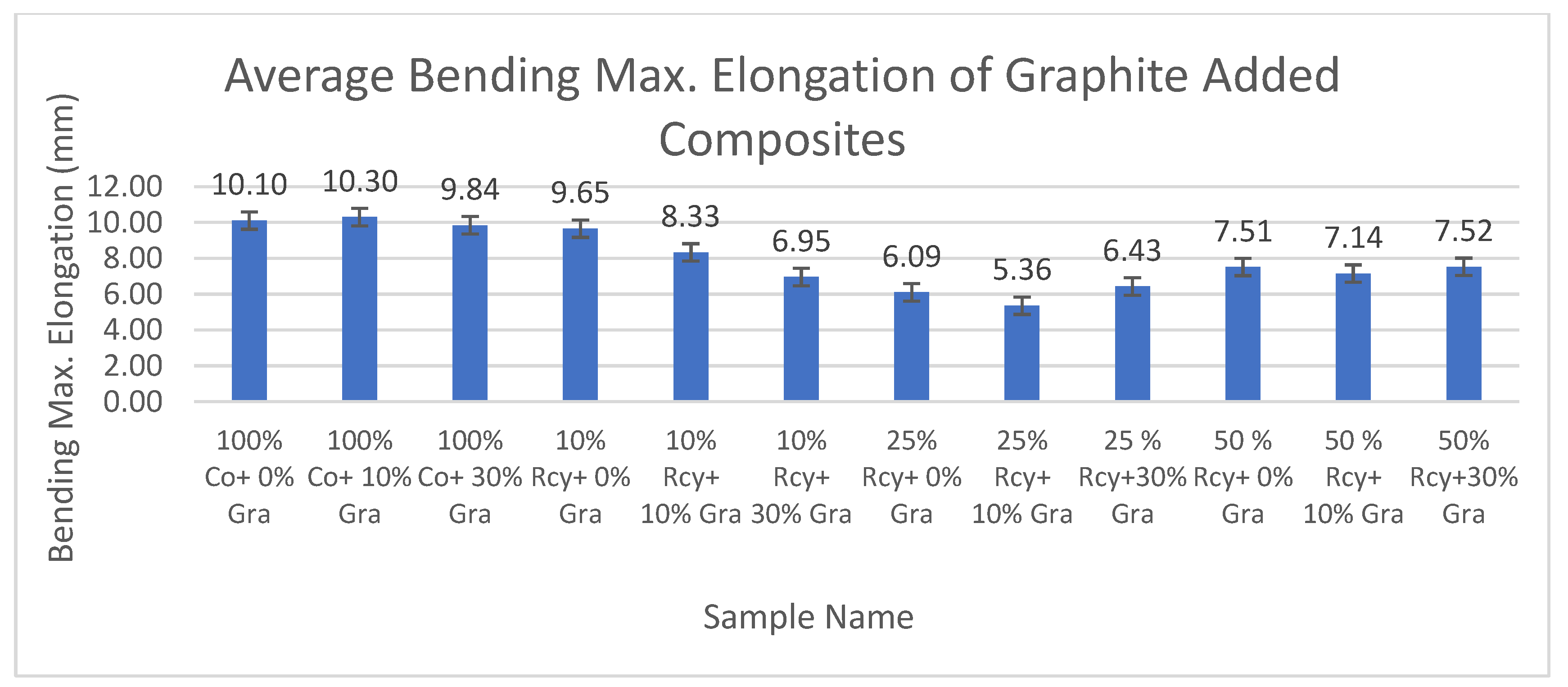

3.6.2. Bending Max. Elongation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Kadoğlu, H.; Duran, D. Electromagnetic shielding characterization of conductive woven fabrics produced with silver-containing yarns. Text. Res. J. 2015, 85, 1009–1021. [Google Scholar]

- Šafářová, V.; Militký, J. Electromagnetic shielding properties of woven fabrics made from high-performance fibers. Text. Res. J. 2014, 84, 1255–1267. [Google Scholar] [CrossRef]

- Yılmaz, R. Elektromanyetik Kalkanlama Özelliği Olan Malzemeler. Ejovoc (Electron. J. Vocat. Coll.) 2014, 4, 136–150. [Google Scholar]

- Parliamentary Assambly, Committee on the Environment, Agriculture and Local and Regional Affairs. The Potential Dangers of Electromagnetic Fields and Their Effect on the Environment, CE, Strasbourg. 2011. Available online: https://assembly.coe.int/nw/xml/XRef/Xref-XML2HTML-en.asp?fileid=17994 (accessed on 30 October 2023).

- Duran, D. A Research on Application Possibilities of Textile Materials in Electromagnetic Shielding Applications. Ph.D. Thesis, Ege University, Bornova, Turkey, 2011. [Google Scholar]

- Oğul, H.; Polat, H.; Akman, F.; Kaçal, M.R.; Dilsiz, K.; Bulut, F.; Agar, O. Gamma and Neutron Shielding Parameters of Polyester-based composites reinforced with boron and tin nanopowders. Radiat. Phys. Chem. 2022, 201, 110474. [Google Scholar] [CrossRef]

- Liu, P.; Ng, V.M.H.; Yao, Z.; Zhou, J.; Lei, Y.; Yang, Z.; Lv, H.; Kong, L.B. Facile Synthesis and Hierarchical Assembly of Flowerlike NiO Structures with Enhanced Dielectric and Microwave Absorption Properties. Appl. Mater. Interfaces 2017, 9, 16404–16416. [Google Scholar] [CrossRef]

- Nan, Z.; Wei, W.; Lin, Z.; Chang, J.; Hao, Y. Flexible Nanocomposite Conductors for Electromagnetic Interference Shielding. Nano-Micro Lett. 2023, 15, 172. [Google Scholar] [CrossRef]

- Fan, Z.; Liu, R.; Cheng, X. Preparation and Characterization of Electromagnetic Shielding Composites Based on Graphene-Nanosheets-Loaded Nonwoven Fabric. Coatings 2021, 11, 424. [Google Scholar] [CrossRef]

- Lu, L.; Xing, D.; Teh, K.S.; Liu, H.; Xie, Y.; Liu, X.; Tang, Y. Structural effects in a composite nonwoven fabric on EMI shielding. Mater. Des. 2017, 120, 354–362. [Google Scholar] [CrossRef]

- Wong, K.H.; Pickering, S.J.; Rudd, C.D. Recycled carbon fibre reinforced polymer composite for electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2010, 41, 693–702. [Google Scholar] [CrossRef]

- Ali, A.; Hussain, F.; Tahir, M.F.; Ali, M.; Zaman Khan, M.; Tomková, B.; Militky, J.; Noman, M.T.; Azeem, M. Fabrication of Conductive, High Strength and Electromagnetic Interference (EMI) Shielded Green Composites Based on Waste Materials. Polymers 2022, 14, 1289. [Google Scholar] [CrossRef]

- Yadong, X.; Yaqi, Y.; Ding-Xiang, Y.; Hongji, D.; Guizhe, Z.; Yaqing, L. Flexible and conductive polyurethane composites for electromagnetic shielding and printable circuit. Chem. Eng. J. 2019, 360, 1427–1436. [Google Scholar]

- Liang, L.; Yao, C.; Yan, X.; Feng, Y.; Hao, X.; Zhou, B.; Wang, Y.; Ma, J.; Liu, C.; Shen, C. High-efficiency electromagnetic interference shielding capability of magnetic Ti3C2Tx MXene/CNT composite film. Mater. Chem. A 2021, 9, 8896. [Google Scholar] [CrossRef]

- Keeling, J.L. Graphite: Properties, uses and Australian resources. Mesa J. 2017, 84, 28–41. [Google Scholar]

- Derek, P.C.; Davenport, W.G. Densities, Electrical Conductivities and Viscosities of CuSO4/H2SO4 Solutions in the Range of Modern Electrorefining and Electrowinning Electrolytes. Metall. Trans. B 1980, 11, 159–163. [Google Scholar]

- Patnaik, P.K.; Swain, P.T.R.; Mishra, S.K.; Purohit, A.; Biswas, S. Recent developments on characterization of needle-punched nonwoven fabric reinforced polymer composites—A review. Mater. Today Proc. 2020, 26, 466–470. [Google Scholar] [CrossRef]

- Rawal, A.; Majumdar, A.; Anand, S.; Shah, T. Predicting the properties of needlepunched nonwovens using artificial neural network. J. Appl. Polym. Sci. 2009, 112, 3575–3581. [Google Scholar] [CrossRef]

- Duran, D. A Research on Thermal Insulatıon Propertıes of Nonwovens Produced With Recycled Jute And Wool Fıbres. Text. Appar. 2016, 26, 22–30. [Google Scholar]

- Cheng, J.; Li, J.; Xiong, Y.; Zhang, H.; Raza, H.; Ullah, S.; Wu, J.; Zheng, G.; Cao, Q.; Zhang, D.; et al. Recent Advances in Design Strategies and Multifunctionality of Flexible Electromagnetic Interference Shielding Materials. Nano-Micro Lett. 2022, 14, 80. [Google Scholar] [CrossRef]

- Atay, M. An Investigation on the Production of Non-Woven Textile Surface Reinforced Electromagnetic Shielding Composites from Recycled Fibers. Master’s Thesis, Ege University, Bornova, Turkey, 2022. [Google Scholar]

- Pakdel, E.; Kashi, S.; Baum, T.; Usman, K.A.S.; Razal, J.M.; Varley, R.; Wang, X. Carbon fibre waste recycling into hybrid nonwovens for electromagnetic interference shielding and sound absorption. J. Clean. Prod. 2021, 315, 128196. [Google Scholar] [CrossRef]

- Zeng, Z.; Jin, H.; Chen, M.; Li, W.; Zhou, L.; Xue, X.; Zhang, Z. Microstructure design of lightweight, fexible, and high electromagnetic shielding porous multiwalled carbon nanotube/polymer composites. Small 2017, 13, 1701388. [Google Scholar] [CrossRef]

- Omrani, F.; Soulat, D.; Ferreira, M.; Wang, P. Effects of needle punching process and structural parameters on mechanical behavior of flax nonwovens preforms. Adv. Aircr. Spacecr. Sci. 2019, 6, 157–168. [Google Scholar]

- Wilson, A. The formation of dry, wet, spunlaid and other types of nonwovens. In Applications of Nonwovens in Technical Textiles; Woodhead Publishing: Cambridge, UK, 2010. [Google Scholar]

- Chen, X.; Chen, L.; Zhang, C.; Song, L.; Zhang, D. Three-dimensional needle-punching for composites—A review. Compos. Part A 2016, 85, 12–30. [Google Scholar] [CrossRef]

- Hu, S.; Wang, D.; Venkataraman, M.; Křemenáková, D.; Militký, J.; Yang, K. Enhanced electromagnetic shielding of lightweight copper-coated nonwoven laminate with carbon filament reinforcement. J. Eng. Fibers Fabr. 2023, 18, 15589250231199970. [Google Scholar] [CrossRef]

- Sedighi, A.; Naderi, M.; Brycki, B. Wearable nonwoven fabric decorated with Fe3O4/rGO/PANI/Ni-P for efficient electromagnetic interference shielding. J. Alloys Compd. 2023, 938, 168454. [Google Scholar] [CrossRef]

- Liu, L.; Wang, H.; Shan, M.; Jiang, Y.; Zhang, X.; Xu, Z. Lightweight sandwich fiber-welded foam-like nonwoven fabrics/graphene composites for electromagnetic shielding. Mater. Chem. Phys. 2019, 232, 246–253. [Google Scholar] [CrossRef]

- Gao, Y.N.; Wang, Y.; Yue, T.N.; Weng, Y.X.; Wang, M. Multifunctional cotton non-woven fabrics coated with silver nanoparticles and polymers for antibacterial, superhydrophobic and high performance microwave shielding. J. Colloid Interface Sci. 2021, 582 Pt A, 112–123. [Google Scholar] [CrossRef]

- Maity, S.; Chatterjee, A. Polypyrrole functionalized polyester needlepunched nonwoven fabrics for electro-magnetic interference shielding. Polym. Compos. 2018, 39, 3696–3704. [Google Scholar] [CrossRef]

- Zhao, X.; Fu, J.; Wang, H. The electromagnetic interference shielding performance of continuous carbon fiber composites with different arrangements. J. Ind. Text. 2016, 46, 45–58. [Google Scholar] [CrossRef]

- Ramírez-Herrera, C.A.; Gonzalez, H.; Torre, F.; Benitez, L.; Cabañas-Moreno, J.G.; Lozano, K. Electrical Properties and Electromagnetic Interference Shielding Effectiveness of Interlayered Systems Composed by Carbon Nanotube Filled Carbon Nanofiber Mats and Polymer Composites. Nanomaterials 2019, 9, 238. [Google Scholar] [CrossRef]

- Lu, H.; Liao, B.; Wang, H.; Xu, Z.; Li, N.; Liu, L.; Wu, N. Electromagnetic shielding of ultrathin, lightweight and strong nonwoven composites decorated by a bandage-style interlaced layer electropolymerized with polyaniline. J. Mater. Sci. Mater. Electron. 2019, 30, 10854. [Google Scholar] [CrossRef]

- Ren, W.; Zhu, H.; Yang, Y.; Chen, Y.; Duan, H.; Zhao, G.; Liu, Y. Flexible and robust silver coated non-woven fabric reinforced waterborne polyurethane films for ultra-efficient electromagnetic shielding. Compos. Part B Eng. 2020, 184, 107745. [Google Scholar] [CrossRef]

- Lin, J.H.; Hsu, P.W.; Huang, C.H.; Lai, M.F.; Shiu, B.C.; Lou, C.W. A Study on Carbon Fiber Composites with Low-Melting-Point Polyester Nonwoven Fabric Reinforcement: A Highly Effective Electromagnetic Wave Shield Textile Material. Polymers 2022, 14, 1181. [Google Scholar] [CrossRef] [PubMed]

- Ütebay, B.; Çelik, P.; Çay, A. Effects of cotton textile waste properties on recycled fibre quality. J. Clean. Prod. 2019, 222, 29–35. [Google Scholar] [CrossRef]

- Araujo, E.M.; Araujo, K.D.; Pereira, O.D.; Ribeiro, P.C.; Melo, T.J.A. Fiberglass Wastes/Polyester Resin Composites: Mechanical Properties and Water Sorption. Polím. Ciênc. E Tecnol. 2006, 16, 332–335. [Google Scholar] [CrossRef]

- ASTM D7291; Standard Test Method for Through-Thickness “Flatwise” Tensile Strength and Elastic Modulus of a Fiber-Reinforced Polymer Matrix Composite Material. ASTM: West Conshohocken, PA, USA, 2022.

- ASTM D792-20; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM: West Conshohocken, PA, USA, 2020.

- TS EN50147-1; Anechoic Chambers-Part-1: Shield Attenuation Measurement. SIST—Slovenian Institute for Standardization: Ljubljana, Slovenia, 2005.

- TTS-FA-003; Test Method of Specified Requirements of Electromagnetic Shielding Textiles. Committee for Conformity Assessment on Accreditation and Certification of Functional and Technical Textiles: Taipei, Taiwan, 2005.

- ASTM D 257-07; Standard Test Methods for DC Resistance or Conductance of Insulating Materials. ASTM: West Conshohocken, PA, USA, 2007.

- ASTM D3039; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM: West Conshohocken, PA, USA, 2014.

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM: West Conshohocken, PA, USA, 2017.

- Liu, X.; Li, Y.; Sun, X.; Tang, W.; Deng, G.; Liu, Y.; Shui, J. Of/on switchable smart electromagnetic interference shielding aerogel. Matter 2021, 4, 1735–1747. [Google Scholar] [CrossRef]

- Tserpers, K.; Tzatzadakis, V.; Bachmann, J. Electrical Conductivity and Electromagnetic Shielding Effectiveness of Bio-Composites. J. Compos. Sci. 2020, 4, 28. [Google Scholar] [CrossRef]

- Afilipoaei, C.; Draghicescu, H.T. A Review over Electromagnetic Shielding Effectiveness of Composite Materials. In Proceedings of the 14th International Conference on Interdisciplinarity in Engineering—INTER-ENG 2020, Târgu Mures, Romania, 8–9 October 2020. [Google Scholar]

| Writer/Year | Reinforcement | Matrix | Method | EMSE (dB) | Difference of Our Study |

|---|---|---|---|---|---|

| Hu et al., 2023 [27] | Cupper Coated PET Nonwoven | Polyamid + Carbon Fiber | Lamination | 88.6 | Recycled fibers, Conductive Particles, Matrix, Productionmethod |

| Sedighi et al., 2022 [28] | PET Nonwoven | Polyaniline (PANI) + rGO and Fe3O4 nanopowders | Layer-by-layer | 76.6 | Recycled Fibers, Conductive particles type, Matrix, Production method |

| Liu et al., 2019 [29] | Fiber-Welded Nonwoven + Graphene Oxide (GO) Sheets | Epoxy | Resin Transfer Molding | 65 | Recycled fibers. Production of Reinforcement, Matrix, Composite production methodMethod |

| Gao et al., 2021 [30] | Cotton Nonwoven | Polydopamine (PDA) + Ag nanoparticles | Coating | 110 | Recycled fibers, Type of conductive particles, Matrix, Production Method |

| Maity and Chatterjee, 2018 [31] | Polyester Nonwoven | Polypyrrole (PPy) | Coating | 20.07 | Recycled Fibers, Conductive Polymer Matrix, Production Method |

| Zhao et al., 2016 [32] | PET Nonwoven | Acrylic Adhesive + Carbon Fiber | Layer-by-layer | 60.49 | Recycled Fibers, Conductice Fibers, Matrix, Method |

| Fan et al., 2021 [9] | PET Nonwoven + Graphene (GE) nanosheets | Polyvinylidenefluoride (PVDF) | Coating | 31.2 | Recycled Fibers, Matrix, Production methodMethod |

| Herrera et al., 2018 [33] | Nonwoven+ MWCNT filled carbon nanofiber | Nanoreinforced Polymer (PP) Composite Sheets (NRPCS) | Compression-molded | 17 | Recycled fibers, Conductive Particles, Matrix, Production Method |

| Lu et al., 2019 [34] | Carbon Fiber Nonwoven (CFNW) + Polyaniline (PANI) | Epoxy | Screen coating | 61 | Recycled fibers, Matrix, ProductionMethod |

| Ren et al., 2020 [35] | Ag Coated Nonwoven | Waterborne Polyurethane (WPU) Film + Ag Particles | Casting | 72.5 | Production of Reinforcement, Conductive Particles Matrix, Method |

| Ali et al., 2022 [12] | Recycled Kevlar Nonwoven | Epoxy + Carbon Particles | Hand Lay Up | 35.6 | Reinforcement material and Matrix, |

| Lin et al., 2022 [36] | Carbon fiber woven fabric and nylon spacer fabric | Low melting point PES nonwoven | Lamination | 65 | Nonwoven reinforcement with recycled fibers |

| Parameter | Value |

|---|---|

| Needle depth (cm) | 0.8 |

| Speed of the conveyor belt of needling and wind up (m/min) | 4 |

| Speed of the conveyor belt of cross lapper (m/min) | 2 |

| Sample Name | Reinforcement | Resin |

|---|---|---|

| 100% Co + 0% Cu | 100% Cotton | 100% PES |

| 100% Co + 10% Cu | 100% Cotton | 90% PES + 10% CuSO4 |

| 100% Co + 30% Cu | 100% Cotton | 70% PES + 30% CuSO4 |

| 10% Rcy + 0% Cu | 10% Recycled fiber + 90% Cotton | 100% PES |

| 10% Rcy + 10% Cu | 10% Recycled fiber + 90% Cotton | 90% PES + 10% CuSO4 |

| 10% Rcy + 30% Cu | 10% Recycled fiber + 90% Cotton | 70% PES + 30% CuSO4 |

| 25% Rcy + 0% Cu | 25% Recycled fiber + 75% Cotton | 100% PES |

| 25% Rcy + 10% Cu | 25% Recycled fiber + 75% Cotton | 90% PES + 10% CuSO4 |

| 25% Rcy + 30% Cu | 25% Recycled fiber + 75% Cotton | 70% PES + 30% CuSO4 |

| 50% Rcy + 0% Cu | 50% Recycled fiber + 50% Cotton | 100% PES |

| 50% Rcy + 10% Cu | 50% Recycled fiber + 50% Cotton | 90% PES + 10% CuSO4 |

| 50% Rcy + 30% Cu | 50% Recycled fiber + 50% Cotton | 70% PES + 30% CuSO4 |

| 100% Co + 0% Gra | 100% Cotton | 100% PES |

| 100% Co + 10% Gra | 100% Cotton | 90% PES + 10% Graphite |

| 100% Co + 30% Gra | 100% Cotton | 70% PES + 30% Graphite |

| 10% Rcy + 0% Gra | 10% Recycled fiber + 90% Cotton | 100% PES |

| 10% Rcy + 10% Gra | 10% Recycled fiber + 90% Cotton | 90% PES + 10% Graphite |

| 10% Rcy + 30% Gra | 10% Recycled fiber + 90% Cotton | 70% PES + 30% Graphite |

| 25% Rcy + 0% Gra | 25% Recycled fiber + 75% Cotton | 100% PES |

| 25% Rcy + 10% Gra | 25% Recycled fiber + 75% Cotton | 90% PES + 10% Graphite |

| 25% Rcy + 30% Gra | 25% Recycled fiber + 75% Cotton | 70% PES + 30% Graphite |

| 50% Rcy + 0% Gra | 50% Recycled fiber + 50% Cotton | 100% PES |

| 50% Rcy + 10% Gra | 50% Recycled fiber + 50% Cotton | 90% PES + 10% Graphite |

| 50% Rcy + 30% Gra | 50% Recycled fiber + 50% Cotton | 70% PES + 30% Graphite |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atay, M.; Duran Kaya, D.; Ülker, A. Development of Electromagnetic Shielding Composites Reinforced with Nonwovens Produced from Recycled Fibers. Polymers 2023, 15, 4469. https://doi.org/10.3390/polym15224469

Atay M, Duran Kaya D, Ülker A. Development of Electromagnetic Shielding Composites Reinforced with Nonwovens Produced from Recycled Fibers. Polymers. 2023; 15(22):4469. https://doi.org/10.3390/polym15224469

Chicago/Turabian StyleAtay, Melisa, Deniz Duran Kaya, and Aydın Ülker. 2023. "Development of Electromagnetic Shielding Composites Reinforced with Nonwovens Produced from Recycled Fibers" Polymers 15, no. 22: 4469. https://doi.org/10.3390/polym15224469

APA StyleAtay, M., Duran Kaya, D., & Ülker, A. (2023). Development of Electromagnetic Shielding Composites Reinforced with Nonwovens Produced from Recycled Fibers. Polymers, 15(22), 4469. https://doi.org/10.3390/polym15224469