Projection Stereolithography 3D-Printed Bio-Polymer with Thermal Assistance

Abstract

:1. Introduction

2. Experimental Section

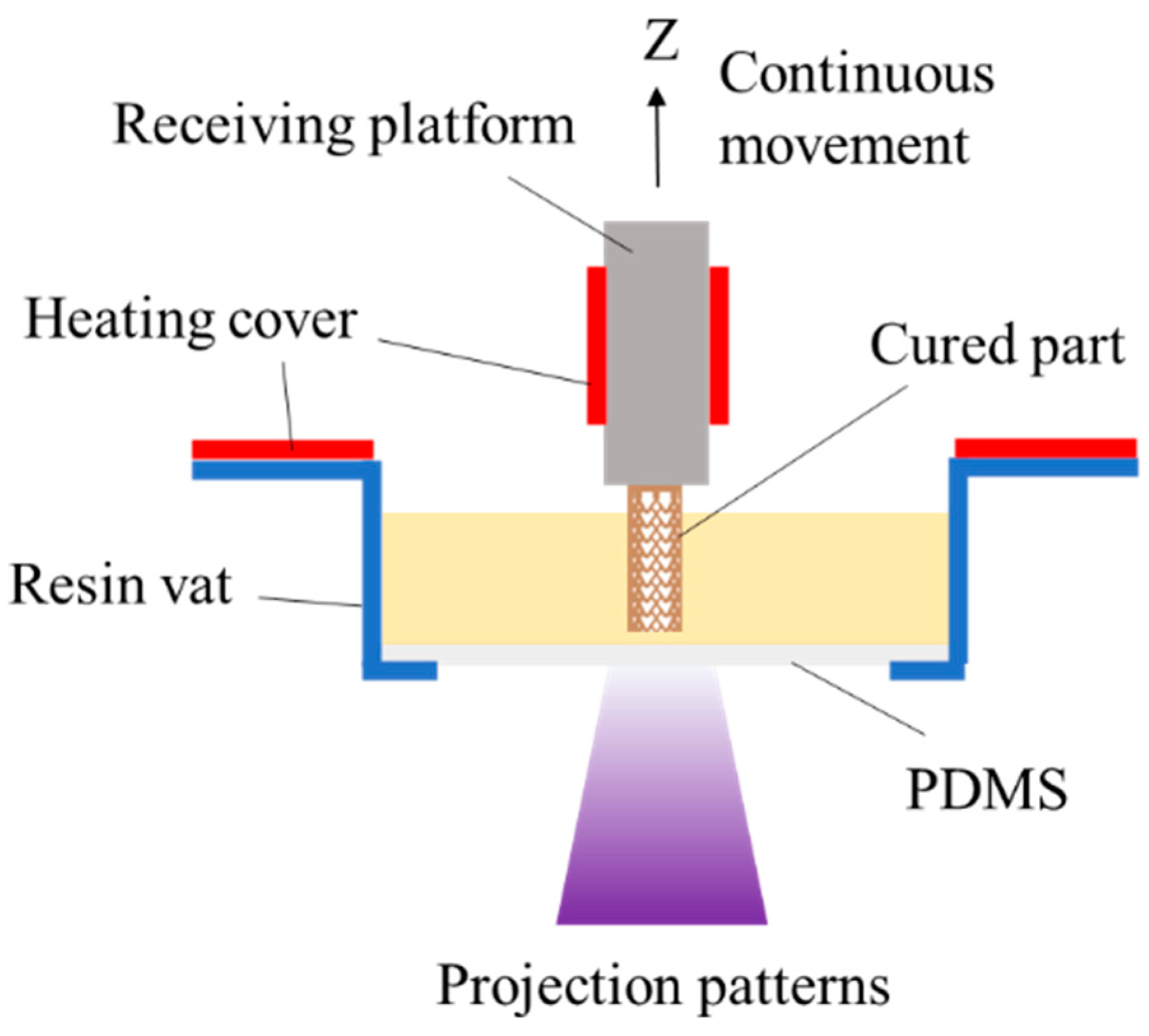

2.1. Projection Stereolithography 3D Printing System

2.2. Material Preparation

2.3. Biocompatibility Experiment

2.4. Characterization

3. Results and Discussion

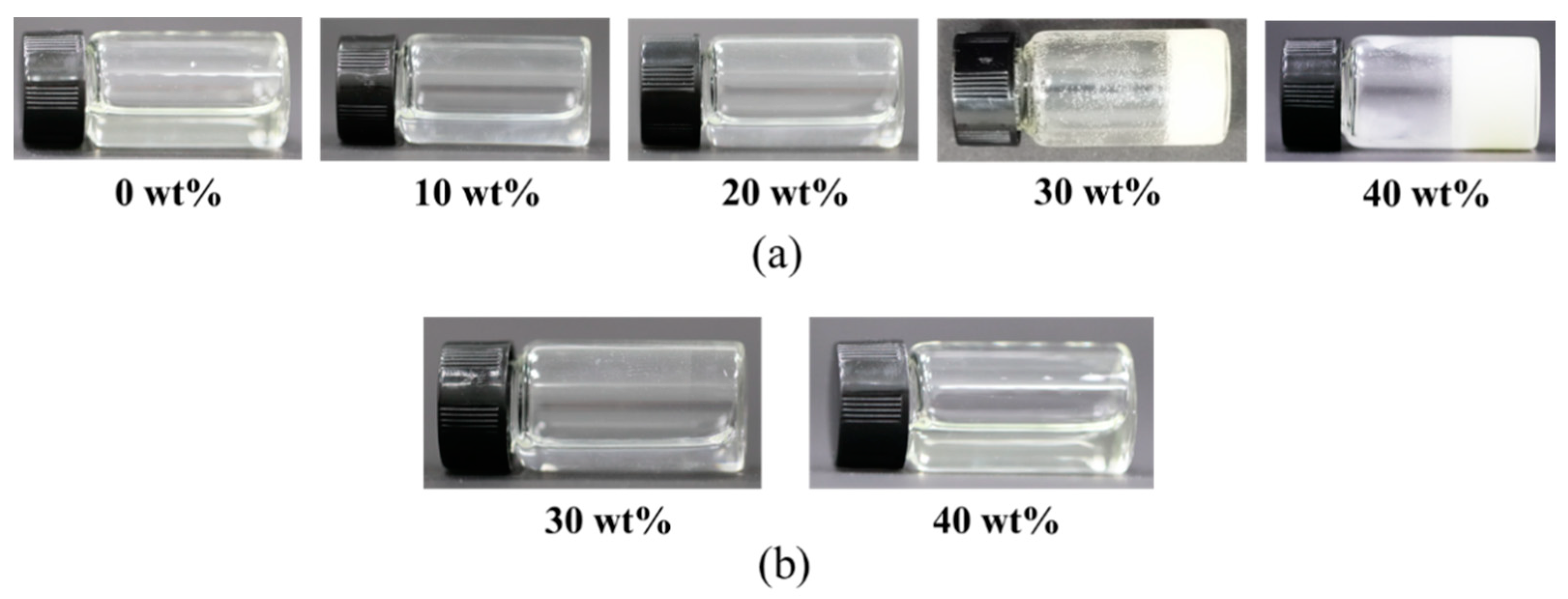

3.1. 3D Printing with Thermal Assistance

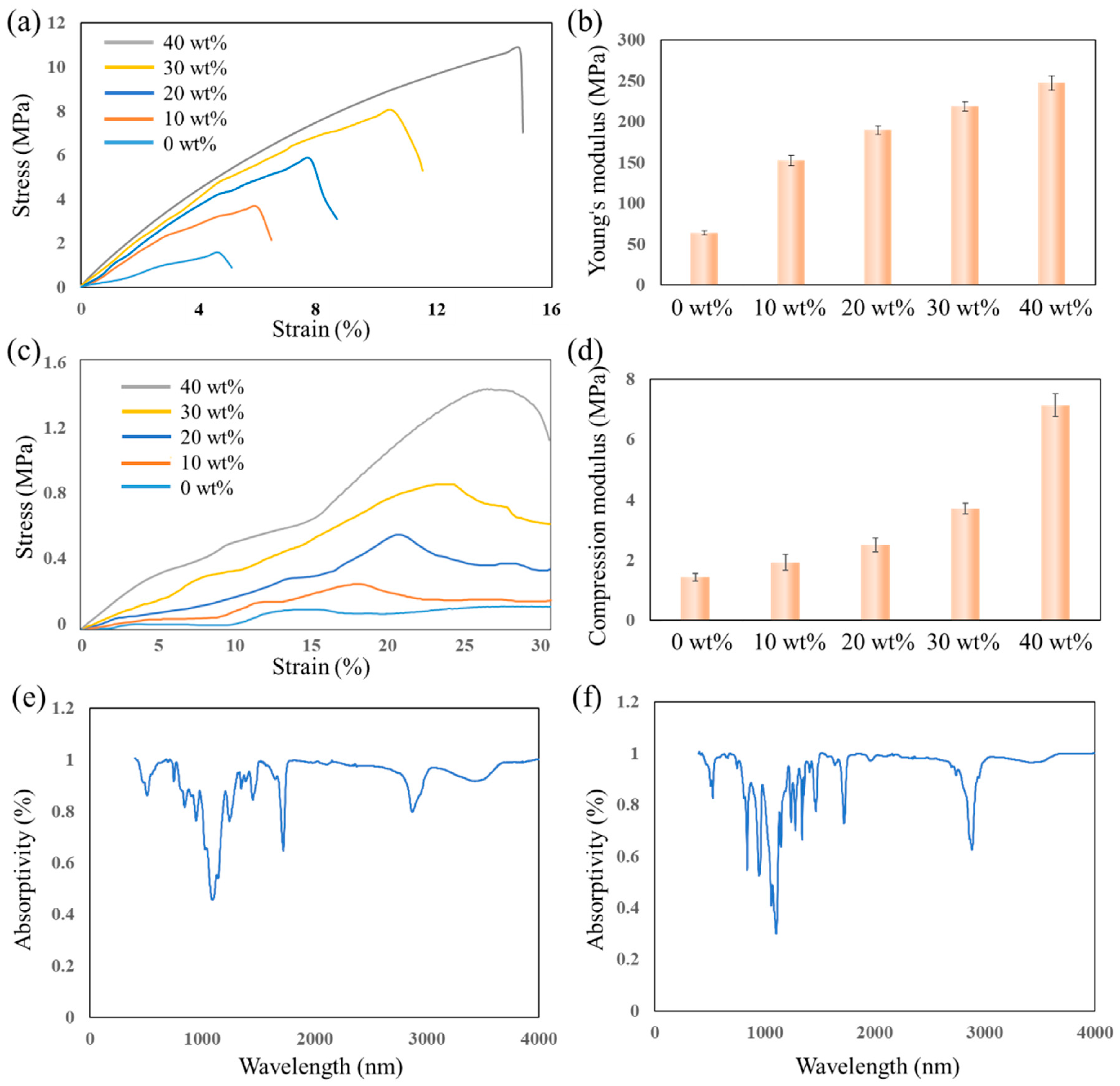

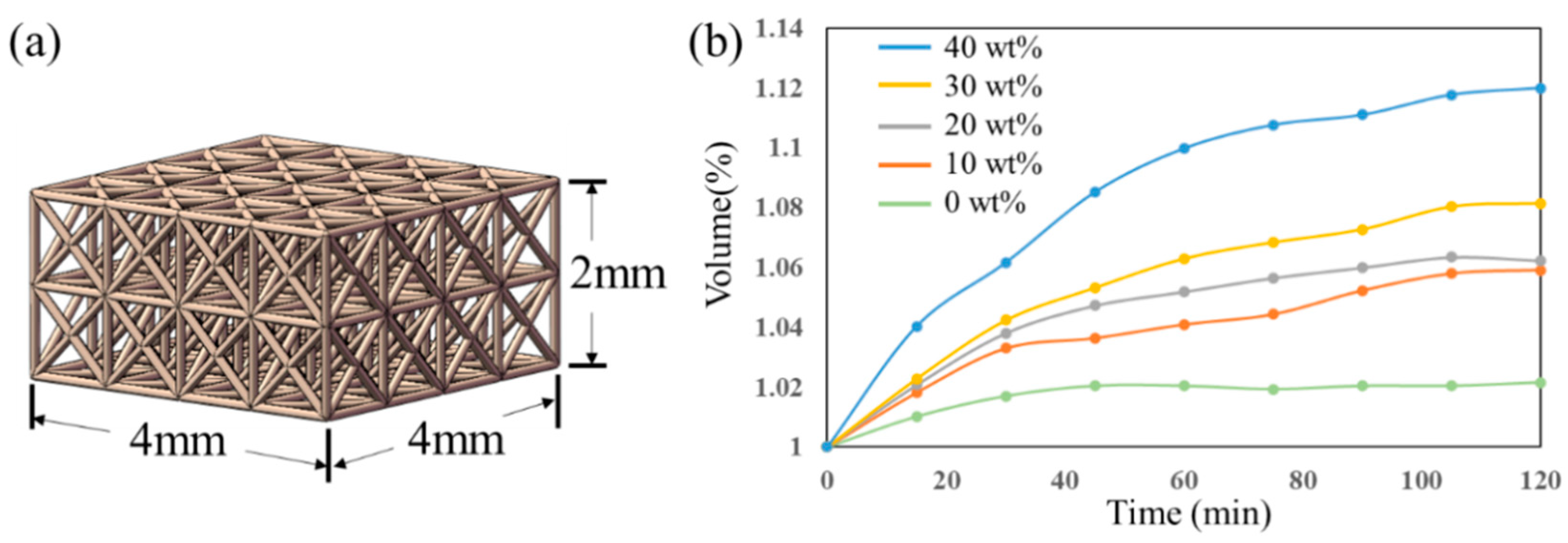

3.2. 3D Printing Experiments

3.3. Biocompatibility Experiment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hua, W.; Shi, W.; Mitchell, K.; Raymond, L.; Coulter, R.; Zhao, D.; Jin, Y. 3D Printing of Biodegradable Polymer Vascular Stents: A Review. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100020. [Google Scholar] [CrossRef]

- Huang, J.; Qin, Q.; Wang, J. A review of stereolithography: Processes and systems. Processes 2020, 8, 1138. [Google Scholar] [CrossRef]

- Wen, C.; Chen, Z.; Chen, Z.; Zhang, B.; Cheng, Z.; Yi, H.; Jiang, G.; Huang, J. Improvement of the Geometric Accuracy for Microstructures by Projection Stereolithography Additive Manufacturing. Crystals 2022, 12, 819. [Google Scholar] [CrossRef]

- Zhu, S.; Du, W.; Wang, X.; Han, G.; Ren, Z.; Zhou, K. Advanced Additive Remanufacturing Technology. Chin. J. Mech. Eng. Addit. Manuf. Front. 2023, 2, 100066. [Google Scholar] [CrossRef]

- Sun, C.; Fang, N.; Wu, D.; Zhang, X. Projection micro-stereolithography using digital micro-mirror dynamic mask. Sens. Actuators A Phys. 2005, 121, 113–120. [Google Scholar] [CrossRef]

- Tumbleston, J.R.; Shirvanyants, D.; Ermoshkin, N.; Janusziewicz, R.; Johnson, A.R.; Kelly, D.; Chen, K.; Pinschmidt, R.; Rolland, J.P.; Ermoshkin, A. Continuous liquid interface production of 3D objects. Science 2015, 347, 1349–1352. [Google Scholar] [CrossRef] [PubMed]

- Janusziewicz, R.; Tumbleston, J.R.; Quintanilla, A.L.; Mecham, S.J.; DeSimone, J.M. Layerless fabrication with continuous liquid interface production. Proc. Natl. Acad. Sci. USA 2016, 113, 11703–11708. [Google Scholar] [CrossRef]

- Huang, J.; Ware, H.O.T.; Hai, R.; Shao, G.; Sun, C. Conformal geometry and multimaterial additive manufacturing through freeform transformation of building layers. Adv. Mater. 2021, 33, 2005672. [Google Scholar] [CrossRef]

- Han, D.; Yang, C.; Fang, N.X.; Lee, H. Rapid multi-material 3D printing with projection micro-stereolithography using dynamic fluidic control. Addit. Manuf. 2019, 27, 606–615. [Google Scholar] [CrossRef]

- Walker, D.A.; Hedrick, J.L.; Mirkin, C.A. Rapid, large-volume, thermally controlled 3D printing using a mobile liquid interface. Science 2019, 366, 360–364. [Google Scholar] [CrossRef]

- Loterie, D.; Delrot, P.; Moser, C. High-resolution tomographic volumetric additive manufacturing. Nat. Commun. 2020, 11, 852. [Google Scholar] [CrossRef] [PubMed]

- Kelly, B.E.; Bhattacharya, I.; Heidari, H.; Shusteff, M.; Spadaccini, C.M.; Taylor, H.K. Volumetric additive manufacturing via tomographic reconstruction. Science 2019, 363, 1075–1079. [Google Scholar] [CrossRef] [PubMed]

- Hahn, V.; Messer, T.; Bojanowski, N.M.; Curticean, E.R.; Wacker, I.; Schröder, R.R.; Blasco, E.; Wegener, M. Two-step absorption instead of two-photon absorption in 3D nanoprinting. Nat. Photonics 2021, 15, 932–938. [Google Scholar] [CrossRef]

- Hahn, V.; Rietz, P.; Hermann, F.; Müller, P.; Barner-Kowollik, C.; Schlöder, T.; Wenzel, W.; Blasco, E.; Wegener, M. Light-sheet 3D microprinting via two-colour two-step absorption. Nat. Photonics 2022, 16, 784–791. [Google Scholar] [CrossRef]

- Zhou, X.; Ren, L.; Liu, Q.; Song, Z.; Wu, Q.; He, Y.; Li, B.; Ren, L. Advances in Field-Assisted 3D Printing of Bio-Inspired Composites: From Bioprototyping to Manufacturing. Macromol. Biosci. 2022, 22, 2100332. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Li, X.; Chu, M.; Sun, H.; Jin, J.; Yu, K.; Wang, Q.; Zhou, Q.; Chen, Y. Electrically assisted 3D printing of nacre-inspired structures with self-sensing capability. Sci. Adv. 2019, 5, eaau9490. [Google Scholar] [CrossRef] [PubMed]

- Greenhall, J.; Raeymaekers, B. 3D Printing macroscale engineered materials using ultrasound directed self-assembly and stereolithography. Adv. Mater. Technol. 2017, 2, 1700122. [Google Scholar] [CrossRef]

- Qiao, J.; Li, Y.; Li, L. Ultrasound-assisted 3D printing of continuous fiber-reinforced thermoplastic (FRTP) composites. Addit. Manuf. 2019, 30, 100926. [Google Scholar] [CrossRef]

- Johnson, K.; Melchert, D.; Gianola, D.S.; Begley, M.; Ray, T.R. Recent progress in acoustic field-assisted 3D-printing of functional composite materials. MRS Adv. 2021, 6, 636–643. [Google Scholar] [CrossRef]

- Li, X.; Lim, K.M.; Zhai, W. A novel class of bioinspired composite via ultrasound-assisted directed self-assembly digital light 3D printing. Appl. Mater. Today 2022, 26, 101388. [Google Scholar] [CrossRef]

- Kokkinis, D.; Schaffner, M.; Studart, A.R. Multimaterial magnetically assisted 3D printing of composite materials. Nat. Commun. 2015, 6, 8643. [Google Scholar] [CrossRef]

- Ma, Y.; Wu, Q.; Duanmu, L.; Wu, S.; Liu, Q.; Li, B.; Zhou, X. Bioinspired composites reinforced with ordered steel fibers produced via a magnetically assisted 3D printing process. J. Mater. Sci. 2020, 55, 15510–15522. [Google Scholar] [CrossRef]

- Pfaffinger, M. Hot Lithography—New Possibilities in Polymer 3D Printing. Laser Tech. J. 2018, 15, 45–47. [Google Scholar] [CrossRef]

- Steyrer, B.; Busetti, B.; Harakály, G.; Liska, R.; Stampfl, J. Hot Lithography vs. room temperature DLP 3D-printing of a dimethacrylate. Addit. Manuf. 2018, 21, 209–214. [Google Scholar] [CrossRef]

- Dall, C.; Hochwallner, A.; Klikovits, N.; Liska, R.; Stampf, J.; Sangermano, M. Hot-Lithography SLA-3D Printing of Epoxy Resin. Macromol. Mater. Eng. 2020, 305, 2000325. [Google Scholar] [CrossRef]

- Ma, H.; Tian, X.; Wang, T.; Tang, K.; Liu, Z.; Hou, S.; Jin, H.; Cao, G. Tailoring pore structures of 3D printed cellular High-Loading cathodes for advanced rechargeable Zinc-Ion batteries. Small 2021, 17, 2100746. [Google Scholar] [CrossRef] [PubMed]

- Shao, G.; Ware, H.O.T.; Li, L.; Sun, C. Rapid 3D printing magnetically active microstructures with high solid loading. Adv. Eng. Mater. 2020, 22, 1900911. [Google Scholar] [CrossRef]

- Gu, D. Additive Manufacturing towards Even Higher Performance. Chin. J. Mech. Eng. Addit. Manuf. Front. 2023, 2, 100070. [Google Scholar] [CrossRef]

- Chen, Z.; Li, J.; Liu, C.; Liu, Y.; Zhu, J.; Lao, C. Preparation of high solid loading and low viscosity ceramic slurries for photopolymerization-based 3D printing. Ceram. Int. 2019, 45, 11549–11557. [Google Scholar] [CrossRef]

- Huang, J.; Chen, Z.; Wen, C.; Ling, T.; Chen, Z. Thermally assisted 3D printing of bio-polymer with high solute loading with improved mechanical properties. Addit. Manuf. 2022, 59, 103088. [Google Scholar] [CrossRef]

- Chen, X.; Liu, W.; Dong, B.; Lee, J.; Ware, H.O.T.; Zhang, H.F.; Sun, C. High-speed 3D printing of millimeter-size customized aspheric imaging lenses with sub 7 nm surface roughness. Adv. Mater. 2018, 30, 1705683. [Google Scholar] [CrossRef] [PubMed]

- Zha, X.-J.; Zhang, B.; Cheng, Z.-C.; Zhang, S.; Pu, J.-H.; Huang, J.-G.; Yang, W. Solvent-exchange triggered hydrogen bond activation strategy toward self-adaptive strong and tough organohydrogel artificial muscle. Chem. Eng. J. 2023, 476, 146548. [Google Scholar] [CrossRef]

- P. ISO, 527-2; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. Organization of Standardization: Geneva, Switzerland, 2012.

- Ge, Q.; Chen, Z.; Cheng, J.; Zhang, B.; Zhang, Y.-F.; Li, H.; He, X.; Yuan, C.; Liu, J.; Magdassi, S. 3D printing of highly stretchable hydrogel with diverse UV curable polymers. Sci. Adv. 2021, 7, eaba4261. [Google Scholar] [CrossRef] [PubMed]

| 0 wt% | 10 wt% | 20 wt% | 30 wt% | 40 wt% | |

|---|---|---|---|---|---|

| Young’s modulus (MPa) | 63.31 ± 2.72 | 152.62 ± 6.23 | 189.75 ± 5.57 | 218.50 ± 5.62 | 247.14 ± 8.97 |

| 0 wt% | 10 wt% | 20 wt% | 30 wt% | 40 wt% | |

|---|---|---|---|---|---|

| Compression modulus (MPa) | 1.43 ± 0.12 | 1.92 ± 0.12 | 2.50 ± 0.24 | 3.71 ± 0.18 | 7.14 ± 0.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pu, H.; Guo, Y.; Cheng, Z.; Chen, Z.; Xiong, J.; Zhu, X.; Huang, J. Projection Stereolithography 3D-Printed Bio-Polymer with Thermal Assistance. Polymers 2023, 15, 4402. https://doi.org/10.3390/polym15224402

Pu H, Guo Y, Cheng Z, Chen Z, Xiong J, Zhu X, Huang J. Projection Stereolithography 3D-Printed Bio-Polymer with Thermal Assistance. Polymers. 2023; 15(22):4402. https://doi.org/10.3390/polym15224402

Chicago/Turabian StylePu, Hao, Yuhao Guo, Zhicheng Cheng, Zhuoxi Chen, Jing Xiong, Xiaoyang Zhu, and Jigang Huang. 2023. "Projection Stereolithography 3D-Printed Bio-Polymer with Thermal Assistance" Polymers 15, no. 22: 4402. https://doi.org/10.3390/polym15224402

APA StylePu, H., Guo, Y., Cheng, Z., Chen, Z., Xiong, J., Zhu, X., & Huang, J. (2023). Projection Stereolithography 3D-Printed Bio-Polymer with Thermal Assistance. Polymers, 15(22), 4402. https://doi.org/10.3390/polym15224402