Geant4 Simulation of Photon- and Neutron-Shielding Capabilities of Biopolymer Blends of Poly(lactic acid) and Poly(hydroxybutyrate)

Abstract

1. Introduction

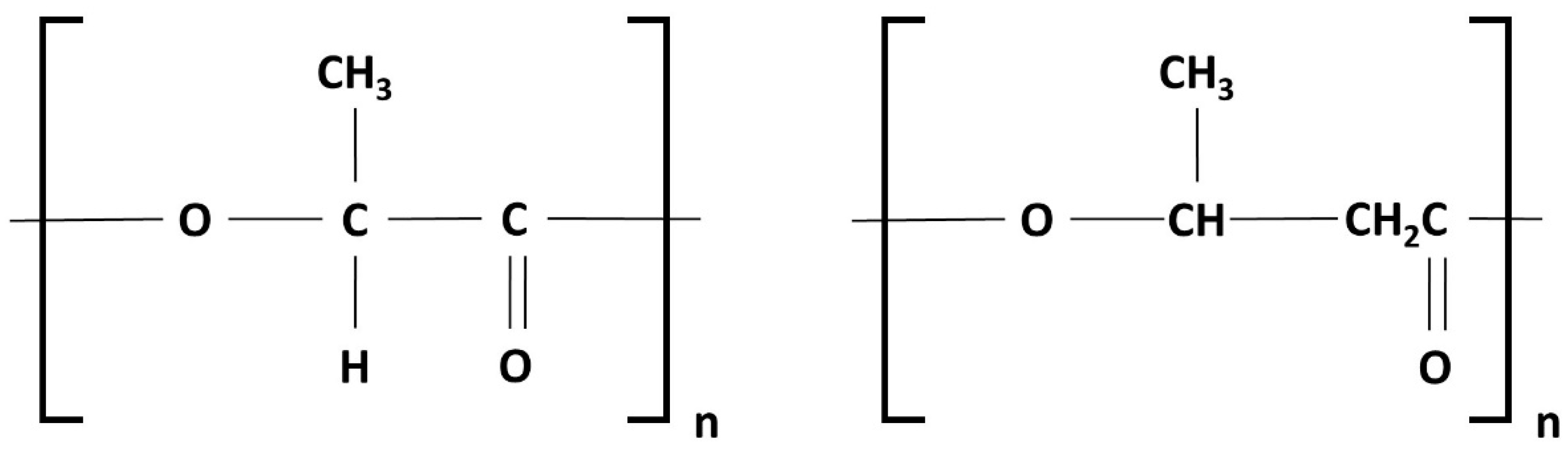

2. Materials

3. Theory

3.1. Photon Attenuation

3.2. Neutron Attenuation

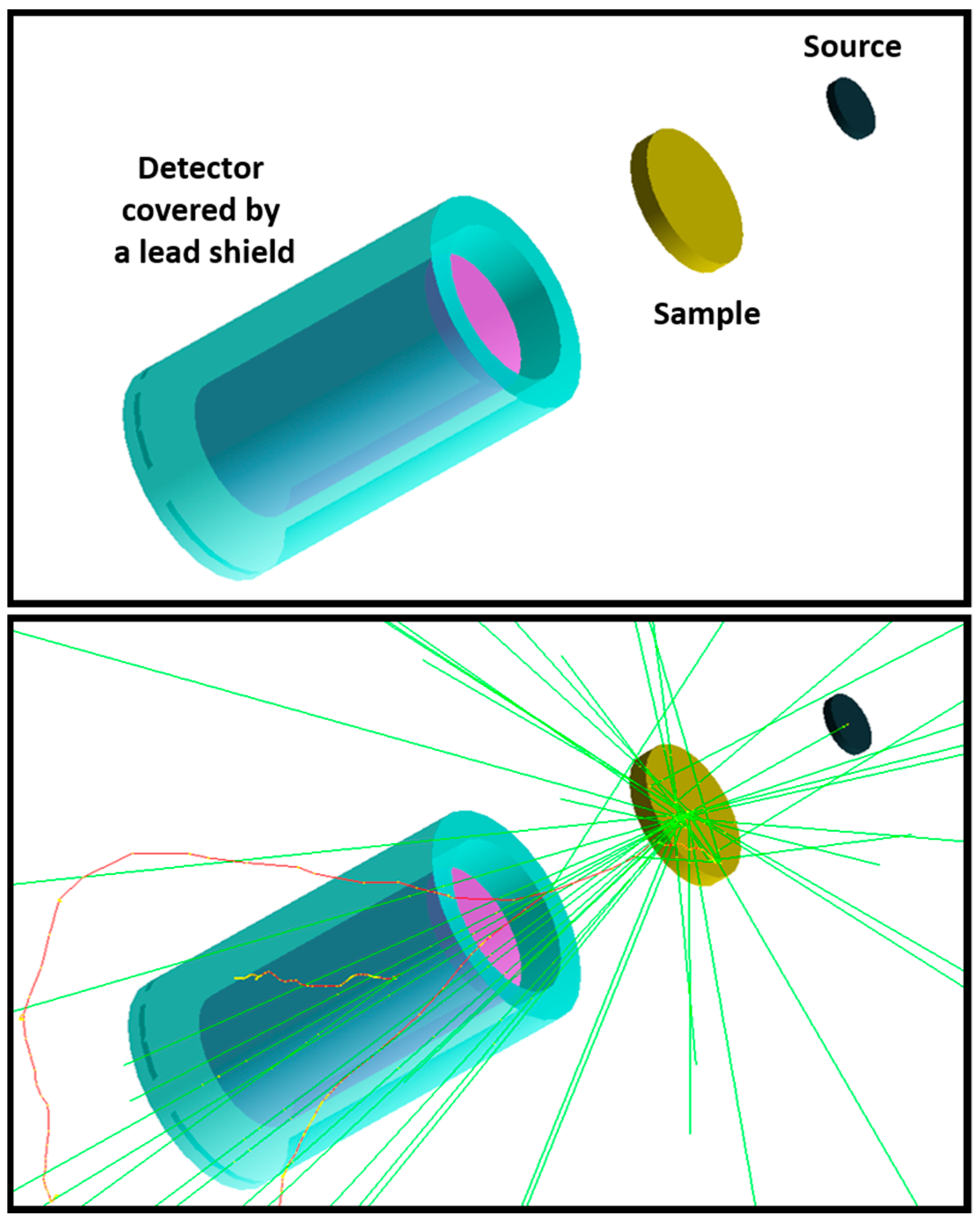

4. Methods

5. PLA Photon-Shielding Properties and Validation of Geant4 Code Results

5.1. PLA Photon-Shielding Capbilities

5.2. PLA Neutron-Shielding Capabilities

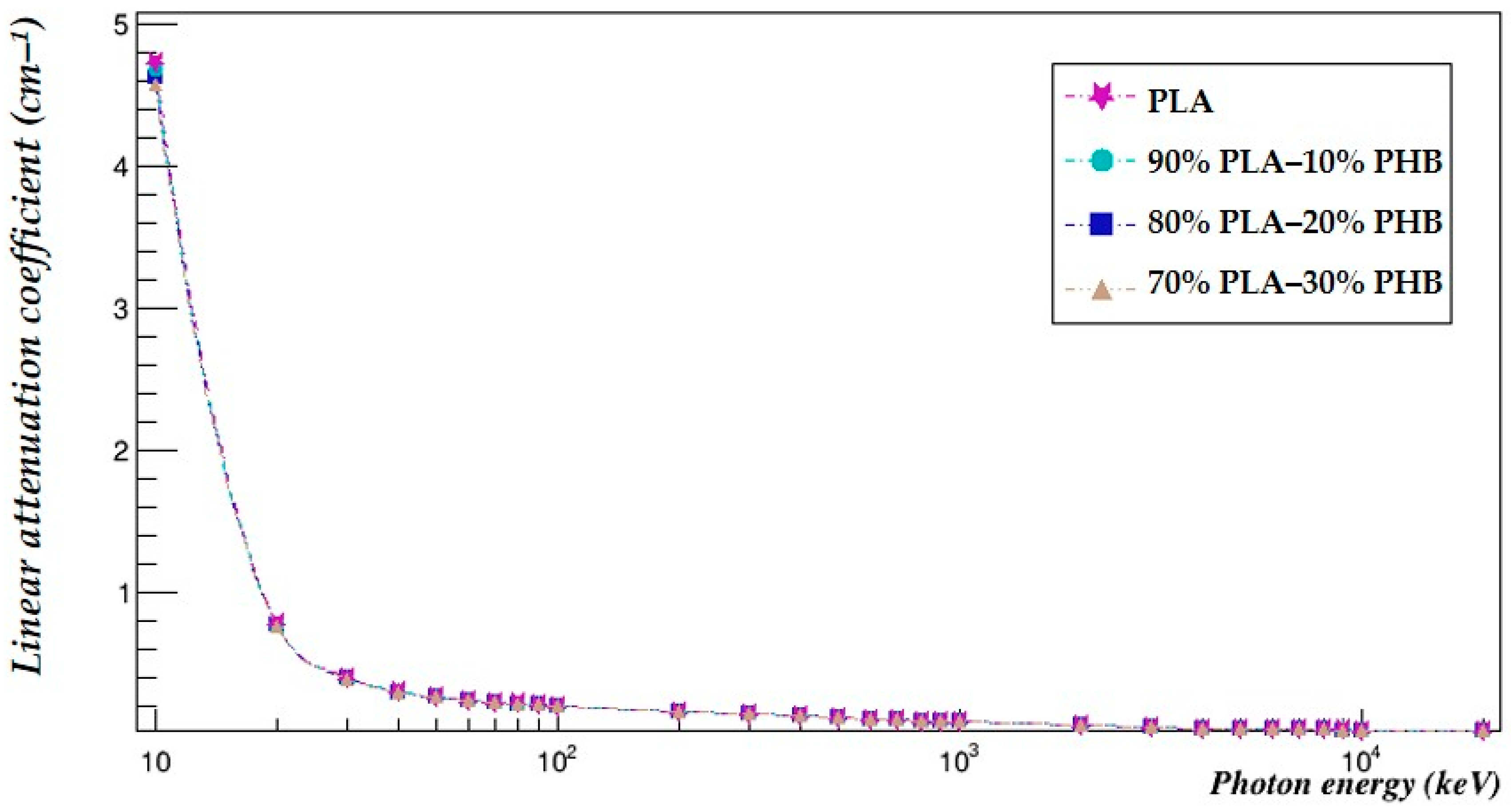

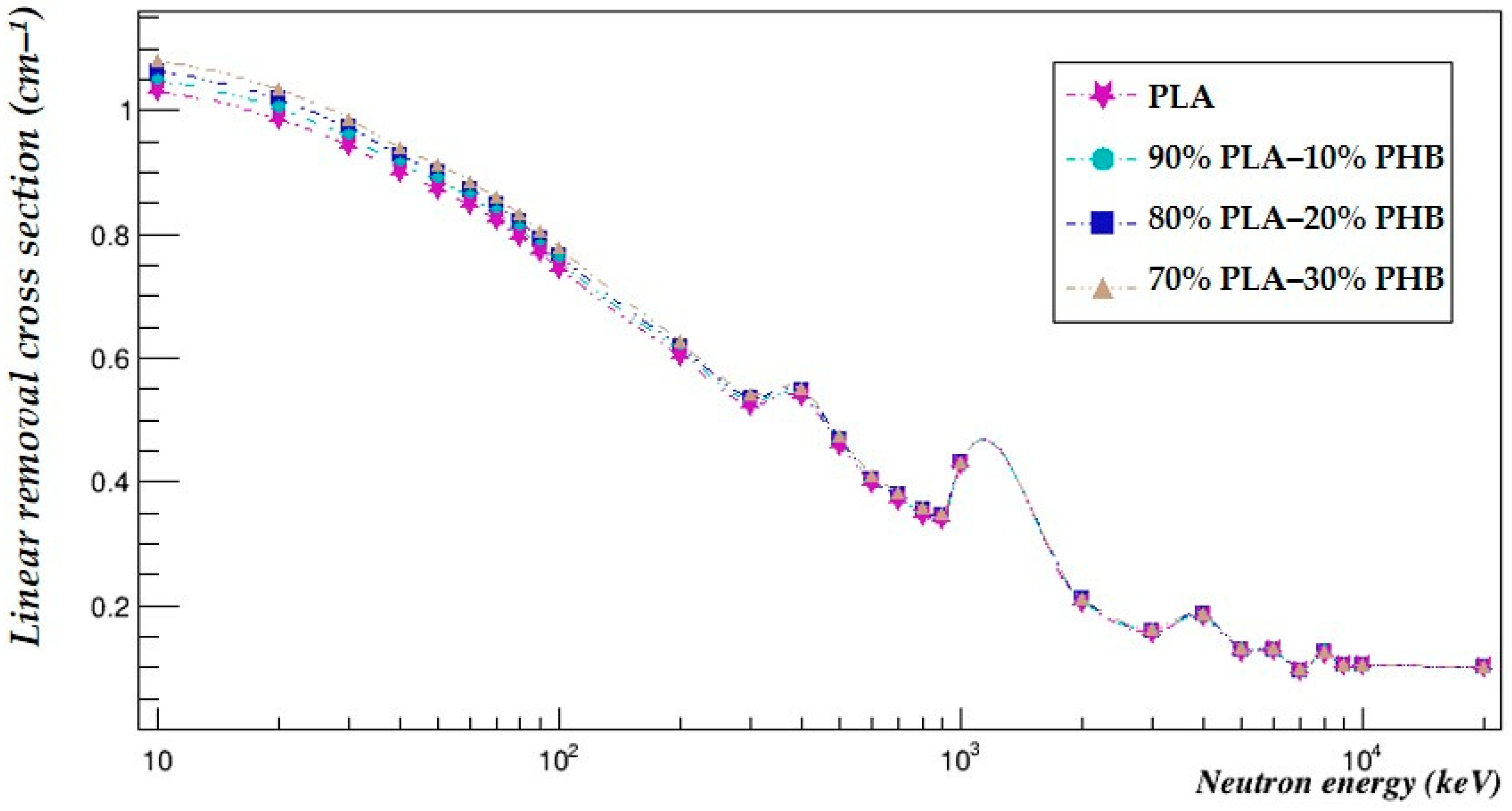

6. Effect of PLA Blending with PHB on the PLA-Shielding Properties

6.1. PLA–PHB Blends’ Photon-Shielding Capabilities

6.2. PLA–PHB Blends’ Neutron-Shielding Capabilities

7. Effect of Metal Oxide Doping on PLA–PHB Blends’ Shielding Properties

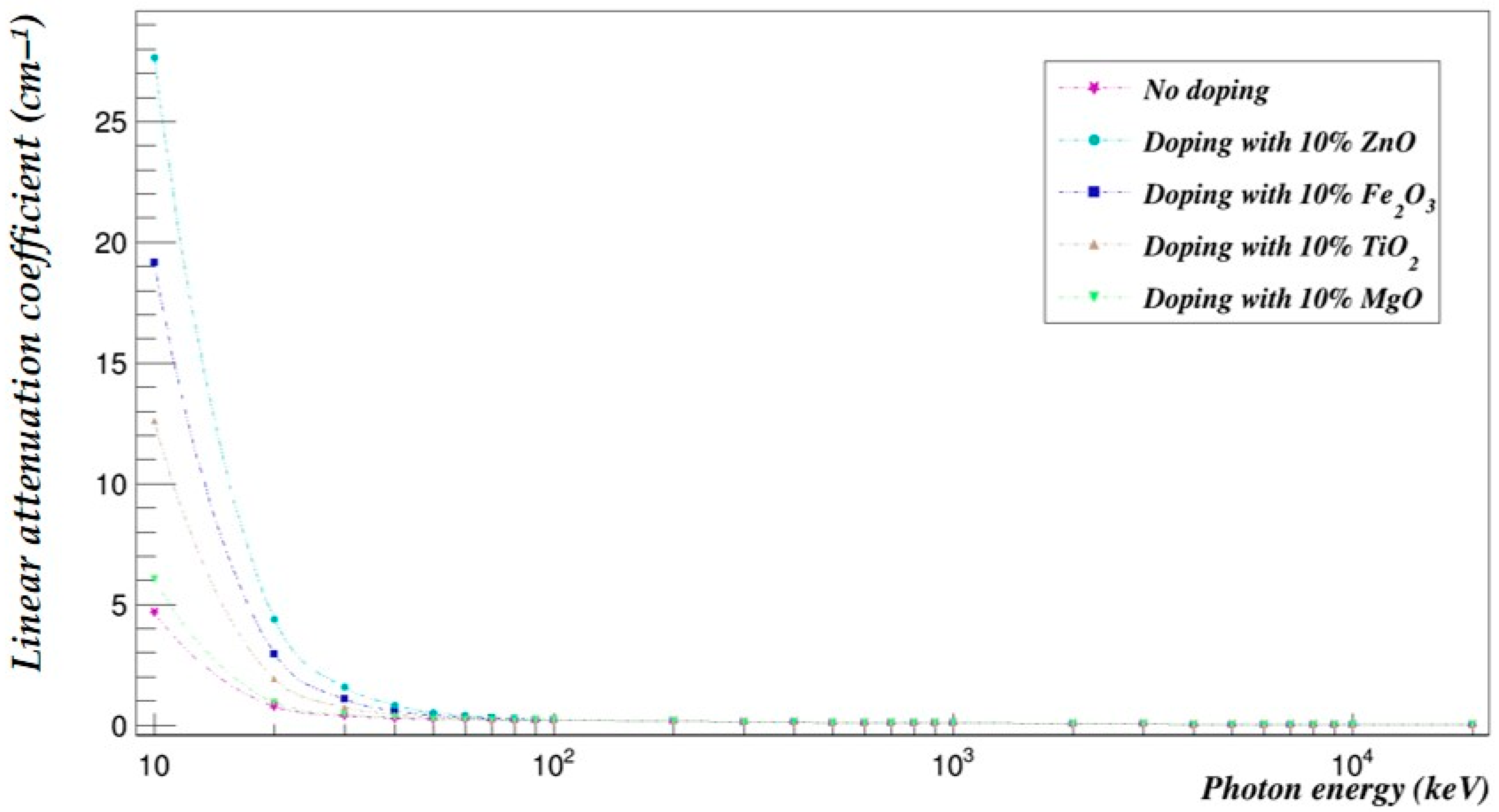

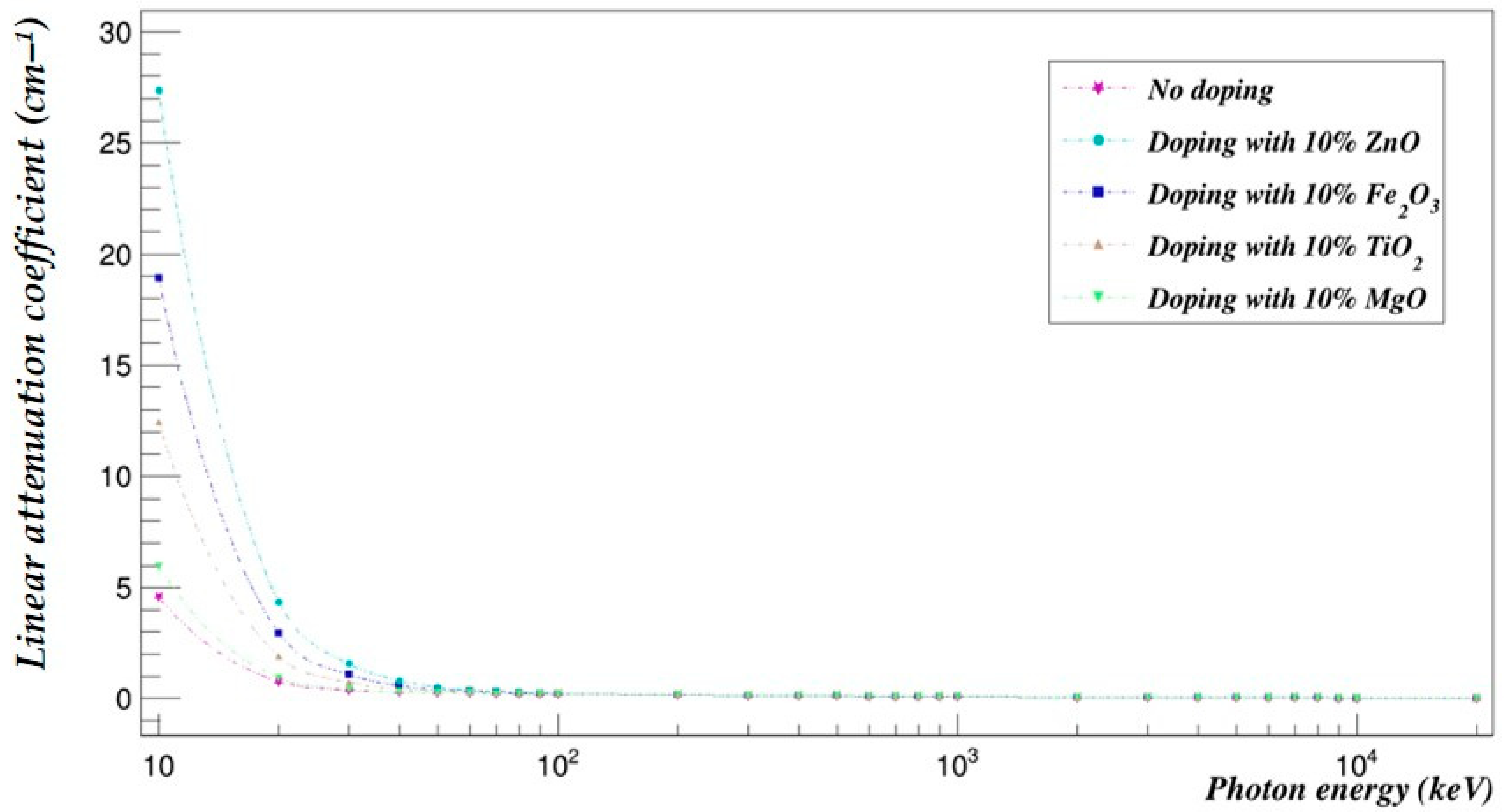

7.1. Effect of Metal Oxide Doping on the PLA–PHB Blends’ Photon-Shielding Capabilities

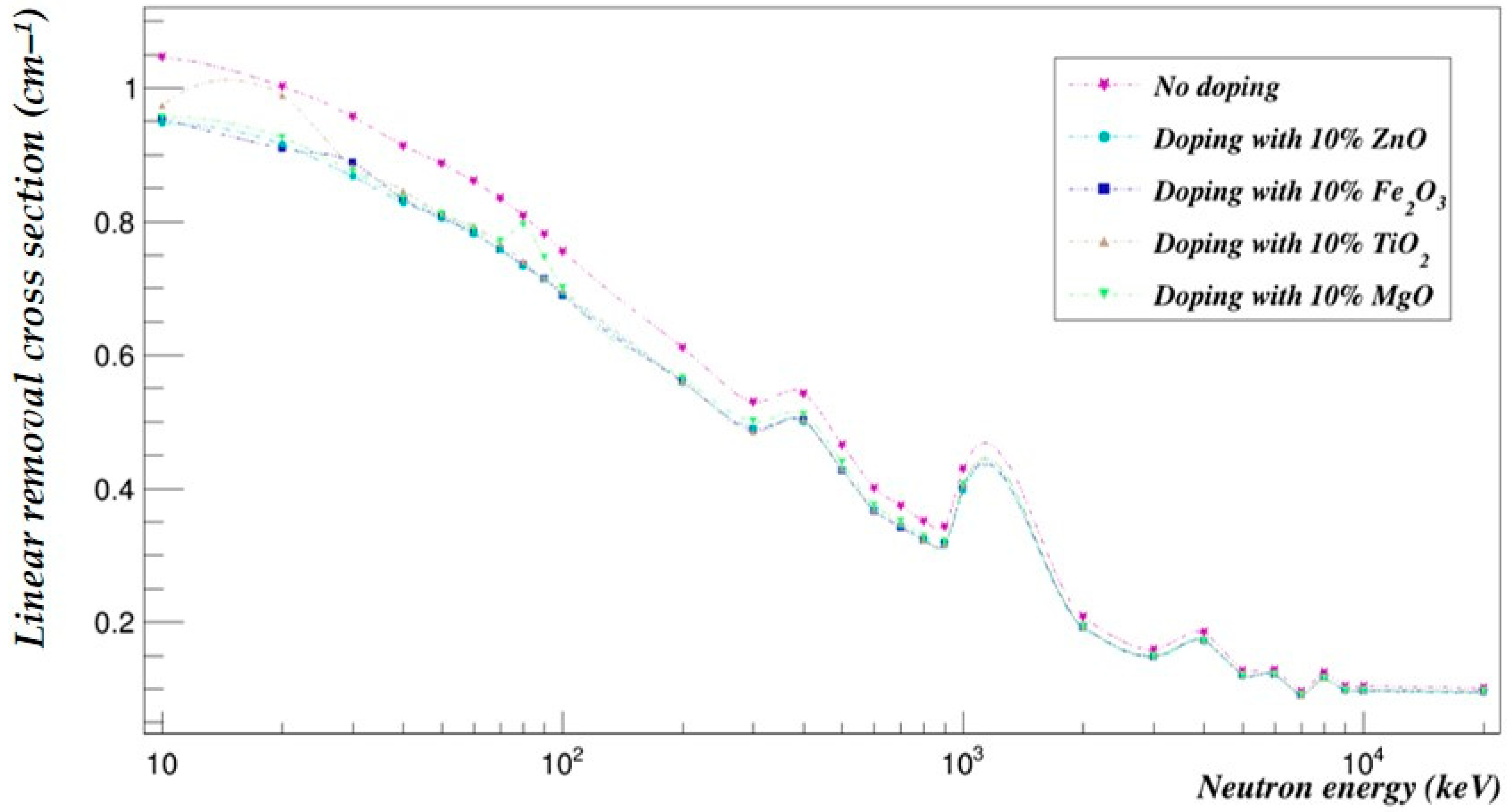

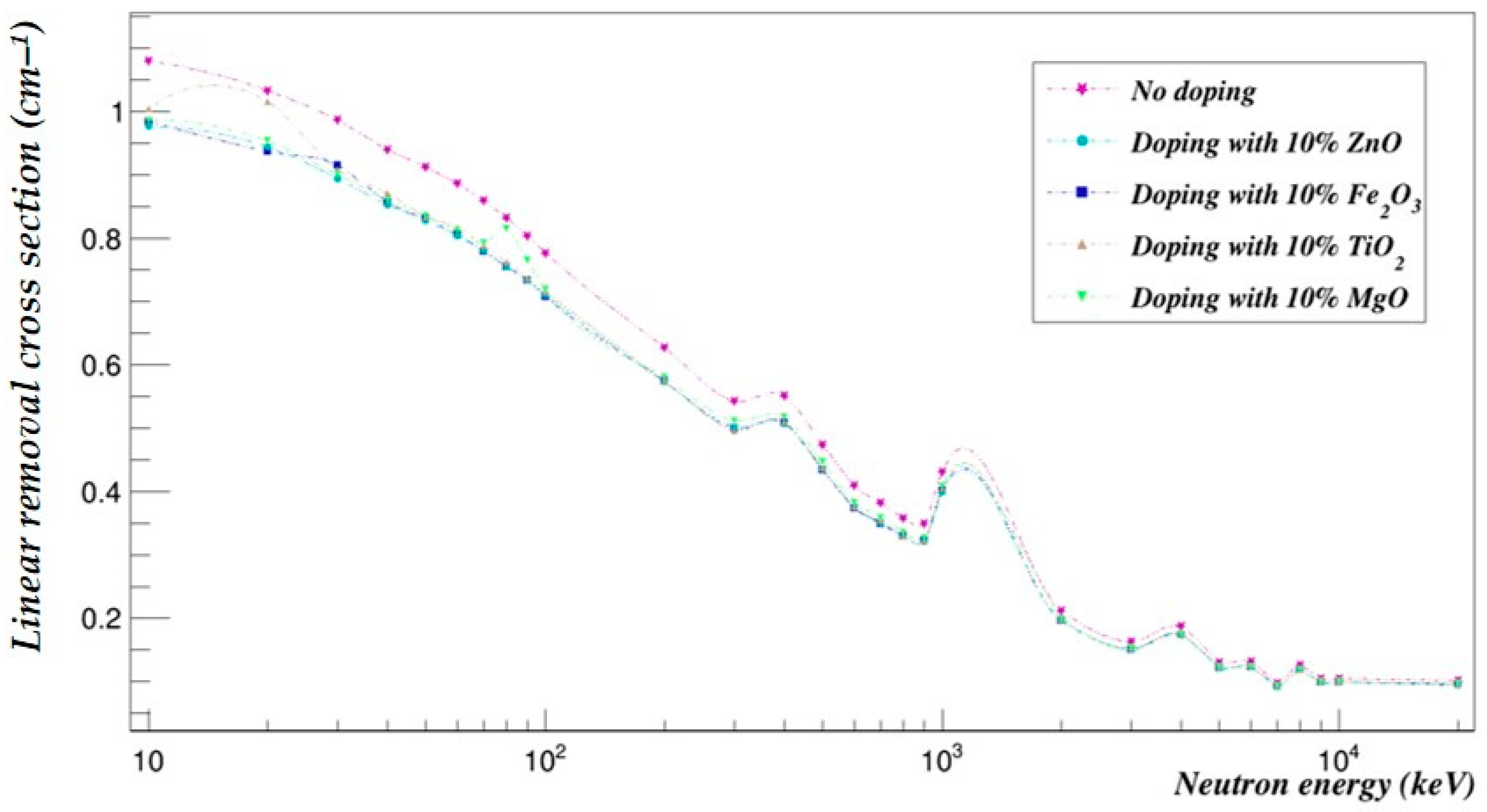

7.2. Effect of Metal Oxide Doping on the PLA–PHB Blends’ Neutron-Shielding Capabilities

8. Discussion

9. Conclusions

- -

- The photon-shielding properties decreased when blending PHB with PLA, while the neutron-shielding abilities were improved by blending.

- -

- Doping the PLA–PHB blends with metal oxides enhanced the photon-shielding capabilities of the studied blends and slightly reduced their neutron-shielding capabilities.

- -

- Geant4 is a very reliable tool which can be used to simulate the interactions of any radiation type with any material and, hence, evaluate the shielding capabilities of different materials.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Laycock, B.; Halley, P.; Pratt, S.; Werker, A.; Lant, P. The chemomechanical properties of microbial polyhydroxyalkanoates. Prog. Polym. Sci. 2014, 39, 397–442. [Google Scholar] [CrossRef]

- Tarrahi, R.; Fathi, Z.; Seydibeyoğlu, M.Ö.; Doustkhah, E.; Khataee, A. Polyhydroxyalkanoates (PHA): From production to nanoarchitecture. Int. J. Biol. Macromol. 2020, 146, 596–619. [Google Scholar] [CrossRef]

- Dintcheva, N.T.; Arrigo, R.; Baiamonte, M.; Rizzarelli, P.; Curcuruto, G. Concentration-dependent anti-/pro-oxidant activity of natural phenolic compounds in bio-polyesters. Polym. Degrad. Stab. 2017, 142, 21–28. [Google Scholar] [CrossRef]

- Stloukal, P.; Kalendova, A.; Mattausch, H.; Laske, S.; Holzer, C.; Koutny, M. The influence of a hydrolysis-inhibiting additive on the degradation and biodegradation of PLA and its nanocomposites. Polym. Test. 2015, 41, 124–132. [Google Scholar] [CrossRef]

- Mokhena, T.C.; Sefadi, J.S.; Sadiku, E.R.; John, M.J.; Mochane, M.J.; Mtibe, A. Thermoplastic Processing of PLA/Cellulose Nanomaterials Composites. Polymers 2018, 10, 1363. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, C.; Gonçalves, I.C.; Magalhães, F.D.; Pinto, A.M. Poly (lactic acid) Composites Containing Carbon-Based Nanomaterials: A Review. Polymers 2017, 9, 269. [Google Scholar] [CrossRef] [PubMed]

- Burzic, I.; Pretschuh, C.; Kaineder, D.; Eder, G.; Smilek, J.; Másilko, J.; Kateryna, W. Impact modification of PLA using biobased biodegradable PHA biopolymers. Eur. Polym. J. 2019, 114, 32–38. [Google Scholar] [CrossRef]

- Requena, R.; Jiménez, A.; Vargas, M.; Chiralt, A. Effect of plasticizers on thermal and physical properties of compression-moulded poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] films. Polym. Test. 2016, 56, 45–53. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Yang, H.W.; Deri, F.; Ko, Y.G. Properties and medical applications of polylactic acid: A review. Express Polym. Lett. 2015, 9, 435–455. [Google Scholar] [CrossRef]

- Battegazzore, D.; Abt, T.; Maspoch, M.L.; Frache, A. Multilayer cotton fabric bio-composites based on PLA and PHB copolymer for industrial load carrying applications. Compos. Part B Eng. 2019, 163, 761–768. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, J. Research progress in toughening modification of poly(lactic acid). J. Polym. Sci. Part B Polym. Phys. 2011, 49, 1051–1083. [Google Scholar] [CrossRef]

- Jin, F.-L.; Hu, R.-R.; Park, S.-J. Improvement of thermal behaviors of biodegradable poly (lactic acid) polymer: A review. Compos. Part B Eng. 2018, 164, 287–296. [Google Scholar] [CrossRef]

- Lenz, A.R.W.; Marchessault, R.H. Bacterial Polyesters: Biosynthesis, Biodegradable Plastics and Biotechnology. Biomacromolecules 2005, 6, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Peña, C.; Castillo, T.; García, A.; Millán, M.; Segura, D. Biotechnological strategies to improve production of microbial poly-(3-hydroxybutyrate): A review of recent research work. Microb. Biotechnol. 2014, 7, 278–293. [Google Scholar] [CrossRef]

- Chen, G.-Q.; Wu, Q. The application of polyhydroxyalkanoates as tissue engineering materials. Biomaterials 2005, 26, 6565–6578. [Google Scholar] [CrossRef] [PubMed]

- Snell, K.D.; Peoples, O.P. PHA bioplastic: A value-added coproduct for biomass biorefineries. Biofuels Bioprod. Biorefining Innov. A Sustain. Econ. 2009, 3, 456–467. [Google Scholar] [CrossRef]

- Baltieri, R.C.; Innocentini Mei, L.H.; Bartoli, J. Study of the influence of plasticizers on the thermal and mechanical properties of poly(3-hydroxybutyrate) compounds. Macromol. Symp. 2003, 197, 33–44. [Google Scholar] [CrossRef]

- Volova, T.G. Polyhydroxyalkanoates-Plastic Materials of the 21st Century: Production, Properties, Applications; Nova Science Publishers: Hauppauge, NY, USA, 2004. [Google Scholar]

- Wady, P.; Wasilewski, A.; Brock, L.; Edge, R.; Baidak, A.; McBride, C.; Leay, L.; Griffiths, A.; Vallés, C. Effect of ionising radiation on the mechanical and structural properties of 3D printed plastics. Addit. Manuf. 2019, 31, 100907. [Google Scholar] [CrossRef]

- Abdelwahab, M.A.; Flynn, A.; Chiou, B.-S.; Imam, S.; Orts, W.; Chiellini, E. Thermal, mechanical and morphological characterization of plasticized PLA–PHB blends. Polym. Degrad. Stab. 2012, 97, 1822–1828. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.D.; Aldas, M.; López, J. On the Use of PLA-PHB Blends for Sustainable Food Packaging Applications. Materials 2017, 10, 1008. [Google Scholar] [CrossRef]

- Dobrovszky, K.; Ronkay, F. Influence of morphology and compatibilizer on burning behavior of PET/HDPE blend. In Proceedings of the Regional Conference Graz 2015–Polymer Processing Society PPS, Graz, Austria, 21–25 September 2015; p. 080012. [Google Scholar]

- D’anna, A.; Arrigo, R.; Frache, A. Rheology, Morphology and Thermal Properties of a PLA/PHB/Clay Blend Nanocomposite: The Influence of Process Parameters. J. Polym. Environ. 2021, 30, 102–113. [Google Scholar] [CrossRef]

- D’anna, A.; Arrigo, R.; Frache, A. PLA/PHB Blends: Biocompatibilizer Effects. Polymers 2019, 11, 1416. [Google Scholar] [CrossRef] [PubMed]

- Lacoste, C.; Gallard, B.; Lopez-Cuesta, J.-M.; Kalaoglu-Altan, O.I.; De Clerck, K. Development of Bionanocomposites Based on Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate)/PolylActide Blends Reinforced with Cloisite 30B. J. Funct. Biomater. 2020, 11, 64. [Google Scholar] [CrossRef]

- Patel, M.K.; Zaccone, M.; De Brauwer, L.; Nair, R.; Monti, M.; Martinez-Nogues, V.; Frache, A.; Oksman, K. Improvement of Poly(lactic acid)-Poly(hydroxy butyrate) Blend Properties for Use in Food Packaging: Processing, Structure Relationships. Polymers 2022, 14, 5104. [Google Scholar] [CrossRef] [PubMed]

- Puglia, D.; Fortunati, E.; D’amico, D.A.; Miri, V.; Stoclet, G.; Manfredi, L.B.; Cyras, V.P.; Kenny, J.M. Influence of Processing Conditions on Morphological, Thermal and Degradative Behavior of Nanocomposites Based on Plasticized Poly(3-hydroxybutyrate) and Organo-Modified Clay. J. Polym. Environ. 2015, 24, 12–22. [Google Scholar] [CrossRef]

- Bekhoukh, A.; Moulefera, I.; Sabantina, L.; Benyoucef, A. Development, Investigation, and Comparative Study of the Effects of Various Metal Oxides on Optical Electrochemical Properties Using a Doped PANI Matrix. Polymers 2021, 13, 3344. [Google Scholar] [CrossRef]

- Obreja, P.; Cristea, D.; Purica, M.; Gavrila, R.; Comanescu, F. Polymers doped with metal oxide nanoparticles with controlled refractive index. Polimery 2007, 52, 679–685. [Google Scholar] [CrossRef][Green Version]

- Abbas, Y.M.; Hasan, A.A. Optical Properties Study of Polypyrrole doped with TiO2, WO3, Fe2O3 and SnO2 Nanoparticles. IOP Conf. Ser. Mater. Sci. Eng. 2020, 928, 072017. [Google Scholar] [CrossRef]

- Yin, S.; Wang, H.; Wang, S.; Zhang, J.; Zhu, Y. Effect of B2O3 on the Radiation Shielding Performance of Telluride Lead Glass System. Crystals 2022, 12, 178. [Google Scholar] [CrossRef]

- Rammah, Y.; El-Agawany, F.; Abu El Soad, A.; Yousef, E.; El-Mesady, I. Ionizing radiation attenuation competences of gallium germanate-tellurite glasses utilizing MCNP5 simulation code and Phy-X/PSD program. Ceram. Int. 2020, 46, 22766–22773. [Google Scholar] [CrossRef]

- Hamad, R.; Mhareb, M.; Alajerami, Y.; Sayyed, M.; Saleh, G.; Hamad, M.K.; Ziq, K. A comprehensive ionizing radiation shielding study of FexSe0.5Te0.5 alloys with various iron concentrations. J. Alloy. Compd. 2020, 858, 157636. [Google Scholar] [CrossRef]

- Olarinoye, I.O.; Alomairy, S.; Sriwunkum, C.; Al-Buriahi, M.S. Effect of Ag2O/V2O5 substitution on the radiation shielding ability of tellurite glass system via XCOM approach and FLUKA simulations. Phys. Scr. 2021, 96, 065308. [Google Scholar] [CrossRef]

- Akhdar, H. Theoretical Investigation of Gamma- and Neutron-Shielding Properties of Polysulfone (PSU) Polymer Material Using Geant4. Polymers 2022, 14, 3374. [Google Scholar] [CrossRef]

- Akhdar, H.; Alotaibi, R. Geant4 Simulation of the Effect of Different Composites on Polyimide Photon and Neutron Shielding Properties. Polymers 2023, 15, 1973. [Google Scholar] [CrossRef]

- Akhdar, H.; Marashdeh, M.; AlAqeel, M. Investigation of gamma radiation shielding properties of polyethylene glycol in the energy range from 8.67 to 23.19 keV. Nucl. Eng. Technol. 2021, 54, 701–708. [Google Scholar] [CrossRef]

- Al-Buriahi, M.S.; Eke, C.; Alomairy, S.; Yildirim, A.; Alsaeedy, H.I.; Sriwunkum, C. Radiation attenuation properties of some commercial polymers for advanced shielding applications at low energies. Polym. Adv. Technol. 2021, 32, 2386–2396. [Google Scholar] [CrossRef]

- Sayyed, M. Investigation of shielding parameters for smart polymers. Chin. J. Phys. 2016, 54, 408–415. [Google Scholar] [CrossRef]

- Abdali, K. Crystal Structural, Morphological and Gamma Ray Shielding (γ-S) Efficiency of PVA/PAAM/PAA Polymer Blend Loaded with Silver Nanoparticles via Casting Method. Research Square, 11 November 2021. [Google Scholar] [CrossRef]

- Yilmaz, M.; Pekdemir, M.E.; Öner, E. Evaluation of Pb doped Poly(lactic acid) (PLA)/Poly(ethylene glycol) (PEG) blend composites regarding physicochemical and radiation shielding properties. Radiat. Phys. Chem. 2023, 202, 110509. [Google Scholar] [CrossRef]

- Hubbell, J. Photon mass attenuation and energy-absorption coefficients. Int. J. Appl. Radiat. Isot. 1982, 33, 1269–1290. [Google Scholar] [CrossRef]

- Kaewkhao, J.; Laopaiboon, J.; Chewpraditkul, W. Determination of effective atomic numbers and effective electron densities for Cu/Zn alloy. J. Quant. Spectrosc. Radiat. Transf. 2008, 109, 1260–1265. [Google Scholar] [CrossRef]

- Un, A.; Demir, F. Determination of mass attenuation coefficients, effective atomic numbers and effective electron numbers for heavy-weight and normal-weight concretes. Appl. Radiat. Isot. 2013, 80, 73–77. [Google Scholar] [CrossRef] [PubMed]

- Singh, K.; Singh, H.; Sharma, V.; Nathuram, R.; Khanna, A.; Kumar, R.; Bhatti, S.S.; Sahota, H.S. Gamma-ray attenuation coefficients in bismuth borate glasses. Nucl. Instruments Methods Phys. Res. Sect. B Beam Interactions Mater. Atoms 2002, 194, 1–6. [Google Scholar] [CrossRef]

- Olukotun, S.; Mann, K.S.; Gbenu, S.; Ibitoye, F.; Oladejo, O.; Joshi, A.; Tekin, H.; Sayyed, M.; Fasasi, M.; Balogun, F.; et al. Neutron-shielding behaviour investigations of some clay-materials. Nucl. Eng. Technol. 2019, 51, 1444–1450. [Google Scholar] [CrossRef]

- Singh Mann, K. Toolkit for Fast Neutron Removal Cross-Section. In Proceedings of the 3rd International Conference Ad-vancements in Engineering and Technology, Kuantan, Malaysia, 18–19 August 2015; Bhai Gurdas Institute of Engineering and Technology: Punjab, India, 2015. [Google Scholar]

- El Abd, A.; Mesbah, G.; Mohammed, N.M.A.; Ellithi, A. A simple Method for Determining the Effective Removal Cross Section for Fast Neutrons. J. Radiat. Nucl. Appl. 2017, 2, 53–58. [Google Scholar] [CrossRef]

- Agostinelli, S.; Allison, J.; Amako, K.; Apostolakis, J.; Araujo, H.; Arce, P.; Asai, M.; Axen, D.; Banerjee, S.; Barrand, G.; et al. Geant4—A simulation toolkit. Nucl. Instrum. Methods Phys. Res. Sect. A 2003, 506, 250–303. [Google Scholar] [CrossRef]

- Hila, F.C.; Asuncion-Astronomo, A.; Dingle, C.A.M.; Jecong, J.F.M.; Javier-Hila, A.M.V.; Gili, M.B.Z.; Balderas, C.V.; Lopez, G.E.P.; Guillermo, N.R.D.; Amorsolo, A.V. EpiXS: A Windows-based program for photon attenuation, dosimetry and shielding based on EPICS2017 (ENDF/B-VIII) and EPDL97 (ENDF/B-VI.8). Radiat. Phys. Chem. 2021, 182, 109331. [Google Scholar] [CrossRef]

- Brun, R.; Rademakers, F. ROOT—An object oriented data analysis framework. Nucl. Instruments Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 1997, 389, 81–86. [Google Scholar] [CrossRef]

| Element | PLA | PHB |

|---|---|---|

| H (Hydrogen) | 0.05595 | 0.07025 |

| C (Carbon) | 0.50001 | 0.55806 |

| O (Oxygen) | 0.44404 | 0.37169 |

| Energy (keV) | Geant4 | EpiXS | ∆% | Geant4 | EpiXS | ∆% |

| μm (cm2/g) | HVL (cm) | |||||

| 10 | 3.8155 | 3.8541 | −1.00% | 0.1465 | 0.1450 | 1.01% |

| 20 | 0.6288 | 0.6269 | 0.31% | 0.8890 | 0.8917 | −0.31% |

| 30 | 0.3181 | 0.3162 | 0.59% | 1.7575 | 1.7676 | −0.57% |

| 40 | 0.2387 | 0.2382 | 0.21% | 2.3417 | 2.3468 | −0.22% |

| 50 | 0.2088 | 0.2071 | 0.80% | 2.6777 | 2.6987 | −0.78% |

| 60 | 0.1919 | 0.1906 | 0.69% | 2.9126 | 2.9330 | −0.70% |

| 70 | 0.1813 | 0.1799 | 0.80% | 3.0830 | 3.1078 | −0.80% |

| 80 | 0.1728 | 0.1723 | 0.30% | 3.2349 | 3.2445 | −0.30% |

| 90 | 0.1666 | 0.1660 | 0.37% | 3.3555 | 3.3676 | −0.36% |

| 100 | 0.1610 | 0.1610 | 0.01% | 3.4716 | 3.4723 | −0.02% |

| 200 | 0.1291 | 0.1299 | −0.65% | 4.3315 | 4.3018 | 0.69% |

| 300 | 0.1123 | 0.1126 | −0.28% | 4.9786 | 4.9637 | 0.30% |

| 400 | 0.1009 | 0.1008 | 0.15% | 5.5393 | 5.5482 | −0.16% |

| 500 | 0.0924 | 0.0919 | 0.49% | 6.0517 | 6.0795 | −0.46% |

| 600 | 0.0855 | 0.0850 | 0.55% | 6.5344 | 6.5739 | −0.60% |

| 700 | 0.0799 | 0.0794 | 0.66% | 6.9918 | 7.0422 | −0.72% |

| 800 | 0.0753 | 0.0747 | 0.86% | 7.4254 | 7.4871 | −0.82% |

| 900 | 0.0713 | 0.0706 | 1.00% | 7.8454 | 7.9183 | −0.92% |

| 1000 | 0.0676 | 0.0671 | 0.75% | 8.2726 | 8.3311 | −0.70% |

| 2000 | 0.0469 | 0.0468 | 0.13% | 11.9291 | 11.9343 | −0.04% |

| 3000 | 0.0375 | 0.0376 | −0.24% | 14.9209 | 14.8707 | 0.34% |

| 4000 | 0.0320 | 0.0322 | −0.56% | 17.4414 | 17.3711 | 0.40% |

| 5000 | 0.0285 | 0.0286 | −0.45% | 19.6034 | 19.5246 | 0.40% |

| 6000 | 0.0260 | 0.0261 | −0.50% | 21.4727 | 21.3925 | 0.37% |

| 7000 | 0.0242 | 0.0243 | −0.29% | 23.1003 | 23.0326 | 0.29% |

| 8000 | 0.0228 | 0.0229 | −0.27% | 24.5232 | 24.4511 | 0.29% |

| 9000 | 0.0217 | 0.0217 | −0.20% | 25.7737 | 25.7091 | 0.25% |

| 10,000 | 0.0208 | 0.0208 | −0.19% | 26.8773 | 26.8239 | 0.20% |

| 20,000 | 0.0169 | 0.0169 | 0.00% | 33.0325 | 33.0776 | −0.14% |

| Energy (keV) | Geant4 | EpiXS | ∆% | Geant4 | EpiXS | ∆% |

| Zeff | Neff (×1023) | |||||

| 10 | 6.107 | 6.121 | −0.22% | 4.700 | 4.603 | 2.10% |

| 20 | 5.486 | 5.880 | −6.71% | 4.190 | 4.423 | −5.26% |

| 30 | 4.897 | 5.392 | −9.19% | 3.710 | 4.056 | −8.52% |

| 40 | 4.583 | 4.938 | −7.19% | 3.460 | 3.714 | −6.83% |

| 50 | 4.470 | 4.673 | −4.34% | 3.360 | 3.515 | −4.40% |

| 60 | 4.395 | 4.523 | −2.83% | 3.300 | 3.402 | −3.00% |

| 70 | 4.360 | 4.437 | −1.74% | 3.270 | 3.337 | −2.02% |

| 80 | 4.314 | 4.384 | −1.59% | 3.240 | 3.297 | −1.73% |

| 90 | 4.302 | 4.349 | −1.09% | 3.230 | 3.271 | −1.26% |

| 100 | 4.277 | 4.326 | −1.13% | 3.210 | 3.254 | −1.34% |

| 200 | 4.219 | 4.261 | −0.99% | 3.160 | 3.205 | −1.41% |

| 300 | 4.231 | 4.251 | −0.48% | 3.170 | 3.198 | −0.86% |

| 400 | 4.248 | 4.247 | 0.01% | 3.180 | 3.195 | −0.46% |

| 500 | 4.260 | 4.246 | 0.33% | 3.190 | 3.194 | −0.11% |

| 600 | 4.266 | 4.245 | 0.49% | 3.200 | 3.193 | 0.22% |

| 700 | 4.271 | 4.245 | 0.62% | 3.200 | 3.193 | 0.23% |

| 800 | 4.275 | 4.245 | 0.72% | 3.200 | 3.192 | 0.24% |

| 900 | 4.279 | 4.244 | 0.82% | 3.210 | 3.192 | 0.56% |

| 1000 | 4.270 | 4.244 | 0.61% | 3.200 | 3.192 | 0.25% |

| 2000 | 4.249 | 4.255 | −0.13% | 3.190 | 3.200 | −0.31% |

| 3000 | 4.252 | 4.282 | −0.71% | 3.190 | 3.221 | −0.96% |

| 4000 | 4.273 | 4.316 | −1.01% | 3.200 | 3.246 | −1.43% |

| 5000 | 4.299 | 4.352 | −1.22% | 3.230 | 3.273 | −1.32% |

| 6000 | 4.327 | 4.388 | −1.38% | 3.250 | 3.300 | −1.52% |

| 7000 | 4.358 | 4.422 | −1.45% | 3.270 | 3.326 | −1.68% |

| 8000 | 4.385 | 4.454 | −1.55% | 3.290 | 3.350 | −1.79% |

| 9000 | 4.413 | 4.485 | −1.60% | 3.320 | 3.373 | −1.57% |

| 10,000 | 4.441 | 4.513 | −1.59% | 3.340 | 3.394 | −1.60% |

| 20,000 | 4.662 | 4.705 | −0.91% | 3.510 | 3.538 | −0.80% |

| Element | Weight Fraction | ΣR/ρ (cm2/g) | Partial Density (g/cm3) | ΣR (cm−1) |

|---|---|---|---|---|

| H (Hydrogen) | 0.0559 | 0.19000 | 0.0694 | 0.013181 |

| C (Carbon) | 0.5000 | 0.05019 | 0.6200 | 0.031118 |

| O (Oxygen) | 0.4440 | 0.04053 | 0.5506 | 0.022316 |

| Total fast neutron removal cross-section = 0.066616 | ||||

| Energy (keV) | ΣR (cm2/g) | HVL (cm) |

|---|---|---|

| 10 | 0.8310 | 0.6726 |

| 20 | 0.7956 | 0.7026 |

| 30 | 0.7603 | 0.7353 |

| 40 | 0.7248 | 0.7713 |

| 50 | 0.7043 | 0.7937 |

| 60 | 0.6837 | 0.8177 |

| 70 | 0.6631 | 0.8430 |

| 80 | 0.6424 | 0.8702 |

| 90 | 0.6216 | 0.8993 |

| 100 | 0.6008 | 0.9305 |

| 200 | 0.4864 | 1.1492 |

| 300 | 0.4222 | 1.3239 |

| 400 | 0.4345 | 1.2865 |

| 500 | 0.3714 | 1.5053 |

| 600 | 0.3199 | 1.7476 |

| 700 | 0.2989 | 1.8702 |

| 800 | 0.2803 | 1.9946 |

| 900 | 0.2742 | 2.0390 |

| 1000 | 0.3456 | 1.6176 |

| 2000 | 0.1660 | 3.3680 |

| 3000 | 0.1269 | 4.4060 |

| 4000 | 0.1478 | 3.7826 |

| 5000 | 0.1023 | 5.4648 |

| 6000 | 0.1038 | 5.3863 |

| 7000 | 0.0766 | 7.2967 |

| 8000 | 0.0997 | 5.6095 |

| 9000 | 0.0832 | 6.7205 |

| 10,000 | 0.0830 | 6.7310 |

| 20,000 | 0.0816 | 6.8480 |

| Energy (keV) | μm (cm2/g) | ||

| 90% PLA–10% PHB | 80% PLA–20% PHB | 70% PLA–30% PHB | |

| 10 | 3.7870 | 3.7584 | 3.7298 |

| 20 | 0.6255 | 0.6222 | 0.6190 |

| 30 | 0.3173 | 0.3165 | 0.3157 |

| 40 | 0.2385 | 0.2383 | 0.2382 |

| 50 | 0.2088 | 0.2088 | 0.2088 |

| 60 | 0.1920 | 0.1921 | 0.1922 |

| 70 | 0.1815 | 0.1816 | 0.1817 |

| 80 | 0.1730 | 0.1731 | 0.1733 |

| 90 | 0.1668 | 0.1669 | 0.1671 |

| 100 | 0.1612 | 0.1614 | 0.1616 |

| 200 | 0.1292 | 0.1294 | 0.1295 |

| 300 | 0.1124 | 0.1126 | 0.1127 |

| 400 | 0.1010 | 0.1012 | 0.1013 |

| 500 | 0.0925 | 0.0926 | 0.0927 |

| 600 | 0.0857 | 0.0858 | 0.0859 |

| 700 | 0.0801 | 0.0802 | 0.0803 |

| 800 | 0.0754 | 0.0755 | 0.0756 |

| 900 | 0.0713 | 0.0714 | 0.0715 |

| 1000 | 0.0677 | 0.0678 | 0.0678 |

| 2000 | 0.0469 | 0.0470 | 0.0470 |

| 3000 | 0.0375 | 0.0376 | 0.0376 |

| 4000 | 0.0321 | 0.0321 | 0.0322 |

| 5000 | 0.0285 | 0.0286 | 0.0286 |

| 6000 | 0.0261 | 0.0261 | 0.0261 |

| 7000 | 0.0242 | 0.0242 | 0.0243 |

| 8000 | 0.0228 | 0.0228 | 0.0228 |

| 9000 | 0.0217 | 0.0217 | 0.0217 |

| 10,000 | 0.0208 | 0.0208 | 0.0208 |

| 20,000 | 0.0169 | 0.0169 | 0.0169 |

| Energy (keV) | Zeff | ||

| 90% PLA–10% PHB | 80% PLA–20% PHB | 70% PLA–30% PHB | |

| 10 | 1.466 | 1.455 | 1.444 |

| 20 | 1.311 | 1.304 | 1.297 |

| 30 | 1.163 | 1.161 | 1.158 |

| 40 | 1.085 | 1.084 | 1.084 |

| 50 | 1.057 | 1.057 | 1.057 |

| 60 | 1.038 | 1.038 | 1.039 |

| 70 | 1.029 | 1.030 | 1.031 |

| 80 | 1.018 | 1.019 | 1.020 |

| 90 | 1.015 | 1.016 | 1.017 |

| 100 | 1.009 | 1.010 | 1.010 |

| 200 | 0.995 | 0.996 | 0.997 |

| 300 | 0.998 | 0.999 | 1.000 |

| 400 | 1.002 | 1.003 | 1.004 |

| 500 | 1.005 | 1.006 | 1.007 |

| 600 | 1.006 | 1.007 | 1.009 |

| 700 | 1.007 | 1.008 | 1.010 |

| 800 | 1.008 | 1.009 | 1.011 |

| 900 | 1.009 | 1.010 | 1.012 |

| 1000 | 1.007 | 1.008 | 1.010 |

| 2000 | 1.002 | 1.003 | 1.005 |

| 3000 | 1.003 | 1.004 | 1.005 |

| 4000 | 1.008 | 1.009 | 1.010 |

| 5000 | 1.014 | 1.015 | 1.016 |

| 6000 | 1.021 | 1.022 | 1.023 |

| 7000 | 1.029 | 1.030 | 1.030 |

| 8000 | 1.035 | 1.036 | 1.037 |

| 9000 | 1.042 | 1.043 | 1.043 |

| 10,000 | 1.049 | 1.050 | 1.050 |

| 20,000 | 1.103 | 1.103 | 1.102 |

| Energy (keV) | Neff (×1023) | ||

| 90% PLA–10% PHB | 80% PLA–20% PHB | 70% PLA–30% PHB | |

| 10 | 4.67 | 4.63 | 4.60 |

| 20 | 4.17 | 4.15 | 4.13 |

| 30 | 3.70 | 3.69 | 3.69 |

| 40 | 3.45 | 3.45 | 3.45 |

| 50 | 3.36 | 3.36 | 3.36 |

| 60 | 3.30 | 3.31 | 3.31 |

| 70 | 3.28 | 3.28 | 3.28 |

| 80 | 3.24 | 3.24 | 3.25 |

| 90 | 3.23 | 3.23 | 3.24 |

| 100 | 3.21 | 3.22 | 3.22 |

| 200 | 3.17 | 3.17 | 3.17 |

| 300 | 3.18 | 3.18 | 3.18 |

| 400 | 3.19 | 3.19 | 3.20 |

| 500 | 3.20 | 3.20 | 3.21 |

| 600 | 3.20 | 3.21 | 3.21 |

| 700 | 3.21 | 3.21 | 3.21 |

| 800 | 3.21 | 3.21 | 3.22 |

| 900 | 3.21 | 3.22 | 3.22 |

| 1000 | 3.20 | 3.21 | 3.21 |

| 2000 | 3.19 | 3.19 | 3.20 |

| 3000 | 3.19 | 3.20 | 3.20 |

| 4000 | 3.21 | 3.21 | 3.22 |

| 5000 | 3.23 | 3.23 | 3.24 |

| 6000 | 3.25 | 3.25 | 3.26 |

| 7000 | 3.27 | 3.28 | 3.28 |

| 8000 | 3.30 | 3.30 | 3.30 |

| 9000 | 3.32 | 3.32 | 3.32 |

| 10,000 | 3.34 | 3.34 | 3.34 |

| 20,000 | 3.51 | 3.51 | 3.51 |

| Energy (keV) | ΣR (cm2/g) | ||

| 90% PLA–10% PHB | 80% PLA–20% PHB | 70% PLA–30% PHB | |

| 10 | 0.8480 | 0.8646 | 0.8816 |

| 20 | 0.8117 | 0.8275 | 0.8436 |

| 30 | 0.7753 | 0.7904 | 0.8055 |

| 40 | 0.7391 | 0.7533 | 0.7674 |

| 50 | 0.7180 | 0.7317 | 0.7454 |

| 60 | 0.6968 | 0.7101 | 0.7233 |

| 70 | 0.6758 | 0.6885 | 0.7012 |

| 80 | 0.6546 | 0.6668 | 0.6790 |

| 90 | 0.6332 | 0.6449 | 0.6566 |

| 100 | 0.6120 | 0.6231 | 0.6343 |

| 200 | 0.4949 | 0.5034 | 0.5119 |

| 300 | 0.4292 | 0.4362 | 0.4431 |

| 400 | 0.4397 | 0.4447 | 0.4498 |

| 500 | 0.3764 | 0.3815 | 0.3866 |

| 600 | 0.3247 | 0.3296 | 0.3344 |

| 700 | 0.3035 | 0.3080 | 0.3126 |

| 800 | 0.2845 | 0.2887 | 0.2929 |

| 900 | 0.2779 | 0.2816 | 0.2854 |

| 1000 | 0.3478 | 0.3500 | 0.3522 |

| 2000 | 0.1685 | 0.1711 | 0.1736 |

| 3000 | 0.1288 | 0.1308 | 0.1328 |

| 4000 | 0.1495 | 0.1511 | 0.1528 |

| 5000 | 0.1038 | 0.1052 | 0.1067 |

| 6000 | 0.1049 | 0.1060 | 0.1071 |

| 7000 | 0.0777 | 0.0787 | 0.0798 |

| 8000 | 0.1009 | 0.1022 | 0.1035 |

| 9000 | 0.0841 | 0.0849 | 0.0858 |

| 10,000 | 0.0838 | 0.0846 | 0.0854 |

| 20,000 | 0.0820 | 0.0823 | 0.0828 |

| Energy (keV) | HVL (cm) | ||

| 90% PLA–10% PHB | 80% PLA–20% PHB | 70% PLA–30% PHB | |

| 10 | 0.6619 | 0.6518 | 0.6419 |

| 20 | 0.6915 | 0.6810 | 0.6707 |

| 30 | 0.7239 | 0.7129 | 0.7025 |

| 40 | 0.7594 | 0.7481 | 0.7373 |

| 50 | 0.7817 | 0.7702 | 0.7591 |

| 60 | 0.8054 | 0.7936 | 0.7823 |

| 70 | 0.8305 | 0.8185 | 0.8070 |

| 80 | 0.8574 | 0.8452 | 0.8334 |

| 90 | 0.8863 | 0.8738 | 0.8618 |

| 100 | 0.9171 | 0.9043 | 0.8921 |

| 200 | 1.1341 | 1.1194 | 1.1054 |

| 300 | 1.3077 | 1.2920 | 1.2769 |

| 400 | 1.2766 | 1.2671 | 1.2580 |

| 500 | 1.4910 | 1.4772 | 1.4638 |

| 600 | 1.7284 | 1.7099 | 1.6919 |

| 700 | 1.8496 | 1.8297 | 1.8103 |

| 800 | 1.9730 | 1.9520 | 1.9316 |

| 900 | 2.0198 | 2.0010 | 1.9829 |

| 1000 | 1.6138 | 1.6101 | 1.6064 |

| 2000 | 3.3305 | 3.2944 | 3.2594 |

| 3000 | 4.3562 | 4.3084 | 4.2621 |

| 4000 | 3.7555 | 3.7293 | 3.7038 |

| 5000 | 5.4091 | 5.3548 | 5.3020 |

| 6000 | 5.3519 | 5.3174 | 5.2852 |

| 7000 | 7.2265 | 7.1584 | 7.0925 |

| 8000 | 5.5603 | 5.5124 | 5.4659 |

| 9000 | 6.6774 | 6.6354 | 6.5947 |

| 10,000 | 6.6943 | 6.6585 | 6.6235 |

| 20,000 | 6.8481 | 6.8511 | 6.8307 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akhdar, H.; Alshehri, M. Geant4 Simulation of Photon- and Neutron-Shielding Capabilities of Biopolymer Blends of Poly(lactic acid) and Poly(hydroxybutyrate). Polymers 2023, 15, 4257. https://doi.org/10.3390/polym15214257

Akhdar H, Alshehri M. Geant4 Simulation of Photon- and Neutron-Shielding Capabilities of Biopolymer Blends of Poly(lactic acid) and Poly(hydroxybutyrate). Polymers. 2023; 15(21):4257. https://doi.org/10.3390/polym15214257

Chicago/Turabian StyleAkhdar, Hanan, and Maryam Alshehri. 2023. "Geant4 Simulation of Photon- and Neutron-Shielding Capabilities of Biopolymer Blends of Poly(lactic acid) and Poly(hydroxybutyrate)" Polymers 15, no. 21: 4257. https://doi.org/10.3390/polym15214257

APA StyleAkhdar, H., & Alshehri, M. (2023). Geant4 Simulation of Photon- and Neutron-Shielding Capabilities of Biopolymer Blends of Poly(lactic acid) and Poly(hydroxybutyrate). Polymers, 15(21), 4257. https://doi.org/10.3390/polym15214257