Ionizing Radiation Synthesis of Hydrogel Nanoparticles of Gelatin and Polyethylene Glycol at High Temperature

Abstract

:1. Introduction

G(eaq−) = G(•OH) = G (H3O+) = 0.29,

G(H) = 0.08 G(H2O2) = 0.08 G(H2) = 0.04

2. Materials and Methods

Sample Preparation

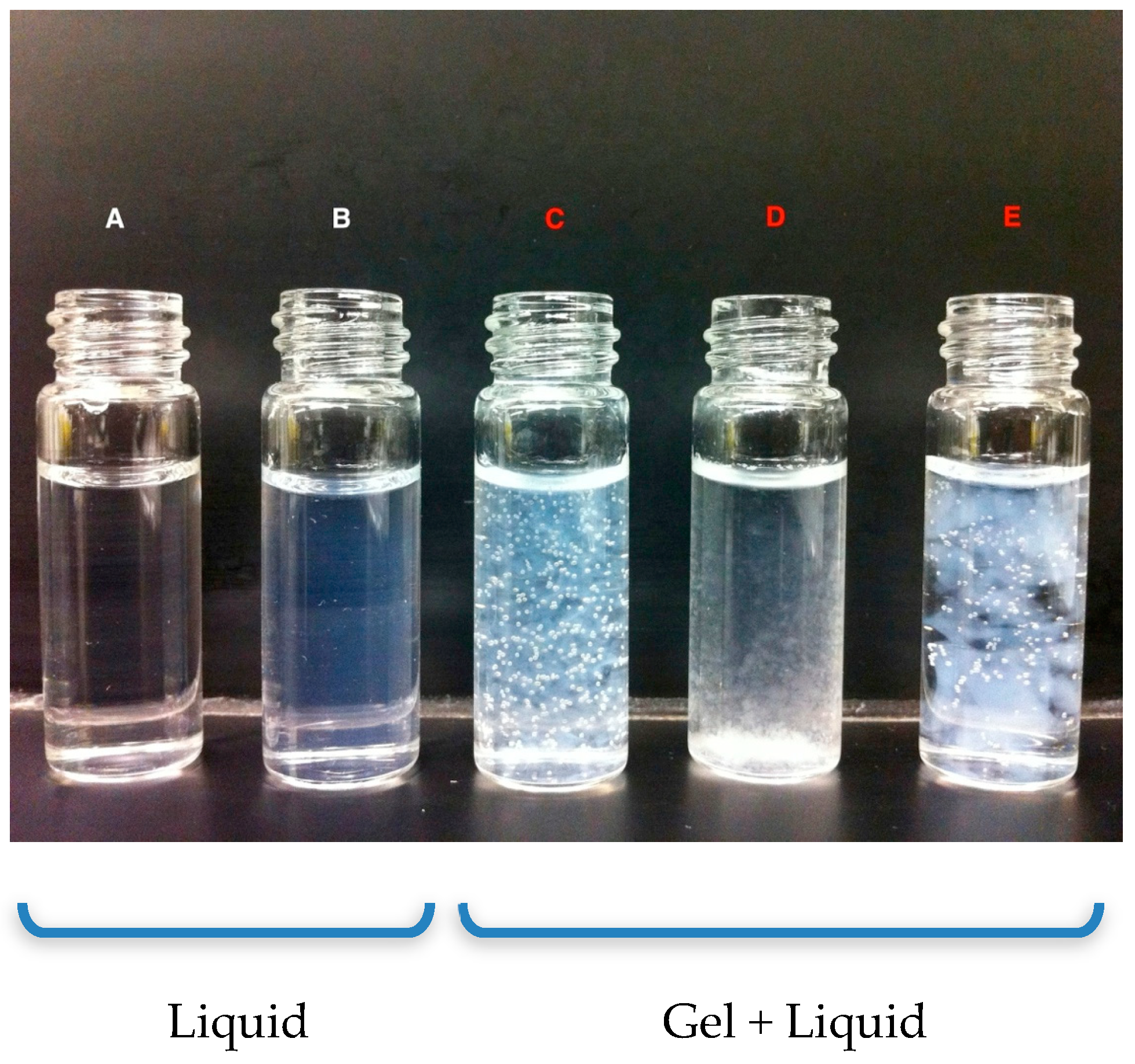

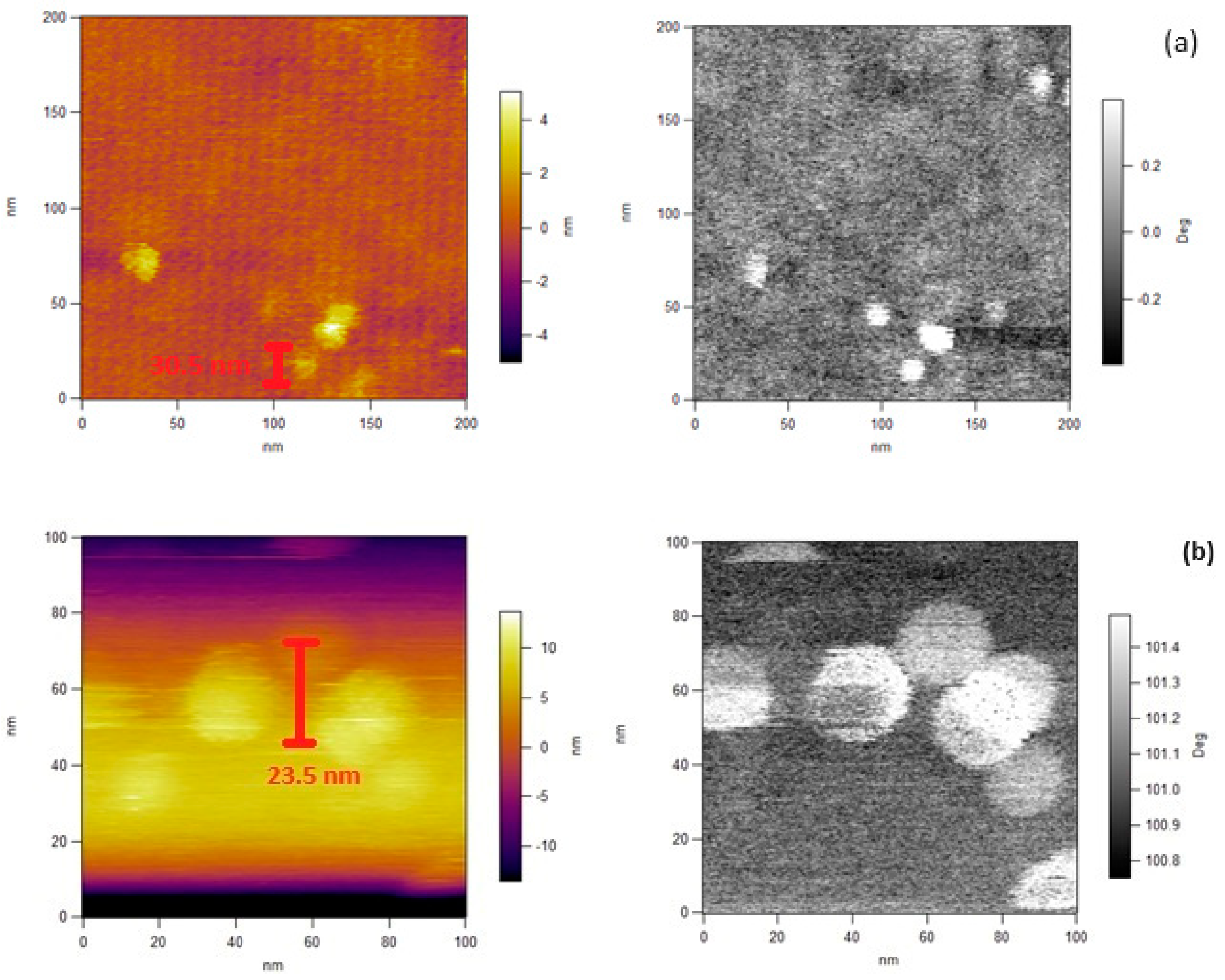

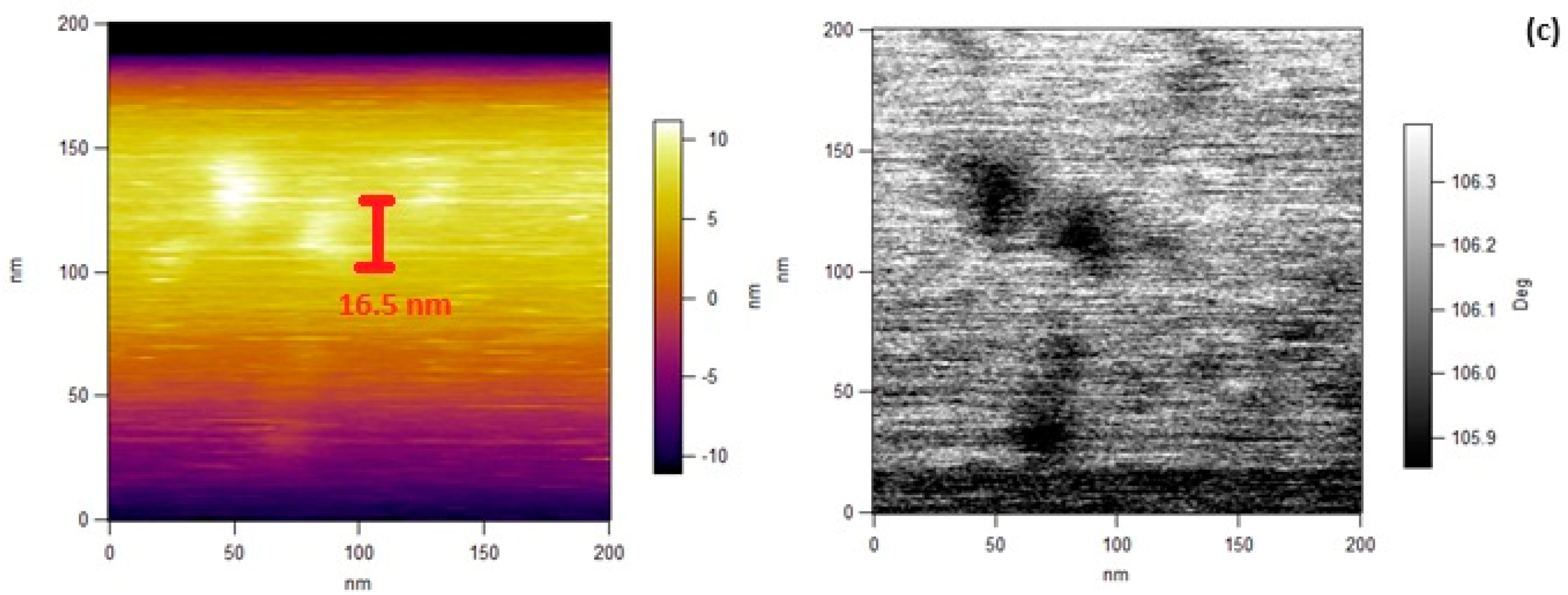

3. Results/Discussion

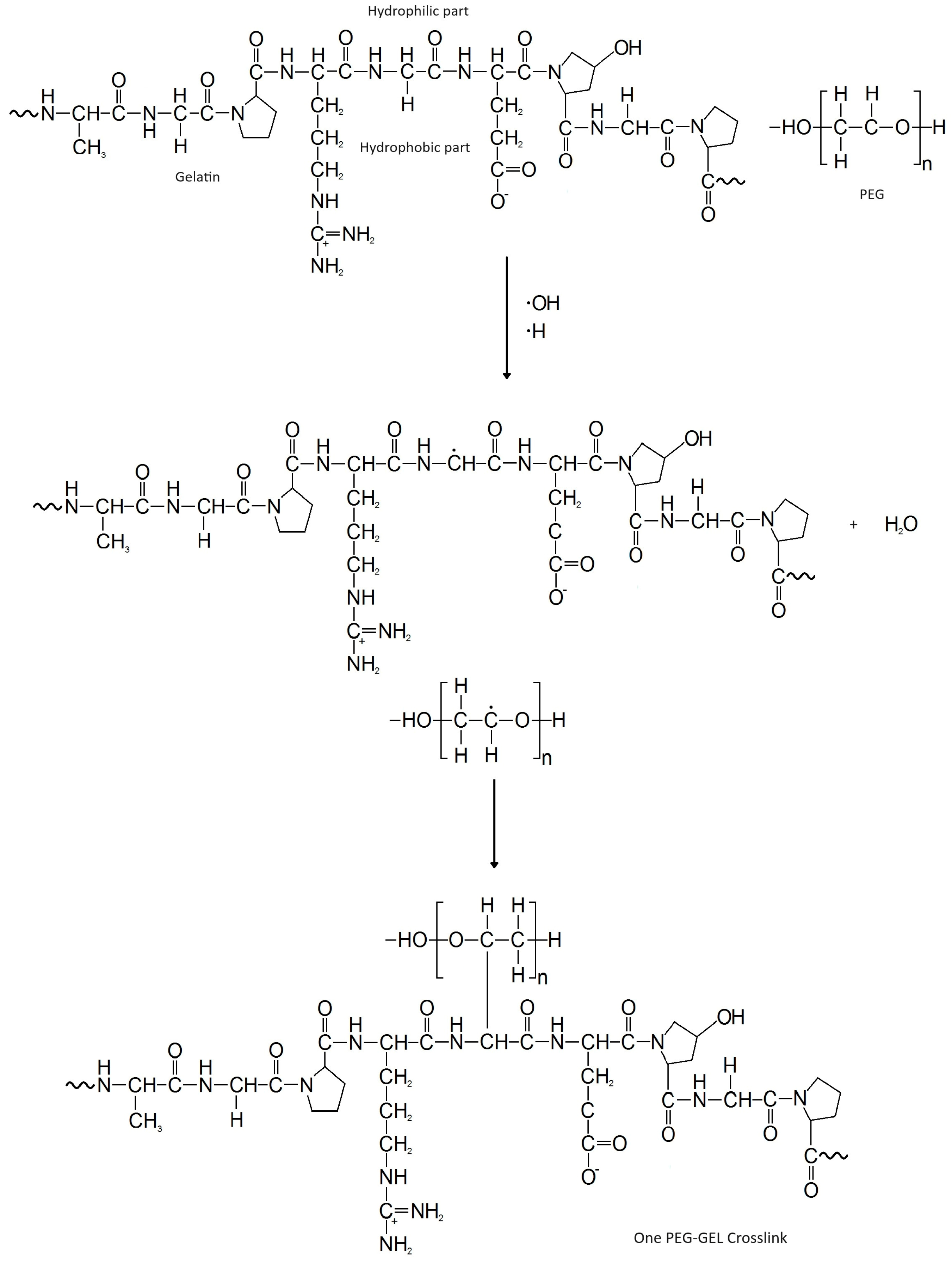

4. Proposed Mechanism Crosslinking of PEG–GEL

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Gorgieva, S.; Kokol, V. Collagen- vs. Gelatine-Based Biomaterials and Their Biocompatibility: Review and Perspectives. Biomater. Appl. Nanomed. 2011, 2, 17–52. [Google Scholar] [CrossRef]

- Terao, K.; Nagasawa, N.; Nishida, H.; Furusawa, K.; Mori, Y.; Yoshii, F.; Dobashi, T. Reagent-free crosslinking of aqueous gelatin: Manufacture and characteristics of gelatin gels irradiated with gamma-ray and electron beam. J. Biomater. Sci. Polym. Ed. 2003, 14, 1197–1208. [Google Scholar] [CrossRef] [PubMed]

- Wisotzki, E.I.; Hennes, M.; Schuldt, C.; Engert, F.; Knolle, W.; Decker, U.; Käs, J.A.; Zink, M.; Mayr, S.G. Tailoring the material properties of gelatin hydrogels by high energy electron irradiation. J. Mater. Chem. B 2014, 2, 4297–4309. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.; Zaman, A.; Islam, S.; Khan, M.A.; Rahman, M.M. Physico-chemical characteristics of gamma-irradiated gelatin. Prog. Biomater. 2014, 3, 21. [Google Scholar] [CrossRef]

- BenBettaïeb, N.; Karbowiak, T.; Bornaz, S.; Debeaufort, F. Spectroscopic analyses of the influence of electron beam irradiation doses on mechanical, transport properties and microstructure of chitosan-fish gelatin blend films. Food Hydrocoll. 2015, 46, 37–51. [Google Scholar] [CrossRef]

- Lee, J.B.; Ko, Y.G.; Cho, D.; Park, W.H.; Kwon, O.H. Modification and optimization of electrospun gelatin sheets by electronbeam irradiation for soft tissue engineering. Biomater. Res. 2017, 21, 1–9. [Google Scholar] [CrossRef]

- Benbettaïeb, N.; Karbowiak, T.; Brachais, C.-H.; Debeaufort, F. Impact of electron beam irradiation on fish gelatin film properties. Food Chem. 2016, 195, 11–18. [Google Scholar] [CrossRef]

- Gonçalves, A.S.C.; Rodrigues, C.F.; Fernandes, N.; de Melo-Diogo, D.; Ferreira, P.; Moreira, A.F.; Correia, I.J. IR780 loaded gelatin-PEG coated gold core silica shell nanorods for cancer-targeted photothermal/photodynamic therapy. Biotechnol. Bioeng. 2022, 119, 644–656. [Google Scholar] [CrossRef]

- Van, T.D.; Tran, N.Q.; Nguyen, D.H.; Nguyen, C.K.; Tran, D.L.; Nguyen, P.T. Injectable Hydrogel Composite Based Gelatin-PEG and Biphasic Calcium Phosphate Nanoparticles for Bone Regeneration. J. Electron. Mater. 2016, 45, 2415–2422. [Google Scholar] [CrossRef]

- Dey, K.; Agnelli, S.; Borsani, E.; Sartore, L. Degradation-Dependent Stress Relaxing Semi-Interpenetrating Networks of Hydroxyethyl Cellulose in Gelatin-PEG Hydrogel with Good Mechanical Stability and Reversibility. Gels 2021, 7, 277. [Google Scholar] [CrossRef] [PubMed]

- Ishikawa, S.; Kamata, H.; Chung, U.-I.; Sakai, T. Tissue-Adhesive Hydrogel Spray System for Live Cell Immobilization on Biological Surfaces. ACS Appl. Bio Mater. 2023. [Google Scholar] [CrossRef]

- Vahidi, M.; Frounchi, M.; Dadbin, S. Porous gelatin/poly(ethylene glycol) scaffolds for skin cells. Soft Mater. 2016, 15, 95–102. [Google Scholar] [CrossRef]

- Liang, J.; Guo, Z.; Timmerman, A.; Grijpma, D.; Poot, A. Enhanced mechanical and cell adhesive properties of photo-crosslinked PEG hydrogels by incorporation of gelatin in the networks. Biomed. Mater. 2019, 14, 024102. [Google Scholar] [CrossRef]

- Zhou, N.; Liu, C.; Lv, S.; Sun, D.; Qiao, Q.; Zhang, R.; Liu, Y.; Xiao, J.; Sun, G. Degradation prediction model and stem cell growth of gelatin-PEG composite hydrogel. J. Biomed. Mater. Res. Part A 2016, 104, 3149–3156. [Google Scholar] [CrossRef]

- Ji, L.; Gong, M.; Qiao, W.; Zhang, W.; Liu, Q.; Dunham, R.E.; Gu, J. A gelatin/PLA-b-PEG film of excellent gas barrier and mechanical properties. J. Polym. Res. 2018, 25, 210. [Google Scholar] [CrossRef]

- Bai, Y.; Moeinzadeh, S.; Kim, S.; Park, Y.; Lui, E.; Tan, H.; Zhao, W.; Zhou, X.; Yang, Y.P. Development of PLGA-PEG-COOH and Gelatin-Based Microparticles Dual Delivery System and E-Beam Sterilization Effects for Controlled Release of BMP-2 and IGF-1. Part. Part. Syst. Charact. 2020, 37, 2000180. [Google Scholar] [CrossRef]

- Han, L.-H.; Tong, X.; Yang, F. Photo-crosslinkable PEG-Based Microribbons for Forming 3D Macroporous Scaffolds with Decoupled Niche Properties. Adv. Mater. 2014, 26, 1757–1762. [Google Scholar] [CrossRef]

- Raman, T.; Kuehnert, M.; Daikos, O.; Scherzer, T.; Krömmelbein, C.; Mayr, S.G.; Abel, B.; Schulze, A. A study on the material properties of novel PEGDA/gelatin hybrid hydrogels polymerized by electron beam irradiation. Front. Chem. 2023, 10, 1094981. [Google Scholar] [CrossRef]

- Ashfaq, A.; Ulanski, P.; Al-Sheikhly, M. Overview of Radiation-Induced Crosslinking of Macromolecules to Synthesize Nanogels for Biomedical Applications. J. Cell Sci. Ther. 2022, 13, 351–353. Available online: https://www.longdom.org/open-access/overview-of-radiationinduced-crosslinking-of-macromolecules-to-synthesize-nanogels-for-biomedical-applications.pdf (accessed on 18 December 2022).

- An, J.-C. Synthesis of the combined inter- and intra-crosslinked nanohydrogels by e-beam ionizing radiation. J. Ind. Eng. Chem. 2010, 16, 657–661. [Google Scholar] [CrossRef]

- An, J.-C.; Weaver, A.; Kim, B.; Barkatt, A.; Poster, D.; Vreeland, W.N.; Silverman, J.; Al-Sheikhly, M. Radiation-induced synthesis of poly(vinylpyrrolidone) nanogel. Polymer 2011, 52, 5746–5755. [Google Scholar] [CrossRef]

- Ashfaq, A.; An, J.-C.; Ulański, P.; Al-Sheikhly, M. On the Mechanism and Kinetics of Synthesizing Polymer Nanogels by Ionizing Radiation-Induced Intramolecular Crosslinking of Macromolecules. Pharmaceutics 2021, 13, 1765. [Google Scholar] [CrossRef] [PubMed]

- Di Fonzo, S.; Bellich, B.; Gamini, A.; Quadri, N.; Cesàro, A. PEG hydration and conformation in aqueous solution: Hints to macromolecular crowding. Polymer 2019, 175, 57–64. [Google Scholar] [CrossRef]

- Bandyopadhyay, S.; Tarek, M.; Lynch, M.L.; Klein, M.L. Molecular Dynamics Study of the Poly(oxyethylene) Surfactant C12E2 and Water. Langmuir 1999, 16, 942–946. [Google Scholar] [CrossRef]

- Grinberg, V.Y.; Burova, T.V.; Grinberg, N.V.; Dubovik, A.S.; Papkov, V.S.; Khokhlov, A.R. Energetics of LCST transition of poly(ethylene oxide) in aqueous solutions. Polymer 2015, 73, 86–90. [Google Scholar] [CrossRef]

- Cataldo, F.; Ursini, O.; Lilla, E.; Angelini, G. Radiation-induced crosslinking of collagen gelatin into a stable hydrogel. J. Radioanal. Nucl. Chem. 2008, 275, 125–131. [Google Scholar] [CrossRef]

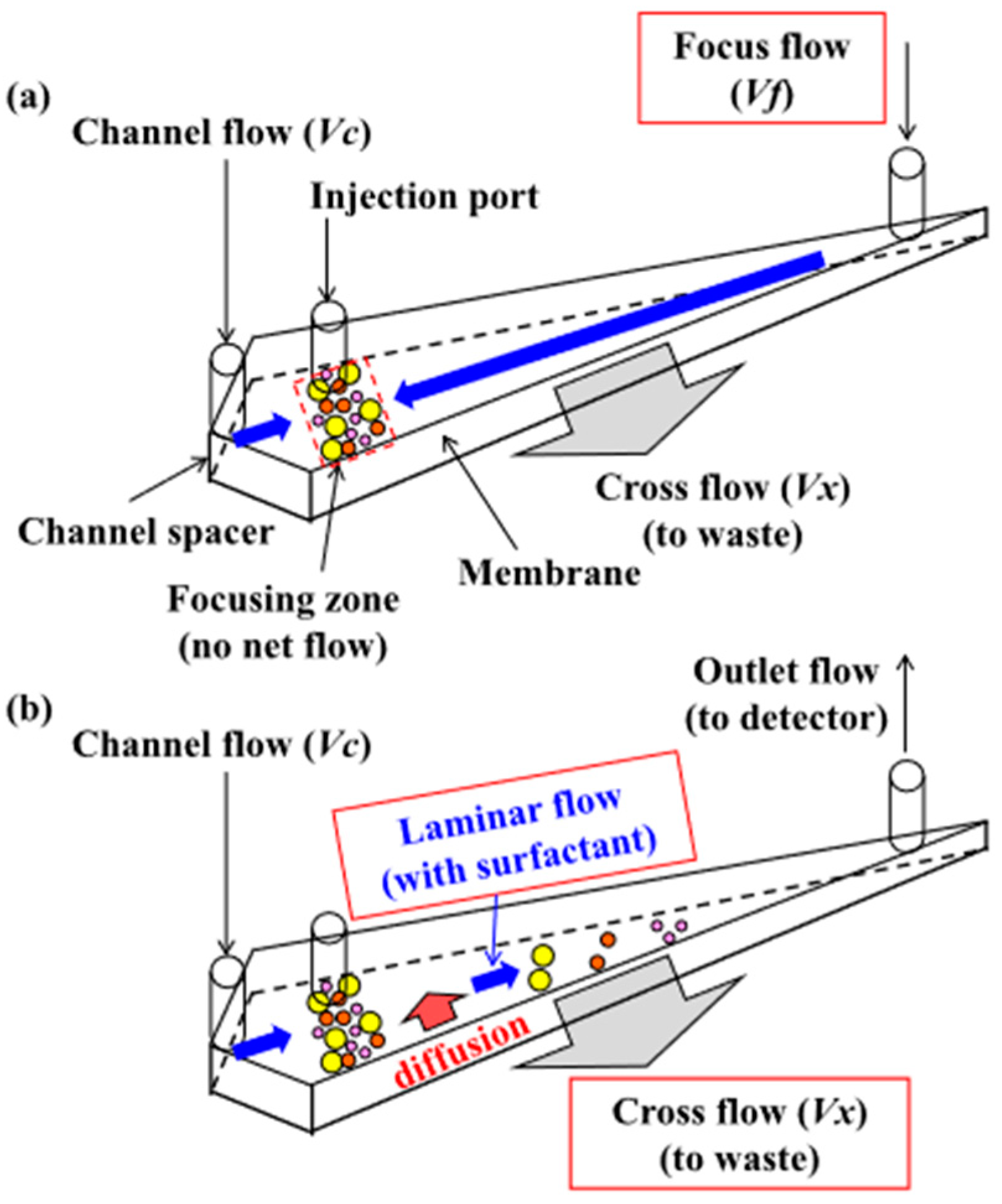

- Itabashi, D.; Murao, R.; Taniguchi, S.; Mizukami, K.; Takagi, H.; Kimura, M. Determination of Size Distribution of Nanoparticles Using Asymmetric Flow Field-flow Fractionation (AF4). ISIJ Int. 2020, 60, 979–987. [Google Scholar] [CrossRef]

- von Sonntag, C. Free-Radical-Induced DNA Damage and Its Repair: A Chemical Perspective; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar] [CrossRef]

- Kimura, A.; Yoshida, F.; Ueno, M.; Taguchi, M. Application of radiation crosslinking technique to development of gelatin scaffold for tissue engineering. Radiat. Phys. Chem. 2021, 180, 109287. [Google Scholar] [CrossRef]

- Haema, K.; Oyama, T.G.; Kimura, A.; Taguchi, M. Radiation stability and modification of gelatin for biological and medical applications. Radiat. Phys. Chem. 2014, 103, 126–130. [Google Scholar] [CrossRef]

- Vieira, F.F.; Del Mastro, N.L. Comparison of γ-radiation and electron beam irradiation effects on gelatin. Radiat. Phys. Chem. 2002, 63, 331–332. [Google Scholar] [CrossRef]

- Ulanski, P.; Rosiak, J. The use of radiation technique in the synthesis of polymeric nanogels. Nucl. Instruments Methods Phys. Res. Sect. B Beam Interactions Mater. Atoms 1999, 151, 356–360. [Google Scholar] [CrossRef]

- Ulanski, P.; Bothe, E.; Rosiak, J.M.; von Sonntag, C. OH-radical-induced crosslinking and strand breakage of poly(vinyl alcohol) in aqueous solution in the absence and presence of oxygen. A pulse radiolysis and product study. Macromol. Chem. Phys. 1994, 195, 1443–1461. [Google Scholar] [CrossRef]

- Mpofu, P.; Addai-Mensah, J.; Ralston, J. Temperature influence of nonionic polyethylene oxide and anionic polyacrylamide on flocculation and dewatering behavior of kaolinite dispersions. J. Colloid Interface Sci. 2004, 271, 145–156. [Google Scholar] [CrossRef] [PubMed]

- Von Sonntag, C.; Bothe, E.; Ulanski, P.; Deeble, D. Pulse radiolysis in model studies toward radiation processing. Radiat. Phys. Chem. 1995, 46, 527–532. [Google Scholar] [CrossRef]

- Bernardes Filho, R.; Osiro, D.; Colnago, L.A. Preparação de Amostras de DNA em Vidro e Mica, para Realização de Microscopia de Força Atômica. Embrapa Instrumentação Agropecuária. 1997. Available online: https://www.infoteca.cnptia.embrapa.br/handle/doc/29898 (accessed on 12 June 2023).

- Israelachvili, J.N. Intermolecular and Surface Forces, 3rd ed.; Academic Press: Santa Barbara, CA, USA, 2011. [Google Scholar]

- Plonka, A. Dispersive Kinetics; Kluwer Academic Publishers: Dordrecht, Germany, 2001. [Google Scholar]

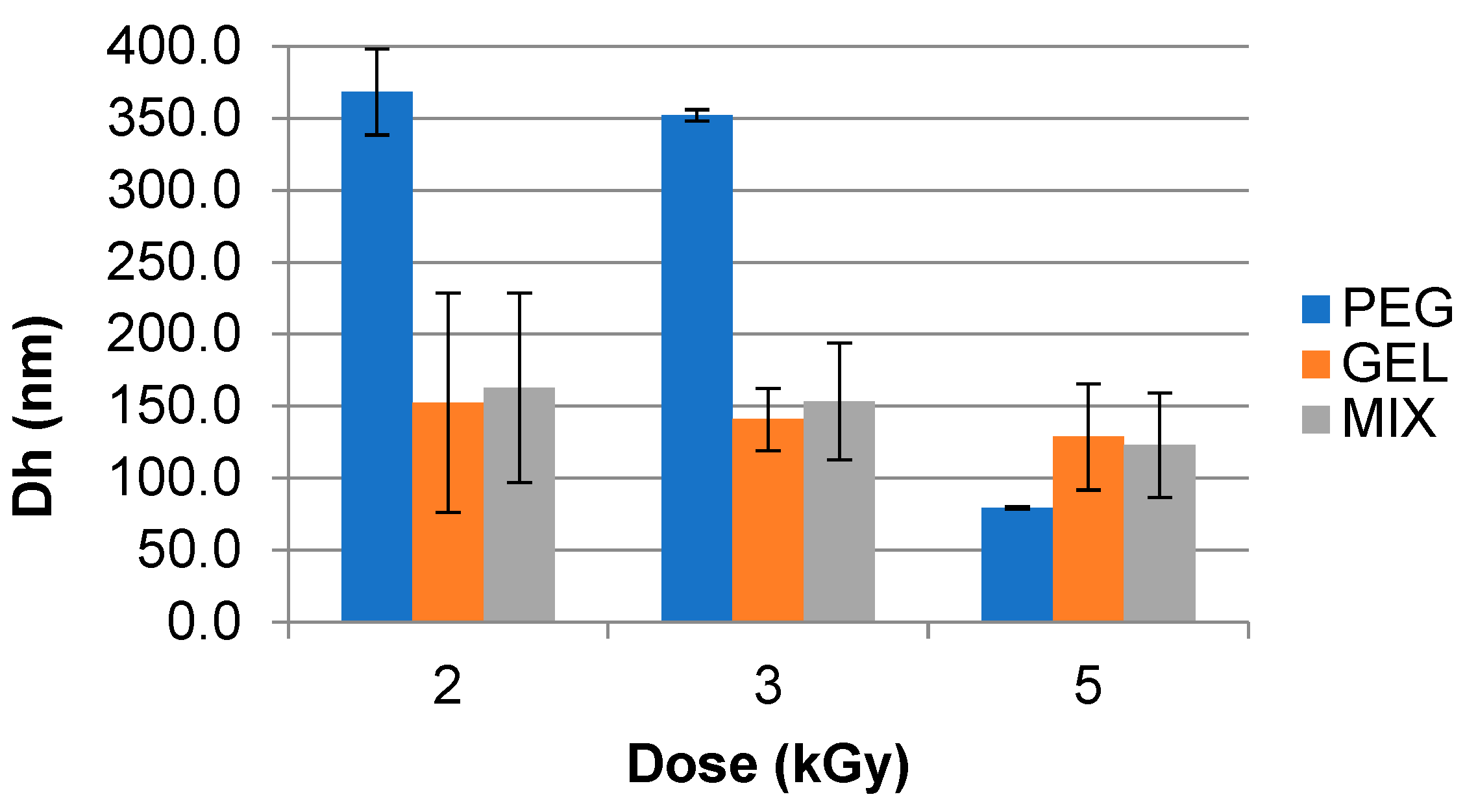

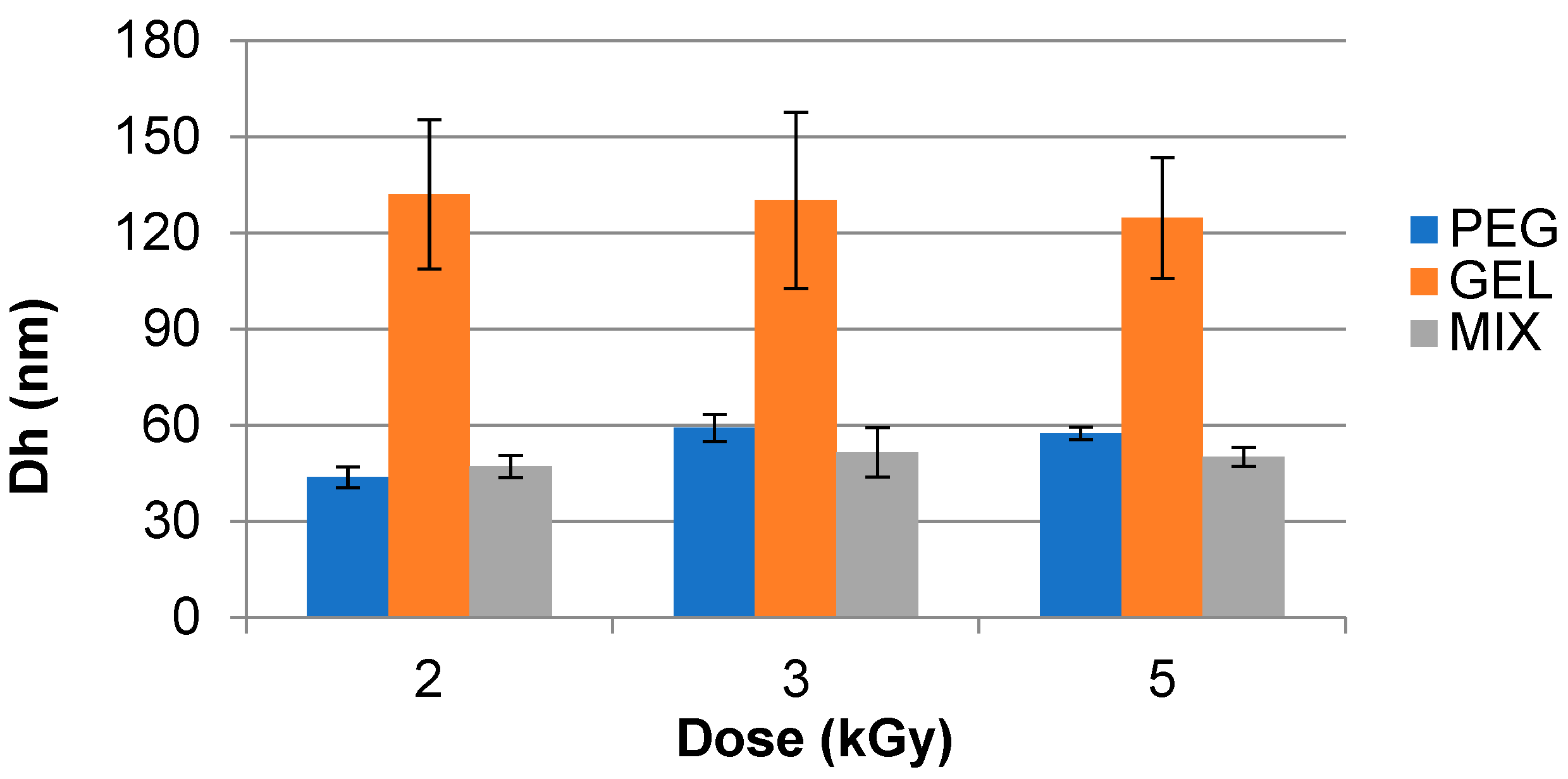

| Dose | Dh (nm) | ||

|---|---|---|---|

| (kGy) | GEL | PEG | MIX |

| 2 | 127 ± 28 | 73 ± 28 | 68 ± 25 |

| 3 | 94 ± 17 | 50 ± 4 | 48 ± 11 |

| 5 | 83 ± 26 | 38 ± 7 | 35 ± 4 |

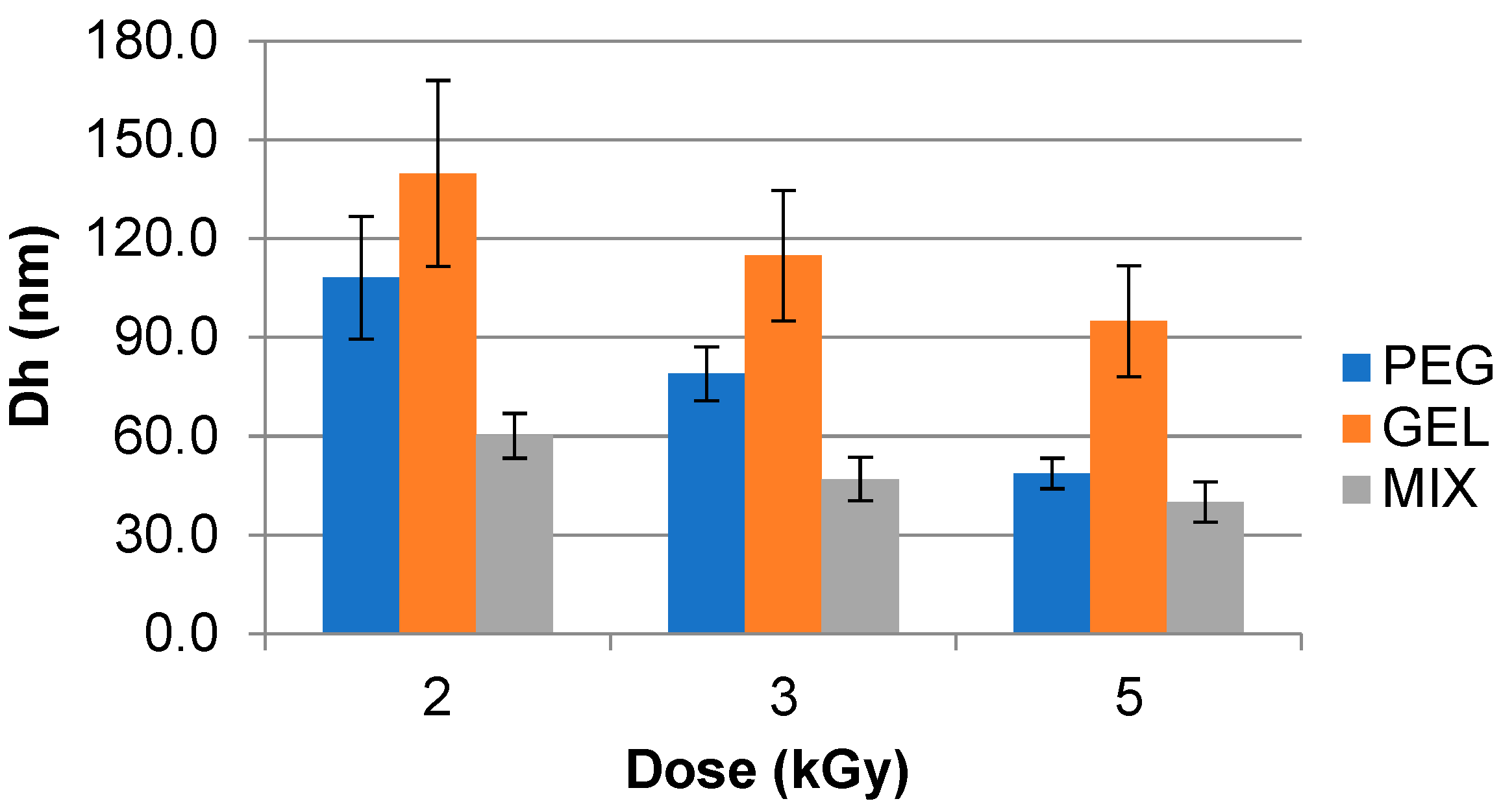

| Dose | Dh (nm) | ||

|---|---|---|---|

| (kGy) | GEL | PEG | MIX |

| 5 | 84 ± 8 | 38 ± 25 | 26 ± 9 |

| 10 | 67 ± 8 | 27 ± 12 | 25 ± 10 |

| 15 | 62 ± 48 | 28 ± 13 | 30 ± 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takinami, P.Y.I.; Mastro, N.L.d.; Ashfaq, A.; Al-Sheikhly, M. Ionizing Radiation Synthesis of Hydrogel Nanoparticles of Gelatin and Polyethylene Glycol at High Temperature. Polymers 2023, 15, 4128. https://doi.org/10.3390/polym15204128

Takinami PYI, Mastro NLd, Ashfaq A, Al-Sheikhly M. Ionizing Radiation Synthesis of Hydrogel Nanoparticles of Gelatin and Polyethylene Glycol at High Temperature. Polymers. 2023; 15(20):4128. https://doi.org/10.3390/polym15204128

Chicago/Turabian StyleTakinami, Patricia Y. I., Nelida L. del Mastro, Aiysha Ashfaq, and Mohamad Al-Sheikhly. 2023. "Ionizing Radiation Synthesis of Hydrogel Nanoparticles of Gelatin and Polyethylene Glycol at High Temperature" Polymers 15, no. 20: 4128. https://doi.org/10.3390/polym15204128

APA StyleTakinami, P. Y. I., Mastro, N. L. d., Ashfaq, A., & Al-Sheikhly, M. (2023). Ionizing Radiation Synthesis of Hydrogel Nanoparticles of Gelatin and Polyethylene Glycol at High Temperature. Polymers, 15(20), 4128. https://doi.org/10.3390/polym15204128