Abstract

Three-dimensional printing technology has fundamentally revolutionized the product development processes in several industries. Three-dimensional printing enables the creation of tailored prostheses and other medical equipment, anatomical models for surgical planning and training, and even innovative means of directly giving drugs to patients. Polymers and their composites have found broad usage in the healthcare business due to their many beneficial properties. As a result, the application of 3D printing technology in the medical area has transformed the design and manufacturing of medical devices and prosthetics. Polymers and their composites have become attractive materials in this industry because of their unique mechanical, thermal, electrical, and optical qualities. This review article presents a comprehensive analysis of the current state-of-the-art applications of polymer and its composites in the medical field using 3D printing technology. It covers the latest research developments in the design and manufacturing of patient-specific medical devices, prostheses, and anatomical models for surgical planning and training. The article also discusses the use of 3D printing technology for drug delivery systems (DDS) and tissue engineering. Various 3D printing techniques, such as stereolithography, fused deposition modeling (FDM), and selective laser sintering (SLS), are reviewed, along with their benefits and drawbacks. Legal and regulatory issues related to the use of 3D printing technology in the medical field are also addressed. The article concludes with an outlook on the future potential of polymer and its composites in 3D printing technology for the medical field. The research findings indicate that 3D printing technology has enormous potential to revolutionize the development and manufacture of medical devices, leading to improved patient outcomes and better healthcare services.

1. Introduction

Recently, 3D printing has become widely recognized as a potentially revolutionary innovation in medical fields. This technological advancement possesses the capacity to fundamentally reshape the manufacturing procedures associated with prosthetics and prostheses, thereby holding immense promise for the future of this field [1]. Additive manufacturing (AM), commonly known as 3D printing, is a process that allows for the rapid prototyping of nearly any structure, no matter how complicated, in a wide variety of materials [2]. Personalized medication distribution systems, anatomy models for surgery planning and training, and patient-specific medical prostheses are just a few medical uses that could benefit from this technology. The field of tissue engineering and regenerative medicine has benefited greatly from creating safe and bioresorbable materials for 3D printing [3]. Furthermore, the advent of 3D printing holds the potential to revolutionize the realm of personalized medicine, wherein individuals are bestowed with tailored healthcare interventions meticulously crafted to align with their distinct anatomical and physiological attributes [4]. This has the potential to improve patient results while also lowering healthcare expenses. The medical field presents its unique obstacles to 3D printing’s widespread adoption. Some problems that need fixing include creating better materials and methods, fine-tuning the printer settings, and standardizing the testing and evaluation procedures. As an added complication, 3D-printed medical gadgets and prostheses still need thorough testing and confirmation before the relevant governing bodies can approve them [5], i.e., 3D-printed renal models help in understanding patients’ renal anatomy [6], orthopedics and maxillofacial reconstruction in cardiovascular and liver diseases [7,8], or pre- and intra-surgical planning in kidney tumor treatment [9].

Despite the myriad of challenges that have impeded the realization of 3D printing’s utmost capabilities within the realm of medicine, diligent endeavors in research and development are currently being undertaken to effectively tackle these obstacles. Patient results, healthcare expenses, and the speed with which medical gadgets and prostheses can be designed and manufactured are just some of the many areas where this technology could have a positive impact [10]. Three-dimensional printing can also alter the structure and composition of materials throughout the life of a produced object [11]. It is possible to design thin-diameter lines and lattices, patterned dots, layers and porous membranes, and depth-changing motifs in functionally graded systems and intricate designs, such as in bone and nacre [12,13]. Using customizable materials allows for the control of new topology, form optimizations, foam density, and surface roughness [14]. Material modifications can be effectively accomplished using 3D printing (3DP) technologies, specifically material and binder jetting. In contrast, others, such as material extrusion and ink writing, allow for discrete control inside or between layers. Three-dimensional printing has several benefits over conventional manufacturing techniques, especially in medicine [15].

Recently, melt mixing has been employed to incorporate biocompatible polycaprolactone (PCL) and polyvinyl chloride (PVC) via 3DP using fused filament fabrication (FFF) [16]. Experimental tests reveal that PVC–PCL compounds are miscible due to high molecular compatibility and strong interaction. This causes extraordinary mechanical properties, especially for PVC–10 wt% PCL. In addition to the desired tensile strength (45 MPa), this material has an entirely rubbery behavior at an ambient temperature, and its total elongation is more than 81%. Programming tests show that PVC–PCL blends have an excellent shape memory effect, resulting in 100% shape recovery [17]. FFF 3D printers are expected to revolutionize the applications of PVC compounds in biomedical 3D and 4D (four-dimensional) printing due to their appropriate thermomechanical properties, supreme printability, and excellent biocompatibility [18]. Besides 3DP, 4D is also progressing, a novel approach to and design for fabricating two-layer composite structures, having a shape memory effect using a fused deposition modeling (FDM) technique with TPU elastomer filaments and the well-known thermoplastics ABS and PCL. The elastomeric layer is constrained by the thermoplastic layer. It is possible to stabilize the temporary shape and store the deformation stress for later recovery of the permanent shape by phase-changing the thermoplastic layer in the opposite direction during a rubber-to-glass transition of the thermoplastic layer. Findings demonstrate that the fixity and recovery rates of ABS–TPU were over 90%. The persistence of the PCL–TPU composite structure was 77.42%, but it also showed complete recovery [19]. These 3D/4D-printed shape memory devices are useful in the medical domain, i.e., in personalized endoluminal devices [20] or smart implants pre-designed to respond to (endogenous or exogenous) stimuli and perform seamless integration with regular/irregular tissue defects [21] or defect-luminal organs [22,23].

Three-dimensional printing allows the creation of implants and other medical tools uniquely suited to each patient based on their morphology and physiology [24]. By reducing the number of necessary surgical procedures and increasing patient satisfaction, personalization has the potential to boost clinical results while decreasing healthcare costs [25]. It helps in creating intricate shapes that would be challenging or impossible to start with more conventional manufacturing techniques [26]. In 2023, a patient’s mandibular morphology was recorded using a cone-beam computed tomography (CBCT) scan, and a virtual model was built using CAD software (AutoCAD 2022 [Version 24.1]) [27]. An implant-supported fixed prosthesis was subsequently designed using this concept. The SLS method is used to 3D-print biocompatible polyamide prosthesis and tissue regeneration [28]. Besides this, 3D printing generates reduced waste. Subtractive production processes such as cutting and milling are notorious for producing large amounts of unwanted scrap [29]. Three-dimensional printing minimizes waste by creating structures layer by layer. Prosthetics production is one practical application of 3D printing for waste reduction [30]. Traditional methods of producing prosthetics require subtractive processes such as cutting and milling, which generate a substantial amount of waste. In addition, 3D printing makes it feasible to design implants that have been tailored to an individual’s anatomy, enhancing a device’s fit and comfort. This customization can reduce the need for additional fittings and adjustments, reducing waste and related costs even further [31]. Furthermore, 3D printing allows for the creation of prosthetics on demand, reducing the need for pre-made device stockpiling and storage. This can result in expense savings and less waste in the supply chain. Three-dimensionally printed medical implants speed up therapy and improve outcomes [32], comprising metallic implants [33] or bone replacement implants [34].

Designing to imitate requires a hierarchical organization that demands a printing process and material selection that works well with the application. Structural integrity is necessitated using polymers based on methacrylic acid to maintain biocompatibility and allow for tissue development, i.e., heart valve prosthesis via TE [35]. Stereolithography printing has been employed to produce the intricate hierarchical truss structure required for the printing process. As a result of ambiguity and component variation in the 3DP process, it is critical to replicate and fine-tune the structure’s configuration. There are many different ways to create tissue scaffolds, depending on the material and printing process that is being employed. It is possible to generate PCL-based tissue scaffolds with a more malleable, biodegradable structure using fused deposition modeling [36]. The use of 3D printing technology to generate patient-specific medical equipment and prosthetic devices, biological models for operative preparation and training, and medication catheters is not an exception to this transformation in the medical industry. Polymers and the corresponding composites are growing increasingly popular in the healthcare sector as an outcome of their distinguishing thermal, mechanical, electrical, and spectral characteristics. This is especially helpful when it is impossible to precisely match the unique anatomical structure of each patient using traditional manufacturing techniques [37,38].

Complicated configurations that are typically challenging to generate using the traditional techniques of manufacturing can now be manufactured via the use of 3D printers. The ultimate result is a medical device that exhibits enhanced efficacy and user satisfaction. Prosthetic devices are manufactured using polymer materials and composites as well [39]. Prostheses have two fundamental purposes: they may either serve as substitutes for missing body parts or enhance the functioning of existing ones. Both functional and aesthetically pleasing prostheses may now be manufactured thanks to the use of 3D printing technology. The customization of the mechanical characteristics of polymers and their composites enables the fulfillment of specific patient needs. Producing anatomical models, medical devices, and prosthetics using 3D printing techniques is performed mostly for medical intervention planning and training. These models let doctors view a patient’s anatomy before treatment. This helps surgeons create a better surgical strategy and reduces risks [40]. Besides this, medical students have hands-on practice using anatomical models.

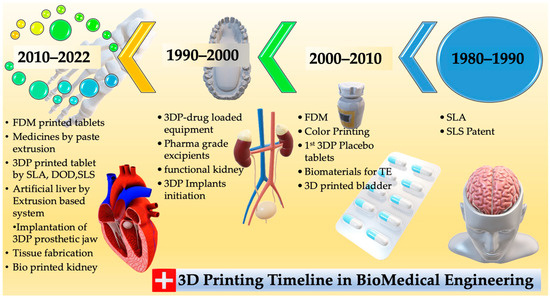

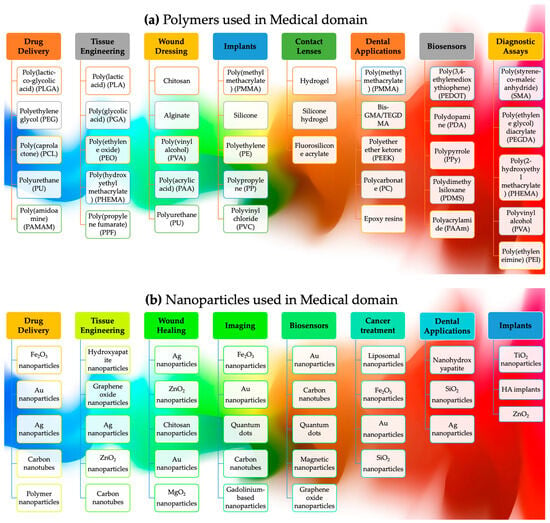

Figure 1 shows 3D printing’s early developmental stage in the 1980s, primarily for small product manufacturing or prototypes. New technical applications have been created since 2009, thanks to rapid development. Figure 2 shows AM discoveries and accomplishments. However, complex, high-precision, multi-material components are still in their infancy. The applications of 3D printing technology using polymers and their composites in the medical area are expanding rapidly, thanks to continued research and development. This is especially helpful for emergencies, in which delays in treatment can have severe consequences. Three-dimensional printing allows for rapid prototyping and optimization by producing multiple design iterations rapidly and cheaply. This can accelerate the creation of better medical implants and devices. This article presents a comprehensive exposition of the utilization of 3DP technology within the realm of medicine. An in-depth exploration is undertaken to analyze the prospective trajectory of 3DP within the realm of medicine alongside a comprehensive evaluation of the merits and demerits associated with employing diverse 3DP techniques for medical applications. This piece aims to aid the ongoing efforts to transform healthcare through this cutting-edge technology by summarizing the current state of the art in 3D printing for medical uses.

Figure 1.

From the 1980s to the present, this timeline shows the history of 3D printing and its most important advances.

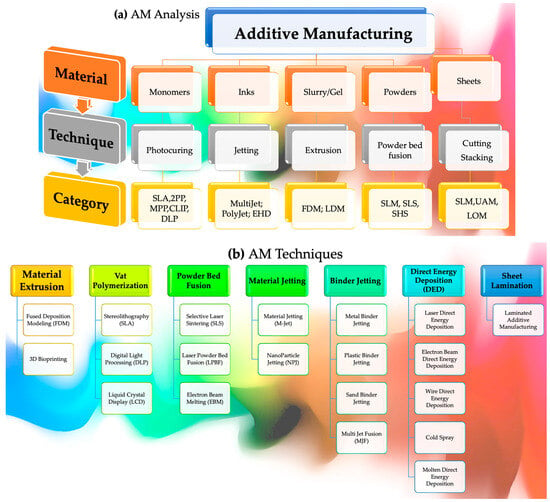

Figure 2.

Critical parameters influencing 3D printing.

2. Polymer Particle Polymerization

A type of 3D printing known as polymer particle polymerization (PPP) uses polymer particles as building elements to construct intricate three-dimensional structures [41]. In PPP, a new structure layer is created by polymerizing a monomer around an already existing polymer molecule. Due to its capacity to produce intricate structures with a high resolution and a degree of control over the end product, this technique has grown in popularity recently, i.e., in the 3DP of carbon fiber [42]. Using tiny polymer particles as building elements in PPP enables the construction of structures with a high resolution. The method enables fine control over the finished product, including the mechanical properties, shape, and size. PPP has the capability to fabricate a diverse range of intricate structures, involving hollowed frameworks, permeable structures, and structures characterized by complex geometries [43,44,45].

Epoxy resins, nanoparticles, and polymeric or mixed materials may be manufactured using 3DP. Several factors, including heat, stress, moisture, the photopolymerization rate, the crosslinking phenomenon, corrosive chemicals, and UV light, can influence the properties of polymer nanocomposites. Intricate physical and chemical processes solidify a liquid monomer solution. When exposed to light, a photoinitiator in a solution breaks down into active radicals, which causes polymerization. In order to create polymer nanocomposites, monomers attack unsaturated double bonds. As a result, polymer chains and molecular weight rise, thickening liquid polymer solutions and changing the properties of the resulting polymers. Equations for the first-order rate of chemical reactions compute species concentrations. The monomer conversion level depends on the volume shrinkage, glass transition temperature, and nonlinear viscoelasticity of cured polymers. Mechanical properties should preferably be adjusted during photopolymerization to produce optimal strength and stability in the 3DP structure [46].

Frameworks, thermal transfer, electromechanical micro-machines, optoelectronics, surface changes, and biomedical applications can be enhanced by incorporating natural polymers with rigid body systems [46]. Polymeric materials are delicate, and most nanoparticles display inconsistency, a lack of adequate linkages with polymeric materials, or stiffness at large concentrations [47]. Increased filler aspect ratios in polymer matrices, for example, according to the shear lag hypothesis in composite dynamics, would boost the efficiency of stress propagation via fiber reinforcement, i.e., in carbon nanotubes [48]. The mechanical load cannot be transferred satisfactorily via discontinuous particles (nanowires or nanorods, i.e., ABS–ZnO nanocomposites) below a certain length, resulting in early fracture development before the composite collapses [49]. Composites’ performance may be improved via nano, micro, and macroscale particles [50]. However, a few key elements will decide the scope of remodeling, i.e., the kinds of polymer matrix and nanofibers, the dispersal or densities of nanomaterial, interfacial interactions, nanomaterial ordering, or the functional monomer [51,52]. Concerning high-performance nanocomposite polymer composites from 3DP technologies, herein, we will focus on three aspects, nanocomposite kinds, colloidal and initial concentration, and their interactions, as shown in Figure 2. The subsequent sections will provide a more comprehensive analysis of each of these aspects.

2.1. Polymer Nanocomposites: The Synergistic Combination of Polymers and Nanoparticles

Polymers and nanoparticles in 3DP have generated considerable attention due to their capacity to augment mechanical, thermal, and electrical properties [53]. Due to their intrinsic biocompatibility and capacity to undergo dissolution inside the human body, biodegradable polymers are often employed in 3DP, i.e., in polyglycolic acid (PGA), polycaprolactone (PCL), and polylactic acid (PLA) [54]. Scaffolding, implants, and systems for the administration of medicine are all examples of common applications for their use in the medical industry. Highly resilient polymers with exceptional thermal stability, specifically designed for employment in demanding sectors such as the aerospace and automotive industries, find their utility in the realm of 3D printing, where the need for materials capable of withstanding elevated temperatures is paramount. They comprise polyether ether ketone (PEEK) and polyphenylene sulfide (PPS) [52], while toughened polymers include acrylonitrile butadiene styrene (ABS) and polypropylene (PP) [53].

Similarly, metal nanoparticles such as Cu, Au, and Ag can be used in 3DP to enhance components’ thermal and electrical conductivity [54]. They are frequently employed in the creation of sensors and electronic gadgets [55]. Adding polymeric nanoparticles to 3D printing may boost the thermal, mechanical, and electric attributes of the generated components, i.e., with polyhedral oligomeric silsesquioxane or graphene oxide (GO) [56]. Ozbolat and Hospodiuk (2016) examined the applications of 3D printing in tissue engineering using biodegradable polymers and composite materials [57]. Three-dimensional printing was used by Shi et al. (2017) to create thermoplastic composites with exceptional performance characteristics through the inclusion of carbon nanotubes [58]. Shukla and his colleagues (2019) developed polymers reinforced with graphene via 3DP, enhancing their mechanical and thermal properties [59]. In addition to liquid polymerization, nanoparticle-suspended particles, and epoxy formulations, 3D printing (3DP) has the potential to operate using various other materials such as copolymers, suspensions, polymeric slurries, and continuous thin sheets [60].

The enhancement of the mechanical qualities of composite materials may be achieved by combining the inherent features of these materials with those of their component phases. The kind of polymer and nanoparticle utilized has an impact on processing parameters, material structures, and system properties [61]. This implies that conditions for 3D printing will be defined by diverse epoxy resins, as well as ultra-high-performance polymers. For example, vat polymerization is ideal for employing light-curable polymers [62]. Material jetting may use low-viscosity inks to obtain fine details. On the other hand, printed green components have poor mechanics and have been best utilized in functional materials, rather than structural materials, since they have weak mechanics [63]. Extruded filaments may be made from various materials for wound membrane use, but their use in fast prototyping and tissue scaffolds is restricted [64].

2.2. Nanoparticle Dispersions and Concentrations

Nanoparticle dispersions and concentrations can greatly impact the properties of 3DP parts [65]. The mechanical characteristics of printed parts are influenced by the distribution of nanoparticles within a polymer matrix, whereas the concentration of nanoparticles influences the thermal and electrical properties, i.e., in Ti3C2/epoxy nanocomposites [66]. A homogeneous dispersion of nanoparticles within the polymer matrix may enhance the mechanical properties of printed components. This can be accomplished using a variety of methods, such as sonication, ultrasonication, and surfactant-assisted blending [67]. Aggregating nanoparticles can cause the weakening of the mechanical properties of printed components within a polymer matrix. This can be prevented by evenly dispersing the nanoparticles and avoiding agglomeration during printing. The properties of printed components can only be slightly altered by low concentrations of nanoparticles in a polymer matrix [68]. However, nanoparticles can enhance the mechanical qualities of printed parts even at modest concentrations. High nanoparticle concentrations within a polymer matrix can enhance printed components’ thermal and electrical properties. However, a concentration that is too great might aggregate and have weaker mechanical properties [69]. Nanoparticle dispersions and concentrations are essential factors in 3DP because of their impact on the mechanical, thermal, and electrical properties of printed objects [70]. By creating a homogeneous dispersion of nanoparticles inside a polymer matrix and selecting an appropriate concentration, the qualities of printed components may be enhanced, i.e., in natural fiber-reinforced PLA or propylene composites [70,71]. Another technique for preventing particle aggregation is to regulate the external fields around the particles [72]. Electrophoresis is a method used for the efficient alignment and dispersion of particles inside a solution via an electrical field to scatter and arrange particles [73]. This high electrical voltage may result in the formation of electrical percolation spots, electricity generation intensities, and electrostatic interactions, all of which may lead to the formation of nanoparticle agglomerates [74]. The intensity of magnetic fields affects both particle density and dispersion in a similar manner to the way electric fields’ strength does. Thus, the presence and concentration of nanoparticles in the polymer matrix significantly impact 3DP resolution [75].

2.3. Interfacial Interactions at the Polymer–Particulate Interface

Understanding and optimizing the interfacial interactions at the polymeric–particulate interface is critical in creating high-performance and functional composite materials for tissue engineering, drug delivery, and surgical planning [76]. When nanoparticles or microspheres are incorporated into a polymeric matrix to form a composite material, interfacial interactions occur at the polymeric–particulate interface [77]. These particles can improve printed components’ mechanical strength, biocompatibility, and drug delivery capacity. Interfacial adhesion and printed component performance might suffer if the particles and polymer matrix fail to interact effectively. Multiple variables may influence these interactions, including surface chemistry, particle dimensions, morphology, concentration, dispersion, and the circumstances of 3D printing processes [78]. Regarding 3DP nanohybrids, interfacial interactions occur at the polymeric–particulate interface, within printing inter-lines, or between inter-layers [79] because an interaction involving polymeric materials and nanoparticles transmits stresses from tougher nanoparticles to softened polymers [80].

Morphologies disclose the kind of bonding and fracture that has occurred, i.e., pull-out, delamination, or fiber breakage. Thermomechanical investigations, residue stress mapping, and numerical micro/nanomechanical testing can be utilized to acquire a deeper understanding of the interactions among polymers and nanoparticles at the interface [81]. These approaches demonstrate how these interactions influence material characteristics. Interfacial interactions between polymers and particles, as opposed to interlayer bonding modification, are more likely to include the chemical alteration of the polymer [82]. Improving hydrophobic particles’ ability to adhere to hydrophilic polymers is important, such as in PVA and PEG [83]. The oxidation process can add functional entities (such as C–O, O–C–O, and –NHCO–), as well as bonds (for example, N–H, O–H), into these particles, influencing the surface tension and interactions [84]. Using enzyme treatment, natural fibers’ hydrophilic surfaces become compatible with hydrophobic polymers, allowing them to be used together. Polypropylene (PP) is an excellent material for the manufacturing of composite materials, owing to its notable characteristics, including its low surface tension and chemical inertness [85]. Using a maleic anhydride coupling agent in conjunction with PP grafting on maleic anhydride may help to improve the binding between polypropylene and glass fibers [86]. Inter-line bonding and inter-layer adhesion are less complicated to investigate than nanoscale polymer/particle interactions, which are more difficult. In the absence of voids, efficient adhesions may prevent fracture. Nozzle temperature and foundation impact bonding neck diameter and volume; for example, they affect interfacial bonding in a significant way [87]. Both the material used and the circumstances under which it is processed impact interlamellar fracture toughness and shear strength. The kinetics of polymer crystallization may be altered by printing layers that are heated and cooled at different periods, resulting in poorer bonding between neighboring lines between successive printing layers. It has been shown that objects manufactured utilizing FDM, SLS, or inkjet exhibit lower-yield ultimate tensile stress along the z-axis versus materials produced by employing traditional manufacturing procedures in several circumstances [88]. Improved interlayer bonding may be achieved in various situations using an increased temperature to cause polymer liquefying, lower printing rates to produce fewer flaws, and a lowered width thickness to avoid porous formation, among other things [89]. The adhesion and particle dispersion rates may be varied by altering the materials used in these products. Figure 3 represents numerous AM techniques, materials, and the processing involved.

Figure 3.

Overall progression displaying (a) AM analysis comprising numerous techniques and categories alongside (b) AM methods.

3. Light-Induced Polymerization for Advanced Materials

During the 3DP process, photosensitive monomers are exposed to high-intensity light sources, which causes them to degrade. Compared to other printing techniques, resin curing procedures often have greater resolutions and produce higher-quality products than other printing techniques. This has resulted in various methods of fabricating parts from resin vats exposed to ultraviolet light, such as stereolithography with direct laser writing. A laser operated via a computer hardens the resin in the tank, resulting in a solid coating layer. Following the exposure of each layer in the printing process, the printing platform advances vertically. To enhance the structure and enable fine-tuning to match the requirements of particular applications, the material is then cleaned and UV-cured. After a 30-h curing period, UV radiation is more effective and boosts mechanical qualities, such as the elastic modulus, while promoting material consistency via enhanced crosslinking. In stereolithography, printing may not always allow the simultaneous printing of several materials despite its high print resolution and speed. Polyjet printing, also known as inkjet printing, is an alternate resin curing technique that does not need ultraviolet light. It is possible to print multi-material objects in a short time using multi-nozzle jetting and support materials. Recently, inkjet printing can be applied to prototyping, electronics, and even bioprinting. Beams with diameters of around 400 nm have been employed to print lattices that exhibited fabrication faults due to the structure’s topology and build orientation. Although polyjet printing has implications in tissue engineering, more research is necessary to decide whether this process is suitable for assembling configurations that can support cell seeding and proliferation.

3.1. Powder Bed Fusion

Powder bed fusion (PBF) uses numerous materials and is a frequently used technique. The direct metal laser sintering (DMLS), electron beam melting (EBM), selective heat sintering (SHS), selective laser melting (SLM), multi-jet fusion (MJF), and selective laser sintering (SLS) printing processes are all included in the PBF process. A few examples of materials that are in use in PBF and demonstrate semicrystalline characteristics are ceramics, polyamides, and polyimides, in addition to metallic materials and titanium alloys [90]. Only a few preparations can produce pure polymer powder in large quantities, i.e., via the mechanical approach, which involves milling and grinding to make microscopic pellets in a cryogenic environment [91]. The solution technique depends on the thermally induced phase separation of a solution. Because of a change in temperature during this procedure, micro-sized particles of a polymer solution precipitate from the solution. Co-extrusion is a commonly used technique in the process of polymer melting. This technique involves melting a polymer extrusion and cooling it in a solvent, which allows the polymer matrix to be dissolved. The spherical particles can be recovered via filtering or screening. It is difficult to achieve a homogeneous distribution of discontinuous reinforcing fillers in SLS-produced polymer composites, which is a key challenge in producing polymer composites [92]. Spray drying, in situ polymerization, solution mixing, mechanical blending, and wet mixing are some methods for dispersing particles, similar to polymer powder technologies [93].

As far as mixing is concerned, mechanical blending relates to the method of merging epoxy resin and particulate granules in a dry condition by integrating them together with the help of a mechanical homogenizer or cryogenic milling as the method of linking [94]. Nanofibers, hydroxyapatite, and black carbon granules were manufactured using cryogenic milling, e.g., in nylon or PEEK matrices [95]. PBT/PC/MgO composite powders can be processed to particle sizes ranging from 20 to 100 microns that are consistent and well-controlled through ball milling [96]. The interaction between polymers, without the use of transesterification, may produce particles that are uniform in shape and have adequate bulk density and rheological properties. This usually leads to the crystallization of the mixture because the two kinds of particles have partly separated and agglomerated. The flexible nature of epoxy resins may also inhibit pellet formation when heated above their glass transition point (i.e., 50 °C). It is important to note that wet mixing differs from drying because it is centered on suspensions or nanoparticle surface coating on polymer granules. Van der Waals interactions, electrostatic forces, and other secondary bonds may aid the production of polymers and particle powders [97]. The use of low-viscosity solvents and a somewhat lower process temperature than is generally utilized may result in powders with a spherical shape. Polymers including PEEK, POM, PBT, and PS may have previously benefited from silica’s effective integration [98]. Carbon black adsorbed on the surface of PA12 particles may be converted into powders via mechanical sonication and mixing that can then be filtered. The shape of these nanocomposites was spherical, and their size distribution was uniform throughout the specimen [99].

To disperse them, extruding particles in polymers during melt mixing is important. They are then reduced to fine particles via grinding or rotating shearing techniques. Ceramic particles such as Al2O3, Fe2O3, SiO2, or CoO are appropriate for inclusion in polymers such as PC, PVC, PE, and polyamidoethylene terephthalate [100]. Micro-sized particles may be more successful in dispersion than nano-sized fillers in polymer melts, partly due to the polymer melts’ high viscosity. Solution mixing dissolves polymer–particle combinations in a solvent before precipitation or solvent evaporation. Ding H et al. produced PEEK/PPS and ketone particles via thermally induced phase separation [101]. They noticed that the powders generated were virtually spherical and had consistent size distributions and smooth flowability, indicating high quality. In most circumstances, the solution mixing of CNT in TPU is more likely to result in better particle dispersion than melt mixing despite being less viscous [102]. In the physicochemical field, spray drying involves applying pressure to an atomizer needle to sprinkle a solution’s droplets over a surface [103]. The solvent evaporates instantly, resulting in the formation of polymer nanocomposite particles. Although the particle sizes are usually too tiny for SLS processing, this is often due to the particles’ small size. This has resulted in composite powders being sprayed in less often than they could have been in the past. The particle size when spraying was 26 microns, but the particle size after milling was 52 microns [104].

Monomers and initiators accelerate polymerization. Particle dispersions are improved, and the adsorption and coating of polymer chains on particle surfaces are enhanced. PVP on PA12 surfaces exhibits higher adsorption and coating [105]. Some polymer–particle hybrid powders have the ability to boost the interactions between their constituents drastically in nickel–PA12 composite [106]. When using a high concentration of reinforcing fillers, the viscosity may increase throughout the sintering process, but increasing laser intensity may enhance flow dynamics. A severe laser pulse must be prevented because of the disintegration of polymer particles that occurs due to high laser intensity. Thermal and residual stress will be generated throughout the printing process as a medium of interaction between the light source and the polymeric material at various stages throughout the process. By analyzing the particles’ optical properties, one can figure out the capacity for absorption and reflection of the energy source and the degree of heat propagation and dissipation. This is performed using laser energy, which melts and fuses particles while simultaneously maintaining the operating temperature within the steady sintered range provided by the light source. As a result of the complexity of management and the difficulty in reaching high temperatures, which results in delayed diffusions, residual tension in printed goods is formed in the printed product manufacturing process [107]. It is required to treat the material after it has been heated since stress is dependent on both the variation in temperature and properties, including its melting point, diffusion kinetics, and surface tension.

3.2. Vat Polymerization

Photopolymerization, a 3D printing technology, relies on the same basic strategy: a liquid photopolymer contained in a vat (or tank) is selectively cured. VAT photopolymerization 3D printing includes stereolithography (SLA), digital light processing (DLP), and continuous liquid interface production (CLIP).

3.2.1. Stereolithography (SLA)

SLA may be utilized to generate innovative composites that include ternary phases or have sensitive features, such as the capacity to absorb energy. More cured resins that are stiff yet brittle may be employed. It is conceivable to enhance their durability through the incorporation of particles endowed with the capacity to assimilate and dissipate energy. Core-shell particles with epoxide functional groups were produced by Li et al. These particles were subsequently observed to effectively adhere to SLA-printed epoxy resins [108]. An emulsion polymerization process was employed to generate an outer shell on the particles composed of a polybutadiene core and PMMA on the outside. The flexibility, durability, and damage tolerance of solid and cellular materials increased. Incorporating self-healing characteristics is another technique for minimizing the risk of brittle failure in SLA-printed epoxy. Beckingham et al. made a discovery about the enhancement of durability and material sustainability in SLA 3D-printed specimens. They found that, by integrating a self-healing microcapsule catalyst system with a readily available photosensitive polymer matrix, significant improvements were achieved [109]. Before the SLA 3DP self-healing composite, polymer microcapsules holding healing fluids were dispersed in resin. The specialized biological and therapeutic functioning of SLA enabled hierarchically ordered biomaterials. When used in place of a filler, reinforcement fillers may increase viscosity. Due to greater viscosity, the processing will be slowed down significantly. As UV light dispersion decreases the UV penetration depth and lateral resolution, it is not practical to employ higher laser powers or UV-reinforcing fillers. Due to localized overheating, the premature curing of polymer breakdown may occur. Adding additives to the resin/particle system may help polymerization, adjust the viscosity, preserve particle stability, and increase interfacial bonding among the particles.

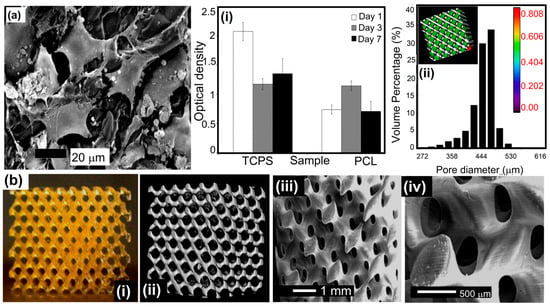

Several novel SLA-based methods, such as two-photon polymerization (2PP)/digital light processing (DLP) and multi-photon polymerization (MPP), have been developed [110]. The CLIP technique is an exception to this judgment since it is not extensively utilized in composites. SLA enables the dependable and repeatable production of a wide range of 3D structures since the final microstructure and form can be accurately controlled. Non-linear scaffold geometries may also be fabricated. Photo cross-linkable poly(e-caprolactone) (PCL)-based resin was produced and applied via stereolithography by Laura Elomaa and colleagues, as shown in Figure 4 [111]. The structure’s preparation did not involve the use of any additional solvents. Gel-rich networks were made by synthesizing PCL oligomers with three arms of varying molecular weights, functionalizing them via MAA anhydride, and then photo-crosslinking the resulting molecules. Stereolithography and a resin made of PCL macromer, the Irgacure 369 photoinitiator, an inhibitor, and a dye were used to make porous scaffolds. The resin was heated during curing until it achieved the proper viscosity. The scaffolds were a perfect replica of the CAD drawings with no evidence of material contraction. The sample porosity was determined to be 70.5 ± 0.8%, having an average pore size of 465 µm. There was a significant interaction between the pores. In tissue engineering, photo-crosslinkable and biodegradable PCL resin is ideal for creating scaffolds via solvent-free stereolithography. In a PLC sample, fibroblasts were seen after 7 days in culture., as shown in Figure 4a. Tissue culture polystyrene (TCPS) served as a standard in an MTS experiment measuring cellular metabolism at the film’s surface. The data are presented in Figure 4(ai,aii). Even after just one day, optical density, which correlates with the quantity of live cells, increased. By day 3, there was a striking resemblance between the optical density and the standard TCPS sample. The PCL networks’ surface area was completely populated by cells. The total number of viable cells dropped as the confluence reached 100%. In cytotoxicity assays, the photo-crosslinked networks made from a methacrylate PCL macromer and Irgacure 2959 photoinitiator were compatible with living tissue. Three-dimensional porous structures were fabricated using SLA at temperatures between 43 °C and 46 °C utilizing a resin made from the PCL 1500-m macromer. The resin had a photoinitiator, inhibitor, dye, and macromer. The scaffolds were very porous, with the pores fully interconnected across the three-dimensional structures. The samples’ exposed surfaces were smooth and homogeneous in quality. After curing, the scaffolds retained the same dimensions as before extraction and drying. That is why we did not see any evidence of material shrinking. The yellow color of the scaffolds, as described in Figure 4(bi), was due to triethylamine forming a colorful complex with MAA anhydride. In lCT reconstruction, the porous structure was found to be open and linked (Figure 4(bii)). The scaffold appeared to have appropriate external and internal surfaces in the SEM data (Figure 4(biii,biv)). The scaffolding was a precise representation of the CAD-drawn framework.

Figure 4.

(a) SEM image: fibroblasts after 7 days in a cell culture showing crosslinked PCL, (i) the activity of cells’ metabolism while grown on TCPS (positive control) and photo-crosslinked PCL networks, and (ii) pore size distribution throughout the porous scaffold via μ-CT. (b) Photographs of (i) a micro-computed tomography visualization and (ii) SEM of a scaffold via SLS using a 1500-m macromer (iii,iv) An enlarged view of the open and linked nature of the porous structure indicates that the scaffold exhibited suitable external and internal surfaces. Reprinted with permission [111].

Organ printing uses tissue spheroids as key components to create living, functioning organs in a 3D configuration. Microtissues and tissue spheroids are living materials that can be studied and traced throughout time due to their unique composition, material, and biochemical characteristics. Tissue fusion is fundamental to the physical and chemical understanding of tissue self-assembly. Small, solid, and lumenized vascular tissue spheres can create tiny branches of an intraorgan vascular tree. This might open the path for the large-scale industrial robotic biofabrication of perfusable intraorgan branching vascular trunks in real human organ structures. Organ printing can potentially improve and alter the field of tissue engineering significantly. Consequently, organ manufacturing is a novel enabling technology that offers a developmental-biology-inspired replacement for the traditional biodegradable solid-scaffold-based techniques of tissue creation.

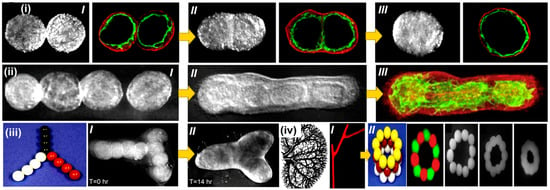

Vladimir Mironov and his colleagues aimed to describe and explore a fresh, rapidly emerging workflow in tissue engineering inspired by embryonic biology [112]. Anatomically precise tissue spheroids can be biofabricated in a lab. Some of the most crucial branches of a vascular tree have already been shown to be individually engineered. Additionally, in vitro and in vivo research shows that microvascular tree fragments as small as 100 nm can reassemble themselves, as shown in Figure 5(i–iii). As a result, it is feasible to build an intraorgan vasculature network having 10–12 orders of branches—specifically for organ printing technology, a bioengineered intraorgan branching vascular tree made up of three different types of self-assembled vascular tissue spheroids. The bioengineered vascular tree may be perfused and integrated into 3D tissue or organ structures after bioprinting, post-printed tissue fusing, and faster tissue maturation. Bioengineering a hierarchically branching intraorgan vascular tree for a bioprinted 3D tissue construct is challenging. It is hard to print functioning human organs without branching intraorgan vascular trees. The scholarly work conducted by C. M. Smith and colleagues delved into the realm of exploring the feasibility of employing three-dimensional direct-write cell deposition as a means of fabricating dynamic frameworks [113]. To facilitate the step-by-step assembly of cells and ECM on different substrates, a direct-write bioassembly device was developed and manufactured. In this experiment, human fibroblasts were coextruded onto a polystyrene slide through positive displacement delivery while suspended in a polyoxyethylene/polyoxypropylene mixture. Approximately 60% of the fibroblasts that were subjected to deposition exhibited viability even after the elapse of a 24-h period, as experimentally proved by Smith CM [113]. By employing a micro dispensing technique, the bovine aortic endothelial cells (BAECs) were coextruded onto the hydrophilic surface of polyethylene terephthalate sheets. Upon being introduced via a 25-gauge tip, a remarkable survival rate of over 86% was observed among the BAECs. The configurations survived in culture for up to 35 days while retaining their initial spatial arrangement. These findings show the possibility of a direct-write, 3D bioassembly strategy to create pattern-driven tissue-engineered structures. The model employed in these investigations was built from pig cardiac angiography. The construct had not yet undergone cell elongation and proliferation two hours after extrusion. The experimental results revealed proliferation, phenotypic differentiation, and pattern persistence when cultures were kept alive for up to 35 days [113].

Figure 5.

Bioprinting intraorgan branching vascular trees with uni-lumenal vascular tissue spheroids. Developmental stages of a ring-shaped vascular architecture during tissue fusion. (i) [I–III] Bioengineered vascular tissue spheroids in the shape of rings made from human smooth muscle cells. To show that no cellular mixing occurred during tissue fusion, tissue spheroids were fluorescently stained with green and red fluorescent stains, respectively. (ii) [I] Uni-lumenal vascular tissue spheroids fusing together in a hanging droplet. (ii) [II–III] Successive procedures for vascular tissue spheroids in collagen type 1 hydrogel fusing together. (iii) Physical representation of the development of branched vascular segments from spheroids of uni-lumenal vascular tissue in the production of type 1 collagen hydrogel (iii) [I] initially; and (iii) [II] after the integration of tissues). (iv) Kidney intraorgan vascular tree segment bioprinting employing solid vascular tissue spheroids. [I] A piece of a vascular tree that was bioprinted. [II] A bioassembly model of a tubular vascular tissue construct in 3D employing spheres of solid tissue. Reprinted with permission [113].

3.2.2. 2PP/MPP 3D Printing

It has been shown that 2PP or MPP, commonly known as direct laser writing (DLW), has a significant manufacturing capacity that may be used in biomedical engineering. When an initiator preferentially absorbs a single UV photon of a short wavelength containing monomers or oligomers, 1 PP takes place, as observed in traditional SLA, and polymer chain production begins to occur. The photosensitive resin absorbs ultraviolet rays within several micrometers of its layer width due to its low penetrating ability. The excitation laser wavelength for 2PP is much less than that of the excitation laser (when compared to one-photon polymerization (1 PP)). The multiphoton polymerization (MPP) process, which occurs during the photo-crosslinking of polymers, absorbs three or more photons simultaneously. CNT alignment in nanostructured resins was achieved via laser writing through 2PP. The changing power of the polymer/CNT curing laser (375–995 nm) affected the composite. This study hypothesized that reducing the nematic order parameter would benefit sensors, actuators, and metamaterials. The thiol-grafting strategy improved concentrations of thiol-acrylate composites by up to 0.2% of the CNT surface modification [114]. The CNT’s inclusion resulted in a significant improvement in mechanical and electrical properties. Achieving this CNT alignment on a large scale in scalable production is challenging. For example, no preferential orientation was observed because of the higher electrical conductivity of CNT cured in resins. Laser curing has also been shown to produce intriguing phenomena in ZnO/resin [115], Au nanorod actuation in liquid crystalline rubbers [116], and gold ion aggregates in SU8 resins [117].

Figure 6 illustrates the selected scaffold design’s top and side views. The scaffolds’ pore array was 10 pores deep and 10 pores wide (250 μm × 250 μm, 300 μm spacing) [118]. On each side of the scaffold, there were also four porous layers. The scaffold was constructed layer by layer in a CAD model with a slice distance of 15 m in the vertical axis. Parallel laser scans from a distance of 2 μm were used to build up each successive layer. To expedite the manufacturing of these massive scaffolds, the average laser power was increased to 3.5 mW, the highest permitted by the current setup. At this power, 2PP manufacturing at 10 mm/s scanning speed took 5 h per scaffold. Utilizing a more potent laser would aid in the reduction of production time. After three washes at 55 °C in distilled water to remove unpolymerized GelMOD, the final structure was uncovered. Prior to the SEM examination, the constructions were freeze-dried. The findings suggest that scaffold perforations have mesh-like patterns (Figure 6(ai,aii)). Researchers think diffusion-driven polymerization formed the mesh since the scaffold pores were not laser-irradiated. From the irradiated zone, laser-generated radicals disperse and induce polymerization. In accordance with the procedure used in material degradation investigation, incubating scaffolds in a collagenase solution (100 CDU/mL) resulted in partial (1 h incubation, Figure 6(bi,bii)) or total (2 h incubation, Figure 6(ci,cii)) meshes’ disintegration. Removing the excess mesh from the scaffold revealed its quality and dimensions. The analysis indicated that the polymer struts shrunk from 50 to 40 μm in width after the scaffolds were cured. When restored to an aqueous environment, the scaffolding expanded and regained its previous size. Figure 6(cii) shows that the polymer struts had linear micro patterns that are 1.5 μm apart. The patterns created via the scaffold manufacturing process resulted from a linear scanning technique. Considering shrinkage processes, the separation of this ridge-like microtopography correlates with the initial laser scanning settings utilized for 2PP manufacturing. Hence, 2PP allows for exact CAD model replication. Furthermore, 2PP affords control over a scaffold’s microtopography in addition to its porous structure and configuration. The engineered scaffolds’ biocompatibility was then assessed in vitro. The cells’ responses after mesenchymal stem cell (MSC) placement were examined to assess the scaffolds’ efficiency. The objective was to investigate the cell response and evaluate the potential usefulness of this technique in tissue engineering. The ability of collagenase-treated and untreated scaffolds with vacant pores and meshes to enable cell seeding was evaluated. To facilitate initial cell adhesion, the scaffolds were seeded with 4 × 104 MSCs and then incubated at 37 °C. The additional medium was introduced to the scaffolds following a duration of 1 h, subsequent to which their progress in cultivation was observed and evaluated. A microscopic examination was conducted on scaffolds that had been seeded with cells one day following the seeding process.

Figure 6.

Gelatin scaffolds were created using the 2PP approach. Scaffold CAD model analysis and SEM images of (ai,aii) untreated scaffolds. Scaffolds using collagenase solution with 100 CDU/mL for (bi,bii) 1 h and (ci,cii) 2 h. Fluorescence images of MSC-seeded gelatin scaffolds (di,dii). High seeding efficiencies were achieved via cell entrapment on an untreated scaffold with mesh-filled pores, a (ei,eii) collagenase-treated scaffold, and (f) an 11-day-old porcine MSC-seeded gelatin scaffold. SEM image (i,ii). Blue and green fluorescence images show cell distributions. (g) EDX confirmed calcium and phosphate on a 2PP-produced scaffold. (i,ii) Calcium phosphate nodules, magnified view. Reprinted with permission [118].

The nuclei of the cells were stained with Hoechst 33342. The determination of cell density and scaffold localization may be inferred by analyzing the staining intensity and autofluorescence shown by the scaffold. Cell densities were found to be the maximum on polymer struts and within untreated scaffold pores when a mesh filled the pores (Figure 6(di,dii)). After 2 h in a collagenase solution, the scaffolds had opened pores. Thus, most cells were unable to adhere to the scaffolds after seeding (Figure 6(ei,eii)). Since the mesh within the pores maintains cells and promotes cell seeding efficiency, untreated scaffolds aid in seeding. Afterward, unprocessed scaffolds were cultivated in 1 mL of full DMEM at 37 °C in a humidified environment (95% air and 5% CO2). The addition of osteoinductive media followed three days of early cell growth. Calcein AM and Hoechst 33342 staining was performed on the cell-seeded scaffolds on day 11. The specimens were then examined by employing fluorescent microscopy. The use of Hoechst for cell localization is due to its ability to stain cell nuclei, while Calcein AM allows for the imaging of live cells and the examination of their adherence and shape. The scaffolds were found to be stable in culture media for 11 days.

There was also no significant swelling or distortion during culturing (Figure 6f). The fluorescence at several focal planes across the scaffold showed that cell migration was not inhibited by the mesh present in the pores after initial seeding. The cells were seeded all over the scaffold (Figure 6(fi,fii)). Calcium and phosphate were both detected through the EDX study (Figure 6g). The cells appeared to adhere and spread out uniformly across the polymer struts in the SEM micrograph (Figure 6(gi)). The presence of calcium phosphate nodules near osteoblast clusters indicated appropriately differentiated cells (Figure 6(gii)). The engineered scaffolds would be robust enough to resist an active cell culture, such as that carried out in a perfusion bioreactor. The mesh had a minimal influence on nutrition transport for the present scaffold size. Based on the degradation behavior, this mesh would break down and release the pores while leaving the rest of the scaffold intact. The results show that, with success, photopolymerizable GelMOD can be used with 2PP scaffolds for skeletal tissue engineering.

3.2.3. 2PP: Conducting Polymers

Recently, conducting polymers were also printed using 2PP. They may be used in power production, wearable electronics, and bioelectronics. Hyunwoo Yuk revealed a high-performance 3D-printable conductive polymer ink called poly(3,4-ethylene-dioxythiophene): polystyrene sulfonate (PEDOT: PSS) [119]. With multi-material 3D printing, insulating elastomers, for example, can be easily incorporated into microstructures made of conducting polymers, maintaining the high aspect ratio and the microstructure’s accuracy. Figure 7 illustrates the possibility of creating highly conductive and efficient hydrogel microstructures using 3DP conducting polymers. Due to their fluidity, conducting polymers cannot be used directly in 3D printing [120]. A PEDOT:PSS aqueous solution can be easily converted into printable ink, providing conducting polymers with the rheological characteristics needed for 3D printing (Figure 7a). Pure PEDOT:PSS solutions have low viscosity and show a sparse distribution of PEDOT:PSS nanofibrils (Figure 7(ai,aii)) (below 30 Pa s). Figure 7(ai) shows that highly concentrated PEDOT:PSS nanofibrils can make 3D-printable conductive polymer ink. This is comparable to how concentrated cellulose nanofiber solutions may be used to produce 3D-printed specimens. Isolating PEDOT:PSS nanofibrils via lyophilization of the pure PEDOT:PSS solution is the first step in testing this idea. Due to the delayed ice crystal formation during lyophilization at high temperatures, researchers lyophilized in a cryogenic environment to avoid the overproduction of PEDOT-rich crystalline domains among PEDOT:PSS nanofibrils that had been solidified in a liquid [121]. After being separated, the PEDOT:PSS nanofibrils were re-dispersed in a binary solvent combination of 85:15 v/v water:DMSO to produce saturated suspensions (Figure 7a(ii)). As the concentration increased, the suspensions gradually transformed from liquids to thixotropic 3D printable inks, as shown in the CryoTEM picture of pure PEDOT:PSS and nanofibrils entangled in the solvent, producing reversible physical networks in Figure 7b,c. The PEDOT caused this: the PSS nanofibrils created reversible physical networks via entanglements inside the solvent. Measurements of the conducting polymer inks’ rheology (Figure 7c) demonstrated the shift in 3D-printed inks from low-viscosity liquids (a low concentration of PEDOT:PSS nanofibrils) to physical gels (a high concentration of PEDOT:PSS nanofibrils). Conducting polymeric inks with low PEDOT:PSS nanofibril concentrations (1–4 wt%) cause the lateral spreading of inks during 3D printing on the substrate due to their low viscosity and negligible yield stress (Figure 7c(ii)).

Figure 7.

(a) Creation of a pristine PEDOT:PSS solution for (i) 3D-printed conducting polymer ink, (ii) using cryogenic lyophilization followed by re-dispersion in a solvent. (Dry annealing followed by swelling in a wet environment can transform the dry state of 3D-printed conducting polymers into a pure PEDOT:PSS, as can the hydrogel state). (b) Cryo-TEMM image of a pristine PEDOT:P SS (i) solution, (ii) 3D-printed conductive polymer ink, and (iii) 3D-printed conductive polymer after dry annealing. (c) and (i) Images of PEDOT:P SS nanofibril concentrations in re-dispersed suspensions and (ii) conducting polymer ink viscosity vs. PEDO T:PSS nanofibril concentration. (d) SEM images of 3D-printed polymer meshes. (e) Sequential images for the conducting polymer ink’s 3D printing of a 20-layered mesh structure [Red arrows display printing process in an alternate manner in each layer]. (f) and (i) Conductivity of 3D-printed dry (17 μm) and hydrogel (78 μm) conducting polymers vs. bending cycles. (ii) Nanoindentation of dry and wet 3D-printed conducting polymers. (g) and (i) 3D-printed soft neural probe images (top) and mouse with inserted probe (bottom). (ii) Soft neural probe 3D-printed with conducting polymer and PDMS inks. Three-dimensionally printed soft neural probe, magnified view. Reprinted with permission [119].

However, as PEDOT:PSS nanofibril concentrations in conducting polymer inks rise above >8 wt%, the nanofibrils cluster into huge clumps that might clog printing nozzles. The intermediate range of PEDOT provides the ideal rheological characteristics and 3D printability with concentration (5–7 wt%). The rheological properties and printability of the conductive polymer ink used in 3D printing exhibit no significant alterations over a one-month storage period at an ambient temperature [96]. The outstanding printability of the conducting polymer ink opens the door for a broad range of cutting-edge 3DP application domains, such as creating high-resolution, high-aspect-ratio structures (Figure 7d). Researchers use nozzles of varied sizes (200 μm, 100 μm, 50 μm, and 30 μm) to print grid patterns of conductive polymer ink (7 wt% PEDOT:PSS nanofibril) to demonstrate microscale high-resolution printing (Figure 7e). Three-dimensional printing conducting materials retain strong electrical conductivity after 10,000 cycles. Conductivity reaches 100 S cm−1 in the dry state and over 15 S cm−1 in the hydrogel state, respectively (Figure 7(fi)). The mechanical characteristics of 3DP conducting polymers are measured utilizing nanoindentation measurements. The dry Young’s modulus (Y.M) values for 3D-printed conducting polymers are 1.5 ± 0.31 GPa, which is comparable to the values published for dry PEDOT:PSS40 (Figure 7(fii)). Hydrogel 3D-printed conducting polymers, on the other hand, have a Y.M of just 1.1 ± 0.36 MPa (Figure 7(fii)), making them mechanically equivalent to soft elastomers such as PDMS (Y.M: 1–10 MPa). Due to their softness and ability to gradually engage biomechanically with biological tissues, printed conducting polymer hydrogels may be beneficial in bioelectronic devices and implants. The 3D-printed delicate neurological sensor was put into the dorsal hippocampus (dHPC) of a mouse with the help of a plastic catheter (Figure 7(gi)). For two weeks, the soft neural probe made with 3D printing could reliably record the local field potential and other brain processes in the free mouse. A delicate neural sensor that can record bioelectronic signals in situ is easy to make.

Unlike conventional fabrication techniques such as electron beam lithography, which necessitate post-assemblies and intricate multi-step strategies, the high-resolution multi-material 3D printing capability enables researchers to print electrodes using conducting polymeric ink and the insulating encapsulation (PDMS-ink) of the neural probe with a straightforward, prolonged printing technique in less than 20 min (Figure 7(gii)). Thanks to its exceptional 3D printability and characteristics, conducting polymer ink printed by 3D printing holds promise as a simple, streamlined method for fabricating multi-material conducting polymer configurations and sensors with a high resolution. This research showed that 2PP may be used to fabricate 3D scaffolds from a CAD model in various ways. The high resolution of 2PP makes it possible to define both the scaffolds’ porosity and their microtopography simultaneously, which is impossible with any other method. According to the findings, the precursor (methacrylamide-modified gelatin) preserves its enzyme-mediated breakdown capacity following the polymerization process and may be cellularly sensitive. Furthermore, 2PP’s GelMOD-based scaffolds promote osteogenic lineage development and the adherence of porcine mesenchymal stem cells. Based on these findings, 2PP shows promise as a tool for creating photosensitive polymer scaffolds for use in TE.

In addition, polymer/semiconductor composites may be created utilizing polypropylene (PP). Several different nanoparticles are included in this combination, including TiO2, ZrO2, CdS and HA, and PbSe [122]. A piezoelectric barium titanate nanoparticle-containing material, such as Ormocomp, was used to print bioinspired 3D structures designed to look like the trabeculae of spongy bone [123]. This approach is also used to print novel ferrofluids with methacrylate-modified Fe3O4 nanoparticles at less than 3% concentration. These 2PP-printed micro-springs and micro-turbines demonstrated a magnetism response and motion control [124]. MPP and 2PP display the pixel-by-pixel control of printing characteristics at resolutions as low as a few hundred nanometers. The microstructures developed by Klein et al. were constructed using PEGDA/Irgacure 369 and PETTA [125]. After fibroblasts formed on the scaffolds, an extracellular matrix (ECM) protein adhered more to the Ormocomp component. Soft polymers have received less attention because of the frequent usage of acrylic and epoxy resins in MPP. Gold nanorods were incorporated into programmable layers by Moller et al. and then tested [126]. When combined with light stimulation, plasmonic heating and light morphing produced large-amplitude deformations, enabling reversible shape morphing and exhibiting many applications in sensors, artificial muscles, and switching systems. It is possible to circumvent the printing speed limitation of 2PP/MPP-based SLA systems via dynamic and projection-based monomer curing methods [127].

3.2.4. DLP Printing

Photosensitive monomers and oligomers are used in both SLA and DLP polymerization, while DLP uses UV light to project an entire layer and cures much quicker than SLA [128]. The restricted variety of materials available with DLP and regular SLA is a disadvantage of both technologies. A common characteristic of free radical and cationic photoresponsive photocurable resins is that they are cured with high brittleness when cured in light. Griffin et al. created high-performance elastomeric materials to address the highly crosslinked framework and fragility of printed specimens. This research aimed to overcome the challenges associated with the highly crosslinked structure and fragility often seen in printed products [129]. PDMS composites were made by merging vinyl-terminated poly (dimethylsiloxane) polysiloxanes with different molecular weights. Modifying the amount of reinforcement fillers (fused and precipitated silica (such as 5% to 20% silica concentrations)), photoresists, and photoinitiators used in silicone/silica composites allowed the researchers to tailor the mechanical properties and durability of the composites to their specific needs [130]. Soft robotics and biomedical equipment might benefit from the use of materials that are highly malleable, biologically friendly, and cytotoxin-free. Preceramic polymer resins made from silicon might have uses in the ceramics industry. DLP’s fast silicone solidification allows porous, cellular, and multilayer lattice structures to be swiftly prototyped, as well as rapidly prototyping porous, cellular, and multilayer lattice structures.

Preceramic silicone and preceramic silicone mixed with alkali–silica photoresists that included alumina particles were used by Colombo et al. to develop improved mullite structures [131]. Highly acrylate polysiloxane produced a 31.8% ceramic output when pyrolyzed in the air, and the material was accessible to photo-cure after pyrolysis. Prior to curing, alumina was combined with phenoxyethanol and polysiloxane to make a suspension and then applied to the surface. Neither the scattering nor the absorption of light had any effect on the formation of the structure or the adhesions between the layers, unlike the total geometry, which decreased by 36% without affecting the geometry or the structure in any way. Their strong creep resistance and low electrical conductivity suit electronic and optical applications well. DLP-processable elastomers with mechanical stretchability, which are widely accessible and can be used on electronic substrates and packaging, may be advantageous for both applications. On the other hand, carbon or metallic nanoparticles enhance conductivity and associated properties. Gao et al. created a composite polymer matrix; two percent of CNT has a wide range of sensitivities (0.01 percent–60 percent) in DLP-cured polyurethane (0.01–60%) [132]. The material compatibility of FDM and DIW is superior to that of DLP-printed sensors, so the vast majority of general strain or chemical sensors manufactured via 3D printing employ them. Metallic nanoparticles, such as nanocarbons, have the potential to perform chemiresistivity-based sensing similarly. Silver nitrate was used to sensitize PEGDA photosensitive monomers before they were exposed to a digital light system with appropriate photoinitiators, as reported by Fantino et al. [133]. At 405 nm and 365 nm, reactive orange dye was utilized to prevent the light from exiting the targeted illumination zone, which regulated the width of the layer under investigation. Afterward, post-fabrication was carried out using ultraviolet (UV) firing. After the initial production, additional radicals were generated from Ag nanoparticles via reducing Ag ions with homogeneous dispersion and high conductance. Soft robotics, conductors, sensors, and actuators are just some of the devices produced using DLP.

Over time, the mechanical deterioration of biomedical polymers may be reduced by utilizing a polymer matrix incorporating ceramic composites or even pure ceramics in in vivo applications to reduce mechanical degradation. In contrast, complicated ceramic morphologies and hierarchies are difficult to fabricate using conventional manufacturing processes; as a result, 3D printing provides significant customization potential for ceramic structures. Zhu et al. investigated surface-modifying compounds to boost the loading capacity of calcium phosphate (CaP) by up to 60% [134]. In addition to high precision and an adjustable macro-pore structure, the 3D-printed CaP ceramics also displayed remarkable mechanical strength, as well as selective cell adhesion and bone growth once the processing settings were optimized. Shen et al. employed DLP to produce zirconia implant scaffolds containing 2–20% hydroxyapatite [135]. Powder technology, a defoamer, printing, cleaning, and ceramic sintering were used to prepare printing ink. Mechanical tests demonstrated a comparable strength to that seen in bone engineering. Following this, deposition and CaP degradation were seen in cell proliferation and differentiation experiments.

3.3. Material Jetting MJ

3.3.1. Water-Based Jetting Processes: Inkjet Printing

Due to its compatibility with various printheads, non-contact properties, and direct scaling, inkjet printing is a promising multi-material method. The constraint on ink formulation, on the other hand, has proven to be the most significant drawback. To maintain the viscosity of the ink below 50 mPa s, it is required to regulate the particle amount tightly and the molecular weight of the polymer used [136]. Raising or decreasing the solute-to-solvent ratio, decreasing the size of polymers, and increasing or decreasing the additives’ concentration may all affect ink’s rheology [137]. Due to the low viscosity requirement, the particle concentration will be restricted, and the surface patterns will be thin and heterogeneous. As a result of removing organic compounds that were previously employed to speed up printing, improving the printing resolution and postprocessing speed may become more challenging. To better understand how ink behaves during printing, it is required to examine fluid rheology individually [138]. Multijet and polyjet printing, for example, produce shear rates in the range of 10–100 kHz, depending on the application [139]. The utilization of a torsional rheometer for viscosity measurement is feasible; nonetheless, its capability to attain elevated shear rates or frequencies is constrained. The genuine residence time of inkjet is in the millisecond range, but that of capillary rheometers is hundreds of times longer. However, capillary rheometers, such as inkjet, are often used in applications with short residence times [140]. Using high-rate cameras and recorders to capture dynamic surface tension and viscosity data straight from fluid might remove these concerns. Based on the assumption that Newtonian fluids behave in a “free-shape” mode, this calculation takes advantage of surface tension and viscosity to restore drop form and suppress oscillations while keeping the fluid steady [141]. It is possible to see the evolution of a droplet using the drop-oscillating method. One of the most desirable fluids for jetted inks is shear-thinning, which does not behave in a Newtonian manner. Ink viscosity, influenced by particle size and concentration, may impact the composites’ deposition speed, mechanical properties, and functional attributes. Ink viscosity may be lowered using hot print heads or reactive diluent additives, among other methods [142].

Nanomaterials comprising carbon nanoparticles, ceramic nanoparticles, or metals are required to regulate the viscous behavior of slurry. Particles with significant volumes or weight fractions cannot be deposited using inkjet technology because the nanoparticles may settle due to gravitational and density discrepancies among the nanoparticles, dispersion fluids, and the ink employed in the process [143]. It is also necessary to include the surface tension caused by the cohesive forces imposed on molecules at the liquid’s surface, which must be considered. For printing nozzles to function properly, the surface tension of the ink should be in the center of the spectrum, between high and low values. Pendant drop tests are quick and straightforward in measuring water’s surface tension accurately. A syringe needle is used to spread a drop of solution across the chamber during the experiment. The droplet’s morphological shift from spherical to elliptical happens concurrently with an increase in syringe capacity, owing to the synergistic interaction of gravitational and capillary forces. It is possible to calculate the equilibrium surface tension, as well as the dynamic surface tension, of a given solute-rich slurry by taking images and measurements of drop morphologies, among other things. H2O has a relatively low surface tension, but the solvents THF, DMF, DMSO, and thiodiglycol have very high surface tension [144]. The optimal range for ink surface tension is between 40 and 70 mJ/m2 [145]. After printing, annealing, curing, and sintering, the layers may eliminate holes, poor adhesion, discontinuities, fractures, and contaminants [146]. This technique can fuse particles, lowering their melting points and enabling them to be merged. Several technologies are necessary to construct high-resolution structures with outstanding performance. The effect of particle–polymer interaction on the inkjet printing of hydrogel composites for 3D bioprinting applications was investigated. Inkjet printing was used to produce PEG hydrogels containing SiO2 nanoparticles. The researchers discovered that the interfacial adhesion between the particles and the polymer matrix was essential for the structural stability of the printed composites [147]. Padmavathi discovered that printing factors such as nozzle diameter and printing speed affected the composites’ interfacial adhesion and ultimate mechanical properties [148].

Researchers looked into the impact of particle–polymer interactions on the inkjet printing of calcium phosphate (CaP) scaffolds for bone tissue engineering applications [149]. The scaffolds were printed using inkjet printing and a mixture of CaP particles and polycaprolactone (PCL) polymer [150]. The interfacial adhesion between the CaP particles and the PCL matrix was discovered to be essential for the mechanical properties and biocompatibility of the printed scaffolds [151]. Printing factors such as nozzle diameter and ink composition affected particle–polymer interactions and the final properties of the scaffolds. The impact of particle–polymer interactions on the inkjet printing process of hydrogel scaffolds was studied when loaded with different kinds of nanoparticles, such as SiO2, HA, and Fe2O3 [152]. The scaffolds were printed using a custom-built inkjet printing method, and their mechanical properties and biocompatibility were assessed. Cheng found that particle–polymer interactions affected the printed scaffolds’ printing resolution, mechanical properties, and biocompatibility [153]. The ink composition, printing parameters, and particle size and distribution all impacted the particle–polymer interactions and the end properties of the printed scaffolds. Magdalena looked at how different particle types, such as calcium phosphate and silica nanoparticles, interacted with alginate-based hydrogels during inkjet printing. Hydrogels were tested for their mechanical characteristics, swelling behavior, and degradation rate utilizing an inkjet printing evaluation system [153]. They discovered that particle–polymer interactions affected the printed hydrogels’ printing resolution, mechanical characteristics, and degradation rate. Besides this, the particle–polymer interactions and final characteristics of the printed hydrogels were affected by the ink composition, printing settings, particle size, and concentration.

Arcs using spheroids or bioinks as building blocks were also used in organ printing, which has the ability to create freeform, layer-by-layer, 3D living organs. The difficulty in appropriately vascularizing the tissues is frequently highlighted as a barrier to developing 3D organs [154]. Thus, the development of 3D biological vascular trees is critical to the viability of the proposed organ manufacturing methodology. Crosslinking agents and supports are used to create vascular-like cell structures via inkjet printing incorporating a calcium chloride solution [155]. Using a buoyant force, this method allows the printing of freeform features that span and hang over the edge. It is necessary to correct horizontal tubular systems’ axially varying deformation to maintain a constant axial diameter. Sodium alginate and mouse-fibroblast-based alginate bioinks were used to print vascular-like structures comprising transverse and longitudinal branching. Even after 24-h of incubation, the printed cellular tubes’ fibroblast cell viability after printing was determined to be greater than 90% when the control effect was taken into account, as shown in Figure 8 [156].

Figure 8.

(a) Basic tubular configuration of blood vessel network. (b) Vertical–horizontal bifurcations. (i) The cellular structure incorporates horizontal and vertical bifurcations and is fabricated using inkjet printing technology, (ii) The accompanying insets depict the designed structure in detail. The corresponding structure composed solely of alginate exhibits greater geometric accuracy. (c) Front and global overview of bifurcated alginate configuration printed (i,ii) horizontally and (iii,iv) vertically. Reprinted with permission [156].

3.3.2. Multijet and Polyjet

Multijet and polyjet are capable of various applications because of their electrohydrodynamic (EHD)-based printing technology [157]. The capillary force of the tiny printing needle must be countered by smaller printing features, which require the reduction of printing channels and an increase in printing pressure. Printer head clogging is a natural consequence that occurs on a regular basis. To avoid the possibility of droplet materials spilling and causing thickness irregularity or spatial heterogeneity, a smaller printing head may not be able to improve the printing resolution [158]. While traditional inkjet systems employ acoustic or thermal stimuli to push liquids out of the jetting channel, the EHD jet uses an electrical field to force liquids out of the channel. The conducting needle can only reach the ink if back pressure is applied to the supply. The Taylor cone is created when an electrical voltage is supplied to a meniscus and the meniscus deforms [159]. Droplet formation will be accelerated beyond surface tension limits due to the electrical stresses induced by the electric field in the surrounding environment.