Experimental Study of the Effect of Temperature on the Circumferential Bending Performance of GFRP Pipes

Abstract

1. Introduction

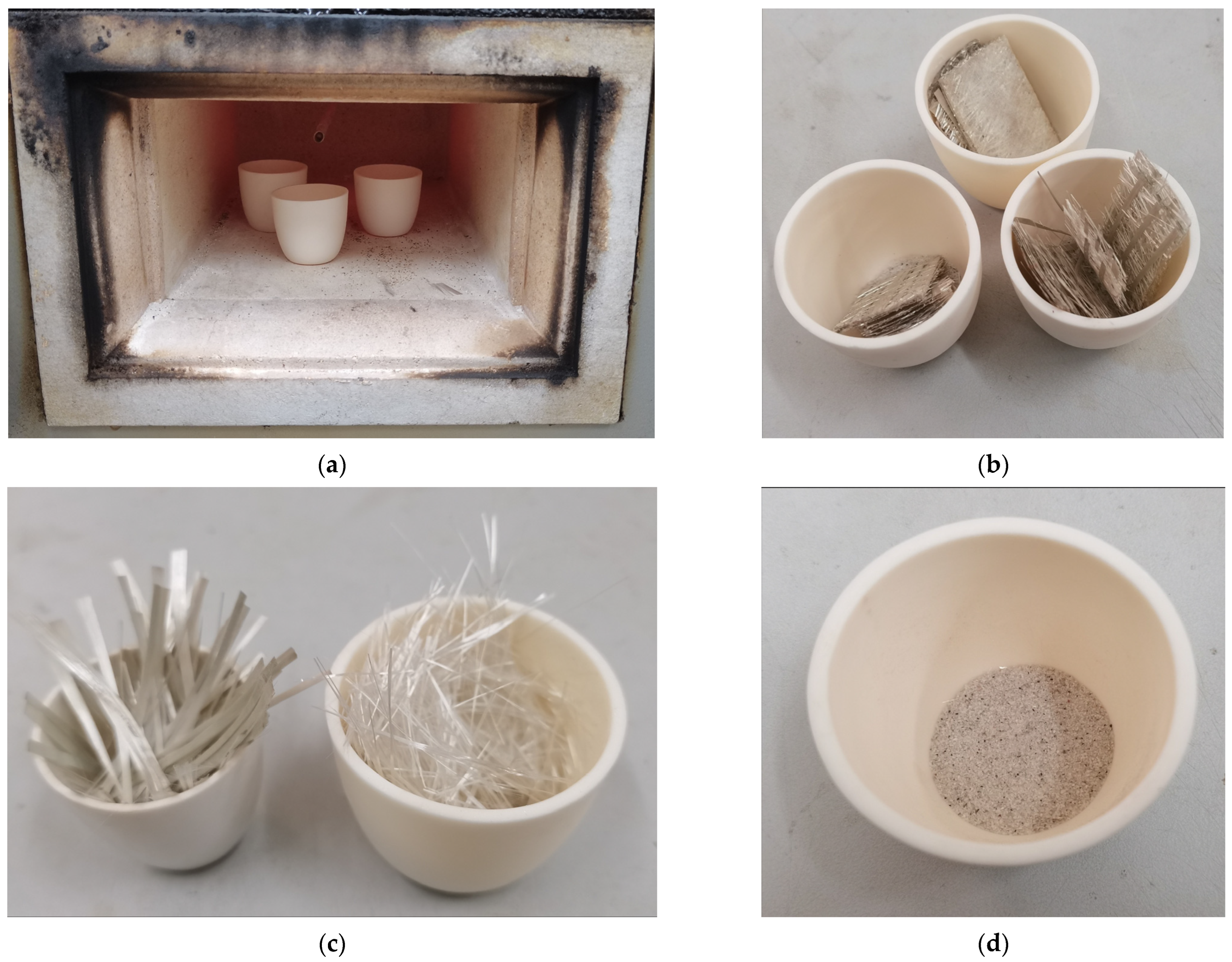

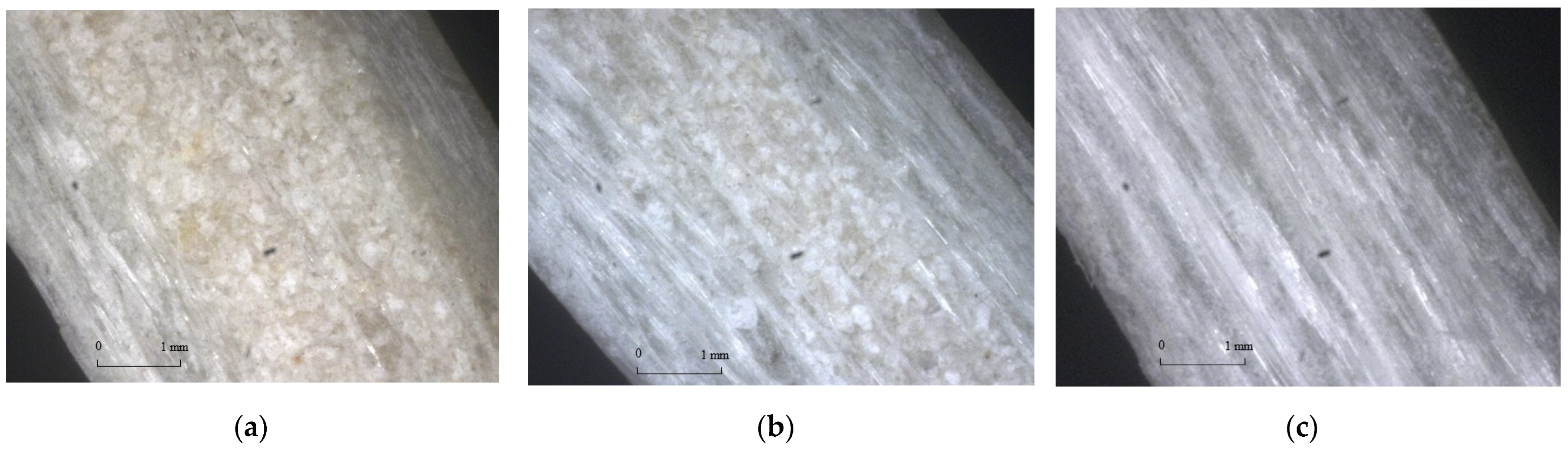

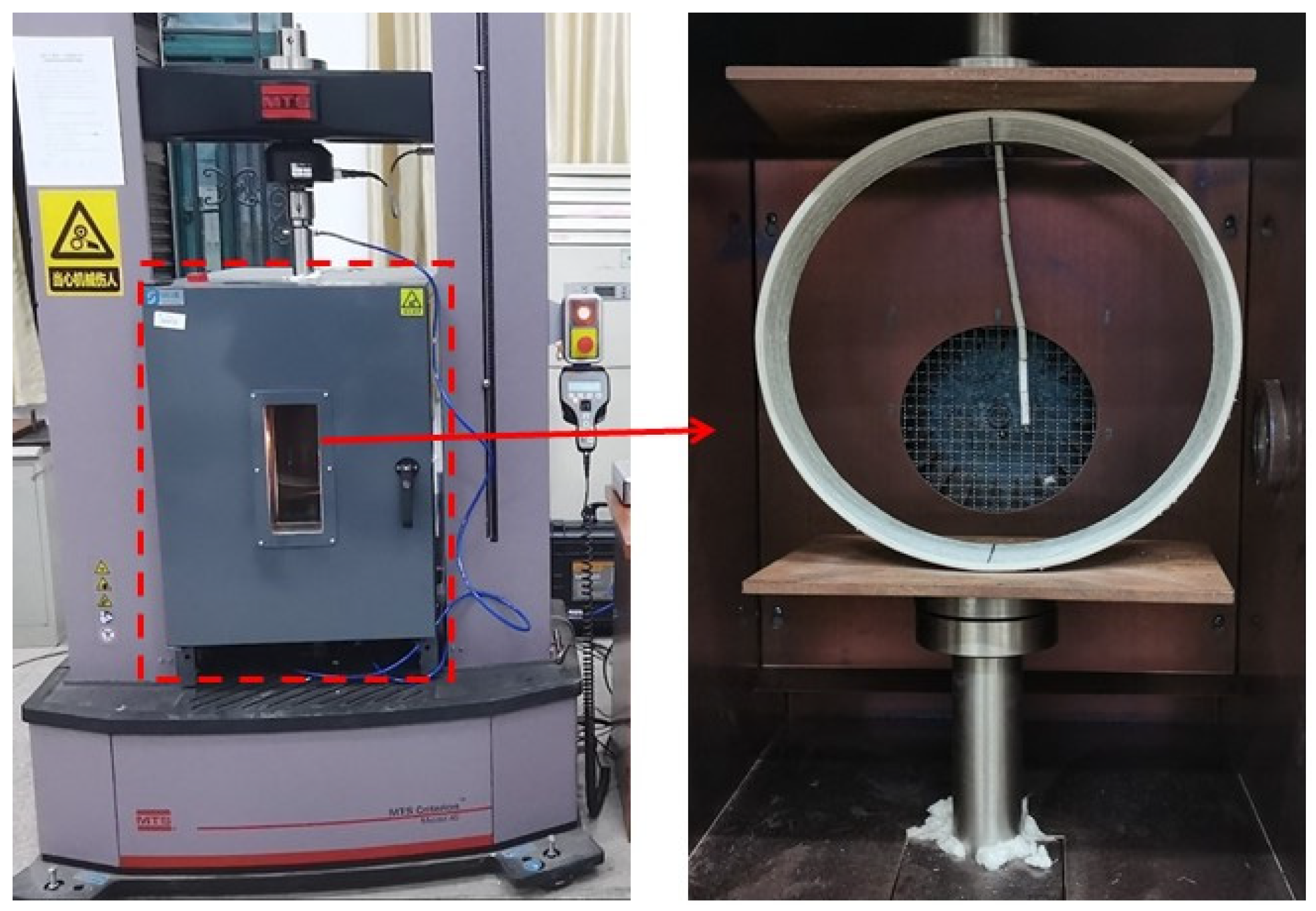

2. Materials and Methods

2.1. Materials

2.2. Test Process

3. Results and Discussion

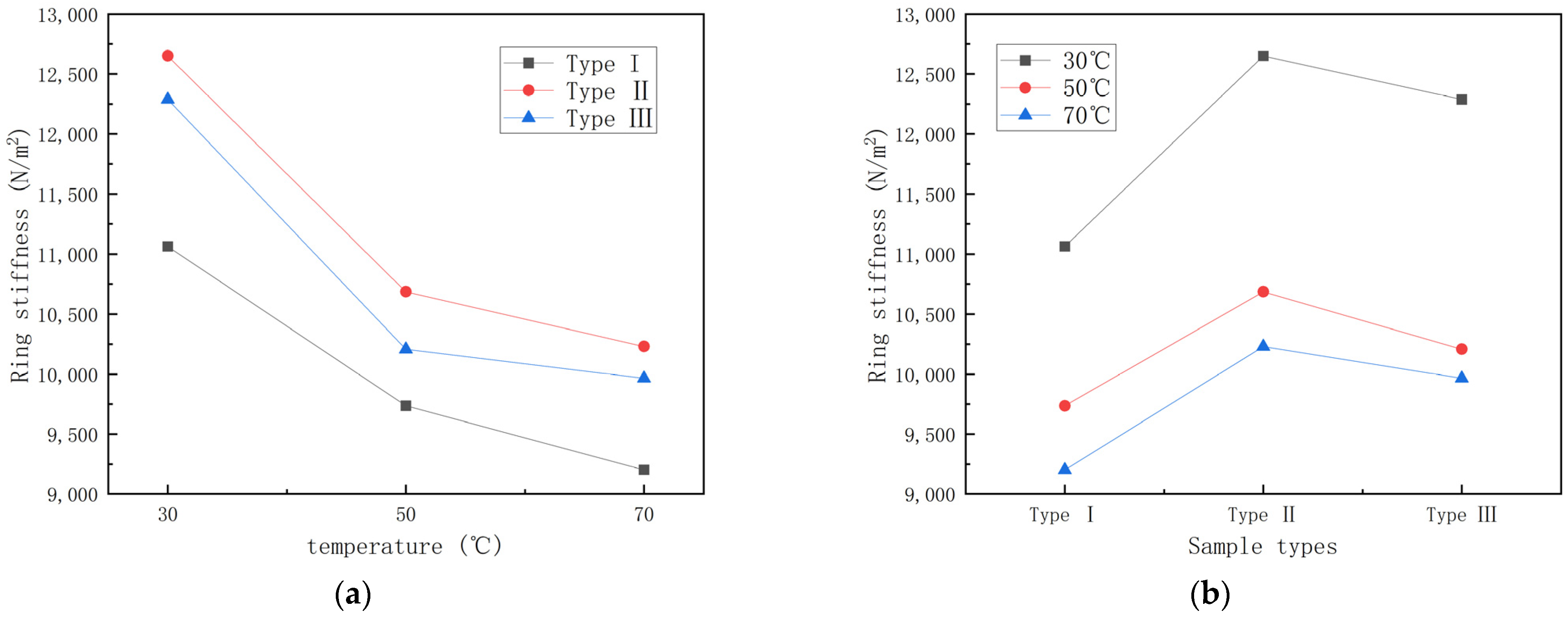

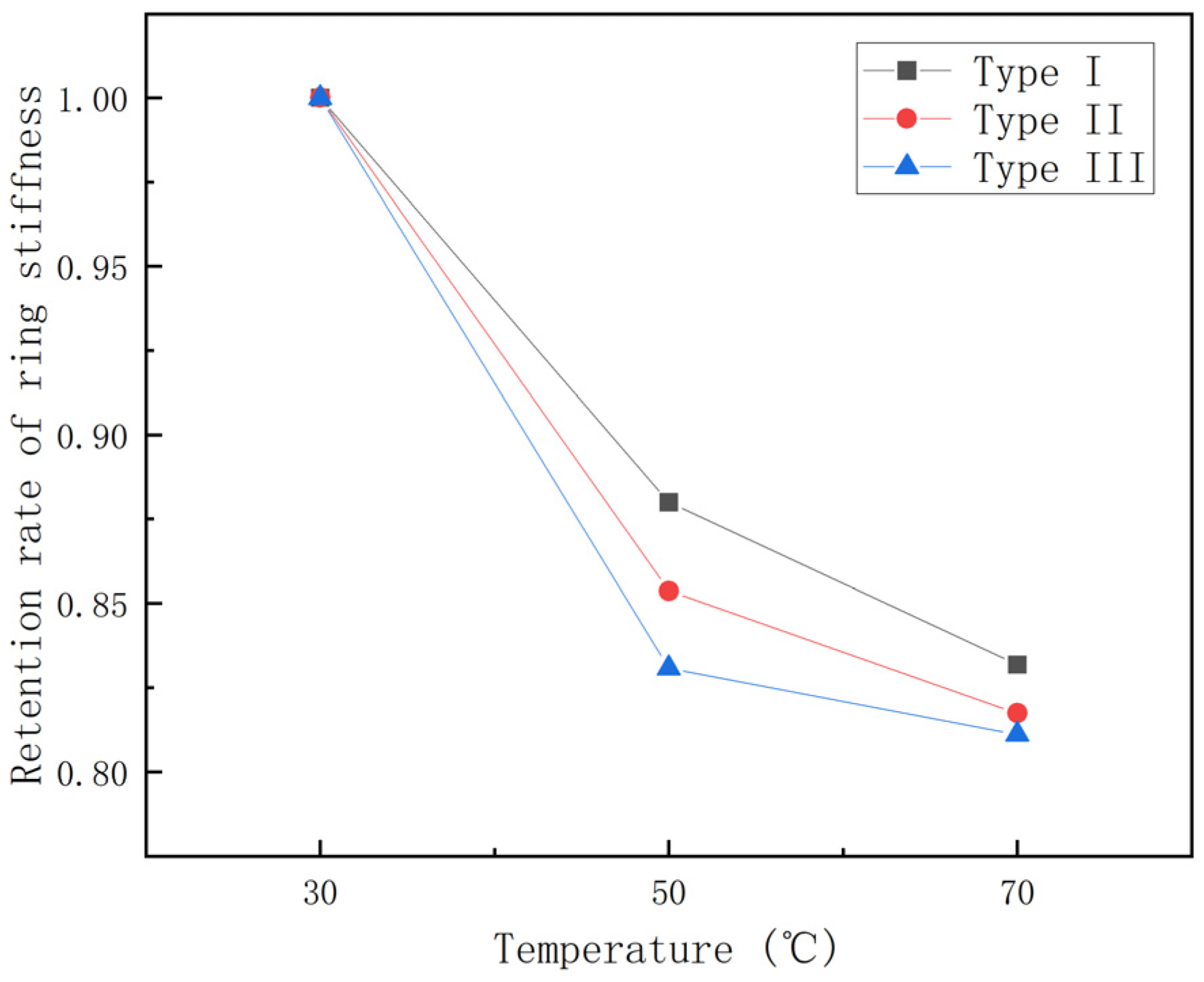

3.1. Ring Stiffness

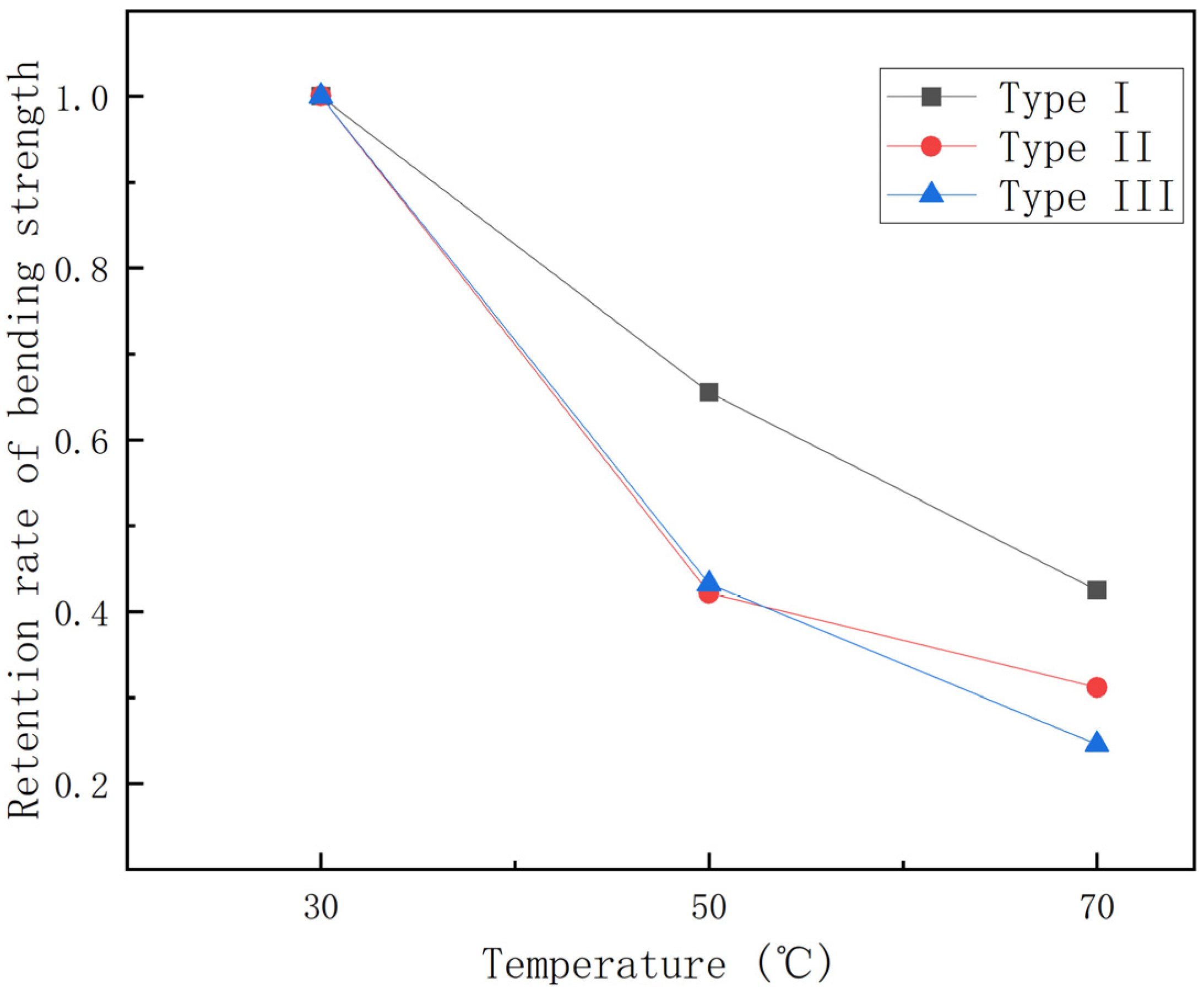

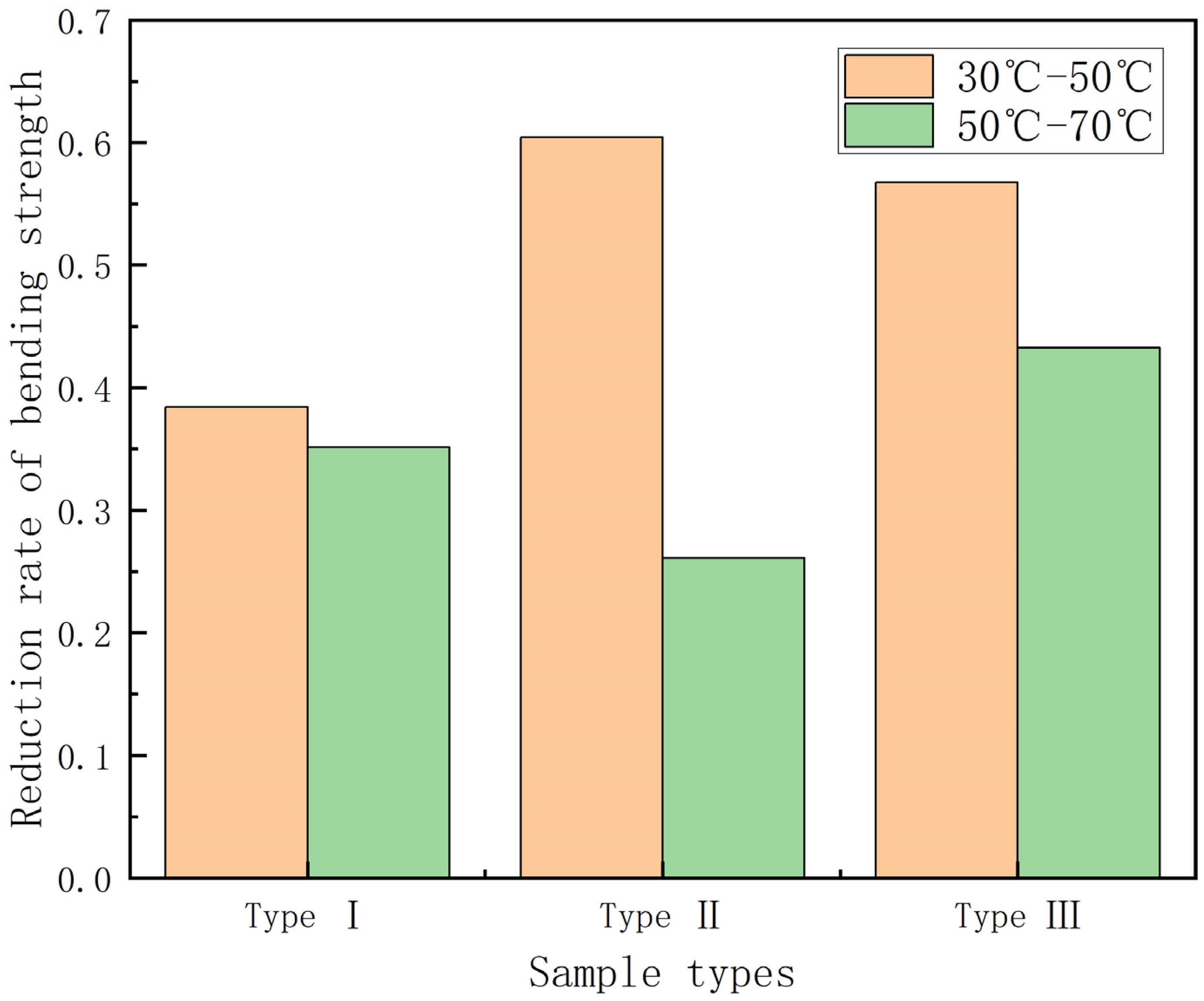

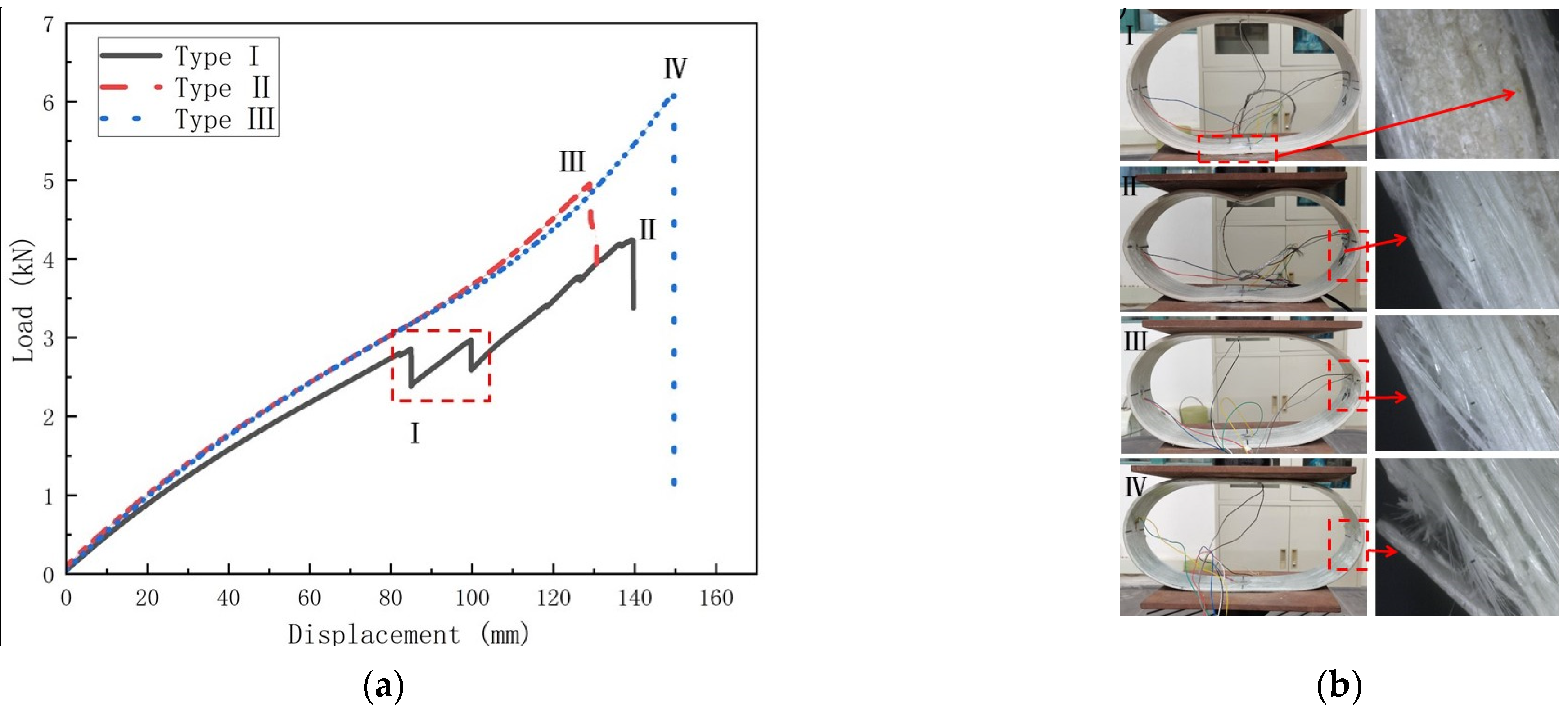

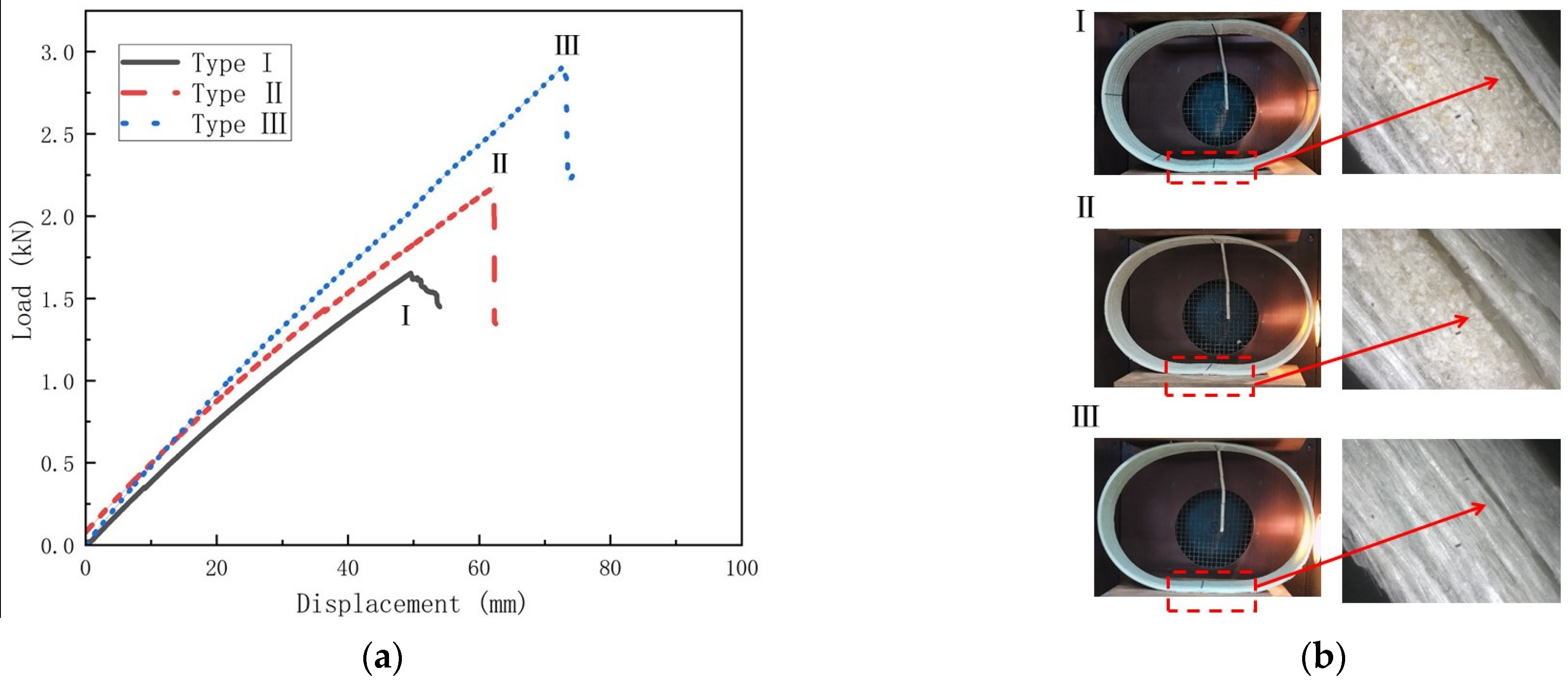

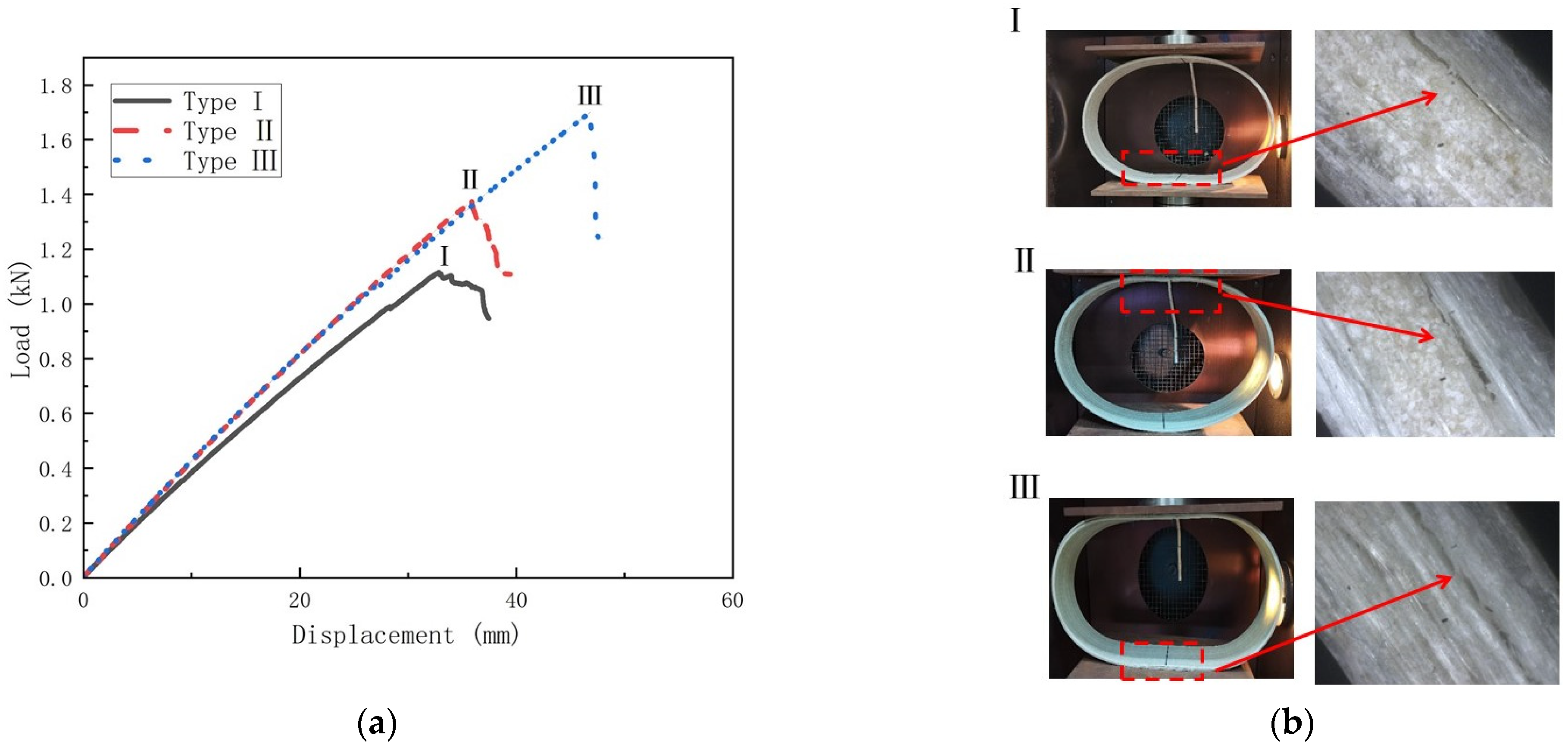

3.2. Bending Strength

3.3. Disruption of Displacement

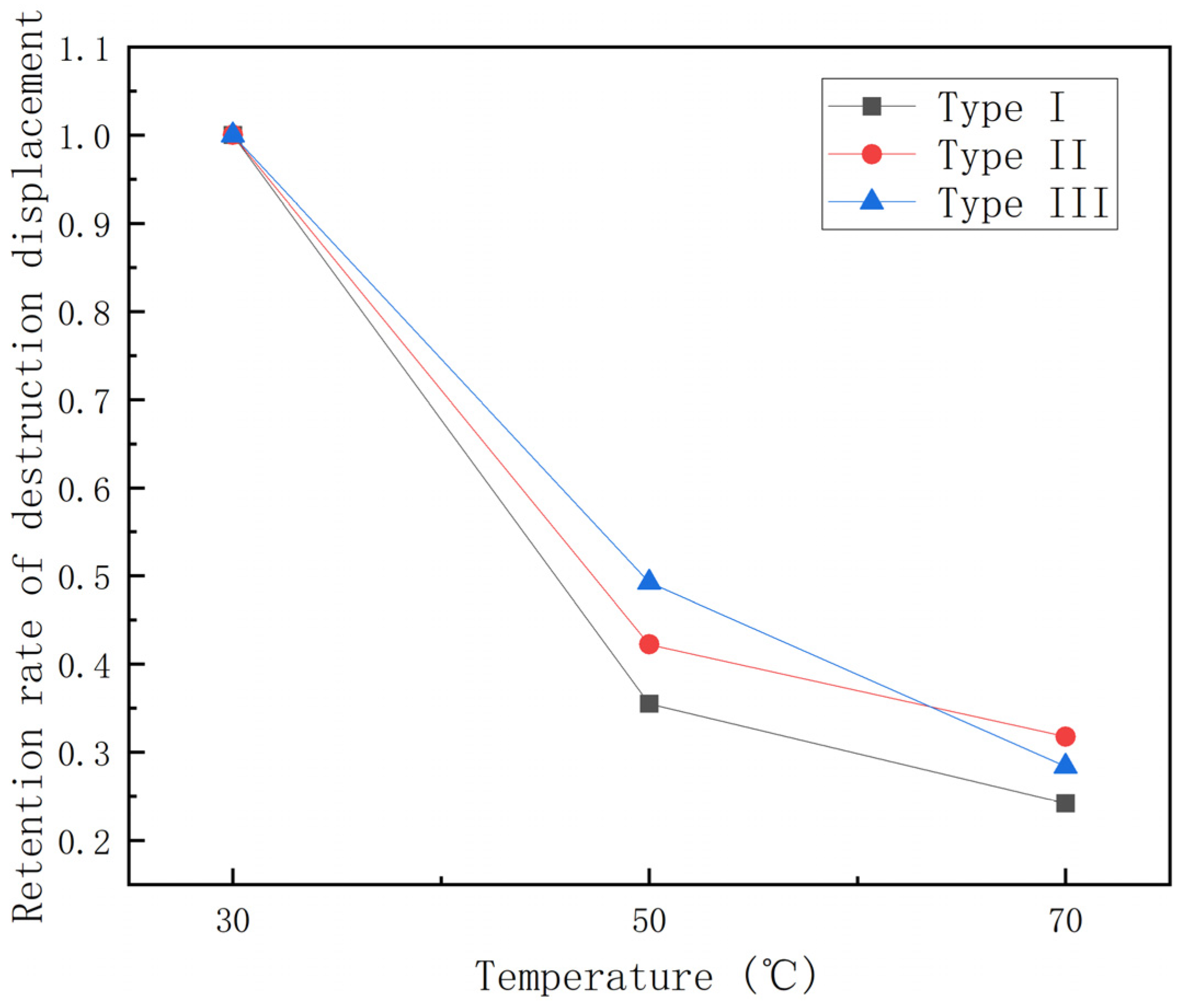

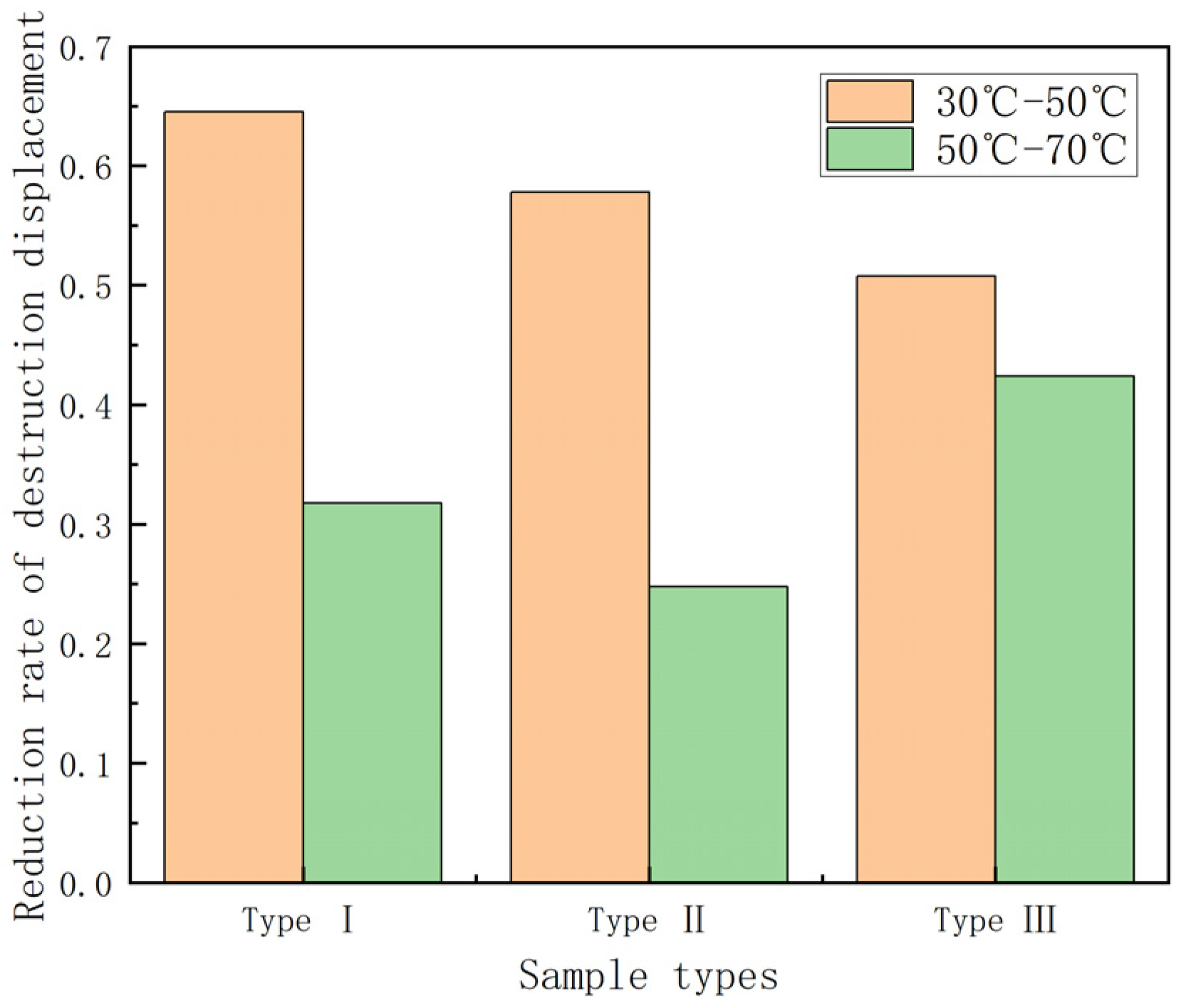

3.4. Failure Mode

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Gaurav, A.; Singh, K.K. Fatigue behavior of FRP composites and CNT-Embedded FRP composites: A review. Polym. Compos. 2018, 39, 1785–1808. [Google Scholar] [CrossRef]

- Rafiee, R. On the mechanical performance of glass-fibre-reinforced thermosetting-resin pipes: A review. Compos. Struct. 2016, 143, 151–164. [Google Scholar] [CrossRef]

- Hollaway, L.C. A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties. Constr. Build. Mater. 2010, 24, 2419–2445. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Manalo, A.C.; Ferdous, W.; Zhuge, Y.; Vijay, P.V.; Alkinani, A.Q.; Fam, A. State-of-the-art of prefabricated FRP composite jackets for structural repair. Eng. Sci. Technol. Int. J. 2020, 23, 1244–1258. [Google Scholar] [CrossRef]

- Al-Rubaye, M.; Manalo, A.; Alajarmeh, O.; Ferdous, W.; Lokuge, W.; Benmokrane, B.; Edoo, A. Flexural behaviour of concrete slabs reinforced with GFRP bars and hollow composite reinforcing systems. Compos. Struct. 2020, 236, 111836. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; AlAjarmeh, O.; Mohammed, A.A.; Salih, C.; Yu, P.; Schubel, P. Static behaviour of glass fibre reinforced novel composite sleepers for mainline railway track. Eng. Struct. 2021, 229, 111627. [Google Scholar] [CrossRef]

- Berardi, V.P.; Perrella, M.; Feo, L.; Cricrì, G. Creep behavior of GFRP laminates and their phases: Experimental investigation and analytical modeling. Compos. Part B Eng. 2017, 122, 136–144. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Manalo, A.C.; Ferdous, W.; Zhuge, Y.; Vijay, P.V.; Pettigrew, J. Experimental and numerical evaluations on the behaviour of structures repaired using prefabricated FRP composites jacket. Eng. Struct. 2020, 210, 110358. [Google Scholar] [CrossRef]

- Rafiee, R. Stochastic fatigue analysis of glass fiber reinforced polymer pipes. Compos. Struct. 2017, 167, 96–102. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, Z.; Jiang, Y.; Zhao, T.; Li, Y.; Chen, J.; Fang, D. Design, fabrication and stiffness analysis of a novel GFRP sandwiched pipe with stiffened core. Thin-Walled Struct. 2020, 156, 106982. [Google Scholar] [CrossRef]

- Chen, J.; Zhen, Y.; Lou, Y.; Lv, Y. Stiffness degradation of GFRP pipes under fatigue loading. Mater. Test. 2019, 61, 435–440. [Google Scholar] [CrossRef]

- Tu, J.; Xie, H.; Gao, K.; Li, Z.; Zhang, J. Durability prediction of GFRP rebar based on elastic modulus degradation. Front. Mater. 2019, 6, 258. [Google Scholar] [CrossRef]

- Rafiee, R.; Habibagahi, M.R. On the stiffness prediction of GFRP pipes subjected to transverse loading. KSCE J. Civ. Eng. 2018, 22, 4564–4572. [Google Scholar] [CrossRef]

- Robert, M.; Benmokrane, B. Behavior of GFRP reinforcing bars subjected to extreme temperatures. J. Compos. Constr. 2010, 14, 353. [Google Scholar] [CrossRef]

- Solyom, S.; Di Benedetti, M.; Guadagnini, M.; Balázs, G.L. Effect of temperature on the bond behaviour of GFRP bars in concrete. Compos. Part B Eng. 2020, 183, 107602. [Google Scholar] [CrossRef]

- Vieira, P.S.C.; de Souza, F.S.; Cardoso, D.C.T.; Vieira, J.D.; de Andrade Silva, F. Influence of moderate/high temperatures on the residual flexural behavior of pultruded GFRP. Compos. Part B Eng. 2020, 200, 108335. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Shakiba, M.; Bazli, M.; Javaheri, A. Using four-point flexure test to investigate effects of temperature and bar size on the tensile properties of GFRP bars. Polym. Test. 2022, 112, 107627. [Google Scholar] [CrossRef]

- Lobanov, D.S.; Babushkin, A.V.; Luzenin, A.Y. Effect of increased temperatures on the deformation and strength characteristics of a GFRP based on a fabric of volumetric weave. Mech. Compos. Mater. 2018, 54, 655–664. [Google Scholar] [CrossRef]

- Liu, J.; Xiang, L.; Kan, T. The effect of temperature on the bending properties and failure mechanism of composite truss core sandwich structures. Compos. Part A Appl. Sci. Manuf. 2015, 79, 146–154. [Google Scholar] [CrossRef]

- Dutta, P.K.; Hui, D. Creep rupture of a GFRP composite at elevated temperatures. Comput. Struct. 2000, 76, 153–161. [Google Scholar] [CrossRef]

- Ashrafi, H.; Bazli, M.; Jafari, A.; Ozbakkaloglu, T. Tensile properties of GFRP laminates after exposure to elevated temperatures: Effect of fiber configuration, sample thickness, and time of exposure. Compos. Struct. 2020, 238, 111971. [Google Scholar] [CrossRef]

- Yu, B.; Kodur, V.K.R. Effect of high temperature on bond strength of near-surface mounted FRP reinforcement. Compos. Struct. 2014, 110, 88–97. [Google Scholar] [CrossRef]

- Correia, J.R.; Gomes, M.M.; Pires, J.M.; Branco, F.A. Mechanical behaviour of pultruded glass fibre reinforced polymer composites at elevated temperature: Experiments and model assessment. Compos. Struct. 2013, 98, 303–313. [Google Scholar] [CrossRef]

- Parodi, E.; Govaert, L.E.; Peters, G.W.M. Glass transition temperature versus structure of polyamide 6: A flash-DSC study. Thermochim. Acta 2017, 657, 110–122. [Google Scholar] [CrossRef]

- Alsayed, S.; Al-Salloum, Y.; Almusallam, T.; El-Gamal, S.; Aqel, M. Performance of glass fiber reinforced polymer bars under elevated temperatures. Compos. Part B Eng. 2012, 43, 2265–2271. [Google Scholar] [CrossRef]

- Rafiee, R.; Habibagahi, M.R. Evaluating mechanical performance of GFRP pipes subjected to transverse loading. Thin-Walled Struct. 2018, 131, 347–359. [Google Scholar] [CrossRef]

- Rafiee, R.; Reshadi, F.; Eidi, S. Stochastic analysis of functional failure pressures in glass fiber reinforced polyester pipes. Mater. Des. 2015, 67, 422–427. [Google Scholar] [CrossRef]

- Ray, B.C. Effects of changing environment and loading speed on mechanical behavior of FRP composites. J. Reinf. Plast. Compos. 2006, 25, 1227–1240. [Google Scholar] [CrossRef]

- ISO 9969-2016; Thermoplastics Pipes—Determination of Ring Stiffness. ISO: Geneva, Switzerland, 2016.

- Yang, J.; Chen, J. Ring stiffness analysis of glass fiber reinforced plastic sandwich pipe. FRP/Compos. 2013, Z2, 36–39. [Google Scholar]

- GB/T 21238-2016; Glass Fiber Reinforced Plastics Mortar Pipes. China Building Materials Association, General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of China: Beijing, China, 2016.

| Sample Types | Resin | Continuous Fibers | Short-Cut Fibers | Quartz Sand |

|---|---|---|---|---|

| Type I | 0.36 | 0.18 | 0.12 | 0.34 |

| Type II | 0.37 | 0.32 | 0.10 | 0.21 |

| Type III | 0.32 | 0.51 | 0.17 | - |

| Sample Type | Temperature (°C) | Destruction Load (KN) | Destruction Displacement (mm) | Bending Strength (MPa) | Ring Stiffness (N/m²) |

|---|---|---|---|---|---|

| Type I | 30 | 2.65 | 138.28 | 275.68 | 11,063.83 |

| 50 | 1.67 | 49.09 | 169.75 | 9736.27 | |

| 70 | 1.15 | 33.50 | 110.11 | 9202.93 | |

| Type II | 30 | 5.21 | 131.31 | 571.43 | 12,650.00 |

| 50 | 1.89 | 55.44 | 226.11 | 10,684.91 | |

| 70 | 1.59 | 41.72 | 167.10 | 10,230.50 | |

| Type III | 30 | 5.81 | 147.11 | 732.48 | 12,287.10 |

| 50 | 2.52 | 72.44 | 316.88 | 10,207.32 | |

| 70 | 1.49 | 41.74 | 179.83 | 9965.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luan, S.; Chen, J.; Lv, Y.; Zhang, X.; Huang, L. Experimental Study of the Effect of Temperature on the Circumferential Bending Performance of GFRP Pipes. Polymers 2023, 15, 392. https://doi.org/10.3390/polym15020392

Luan S, Chen J, Lv Y, Zhang X, Huang L. Experimental Study of the Effect of Temperature on the Circumferential Bending Performance of GFRP Pipes. Polymers. 2023; 15(2):392. https://doi.org/10.3390/polym15020392

Chicago/Turabian StyleLuan, Songdan, Jianzhong Chen, Yong Lv, Xiaoyu Zhang, and Li Huang. 2023. "Experimental Study of the Effect of Temperature on the Circumferential Bending Performance of GFRP Pipes" Polymers 15, no. 2: 392. https://doi.org/10.3390/polym15020392

APA StyleLuan, S., Chen, J., Lv, Y., Zhang, X., & Huang, L. (2023). Experimental Study of the Effect of Temperature on the Circumferential Bending Performance of GFRP Pipes. Polymers, 15(2), 392. https://doi.org/10.3390/polym15020392