Effects of Electrode Materials and Compositions on the Resistance Behavior of Dielectric Elastomer Transducers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

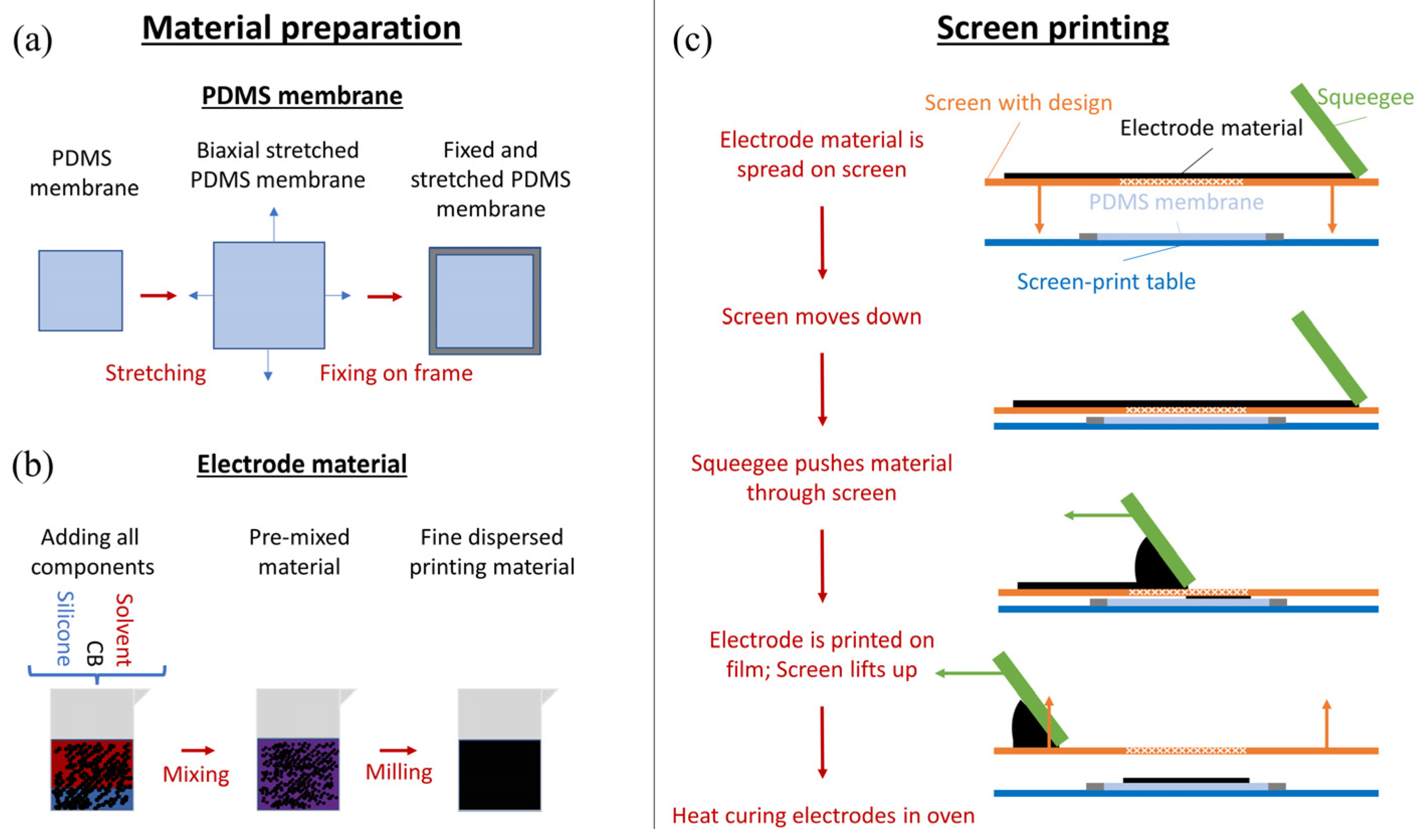

- Elastosil 2030 silicone film with a thickness of 50 µm is transferred to metal frames. In this study, the films are pre-stretched by 5% biaxially. The steps for preparing the dielectric membrane are shown in Figure 2a. The pre-stretch improves the handling of the film and allows an easier and more homogenous preparation of dielectric elastomers. In addition, pre-stretching the film increases the breakdown strength of the silicone membrane [44]. Pre-stretching the film also decreases its thickness, and therefore a lower voltage can be applied to reach the same electrical fields. These are reasons why pre-stretching the dielectric membrane is commonly performed. In this paper, no electro-mechanical measurements are performed, but the pre-stretching is still carried out due to the better handling of the membranes.

- Preparation of electrode material: CB and silicone are mixed with solvent (VD60 from SunChemical, Parsippany, NJ, USA) and homogenized in a three-roll mill from EXAKT (Norderstedt, Germany) and a Thinky (Laguna Hills, CA, USA) planetary mixer to provide screen-printability (see Figure 2b). To adjust the viscosity of the screen-print material, and thus ensure the screen-printability of the samples, solvent is added to the mixture. More solvent is needed if the CB to silicone ratio increases, otherwise the printing material becomes too dry. While screen-printing, a specific amount of electrode material is squeezed through the screen, independent of the used material. If there is proportionally more solvent in the printed electrode composition, more of the material will vaporize during curing, therefore leading to a thinner electrode. If the amount of solvent required to enable screen-printability is too high, matrix material and CB filler will separate during the printing process and the mixture is not homogeneous anymore. This leads potentially to more imperfections in the printed electrodes. Such electrodes are not usable for the measurements conducted in this work. The prepared electrode compositions (CB to silicone ratios) and the corresponding amount of solvent needed to provide screen-printability are discussed in detail in Section 2.4. The mixtures containing too much solvent to yield a homogeneous print image are also reported in that section.

- The electrodes are screen-printed on one side of the silicone film, using a SEFAR (Heiden, Switzerland) 90/48Y screen (90 threads per centimeter and a thread thickness of 48 µm) with a polyethylenterephthalate (PET) mesh. The influence of screen print parameters on the electrodes for DEs was previously investigated in [34]. Using this study, a screen was selected with a mesh size in between the very fine and medium coarse mesh of the study, yielding a higher ink throughput and clear print edges. This screen is a standard low-cost screen size. One electrode layer is printed, which is the standard procedure for screen-printing. A schematic screen-printing procedure is shown in Figure 2c.

- After screen-printing, the electrodes are cured for one hour at 150 °C.

- Finally, two monolithic 3D-printed reinforcement frames are applied to sandwich the film. These frames allow exact repeatability of the sample placement in the test rig.

2.3. Sample Geometry

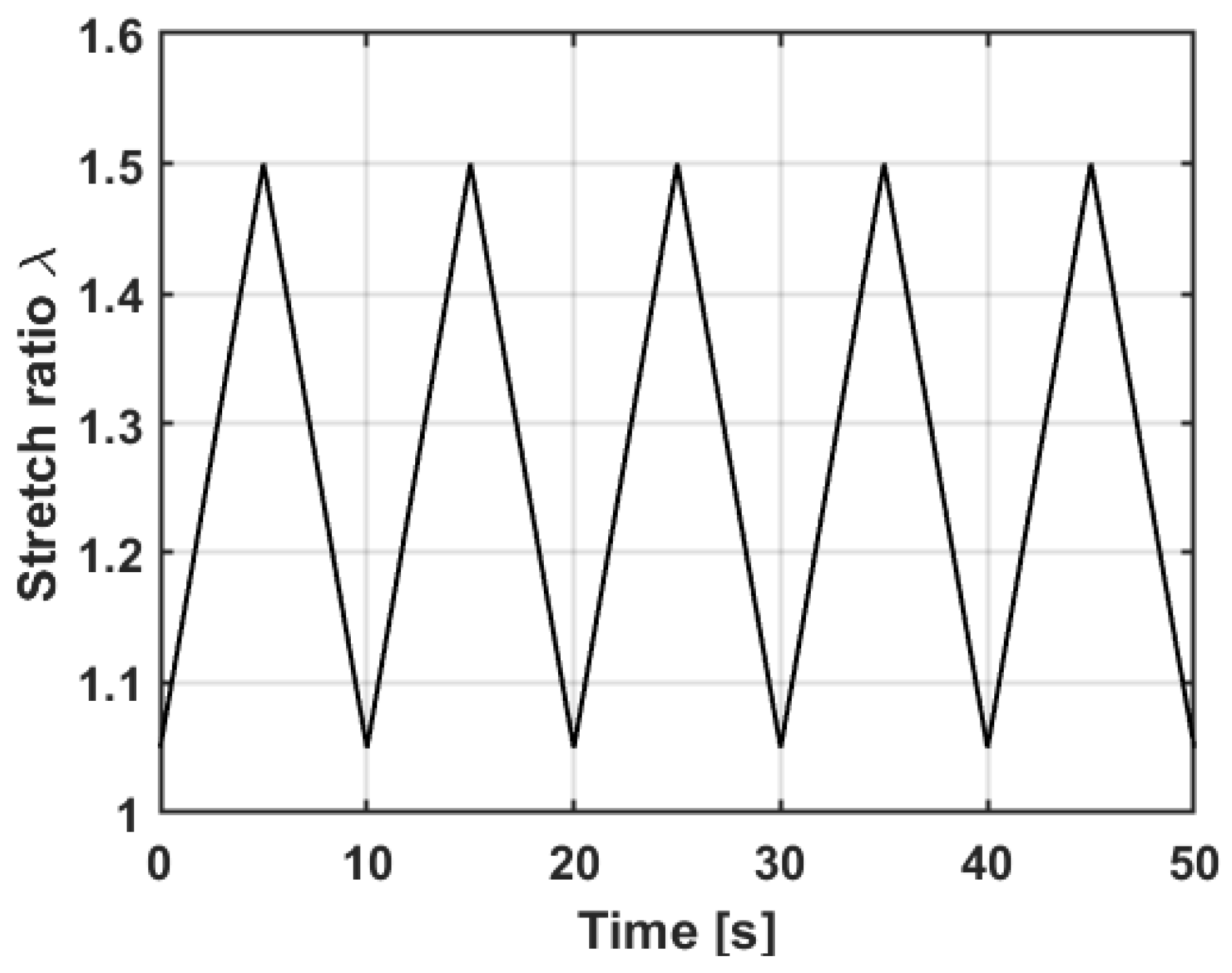

2.4. Experiments

3. Results and Discussion

3.1. Influence of Carbon Black

- The amount of silicone is too low to hold the electrode together, resulting in a bad adhesion to the silicone membrane, worsening cohesion of the electrode itself and consequently easily rubbing off the electrode.

- Due to the fabrication process, an increasing CB ratio also leads to an increasing amount of solvent in the electrode material to ensure screen-printability, leading to thinner electrodes and due to the manufacturing process to potentially more imperfections, as described in Section 2.2.

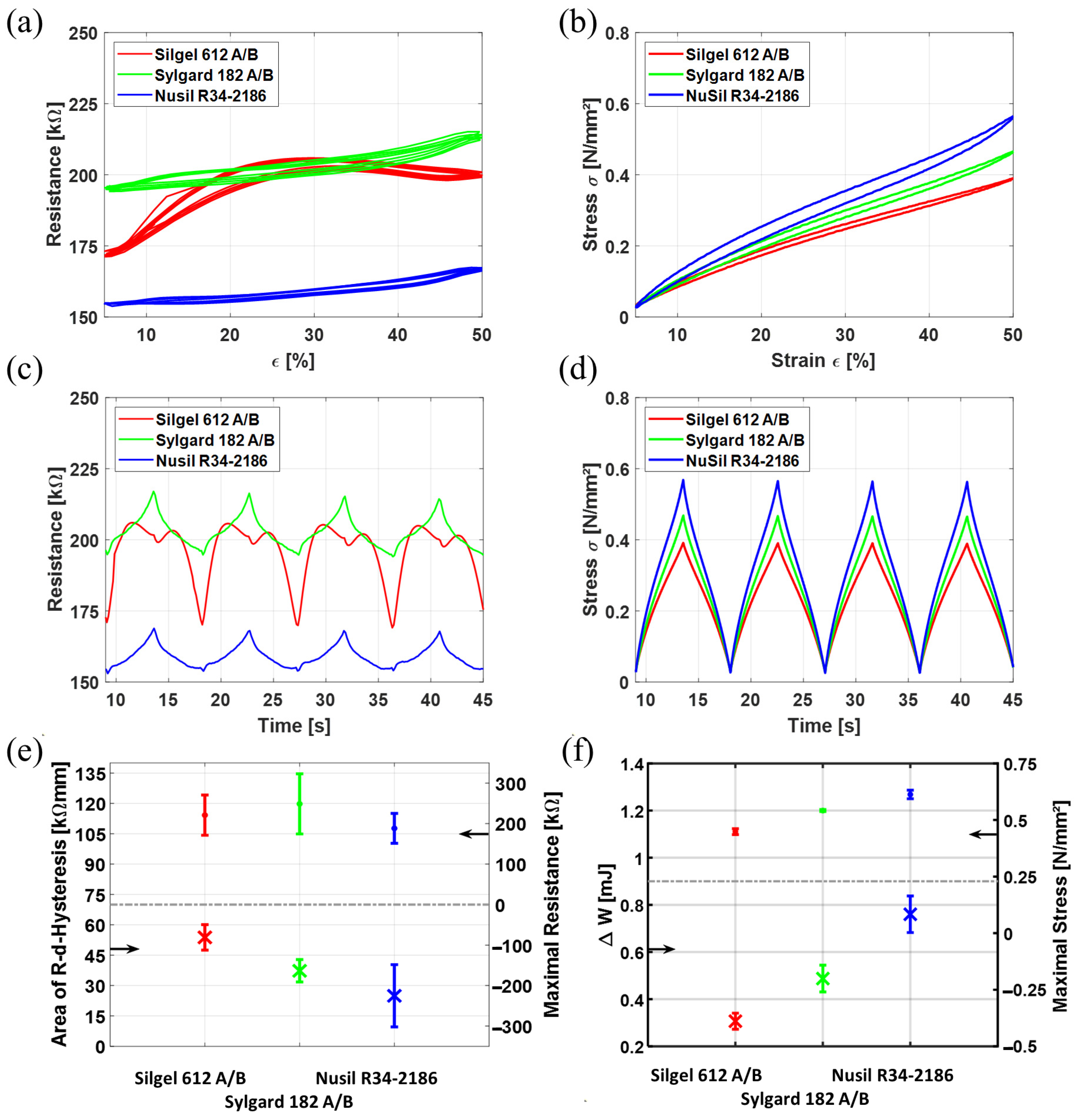

3.2. Influence of Silicone Matrices

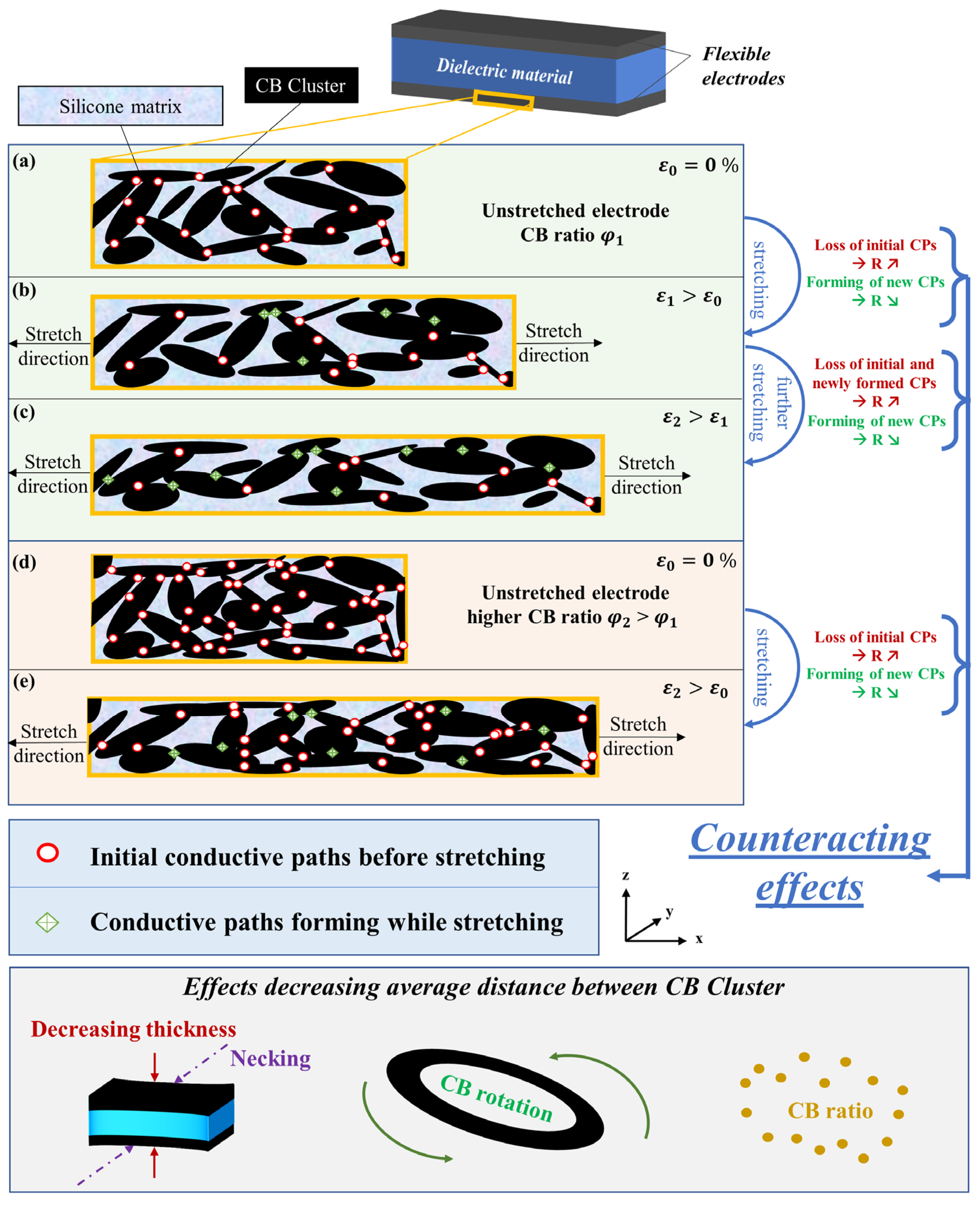

3.3. Physical Explanation of CB Behavior in Silicone Matrices

- CPloss > CPform → R ↗

- CPloss = CPform → R →

- CPloss < CPform → R ↘

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hill, M.; Rizzello, G.; Seelecke, S. Development and experimental characterization of a pneumatic valve actuated by a dielectric elastomer membrane. Smart Mater. Struct. 2017, 26, 8. [Google Scholar] [CrossRef]

- Meyer, A.; Lenz, S.; Gratz-Kelly, S.; Motzki, P.; Nalbach, S.; Seelecke, S.; Rizzello, G. Experimental characterization of a smart dielectric elastomer multi-sensor grid. In Proceedings of the SPIE, San Fancisco, CA, USA, 22 April 2020; Volume 11375. [Google Scholar] [CrossRef]

- Hau, S.; Rizzello, G.; Hodgins, M.; York, A.; Seelecke, S. Design and control of a high-speed positioning system based on dielectric elastomer membrane actuators. IEEE/ASME Trans. Mechatron. 2017, 22, 1259–1267. [Google Scholar] [CrossRef]

- Nalbach, S.; Banda, R.M.; Croce, S.; Rizzello, G.; Naso, D.; Seelecke, S. Modeling and Design Optimization of a Rotational Soft Robotic System Driven by Double Cone Dielectric Elastomer Actuators. Front. Robot. AI 2020, 6, 150. [Google Scholar] [CrossRef] [PubMed]

- Shian, S.; Bertoldi, K.; Clarke, D.R. Dielectric Elastomer Based ‘grippers’ for Soft Robotics. Adv. Mater. 2015, 27, 6814–6819. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.; Li, B.; Zhang, F.; Fang, C.; Lu, Y.; Gao, X.; Cao, C.; Chen, G.; Zhang, C.; Wanf, Z.L. TENG-Bot: Triboelectric nanogenerator powered soft robot made of uni-directional dielectric elastomer. Nano Energy 2021, 85, 106012. [Google Scholar] [CrossRef]

- Lacasse, M.A.; Duchaine, V.; Gosselin, C. Characterization of the electrical resistance of carbon-black-filled silicone: Application to a flexible and stretchable robot skin. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Anchorage, AK, USA, 3–7 May 2010; pp. 4842–4848. [Google Scholar] [CrossRef]

- Tairych, A.; Anderson, I.A. Capacitive stretch sensing for robotic skins. Soft Robot. 2019, 6, 389–398. [Google Scholar] [CrossRef]

- Duduta, M.; Hajiesmaili, E.; Zhao, H.; Wood, R.J.; Clarke, D.R. Realizing the potential of dielectric elastomer artificial muscles. Proc. Natl. Acad. Sci. USA 2019, 116, 2476–2481. [Google Scholar] [CrossRef]

- Kunze, J.; Prechtl, J.; Bruch, D.; Nalbach, S.; Motzki, P.; Seelecke, S.; Rizzello, G. Design and Fabrication of Silicone-based Dielectric Elastomer Rolled Actuators for Soft Robotic Applications. In Proceedings of the SPIE, San Francisco, CA, USA, 27 April–5 May 2020; Volume 11375. [Google Scholar] [CrossRef]

- Shintake, J.; Piskarev, E.; Jeong, S.H.; Floreano, D. Ultrastretchable Strain Sensors Using Carbon Black-Filled Elastomer Composites and Comparison of Capacitive Versus Resistive Sensors. Adv. Mater. Technol. 2018, 3, 3. [Google Scholar] [CrossRef]

- Thonking, W.; Wiranata, A.; Minaminosono, A.; Mao, Z.; Maeda, S. Soft Robotic Gripper Based on Multi-Layers of Dielectric Elastomer Actuators. J. Robot. Mechatron. 2021, 33, 968–974. [Google Scholar] [CrossRef]

- Carpi, F.; Chiarelli, P.; Mazzoldi, A.; de Rossi, D. Electromechanical characterisation of dielectric elastomer planar actuators: Comparative evaluation of different electrode materials and different counterloads. Sens. Actuators A Phys. 2003, 107, 85–95. [Google Scholar] [CrossRef]

- Zhu, F.B.; Zhang, C.L.; Qian, J.; Chen, W.Q. Mechanics of dielectric elastomers: Materials, structures, and devices. J. Zhejiang Univ. Sci. A 2016, 17, 1–21. [Google Scholar] [CrossRef]

- Wang, W.; Ren, G.; Zhou, M.; Deng, W. Preparation and characterization of ccto/pdms dielectric elastomers with high dielectric constant and low dielectric loss. Polymers 2021, 17, 1075. [Google Scholar] [CrossRef] [PubMed]

- Ellingford, C.; Zhang, R.; Wemyss, A.M.; Zhang, Y.; Brown, O.B.; Zhou, H.; Keogh, P.; Bowen, C.; Wan, C. Self-healing dielectric elastomers for damage-Tolerant actuation and energy harvesting. ACS Appl. Mater. Interfaces 2020, 12, 7595–7604. [Google Scholar] [CrossRef]

- Mehnert, M.; Hossain, M.; Steinmann, P. A complete thermo-electro-viscoelastic characterization of dielectric elastomers, Part II: Continuum modeling approach. J. Mech. Phys. Solids 2019, 40, 16. [Google Scholar] [CrossRef]

- Sheima, Y.; Caspari, P.; Opris, D.M. Artificial Muscles: Dielectric Elastomers Responsive to Low Voltages. Macromol. Rapid Commun. 2019, 40, 16. [Google Scholar] [CrossRef]

- Huang, J.C. Carbon black filled conducting polymers and polymer blends. Adv. Polym. Technol. 2002, 21, 299–313. [Google Scholar] [CrossRef]

- Albuquerque, F.B.; Shea, H. Influence of electric field, temperature, humidity, elastomer material, and encapsulation on the lifetime of dielectric elastomer actuators (DEAs) under DC actuation. Smart Mater. Struct. 2021, 30, 12. [Google Scholar] [CrossRef]

- Moretti, G.; Righi, M.; Vertechy, R.; Fontana, M. Fabrication and test of an inflated circular diaphragm dielectric elastomer generator based on PDMS rubber composite. Polymers 2017, 9, 283. [Google Scholar] [CrossRef]

- Almanza, M.; Clavica, F.; Chavanne, J.; Moser, D.; Obrist, D.; Carrel, T.; Civet, Y.; Perriard, Y. Feasibility of a Dielectric Elastomer Augmented Aorta. Adv. Sci. 2021, 8, 6. [Google Scholar] [CrossRef]

- Karuthedath, C.B.; Fikri, U.; Ruf, F.; Schwesinger, N. Characterization of carbon black filled PDMS-composite membranes for sensor applications. Key Eng. Mater. 2017, 753, 18–27. [Google Scholar] [CrossRef]

- Yamaguchi, K.; Busfield, J.J.C.; Thomas, A.G. Electrical and mechanical behavior of filled elastomers. I. The effect of strain. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 2079–2089. [Google Scholar] [CrossRef]

- Tang, C.; Ma, W.; Li, B.; Jin, M.; Chen, H. Cephalopod-Inspired Swimming Robot Using Dielectric Elastomer Synthetic Jet Actuator. Adv. Eng. Mater. 2020, 22, 4. [Google Scholar] [CrossRef]

- Bozlar, M.; Punckt, C.; Korkut, S.; Zhu, J.; Foo, C.C.; Suo, Z.; Aksay, I.A. Dielectric elastomer actuators with elastomeric electrodes. Appl. Phys. Lett. 2012, 101, 9. [Google Scholar] [CrossRef]

- Yang, H.; Yao, X.; Yuan, L.; Gong, L.; Liu, Y. Strain-sensitive electrical conductivity of carbon nanotube-graphene-filled rubber composites under cyclic loading. Nanoscale 2019, 11, 578–586. [Google Scholar] [CrossRef]

- Zois, H.; Apekis, L.; Omastová, M. Electrical Properties of Carbon Black-filled Polymer composites. Macromol. Symp. 2001, 170, 1. [Google Scholar] [CrossRef]

- Lau, G.K.; Goh, S.C.K.; Shiau, L.L. Dielectric elastomer unimorph using flexible electrodes of electrolessly deposited (ELD) silver. Sens. Actuators 2011, 169, 234–241. [Google Scholar] [CrossRef]

- Hubertus, J.; Neu, J.; Croce, S.; Rizzello, G.; Seelecke, S.; Schultes, G. Nanoscale Nickel-Based Thin Films as Highly Conductive Electrodes for Dielectric Elastomer Applications with Extremely High Stretchability up to 200%. ACS Appl. Mater. Interfaces 2021, 13, 39894–39904. [Google Scholar] [CrossRef] [PubMed]

- Mohd Radzuan, N.A.; Yusuf Zakari, M.; Sulong, A.B.; Sahari, J. The effect of milled carbon fibre filler on electrical conductivity in highly conductive polymer composites. Compos. Part B Eng. 2017, 110, 153–160. [Google Scholar] [CrossRef]

- Yuan, W.; Hu, L.B.; Yu, Z.B.; Lam, T.; Biggs, J.; Ha, S.M.; Xi, D.J.; Chen, B.; Senesky, M.K.; Grüner, G.; et al. Fault-tolerant dielectric elastomer actuators using single-walled carbon nanotube electrodes. Adv. Mater. 2008, 20, 621–625. [Google Scholar] [CrossRef]

- Song, P.; Wu, J.; Wang, G.; Zhang, Y. Effects of crosslinking reaction and extension strain on the electrical properties of silicone rubber/carbon nanofiller composites. J. Appl. Polym. Sci. 2021, 138, 30. [Google Scholar] [CrossRef]

- Fasolt, B.; Hodgins, M.; Rizzello, G.; Seelecke, S. Effect of screen printing parameters on sensor and actuator performance of dielectric elastomer (DE) membranes. Sens. Actuators A Phys. 2017, 265, 10–19. [Google Scholar] [CrossRef]

- Kost, J.; Israel, S.; Foux, A.; Narkis, M. Quantitative Model Relating Electrical Resistance, Strain, and Time for Carbon Black Loaded Silicone Rubber. Polym. Eng. Sci. 1994, 34, 1628–1634. [Google Scholar] [CrossRef]

- Hodgins, M.; York, A.; Seelecke, S. Systematic experimental characterization of dielectric elastomer membranes using a custom-built tensile test rig. J. Intell. Mater. Syst. Struct. 2017, 28, 2117–2128. [Google Scholar] [CrossRef]

- Luheng, W.; Tianhuai, D.; Peng, W. Influence of carbon black concentration on piezoresistivity for carbon-black-filled silicone rubber composite. Carbon N. Y. 2009, 47, 3151–3157. [Google Scholar] [CrossRef]

- Psarras, G.C. Charge transport properties in carbon black/polymer composites. J. Polym. Sci. Part B Polym. Phys. 2007, 45, 2535–2545. [Google Scholar] [CrossRef]

- Balberg, I. A comprehensive picture of the electrical phenomena in carbon black-polymer composites. Carbon 2002, 40, 139–143. [Google Scholar] [CrossRef]

- Spahr, M.E.; Gilardi, R.; Bonacchi, D. Carbon Black for Electrically Conductive Polymer Applications. In Encyclopedia of Polymers and Composites; Palsule, S., Ed.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 1–20. [Google Scholar] [CrossRef]

- Ren, D.; Zheng, S.; Wu, F.; Yang, W.; Liu, Z.; Yang, M. Formation and evolution of the carbon black network in polyethylene/carbon black composites: Rheology and conductivity properties. J. Appl. Polym. Sci. 2014, 131, 7. [Google Scholar] [CrossRef]

- Balasooriya, W.; Schrittesser, B.; Pinter, G.; Schwarz, T.; Conzatti, L. The effect of the surface area of carbon black grades on HNBR in harsh environments. Polymers 2019, 11, 61. [Google Scholar] [CrossRef]

- Mazzaracchio, V.; Tomei, M.R.; Cacciotti, I.; Chiodoni, A.; Novara, C.; Castellino, M.; Scordo, G.; Amine, A.; Moscone, D.; Arduini, F. Inside the different types of carbon black as nanomodifiers for screen-printed electrodes. Electrochim. Acta 2019, 317, 673–683. [Google Scholar] [CrossRef]

- Fasolt, B.; Welsch, F.; Jank, M.; Seelecke, S. Effect of actuation parameters and environment on the breakdown voltage of silicone dielectric elastomer films. Smart Mater. Struct. 2019, 28, 9. [Google Scholar] [CrossRef]

- Diani, J.; Fayolle, B.; Gilormini, P. A review on the Mullins effect. Eur. Polym. J. 2009, 45, 601–612. [Google Scholar] [CrossRef]

| Silicones | Carbon Blacks | ||

|---|---|---|---|

| Company | Product Name | Company | Product Name |

| Wacker Chemie AG (Munich, Germany) | Silgel 612 A/B | Akzonobel (Amsterdam, The Netherlands) | Ketjenblack EC-600JD |

| NuSil Technology (Carpenteria, CA, USA) | Nusil R34-2186 | Imerys (Paris, France) | Ensaco 350G |

| Dow Chemical Company (Midland, MI, USA) | Sylgard 182 A/B | Cabot Corporation (Boston, MA, USA) | Vulcan XC-72 |

| Carbon Black | BET Surface Area [m²/g] |

|---|---|

| Ketjenblack EC-600JD | 1400 |

| Ensaco 350G | 770 |

| Vulcan XC-72 | 241 |

| Silicone to CB Ratio in Cured Electrodes | Prepared Samples with Different CB and the Required Amount of Solvent in the Electrode Printing Ink [wt%] | |||

|---|---|---|---|---|

| Silgel 612 A/B [wt%] | CB [wt%] | Ketjenblack EC-600 JD | Ensaco 350G | Vulcan XC-72 |

| 95 | 5 | 58 (n.e.c.) | 46 (n.e.c.) | 33 (n.e.c.) |

| 90 | 10 | 74 | 65 | 50 |

| 85 | 15 | 84 | 74 | 61 |

| 80 | 20 | 88 | 79 | 68 |

| 75 | 25 | 90 | 83 | 73 |

| 70 | 30 | n.s.p. | 86 | 76 |

| 65 | 35 | n.s.p. | 89 | 79 |

| 60 | 40 | n.s.p. | n.s.p. | 81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Willian, T.P.; Fasolt, B.; Motzki, P.; Rizzello, G.; Seelecke, S. Effects of Electrode Materials and Compositions on the Resistance Behavior of Dielectric Elastomer Transducers. Polymers 2023, 15, 310. https://doi.org/10.3390/polym15020310

Willian TP, Fasolt B, Motzki P, Rizzello G, Seelecke S. Effects of Electrode Materials and Compositions on the Resistance Behavior of Dielectric Elastomer Transducers. Polymers. 2023; 15(2):310. https://doi.org/10.3390/polym15020310

Chicago/Turabian StyleWillian, Tobias Pascal, Bettina Fasolt, Paul Motzki, Gianluca Rizzello, and Stefan Seelecke. 2023. "Effects of Electrode Materials and Compositions on the Resistance Behavior of Dielectric Elastomer Transducers" Polymers 15, no. 2: 310. https://doi.org/10.3390/polym15020310

APA StyleWillian, T. P., Fasolt, B., Motzki, P., Rizzello, G., & Seelecke, S. (2023). Effects of Electrode Materials and Compositions on the Resistance Behavior of Dielectric Elastomer Transducers. Polymers, 15(2), 310. https://doi.org/10.3390/polym15020310