Innovative Strategies for Technical-Economical Optimization of FDM Production

Abstract

:1. Introduction

- ✓

- Increasing product performance while maintaining a constant price;

- ✓

- Reducing the price while maintaining constant performance;

- ✓

- Increasing performance more than cost;

- ✓

- Increasing performance levels while reducing costs;

- ✓

- Reducing performance, but with an even greater reduction in cost.

2. Materials and Methods

3. Results and Discussion

3.1. Application of Value Analysis for Analyzing the Mechanical Behavior of ABS and PLA 3D-Printed Materials

3.1.1. Tensile Testing

3.1.2. Compression Testing

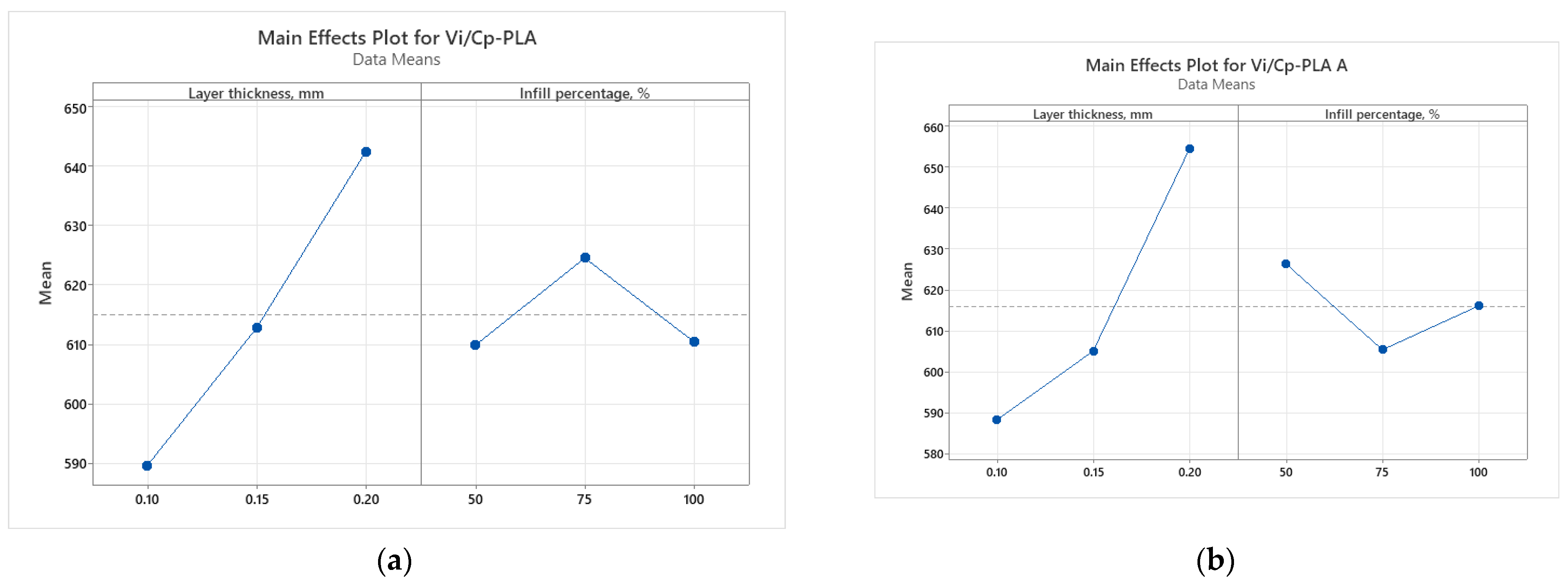

3.1.3. Flexural Strength Testing

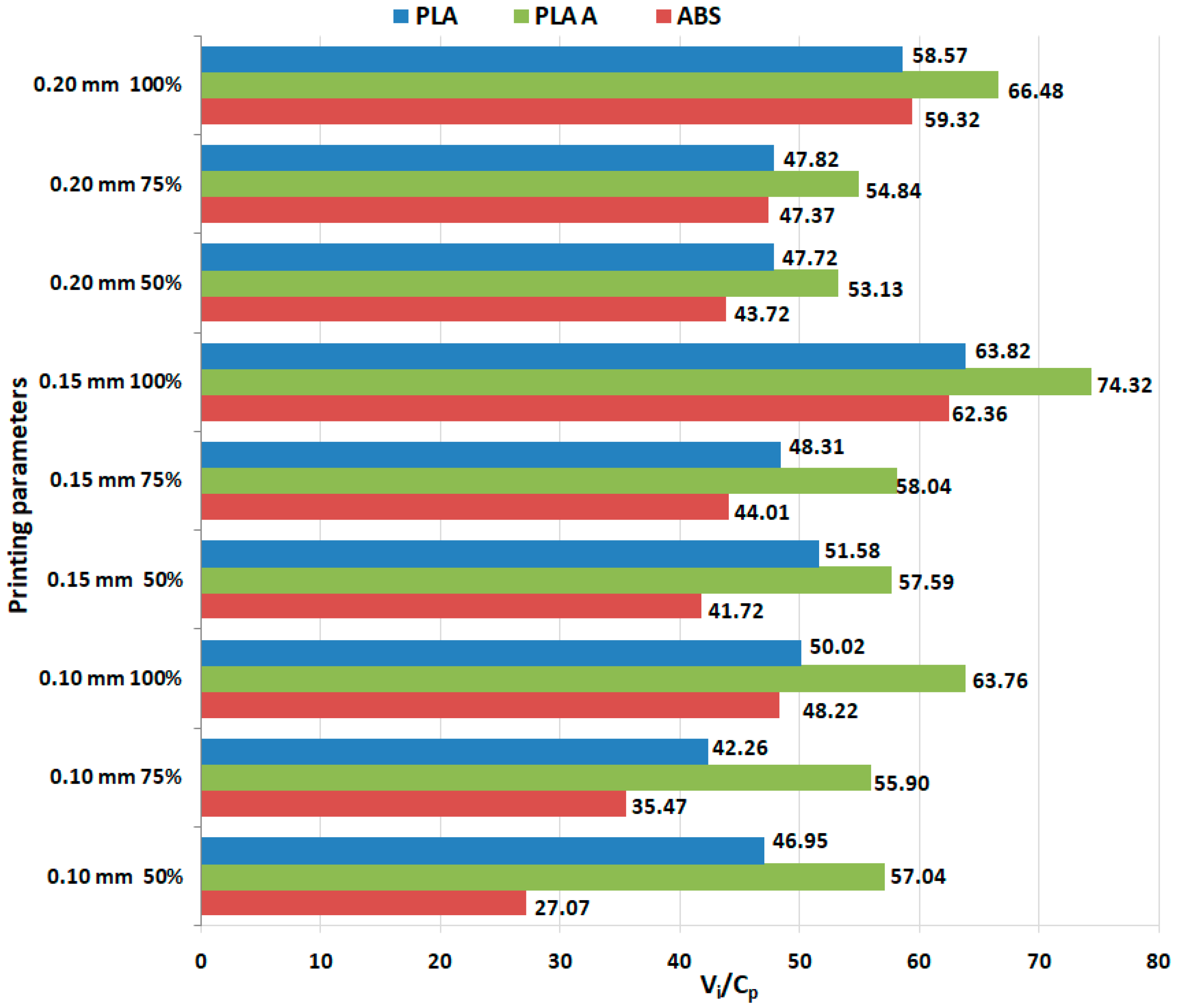

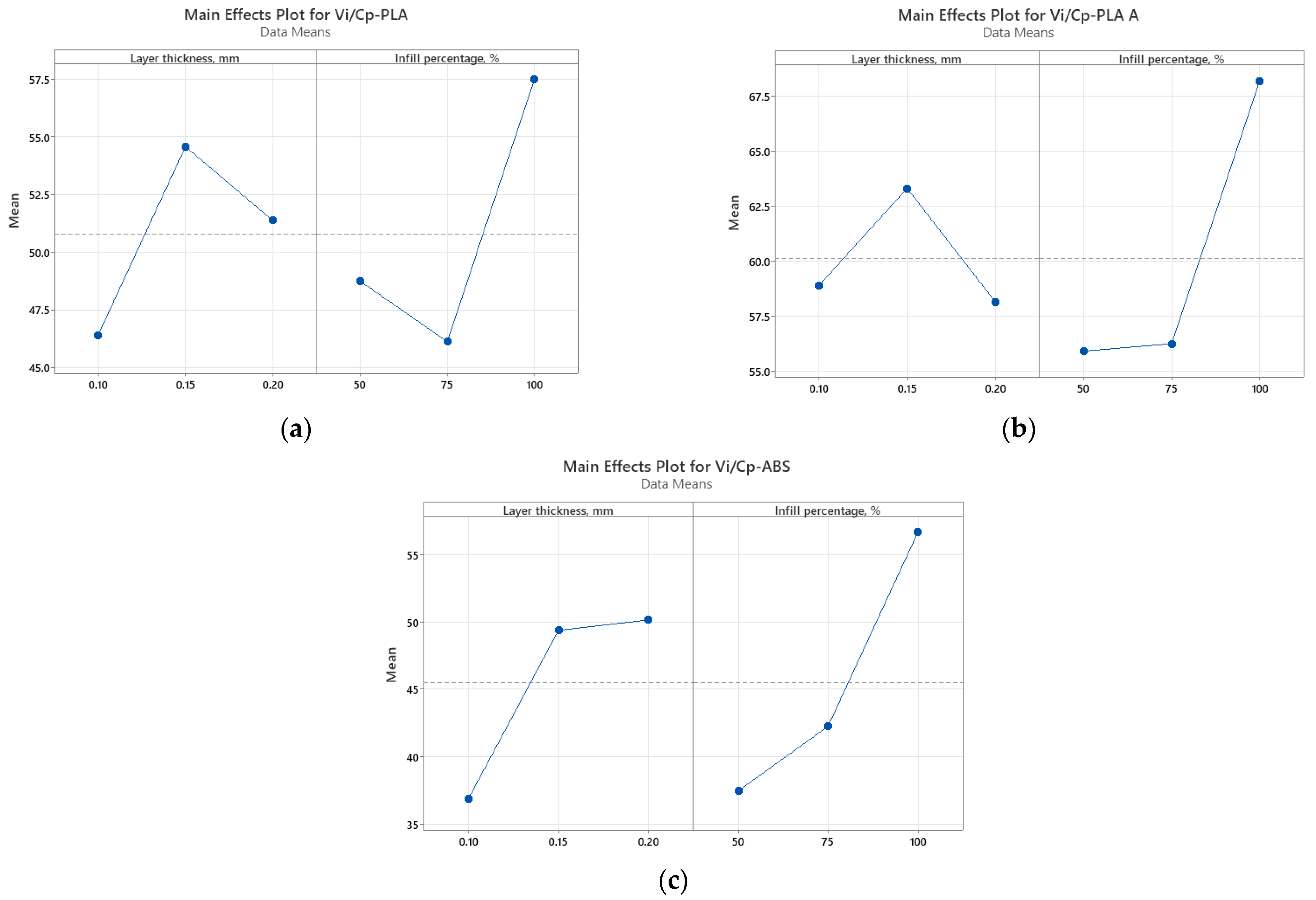

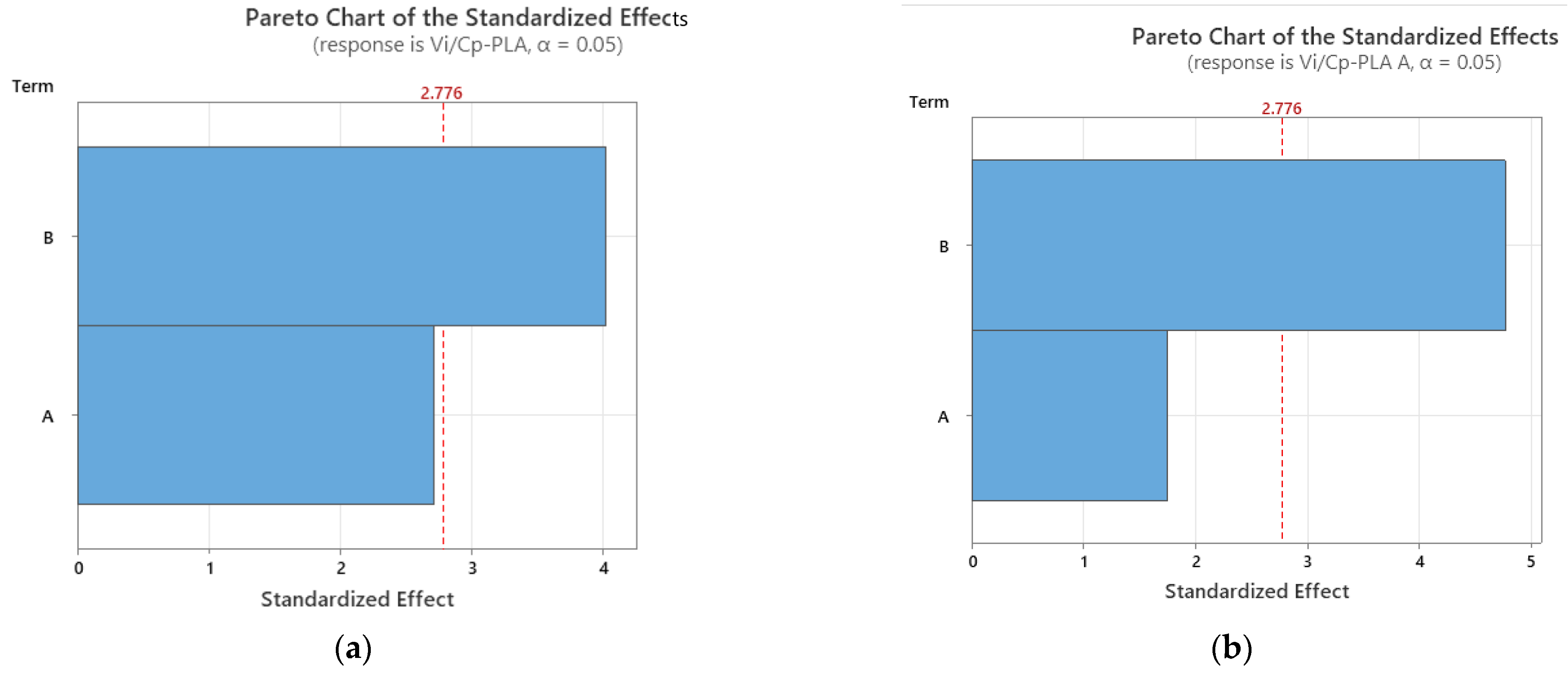

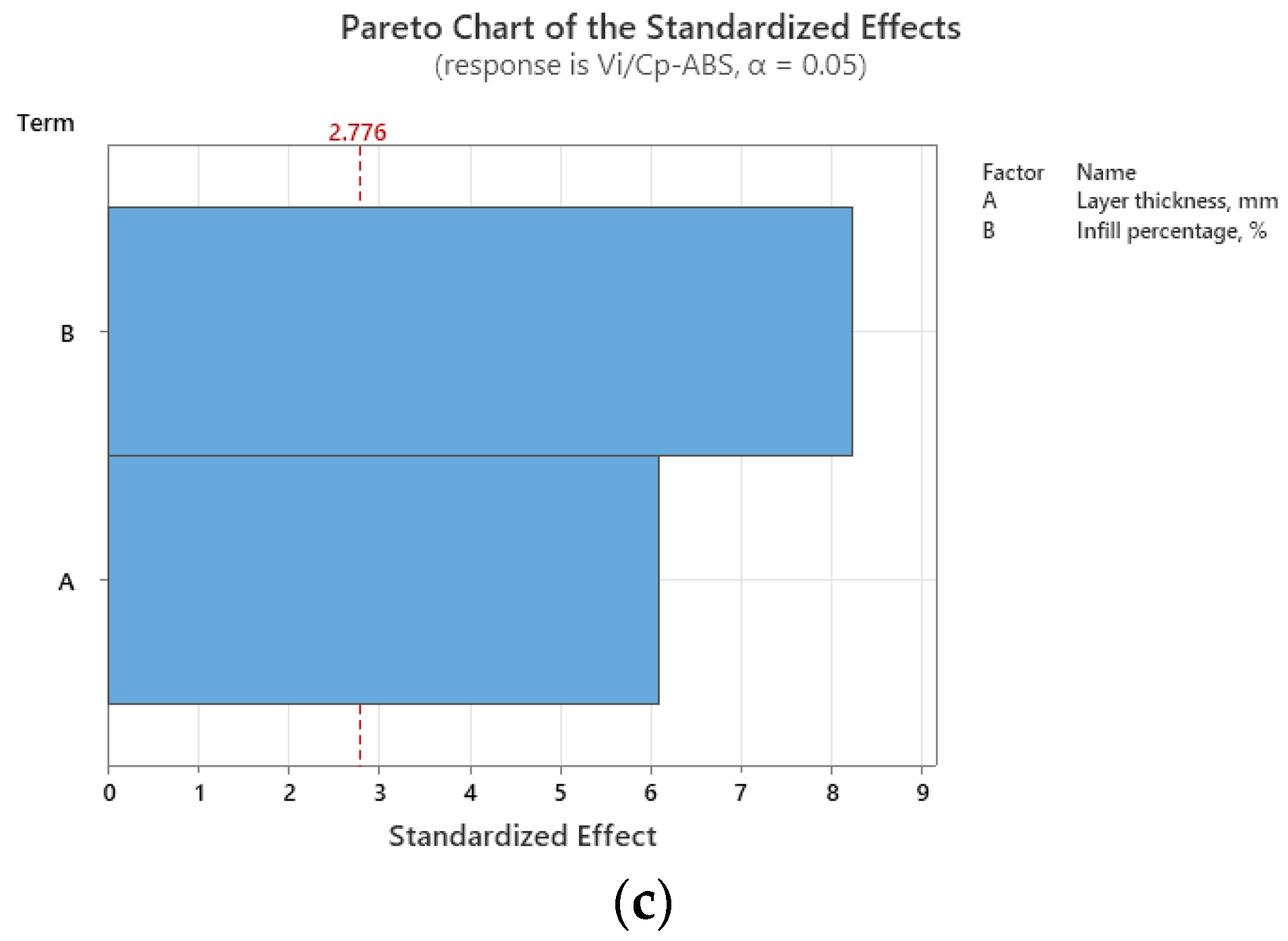

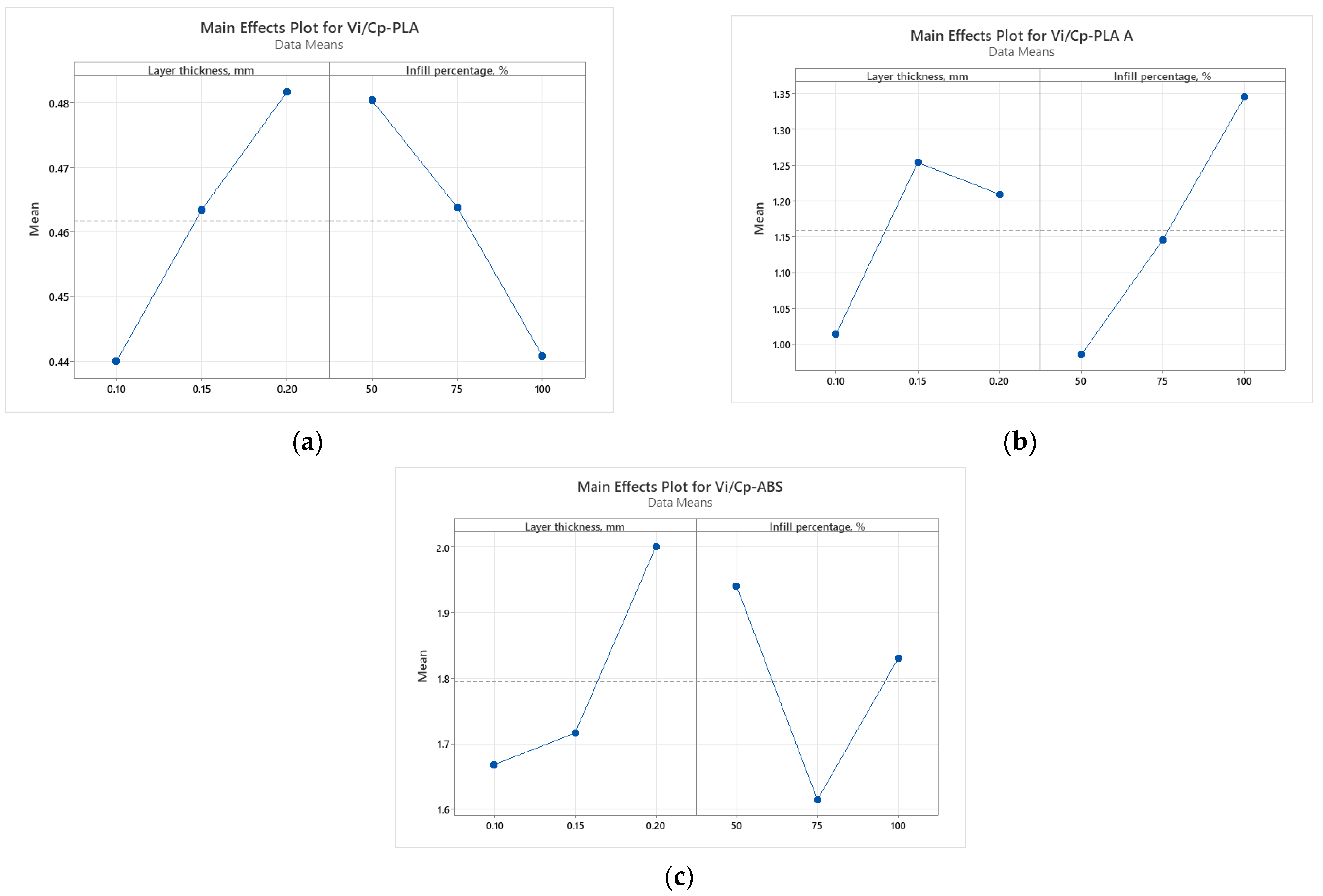

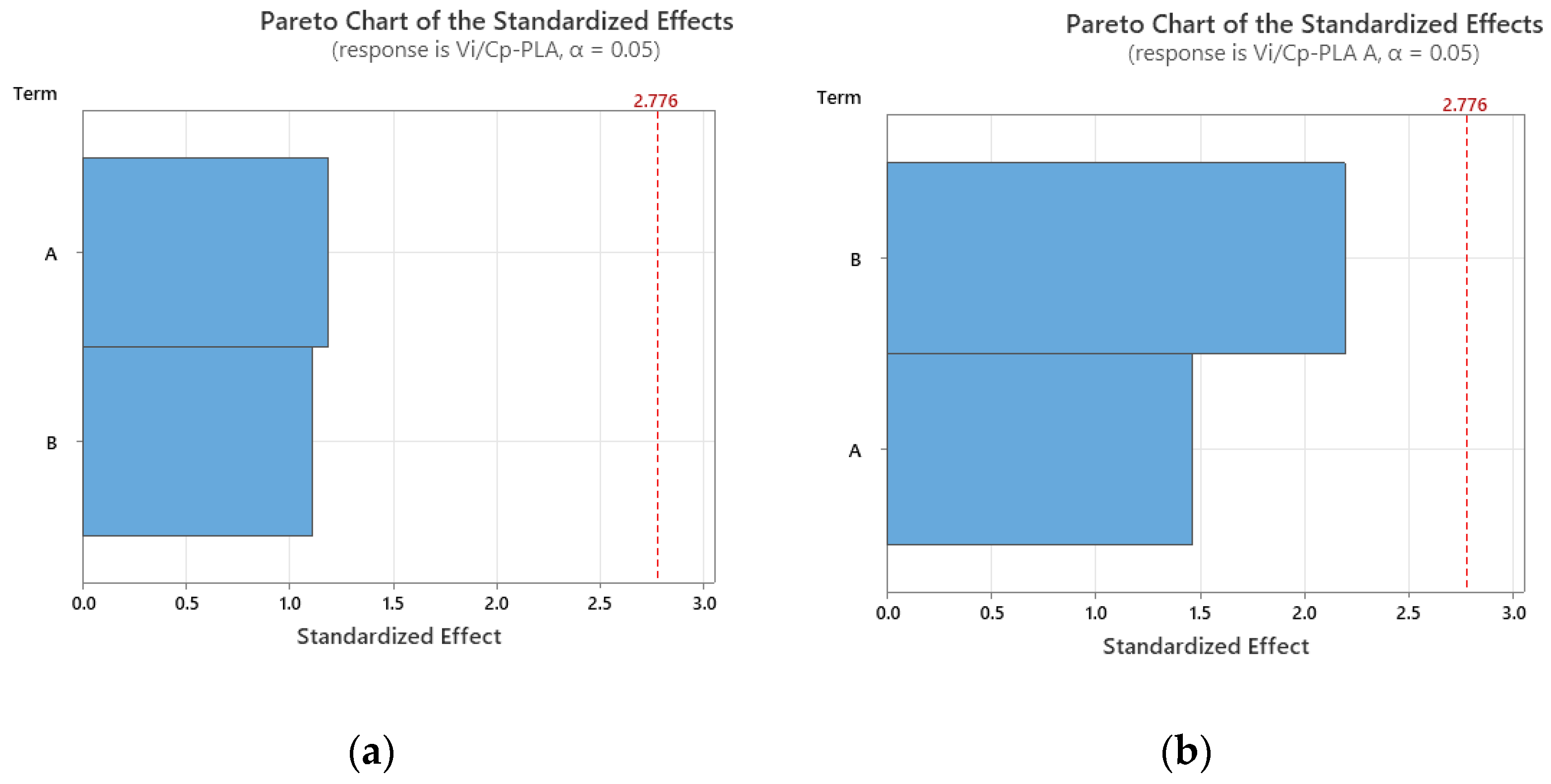

3.1.4. Impact Testing

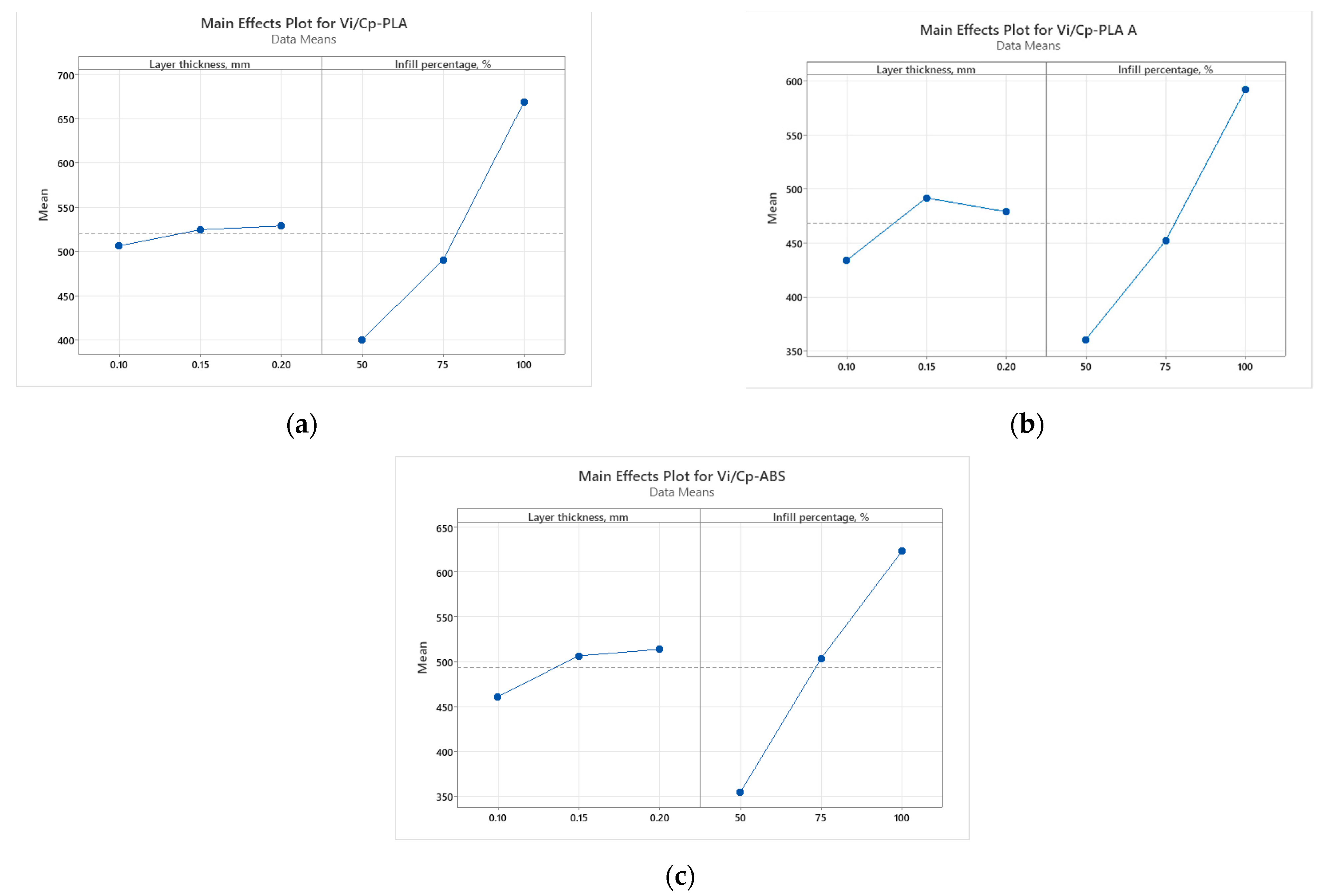

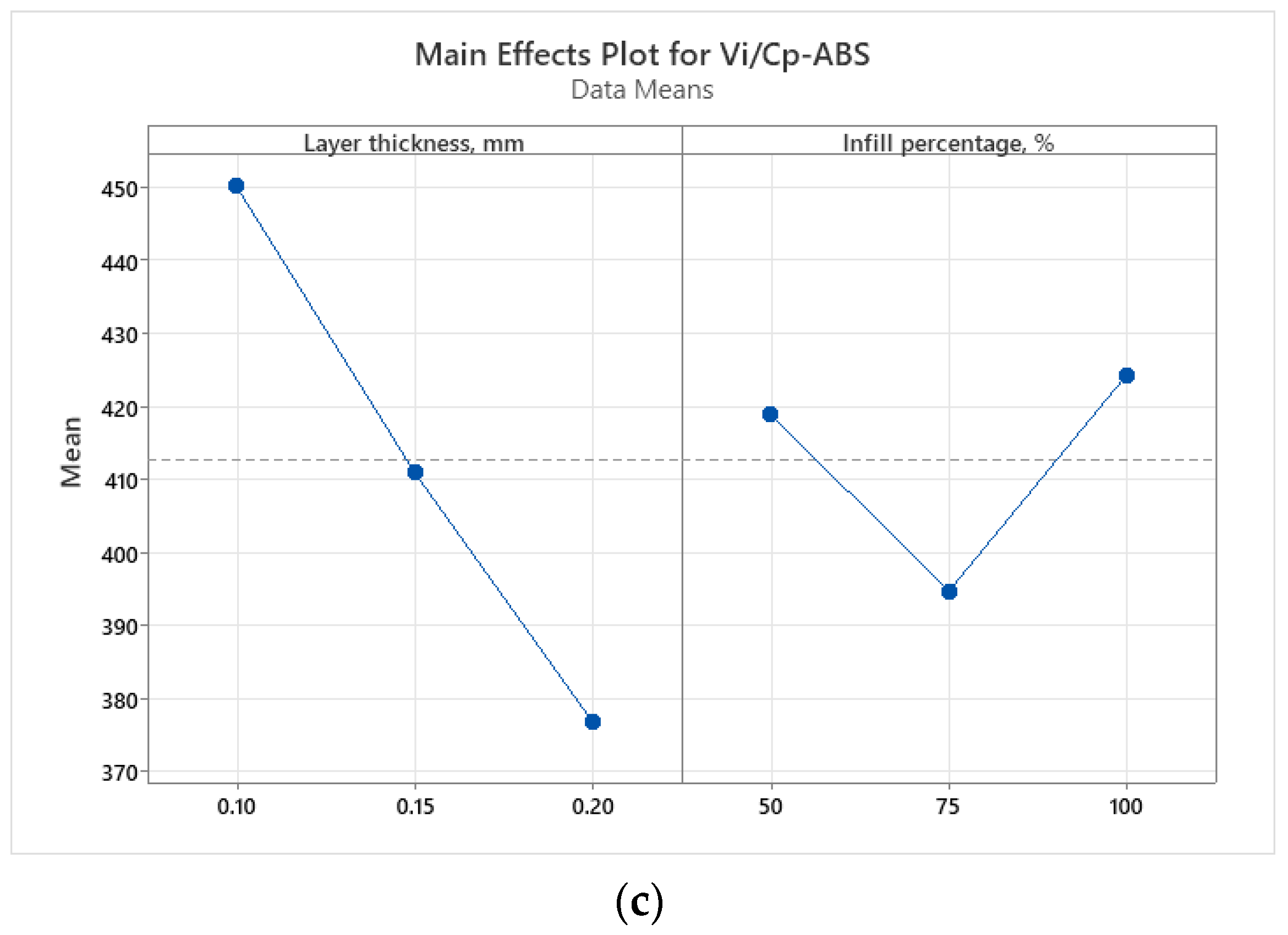

3.1.5. Hardness Testing

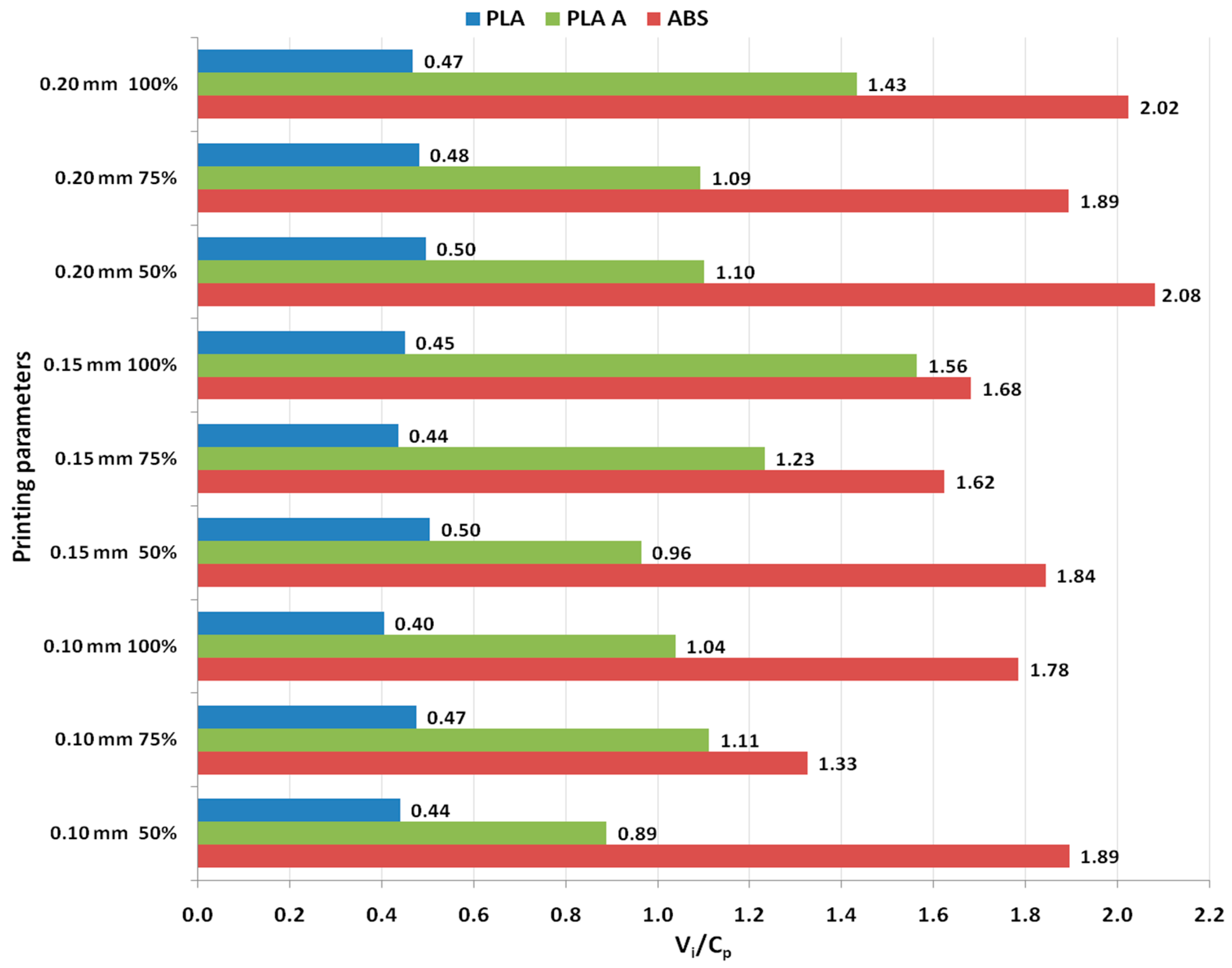

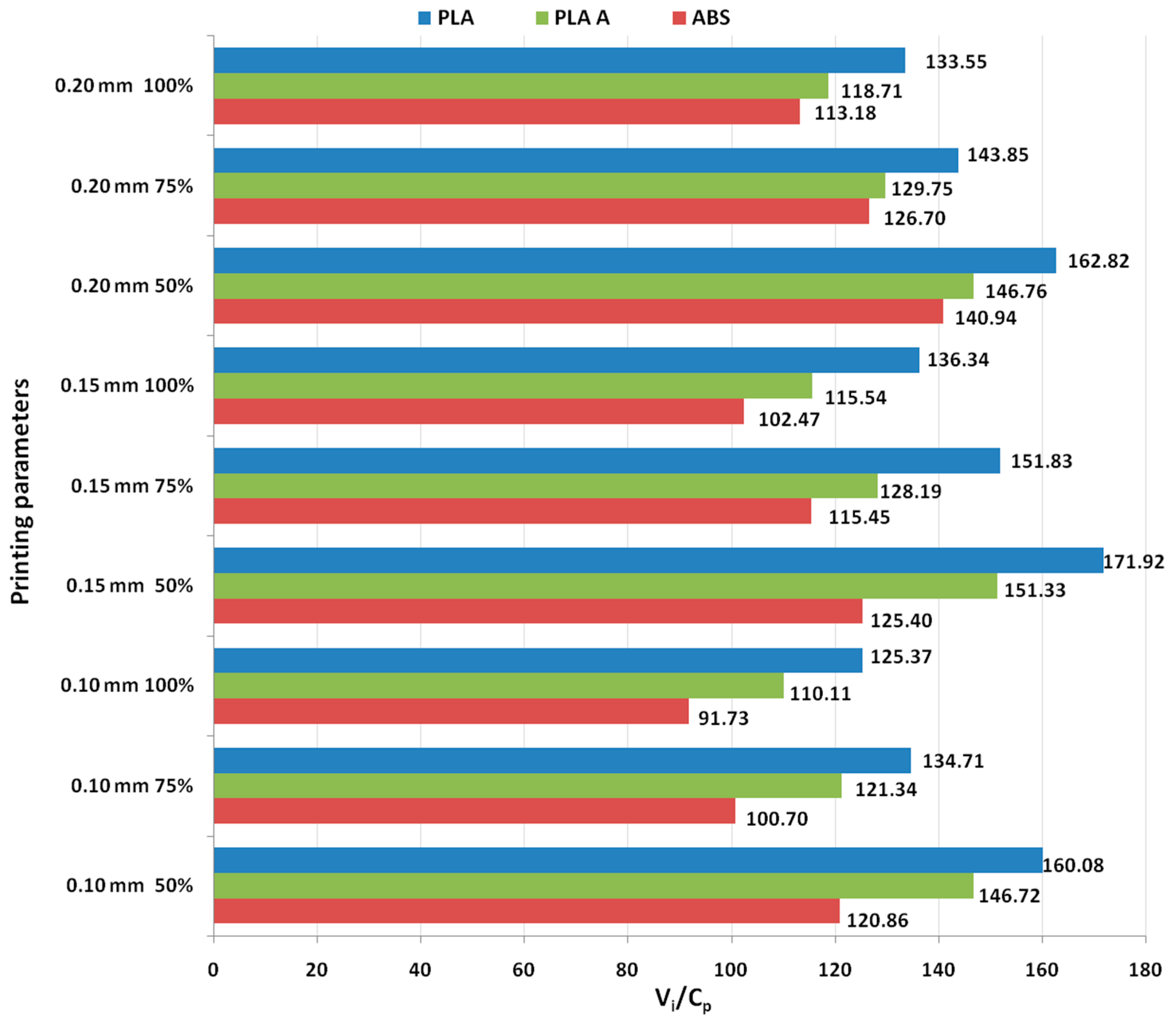

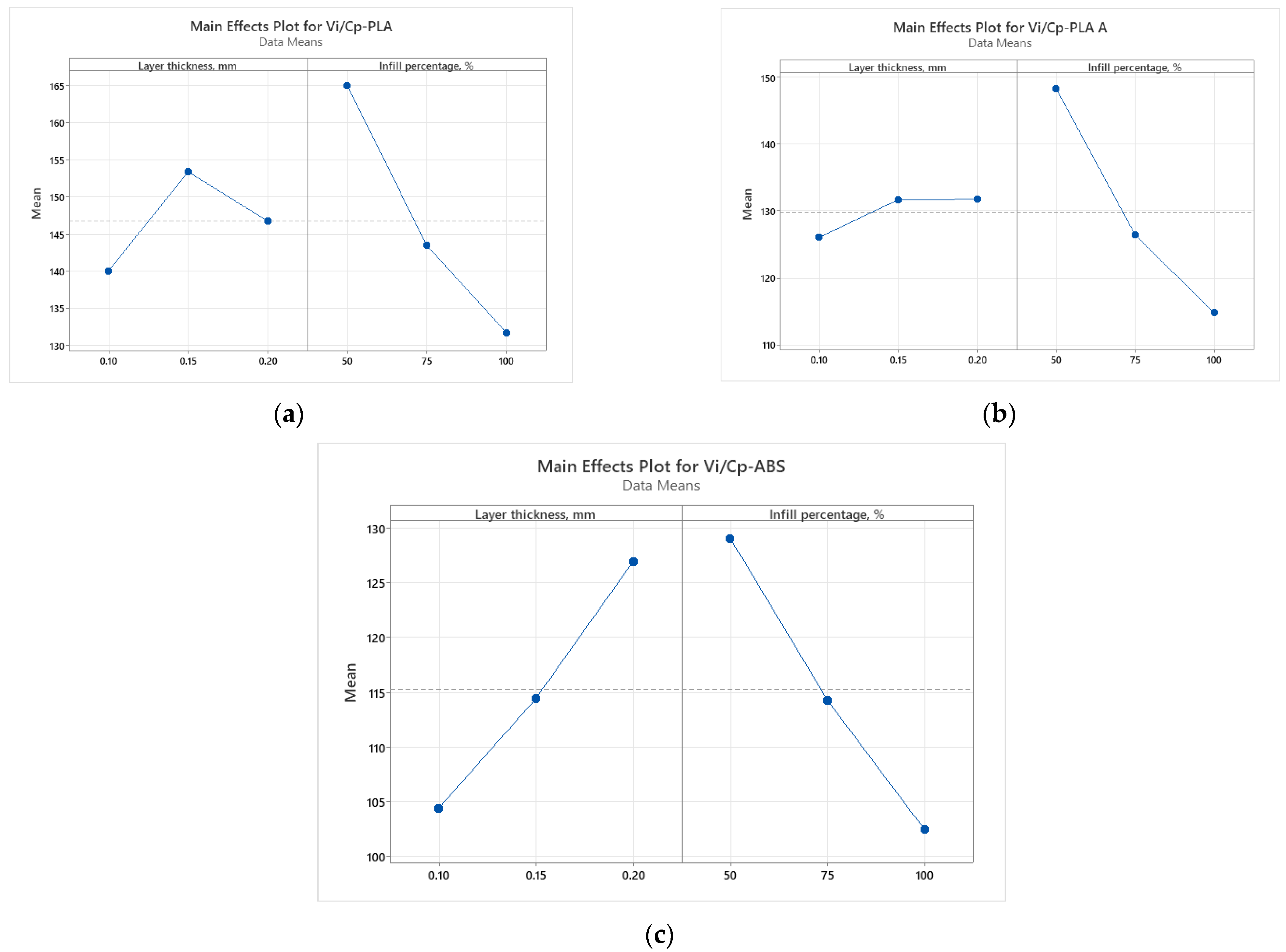

3.2. Multi-Response Optimization Using Desirability Function Based on Value Analysis for Enhancing the 3D-Printing Efficiency of PLA and ABS Materials

4. Conclusions

- ✓

- For the FDM process under investigation, taking into account the mechanical characteristics (tensile strength, compression strength, flexural strength, impact strength, hardness) and the use value and production cost of specimens made of different materials, the optimum parameters were found.

- ✓

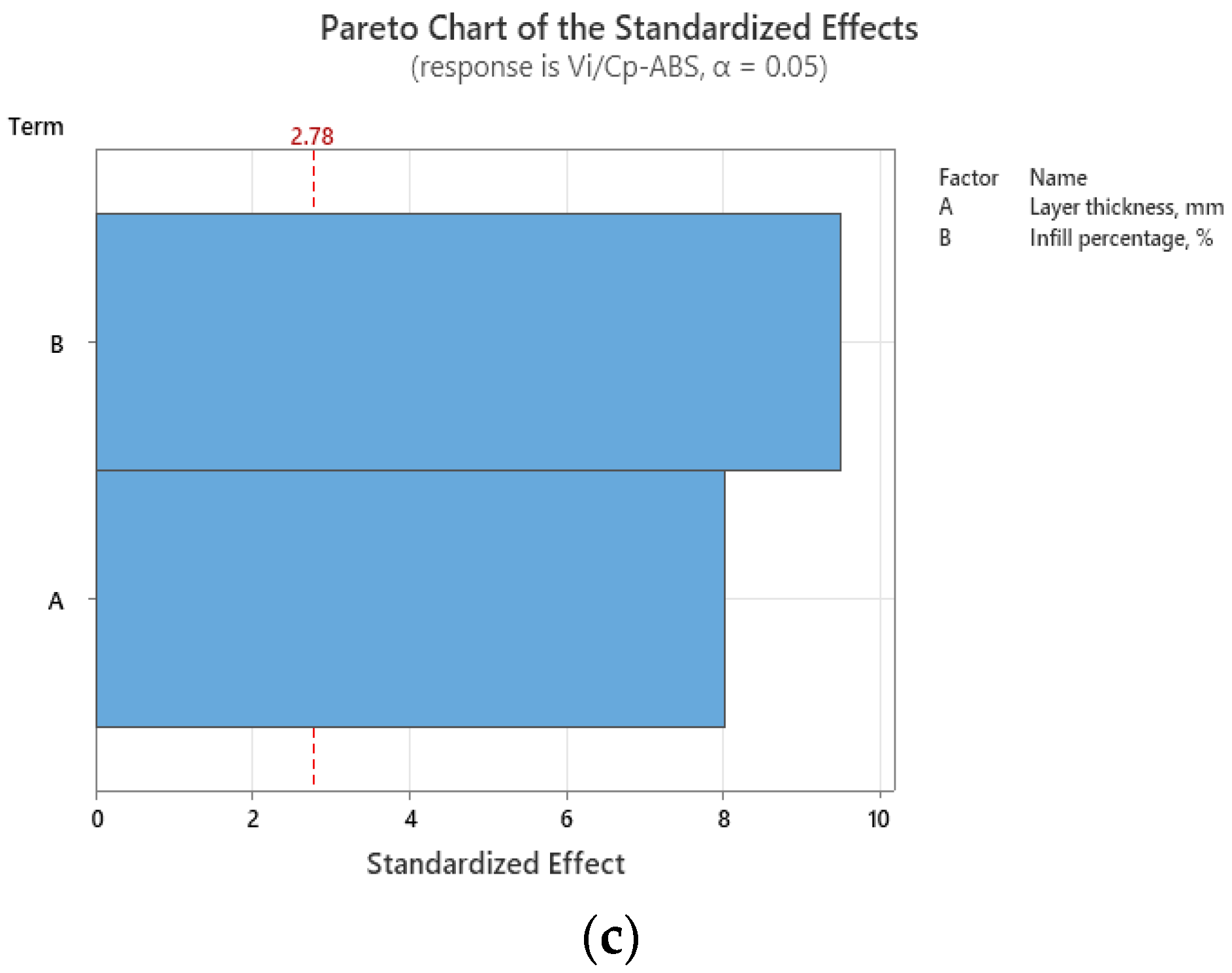

- The ANOVA analysis demonstrated that the infill percentage is the significant factor with statistical influence on the Vi/Cp ratio in the case of tensile, compression, and hardness testing specimens, while for flexural testing specimens, the layer thickness makes the most important contribution. When analyzing impact strength, both layer thickness and infill percentage exhibit nearly equal influence on the Vi/Cp ratio. However, for PLA and ABS materials, layer thickness holds a slightly greater impact, while for annealed PLA, the infill percentage has a slightly higher influence.

- ✓

- Annealing has been proven to significantly enhance some mechanical characteristics of PLA 3D-printed parts. In order to obtain a favorable ratio between mechanical performance and production cost, a certain number of samples must be heat-treated simultaneously for an efficient use of energy. The gains in mechanical strength per piece, combined with the efficient use of energy and time during annealing, contribute positively to the cost-effectiveness of the process.

- ✓

- Prospective investigations within this domain necessitate a targeted assessment of value, centered on the specific applications demanded, with a keen focus on enhancing both utility and production-cost efficiency for industry-specific components. To enhance the rigor of future studies, it would be useful to use precise measurements for factors such as energy consumption and labor costs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kumar, K.; Singh, H. Multi-Objective Optimization of Fused Deposition Modeling for Mechanical Properties of Biopolymer Parts Using the Grey-Taguchi Method. Chin. J. Mech. Eng. 2023, 36, 30. [Google Scholar] [CrossRef]

- Wang, S.; Daelemans, L.; Fiorio, R.; Gou, M.; D’hooge, D.R.; De Clerck, K.; Cardon, L. Improving Mechanical Properties for Extrusion-Based Additive Manufacturing of Poly(Lactic Acid) by Annealing and Blending with Poly(3-Hydroxybutyrate). Polymers 2019, 11, 1529. [Google Scholar] [CrossRef]

- D’Addona, D.M.; Raykar, S.J.; Singh, D.; Kramar, D. Multi Objective Optimization of Fused Deposition Modeling Process Parameters with Desirability Function. Procedia CIRP 2021, 99, 707–710. [Google Scholar] [CrossRef]

- Pereira, R.J.R.; de Almeida, F.A.; Gomes, G.F. A multiobjective optimization parameters applied to additive manufacturing: DOE-based approach to 3D printing. Structures 2023, 55, 1710–1731. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Huynh, T.N.; Nguyen, T.P.; Tran, T.T. Single and Multi-objective Optimization of Processing Parameters for Fused Deposition Modeling in 3D Printing Technology. Int. J. Automot. Mech. Eng. 2020, 17, 7542–7551. [Google Scholar] [CrossRef]

- Portoaca, A.; Nae, I.; Zisopol, D.G.; Ramadan, I. Studies on the influence of FFF parameters on the tensile properties of samples made of ABS. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1235, 012008. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Nae, I.; Portoaca, A.I.; Ramadan, I. A Statistical Approach of the Flexural Strength of PLA and ABS 3D Printed Parts. Eng. Technol. Appl. Sci. Res. 2022, 12, 8248–8252. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Nae, I.; Portoaca, A.I. Compression Behavior of FFF Printed Parts Obtained by Varying Layer Height and Infill Percentage. Eng. Technol. Appl. Sci. Res. 2022, 12, 9747–9751. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Portoaca, A.I.; Nae, I.; Ramadan, I. A Comparative Analysis of the Mechanical Properties of Annealed PLA. Eng. Technol. Appl. Sci. Res. 2022, 12, 8978–8981. [Google Scholar] [CrossRef]

- Frunzaverde, D.; Cojocaru, V.; Ciubotariu, C.-R.; Miclosina, C.-O.; Ardeljan, D.D.; Ignat, E.F.; Marginean, G. The Influence of the Printing Temperature and the Filament Color on the Dimensional Accuracy, Tensile Strength, and Friction Performance of FFF-Printed PLA Specimens. Polymers 2022, 14, 1978. [Google Scholar] [CrossRef]

- Maguluri, N.; Suresh, G.; Guntur, S.R. Effect of printing parameters on the hardness of 3D printed poly-lactic acid parts using DOE approach. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1248, 012004. [Google Scholar] [CrossRef]

- Lokesh, N.; Praveena, B.A.; Sudheer Reddy, J.; Vasu, V.K.; Vijaykumar, S. Evaluation on effect of printing process parameter through Taguchi approach on mechanical properties of 3D printed PLA specimens using FDM at constant printing temperature. Mater. Today Proc. 2022, 52, 1288–1293. [Google Scholar] [CrossRef]

- Patil, P.; Singh, D.; Raykar, S.J.; Bhamu, J. Multi-objective optimization of process parameters of Fused Deposition Modeling (FDM) for printing Polylactic Acid (PLA) polymer components. Mater. Today Proc. 2021, 45, 4880–4885. [Google Scholar] [CrossRef]

- Wankhede, V.; Jagetiya, D.; Joshi, A.; Chaudhari, R. Experimental investigation of FDM process parameters using Taguchi analysis. Mater. Today Proc. 2020, 27, 2117–2120. [Google Scholar] [CrossRef]

- Vishwas, M.; Basavaraj, C.K.; Vinyas, M. Experimental Investigation using Taguchi Method to Optimize Process Parameters of Fused Deposition Modeling for ABS and Nylon Materials. Mater. Today Proc. 2018, 5, 7106–7114. [Google Scholar] [CrossRef]

- Tamașag, I.; Beșliu-Băncescu, I.; Severin, T.-L.; Dulucheanu, C.; Cerlincă, D.-A. Experimental Study of In-Process Heat Treatment on the Mechanical Properties of 3D Printed Thermoplastic Polymer PLA. Polymers 2023, 15, 2367. [Google Scholar] [CrossRef] [PubMed]

- Jackson, B.; Fouladi, K.; Eslami, B. Multi-Parameter Optimization of 3D Printing Condition for Enhanced Quality and Strength. Polymers 2022, 14, 1586. [Google Scholar] [CrossRef]

- John, J.; Devjani, D.; Ali, S.; Abdallah, S.; Pervaiz, S. Optimization of 3D printed polylactic acid structures with different infill patterns using Taguchi-grey relational analysis. Adv. Ind. Eng. Polym. Res. 2023, 6, 62–78. [Google Scholar] [CrossRef]

- Camposeco-Negrete, C. Optimization of printing parameters in fused deposition modeling for improving part quality and process sustainability. Int. J. Adv. Manuf. Technol. 2020, 108, 2131–2147. [Google Scholar] [CrossRef]

- Yang, C.-J.; Wu, S.-S. Sustainable Manufacturing Decisions through the Optimization of Printing Parameters in 3D Printing. Appl. Sci. 2022, 12, 10060. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Mountakis, N.; Karapidakis, E. Box-Behnken modeling to quantify the impact of control parameters on the energy and tensile efficiency of PEEK in MEX 3D-printing. Heliyon 2023, 9, e18363. [Google Scholar] [CrossRef] [PubMed]

- Petousis, M.; Vidakis, N.; Mountakis, N.; Karapidakis, E.; Moutsopoulou, A. Compressive response versus power consumption of acrylonitrile butadiene styrene in material extrusion additive manufacturing: The impact of seven critical control parameters. Int. J. Adv. Manuf. Technol. 2023, 126, 1233–1245. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Karapidakis, E.; Mountakis, N.; David, C.; Sagris, D. Energy consumption versus strength in MEΧ 3D printing of polylactic acid. Adv. Ind. Manuf. Eng. 2023, 6, 100119. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Mountakis, N.; Moutsopoulou, A.; Karapidakis, E. Energy Consumption vs. Tensile Strength of Poly[methyl methacrylate] in Material Extrusion 3D Printing: The Impact of Six Control Settings. Polymers 2023, 15, 845. [Google Scholar] [CrossRef] [PubMed]

- Petousis, M.; Vidakis, N.; Mountakis, N.; Karapidakis, E.; Moutsopoulou, A. Functionality Versus Sustainability for PLA in MEX 3D Printing: The Impact of Generic Process Control Factors on Flexural Response and Energy Efficiency. Polymers 2023, 15, 1232. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; David, C.N.; Sagris, D.; Mountakis, N.; Karapidakis, E. Mechanical Performance over Energy Expenditure in MEX 3D Printing of Polycarbonate: A Multiparametric Optimization with the Aid of Robust Experimental Design. J. Manuf. Mater. Process. 2023, 7, 38. [Google Scholar] [CrossRef]

- Zisopol, D.G. Ingineria valorii; Editura Universității Petrol-Gaze din Ploiești: Ploieşti, Romania, 2004; ISBN 973-7965-96-5. [Google Scholar]

- Zisopol, D.G.; Nae, I.; Portoaca, A.I.; Ramadan, I. A Theoretical and Experimental Research on the Influence of FDM Parameters on Tensile Strength and Hardness of Parts Made of Polylactic Acid. Eng. Technol. Appl. Sci. Res. 2021, 11, 7458–7463. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Ion, N.; Portoaca, A.I. Comparison of the Charpy Resilience of Two 3D Printed Materials: A Study on the Impact Resistance of Plastic Parts. Eng. Technol. Appl. Sci. Res. 2023, 13, 10781–10784. [Google Scholar] [CrossRef]

- Portoacă, A.I.; Ripeanu, R.G.; Diniță, A.; Tănase, M. Optimization of 3D Printing Parameters for Enhanced Surface Quality and Wear Resistance. Polymers 2023, 15, 3419. [Google Scholar] [CrossRef]

- Homepage. Available online: https://formwerk.ro/ (accessed on 7 September 2023).

- Eurostat Statistics Explained. Electricity Price Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Electricity_price_statistics (accessed on 5 September 2023).

| Printing Options for 1 Set of Samples | ABS | PLA |

|---|---|---|

| Shell width (mm) | 1 | 1 |

| Infill speed (mm/s) | 40 | 70 |

| Estimated print time (min) | 60 | 46 |

| Estimated filament used (g) | 10.60 | 10.60 |

| Extruder temperature (°C) | 240 | 210 |

| Bed temperature (°C) | 110 | 60 |

| Platform addition | Raft only | Raft only |

| Materials | Extrusion Temperature (°C) | Bed Temperature (°C) | Density (g/cm3) | Tensile Strength (MPa) | Specific Deformation (%) | Charpy Impact Strength (kJ/m2) |

|---|---|---|---|---|---|---|

| PLA | 210 ± 10 | 25–60 | 1.31 ± 0.02 | 15.5–72 | 34.5 ± 8.1 | 5.7 ± 0.4 |

| ABS | 210 + 40 | 110 ± 10 | 1.10 | 33.9 | 4.8 | 10.5 |

| Parameter | Level | ||

|---|---|---|---|

| 1 | 2 | 3 | |

| Infill percentage, % | 50 | 75 | 100 |

| Layer thickness, mm | 0.10 | 0.15 | 0.20 |

| Experiment no. | Layer Thickness, mm | Infill Percentage, % |

|---|---|---|

| 1 | 0.10 | 50 |

| 2 | 75 | |

| 3 | 100 | |

| 4 | 0.15 | 50 |

| 5 | 75 | |

| 6 | 100 | |

| 7 | 0.20 | 50 |

| 8 | 75 | |

| 9 | 100 |

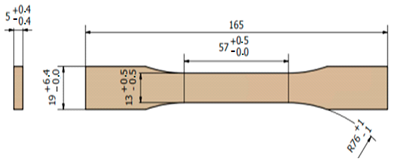

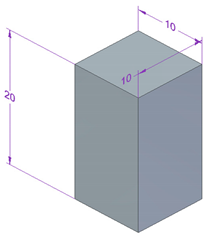

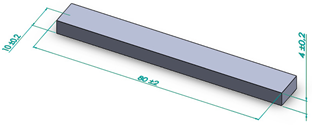

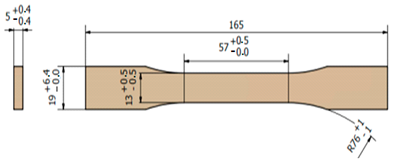

| Mechanical Test | Testing Conditions | Shape and Dimensions of Specimen |

|---|---|---|

| Tensile testing | - electro-mechanical machine - force cell of 2.5 kN, - speed of 5 mm/min - with extensometer - ambient temperature 20 °C - humidity 40% |  |

| Compression testing | MU 400 Kn universal machine 20 N preload 10 mm/min the speed test ambient temperature 20 °C humidity 40% |  |

| Flexural strength testing | Lloyd LRX Force Tester electro-mechanical - force cell of 2.5 kN, - speed of 5 mm/min - ambient temperature 20 °C humidity 40% |  |

| Impact testing | Instron Pendulum Charpy tester Impact velocity 2.9 m/s - ambient temperature 20 °C humidity 40% |  |

| Hardness testing | Shore D type durometer ambient temperature 20 °C humidity 40% |  |

| Experiment No. | Cmat, Euro | Ce, Euro | Cp, Euro | Cpa, Euro |

|---|---|---|---|---|

| 1 | 0.35 | 0.18 | 0.52 | 0.54 |

| 2 | 0.41 | 0.22 | 0.62 | 0.64 |

| 3 | 0.47 | 0.20 | 0.67 | 0.69 |

| 4 | 0.36 | 0.14 | 0.50 | 0.52 |

| 5 | 0.42 | 0.16 | 0.58 | 0.60 |

| 6 | 0.47 | 0.15 | 0.63 | 0.65 |

| 7 | 0.38 | 0.12 | 0.50 | 0.52 |

| 8 | 0.43 | 0.14 | 0.56 | 0.58 |

| 9 | 0.48 | 0.13 | 0.61 | 0.63 |

| Experiment No. | Cmat, Euro | Ce, Euro | Cp, Euro |

|---|---|---|---|

| 1 | 0.29 | 0.21 | 0.50 |

| 2 | 0.34 | 0.26 | 0.60 |

| 3 | 0.39 | 0.26 | 0.64 |

| 4 | 0.29 | 0.16 | 0.45 |

| 5 | 0.34 | 0.19 | 0.52 |

| 6 | 0.38 | 0.18 | 0.57 |

| 7 | 0.31 | 0.13 | 0.44 |

| 8 | 0.35 | 0.15 | 0.50 |

| 9 | 0.48 | 0.13 | 0.61 |

| Experiment No. | Difference, % | ||

|---|---|---|---|

| Ultimate Tensile Strength | Cp | Vi/Cp | |

| 1 | 25.82 | 3.56 | 21.50 |

| 2 | 36.25 | 2.99 | 32.29 |

| 3 | 31.04 | 2.79 | 27.48 |

| 4 | 15.80 | 3.71 | 11.65 |

| 5 | 24.01 | 3.22 | 20.15 |

| 6 | 19.91 | 2.97 | 16.45 |

| 7 | 15.52 | 3.74 | 11.35 |

| 8 | 18.47 | 3.31 | 14.67 |

| 9 | 17.00 | 3.07 | 13.51 |

| Experiment No. | Cmat, Euro | Ce, Euro | Cp, Euro | Cpa, Euro |

|---|---|---|---|---|

| 1 | 0.05 | 0.04 | 0.09 | 0.11 |

| 2 | 0.06 | 0.04 | 0.10 | 0.12 |

| 3 | 0.07 | 0.04 | 0.11 | 0.12 |

| 4 | 0.05 | 0.03 | 0.08 | 0.10 |

| 5 | 0.06 | 0.03 | 0.09 | 0.11 |

| 6 | 0.07 | 0.03 | 0.09 | 0.11 |

| 7 | 0.05 | 0.02 | 0.07 | 0.09 |

| 8 | 0.06 | 0.02 | 0.08 | 0.10 |

| 9 | 0.07 | 0.02 | 0.09 | 0.11 |

| Experiment No. | Cmat, Euro | Ce, Euro | Cp, Euro |

|---|---|---|---|

| 1 | 0.04 | 0.04 | 0.08 |

| 2 | 0.05 | 0.05 | 0.10 |

| 3 | 0.05 | 0.05 | 0.10 |

| 4 | 0.04 | 0.03 | 0.07 |

| 5 | 0.05 | 0.03 | 0.08 |

| 6 | 0.05 | 0.03 | 0.09 |

| 7 | 0.04 | 0.02 | 0.06 |

| 8 | 0.05 | 0.03 | 0.07 |

| 9 | 0.05 | 0.03 | 0.08 |

| Experiment no. | Difference, % | ||

|---|---|---|---|

| Compressive Stress | Cp | Vi/Cp | |

| 1 | 5.78 | 20.84 | −14.24 |

| 2 | 9.36 | 18.04 | −7.93 |

| 3 | −5.88 | 17.74 | −25.10 |

| 4 | 13.84 | 23.33 | −8.34 |

| 5 | 13.60 | 20.57 | −6.14 |

| 6 | 13.02 | 19.98 | −6.16 |

| 7 | 13.07 | 25.52 | −11.01 |

| 8 | 9.72 | 22.25 | −11.42 |

| 9 | 10.29 | 20.57 | −9.33 |

| Experiment No. | Cmat, Euro | Ce, Euro | Cp, Euro | Cpa, Euro |

|---|---|---|---|---|

| 1 | 0.12 | 0.05 | 0.17 | 0.19 |

| 2 | 0.13 | 0.06 | 0.19 | 0.21 |

| 3 | 0.13 | 0.06 | 0.19 | 0.21 |

| 4 | 0.12 | 0.04 | 0.17 | 0.18 |

| 5 | 0.13 | 0.05 | 0.18 | 0.19 |

| 6 | 0.13 | 0.05 | 0.18 | 0.20 |

| 7 | 0.13 | 0.04 | 0.16 | 0.18 |

| 8 | 0.13 | 0.04 | 0.17 | 0.19 |

| 9 | 0.13 | 0.04 | 0.17 | 0.19 |

| Experiment No. | Cmat, Euro | Ce, Euro | Cp, Euro |

|---|---|---|---|

| 1 | 0.09 | 0.06 | 0.15 |

| 2 | 0.10 | 0.08 | 0.17 |

| 3 | 0.11 | 0.08 | 0.18 |

| 4 | 0.09 | 0.05 | 0.14 |

| 5 | 0.10 | 0.06 | 0.15 |

| 6 | 0.11 | 0.06 | 0.16 |

| 7 | 0.09 | 0.04 | 0.13 |

| 8 | 0.10 | 0.05 | 0.14 |

| 9 | 0.11 | 0.05 | 0.15 |

| Experiment No. | Difference, % | ||

|---|---|---|---|

| Flexural Strength | Cp | Vi/Cp | |

| 1 | 9.88 | 10.93 | −0.95 |

| 2 | 11.66 | 9.91 | 1.59 |

| 3 | 8.10 | 9.57 | −1.34 |

| 4 | 16.37 | 11.29 | 4.57 |

| 5 | 2.12 | 10.61 | −7.68 |

| 6 | 10.20 | 10.36 | −0.14 |

| 7 | 16.72 | 11.55 | 4.63 |

| 8 | 8.05 | 11.17 | −2.81 |

| 9 | 15.23 | 10.89 | 3.92 |

| Experiment No. | Cmat, Euro | Ce, Euro | Cp, Euro | Cpa, Euro |

|---|---|---|---|---|

| 1 | 0.11 | 0.06 | 0.16 | 0.18 |

| 2 | 0.12 | 0.07 | 0.19 | 0.21 |

| 3 | 0.13 | 0.06 | 0.19 | 0.21 |

| 4 | 0.11 | 0.04 | 0.15 | 0.17 |

| 5 | 0.12 | 0.05 | 0.17 | 0.19 |

| 6 | 0.13 | 0.05 | 0.18 | 0.20 |

| 7 | 0.12 | 0.04 | 0.15 | 0.17 |

| 8 | 0.13 | 0.04 | 0.17 | 0.18 |

| 9 | 0.14 | 0.04 | 0.18 | 0.19 |

| Experiment No. | Cmat, Euro | Ce, Euro | Cp, Euro |

|---|---|---|---|

| 1 | 0.09 | 0.06 | 0.15 |

| 2 | 0.10 | 0.08 | 0.18 |

| 3 | 0.11 | 0.08 | 0.19 |

| 4 | 0.09 | 0.05 | 0.14 |

| 5 | 0.10 | 0.06 | 0.16 |

| 6 | 0.11 | 0.06 | 0.17 |

| 7 | 0.09 | 0.04 | 0.13 |

| 8 | 0.10 | 0.05 | 0.15 |

| 9 | 0.11 | 0.05 | 0.16 |

| Experiment No. | Difference, % | ||

|---|---|---|---|

| Impact Energy | Cp | Vi/Cp | |

| 1 | 125.08 | 11.43 | 101.99 |

| 2 | 157.63 | 10.02 | 134.17 |

| 3 | 181.30 | 9.67 | 156.49 |

| 4 | 114.11 | 12.07 | 91.05 |

| 5 | 213.64 | 10.84 | 182.96 |

| 6 | 283.73 | 10.37 | 247.66 |

| 7 | 148.98 | 12.11 | 122.09 |

| 8 | 152.84 | 11.23 | 127.32 |

| 9 | 238.83 | 10.63 | 206.27 |

| Experiment No. | Cmat, Euro | Ce, Euro | Cp, Euro | Cpa, Euro |

|---|---|---|---|---|

| 1 | 0.35 | 0.18 | 0.52 | 0.54 |

| 2 | 0.41 | 0.22 | 0.62 | 0.64 |

| 3 | 0.05 | 0.20 | 0.25 | 0.69 |

| 4 | 0.36 | 0.14 | 0.50 | 0.52 |

| 5 | 0.42 | 0.16 | 0.58 | 0.60 |

| 6 | 0.47 | 0.15 | 0.63 | 0.65 |

| 7 | 0.38 | 0.12 | 0.50 | 0.52 |

| 8 | 0.43 | 0.14 | 0.56 | 0.58 |

| 9 | 0.48 | 0.13 | 0.61 | 0.63 |

| Experiment No. | Cmat, Euro | Ce, Euro | Cp, Euro |

|---|---|---|---|

| 1 | 0.29 | 0.21 | 0.50 |

| 2 | 0.34 | 0.26 | 0.60 |

| 3 | 0.39 | 0.26 | 0.64 |

| 4 | 0.29 | 0.16 | 0.45 |

| 5 | 0.34 | 0.19 | 0.52 |

| 6 | 0.38 | 0.18 | 0.57 |

| 7 | 0.31 | 0.13 | 0.44 |

| 8 | 0.35 | 0.15 | 0.50 |

| 9 | 0.39 | 0.15 | 0.55 |

| Experiment No. | Difference, % | ||

|---|---|---|---|

| Shore D Hardness | Cp | Vi/Cp | |

| 1 | −5.08 | 3.56 | −8.34 |

| 2 | −7.23 | 2.99 | −9.92 |

| 3 | −9.73 | 2.79 | −12.17 |

| 4 | −8.71 | 3.71 | −11.98 |

| 5 | −12.86 | 3.22 | −15.57 |

| 6 | −12.73 | 2.97 | −15.25 |

| 7 | −6.49 | 3.74 | −9.86 |

| 8 | −6.82 | 3.31 | −9.80 |

| 9 | −8.38 | 3.07 | −11.11 |

| Response, Vi/Cp | Goal | Lower | Target | Weight | Importance | ||||

|---|---|---|---|---|---|---|---|---|---|

| PLA | PLA A | ABS | PLA | PLA A | ABS | ||||

| Hardness, [Shore D hardness/Euro] | Maximum | 125.37 | 110.111 | 91.73 | 171.92 | 151.33 | 140.94 | 1 | 1 |

| Impact, [J/Euro] | 0.40 | 0.889 | 1.32 | 0.50 | 1.56 | 2.08 | |||

| Flexural, [MPa/Euro] | 553.49 | 546.066 | 363.17 | 653.72 | 673.24 | 486.46 | |||

| Compression, [MPa/Euro] | 386.33 | 338.179 | 268.93 | 678.70 | 635.11 | 653.83 | |||

| Tensile, [MPa/Euro] | 42.26 | 53.132 | 27.06 | 63.82 | 74.32 | 62.35 | |||

| Printing Parameters | Material | ||||||

|---|---|---|---|---|---|---|---|

| PLA | PLA A | ABS | |||||

| Layer Thickness, mm | Infill Percentage, % | Composite Desirability | Rank | Composite Desirability | Rank | Composite Desirability | Rank |

| 0.10 | 50 | 0.0092 | 7 | 0.0000 | 9 | 0.0000 | 7 |

| 75 | 0.0000 | 9 | 0.2664 | 5 | 0.0252 | 6 | |

| 100 | 0.0000 | 9 | 0.0002 | 7 | 0.0000 | 7 | |

| 0.15 | 50 | 0.3302 | 6 | 0.2528 | 6 | 0.3840 | 4 |

| 75 | 0.4318 | 4 | 0.3681 | 3 | 0.0000 | 7 | |

| 100 | 0.6026 | 1 * | 0.6121 | 2 | 0.6187 | 1 * | |

| 0.20 | 50 | 0.4298 | 5 | 0.0000 | 9 | 0.5058 | 2 |

| 75 | 0.5093 | 3 | 0.3209 | 4 | 0.4674 | 3 | |

| 100 | 0.5909 | 2 | 0.6213 | 1 * | 0.3690 | 5 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zisopol, D.G.; Tănase, M.; Portoacă, A.I. Innovative Strategies for Technical-Economical Optimization of FDM Production. Polymers 2023, 15, 3787. https://doi.org/10.3390/polym15183787

Zisopol DG, Tănase M, Portoacă AI. Innovative Strategies for Technical-Economical Optimization of FDM Production. Polymers. 2023; 15(18):3787. https://doi.org/10.3390/polym15183787

Chicago/Turabian StyleZisopol, Dragoș Gabriel, Maria Tănase, and Alexandra Ileana Portoacă. 2023. "Innovative Strategies for Technical-Economical Optimization of FDM Production" Polymers 15, no. 18: 3787. https://doi.org/10.3390/polym15183787

APA StyleZisopol, D. G., Tănase, M., & Portoacă, A. I. (2023). Innovative Strategies for Technical-Economical Optimization of FDM Production. Polymers, 15(18), 3787. https://doi.org/10.3390/polym15183787