Microstructure and Tensile Properties of Melt-Spun Filaments of Polybutene-1 and Butene-1/Ethylene Copolymer

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

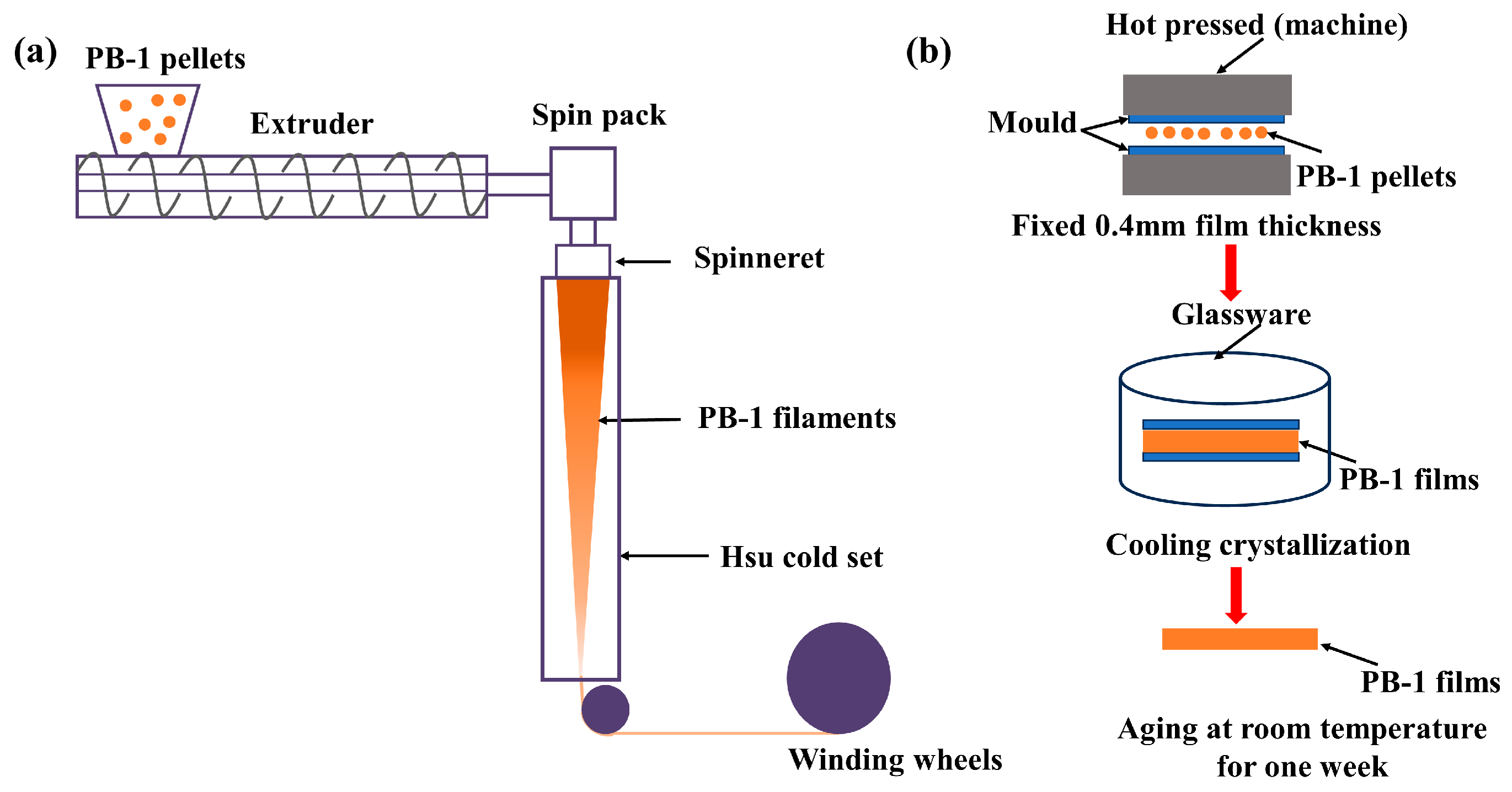

2.2. Preparation of Filaments and Films

2.3. Characterizations

3. Results and Discussion

3.1. Surface Morphology Characterization

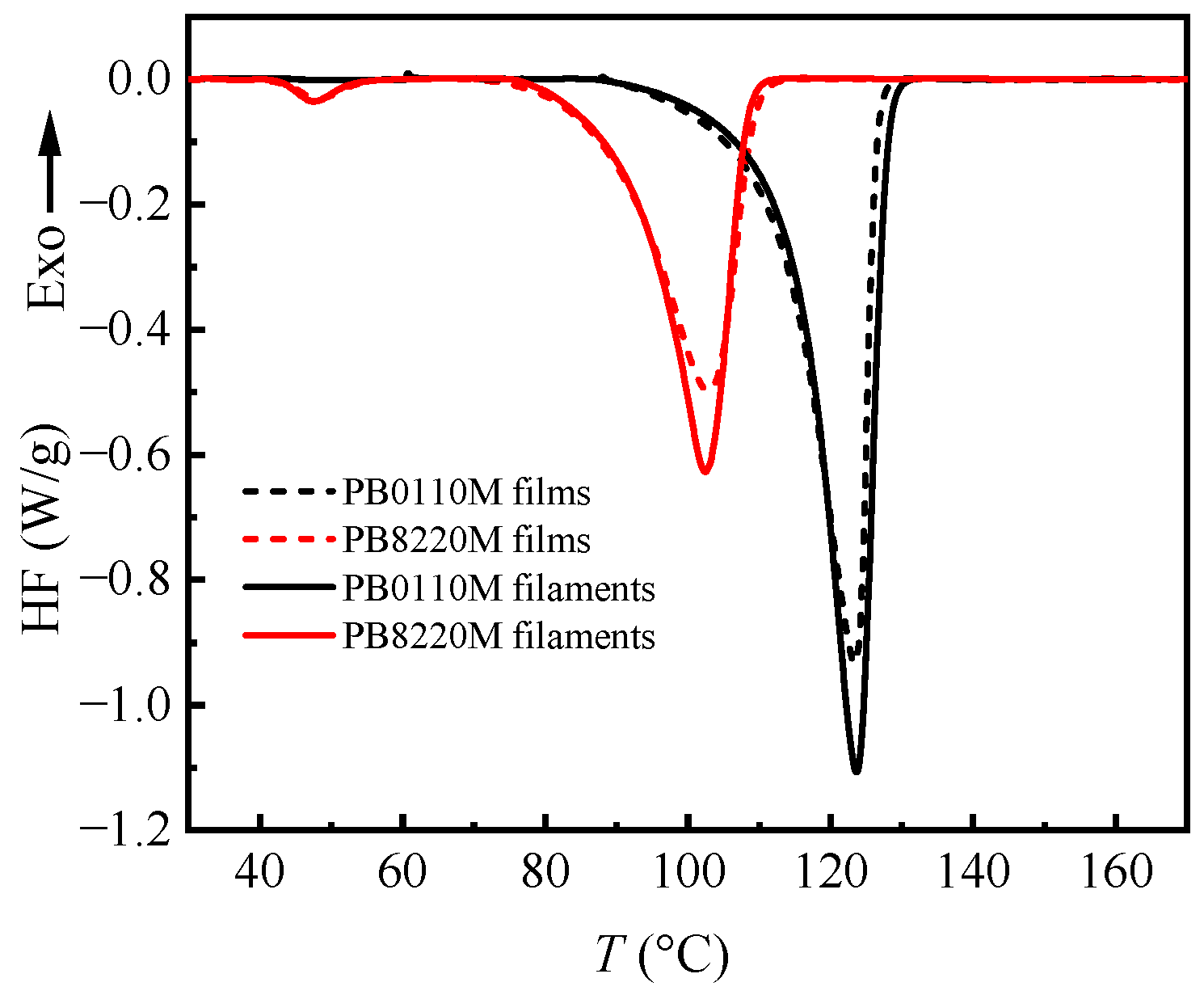

3.2. Thermal Analysis

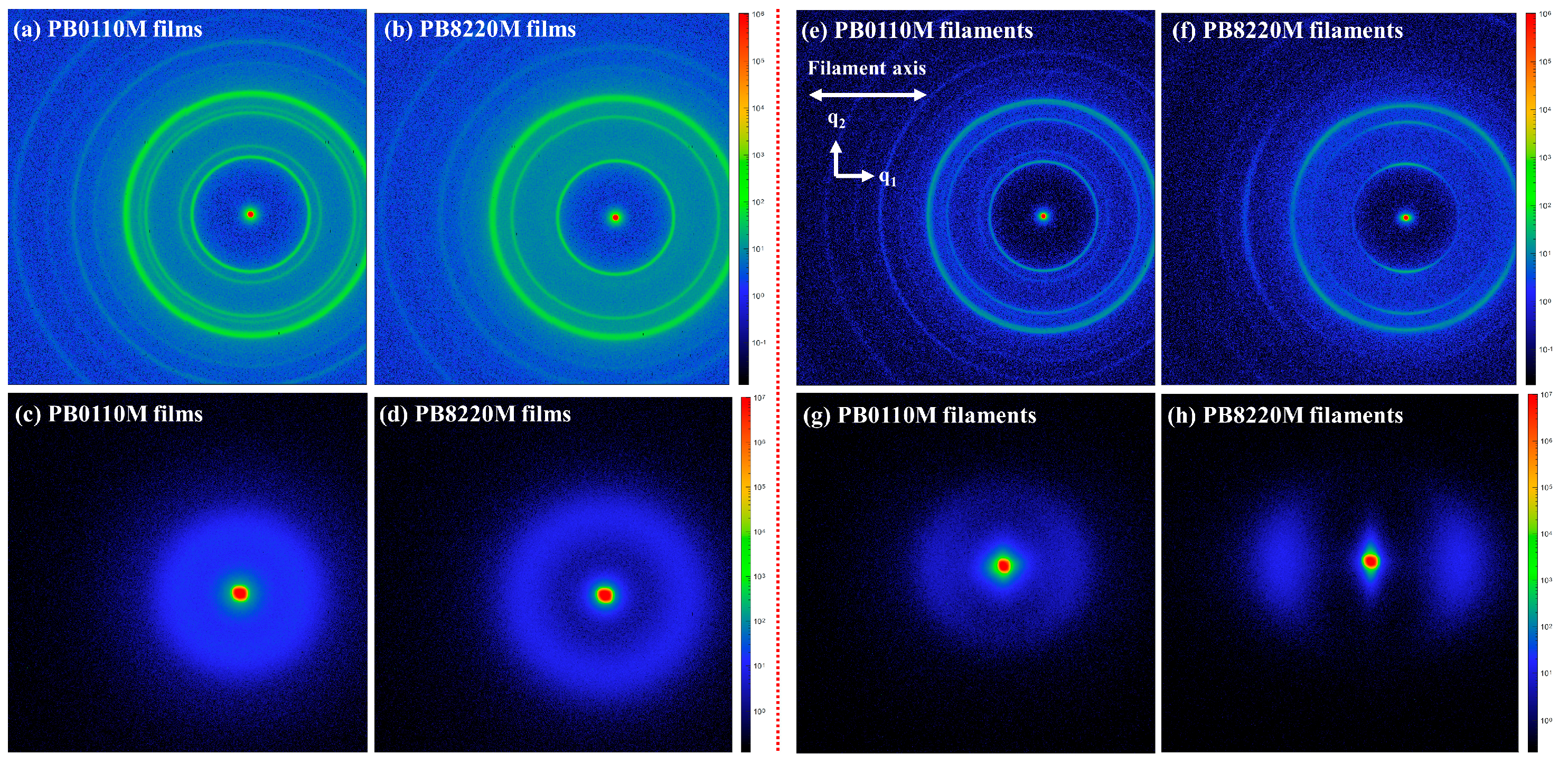

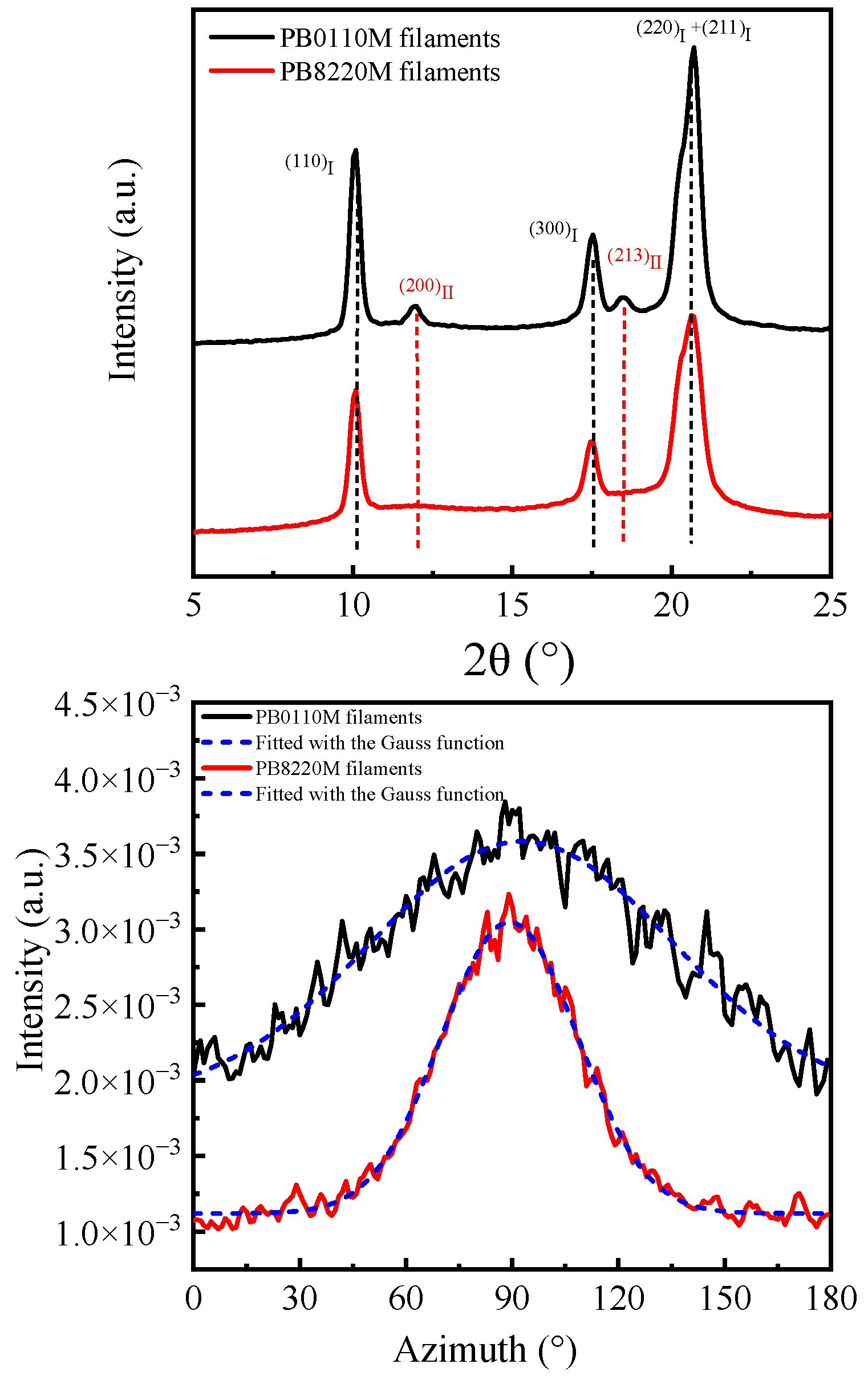

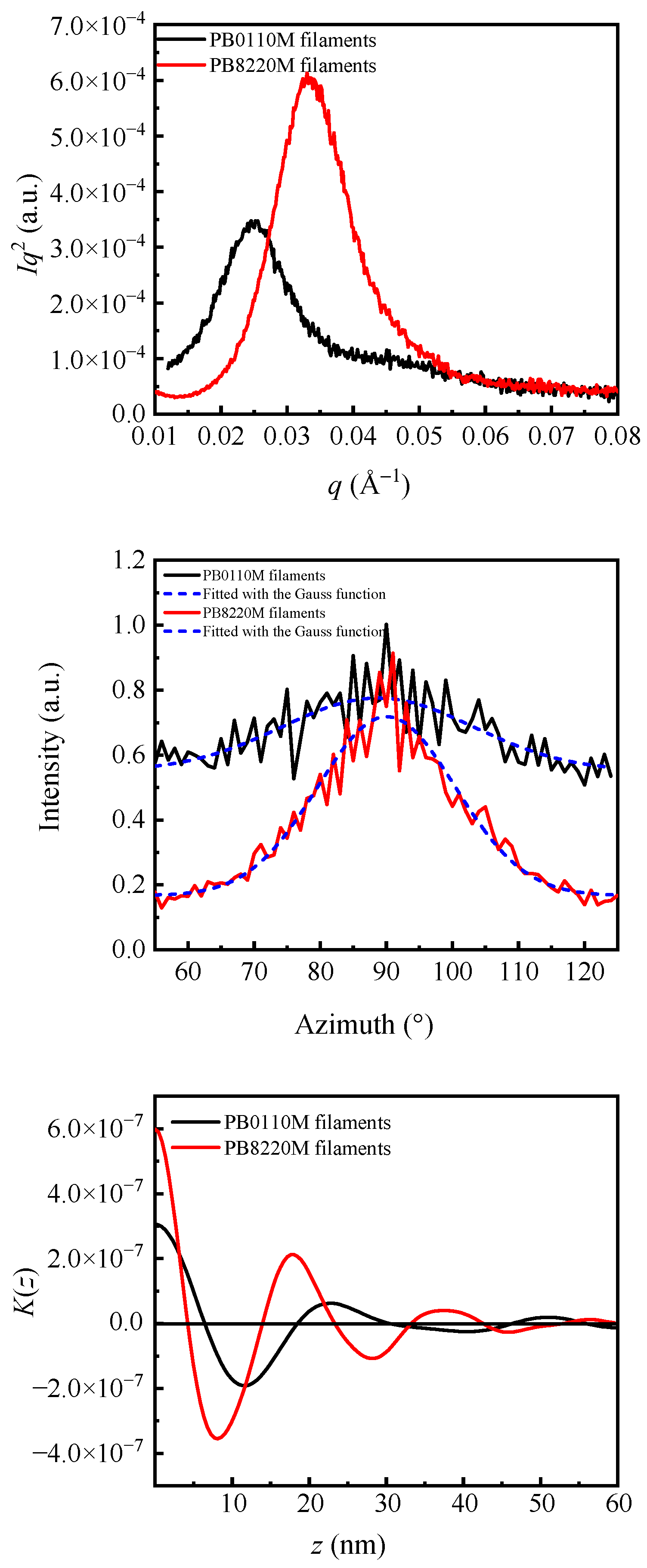

3.3. Microstructure Characterization

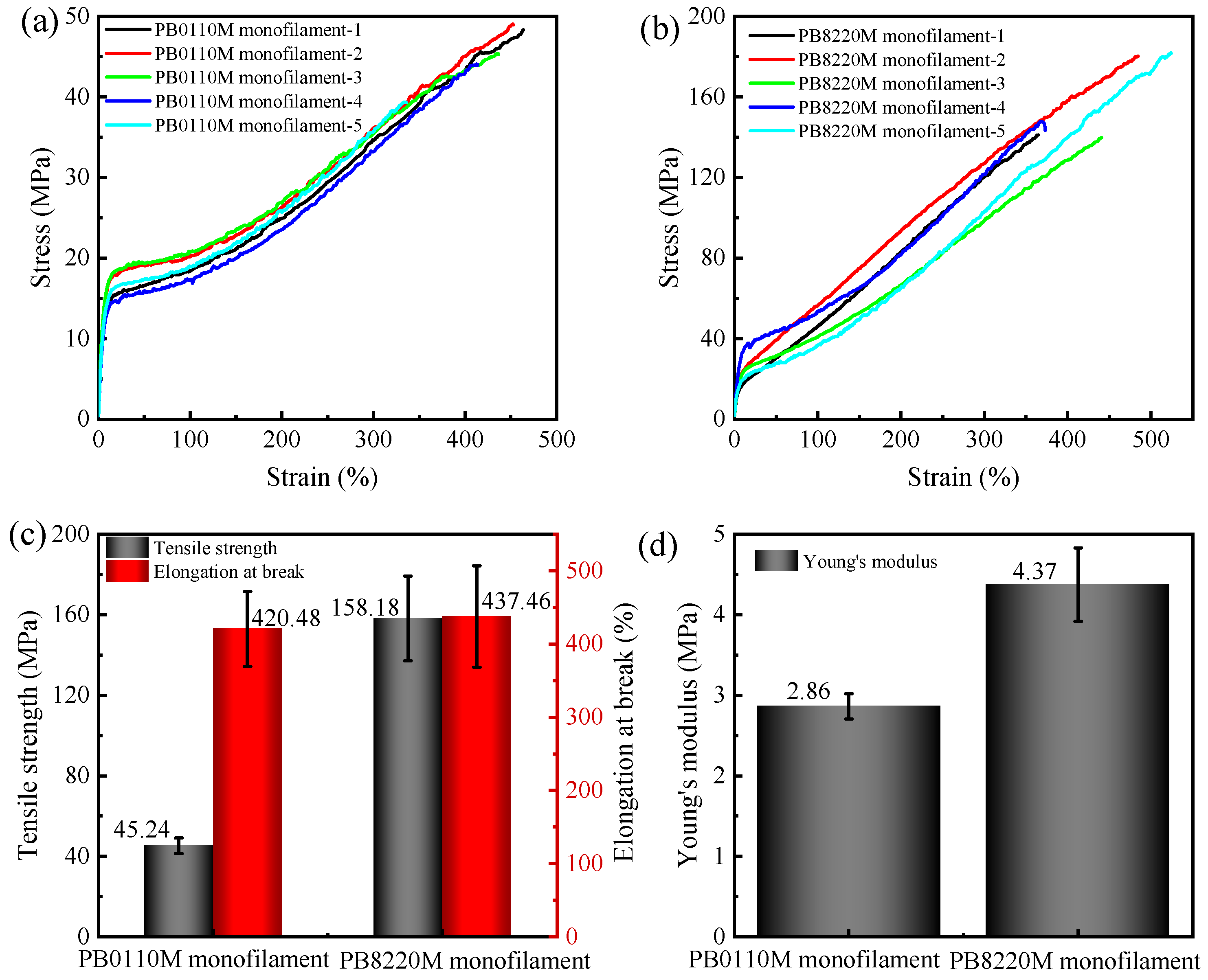

3.4. Mechanical Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Gleissner, C.; Landsiedel, J.; Bechtold, T.; Pham, T. Surface activation of high performance polymer fibers: A review. Polym. Rev. 2022, 62, 757–788. [Google Scholar] [CrossRef]

- Baye, B.; Tesfaye, T. The new generation fibers: A review of high performance and specialty fibers. Polym. Bull. 2022, 79, 9221–9235. [Google Scholar] [CrossRef]

- Wang, W.; Zhou, B.; Xu, S.; Yang, Z.; Zhang, Q. Recent advances in soft optical glass fiber and fiber lasers. Prog. Mater. Sci. 2019, 101, 90–171. [Google Scholar] [CrossRef]

- Hearle, J.; Greer, R. Fibre Structure; Textile Progress; Textile Institute: Manchester, UK, 1970; Volume 2, pp. 1–187. [Google Scholar] [CrossRef]

- Gajjar, C.; Stallrich, J.; Pasquinelli, M.; King, M. Process-Property relationships for melt-spun poly(lactic acid) yarn. ACS Omega 2021, 6, 15920–15928. [Google Scholar] [CrossRef]

- Luciani, L.; Seppala, J.; Lofgren, B. Poly-1-buten—Its preparation, properties and challenges. Prog. Polym. Sci. 1988, 13, 37–62. [Google Scholar] [CrossRef]

- Miller, R.; Holland, V. On transformations in isotactic polybutene-1. J. Polym. Sci. Part B-Polym. Lett. 1964, 2, 519–521. [Google Scholar] [CrossRef]

- Boor, J.; Youngman, E. Polymorphism in poly-1-butene—Apparent direct formation of modification I. J. Polym. Sci. Part B-Polym. Lett. 1964, 2, 903–907. [Google Scholar] [CrossRef]

- Jones, A.; Aizlewood, J. Crystalline forms of polypentene-1. J. Polym. Sci. Part B-Polym. Lett. 1963, 1, 471–476. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, P.; Lu, Y.; Men, Y. Mechanism of polymorph selection during crystallization of random butene-1/ethylene copolymer. Chin. J. Polym. Sci. 2016, 34, 1014–1020. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, Y.; Zhao, J.; Jiang, Z.; Men, Y. Direct formation of different crystalline forms in butene-1/ethylene copolymer via manipulating melt temperature. Macromolecules 2014, 47, 8653–8662. [Google Scholar] [CrossRef]

- Jones, A. Polybutene-1—Type II crystalline form. J. Polym. Sci. Part B-Polym. Lett. 1963, 1, 455–456. [Google Scholar] [CrossRef]

- Natta, G.; Corradini, P.; Bassi, I. Crystal structure of isotactic poly-alpha-butene. Nuovo C. 1960, 15, 52–67. [Google Scholar] [CrossRef]

- Rubin, I. Relative stabilities of polymorphs of polybutene-1 obtained from melt. J. Polym. Sci. Part B-Polym. Lett. 1964, 2, 747–749. [Google Scholar] [CrossRef]

- Liu, Y.; Cui, K.; Tian, N.; Zhou, W.; Meng, L.; Li, L.; Ma, Z.; Wang, X. Stretch-induced crystal–crystal transition of polybutene-1: An in situ synchrotron radiation wide-angle x-ray scattering study. Macromolecules 2012, 45, 2764–2772. [Google Scholar] [CrossRef]

- Tanaka, A.; Sugimoto, N.; Asada, T.; Onogi, S. Orientation and crystal transformation in polybutene-1 under stress relaxation. Polym. J. 1975, 7, 529–537. [Google Scholar] [CrossRef]

- Chen, W.; Li, X.; Li, H.; Su, F.; Zhou, W.; Li, L. Deformation-induced crystal–crystal transition of polybutene-1: An in situ FTIR imaging study. J. Mater. Sci. 2013, 48, 4925–4933. [Google Scholar] [CrossRef]

- Cavallo, D.; Kanters, M.; Caelers, H.; Portale, G.; Govaert, L. Kinetics of the polymorphic transition in isotactic poly(1-butene) under uniaxial extension. New insights from designed mechanical histories. Macromolecules 2014, 47, 3033–3040. [Google Scholar] [CrossRef]

- Zheng, L.; Liu, L.; Shao, C.; Wang, W.; Wang, B.; Pan, L.; Li, Y.; Ma, Z. Phase transition from tetragonal form II to hexagonal form i of butene-1/4-methyl-1-pentene random copolymers: Molecular factor versus stretching stimuli. Macromolecules 2019, 52, 1188–1199. [Google Scholar] [CrossRef]

- Wang, W.; Zheng, L.; Liu, L.; Li, W.; Li, Y.; Ma, Z. Stretching behavior of the butene-1/ethylene random copolymer: A direct correspondence between triggering of II-I phase transition and mechanical yielding. Polym. Cryst. 2019, 2, e10052. [Google Scholar] [CrossRef]

- Nakafuku, C.; Miyaki, T. Effect of pressure on the melting and crystallization behavior of isotactic polybutene-1. Polymer 1983, 24, 141–148. [Google Scholar] [CrossRef]

- Li, L.; Liu, T.; Zhao, L.; Yuan, W. CO2-Induced crystal phase transition from form II to I in isotactic poly-1-butene. Macromolecules 2009, 42, 2286–2290. [Google Scholar] [CrossRef]

- Shi, J.; Wu, P.; Li, L.; Liu, T.; Zhao, L. Crystalline transformation of isotactic polybutene-1 in supercritical CO2 studied by in-situ fourier transform infrared spectroscopy. Polymer 2009, 50, 5598–5604. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, T.; Li, L.; Li, D.; Yuan, W.; Zhao, L. Controlling crystal phase transition from form II to I in isotactic poly-1-butene using CO2. Polymer 2012, 53, 6102–6111. [Google Scholar] [CrossRef]

- An, C.; Lou, Y.; Li, Y.; Wang, B.; Pan, L.; Ma, Z.; Li, Y. Unusual II-I phase transition behavior of polybutene-1 lonomers in the presence of long-chain branch and ionic functional groups. Macromolecules 2019, 52, 4634–4645. [Google Scholar] [CrossRef]

- Jones, A. Cocrystallization in copolymers of α-olefins II—Butene-1 copolymers and polybutene type II/I crystal phase transition. Polymer 1966, 7, 23–59. [Google Scholar] [CrossRef]

- Lou, Y.; Liao, Y.; Pan, L.; Wang, B.; Li, Y.; Ma, Z. Effect of linear and ring-like co-units on the temperature dependence of nucleation and growth in II-I phase transition of butene-1 copolymers. Chin. J. Polym. Sci. 2018, 36, 1269–1276. [Google Scholar] [CrossRef]

- Wang, W.; Shao, C.; Zheng, L.; Wang, B.; Pan, L.; Ma, G.; Li, Y.; Wang, Y.; Liu, C.; Ma, Z. Stretching-induced phase transition of the butene-1/ethylene random copolymer: Orientation and kinetics. J. Polym. Sci. Part B-Polym. Phys. 2019, 57, 116–126. [Google Scholar] [CrossRef]

- Hufenus, R.; Yan, Y.; Dauner, M.; Kikutani, T. Melt-spun fibers for textile applications. Materials 2020, 13, 4298. [Google Scholar] [CrossRef]

- Choi, C.; White, J. Comparative study of structure development in melt spinning polyolefin fibers. Int. Polym. Process. 1998, 13, 78–87. [Google Scholar] [CrossRef]

- Samon, J.; Schultz, J.; Hsiao, B.; Wu, J.; Khot, S. Structure development during melt spinning and subsequent annealing of polybutene-1 fibers. J. Polym. Sci. Part B-Polym. Phys. 2000, 38, 1872–1882. [Google Scholar] [CrossRef]

- Samon, J.; Schultz, J.; Hsiao, B. Morphological changes during the annealing of polybutene-1 fiber. Macromolecules 2001, 34, 2008–2011. [Google Scholar] [CrossRef]

- Ortiz, D.; Robert, L. Melt-spun polybutylene fibers and nonwovens. Int. Nonwovens J. 2005, 14, 36–54. [Google Scholar] [CrossRef]

- Lee, K.; Givens, S.; Snively, C.; Chase, B.; Rabolt, J. Crystallization behavior of electrospun PB/PMP blend fibrous membranes. Macromolecules 2008, 41, 3144–3148. [Google Scholar] [CrossRef]

- An, C.; Li, Y.; Lou, Y.; Song, D.; Wang, B.; Pan, L.; Ma, Z.; Li, Y. Thermal analysis of crystallization and phase transition in novel polyethylene glycol grafted butene-1 copolymers. Polymers 2019, 11, 837. [Google Scholar] [CrossRef]

- He, L.; Wang, B.; Yang, F.; Li, Y.; Ma, Z. Featured crystallization polymorphism and memory effect in novel butene-1/1,5-hexadiene copolymers synthesized by post-metallocene hafnium catalyst. Macromolecules 2016, 49, 6578–6589. [Google Scholar] [CrossRef]

- Mani, M.; Gebrekrstos, A.; Madras, G.; Potschke, P.; Bose, S. PVDF-MWNT interactions control process induced beta-lamellar morphology and orientation in the nanocomposites. Phys. Chem. Chem. Phys. 2018, 20, 24821–24831. [Google Scholar] [CrossRef]

- ASTM D 3822/D 3822 M-14; Standard Test Method for Tensile Properties of Single Textile Fibers. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D 882-18; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. ASTM International: West Conshohocken, PA, USA, 2018.

- Wang, L.; Pai, C.; Boyce, M.; Rutledge, G. Wrinkled surface topographies of electrospun polymer fibers. Appl. Phys. Lett. 2009, 94, 151916. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, D.; Xu, L.; Sun, Y.; Xu, M. Influence of carbon fiber morphology structure on electrochemical oxidation behaviors and interfacial properties of its composites. Acta Mater. Compos. Sin. 2015, 32, 1218–1224. [Google Scholar] [CrossRef]

- Flory, P. Thermodynamics of crystallization in high polymers. 4. a theory of crystalline states and fusion in polymers, copolymers, and their mixtures with diluents. J. Chem. Phys. 1949, 17, 223–240. [Google Scholar] [CrossRef]

- Qiao, Y.; Schulz, M.; Wang, H.; Chen, R.; Schäfer, M.; Thurn-Albrecht, T.; Men, Y. Hierarchical structure of polybutene-1 in crystal blocks resulting from the form II to I solid-to-solid transition as revealed by small-angle X-ray scattering. Polymer 2020, 195, 122425. [Google Scholar] [CrossRef]

- Sun, F.; Guo, J.; Li, Y.; Bai, S.; Wang, Q. Preparation of high-performance polyethylene tubes under the coexistence of silicone cross-linked polyethylene and rotation extrusion. R. Soc. Open Sci. 2019, 6, 182095. [Google Scholar] [CrossRef]

- Zhao, X.; Chen, F.; Li, Y.; Lu, H.; Zhang, N.; Ma, M. Bioinspired ultra-stretchable and anti-freezing conductive hydrogel fibers with ordered and reversible polymer chain alignment. Nat. Commun. 2018, 9, 3579. [Google Scholar] [CrossRef] [PubMed]

- An, M.; Xu, H.; Lv, Y.; Gu, Q.; Tian, F.; Wang, Z. An in situ small-angle X-ray scattering study of the structural effects of temperature and draw ratio of the hot-drawing process on ultra-high molecular weight polyethylene fibers. RSC Adv. 2016, 6, 51125–51134. [Google Scholar] [CrossRef]

- Tian, Y.; Zhu, C.; Gong, J.; Ma, J.; Xu, J. Transition from shish-kebab to fibrillar crystals during ultra-high hot stretching of ultra-high molecular weight polyethylene fibers: In situ small and wide angle X-ray scattering studies. Eur. Polym. J. 2015, 73, 127–136. [Google Scholar] [CrossRef]

- Nakamura, K.; Aoike, T.; Usaka, K.; Kanamoto, T. Phase transformation in poly(1-butene) upon drawing. Macromolecules 1999, 32, 4975–4982. [Google Scholar] [CrossRef]

- Qiao, Y.; Wang, H.; Men, Y. Retardance of form II to form I transition in polybutene-1 at late stage: A proposal of a new mechanism. Macromolecules 2018, 51, 2232–2239. [Google Scholar] [CrossRef]

- Qiao, Y.; Yang, F.; Lu, Y.; Liu, P.; Li, Y.; Men, Y. Spontaneous form II to I transition in low molar mass polybutene-1 at crystallization temperature reveals stabilization role of intercrystalline links and entanglements for metastable form II crystals. Macromolecules 2018, 51, 8298–8305. [Google Scholar] [CrossRef]

- De Rosa, C.; de Ballesteros, O.; Auriemma, F.; Di Girolamo, R.; Scarica, C.; Giusto, G.; Esposito, S.; Guidotti, S.; Camurati, I. Polymorphic behavior and mechanical properties of isotactic 1-butene-ethylene copolymers from metallocene catalysts. Macromolecules 2014, 47, 4317–4329. [Google Scholar] [CrossRef]

- Zhang, H.; Li, J.; Guo, Y.; Tian, F.; Qiao, Y.; Tang, Z.; Zhu, C.; Xu, J. Orientation evaluation of ultra-high molecular weight polyethylene fibers: Previous studies and an improved method. J. Appl. Crystallogr. 2022, 55, 876–881. [Google Scholar] [CrossRef]

- Wang, H.; Quan, J.; Wang, X.; Yu, J.; Zhu, J.; Wang, Y.; Hu, Z. The effect of shrinkage on the structure and properties of ultra-high molecular weight polyethylene fibers with different concentration. J. Appl. Polym. Sci. 2021, 138, 50198. [Google Scholar] [CrossRef]

- Kyu, T.; Vadhar, P. Cocrystallization and miscibility studies of blends of ultrahigh molecular-weight polyethylene with conventional polyethylenes. J. Appl. Polym. Sci. 1986, 32, 5575–5584. [Google Scholar] [CrossRef]

- Zherebtsov, D.; Chukov, D.; Statnik, E.; Torokhov, V. Hybrid self-reinforced composite materials based on ultra-high molecular weight polyethylene. Materials 2020, 13, 1739. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Bin, Y.; Wang, H.; Ge, Z. Rheological properties of UHMWPE/HDPE blend gels and morphology and mechanical properties of gel-spun fibers. Polym. Eng. Sci. 2021, 61, 2127–2136. [Google Scholar] [CrossRef]

| Samples * | Tm/°C | Crystallinity/% |

|---|---|---|

| PB0110M films | 122.95 ± 0.86 | 52.19 ± 1.43 |

| PB8220M films | 101.31 ± 1.39 | 36.46 ± 1.05 |

| PB0110M filaments | 123.67 ± 0.09 | 56.91 ± 1.63 |

| PB8220M filaments | 102.38 ± 0.58 | 39.15 ± 0.45 |

| Samples | WAXD Orientation along (110) | SAXS Orientation along q2 | Long Spacing | Lamellar Thickness | Amorphous Layers | ||

|---|---|---|---|---|---|---|---|

| FWHM (°) | π (%) | FWHM (°) | π (%) | dac (nm) | dc (nm) | da (nm) | |

| PB0110M films | - | - | - | - | 22.58 | 15.37 | 7.21 |

| PB8220M films | - | - | - | - | 17.61 | 6.28 | 11.33 |

| PB0110M filaments | 100.47 | 44.18 | 34.05 | 81.08 | 22.68 | 13.37 | 9.31 |

| PB8220M filaments | 45.38 | 74.79 | 24.57 | 86.35 | 17.82 | 6.20 | 11.62 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Qiao, Y.; Zhang, H.; Zheng, Y.; Tang, Z.; Zeng, Z.; Yao, P.; Bao, F.; Liu, H.; Yu, J.; et al. Microstructure and Tensile Properties of Melt-Spun Filaments of Polybutene-1 and Butene-1/Ethylene Copolymer. Polymers 2023, 15, 3729. https://doi.org/10.3390/polym15183729

Li J, Qiao Y, Zhang H, Zheng Y, Tang Z, Zeng Z, Yao P, Bao F, Liu H, Yu J, et al. Microstructure and Tensile Properties of Melt-Spun Filaments of Polybutene-1 and Butene-1/Ethylene Copolymer. Polymers. 2023; 15(18):3729. https://doi.org/10.3390/polym15183729

Chicago/Turabian StyleLi, Jianrong, Yongna Qiao, Hao Zhang, Yifei Zheng, Zheng Tang, Zhenye Zeng, Pingping Yao, Feng Bao, Huichao Liu, Jiali Yu, and et al. 2023. "Microstructure and Tensile Properties of Melt-Spun Filaments of Polybutene-1 and Butene-1/Ethylene Copolymer" Polymers 15, no. 18: 3729. https://doi.org/10.3390/polym15183729

APA StyleLi, J., Qiao, Y., Zhang, H., Zheng, Y., Tang, Z., Zeng, Z., Yao, P., Bao, F., Liu, H., Yu, J., Zhu, C., & Xu, J. (2023). Microstructure and Tensile Properties of Melt-Spun Filaments of Polybutene-1 and Butene-1/Ethylene Copolymer. Polymers, 15(18), 3729. https://doi.org/10.3390/polym15183729