Construction of Multifunctional Hierarchical Biofilms for Highly Sensitive and Weather-Resistant Fire Warning

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Measurements

2.3. Preparation of LCNFs

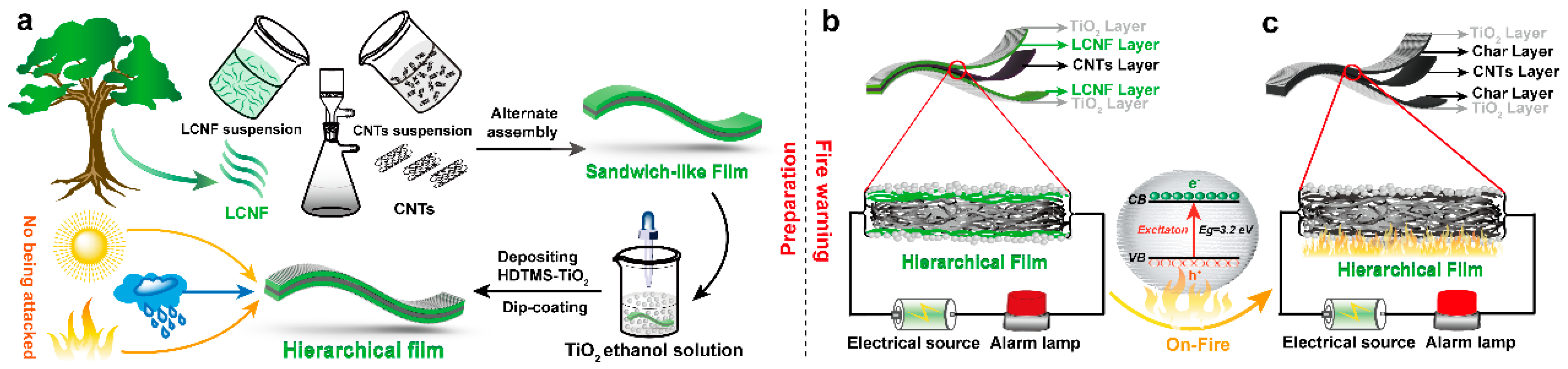

2.4. Preparation of the Hierarchical Films

3. Results and Discussion

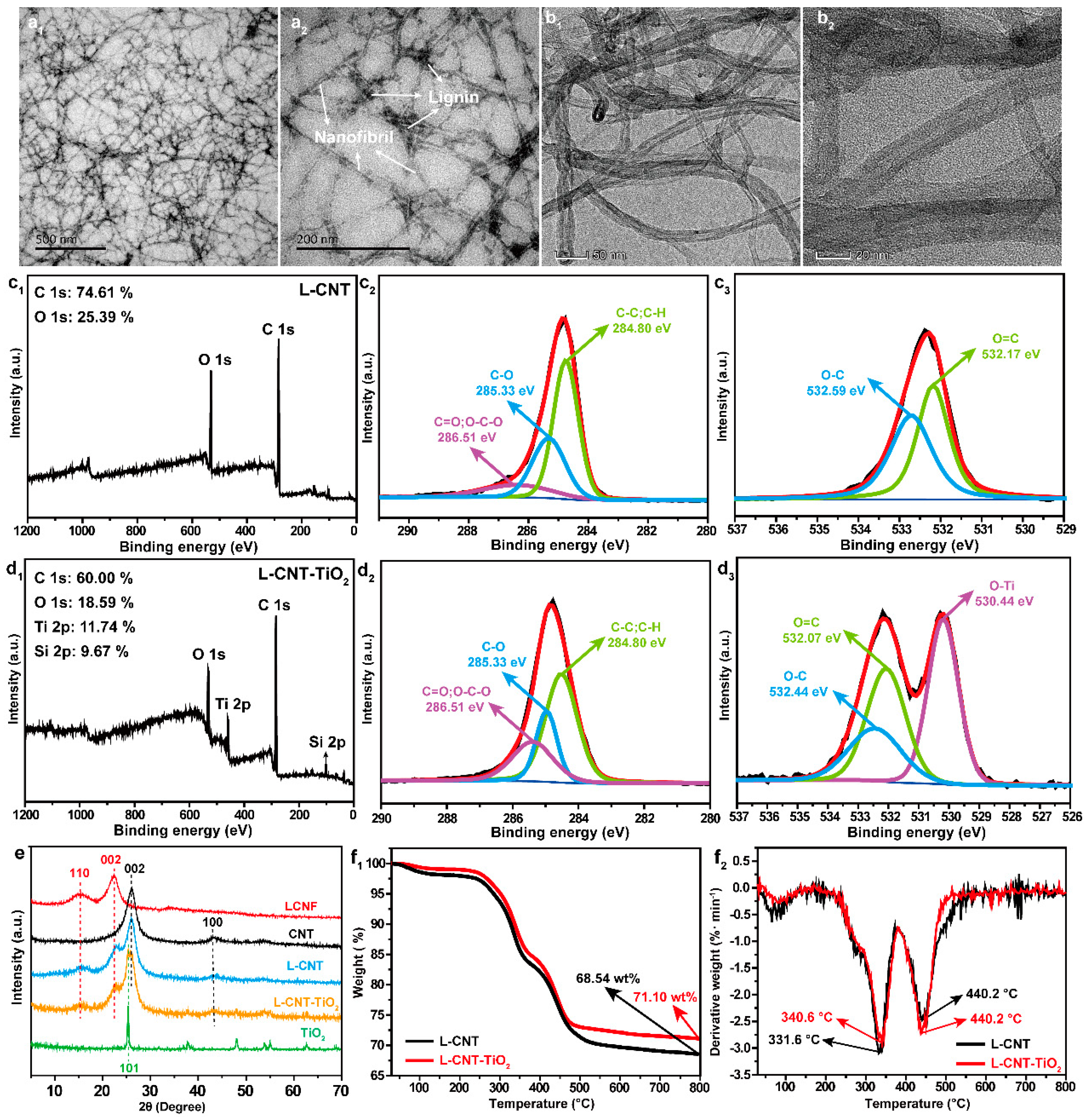

3.1. Structure and Thermal Stability Characterizations

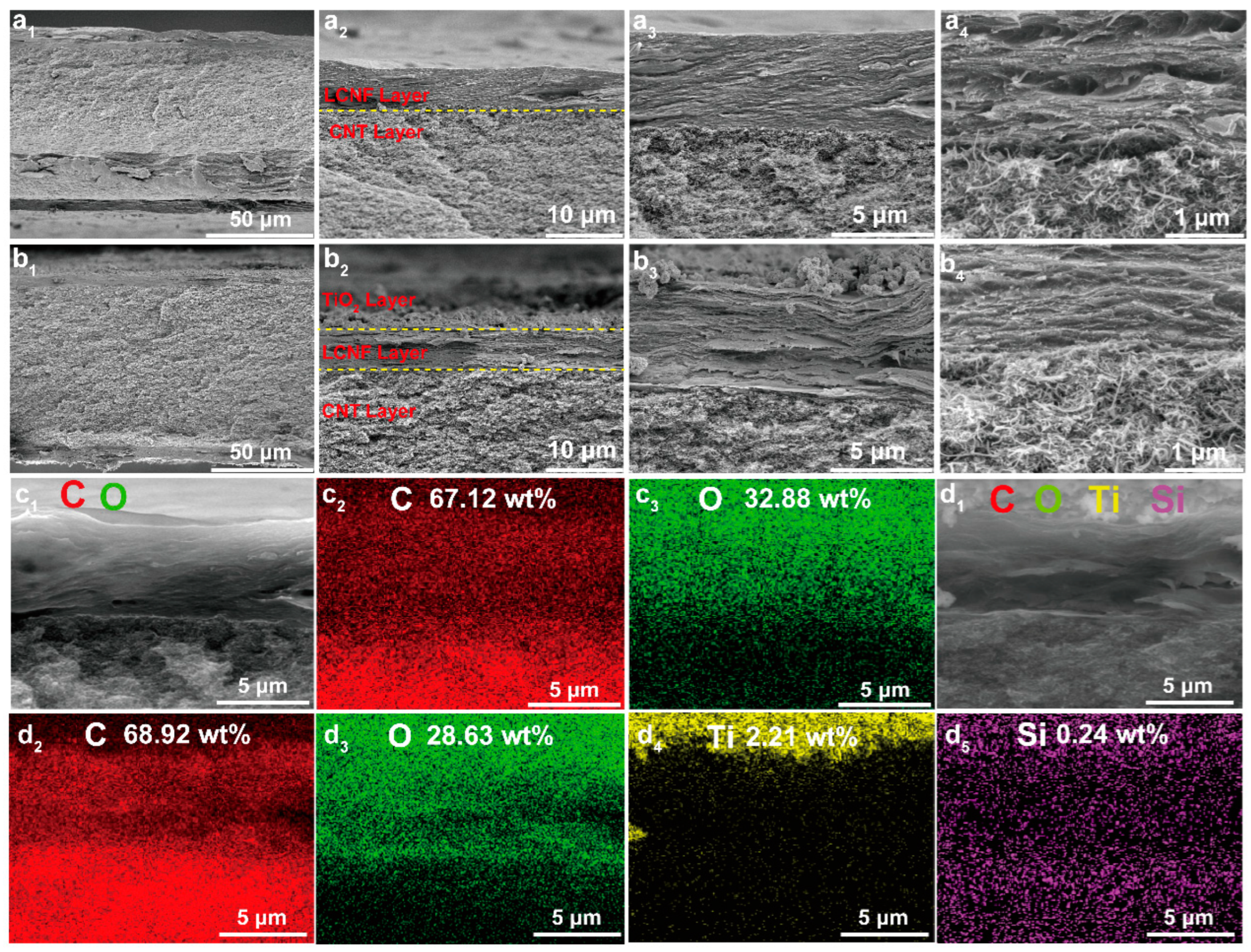

3.2. Surface and Cross-Section Morphology Observations

3.3. Early Fire-Warning and Flame Resistance Behaviors

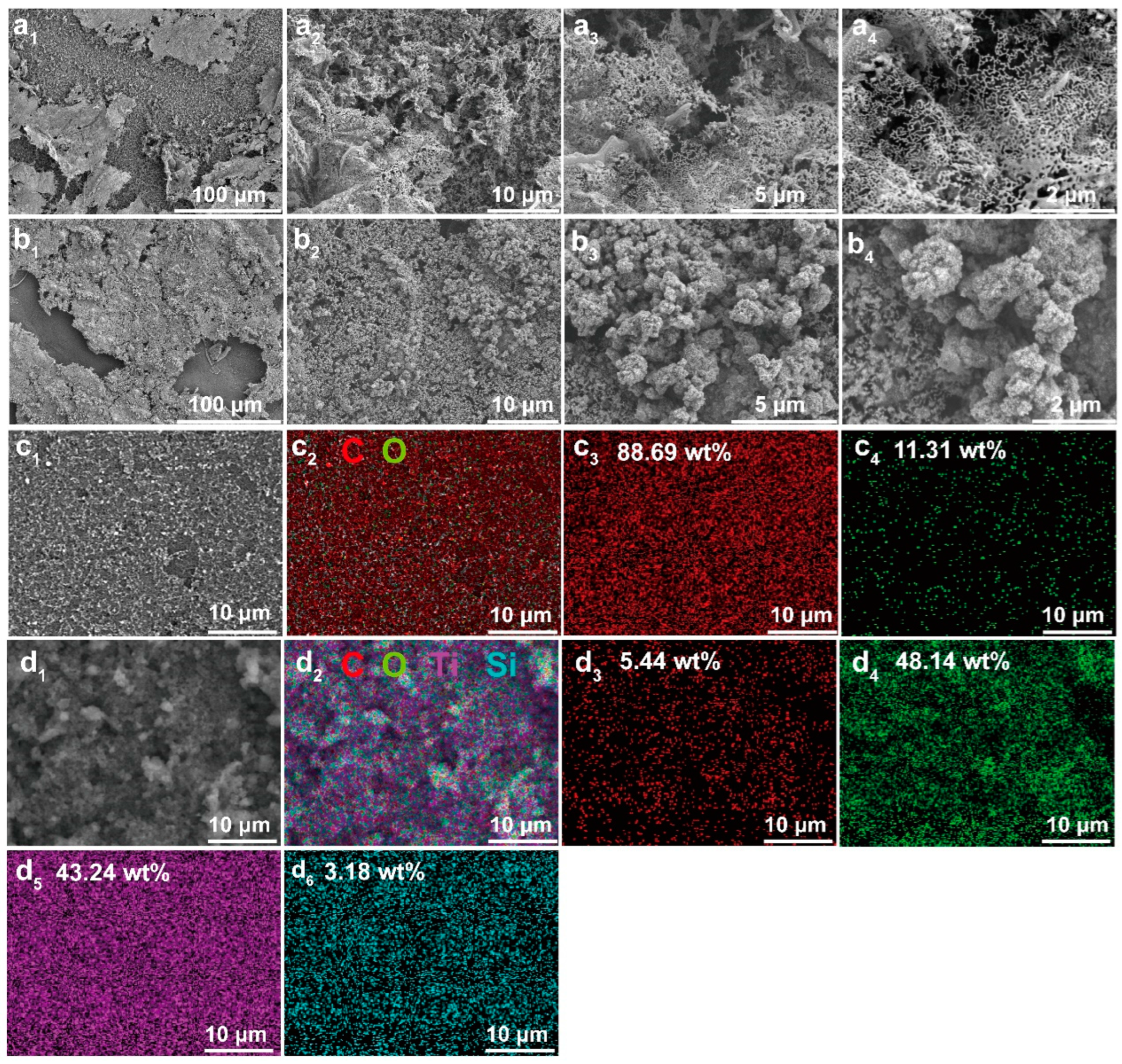

3.4. Residual Char Structures and Enhanced Mechanism

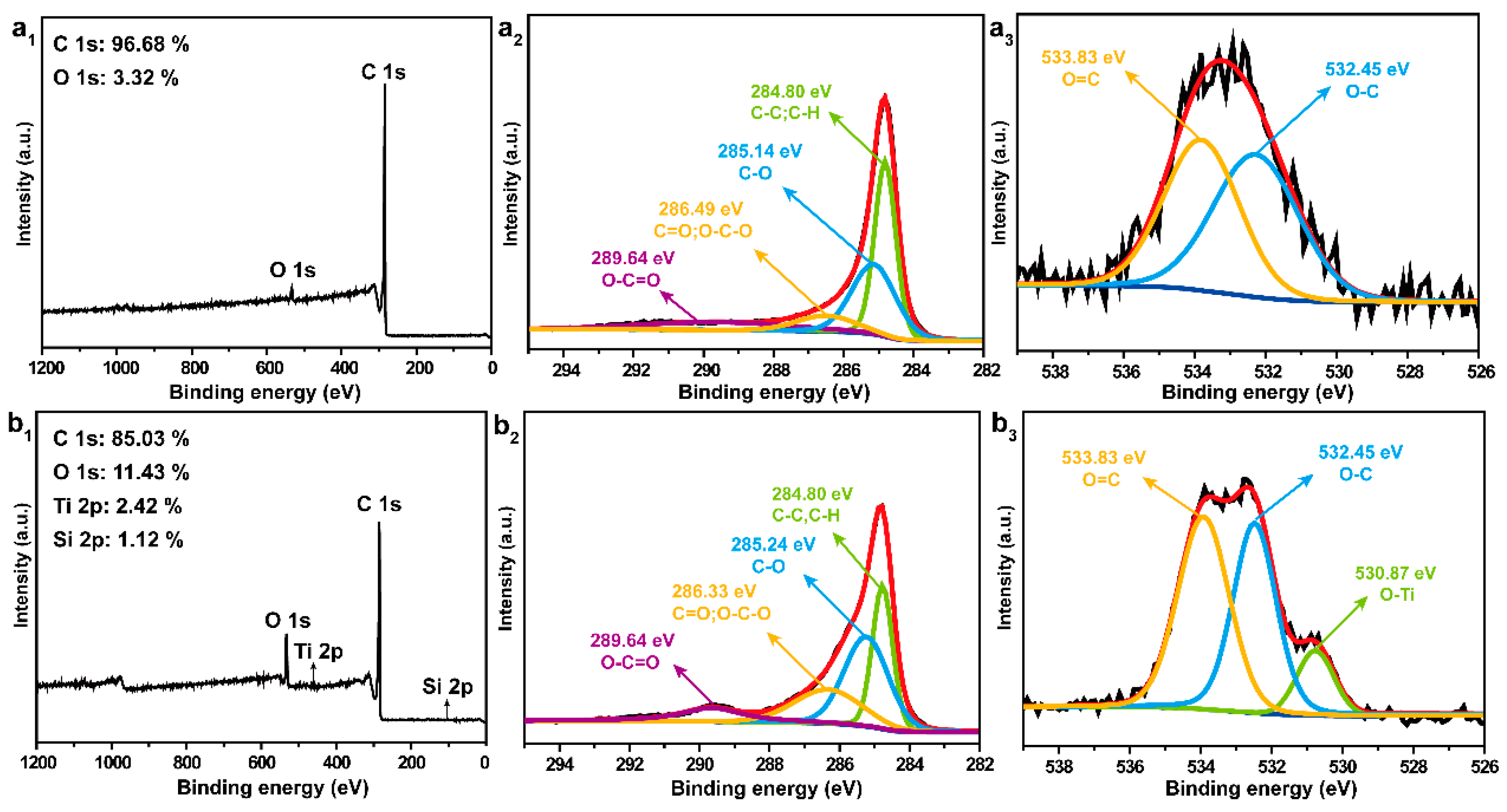

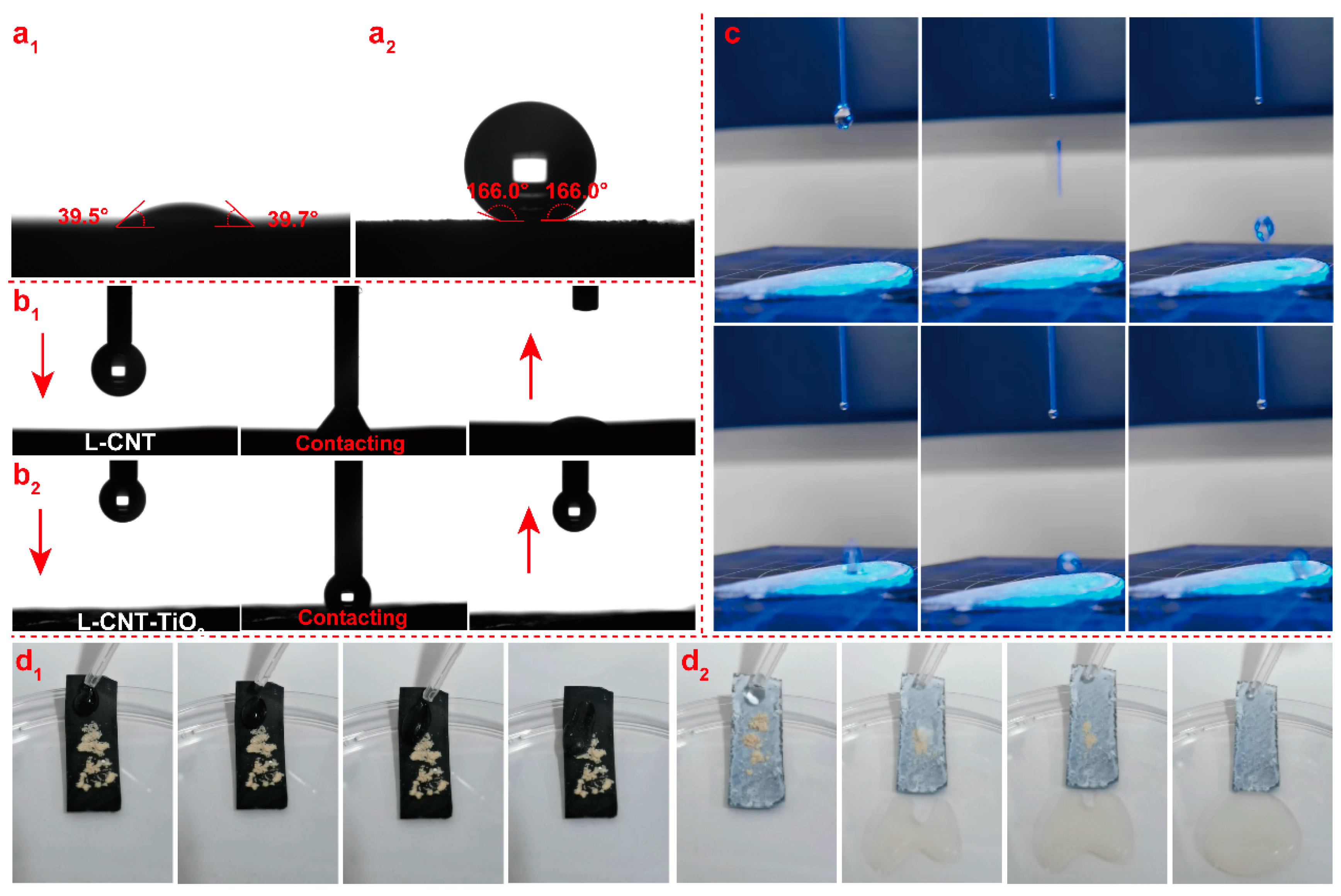

3.5. Characterization of Superhydrophobic and UV Resistance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, L.; Feng, J.; Xue, Y.; Chevali, V.; Zhang, Y.; Shi, Y.; Tang, L.C.; Song, P. 2D MXenes for fire retardancy and fire-warning applications: Promises and prospects. Adv. Funct. Mater. 2023, 33, 2212124. [Google Scholar] [CrossRef]

- He, X.; Feng, Y.; Xu, F.; Chen, F.-F.; Yu, Y. Smart fire alarm systems for rapid early fire warning: Advances and challenges. Chem. Eng. J. 2022, 450, 137927. [Google Scholar] [CrossRef]

- Zhang, Z.-H.; Zhang, J.-W.; Cao, C.-F.; Guo, K.-Y.; Zhao, L.; Zhang, G.-D.; Gao, J.-F.; Tang, L.-C. Temperature-responsive resistance sensitivity controlled by L-ascorbic acid and silane co-functionalization in flame-retardant GO network for efficient fire early-warning response. Chem. Eng. J. 2020, 386, 123894. [Google Scholar] [CrossRef]

- Huang, N.-J.; Xia, Q.-Q.; Zhang, Z.-H.; Zhao, L.; Zhang, G.-D.; Gao, J.-F.; Tang, L.-C. Simultaneous improvements in fire resistance and alarm response of GO paper via one-step 3-mercaptopropyltrimethoxysilane functionalization for efficient fire safety and prevention. Compos. Part A-Appl. Sci. Manuf. 2020, 131, 105797. [Google Scholar] [CrossRef]

- Ma, T.; Zhou, Q.; Li, L.; Pan, M.; Guo, C.; Mei, C. Nacre-inspired intumescent flame retardant bridging network for intelligent fire warning and prevention. Chem. Eng. J. 2023, 468, 143786. [Google Scholar] [CrossRef]

- Zhu, Y.B.; Kong, G.; Che, C.S. Thermally-induced self-cutting surfaced reduced graphene oxide fibers for smart fire alarm. Colloids Surf. A 2023, 675, 132032. [Google Scholar] [CrossRef]

- Mao, M.; Xu, H.; Guo, K.-Y.; Zhang, J.-W.; Xia, Q.-Q.; Zhang, G.-D.; Zhao, L.; Gao, J.-F.; Tang, L.-C. Mechanically flexible, super-hydrophobic and flame-retardant hybrid nano-silica/graphene oxide wide ribbon decorated sponges for efficient oil/water separation and fire warning response. Compos. Part A-Appl. Sci. Manuf. 2021, 140, 106191. [Google Scholar] [CrossRef]

- Wang, K.; Wu, K.; Qu, Z.; Wu, Y.; Jiao, E.; Zheng, X.; Shi, J. Flame-Retardant and Alarm-Sensitive composite films by covalent modification of MWCNT with dopamine. Eur. Polym. J. 2022, 164, 110986. [Google Scholar] [CrossRef]

- Mao, M.; Yu, K.-X.; Cao, C.-F.; Gong, L.-X.; Zhang, G.-D.; Zhao, L.; Song, P.; Gao, J.-F.; Tang, L.-C. Facile and green fabrication of flame-retardant Ti3C2Tx MXene networks for ultrafast, reusable and weather-resistant fire warning. Chem. Eng. J. 2022, 427, 131615. [Google Scholar] [CrossRef]

- Guo, K.-Y.; Wu, Q.; Mao, M.; Chen, H.; Zhang, G.-D.; Zhao, L.; Gao, J.-F.; Song, P.; Tang, L.-C. Water-based hybrid coatings toward mechanically flexible, super-hydrophobic and flame-retardant polyurethane foam nanocomposites with high-efficiency and reliable fire alarm response. Compos. Part B-Eng. 2020, 193, 108017. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, J.; Liu, L.; Zheng, H.; Dai, J.; Tang, L.-C.; Song, P. A highly fire-retardant rigid polyurethane foam capable of fire-warning. Compos. Commun. 2022, 29, 101046. [Google Scholar] [CrossRef]

- Lv, L.-Y.; Cao, C.-F.; Qu, Y.-X.; Zhang, G.-D.; Zhao, L.; Cao, K.; Song, P.; Tang, L.-C. Smart fire-warning materials and sensors: Design principle, performances, and applications. Mat. Sci. Eng. R. 2022, 150, 100690. [Google Scholar] [CrossRef]

- Chen, W.; Liu, P.; Liu, Y.; Wang, Q.; Duan, W. A temperature-induced conductive coating via layer-by-layer assembly of functionalized graphene oxide and carbon nanotubes for a flexible, adjustable response time flame sensor. Chem. Eng. J. 2018, 353, 115–125. [Google Scholar] [CrossRef]

- De Volder, M.F.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon nanotubes: Present and future commercial applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef] [PubMed]

- Xia, L.; Lv, Y.; Miao, Z.; Luo, L.; Luo, W.; Xu, Y.; Yuan, C.; Zeng, B.; Dai, L. A flame retardant fabric nanocoating based on nanocarbon black particles@ polymer composite and its fire-alarm application. Chem. Eng. J. 2022, 433, 133501. [Google Scholar] [CrossRef]

- Yang, N.; Yuan, R.; You, D.; Zhang, Q.; Yang, R.; Wang, J.; Cheng, Q.; Ge, L. Dual fire-alarm LBL safeguarding coatings with flame-retardant, EMI shielding and antibacterial properties. Colloids Surf. A 2022, 643, 128763. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, W.; Liu, P.; Liu, Y.; Liu, Z. A multifunctional polyurethane sponge based on functionalized graphene oxide and carbon nanotubes for highly sensitive and super durable fire alarming. Compos. Part A-Appl. Sci. Manuf. 2021, 150, 106598. [Google Scholar] [CrossRef]

- Ren, Y.; Ling, Z.; Cheng, Z.; Wang, B.; Huang, C.; Lai, C.; Yong, Q. Grafting natural nicotinamide on tempo-oxidized cellulose nanofibrils to prepare flexible and transparent nanocomposite films with fascinating mechanical strength and UV shielding performance. Int. J. Biol. Macromol. 2022, 223, 1633–1640. [Google Scholar] [CrossRef]

- Zeng, Q.; Zhou, H.; Huang, J.; Guo, Z. Review on the recent development of durable superhydrophobic materials for practical applications. Nanoscale 2021, 13, 11734–11764. [Google Scholar] [CrossRef]

- Sun, L.; Fang, K.; Chen, W.; Liu, K.; Zhu, J.; Zhang, C. Fabrication of a novel superhydrophobic cotton by HDTMS with TiO2 supported activated carbon nanocomposites for photocatalysis and oil/water separation. Ind. Crop. Prod. 2022, 189, 115836. [Google Scholar] [CrossRef]

- Zhu, Y.; Lu, Y.; Yu, H.; Jiang, G.; Zhao, X.; Gao, C.; Xue, L. Super-hydrophobic F-TiO2@ PP membranes with nano-scale “coral”-like synapses for waste oil recovery. Sep. Purif. Technol. 2021, 267, 118579. [Google Scholar] [CrossRef]

- Chen, Z.; Su, X.; Wu, W.; Chen, S.; Zhang, X.; Wu, Y.; Xie, H.; Li, K. Superhydrophobic PDMS@TiO2 wood for photocatalytic degradation and rapid oil-water separation. Surf. Coat. Technol. 2022, 434, 128182. [Google Scholar] [CrossRef]

- Zhang, N.; Hu, R.; Wang, Y.; Zhang, E.; Zhou, Y.; Dong, S.; Wu, C. Surface-functionalized mesoporous nanoparticles as heterogeneous supports to transfer bifunctional catalysts into organic solvents for tandem catalysis. ACS Appl. Nano Mater. 2018, 1, 6378–6386. [Google Scholar] [CrossRef]

- Yang, J.; He, T.; Li, X.; Wang, R.; Wang, S.; Zhao, Y.; Wang, H. Rapid dipping preparation of superhydrophobic TiO2 cotton fabric for multifunctional highly efficient oil-water separation and photocatalytic degradation. Colloids Surf. A 2023, 657, 130590. [Google Scholar] [CrossRef]

- Wan, J.; Xu, J.; Zhu, S.; Li, J.; Wang, B.; Zeng, J.; Li, J.; Chen, K. Eco-Friendly Superhydrophobic Composites with Thermostability, UV Resistance, and Coating Transparency. ACS Appl. Mater. Interfaces 2021, 13, 61681–61692. [Google Scholar] [CrossRef]

- Liu, Y.; Li, W.; Li, K.; Annamalai, P.K.; Pratt, S.; Hassanpour, M.; Lu, H.; Zhang, Z. Tailored production of lignin-containing cellulose nanofibrils from sugarcane bagasse pretreated by acid-catalyzed alcohol solutions. Carbohyd. Polym. 2022, 291, 119602. [Google Scholar] [CrossRef]

- Dong, L.; Hu, C.; Song, L.; Huang, X.; Chen, N.; Qu, L. A large-area, flexible, and flame-retardant graphene paper. Adv. Funct. Mater. 2016, 26, 1470–1476. [Google Scholar] [CrossRef]

- Ma, T.; Li, L.; Pan, M.; Guo, C.; Mei, C. Multifunctional MXene-based fire alarm wallpaper with sandwich-like structure for enhanced fire safety and prevention. Chem. Eng. J. 2023, 451, 138517. [Google Scholar] [CrossRef]

- Mansfield, E.; Kar, A.; Hooker, S.A. Applications of TGA in quality control of SWCNTs. Anal. Bioanal. Chem. 2010, 396, 1071–1077. [Google Scholar] [CrossRef]

- Yousefi, S.Z.; Tabatabaei-Panah, P.-S.; Seyfi, J. Emphasizing the role of surface chemistry on hydrophobicity and cell adhesion behavior of polydimethylsiloxane/TiO2 nanocomposite films. Colloids Surf. B 2018, 167, 492–498. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Liu, J.; Zhao, Y.; Qin, Y.; Zhu, Z.; Yu, Z.; He, H. Temperature-triggered fire warning PEG@wood powder/carbon nanotube/calcium alginate composite aerogel and the application for firefighting clothing. Compos. Part B-Eng. 2022, 247, 110348. [Google Scholar] [CrossRef]

- Zhao, T.; Teng, D.; Xu, Y.; Zhang, X.; Li, Y.; Zeng, Y. Multi-functional air filters with excellent flame retardancy and fire-warning capability. J. Colloid Interfaces Sci. 2022, 617, 236–245. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Wang, M.; Zhang, M.; Yang, C.; Li, Y.; Zhang, Y.; Hu, J.; Wu, G. Flexible and thermally induced switchable fire alarm fabric based on layer-by-layer self-assembled silver sheet/Fe3O4 nanowire composite. ACS Appl. Mater. Interfaces 2019, 11, 47456–47467. [Google Scholar] [CrossRef]

- Chen, G.; Yuan, B.; Wang, Y.; Chen, X.; Huang, C.; Shang, S.; Tao, H.; Liu, J.; Sun, W.; Yang, P.; et al. Nacre-biomimetic graphene oxide paper intercalated by phytic acid and its ultrafast fire-alarm application. J. Colloid Interf. Sci. 2020, 578, 412–421. [Google Scholar] [CrossRef]

- Chen, G.; Yuan, B.; Wang, Y.; Shang, S.; Chen, X.; Tao, H.; Zhan, Y. Inhibited combustion of graphene paper by in situ phosphorus doping and its application for fire early-warning sensor. Sens. Actuators A-Phys. 2020, 312, 112111. [Google Scholar] [CrossRef]

- Zuo, B.; Yuan, B. Flame-retardant cellulose nanofiber aerogel modified with graphene oxide and sodium montmorillonite and its fire-alarm application. Polym. Adv. Technol. 2021, 32, 1877–1887. [Google Scholar] [CrossRef]

- Cao, C.-F.; Yu, B.; Guo, B.-F.; Hu, W.-J.; Sun, F.-N.; Zhang, Z.-H.; Li, S.-N.; Wu, W.; Tang, L.-C.; Song, P.; et al. Bio-inspired, sustainable and mechanically robust graphene oxide-based hybrid networks for efficient fire protection and warning. Chem. Eng. J. 2022, 439, 134516. [Google Scholar] [CrossRef]

- Cao, C.-F.; Yu, B.; Chen, Z.-Y.; Qu, Y.-X.; Li, Y.-T.; Shi, Y.-Q.; Ma, Z.-W.; Sun, F.-N.; Pan, Q.-H.; Tang, L.-C.; et al. Mechanically Flexible Graphene Oxide Network for Exceptional Fire Shielding and Ultra-Fast Fire Warning. Nano-Micro Lett. 2022, 14, 92. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, D.; Yang, H.; Li, Y.; Lu, S.; Cai, R.; Tan, W. A hydrophobic sisal cellulose microcrystal film for fire alarm sensors. Nano Lett. 2021, 21, 2104–2110. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Gong, L.-X.; Li, Y.; Cao, C.-F.; Tang, L.-C.; Wu, L.; Zhao, L.; Zhang, G.-D.; Li, S.-N.; Gao, J. Efficient flame detection and early warning sensors on combustible materials using hierarchical graphene oxide/silicone coatings. ACS Nano 2018, 12, 416–424. [Google Scholar] [CrossRef] [PubMed]

- Luo, Z.; Ning, H.; Zhou, X.; Yuan, B. Efficient flame-retardant biomass aerogel endowed with graphene oxide interconnected networks for ultrasensitive fire warning. Mater. Lett. 2022, 318, 132237. [Google Scholar] [CrossRef]

- Chen, B.; Liu, Y.; Wu, K.; Lu, M.; Jiao, E.; Shi, J.; Lu, M. Enhanced thermal conductivity and fire safety of flexible hybrid film via synergistic effects between boron nitride and functionalized graphene. J. Therm. Anal. Calorim. 2022, 147, 4047–4058. [Google Scholar] [CrossRef]

- Song, S.; Zhang, C.; Wang, J.; Li, W.; Jiang, Z.; Zhang, Y. High-performance nacre-like graphene@polymer supported montmorillonite composite actuator and sensor. Sens. Actuators B Chem. 2021, 332, 129446. [Google Scholar] [CrossRef]

- Yang, F.; Yuan, B.; Wang, Y.; Chen, X.; Wang, L.; Zhang, H. Graphene oxide/chitosan nano-coating with ultrafast fire-alarm response and flame-retardant property. Polym. Adv. Technol. 2022, 33, 795–806. [Google Scholar] [CrossRef]

- Cao, C.; Yuan, B. Thermally induced fire early warning aerogel with efficient thermal isolation and flame-retardant properties. Polym. Adv. Technol. 2021, 32, 2159–2168. [Google Scholar] [CrossRef]

- Yuan, B.; Wang, Y.; Chen, G.; Yang, F.; Zhang, H.; Cao, C.; Zuo, B. Nacre-like graphene oxide paper bonded with boric acid for fire early-warning sensor. J. Hazard. Mater. 2021, 403, 123645. [Google Scholar] [CrossRef]

- Jiang, C.; Chen, J.; Lai, X.; Li, H.; Zeng, X.; Zhao, Y.; Zeng, Q.; Gao, J.; Wu, Z.; Qiu, Y. Mechanically robust and multifunctional polyimide/MXene composite aerogel for smart fire protection. Chem. Eng. J. 2022, 434, 134630. [Google Scholar] [CrossRef]

- Zeng, Q.; Wang, B.; Lai, X.; Li, H.; Chen, Z.; Xie, H.; Zeng, X. Multifunctional MXene-coated cotton fabric with enhanced thermopower for smart fire protection. Compos. Part A-Appl. Sci. Manuf. 2023, 164, 107305. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, Y.; Dong, H.; Xu, R.; Jiang, S. Flame-retardant shape memory polyurethane/MXene paper and the application for early fire alarm sensor. Compos. Part B-Eng. 2021, 223, 109149. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; He, X.; Xiang, Z.; Heinze, T.; Qi, H. Lignocellulose nanofibril/gelatin/MXene composite aerogel with fire-warning properties for enhanced electromagnetic interference shielding performance. Chem. Eng. J. 2022, 431, 133907. [Google Scholar] [CrossRef]

- Mao, Y.; Wang, D.; Hu, J.; Fu, S. Mechanically flexible and flame retardant polyphenol-bridged casein/MXene composite for fire proofing repeatable contact/non-contact fire monitoring. Chem. Eng. J. 2023, 454, 140161. [Google Scholar]

- Wang, B.; Lai, X.; Li, H.; Jiang, C.; Gao, J.; Zeng, X. Multifunctional MXene/Chitosan-Coated Cotton Fabric for Intelligent Fire Protection. ACS Appl. Mater. Interfaces 2021, 13, 23020–23029. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Q.; Zhao, Y.; Lai, X.; Jiang, C.; Wang, B.; Li, H.; Zeng, X.; Chen, Z. Skin-inspired multifunctional MXene/cellulose nanocoating for smart and efficient fire protection. Chem. Eng. J. 2022, 446, 136899. [Google Scholar]

- Wang, F.; Pi, J.; Song, F.; Feng, R.; Xu, C.; Wang, X.-L.; Wang, Y.-Z. A superhydrophobic coating to create multi-functional materials with mechanical/chemical/physical robustness. Chem. Eng. J. 2020, 381, 122539. [Google Scholar]

| Composition and Type of Composite Materials a | Sensors | Alarm Trigger Time/s | Fire Duration Time/s | Ref. |

|---|---|---|---|---|

| FRPU@GO/CNTs@BN foam | GO/CNTs | ~8 | >120 | [11] |

| CB@KF/CNT/PVA CF | CNTs | 4 | NM b | [15] |

| CNTs@CCS/PANI@PAA | CNTs | ~1 | NM | [16] |

| GO/DCNT composite films | GO/CNTs | 1 | NM | [8] |

| PEG@wood/CNT/CA aerogel | CNTs | ~2.03 | NM | [31] |

| PAN/CNTs/APP fiber filters | CNTs | 5 | NM | [32] |

| Silver/Fe3O4 nanowire | Silver | 2 | >900 | [33] |

| GO-PTA paper | GO | 0.5 | 283 | [34] |

| GO-PA paper | GO | ~0.5 | 433 | [35] |

| CNF-MMT-GO aerogel | GO | 1.9 | 137 | [36] |

| GO/TA/P-CNF paper | GO | 1 | >120 | [37] |

| GO/HCPA nanocomposite papers | GO | 0.6 | >600 | [38] |

| CNF-MMT-GO aerogel | GO | 1.9 | 138.9 | [36] |

| SPI/MSF/CA/GN film | GN | 1 | 220 | [39] |

| GO/silicone coating | GO | 2~3 | ~90 | [40] |

| SA/HAP/GO aerogel | GO | ~1.5 | >60 | [41] |

| Phosphorylated GO/BNNS film | GO | <2 | 131 | [42] |

| Graphene/SPI/MSF-g-COOH/CA/GN films | Graphene | 1 | >220 | [39] |

| rGO@XNBR/MMT film | GO | <2 | >180 | [43] |

| LAA-MPMS-GO | GO | ~1 | >180 | [3] |

| Chitosan/GO | GO | ~3 | 1280 | [44] |

| CNF-GO/APP agrogel | GO | 2.6 | 129 | [45] |

| BA/GO paper | GO | 0.8 | 205.4 | [46] |

| Polyimide/MXene aerogel | MXene | <5 | >60 | [47] |

| MXene/TA/CaCl2 cotton fabric | MXene | ~3 | NM | [48] |

| MXene/SMPU paper | MXene | 4 s | NM | [49] |

| PVP/PEG-MXene networks | MXene | 1.8 | NM | [9] |

| PLCNF/gelatin/MXene aerogel | MXene | ~1 | NM | [50] |

| CAS/TA/MXene film | MXene | 0.982 | NM | [51] |

| CCS/MXene cotton fabric | MXene | 3.8 | NM | [52] |

| MXene/cellulose nanocoating | MXene | 3.1 | NM | [53] |

| PU/MXene paper | MXene | 11 | NM | [49] |

| L-CNT-TiO2 film | CNTs | ~0.30 | ~1238 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, T.; Zhou, Q.; Liu, C.; Li, L.; Guo, C.; Mei, C. Construction of Multifunctional Hierarchical Biofilms for Highly Sensitive and Weather-Resistant Fire Warning. Polymers 2023, 15, 3666. https://doi.org/10.3390/polym15183666

Ma T, Zhou Q, Liu C, Li L, Guo C, Mei C. Construction of Multifunctional Hierarchical Biofilms for Highly Sensitive and Weather-Resistant Fire Warning. Polymers. 2023; 15(18):3666. https://doi.org/10.3390/polym15183666

Chicago/Turabian StyleMa, Tongtong, Qianqian Zhou, Chaozheng Liu, Liping Li, Chuigen Guo, and Changtong Mei. 2023. "Construction of Multifunctional Hierarchical Biofilms for Highly Sensitive and Weather-Resistant Fire Warning" Polymers 15, no. 18: 3666. https://doi.org/10.3390/polym15183666

APA StyleMa, T., Zhou, Q., Liu, C., Li, L., Guo, C., & Mei, C. (2023). Construction of Multifunctional Hierarchical Biofilms for Highly Sensitive and Weather-Resistant Fire Warning. Polymers, 15(18), 3666. https://doi.org/10.3390/polym15183666