Abstract

Recent advancements in wood modification aim to enhance the inherent qualities of this versatile biological material, which includes renewability, ease of processing, and thermal insulation. This study focuses on evaluating the effectiveness of lignin as a protective agent for less durable wood species, namely, Pinus nigra and Fagus sylvatica L. The impregnation of wood with three various forms of lignin, such as kraft lignin, acetylated kraft lignin, and lignin nanoparticles, was carried out using the vacuum technique at room conditions. The results showed that the treatments significantly improve the hydrophobicity of wood surfaces, particularly in pine wood, and provide protection against UV ageing. Additionally, the treatments contributed to the stabilisation of moisture content at different humidity levels. Although slight colour variations were observed, their impact on the visual appearance was minimal, and the thermal analysis confirmed enhanced thermal properties. Additionally, plasma treatment further enhanced hydrophobicity after treatments, offering potential benefits in terms of moisture resistance and durability. The findings of this study highlight the promising effects of lignin-based treatments on wood properties, providing sustainable solutions for wood protection in various sectors. However, further optimisation is needed to fully explore the potential of lignin and lignin nanoparticles.

1. Introduction

Wood is a highly adaptable biological material with numerous advantages, including its renewability, ease of processing, thermal, and acoustic insulation properties. In contrast to commonly used fossil-based materials like concrete, steel, and plastics, wood offers additional benefits such as carbon fixation and the ability to reduce carbon footprint [1,2]. However, due to its hydrophilic nature, wood tends to expand or shrink, which can compromise its dimensional stability, durability, and restrict its range of applications. Consequently, the natural characteristics of wood necessitate treatments to address these issues and extend its service life, thereby expanding the areas for potential applications [3].

Furthermore, wood is often perceived as a less durable material, and the visual appearance of wood-based products plays a crucial role, particularly since wood tends to undergo colour variations when exposed to direct sunlight, resulting in a general greying or darkening effect [4,5]. Additionally, excessive exposure to water accelerates the process of photo degradation, as it opens up the cell wall regions of the wood, making them susceptible to ultraviolet (UV) radiation [6]. The energy carried by UV radiation can lead to the degradation of non-structural components within the wood. These natural effects pose significant challenges to the widespread acceptance of wood as a bio-building material, requiring measures to enhance the service life of wood products [7,8].

Currently, various methods are employed to protect wood from external factors, including chemical modifications, thermal treatments, and the application of additives or chemicals as coatings or penetrating finishes with protective formulations [9,10,11,12]. These approaches often involve the covalent bonding of chemicals, altering wood moisture sorption properties or filling the cell wall with chemical compounds to block hygroscopic groups and reduce sorption sites. These methods contribute to the long-term durability and enhance the dimensional stability of wood. To address concerns related to the toxicity and environmental impact of the chemical treatments traditionally used, there remains a need for sustainable and bio-based solutions that target multifunctional material protection while addressing the limitations of current approaches.

Innovative wood treatments explore the use of natural bioactive additives or products that can be impregnated into the wood, as well as the use of micro or nanocarriers that can deliver components at various scales, targeting multiple properties [13,14]. In this context, lignin, a macromolecule abundant in nature, emerges as one of the most promising raw materials. This polyphenolic polymer is primarily derived from the underutilised byproduct of the pulp and paper industry (as precipitated kraft pulping black liquor), but is also a native and intrinsic component of wood [15].

The utilisation of lignin for wood protection presents an interesting alternative, given its significant phenolic content and inherent functionalities, such as pathogen resistance, thermal stability, biodegradability, antioxidant activity, and UV radiation absorption [15,16,17]. However, to unlock the full potential of lignin in wood applications, modifications are necessary to break down its molecular structure and enhance its reactivity. Gordobil et al. 2016 [18] used esterified organosolv lignins isolated from hardwood and softwood as protective agent for wood products resulting in a stable hydrophobic and oleophobic behaviour on wood veneers over time, which was confirmed by the accelerated aging test. Other authors [19] evaluated the use of lignin nanoparticles for wood surface treatment using a dip-coating technique and observed higher protection to UV irradiation and oxidation of treated than untreated wood samples. Additionally, an innovative approach to wood treatment involves surface preparation through plasma treatment, which offers an environmentally friendly method to modify or enhance the effects of applied products on wood surfaces [20].

In this study, the potential use of lignin as a sustainable protective agent for less durable wood species, such as beech and pine, was evaluated. The objective was to simultaneously improve relevant properties of wood, such as dimensional stability and UV resistance, by means of sustainable and eco-friendly modification process to enhance its service life performance. Simple vacuum impregnation methodologies were employed to impregnate lignin in various forms, and their effectiveness in reducing the hydrophilic nature of wood and protecting its surface against UV ageing was compared. To enhance wood hydrophobicity, kraft lignin was acetylated to shield the phenolic hydroxyl groups, and lignin nanoparticles were utilised to address their inherent heterogeneity, making them more homogeneous, and thus to improve stability. The results were evaluated based on the targeted properties, and the hydrophobic effect was further enhanced through the application of plasma treatment.

2. Materials and Methods

2.1. Wood Material

Samples from Slovenian plantation-grown wood were used for this study, the softwood species European black pine (Pinus nigra) and the hardwood species European beech (Fagus sylvatica L.). Samples of heartwood boards free of defects were cut with dimensions of 2 mm (rad.) × 15 mm (tang.) × 30 mm (long.) and conditioned (moisture content: 6.75% (Pinus nigra); 7.83% (Fagus sylvatica L.), both at 25 °C; 65% relative humidity). Thirty replicates were used for each modification set and for the reference set.

2.2. Lignin Material

Three different types of lignin were used to impregnate the wood: (1) Softwood kraft lignin (L) isolated from the Lignoboost process [21], (2) softwood kraft acetylated lignin (AL) [22], and (3) softwood kraft lignin nanoparticles (LNPs) produced in a pilot plant with an average size of 183.6 nm [23]. For the impregnation process, L and AL were prepared in NaOH solution (1%) at a concentration of 2% (w/v) and LNPs in water at a concentration of 2% wt.

2.3. Impregnation Methodology

Each set of samples was kept at 50 °C for 48 h and then weighed and impregnated with lignin solutions in a vessel connected to a pump, applying a vacuum impregnation cycle for approximately 2 h at room temperature. After the impregnation process, the excess product was removed by rinsing wood with water, and the samples were conditioned at 50 °C for 48 h.

2.4. Samples Characterisation

2.4.1. Physical Properties

The physical changes in wood after impregnations were measured in terms of weight percent gain (WPG), absorption dose (AD), and density (). These parameters were calculated using the following Equations (1–3):

where w1 is the oven dry weight of the sample (50 °C) before impregnation (g); w2 is the oven dry weight of sample (50 °C) after impregnation (g); w3 is the wet weight of sample (23 °C, 65% RH); and v3 is the volume of sample (23 °C, 65% RH).

2.4.2. Wettability and Surface Free Energy

Changes in wettability and surface free energy of wood were evaluated by the sessile-drop technique at the state of equilibrium contact angle θ using optical tensiometer Attention Theta Flex Auto 4 (Biolin Scientific, Gothenburg, Sweden). Three replica measurements were performed on each sample (10 samples per treatment) with distilled water, ethylene glycol, and diiodomethane as test liquids. The measurement of the drop shape (volume 4 μL) started at the initial drop contact with the assessed sample surface and lasted for 60 s. The free surface energy was calculated from the interactions of the liquid and the solid states following the routine proposed by Owens, Wendt, Rabel and Kaelble (OWRK). The total surface free energy (γtot), as well as its polar (γp) and disperse (γd) components were determined for all samples. A multiple comparison procedure analysis of variance (ANOVA) was used to determine which means were significantly different from others, as well as the confidence levels and Tukey significant difference (TSD) was applied after rejecting the null hypothesis.

2.4.3. Dimensional Stability

For each set of treatments, water sorption and desorption isotherms were calculated using a dynamic vapour sorption apparatus (DVS—surface measurement system). Each sample was cut and a small piece (±20 mg) was taken including the surface and the internal part of the wood. It was then placed on an aluminium plate connected to an ultra-sensitive microbalance capable of recording mass changes at a resolution of 0.1 mg at established sorption–desorption conditions. Climate control is assured by mixing dry nitrogen (0% RH) with saturated water vapour (100% RH). The mixture of both gases was controlled in the closed loop system by continuous monitoring of the relative humidity with ultrasonic (time of flight) sensors. The samples were subjected to a gradual increase in relative humidity (20, 40, 60, 80, and 95% RH), followed by a sequential reduction to 0% RH. The instrument maintained the sample at a constant RH until the weight change per minute fell below 0.002% (dm/dt = 0.002) for at least 15 min. The maximum period of the sorption–desorption step was set as 360 min. The moisture content was computed on the dry mass basis (absolute moisture content) as a percentage ratio of the water mass to the dry matter’s mass of the tested material. From the obtained data, the hysteresis and the sorption–desorption curves after two consecutive cycles were calculated, which is a recommended protocol for all materials of unknown sorption characteristics. These may be altered by the permanent physical–chemical changes (or chemical reactions) occurring in the presence (or absence) of moisture.

2.4.4. UV Stability and Colour Changes

A set of samples (5 samples per treatment) was subjected to cycles of UVA (100%, 8 mW/cm2), UVB (100%, 2.4 mW/cm2), and UVC (20%, 10 mW/cm2) radiation (Irradiation chamber Opsytec) at 15 cm and 25 °C. The effect of radiation was monitored by measuring the colour changes after 300 h of UV cycles. Samples were scanned with an office scanner HP Scanjet 2710 (300 dpi, 24 bit) and saved as TIF files. Colour changes were assessed by means of a MicroFlash 200D spectrophotometer (DataColor Int, Lawrenceville, IL, USA) following the CIE Lab system where colour is expressed with three parameters: L* (lightness), a* (red-green tone), and b* (yellow-blue tone). The selected illuminant was D65 and the viewer angle was 10°. Five replica measurements were performed on each sample and the confidence levels and TSD were applied in the same way as was described in Section 2.4.2.

2.4.5. Thermal Stability

Thermogravimetric analyses were performed using a thermogravimetric analyser Discovery TGA-5500 (Waters TA Instruments, New Castle, DE, USA). For the thermal analysis, 5–10 mg of each wood sample was cut including the surface and the internal part of the wood, then placed in a platinum crucible and analysed under N2 and O2 atmosphere (25 mL/min) from 25 to 800 °C with a heating rate of 20 °C/min. Thermogravimetric (TG) and derivative thermogravimetric (DTG) data generated by the instruments were decoded using TA Instruments TRIOS software (2021).

2.5. Product Performance

2.5.1. Measurement of Leachability and Performance

Leaching tests were performed according to EN84 with some modifications. Briefly, each set of treatments (5 samples each) was subjected to vacuum for 2 h and then immersed into 500 mL of distilled water for 240 h, with the water being changed every 24 h. Subsequently, the wood samples were collected and dried at 50 °C for 48 h to calculate the weight loss, wettability changes by WCA measurements, and colour changes.

2.5.2. Surface Post Treatment by Plasma Technology

An atmospheric plasma diffuse coplanar surface barrier discharge (DCSBD) was used as a post treatment method with the objective of determining changes in the hydrophobicity of the treated surfaces. Five samples from each treatment were exposed to a micro discharge for 2 s/mm of sample at 1 mm distance from the surface under ambient conditions. After plasma exposure, samples were conditioned (23 °C, 65% RH) and the WCA was measured according to the procedure described in Section 2.4.2.

3. Results and Discussion

3.1. Physical Properties

The degree of impregnation was evaluated through the weight percent gain (WPG) resulting from the treatments applied to the wood, and by calculating the absorption dose of the product. The absorption dose is the difference between the oven-dried weight and the conditioned weight of the samples (Table 1). The results showed no statistical differences in WPG among the different treatments. However, when considering the wood species, it was observed that hardwood samples (beech) exhibited WPG values that were 40% lower compared to softwood samples (pine), irrespective of the specific lignin treatment employed. Additionally, the absorption dose of the products was similar in both species, with a slightly higher percentage observed in the softwood samples. The results suggest that beech, which has a higher density and cell wall thickness compared to softwood, exhibits reduced permeability and slower moisture loss during the conditioning process. This is supported by the slight increase in moisture content (MC) observed after treatment.

Table 1.

Physical properties of wood after lignin-based treatments.

Nevertheless, a linear correlation was identified between WPG and density for both pine wood (R2 = 0.996) and beech wood (R2 = 0.981). The findings suggest that the effectiveness of the lignin treatment is primarily influenced by the substrate. In general, the treatments are better suited for low-density species [24] since they possess a higher impregnation capacity and have a more suitable anatomical configuration [25,26]. In contrast, denser species may require longer impregnation times or cycles to penetrate the cell wall adequately, thereby achieving more optimal results.

3.2. Wetting Behaviour and Hygroscopic Properties

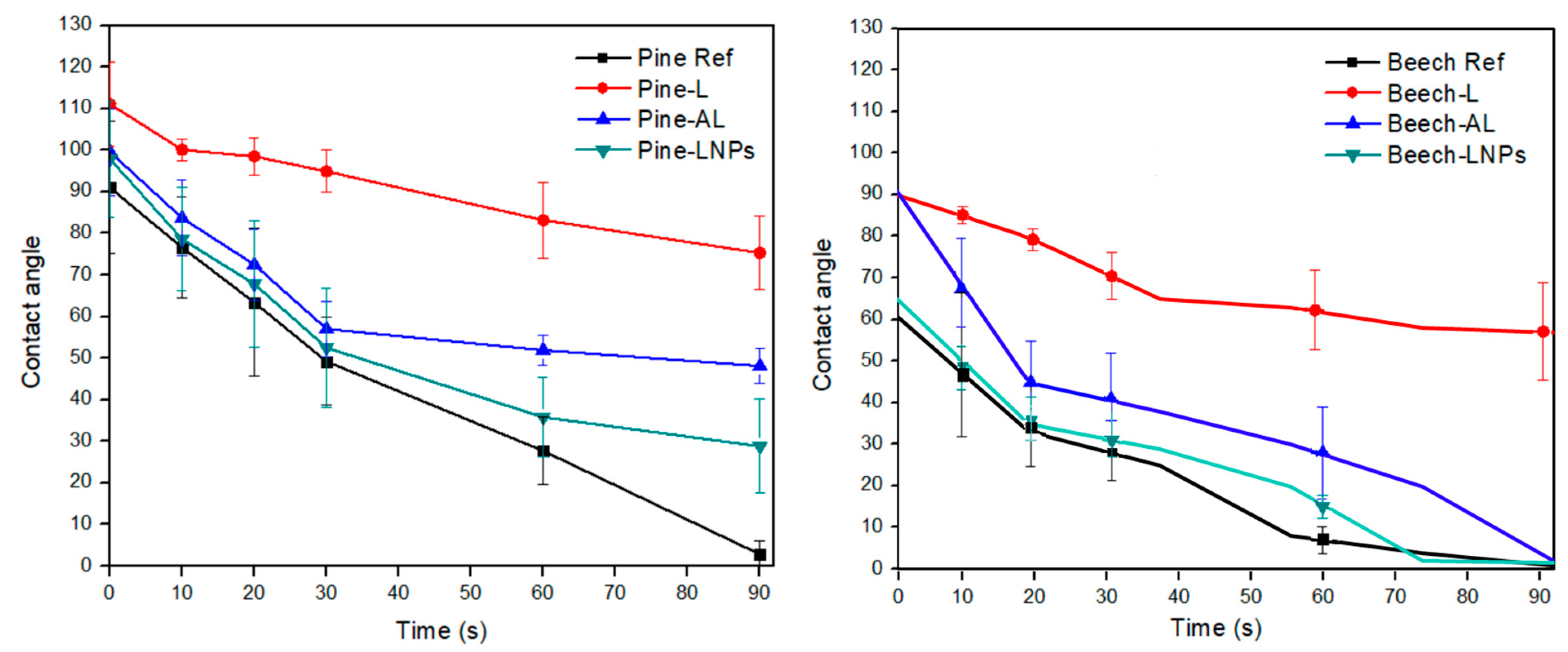

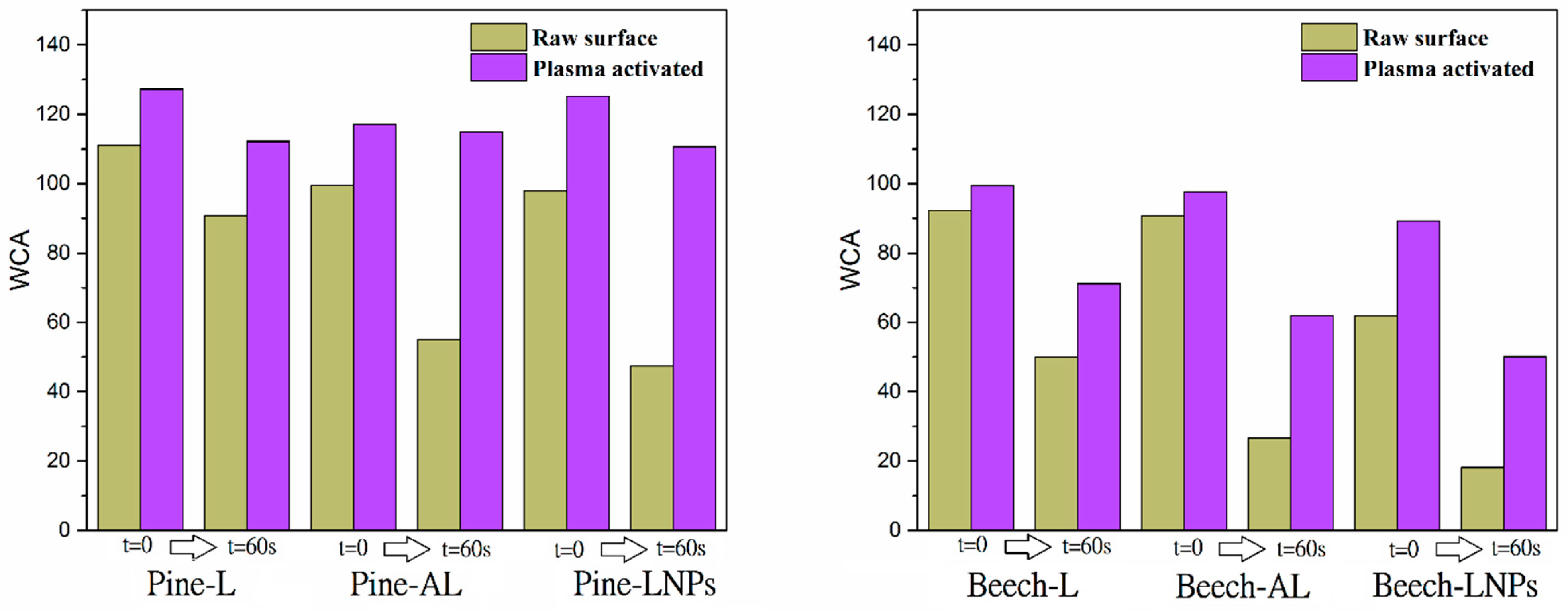

To assess the effectiveness of water repellence, the static water contact angle (WCA) was evaluated over time (Figure 1) and changes in the surface free energy of the wood were calculated (Table 2). Both treated wood species exhibited an increase in WCA, but higher values were observed in the softwood species, showing hydrophobic values (WCA > 90°), during the first few seconds in all treatments except for beech-LNPs treatment, which was slightly higher than the reference hardwood sample. After 90 s, the WCA were smaller in all samples, but the values for pine-L and beech-L treatments remained relatively steady, indicating that this treatment allows for only a partial wetting of wood surfaces. It is important to note that all samples were sanded (280-grit sandpaper) to achieve the same surface roughness, ensuring that the evaluation of surface properties occurred under consistent conditions [27]. Consequently, the variations observed in WCA were primarily attributed to the surface chemistry of each wood species and their interaction with the functional groups present in the lignin solutions (mainly carboxyl, methoxy, and hydroxyl groups) [28].

Figure 1.

WCA of impregnated wood samples over time.

Table 2.

Contact angle of wood with different liquids and changes in surface free energy after lignin-based treatments.

The analysis of the surface free energy components of wood showed that the polar share was reduced to values below 1 mJ/m2 in the treatments applied to pine wood and beech-AL (Table 2). This indicates a decrease in the wettability of the wood after these treatments, particularly with acetylated lignin, where higher water contact angles (WCA) and lower polar interaction on the surfaces were observed. This shift toward lower wettability in pine wood treatments and beech-AL can be attributed to the modification of the surface free energy as a consequence of the applied treatments. Acetylated lignin, for example, may introduce hydrophobic characteristics to the wood surface, reducing the polar interaction and making it less susceptible to wetting [29].

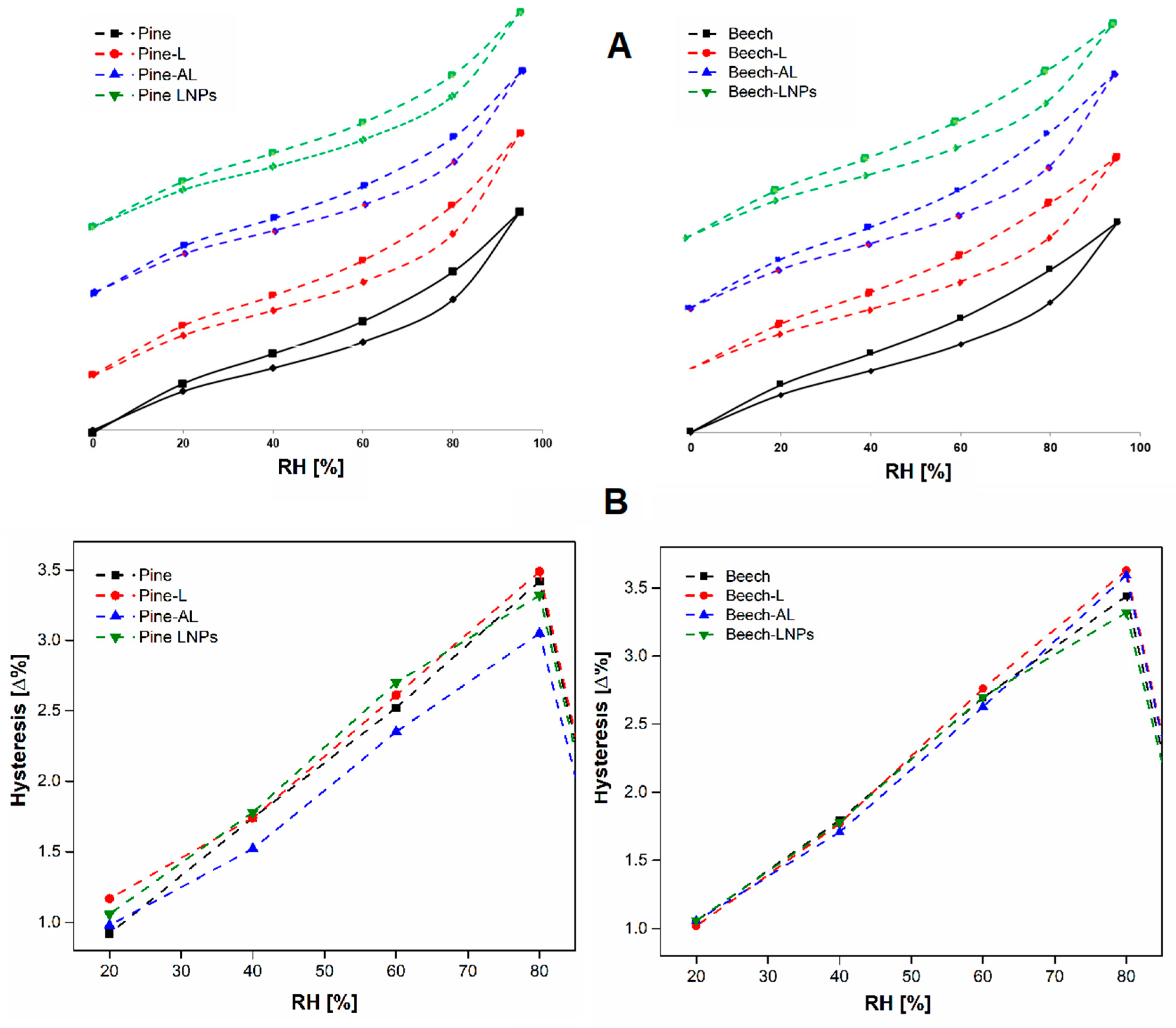

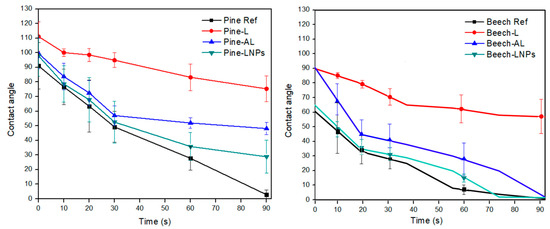

To study the changes in the dimensional stability of wood samples at different moisture contents, experimental adsorption and desorption tests were performed and the sorption isotherms and the hysteresis behaviour were analysed. Figure 2a shows similar isotherms of both untreated and lignin-based treated wood, with a sigmoid shape isotherm (type II), typical adsorption performance of monolayer-multilayer lignocellulosic materials [30,31].

Figure 2.

Sorption isotherms (A) and hysteresis (B) plotted as a function of relative humidity for reference and treated wood specimens measured by dynamic vapour sorption (DVS).

Analysis of the hysteresis plot (Figure 2b) revealed varying effects on the hygroscopic behaviour of wood among the treatments and wood species. The width of the hysteresis loop in wood depends on internal bonding between individual cell wall polymers. With the increased number of bonds, the loop increases [32]. In the case of treatments on softwood, pine-AL exhibited a stable performance across the entire moisture range, while pine-LNPs showed stability from 75% relative humidity (RH) onwards. On the other hand, in hardwood treatments, beech-AL displayed minor differences in equilibrium moisture content (EMC) within the 35–65% RH range, while beech-LNPs showed similar behaviour from 65% RH. However, both pine-L and beech-L did not demonstrate significant improvements in dimensional stability, exhibiting similar dimensional changes to those observed in the untreated samples.

Furthermore, the reduced effect of LNPs treatment on hygroscopic properties could be explained by the mechanism of lignin nanoparticle formation, in which dissolved lignin is precipitated in water (antisolvent). This process leads to the formation of a core-shell structure, where hydrophobic regions are assembled first to form the particle’s core, while the most polar molecules are adsorbed on the surface, creating a layer with low water repellence.

The observed differences in moisture sorption and release rates can be attributed to various factors, including the wood microstructure, chemical composition, and pore structure [3]. These characteristics play a significant role in determining the dimensional stability of wood. In this study, it was evident that the softwood species, with their distinct microstructure and chemical composition, may possess favourable attributes that contribute to their enhanced dimensional stability when compared to hardwood. Moreover, the changes in the EMC after treatments are crucial in determining a wood’s ability to withstand dimensional changes. The treatments had a notable impact on the EMC, particularly in the case of beech wood. This suggests the need for potential improvements in impregnation parameters or sample preparation to enhance its dimensional stability. Although the dynamic vapour sorption (DVS) analysis does not follow the standard for the determination of moisture stability on wood samples, it is considered a useful technique for the determination of sorption isotherms of materials providing numerous advantages in comparison with a traditional static method [33,34].

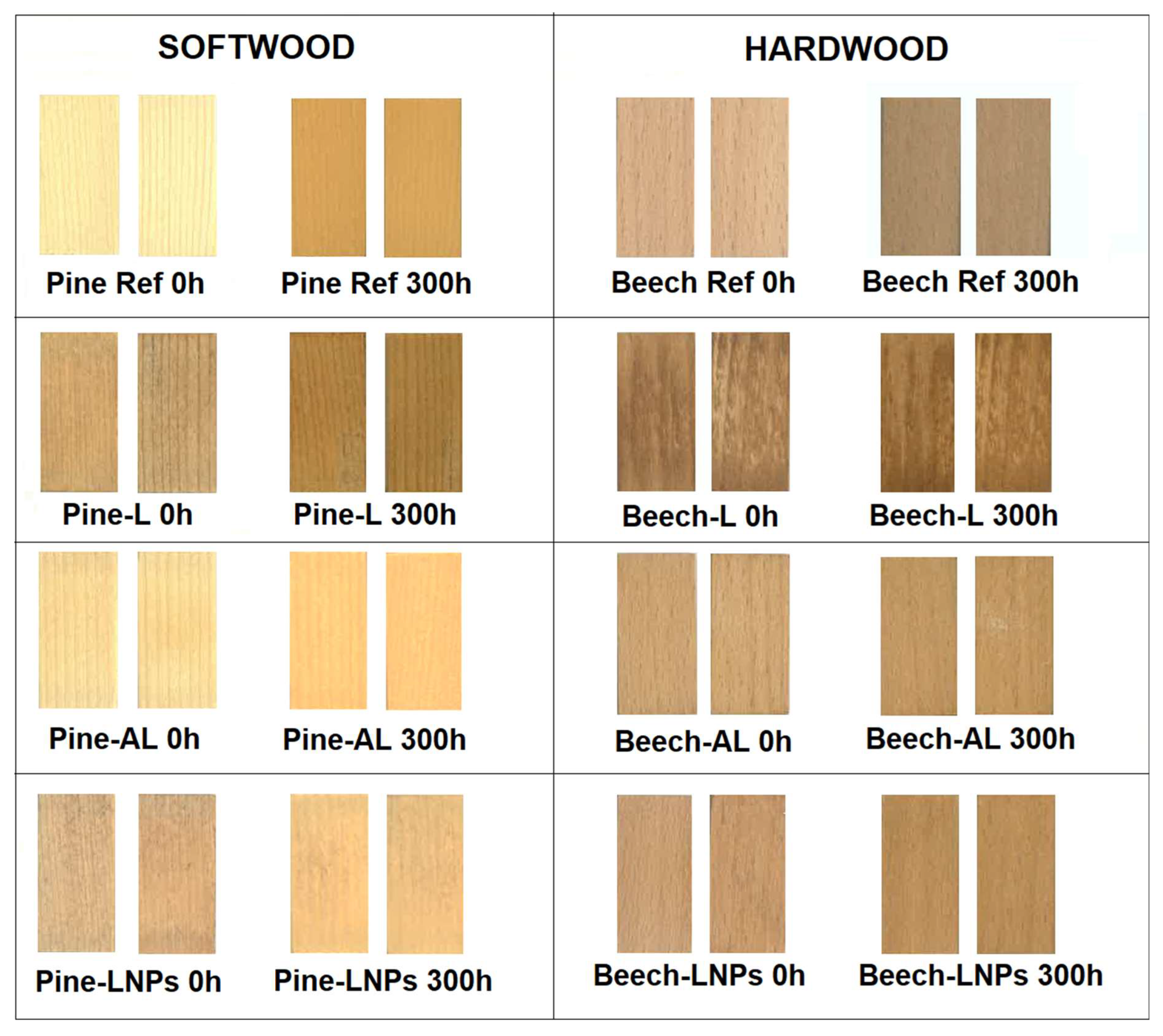

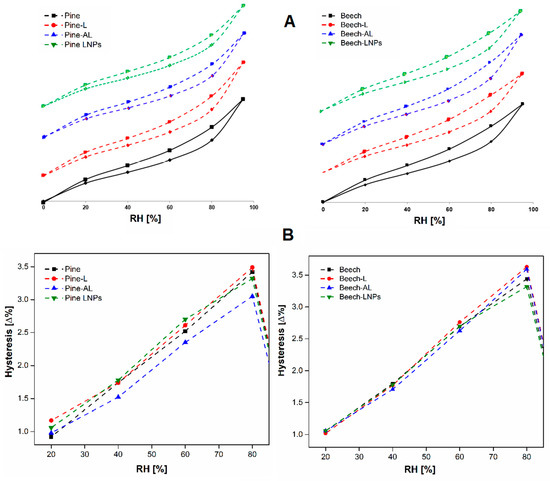

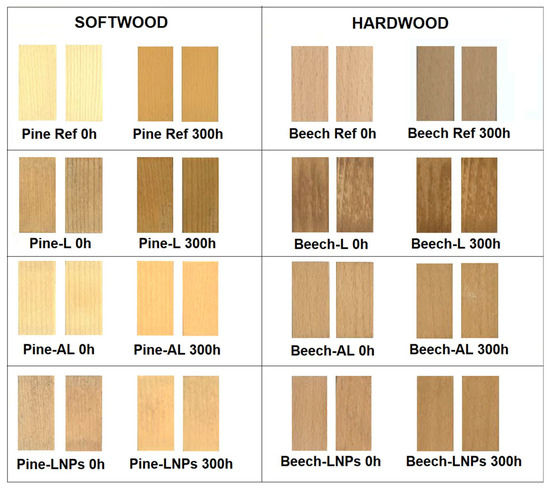

3.3. Colour Changes and UV Stability

The colour changes observed in the treated samples compared to the reference samples indicate the influence of the treatment methods on the visual appearance of the wood. As observed in Figure 3, the samples underwent a change in their original colour after treatment, exhibiting lower lightness values (L*) compared to the reference samples (Table 3). This effect was particularly prominent in pine-L, pine-LNPs, and beech-L treatments, where the colour appeared darker and less homogeneous compared to other treatments. In contrast, the appearance of pine-AL, beech-AL, and beech-LNPs treatments was similar to the reference samples, with minor changes in the colour parameters, suggesting a relatively minor impact on the visual appearance. The colour of treated wood might be later optimised by changing the source of lignin used for impregnation [19].

Figure 3.

Sample scans before and after 300 h of UV radiation.

Table 3.

Lab colour values before and after 300 h of UV ageing test.

Furthermore, the results from the UV ageing tests revealed interesting findings regarding colour stability. After 300 h of UV exposure, the total colour difference (Δcolour) was higher in the reference samples compared to the treated samples, which implies that the treated samples exhibited better resistance to colour degradation caused by UV radiation. The specific order of colour stability varied for each species, in which the following variations were observed: Pine-Ref > Pine-AL > Pine-L > Pine-LNPs, and Beech-Ref > Beech-LNPs > Beech-AL > Beech-L. The colour stability of the treated samples after UV testing can be attributed to the effect of lignin addition. Previous studies have suggested that lignin can act as a natural UV absorber, providing protection against the detrimental effects of UV radiation on wood surfaces [19,35].

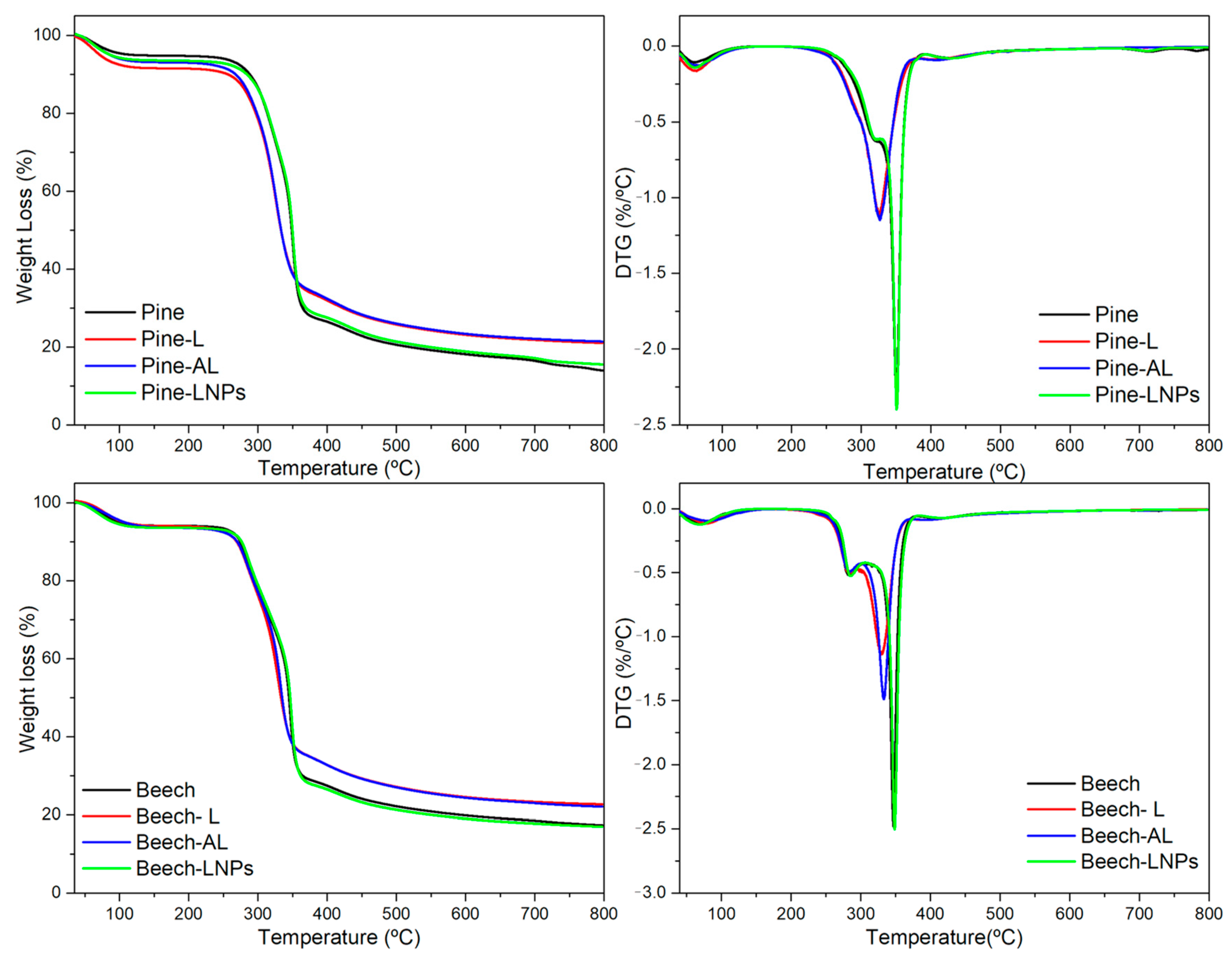

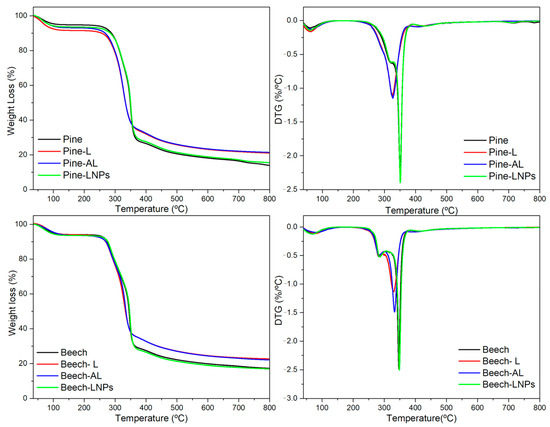

3.4. Thermal Properties

Thermogravimetric analyses were performed under inert and oxidative atmospheres to assess the decomposition behaviour and thermal characteristics of wood following impregnation. Figure 4 displays the TG profiles in N2 and the corresponding derivative curves, revealing distinct degradation temperatures between the reference samples (pine and beech) and the samples treated with lignin and acetylated lignin. In the case of pine wood, the treatments exhibited a less prominent peak at approximately 330 °C, while the reference and LNPs-treated samples displayed a shoulder at this temperature and a more pronounced peak at around 349 °C. Similarly, for beech wood, thermal degradation occurred in two distinct stages, featuring a common, less intense peak at 265–275 °C and a subsequent peak representing maximum weight loss rates at approximately 330 °C for beech-L and beech-AL, and around 345 °C for beech-ref and beech-LNPs. Remarkably, the results indicated that impregnation with lignin and acetylated lignin may have contributed to the formation of more stable compounds during the thermal decomposition process, resulting in a lower mass loss with higher residual mass (>20%) in these treatments.

Figure 4.

TGA and DTG of treated samples and references in N2.

Similar trends were observed in the TGA analysis conducted under oxidative atmosphere (O2), where lower degradation peaks were observed (Table 4). Notably, in the case of beech samples (all treatments), the degradation temperature (T10) was similar to the reference sample but with a reduced mass loss, indicating an oxidative stability and reduced flammability [36]. The observed reduction in mass loss at the degradation steps further suggests enhanced thermal stability in both species treated with lignin and acetylated lignin.

Table 4.

Parameters determined from the thermogravimetric analysis in O2.

The results obtained from the TGA analyses provide valuable insights into the thermal performance and stability of wood samples, especially after impregnation with lignin and acetylated lignin. The lower degradation peaks observed in both N2 and O2 atmospheres suggest that the impregnation process influenced the decomposition behaviour of the wood components. This can be attributed to the interaction between lignin or acetylated lignin and the wood matrix, leading to the formation of a protective layer or barrier that inhibits the access of oxygen to the wood surface, thereby reducing the susceptibility to oxidative degradation and enhancing the overall fire resistance properties [37].

3.5. Product Performance: Properties after Leaching Cycle

The retention levels, WCA, and colour changes in the treated wood after a leaching cycle are presented in Table 5. The WPG loss in all treated samples was lower than the initial WPG, particularly in softwood, where more than 70% of the product was retained in all treated samples. Conversely, the retention of lignin in hardwood samples was negligible for beech-L (1%), while it reached a maximum of 58% for beech-LNPs. The observed WPG loss in all cases can be attributed primarily to the removal of water-soluble wood extracts and unreacted solution. The effectiveness of the impregnation process is directly correlated with the permeability of the wood species. It can be concluded that pine wood is suitable for impregnation with lignin-based treatments, as it exhibits lower leaching compared to beech wood. Treatment of beech was found to be less effective, most likely due to a more closed cell structure, making it less receptive to lignin impregnation.

Table 5.

WPG loss and colour changes after leaching.

The type of lignin affects treatment effectiveness. It was observed that impregnation with unmodified lignin was more leachable in both species. This indicates that it is more difficult for untreated kraft lignin to penetrate the wood structure, and thus further modifications to the lignin or adjustments in particle size are necessary to enhance its retention [38]. The water contact angle (WCA) was measured after the leaching test to assess changes in the surface wettability of the treated samples. It is noteworthy that all treated samples exhibited similar tendencies in terms of WCA values after 60 s. However, it is particularly interesting to notice the hydrophobic behaviour in the pine-L treatment. This suggests that the impregnation of pine wood with the specific treatment resulted in a surface that repels water, indicating improved water resistance and potential durability of the treated wood.

Additionally, colour changes (∆L, ∆a, ∆b, ∆E) were measured after leaching to assess the impact on the appearance, considering that the original wood colour was noticeably altered due to the treatment (Figure 2). The results showed no tendency regarding the treatment or wood species after leaching. However, it is noteworthy that both the pine-L treatment and the beech-LNPs treatment overall exhibited reduced colour changes (∆colour). Furthermore, it was observed that pine-LNPs and beech-AL treatments shift toward a darker surface and reddish tone on the surfaces, as indicated by their negative lightness values (∆L) and positive ∆a values.

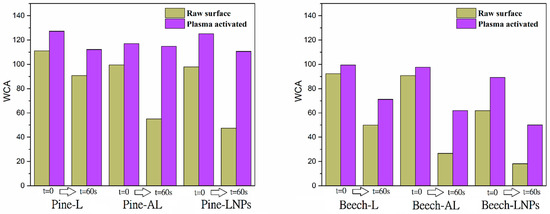

3.6. Improvement in Water Repellence: Plasma Treatment on Surface

All target properties were enhanced after the lignin-based treatments. However, to explore potential post treatments that could enhance the effectiveness of lignin treatments, samples were subjected to micro discharge using ambient air as the process gas with an atmospheric plasma (DCSBD). First, reference samples were tested, resulting in a decrease of approximately 30% in WCA from its initial value for pine wood and approximately 50% for beech wood. This effect indicates that surface activation in the reference samples led to increased liquid absorption rather than repellence, aligning with findings reported by other researchers. [39]. With regards to the treated samples, the results were compared with the obtained values of water contact angle (WCA) without plasma treatment (Figure 5). All the treated samples, after plasma micro discharge, showed a decrease in polarity at the initial time (WCA > 10%). This tendency remained constant over time, with improved WCA values exceeding 50%. The treated surfaces exhibited hydrophobic characteristics (WCAs > 90°), particularly in the case of softwood surfaces (pine). This hydrophobic nature was maintained over time, with contact angles exceeding 110° after 60 s.

Figure 5.

Changes in WCA of impregnated wood samples at t = 0 and after 60 s.

The resulting values after surface plasma treatment suggest that the changes in surface chemistry or composition, such as oxidation or modification of hydroxyl, carbonyl, and carboxyl groups associated with the added lignin, could be responsible for the observed effects. In previous studies using DCSBD treatment to modify surface polarity, researchers reported an increase in water contact angles (WCA) due to the degradation of hemicellulose on the surface during the discharge process [40,41]. These findings indicate that plasma treatment has the potential to further alter the surface properties of the samples and enhance their hydrophobicity.

However, it is important to note that the exact mechanisms underlying these changes in surface structure and chemistry are still not fully understood. Further research is needed to investigate the specific molecular interactions and transformations that occur during plasma treatment. Additionally, the long-term stability and durability of the modified surfaces should be assessed to determine their practical implementation in various applications.

4. Conclusions

The results of this study provide valuable insights into the effects of kraft lignin (L), acetylated lignin (AL), and lignin nanoparticles (LNPs) treatment on wood properties when applied at ambient temperature within short impregnation cycles. Similar weight percent gain (WPG) was found among the treatments. However, hardwood samples (beech) exhibited lower WPG values than softwood samples (pine), indicating reduced permeability and slower moisture loss during the conditioning process. The treatments improved the hydrophobicity of the wood surfaces, with higher water contact angles (WCA), particularly in softwood species. This suggests that the treatments had a more pronounced effect on the surface chemistry of pine wood, allowing for only partial wetting of the surfaces.

The hygroscopic behaviour of the treated wood varied among the different treatments and wood species. While pine-AL and pine-LNPs showed stability in terms of equilibrium moisture content (EMC) at higher relative humidity levels, beech-AL and beech-LNPs exhibited minor differences in EMC within specific RH ranges. Although the treatments resulted in a darker and less homogeneous colour of the samples, pine-AL, beech-AL, and beech-LNPs treatments exhibited relatively minor changes in colour parameters, indicating a lesser impact on the visual appearance.

Thermal analysis showed lower degradation in L and AL treatments, indicating that these treatments contributed to the formation of a protective layer or barrier, reducing susceptibility to oxidative degradation and enhancing fire resistance properties. Moreover, UV ageing tests indicated that the treated samples exhibited better resistance to degradation caused by UV radiation compared to the reference samples. The leaching tests demonstrated the effectiveness of the impregnation process. Pine wood showed less leaching compared to beech wood, suggesting its suitability for lignin-based treatments.

Additionally, the micro discharge plasma treatment (DSCBD) applied to the treated surfaces increased their hydrophobic character with WCA values exceeding 90° and remaining consistent over time. This surface post treatment could improve moisture resistance and durability of lignin-based impregnations.

In summary, the investigated lignin-based treatments showed promising effects on various wood properties, including moisture sorption, hydrophobicity, colour stability, thermal performance, and leaching. Bio-based wood treatments simultaneously improving relevant wood properties are particularly interesting for future industrial upscale due to the lack of sustainable and eco-friendly solutions targeting multifunctional material protection. Conducted research contributes toward understanding the effects of bio-based treatments on different wood species and provides insights for their application in various sectors. Further research is necessary to explore the full potential of lignin and further improve its effectiveness, optimisation, as well as to upscale the treatment process.

Author Contributions

Conceptualization, R.H. and O.G.; methodology, R.H. and O.G.; software, R.H. and O.G.; validation, R.H., O.G. and A.S.; formal analysis, R.H., O.G., F.P. and A.S.; investigation, R.H. and O.G.; resources, R.H., O.G., F.P. and A.S.; data curation, R.H., F.P. and O.G.; writing—original draft preparation, R.H.; writing—review and editing, R.H., O.G. and A.S.; visualization, R.H.; supervision, A.S.; project administration, R.H. and O.G.; funding acquisition, R.H., O.G. and A.S. All authors have read and agreed to the published version of the manuscript.

Funding

R. Herrera thanks the (IJC2020-043740-I) grant funded by MCIN/AEI/10.13039/501100011033 and by European Union NextGenerationEU/PRTR, and University of the Basque Country UPV/EHU (JDCI20/14) for the mobility grant. O. Gordobil acknowledges the financial support from the Spanish research agency (aei) (ryc-2021-031328-i) funded by mcin/aei/ 10.13039/501100011033 by European Union NextGenerationEU/prtr.4. Financial support from the Basque Government in the frame of Grupos Consolidados (IT-1498-22) and (IT-1690-22) is acknowledged. This research was funded by the European commission’s funding of the Innorenew project (grant agreement #739574 under the horizon 2020 widespread-2-teaming program) and the republic of Slovenia (investment funding from the republic of Slovenia and the European regional development fund). Co-funded by the European Union (ERC, ARCHI-SKIN, #101044468). Views and opinions expressed are, however, those of the author(s) only and do not necessarily reflect those of the European Union or the European Research Council. Neither the European Union nor the granting authority can be held responsible for them. This research presents a preliminary study related to MULTI-WOOD project #101067636 funded by Horizon Europe MSCA PF.

Data Availability Statement

The data presented in this study are available on request from the corresponding authors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The Wood from the Trees: The Use of Timber in Construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Himes, A.; Busby, G. Wood Buildings as a Climate Solution. Dev. Built Environ. 2020, 4, 100030. [Google Scholar] [CrossRef]

- Chen, C.; Kuang, Y.; Zhu, S.; Burgert, I.; Keplinger, T.; Gong, A.; Li, T.; Berglund, L.; Eichhorn, S.J.; Hu, L. Structure–Property–Function Relationships of Natural and Engineered Wood. Nat. Rev. Mater. 2020, 5, 642–666. [Google Scholar] [CrossRef]

- Sandak, A.; Sandak, J.; Dimitriou, A.; Burud, I.; Thiis, T.; Gobakken, L.R.; Ormondroyd, G.A.; Kraniotis, D. Assessment and Monitoring of Aesthetic Appearance of Building Biomaterials during the Service Life; WIT Press: Cambridge, MA, USA, 2017; pp. 527–536. [Google Scholar]

- Lie, S.K.; Vestøl, G.I.; Høibø, O.; Gobakken, L.R. Visual Appearance of Unpainted Wood: Mould Coverage, Lightness and Uniformity. Int. Wood Prod. J. 2019, 10, 9–15. [Google Scholar] [CrossRef]

- George, B.; Suttie, E.; Merlin, A.; Deglise, X. Photodegradation and Photostabilisation of Wood—The State of the Art. Polym. Degrad. Stab. 2005, 88, 268–274. [Google Scholar] [CrossRef]

- Petrillo, M.; Sandak, J.; Grossi, P.; Sandak, A. Chemical and Appearance Changes of Wood Due to Artificial Weathering—Dose–Response Model. J. Near Infrared Spectrosc. 2019, 27, 26–37. [Google Scholar] [CrossRef]

- Sandak, A.; Sandak, J.; Brzezicki, M.; Kutnar, A. Biomaterials for Building Skins; Springer: Berlin/Heidelberg, Germany, 2019; pp. 27–64. [Google Scholar]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood Modification Technologies—A Review. iForest 2017, 10, 895–908. [Google Scholar] [CrossRef]

- Zelinka, S.L.; Altgen, M.; Emmerich, L.; Guigo, N.; Keplinger, T.; Kymäläinen, M.; Thybring, E.E.; Thygesen, L.G. Review of Wood Modification and Wood Functionalization Technologies. Forests 2022, 13, 1004. [Google Scholar] [CrossRef]

- Jirouš-Rajković, V.; Miklečić, J. Enhancing Weathering Resistance of Wood—A Review. Polymers 2021, 13, 1980. [Google Scholar] [CrossRef]

- Acosta, A.P.; Diaz, R.H.; Amico, S.C.; Beltrame, R.; Barbosa, K.T.; Delucis, R.A.; Gatto, D.A. Effect of the Temperature of the Heat Treatment of Pine Wood on Subsequent in Situ Polymerization with Poly(Methyl Methacrylate). Biofuels Bioprod. Biorefin. 2023, 17, 499–509. [Google Scholar] [CrossRef]

- Papadopoulos, A.N.; Bikiaris, D.N.; Mitropoulos, A.C.; Kyzas, G.Z. Nanomaterials and Chemical Modifications for Enhanced Key Wood Properties: A Review. Nanomaterials 2019, 9, 607. [Google Scholar] [CrossRef] [PubMed]

- Papadopoulos, A.N.; Taghiyari, H.R. Innovative Wood Surface Treatments Based on Nanotechnology. Coatings 2019, 9, 866. [Google Scholar] [CrossRef]

- Zevallos Torres, L.A.; Lorenci Woiciechowski, A.; de Andrade Tanobe, V.O.; Karp, S.G.; Guimarães Lorenci, L.C.; Faulds, C.; Soccol, C.R. Lignin as a Potential Source of High-Added Value Compounds: A Review. J. Clean. Prod. 2020, 263, 121499. [Google Scholar] [CrossRef]

- Zhang, Y.; Naebe, M. Lignin: A Review on Structure, Properties, and Applications as a Light-Colored UV Absorber. ACS Sustain. Chem. Eng. 2021, 9, 1427–1442. [Google Scholar] [CrossRef]

- Liao, J.J.; Latif, N.H.A.; Trache, D.; Brosse, N.; Hussin, M.H. Current Advancement on the Isolation, Characterization and Application of Lignin. Int. J. Biol. Macromol. 2020, 162, 985–1024. [Google Scholar] [CrossRef]

- Gordobil, O.; Herrera, R.; Llano-Ponte, R.; Labidi, J. Esterified Organosolv Lignin as Hydrophobic Agent for Use on Wood Products. Prog. Org. Coat. 2017, 103, 143–151. [Google Scholar] [CrossRef]

- Zikeli, F.; Vinciguerra, V.; D’Annibale, A.; Capitani, D.; Romagnoli, M.; Scarascia Mugnozza, G. Preparation of Lignin Nanoparticles from Wood Waste for Wood Surface Treatment. Nanomaterials 2019, 9, 281. [Google Scholar] [CrossRef] [PubMed]

- Avramidis, G.; Hauswald, E.; Lyapin, A.; Militz, H.; Viöl, W.; Wolkenhauer, A. Plasma Treatment of Wood and Wood-Based Materials to Generate Hydrophilic or Hydrophobic Surface Characteristics. Wood Mater. Sci. Eng. 2009, 4, 52–60. [Google Scholar] [CrossRef]

- Kienberger, M.; Maitz, S.; Pichler, T.; Demmelmayer, P. Systematic Review on Isolation Processes for Technical Lignin. Processes 2021, 9, 804. [Google Scholar] [CrossRef]

- Buono, P.; Duval, A.; Verge, P.; Averous, L.; Habibi, Y. New Insights on the Chemical Modification of Lignin: Acetylation versus Silylation. ACS Sustain. Chem. Eng. 2016, 4, 5212–5222. [Google Scholar] [CrossRef]

- Gordobil, O.; Li, H.; Izquierdo, A.A.; Egizabal, A.; Sevastyanova, O.; Sandak, A. Surface Chemistry and Bioactivity of Colloidal Particles from Industrial Kraft Lignins. Int. J. Biol. Macromol. 2022, 220, 1444–1453. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Li, Y.; Ren, R.; Li, L.; Chen, Y. Enhanced Mechanical and Humidity Resistance Properties of Heat-Treated Wood by Impregnation of Low-Molecular-Weight Lignin. Wood Sci. Technol. 2022, 56, 1551–1565. [Google Scholar] [CrossRef]

- Wen, M.-Y.; Kang, C.-W.; Park, H.-J. Impregnation and Mechanical Properties of Three Softwoods Treated with a New Fire Retardant Chemical. J. Wood Sci. 2014, 60, 367–375. [Google Scholar] [CrossRef]

- Tondi, G.; Thevenon, M.F.; Mies, B.; Standfest, G.; Petutschnigg, A.; Wieland, S. Impregnation of Scots Pine and Beech with Tannin Solutions: Effect of Viscosity and Wood Anatomy in Wood Infiltration. Wood Sci. Technol. 2013, 47, 615–626. [Google Scholar] [CrossRef]

- Laina, R.; Sanz-Lobera, A.; Villasante, A.; López-Espí, P.; Martínez-Rojas, J.A.; Alpuente, J.; Sánchez-Montero, R.; Vignote, S. Effect of the Anatomical Structure, Wood Properties and Machining Conditions on Surface Roughness of Wood. Maderas. Cienc. Tecnol. 2017, 19, 203–212. [Google Scholar] [CrossRef][Green Version]

- Sadeghifar, H.; Argyropoulos, D.S. Correlations of the Antioxidant Properties of Softwood Kraft Lignin Fractions with the Thermal Stability of Its Blends with Polyethylene. ACS Sustain. Chem. Eng. 2015, 3, 349–356. [Google Scholar] [CrossRef]

- Hwang, U.; Lee, B.; Oh, B.; Shin, H.S.; Lee, S.S.; Kang, S.G.; Kim, D.; Park, J.; Shin, S.; Suhr, J.; et al. Hydrophobic Lignin/Polyurethane Composite Foam: An Eco-Friendly and Easily Reusable Oil Sorbent. Eur. Polym. J. 2022, 165, 110971. [Google Scholar] [CrossRef]

- Herrera Díaz, R.; Gordobil, O.; de Hoyos-Martinez, P.L.; Sandak, A.; Labidi, J. Hydrophobization and Photo-Stabilization of Radiata Pinewood: The Effect of the Esterification on Thermal and Mechanical Properties. Forests 2020, 11, 1243. [Google Scholar] [CrossRef]

- Hou, S.; Wang, J.; Yin, F.; Qi, C.; Mu, J. Moisture Sorption Isotherms and Hysteresis of Cellulose, Hemicelluloses and Lignin Isolated from Birch Wood and Their Effects on Wood Hygroscopicity. Wood Sci. Technol. 2022, 56, 1087–1102. [Google Scholar] [CrossRef]

- Irbe, I.; Andersons, B.; Chirkova, J.; Kallavus, U.; Andersone, I.; Faix, O. On the Changes of Pinewood (Pinus sylvestris L.) Chemical Composition and Ultrastructure during the Attack by Brown-Rot Fungi Postia placenta and Coniophora puteana. Int. Biodeterior. Biodegrad. 2006, 57, 99–106. [Google Scholar] [CrossRef]

- Hill, C.A.S.; Norton, A.; Newman, G. The Water Vapor Sorption Behavior of Natural Fibers. J. Appl. Polym. Sci. 2009, 112, 1524–1537. [Google Scholar] [CrossRef]

- Almeida, G.; Rémond, R.; Perré, P. Hygroscopic Behaviour of Lignocellulosic Materials: Dataset at Oscillating Relative Humidity Variations. J. Build. Eng. 2018, 19, 320–333. [Google Scholar] [CrossRef]

- Sadeghifar, H.; Ragauskas, A. Lignin as a UV Light Blocker—A Review. Polymers 2020, 12, 1134. [Google Scholar] [CrossRef] [PubMed]

- De Hoyos-Martínez, P.L.; Issaoui, H.; Herrera, R.; Labidi, J.; Charrier-El Bouhtoury, F. Wood Fireproofing Coatings Based on Biobased Phenolic Resins. ACS Sustain. Chem. Eng. 2021, 9, 1729–1740. [Google Scholar] [CrossRef]

- Popescu, C.; Pfriem, A. Treatments and Modification to Improve the Reaction to Fire of Wood and Wood Based Products—An Overview. Fire Mater. 2020, 44, 100–111. [Google Scholar] [CrossRef]

- Zikeli, F.; Romagnoli, M.; Mugnozza, G.S. Lignin Nanoparticles in Coatings for Wood Preservation. In Micro and Nanolignin in Aqueous Dispersions and Polymers; Elsevier: Amsterdam, The Netherlands, 2022; pp. 357–384. [Google Scholar]

- Lux, C.; Szalay, Z.; Beikircher, W.; Kováčik, D.; Pulker, H.K. Investigation of the Plasma Effects on Wood after Activation by Diffuse Coplanar Surface Barrier Discharge. Eur. J. Wood Wood Prod. 2013, 71, 539–549. [Google Scholar] [CrossRef]

- Jablonský, M.; Šmatko, L.; Botková, M.; Tiňo, R.; Šima, J. Modification of Wood Wettability (European Beech) by Diffuse Coplanar Surface Barrier Discharge Plasma. Surfaces 2016, 28, 30. [Google Scholar]

- Talviste, R.; Galmiz, O.; Stupavská, M.; Ráhel’, J. Effect of DCSBD Plasma Treatment Distance on Surface Characteristics of Wood and Thermally Modified Wood. Wood Sci. Technol. 2020, 54, 651–665. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).