Crystallization and Performance of Polyamide Blends Comprising Polyamide 4, Polyamide 6, and Their Copolymers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Differential Scanning Calorimetry (DSC)

2.3. Dynamic Mechanical Analysis (DMA)

2.4. Thermogravimetric Analysis (TGA)

2.5. Wide-Angle X-ray Diffraction (WAXD)

2.6. Scanning Electron Microscopy (SEM)

2.7. Mechanical Analysis

2.8. Molecular Dynamics (MD) Simulations

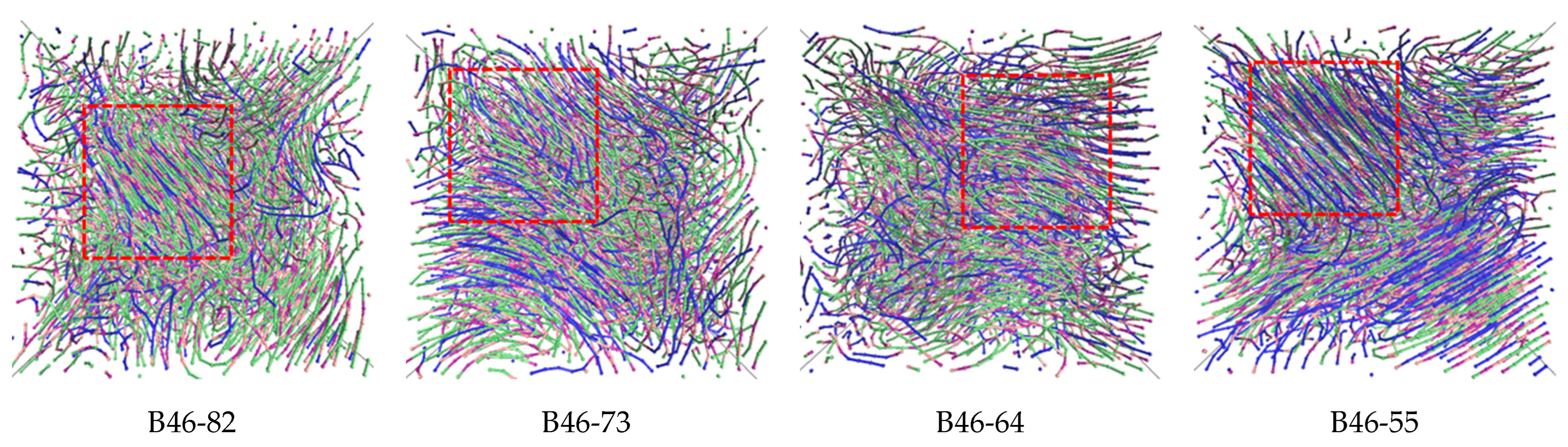

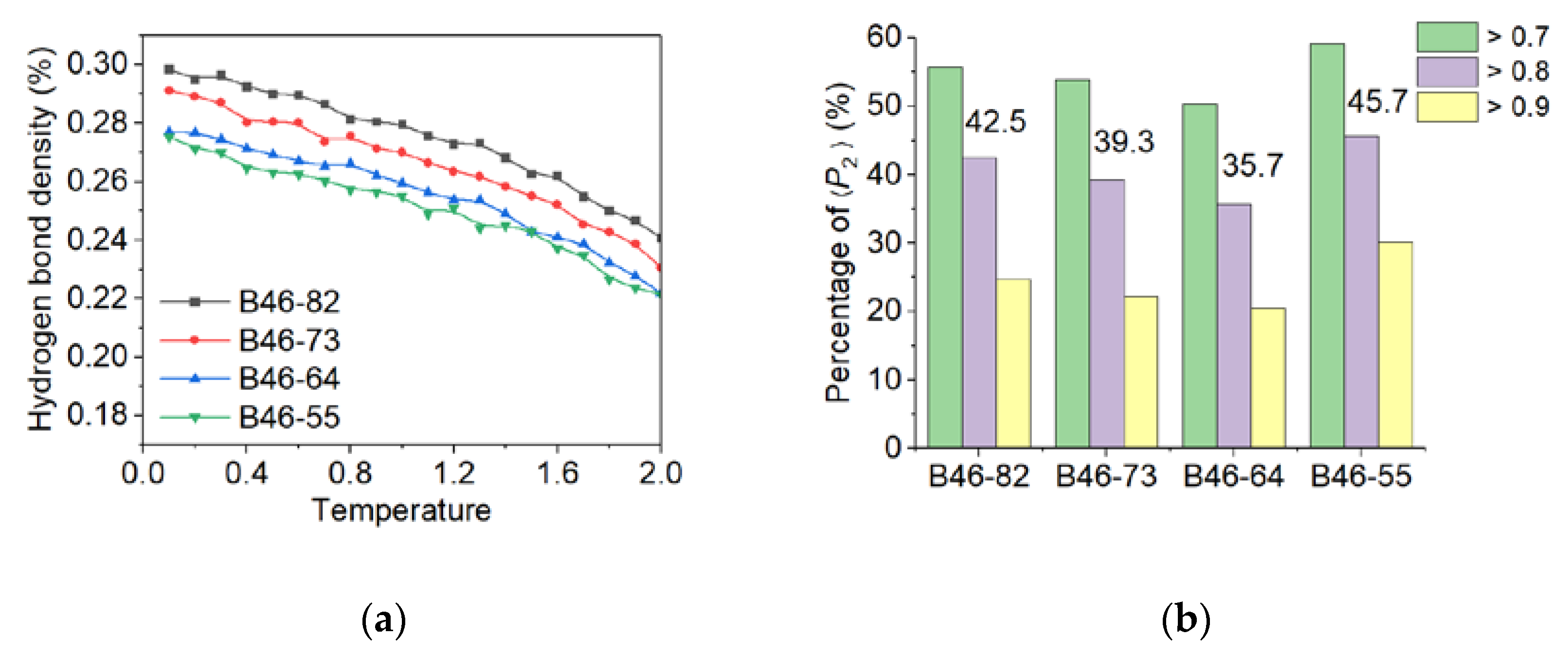

3. Results and Discussion

3.1. Crystalline Properties

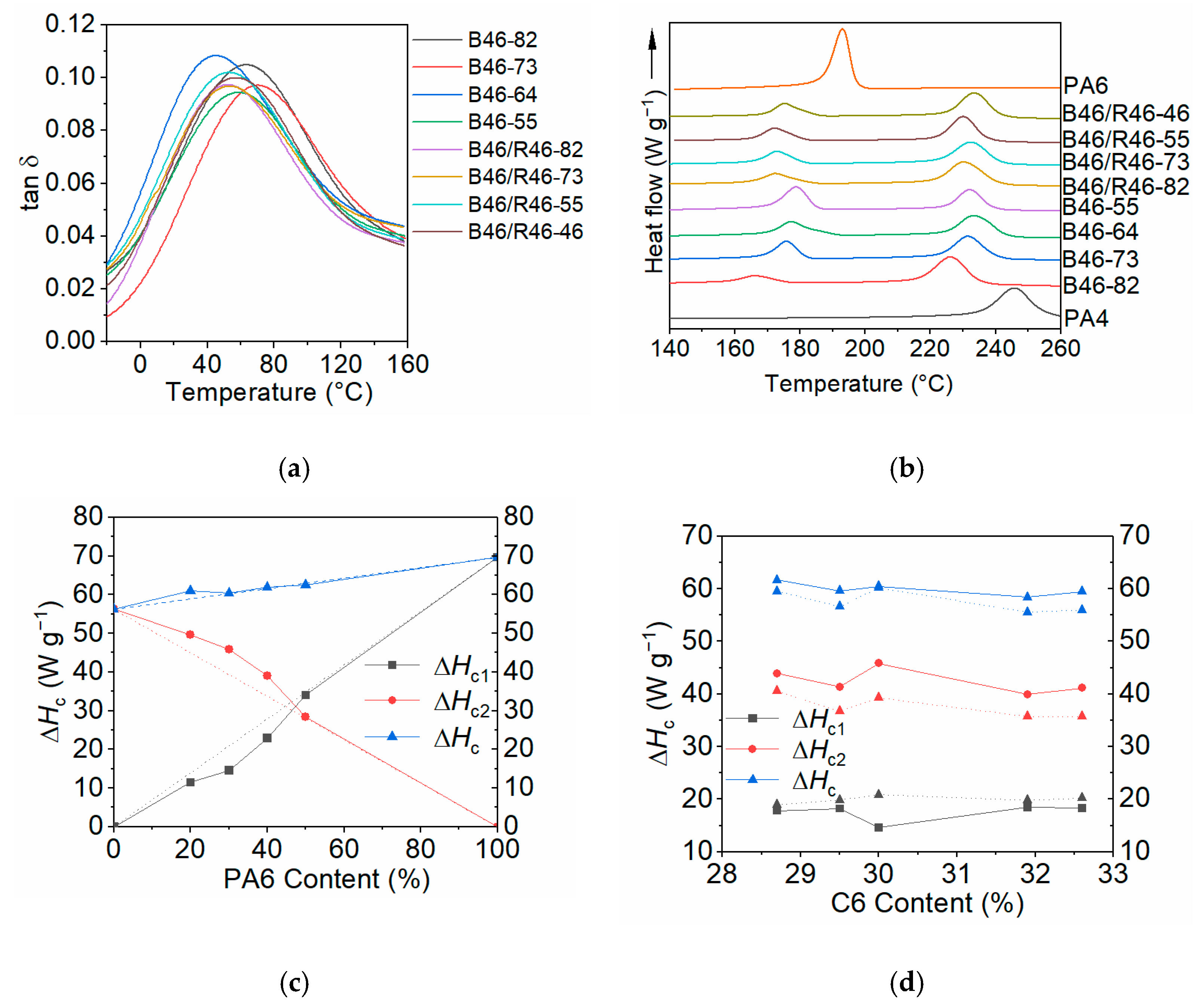

3.2. Thermal Properties

3.2.1. Thermomechanical Properties

3.2.2. Crystallization Behavior

3.2.3. Thermal Stability

3.3. Mechanical Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Yamano, N.; Kawasaki, N.; Takeda, S.; Nakayama, A. Production of 2-pyrrolidone from biobased glutamate by using Escherichia coli. J. Polym. Environ. 2013, 21, 528–533. [Google Scholar] [CrossRef]

- Kawasaki, N.; Yamano, N.; Nakayama, A. Synthesis, properties, and biodegradability of three-branched copolyamide (4/6). J. Appl. Polym. Sci. 2020, 137, e49165. [Google Scholar] [CrossRef]

- Yamano, N.; Kawasaki, N.; Ida, S.; Nakayama, A. Biodegradation of polyamide 4 in seawater. Polym. Degrad. Stab. 2019, 166, 230–236. [Google Scholar] [CrossRef]

- Yamano, N.; Kawasaki, N.; Ida, S.; Nakayama, Y.; Nakayama, A. Biodegradation of polyamide 4 in vivo. Polym. Degrad. Stab. 2017, 137, 281–288. [Google Scholar] [CrossRef]

- Kim, N.C.; Kim, J.H.; Nam, S.W.; Jeon, B.S.; Kim, Y.J. Preparation of Nylon 4 microspheres via heterogeneous polymerization of 2-pyrrolidone in a paraffin oil continuous phase. J. Ind. Eng. Chem. 2015, 28, 236–240. [Google Scholar] [CrossRef]

- Pagacz, J.; Leszczynska, A.; Modesti, M.; Boaretti, C.; Roso, M.; Malka, I.; Pielichowski, K. Thermal decomposition studies of bio-resourced polyamides by thermogravimetry and evolved gas analysis. Thermochim. Acta 2015, 612, 40–48. [Google Scholar] [CrossRef]

- de Gortari, M.G.; Wu, F.; Mohanty, A.K.; Misra, M. Evaluating the Performance of a Semiaromatic/Aliphatic Polyamide Blend: The Case for Polyphthalamide (PPA) and Polyamide 4,10 (PA410). Polymers 2021, 13, 3391. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.Y.; Ha, J.U.; Shin, D.; Jung, W.; Lee, P.C. Mechanical properties and morphology of polyamide/polypropylene blends. Elastom. Compos. 2020, 55, 1–5. [Google Scholar]

- Chen, X.H.; Shi, W.X.; Yang, S.H.; Li, Y.Y.; Ma, G.Q.; Sheng, J. Fractal analysis of morphology of PE/PA blends: Composition. J. Appl. Polym. Sci. 2008, 109, 2496–2502. [Google Scholar] [CrossRef]

- Evstatiev, M.; Schultz, J.M.; Fakirov, S.; Friedrich, K. In situ fibrillar reinforced PET/PA-6/PA-66 blend. Polym. Eng. Sci. 2001, 41, 192–204. [Google Scholar] [CrossRef]

- Puglisi, R.; Scamporrino, A.A.; Dintcheva, N.T.; Filippone, G.; Bruno, E.; Scarfato, P.; Cerruti, P.; Carroccio, S.C. Photo- and water-degradation phenomena of ZnO bio-blend based on poly(lactic acid) and polyamide 11. Polymers 2023, 15, 1434. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, J.P.C.; Castro, L.D.C.; Mareau, V.H.; Pessan, L.A.; Gonon, L. New insights on the compatibilization of PA6/ABS blends: A co-localized AFM-Raman study. Polymer 2018, 146, 151–160. [Google Scholar] [CrossRef]

- Hashimoto, K.; Sudo, M.; Ohta, K.; Sugimura, T.; Yamada, H.; Aoki, T. Biodegradation of nylon4 and its blend with nylon6. J. Appl. Polym. Sci. 2002, 86, 2307–2311. [Google Scholar] [CrossRef]

- Wang, Y.; Kang, H.L.; Wang, R.; Liu, R.G.; Hao, X.M. Crystallization of polyamide 56/polyamide 66 blends: Non-isothermal crystallization kinetics. J. Appl. Polym. Sci. 2018, 135, e46409. [Google Scholar] [CrossRef]

- Moran, C.S.; Barthelon, A.; Pearsall, A.; Mittal, V.; Dorgan, J.R. Biorenewable blends of polyamide-4,10 and polyamide-6,10. J. Appl. Polym. Sci. 2016, 133, 43626. [Google Scholar] [CrossRef]

- Safari, M.; Otaegi, I.; Aramburu, N.; Wang, Y.; Liu, G.M.; Dong, X.; Wang, D.J.; Guerrica-Echevarria, G.; Muller, A.J. Composition dependent miscibility in the crystalline state of polyamide 6/polyamide 4,10 blends: From single to double crystalline blends. Polymer 2021, 219, 123570. [Google Scholar] [CrossRef]

- Zhang, G.Z.; Yoshida, H.; Kawai, T. Miscibility of nylon 66 and nylon 48 blend evaluated by crystallization dynamics. Thermochim. Acta 2004, 416, 79–85. [Google Scholar] [CrossRef]

- Wei, M.; Shin, I.D.; Urban, B.; Tonelli, A.E. Partial miscibility in a nylon-6/nylon-66 blend coalesced from their common alpha-cyclodextrin inclusion complex. J. Polym. Sci. Pol. Phys. 2004, 42, 1369–1378. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, N.; Kang, H.L.; Hao, X.M.; Liu, R.G. Isodimorphism in polyamide 56/polyamide 66 blends with controllable thermal and mechanical properties. ACS Appl. Polym. Mater. 2022, 4, 9407–9416. [Google Scholar] [CrossRef]

- Jose, S.; Aprem, A.S.; Francis, B.; Chandy, M.C.; Werner, P.; Alstaedt, V.; Thomas, S. Phase morphology, crystallisation behaviour and mechanical properties of isotactic polypropylene/high density polyethylene blends. Eur. Polym. J. 2004, 40, 2105–2115. [Google Scholar] [CrossRef]

- Ruehle, D.A.; Perbix, C.; Castaneda, M.; Dorgan, J.R.; Mittal, V.; Halley, P.; Martin, D. Blends of biorenewable polyamide-11 and polyamide-6,10. Polymer 2013, 54, 6961–6970. [Google Scholar] [CrossRef]

- Higuchi, Y.; Kubo, M. Deformation and fracture processes of a lamellar structure in polyethylene at the molecular level by a coarse-grained molecular dynamics simulation. Macromolecules 2017, 50, 3690–3702. [Google Scholar] [CrossRef]

- Zhaio, Z.Q.; Fusco, C.; Morthomas, J.; Perez, M.; Lame, O. Disentangling and lamellar thickening of linear polymers during crystallization: Simulation of bimodal and unimodal molecular weight distribution systems. ACS Nano 2019, 13, 11310–11319. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.W.; Song, M. A computer simulation of stress transfer in carbon nanotube/polymer nanocomposites. Compos. Pt. B-Eng. 2019, 163, 236–242. [Google Scholar] [CrossRef]

- Pisani, W.A.; Newman, J.K.; Shukla, M.K. Multiscale modeling of polyamide 6 using molecular dynamics and micromechanics. Ind. Eng. Chem. Res. 2021, 60, 13604–13613. [Google Scholar] [CrossRef]

- Kulshreshtha, A.; Hayward, R.C.; Jayaraman, A. Impact of composition and placement of hydrogen-bonding groups along polymer chains on blend phase behavior: Coarse-grained molecular dynamics simulation study. Macromolecules 2022, 55, 2675–2690. [Google Scholar] [CrossRef]

- Ramachandran, A.A.R.A.; Maria, H.J.; Thomas, S. Role of Functional Polymers in the Compatibilization of Polymer Blends. In Reactive and Functional Polymers Volume Two: Modification Reactions, Compatibility and Blends; Gutiérrez, T.J., Ed.; Springer International Publishing: Cham, Switzerland, 2020; Volume 2, pp. 5–21. [Google Scholar]

- Lin, Z.D.; Guan, Z.X.; Xu, B.F.; Chen, C.; Guo, G.H.; Zhou, J.X.; Xian, J.M.; Cao, L.; Wang, Y.L.; Li, M.Q.; et al. Crystallization and melting behavior of polypropylene in beta-PP/polyamide 6 blends containing PP-g-MA. J. Ind. Eng. Chem. 2013, 19, 692–697. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Cai, Z.L.; Wang, Y.B.; Liu, J.; Chen, T.; Zhao, L.M. Effect of sequence distribution on the non-isothermal crystallization of copolyamide 4/6. J. Mater. Sci. 2022, 57, 17883–17901. [Google Scholar] [CrossRef]

- ISO 37; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties. International Organization for Standardization: Geneva, Switzerland, 2005.

- ISO 527-2; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. International Organization for Standardization: Geneva, Switzerland, 2012.

- LAMMPS Molecular Dynamics Simulator. Available online: https://lammps.sandia.gov/ (accessed on 18 January 2023).

- Kremer, K.; Grest, G.S. Dynamics of entangled linear polymer melts: A molecular-dynamics simulation. J. Chem. Phys. 1990, 92, 5057–5086. [Google Scholar] [CrossRef]

- Yeung, C.; Herrmann, K.A. Molecular dynamics simulation of reactive compatibilization of polymer blends. Macromolecules 2003, 36, 229–237. [Google Scholar] [CrossRef]

- Hsieh, C.C.; Jain, S.; Larson, R.G. Brownian dynamics simulations with stiff finitely extensible nonlinear elastic-Fraenkel springs as approximations to rods in bead-rod models. J. Chem. Phys. 2006, 124, 044911. [Google Scholar] [CrossRef] [PubMed]

- Hossain, D.; Tschopp, M.A.; Ward, D.K.; Bouvard, J.L.; Wang, P.; Horstemeyer, M.F. Molecular dynamics simulations of deformation mechanisms of amorphous polyethylene. Polymer 2010, 51, 6071–6083. [Google Scholar] [CrossRef]

- Hong, W.; Lin, J.P.; Tian, X.H.; Wang, L.Q. Linear and nonlinear viscoelasticity of self-associative hydrogen-bonded polymers. Polymer 2021, 235, 124301. [Google Scholar] [CrossRef]

- Liu, J.; Wu, S.Z.; Zhang, L.Q.; Wang, W.C.; Cao, D.P. Molecular dynamics simulation for insight into microscopic mechanism of polymer reinforcement. Phys. Chem. Chem. Phys. 2011, 13, 518–529. [Google Scholar] [CrossRef] [PubMed]

- Durmaz, B.U.; Aytac, A. Enhanced mechanical and thermal properties of graphene nanoplatelets-reinforced polyamide11/poly(lactic acid) nanocomposites. Polym. Eng. Sci. 2023, 63, 105–117. [Google Scholar] [CrossRef]

- Ridhore, A.; Jog, J. Synergistic mechanical response of nylon 6/trogamid (R) T blends. J. Appl. Polym. Sci. 2013, 129, 65–72. [Google Scholar] [CrossRef]

- Vallejo, F.J.; Eguiazabal, J.I.; Nazabal, J. Solid state features and mechanics properties of PEI/PBT blends. J. Appl. Polym. Sci. 2001, 80, 885–892. [Google Scholar] [CrossRef]

| Sample | PA4/PA6 (w/w) | R46-82 (wt%) 1 | R46-73 (wt%) | R46-55 (wt%) | R46-46 (wt%) |

|---|---|---|---|---|---|

| B46-82 | 80/20 | - | - | - | - |

| B46-73 | 70/30 | - | - | - | - |

| B46-64 | 60/40 | - | - | - | - |

| B46-55 | 50/50 | - | - | - | - |

| B46/R46-82 | 70/30 | 10 | - | - | - |

| B46/R46-73 | 70/30 | - | 10 | - | - |

| B46/R46-55 | 70/30 | - | - | 10 | - |

| B46/R46-46 | 70/30 | - | - | - | 10 |

| Sample | 2θ (°) | A1/A2 | Grain Size | Interplanar Spacing (Å) | Crystallinity (%) |

|---|---|---|---|---|---|

| B46-82 | 20.9/23.9 | 0.06 | 78 | 4.24/3.73 | 55.1 |

| B46-73 | 20.7/23.7 | 0.05 | 67 | 4.29/3.75 | 55.6 |

| B46-64 | 20.6/23.8 | 0.04 | 53 | 4.31/3.73 | 47.8 |

| B46-55 | 20.6/23.9 | 0.04 | 52 | 4.31/3.73 | 45.1 |

| B46/R46-82 | 20.7/23.8 | 0.12 | 48 | 4.29/3.73 | 47.9 |

| B46/R46-73 | 20.7/23.8 | 0.11 | 46 | 4.29/3.73 | 43.8 |

| B46/R46-55 | 20.7/23.8 | 0.10 | 44 | 4.30/3.74 | 44.9 |

| B46/R46-46 | 20.7/23.8 | 0.15 | 48 | 4.30/3.74 | 43.7 |

| Sample | T5 (°C) | T10 (°C) | T50 (°C) | DTG Peak 1 | DTG Peak 2 | ||

|---|---|---|---|---|---|---|---|

| Tdeg1 (°C) | TG (%) | Tdeg2 (°C) | TG (%) | ||||

| PA4 | 264.2 | 276.2 | 296.5 | 301.2 | 35.3 | - | - |

| B46-82 | 265.0 | 281.8 | 307.6 | 302.5 | 60.7 | 454.0 | 6.5 |

| B46-73 | 261.2 | 281.0 | 312.4 | 304.6 | 61.5 | 448.8 | 8.9 |

| B46-64 | 250.8 | 282.2 | 317.1 | 305.9 | 65.7 | 448.0 | 14.0 |

| B46-55 | 246.5 | 286.1 | 338.2 | 310.7 | 69.9 | 451.9 | 18.3 |

| B46/R46-82 | 261.6 | 283.1 | 311.5 | 305.9 | 60.3 | 449.3 | 10.4 |

| B46/R46-73 | 255.1 | 282.3 | 311.9 | 304.6 | 62.1 | 448.0 | 11.4 |

| B46/R46-55 | 251.3 | 281.0 | 313.7 | 303.8 | 64.5 | 448.4 | 11.5 |

| B46/R46-46 | 259.4 | 283.1 | 318.8 | 306.4 | 65.4 | 448.8 | 13.3 |

| PA6 | 389.0 | 407.9 | 442.4 | - | - | 448.0 | 38.6 |

| Sample | Tensile Strength (MPa) | Fracture Strain (%) | Young’s Moduli (MPa) |

|---|---|---|---|

| PA4 | 31.99 ± 2.36 | 112.88 ± 12.35 | 870.35 ± 13.44 |

| B46-82 | 35.17 ± 4.97 | 225.88 ± 51.39 | 850.16 ± 21.57 |

| B46-73 | 63.11 ± 15.39 | 348.72 ± 87.17 | 921.95 ± 40.35 |

| B46-64 | 67.40 ± 11.61 | 369.88 ± 27.37 | 913.87 ± 20.85 |

| B46-55 | 56.49 ± 1.70 | 298.23 ± 40.11 | 866.49 ± 31.21 |

| B46/R46-82 | 48.17 ± 2.02 | 224.09 ± 4.26 | 825.71 ± 4.56 |

| B46/R46-73 | 41.30 ± 3.23 | 262.00 ± 26.04 | 791.91 ± 19.82 |

| B46/R46-55 | 51.21 ± 0.08 | 309.24 ± 26.25 | 727.95 ± 22.36 |

| B46/R46-46 | 55.57 ± 4.54 | 299.31 ± 28.70 | 797.43 ± 19.64 |

| PA6 | 71.38 ± 4.42 | 338.06 ± 20.44 | 669.38 ± 21.68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Wang, M.; Zhang, D.; Wang, Y.; Wang, L.; Qiu, Y.; Wang, L.; Chen, T.; Zhao, L. Crystallization and Performance of Polyamide Blends Comprising Polyamide 4, Polyamide 6, and Their Copolymers. Polymers 2023, 15, 3399. https://doi.org/10.3390/polym15163399

Zhang Y, Wang M, Zhang D, Wang Y, Wang L, Qiu Y, Wang L, Chen T, Zhao L. Crystallization and Performance of Polyamide Blends Comprising Polyamide 4, Polyamide 6, and Their Copolymers. Polymers. 2023; 15(16):3399. https://doi.org/10.3390/polym15163399

Chicago/Turabian StyleZhang, Yajing, Mingda Wang, Di Zhang, Yibing Wang, Li Wang, Yongjun Qiu, Liquan Wang, Tao Chen, and Liming Zhao. 2023. "Crystallization and Performance of Polyamide Blends Comprising Polyamide 4, Polyamide 6, and Their Copolymers" Polymers 15, no. 16: 3399. https://doi.org/10.3390/polym15163399

APA StyleZhang, Y., Wang, M., Zhang, D., Wang, Y., Wang, L., Qiu, Y., Wang, L., Chen, T., & Zhao, L. (2023). Crystallization and Performance of Polyamide Blends Comprising Polyamide 4, Polyamide 6, and Their Copolymers. Polymers, 15(16), 3399. https://doi.org/10.3390/polym15163399