Single, Double and ETL-Sandwiched PVPy Interlayer Effect on Charge Injection Balance and Performance of Inverted Quantum Dot Light-Emitting Diodes

Abstract

1. Introduction

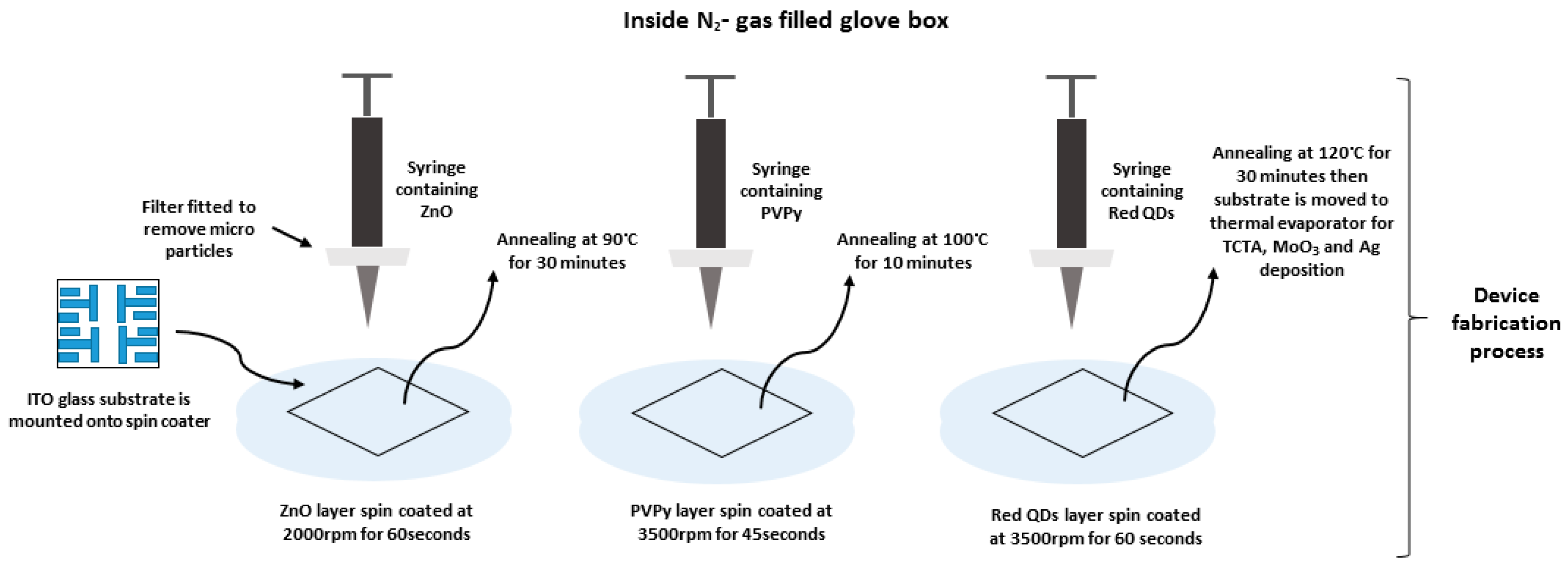

2. Materials and Experiments

2.1. Materials

2.2. Preparation of PVPy Solutions for Stacked Interlayer

2.3. Device Fabrication

2.4. Characterization

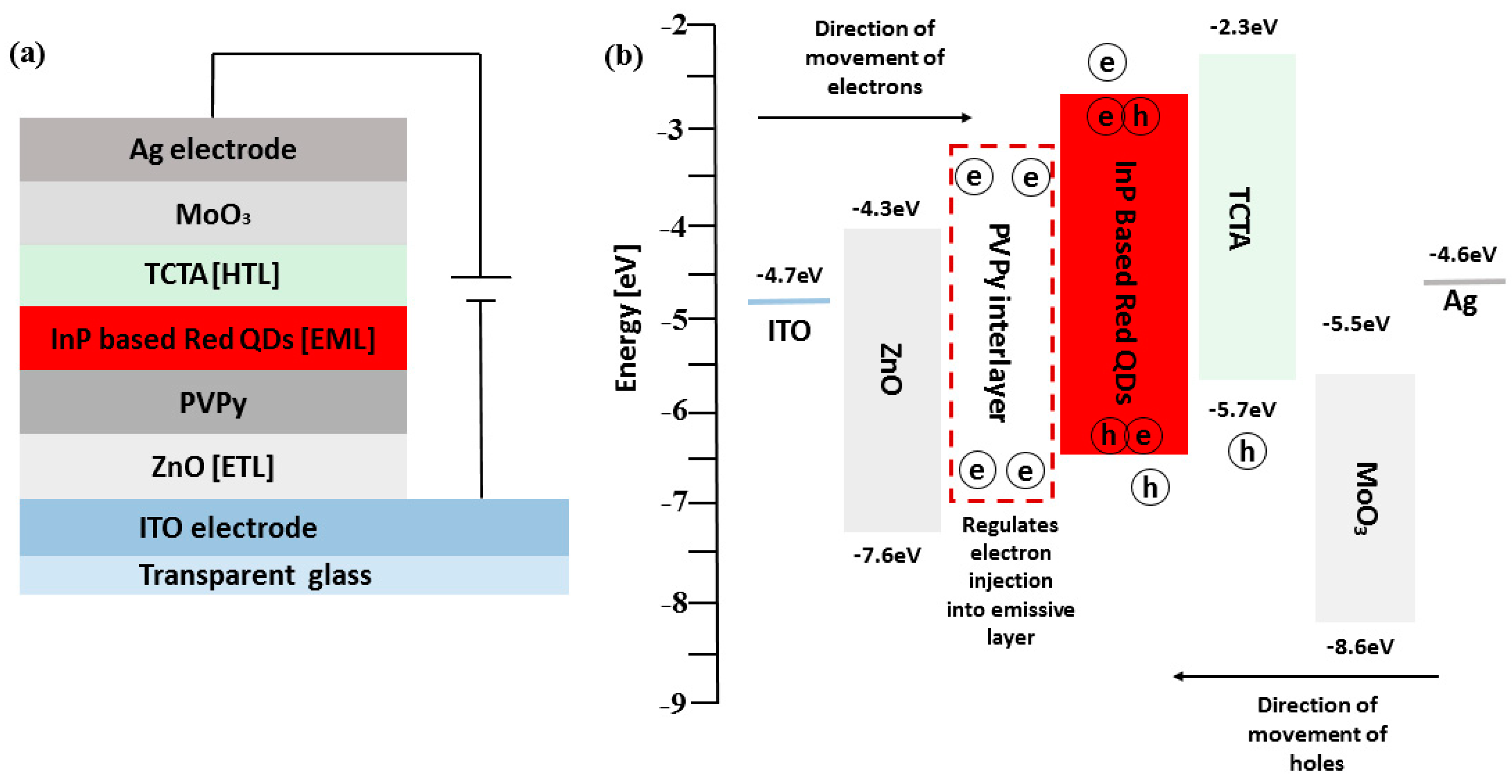

3. Results and Discussion

- i.

- ITO/ZnO/nP-red QDs/ZnO/Ag [reference] (without PVPy).

- ii.

- ITO/ZnO/PVPy [0.1 mg/mL]/InP-red QDs/ZnO/Ag.

- iii.

- ITO/ZnO/PVPy [0.2 mg/mL]/InP-red QDs/ZnO/Ag.

- iv.

- ITO/ZnO/PVPy [0.3 mg/mL]/InP-red QDs/ZnO/Ag.

- v.

- ITO/ZnO/PVPy [0.5 mg/mL]/InP-red QDs/ZnO/Ag.

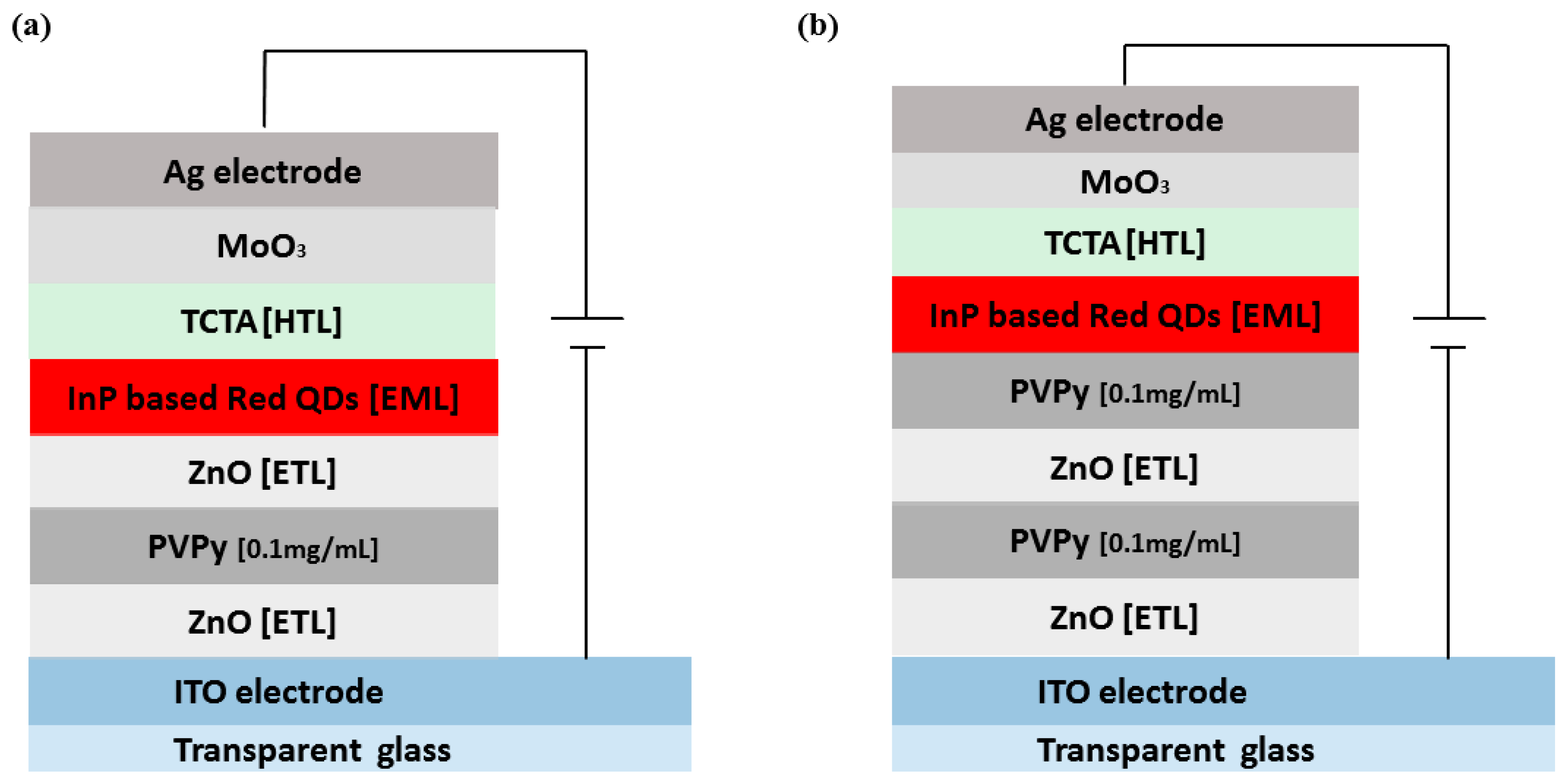

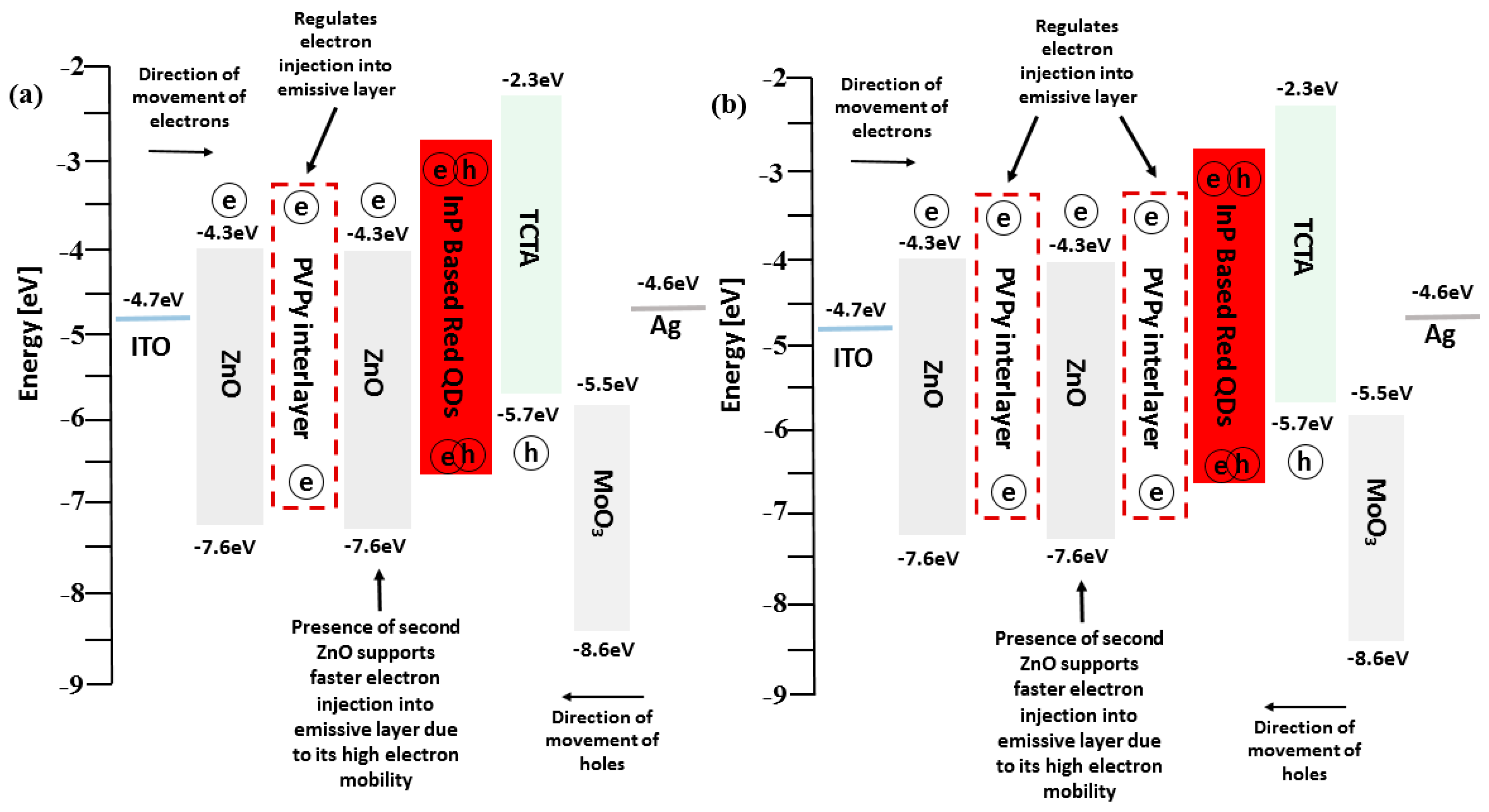

- vi.

- ITO/ZnO/PVPy [0.1 mg/mL]/ZnO/InP-red QDs/ZnO/Ag.

- vii.

- ITO/ZnO/PVPy [0.1 mg/mL]/ZnO/PVPy [0.1 mg/mL]/InP-red QDs/ZnO/Ag.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Mônica, A.C. Quantum Dots and their Applications: What lies ahead? ACS Appl. Nano Mater. 2020, 3, 4920–4924. [Google Scholar]

- Jang, E.J.; Jang, H.S. Quantum Dot light-Emitting Diodes. Chem. Rev. 2023, 123, 4663–4692. [Google Scholar] [CrossRef] [PubMed]

- Meng, T.; Zheng, Y.; Zhao, D.; Hu, H.; Zhu, Y.; Xu, Z.; Ju, S.; Jing, J.; Chen, X.; Gao, H.; et al. Ultrahigh-resolution quantum-dot light-emitting diodes. Nat. Photonics 2022, 16, 297–303. [Google Scholar] [CrossRef]

- Zhang, H.; Ma, X.; Lin, Q.; Zeng, Z.; Wang, H.; Li, L.S.; Shen, H.; Jia, Y.; Du, Z. High-Brightness Blue InP Quantum Dot-Based Electroluminescent Devices: The Role of Shell Thickness. J. Phys. Chem. Lett. 2020, 11, 960–967. [Google Scholar] [CrossRef]

- Shirasaki, Y.; Supran, G.; Moungi, G.; Bawendi, M.; Bulović, V. Emergence of colloidal quantum-dot light-emitting technologies. Nat. Photonics 2013, 7, 13–23. [Google Scholar] [CrossRef]

- Vasilopoulou, M.; Fakharuddin, A.; García de Arquer, F.P.; Georgiadou, D.; Kim, H.B.; Yusoff, A.R.M.; Gao, F.; Nazeeruddin, M.; Bolink, H.; Sargent, E. Advances in solution-processed near-infrared light-emitting diodes. Nat. Photonics 2021, 15, 656–669. [Google Scholar] [CrossRef]

- Zaiats, G.; Ikeda, S.; Kamat, P.V. Optimization of the electron transport layer in quantum dot light-emitting devices. NPG Asia Mater. 2020, 12, 83. [Google Scholar] [CrossRef]

- Choi, M.K.; Yang, J.W.; Kang, K.H.; Kim, D.C.; Choi, C.S.; Park, C.E.; Kim, S.J.; Chae, S.I.; Kim, T.-H.; Kim, J.H.; et al. Wearable red–green–blue quantum dot light-emitting diode array using high-resolution intaglio transfer printing. Nat. Commun. 2015, 6, 7149. [Google Scholar] [CrossRef]

- Alexandrov, A.; Zvaigzne, M.; Lypenko, D.; Nabiev, I.; Samokhvalov, P. Al-, Ga-, Mg-, or Li-doped zinc oxide nanoparticles as electron transport layers for quantum dot light-emitting diodes. Sci. Rep. 2020, 10, 7496. [Google Scholar] [CrossRef]

- Yun, J.Y.; Jae, Y.K.; Jung, J.B.; Kim, G.T.; Kwak, J.H. Enhanced efficiency and high temperature stability of hybrid quantum dot light-emitting diodes using molybdenum oxide doped hole transport layer. RSC Adv. 2019, 9, 16252. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Nguyen, N.D.; Lee, S. Application of solution-processed metal oxide layers as charge transport layers for CdSe/ZnS quantum-dots LEDs. Nanotechology 2013, 24, 115201. [Google Scholar] [CrossRef] [PubMed]

- Sharma, D.K.; Shukla, S.; Sharma, K.K.; Kumar, V. A review on ZnO: Fundamental properties and applications. Mater. Today Proc. 2022, 49, 3028–3035. [Google Scholar] [CrossRef]

- Moyen, E.; Kim, J.H.; Kim, J.G.; Jang, J. ZnO Nanoparticles for Quantum-Dot-Based Light Emitting Diodes. ASC Appl. Nano Mater. 2020, 3, 5203–5211. [Google Scholar] [CrossRef]

- Huh, D.H.; Kim, G.W.; Kim, G.H.; Kulshershtha, C. High hole mobility hole transport material for organic light-emitting devices. Systhesis Met. 2013, 180, 79–84. [Google Scholar] [CrossRef]

- Cao, W.; Xiang, C.; Yang, Y.; Chen, Q.; Chen, L.; Yan, X.; Qian, L. Highly stable QLEDs with improved hole injection via quantum dot structure tailoring. Nat. Commun. 2018, 9, 2608. [Google Scholar] [CrossRef]

- Zhang, X.; Dai, H.; Zhao, J.; Wang, S.; Sun, X. All-solution processed composited hole transport layer for quantum dot light emitting diode. Thin Solid Film. 2016, 603, 187–192. [Google Scholar] [CrossRef]

- Huang, Q.; Zhao, S.; Guo, L.Z.; Wang, P.; Qin, Z. Effect of the charge balance on high-efficiency inverted polymer light-emitting diodes. Org. Electron. 2017, 49, 123–128. [Google Scholar] [CrossRef]

- Yuan, Q.; Wang, T.; Yu, P.; Zhang, H.; Zhang, H.; Ji, W. A review on the electroluminescence properties of quantum-dot light emitting diodes. Org. Electron. 2021, 90, 106086. [Google Scholar] [CrossRef]

- Chang, J.H.; Park, P.; Jung, H.Y.; Jeong, B.G.; Hahm, D.H.; Nagamine, G.; Ko, J.K.; Cho, J.H.; Padilha, L.A.; Lee, D.C.; et al. Unravelling the Origin of Operational Instability of Quantum Dot Based Light-Emitting Diodes. ASC Nano 2018, 12, 10231–10239. [Google Scholar] [CrossRef]

- Chiu, P.-C.; Yang, S.-H. Improvement in hole transporting ability and device performance of quantum dot light emitting diodes. Nanoscale Adv. 2020, 2, 401–407. [Google Scholar] [CrossRef]

- Zheng, W.; Xu, Z.; Song, D.; Zhao, S.; Qiao, B.; Chen, J.; Wang, P.; Zheng, X. Enhancing the efficiency and luminance of quantum dot light-emitting diodes by inserting a leaked electron harvesting layer with thermal-activated delayed fluorescence material. Org. Electron. 2019, 65, 357–362. [Google Scholar] [CrossRef]

- Wang, F.; Sun, W.; Liu, P.; Wang, Z.; Zhang, Z.; Wei, J.; Li, Y.; Hayat, T.; Alsaedi, T.; Tan, Z. Achieving Balanced Charge Injection of Blue Quantum Dot Light Emitting Diodes through Transport Layer Doping Strategies. J. Phys. Chem. Lett. 2019, 10, 960–965. [Google Scholar] [CrossRef] [PubMed]

- Yun, J.Y.; Kim, J.Y.; Jang, H.-K.; Lee, K.J.; Seo, J.H.; Jung, B.J.; Kim, G.T.; Kwak, J.H. Controlling charge balance using non-conjugated polymer interlayer in quantum dot light-emitting diodes. Org. Electron. 2017, 50, 82–86. [Google Scholar] [CrossRef]

- Yavari, M.; Mohammad, M.-A.; Gholipour, S.; Tavakoli, M.M.; Taghavinia, N.; Hagfeldt, A.; Tress, W. Reducing Surface Recombination by a Poly(4-vinylpyridine) Interlayer in Perovskite Solar Cells with High Open-Circuit Voltage and Efficiency. ACS Omega 2018, 3, 5038–5043. [Google Scholar] [CrossRef]

- Vishwakarma, A.; Singh, S.P. Synthesis of Zinc Oxide Nanoparticle by Sol-Gel Method and Study its Characterization. Int. J. Res. Appl. Sci. Eng. Technol. 2020, 8, 4. [Google Scholar] [CrossRef]

- Hasnidawani, J.N.; Azlina, H.N.; Norita, H.; Bonnia, N.N.; Ratim, S.; Ali, E.S. Synthesis of ZnO Nanostructures Using Sol-Gel Method. Procedia Chem. 2019, 19, 211–216. [Google Scholar] [CrossRef]

- Qian, L.; Zheng, Y.; Xue, J.; Holloway, P.H. Stable and efficient quantum-dot light-emitting diodes based on solution-processed multilayer structures. Nat. Photonics 2011, 5, 543–548. [Google Scholar] [CrossRef]

- Stouwdam, J.W.; Janssen, R.A.J. Red, Green and Blue Quantum Dots LEDs with solution Processible ZnO Nanocrystal Electron Injection Layers. J. Mater.Chem. 2008, 18, 1889–1894. [Google Scholar] [CrossRef]

- Kim, H.H.; Park, S.; Yi, Y.; Son, D.I.; Park, C.; Hwang, D.K.; Choi, W.K. Inverted Quantum Dot Light Emitting Diodes using Polyethyleneimine Ethoxylated Modified ZnO. Sci. Rep. 2015, 5, 8968. [Google Scholar] [CrossRef]

- Sasaki, T.; Hasegawa, M.; Inagaki, K.; Ito, H.; Suzuki, K.; Oono, T.; Morii, K.; Shimizu, T.; Fukagawa, H. Unravelling the electron injection/transport mechanism in organic light-emitting diodes. Nat. Commun. 2021, 12, 2706. [Google Scholar] [CrossRef]

- Chen, Y.; Chu, S.; Li, R.; Qin, Y.; Xu, Y.; Zhang, X.; Wang, J.; Liu, M.; Lai, W.-Y.; Huang, W. Highly efficient inverted organic light-emitting devices adopting solution-processed double electron-injection layers. Org. Electron. 2019, 66, 1–6. [Google Scholar] [CrossRef]

- Xiao, X.; Wang, K.; Ye, T.; Cai, R.; Wu, D.; Qu, X.; Sun, J.; Ding, S.; Sun, X.W. Enhanced hole injection assisted by electric dipoles for efficient Perovskite light-emitting diodes. Commun. Mater. 2020, 1, 81. [Google Scholar] [CrossRef]

- Yan, H.; Limbu, S.; Wang, X.; Nightingale, J.; Hamilton, I.; Wade, J.; Kwon, S.C.; Lee, K.H.; Kim, J.-S. Efficient Charge Carrier injection and Balance Achieved by Low Electrochemical Doping in Solution-Processed Polymer Light Emitting Diodes. Adv. Funct. Mater. 2019, 29, 1904092. [Google Scholar] [CrossRef]

- Ji, W.; Liu, S.; Zhang, H.; Wang, R.; Xie, W.; Zhang, H. Ultrasonic Spray Processed, Highly Efficient All-Inorganic Quantum Dot Light Emitting Diodes. ACS Photonics 2017, 4, 1271–1278. [Google Scholar] [CrossRef]

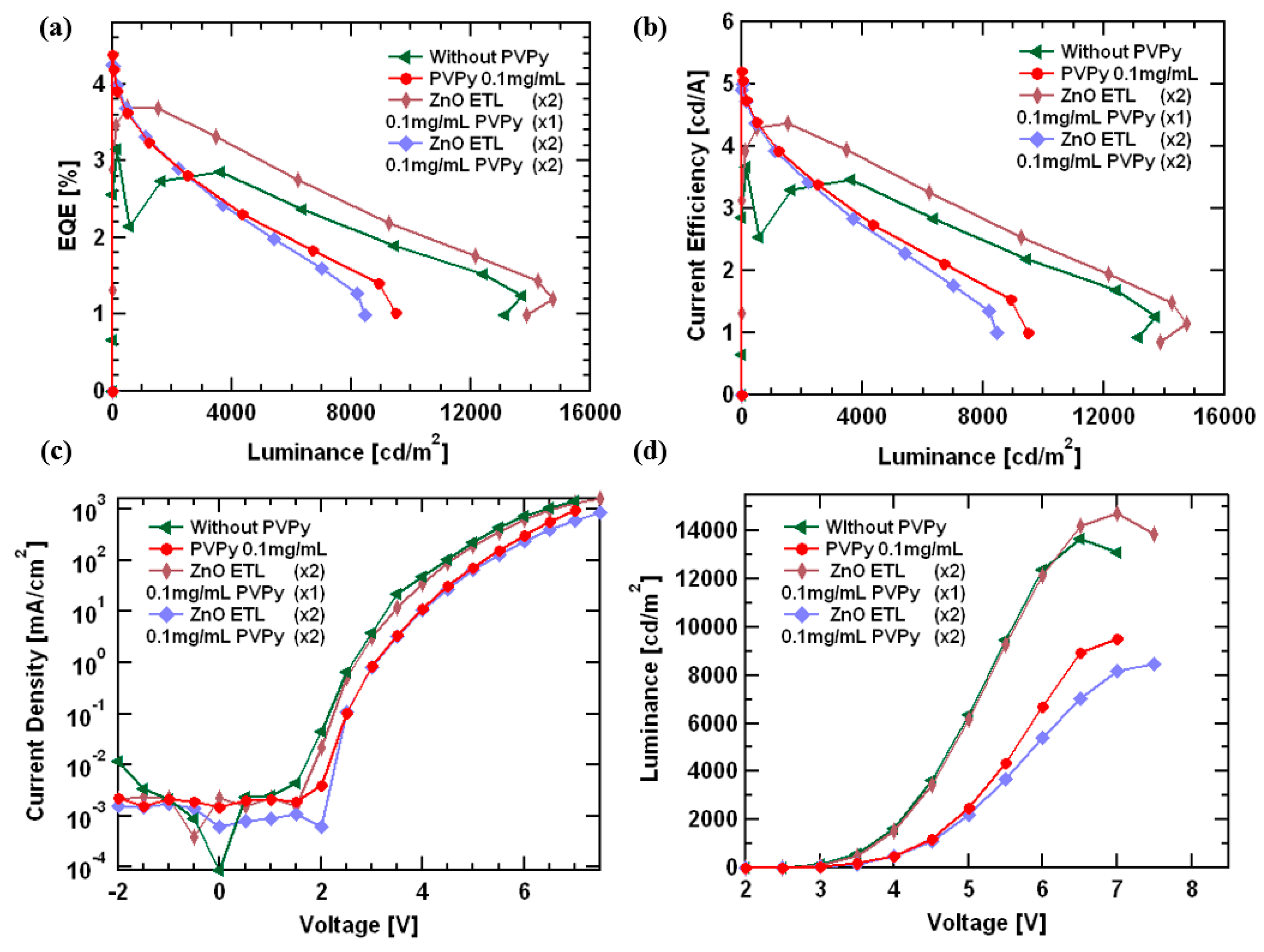

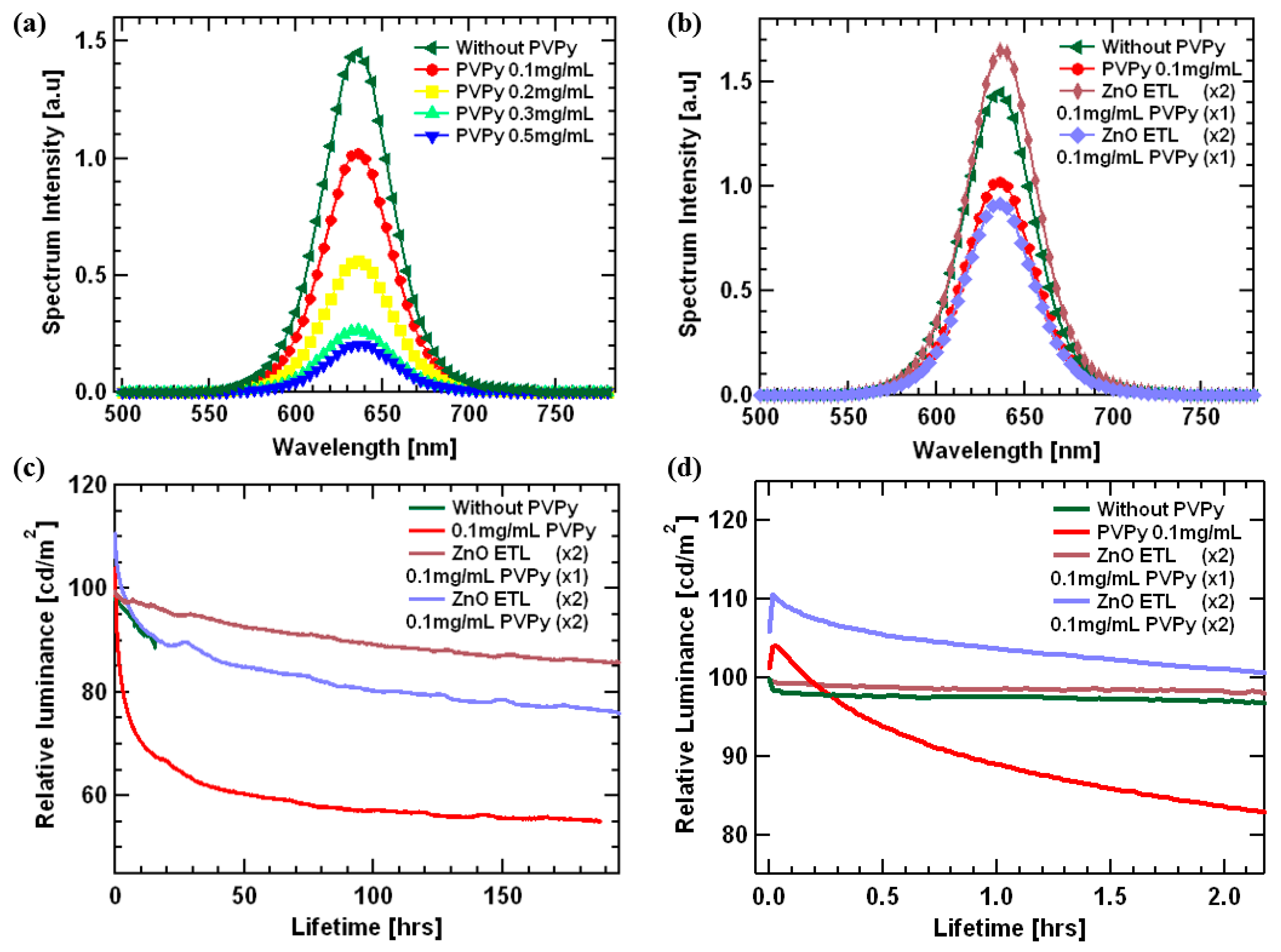

| Device | Turn-On Voltage [V] | Max EQE [%] | EQE@100 nits [%] | Current Efficiency@100 nits [cd/A] | Device Max Luminance [cd/m2] | Lifetime @ T90 |

|---|---|---|---|---|---|---|

| Reference device (Without PVPy) | 2.5 | 3.15@3.0 V | 2.96 | 3.47 | 13,700 | 14.4 |

| 0.1 mg/mL PVPy | 2.5 | 4.39@2.5 V | 4.06 | 4.91 | 9501 | 0.86 |

| 0.2 mg/mL PVPy | 2.5 | 4.01@3.0 V | 3.15 | 4.15 | 5173 | - |

| 0.3 mg/mL PVPy | 2.5 | 4.99@2.5 V | 2.92 | 3.15 | 2465 | - |

| 0.5 mg/mL PVPy | 2.5 | 4.36@3.0 V | 2.17 | 2.54 | 1825 | - |

| Double ZnO ETL Single 0.1 mg/mL PVPy | 2.5 | 3.69@3.5 V | 3.36 | 3.78 | 14,750 | 87.3 |

| Double ZnO ETL Double 0.1 mg/mL PVPy | 2.5 | 4.25@2.5 V | 4.11 | 4.85 | 8446 | 16.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kiguye, C.; Jeong, W.J.; Jeong, G.H.; Park, J.H.; Kwak, H.J.; Kim, G.W.; Jang, S.H.; Kim, J.Y. Single, Double and ETL-Sandwiched PVPy Interlayer Effect on Charge Injection Balance and Performance of Inverted Quantum Dot Light-Emitting Diodes. Polymers 2023, 15, 3308. https://doi.org/10.3390/polym15153308

Kiguye C, Jeong WJ, Jeong GH, Park JH, Kwak HJ, Kim GW, Jang SH, Kim JY. Single, Double and ETL-Sandwiched PVPy Interlayer Effect on Charge Injection Balance and Performance of Inverted Quantum Dot Light-Emitting Diodes. Polymers. 2023; 15(15):3308. https://doi.org/10.3390/polym15153308

Chicago/Turabian StyleKiguye, Collins, Woo Jin Jeong, Gwang Hyun Jeong, Jin Ho Park, Hee Jung Kwak, Gun Woong Kim, Seok Hwan Jang, and Jun Young Kim. 2023. "Single, Double and ETL-Sandwiched PVPy Interlayer Effect on Charge Injection Balance and Performance of Inverted Quantum Dot Light-Emitting Diodes" Polymers 15, no. 15: 3308. https://doi.org/10.3390/polym15153308

APA StyleKiguye, C., Jeong, W. J., Jeong, G. H., Park, J. H., Kwak, H. J., Kim, G. W., Jang, S. H., & Kim, J. Y. (2023). Single, Double and ETL-Sandwiched PVPy Interlayer Effect on Charge Injection Balance and Performance of Inverted Quantum Dot Light-Emitting Diodes. Polymers, 15(15), 3308. https://doi.org/10.3390/polym15153308