Flexible BaTiO3-PDMS Capacitive Pressure Sensor of High Sensitivity with Gradient Micro-Structure by Laser Engraving and Molding

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals and Materials

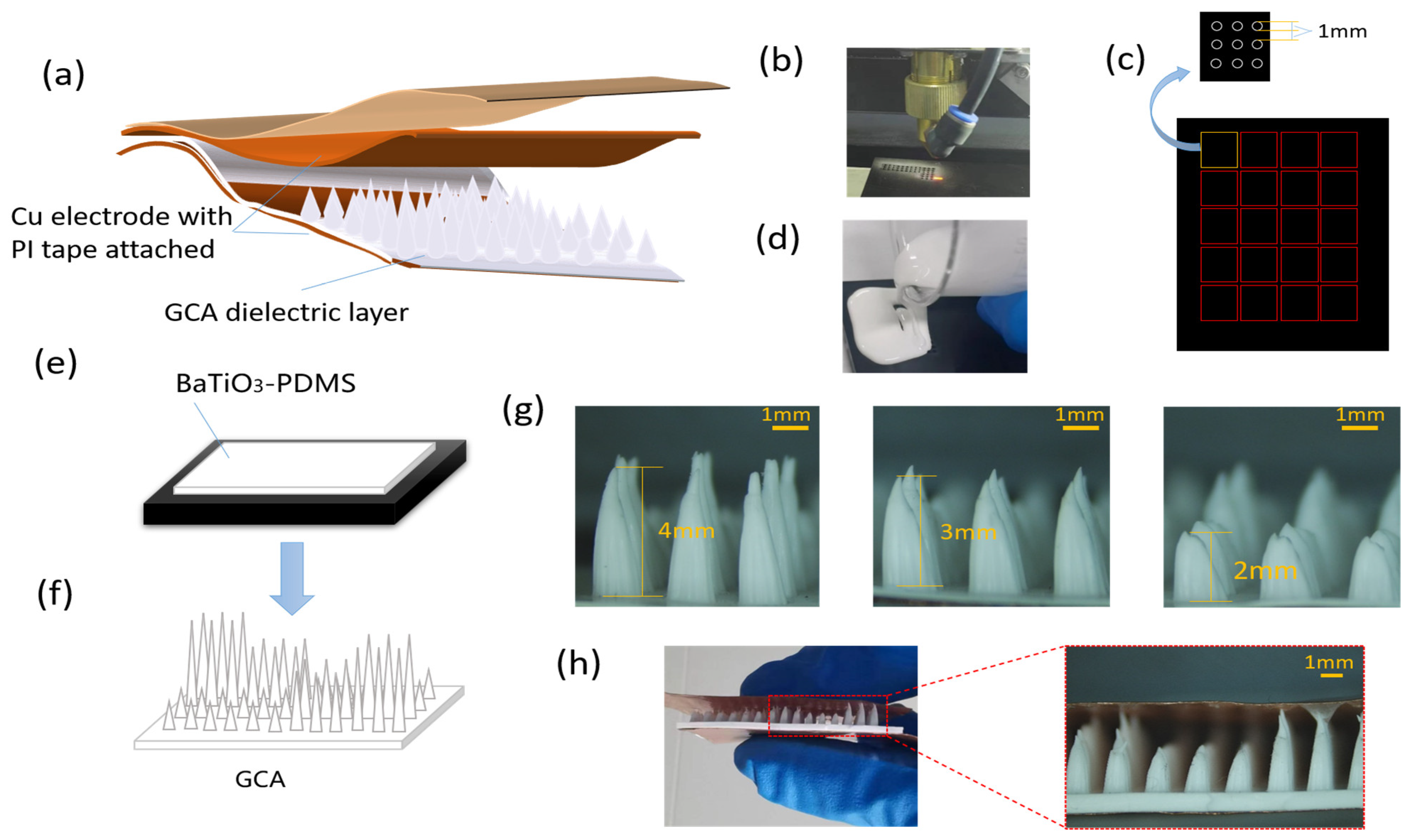

2.2. Sensor Fabrication

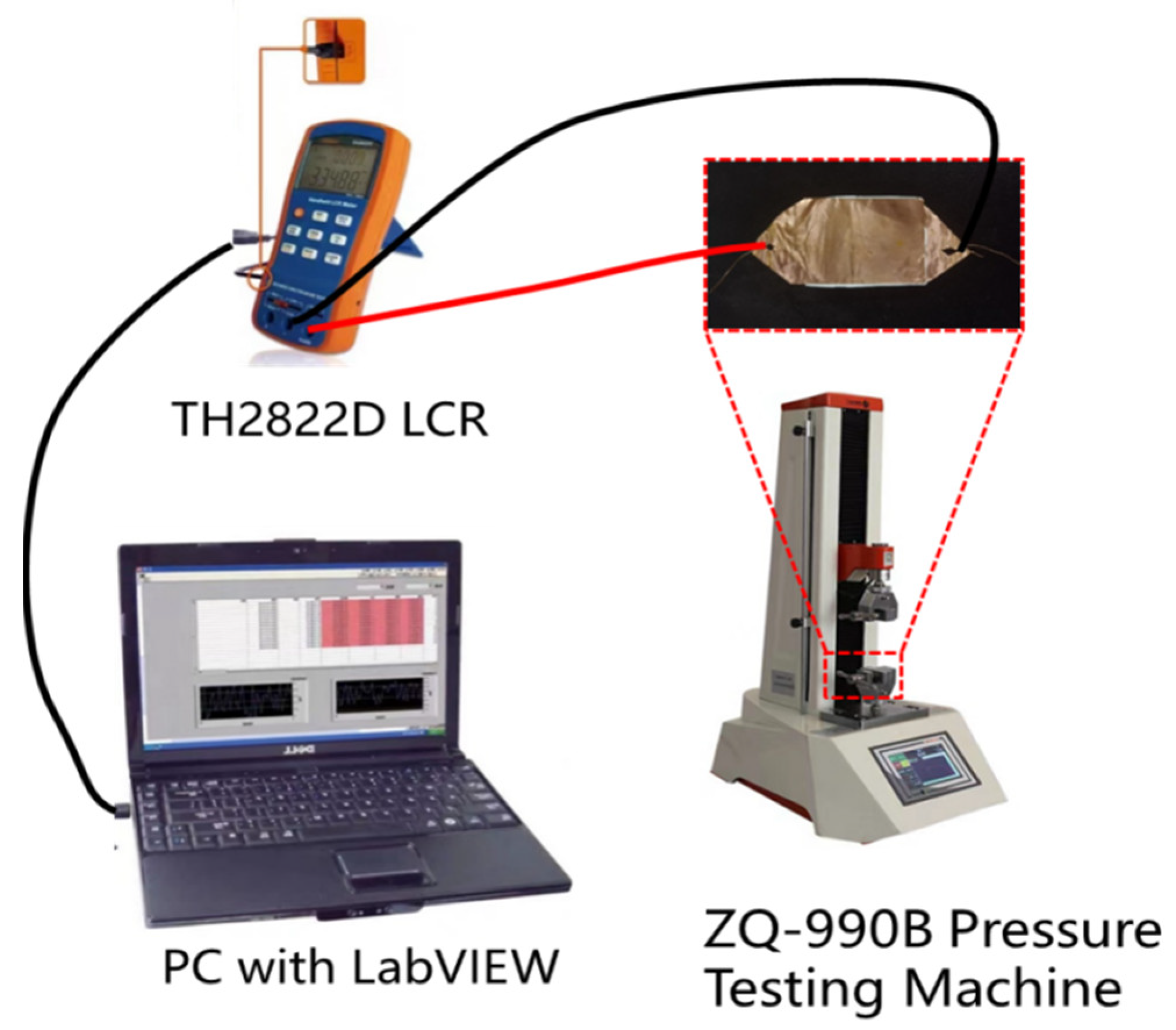

2.3. Experiment Setup

3. Results and Discussion

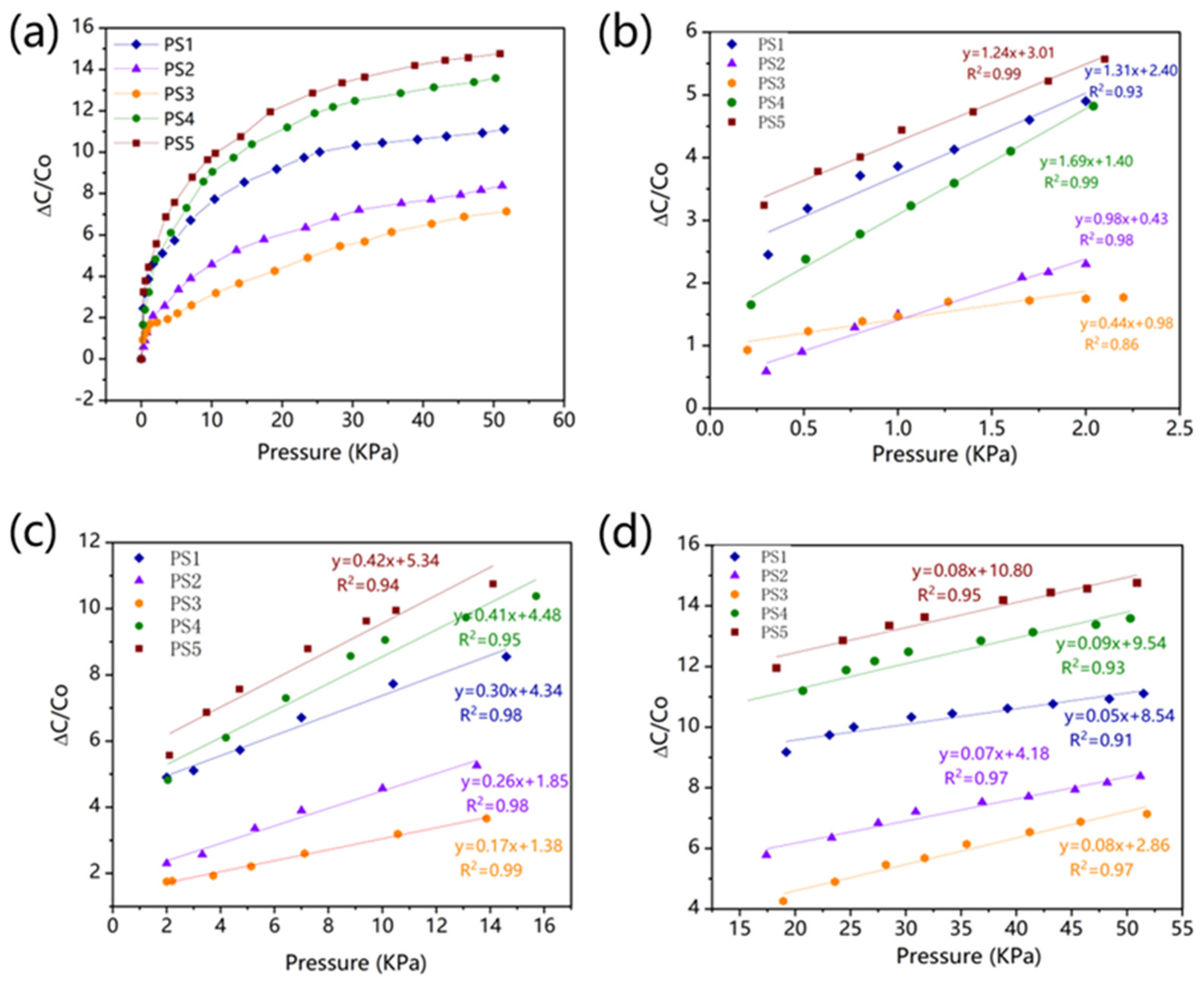

3.1. Capacitive Pressure Sensor Response

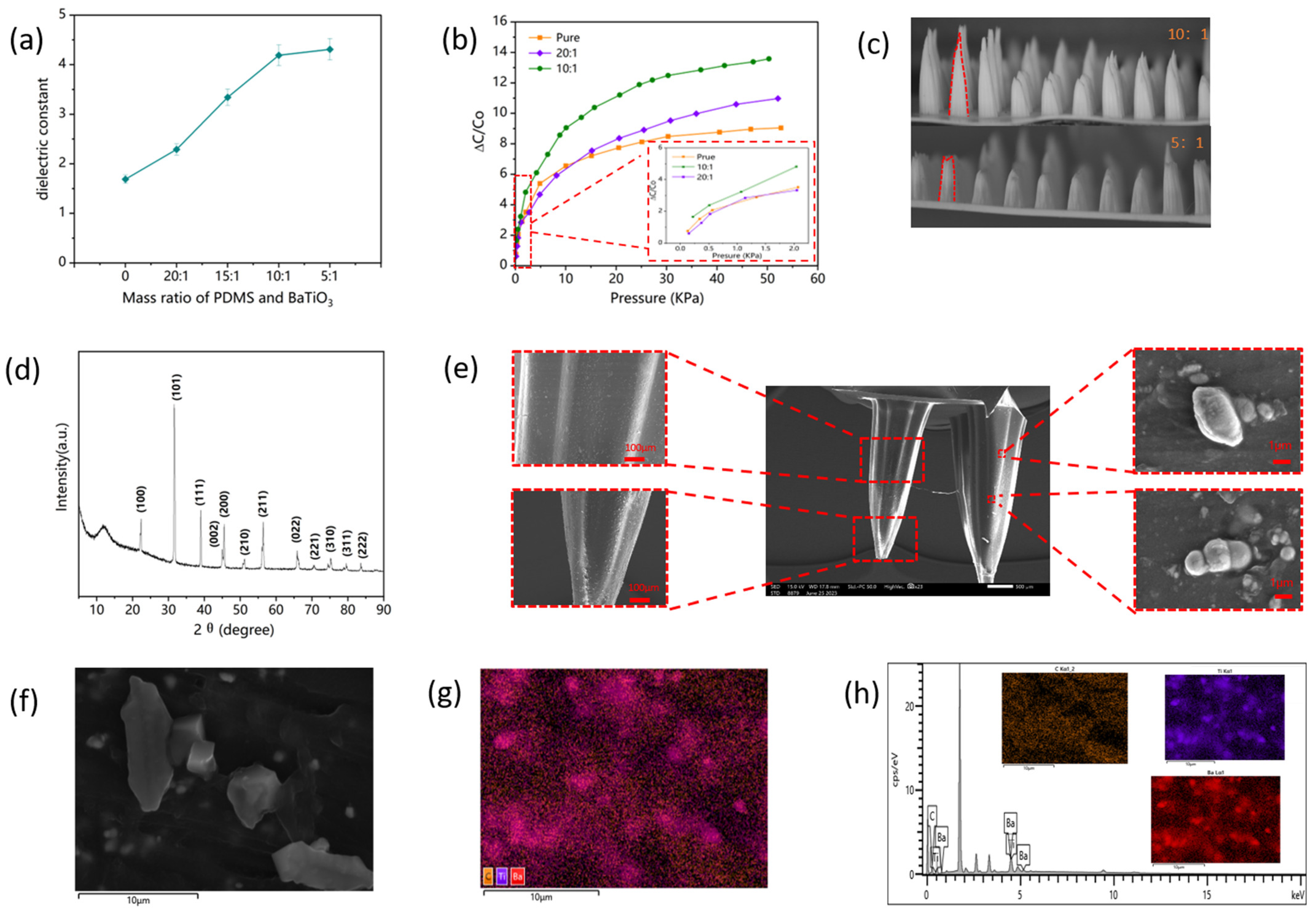

3.2. The Impact of BaTiO3 on Sensor Performance and Content Determination

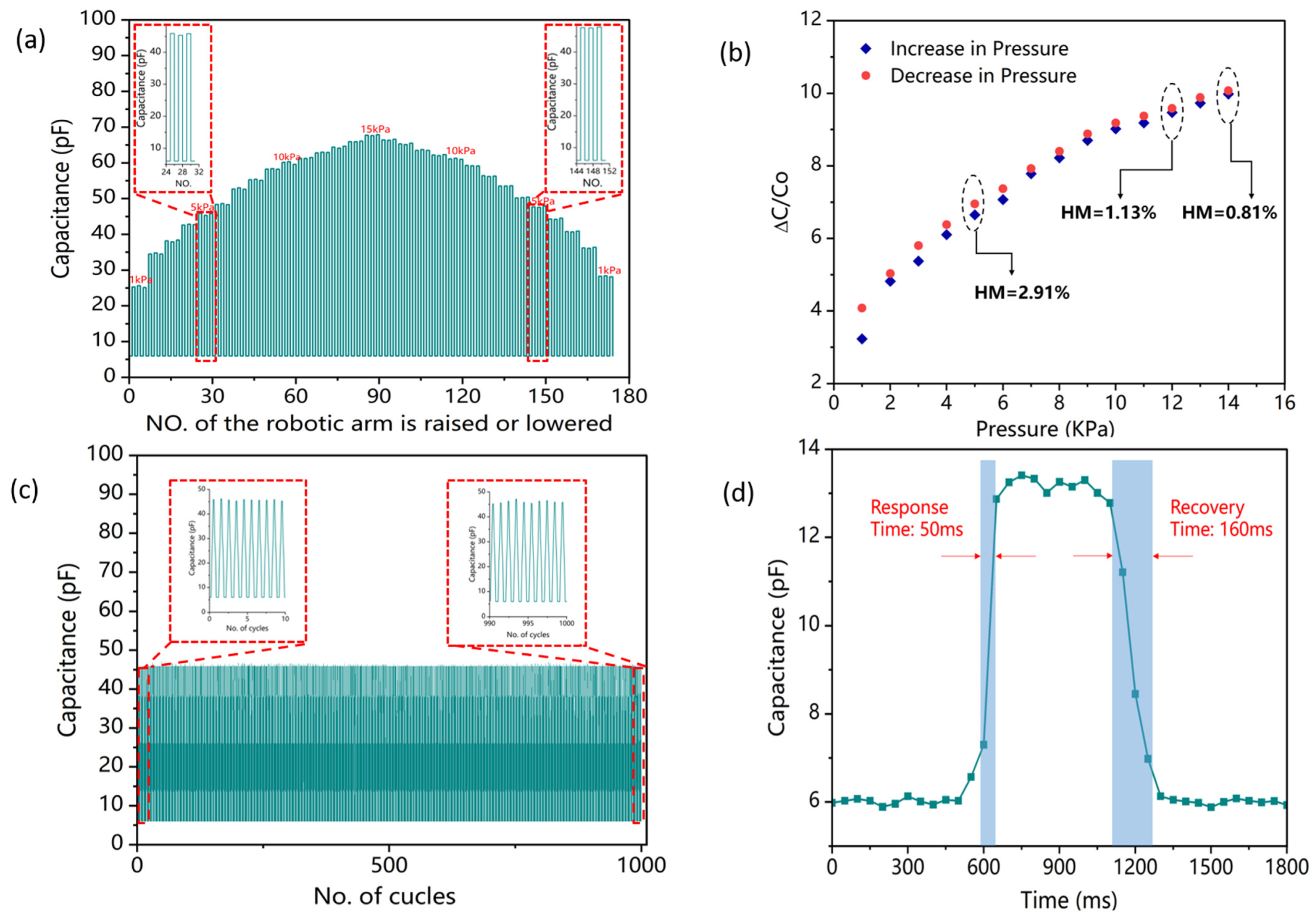

3.3. Hysteresis Response

3.4. Repeatability

3.5. Response and Recovery Time

3.6. Comparison of the Performance Indicators of Various Microstructure Capacitive Pressure Sensors

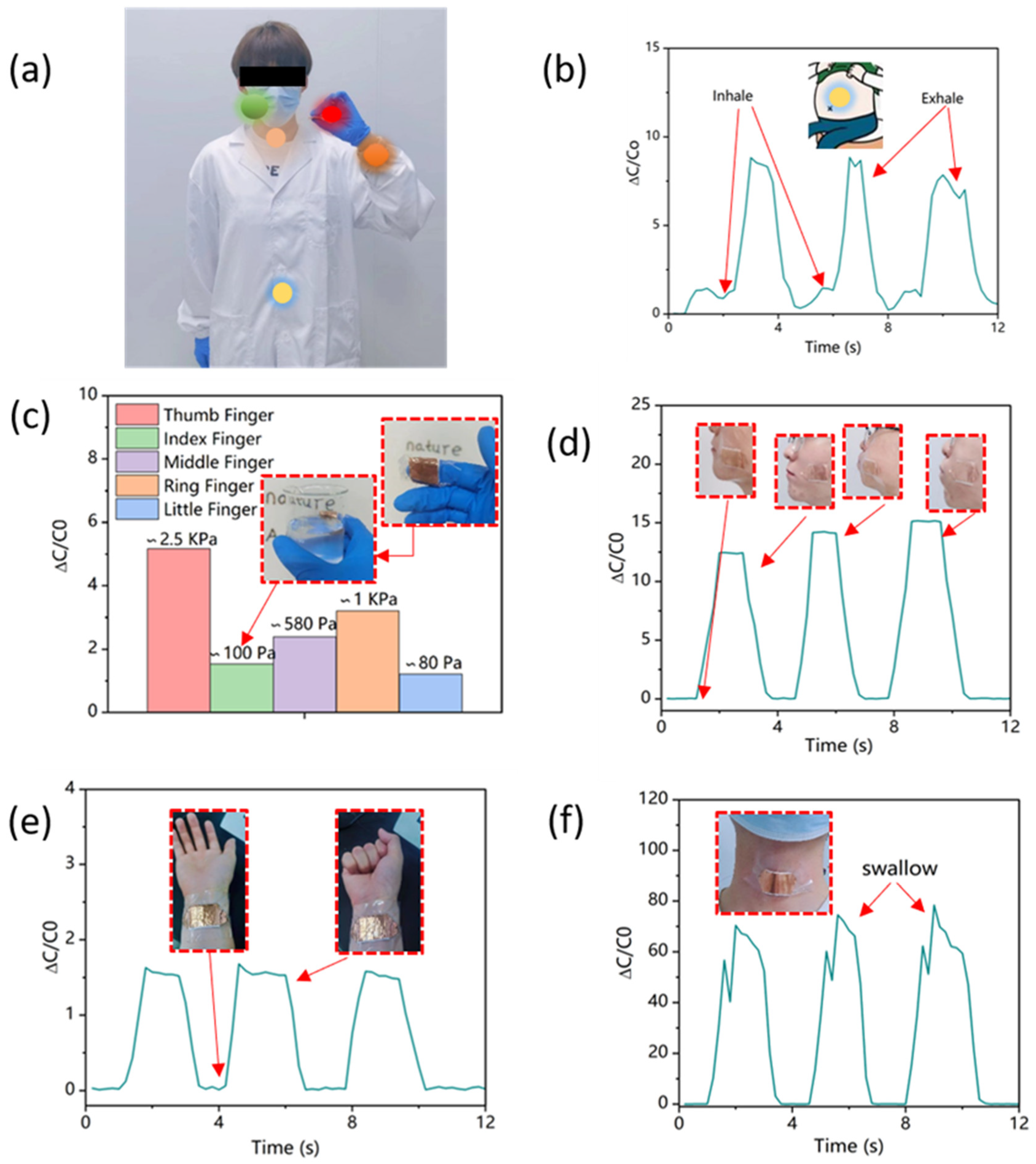

3.7. Application Demonstration

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Araromi, O.A.; Graule, M.A.; Dorsey, K.L. Ultra-Sensitive and Resilient Compliant Strain Gauges for Soft Machines. Nature 2020, 587, 219–224. [Google Scholar] [CrossRef]

- Zhan, Z.; Lin, R.; Tran, V.-T.; An, J.; Wei, Y.; Du, H.; Tran, T.; Lu, W. Self-Powered Nanofluidic Pressure Sensor with A Linear Transfer Mechanism. ACS Appl. Mater. Interfaces 2017, 9, 37921–37928. [Google Scholar] [CrossRef] [PubMed]

- Pyo, S.; Lee, J.; Bae, K.; Sim, S.; Kim, J. Recent Progress in Flexible Tactile Sensors for Human-Interactive Systems: From Sensors to Advanced Applications. Adv. Mater. 2021, 33, 2005902. [Google Scholar] [CrossRef] [PubMed]

- Wadm, J.; Qi, K.; Qin, Y.; Chin, A.; Serrano-García, W.; Baskar, C.; Wang, H.; He, J.; Cui, S. Significance of Nanomaterials in Wearables: A Review on Wearable Actuators and Sensors. Adv. Mater. 2019, 31, e1805921. [Google Scholar] [CrossRef]

- Pang, Y.; Zhang, K.; Yang, Z.; Jiang, S.; Ju, Z.; Li, Y.; Wang, X.; Wang, D.; Jian, M.; Zhang, Y.; et al. Epidermis Microstructure Inspired Graphene Pressure Sensor with Random Distributed Spinosum for High Sensitivity and Large Linearity. ACS Nano 2018, 12, 2346–2354. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Z.; Zhang, T. Flexible Sensing Electronics for Wearable/Attachable Health Monitoring. Small 2017, 13, 1602790. [Google Scholar] [CrossRef]

- Yao, S.; Ren, P.; Song, R.; Liu, Y.; Huang, Q.; Dong, J.; O’Connor, B.T.; Zhu, Y. Nanomaterial-Enabled Flexible and Stretchable Sensing Systems: Processing, Integration, and Applications. Adv. Mater. 2020, 32, 1902343. [Google Scholar] [CrossRef]

- Soni, M.; Dahiya, R. Soft eSkin: Distributed Touch Sensing with Harmonized Energy and Computing. Philos. Trans. Royal Soc. A Math. Phys. Eng. Sci. 2020, 378, 2164. [Google Scholar] [CrossRef]

- Wang, N.; Tong, J.; Wang, J.; Wang, Q.; Chen, S.; Sheng, B. Polyimide-Sputtered and Polymerized Films with Ultrahigh Moisture Sensitivity for Respiratory Monitoring and Contactless Sensing. ACS Appl. Mater. Interfaces 2022, 14, 11842–11853. [Google Scholar] [CrossRef]

- Ji, B.; Zhou, Q.; Hu, B.; Zhong, J.; Zhou, J.; Zhou, B. Bio-Inspired Hybrid Dielectric for Capacitive and Triboelectric Tactile Sensors with High Sensitivity and Ultrawide Linearity Range. Adv. Mater. 2021, 33, 2100859. [Google Scholar] [CrossRef]

- Ruth, S.R.A.; Feig, V.R.; Tran, H.; Bao, Z. Microengineering Pressure Sensor Active Layers for Improved Performance. Adv. Funct. Mater. 2020, 30, 2003491. [Google Scholar] [CrossRef]

- Tian, H.; Shu, Y.; Wang, X.-F.; Ali Mohammad, M.; Bie, Z.; Xie, Q.-Y.; Li, C.; Mi, W.-T.; Yang, Y.; Ren, T.-L. A Graphene-Based Resistive Pressure Sensor with Recordhigh Sensitivity in a Wide Pressure Range. Sci. Rep. 2015, 5, 8603. [Google Scholar] [CrossRef] [PubMed]

- Xiao, F.; Jin, S.; Zhang, W.; Zhang, Y.; Zhou, H.; Huang, Y. Wearable Pressure Sensor Using Porous Natural Polymer Hydrogel Elastomers with High Sensitivity Over a Wide Sensing Range. Polymers 2023, 15, 2736. [Google Scholar] [CrossRef] [PubMed]

- Ali, S.; Maddipatla, D.; Narakathu, B.-B.; Chlaihawi, A.-A.; Emamian, S.; Janabi, F. Flexible Capacitive Pressure Sensor Based on PDMS Substrate and Ga–In Liquid Metal. IEEE Sens. J. 2019, 19, 97–104. [Google Scholar] [CrossRef]

- Mitrakos, V.; Macintyre, L.; Denison, F.; Hands, P.; Desmulliez, M. Design. Manufacture and Testing of Capacitive Pressure Sensors for Low-Pressure Measurement Ranges. Micromachines 2017, 8, 41. [Google Scholar] [CrossRef]

- Ke, K.; Sang, Z.; Manas-Zloczower, I. Hybrid Systems of Three-Dimensional Carbon Nanostructures with Low Dimensional Fillers for Piezoresistive Sensors. Polym. Compos. 2020, 41, 468–477. [Google Scholar] [CrossRef]

- Xiao, J.; Xiong, Y.; Chen, J.; Zhao, S.; Chen, S.; Xu, B.; Sheng, B. Ultrasensitive and Highly Stretchable Fibers with Dual Conductive Microstructural Sheaths for Human Motion and Micro Vibration Sensing. Nanoscale 2022, 14, 1962–1970. [Google Scholar] [CrossRef]

- Kang, S.; Lee, J.; Lee, S.; Kim, S.; Kim, J.-K.; Algadi, H.; Al-Sayari, S.; Kim, D.-E.; Kim, D.; Lee, T. Highly Sensitive Pressure Sensor Based on Bioinspired Porous Structure for Real-Time Tactile Sensing. Adv. Electron. Mater. 2016, 2, 1600356. [Google Scholar] [CrossRef]

- Niu, H.; Yue, W.; Li, Y.; Yin, F.; Gao, S.; Zhang, C.; Kan, H.; Yao, Y.; Jiang, C.; Wang, C. Ultrafast-Response/Recovery Capacitive Humidity Sensor Based on Arc-Shaped Hollow Structure with Nanocone Arrays for Human Physiological Signals Monitoring. Sens. Actuators B-Chem. 2021, 334, 129637. [Google Scholar] [CrossRef]

- Mao, Y.; Robust, B.J. Wearable Pressure Sensor Assembled from Agnw-Coated PDMS Micropillar Sheets with High Sensitivity and Wide Detection Range. ACS Appl. Nano Mater. 2019, 2, 3196–3205. [Google Scholar] [CrossRef]

- Ha, K.-H.; Huh, H.; Li, Z.; Lu, N. Soft Capacitive Pressure Sensors: Trends, Challenges, and Perspectives. ACS Nano 2022, 16, 3442–3448. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Suzuki, R.; Shao, M.; Gillot, F.; Shiratori, S. Capacitive Pressure Sensor with Wide-Range, Bendable, and High Sensitivity Based on the Bionic Komochi Konbu Structure and Cu/Ni Nanofiber Network. ACS Appl. Mater. Interfaces 2019, 11, 11928–11935. [Google Scholar] [CrossRef]

- Bai, N.; Wang, L.; Wang, Q.; Deng, J.; Wang, Y.; Lu, P.; Huang, J.; Li, G.; Zhang, Y.; Yang, J.; et al. Graded Intrafillable Architecture-Based Iontronic Pressure Sensor with Ultra-Broad-Range High Sensitivity. Nat. Commun. 2020, 11, 209. [Google Scholar] [CrossRef] [PubMed]

- Ji, B.; Zhou, Q.; Wu, J.; Gao, Y.; Wen, W.; Zhou, B. Synergistic Optimization Toward the Sensitivity and Linearity of Flexible Pressure Sensor Via Double Conductive Layer and Porous Microdome Array. ACS Appl. Mater. Interfaces 2020, 12, 31021–31035. [Google Scholar] [CrossRef] [PubMed]

- Ji, B.; Zhou, Q.; Lei, M.; Ding, S.; Song, Q.; Gao, Y.; Li, S.; Xu, Y.; Zhou, Y. Gradient Architecture-Enabled Capacitive Tactile Sensor with High Sensitivity and Ultrabroad Linearity Range. Small 2021, 17, 2103312. [Google Scholar] [CrossRef] [PubMed]

- Pan, L.; Chortos, A.; Yu, G.; Wang, Y.; Isaacson, S.; Allen, R.; Shi, Y.; Dauskardt, R.; Bao, Z. An Ultra-Sensitive Resistive Pressure Sensor Based on Hollow-Sphere Microstructure Induced Elasticity in Conducting Polymer Film. Nat. Commun. 2013, 5, 3002. [Google Scholar] [CrossRef]

- Luo, Y.; Shao, J.; Chen, S.; Chen, X.; Tian, H.; Li, X.; Wang, L.; Wang, D.; Lu, B. Flexible Capacitive Pressure Sensor Enhanced by Tilted Micropillar Arrays. ACS Appl. Mater. Interfaces 2019, 11, 17796–17803. [Google Scholar] [CrossRef]

- Masihi, S.; Panahi, M.; Maddipatla, D.; Bose, A.-K.; Palaniappan, V.; Narakathu, B.-B.; Hanson, A.-J. A Novel Printed Fabric Based Porous Capacitive Pressure Sensor for Flexible Electronic Applications. In Proceedings of the IEEE Sensors, Montreal, QC, Canada, 27–30 October 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Luo, S.; Yang, J.; Song, X.; Zhou, X.; Yu, L.; Sun, T.; Yu, C.; Huang, D.; Du, C.; Wei, D. Tunable-Sensitivity Flexible Pressure Sensor Based on Graphene Transparent Electrode. Solid-State Electron. 2018, 145, 29–33. [Google Scholar] [CrossRef]

- Kim, H.; Kim, G.; Kim, T.; Lee, S.; Kang, D.; Hwang, M.-S.; Chae, Y.; Kang, S.; Lee, H.; Park, H.-G.; et al. Transparent, Flexible, Conformal Capacitive Pressure Sensors with Nanoparticles. Small 2018, 14, 1703432. [Google Scholar] [CrossRef]

- Li, F.; Kong, Z.; Wu, J.-H.; Ji, X.-Y.; Liang, J. Advances in Flexible Piezoresistive Pressure Sensor. Acta Phys. Sin. 2021, 70, 100703. [Google Scholar] [CrossRef]

- Hao, D.; Yang, R.; Yi, N. Highly sensitive piezoresistive pressure sensors based on laser-induced graphene with molybdenum disulfide nanoparticles. Sci. China Technol. 2021, 64, 2408–2414. [Google Scholar] [CrossRef]

- Zhou, Q.; Ji, B.; Wei, Y.; Hu, B.; Gao, Y.; Xu, Q.; Zhou, J.; Zhou, B. A Bio-Inspired Cilia Array as The Dielectric Layer for Flexible Capacitive Pressure Sensors with High Sensitivity and a Broad Detection Range. J. Mater. Chem. A 2019, 7, 27334–27346. [Google Scholar] [CrossRef]

- Mannsfeld, S.; Tee, B.; Stoltenberg, R.; Chen, C.; Barman, S.; Muir, B.; Sokolov, A.; Reese, C.; Bao, Z. Highly Sensitive Flexible Pressure Sensors with Microstructured Rubber Dielectric Layers. Nat. Mater. 2010, 9, 859–864. [Google Scholar] [CrossRef]

- Wang, D.; Sheng, B.; Peng, L.; Huang, Y.; Ni, Z. Flexible and Optical Fiber Sensors Composited by Graphene and PDMS for Motion Detection. Polymers 2019, 11, 1433. [Google Scholar] [CrossRef]

- Wang, Q.; Tong, J.; Wang, N.; Chen, S.; Sheng, B. Humidity Sensor of Tunnel-Cracked Nickel@Polyurethane Sponge for Respiratory and Perspiration Sensing. Sens. Actuators B Chem. 2021, 330, 129322. [Google Scholar] [CrossRef]

- Jiang, N.; Chang, X.; Hu, D.; Chen, L.; Wang, Y.; Chen, J.; Zhu, Y. Flexible, Transparent, and Antibacterial Ionogels Toward Highly Sensitive Strain and Temperature Sensors. Chem. Eng. J. 2021, 424, 130418. [Google Scholar] [CrossRef]

- Qin, J.; Yin, L.-J.; Hao, Y.-N.; Zhong, S.-L.; Zhang, D.-L.; Bi, L.; Zhang, Y.-X.; Zhao, Y.; Dang, Z.-M. Flexible and Stretchable Capacitive Sensors with Different Microstructures. Adv. Mater. 2021, 33, e2008267. [Google Scholar] [CrossRef]

- Choi, J.; Kwon, D.; Kim, K.; Park, J.; Orbe, D.-D.; Gu, J.; Ahn, J.; Cho, I.; Jeong, Y.; Oh, Y.; et al. Synergetic Effect of Porous Elastomer and Percolation of Carbon Nanotube Filler toward High Performance Capacitive Pressure Sensors. ACS Appl. Mater. Interfaces 2020, 12, 1698–1706. [Google Scholar] [CrossRef]

- Cheng, W.; Wang, J.; Ma, Z.; Yan, K.; Wang, Y.; Wang, H.; Li, S.; Li, Y.; Pan, L.; Shi, Y. Flexible Pressure Sensor with High Sensitivity and Low Hysteresis Based on a Hierarchically Microstructured Electrode. IEEE Electron. Device Lett. 2018, 39, 288–291. [Google Scholar] [CrossRef]

- Chhetry, A.; Sharma, S.; Yoon, H.; Ko, S.; Park, J.Y. Enhanced Sensitivity of Capacitive Pressure and Strain Sensor Based on CaCu3Ti4O12 Wrapped Hybrid Sponge for Wearable Applications. Adv. Funct. Mater. 2020, 30, 1910020. [Google Scholar] [CrossRef]

- Liang, J.; Zhao, Z.; Tang, Y.; Liang, Z.; Sun, L.; Pan, X.; Wang, X.; Qiu, J. A Wearable Strain Sensor Based on Carbon Derived from Linen Fabrics. New Carbon. Mater. 2020, 35, 522–530. [Google Scholar] [CrossRef]

- Sharma, S.; Chhetry, A.; Sharifuzzaman, M.; Yoon, H.; Park, J.-Y. Wearable Capacitive Pressure Sensor Based on MXene Composite Nanofibrous Scaffolds for Reliable Human Physiological Signal Acquisition. ACS Appl. Mater. Interfaces 2020, 12, 22212–22224. [Google Scholar] [CrossRef]

- Arlt, G.; Hennings, D.; With, G.-D. Dielectric Properties of Fine-Grained Barium Titanate Ceramics. J. Appl. Phys. 1985, 58, 1619–1625. [Google Scholar] [CrossRef]

- Li, T.; Luo, H.; Qin, L.; Wang, X.; Xiong, Z.; Ding, H.; Gu, Y.; Liu, Z.; Zhang, T. Flexible Capacitive Tactile Sensor Based on Micropatterned Dielectric Layer. Small 2016, 12, 5042–5048. [Google Scholar] [CrossRef]

- Maddipatla, D.; Narakathu, B.; Turkani, V.-S. A Flexible Copper Based Electrochemical Sensor Using Laser-Assisted Patterning Process. In Proceedings of the IEEE Sensors, New Delhi, India, 28–31 October 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Shelly, M.; Lee, S.; Suarato, G.; Meng, Y.; Pautot, S. Photolithography-Based Substrate Microfabrication for Patterning Semaphorin 3A to Study Neuronal Development, in Semaphorin Signaling; Humana Press: New York, NY, USA, 2017; pp. 321–343. [Google Scholar]

- Tee, B.C.-K.; Chortos, A.; Dunn, R.R.; Schwartz, G.; Eason, E.; Bao, Z. Tunable Flexible Pressure Sensors using Microstructured Elastomer Geometries for Intuitive Electronics. Adv. Funct. Mater. 2014, 24, 5427–5434. [Google Scholar] [CrossRef]

- Luo, S.; Zhou, X.; Tang, X.; Li, J.; Wei, D.; Tai, G.; Chen, Z.; Liao, T.; Fu, J.; Wei, D.; et al. Microconformal Electrode-Dielectric Integration for Flexible Ultrasensitive Robotic Tactile Sensing. Nano Energy 2021, 80, 105580. [Google Scholar] [CrossRef]

- Yang, J.-C.; Kim, J.-O.; Oh, J.; Kwon, S.-Y.; Sim, J.-Y.; Kim, D.-W.; Choi, H.-B.; Park, S. Microstructured Porous Pyramid-Based Ultrahigh Sensitive Pressure Sensor Insensitive to Strain and Temperature. ACS Appl. Mater. Interfaces 2019, 11, 19472–19480. [Google Scholar] [CrossRef]

- Palaniappan, V.; Panahi, M.; Masihi, S.; Maddipatla, D.; Bose, A.-K. Laser-Assisted Fabrication of a Highly Sensitive and Flexible Micro Pyramid-Structured Pressure Sensor for E-Skin Applications. IEEE Sens. J. 2020, 20, 7605–7613. [Google Scholar] [CrossRef]

- Wang, J.; Wang, N.; Xu, D.; Tang, L.; Sheng, B. Flexible Humidity Sensors Composed With Electrodes of Laser Induced Graphene and Sputtered Sensitive Films Derived from Poly(Ether-Ether-Ketone). Sens. Actuators B Chem. 2023, 375, 132846. [Google Scholar] [CrossRef]

- Shi, S.; Liang, J.; Qu, C.; Chen, S.; Sheng, B.; Fabric, R. Treated with Carboxymethylcellulose and Laser Engraved for Strain and Humidity Sensing. Micromachines 2022, 13, 1309. [Google Scholar] [CrossRef]

- Bose, A.-K.; Beaver, C.L.; Narakathu, B.; Rossbach, S.; Bazuin, B.-J.; Atashbar, M.-Z. Development of Flexible Microplasma Discharge Device for Sterilization Applications. In Proceedings of the IEEE Sensors, New Delhi, India, 28–31 October 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Mannion, P.-T.; Magee, J.; Coyne, E.; O’Connor, G.-M.; Glynn, T.-J. The Effect of Damage Accumulation Behaviour on Ablation Thresholds and Damage Morphology in Ultrafast Laser Micro-Machining of Common Metals in Air. Appl. Surf. Sci. 2004, 233, 275–287. [Google Scholar] [CrossRef]

- Qu, C.; Lu, M.; Zhang, Z.; Chen, S.; Liu, D.; Zhang, D.; Wang, J.; Sheng, B. Flexible Microstructured Capacitive Pressure Sensors Using Laser Engraving and Graphitization from Natural Wood. Molecules 2023, 28, 5339. [Google Scholar] [CrossRef] [PubMed]

- Kinoshita, K.; Yamaji, A. Grain-Size Effects on Dielectric Properties in Barium Titanate Ceramics. J. Appl. Phys. 1976, 47, 371–373. [Google Scholar] [CrossRef]

- Shi, H.; Pinto, T.; Zhang, Y.; Wang, C.; Tan, X. Screen-Printed Soft Capacitive Sensors for Spatial Mapping of Both Positive and Negative Pressures. Adv. Funct. Mater. 2019, 29, 1809116. [Google Scholar] [CrossRef]

- Kim, Y.; Yang, H.; Oh, J.-H. Simple Fabrication of Highly Sensitive Capacitive Pressure Sensors Using a Porous Dielectric Layer with Coneshaped Patterns. Mater. Des. 2020, 197, 109203. [Google Scholar] [CrossRef]

- Zeng, X.; Wang, Z.; Zhang, H.; Yang, W.; Xiang, L.; Zhao, Z.; Peng, L.-M.; Hu, Y. Tunable, Ultrasensitive, and Flexible Pressure Sensors Based on Wrinkled Microstructures for Electronic Skins. ACS Appl. Mater. Inter. 2019, 11, 21218–21226. [Google Scholar] [CrossRef]

- Lee, B.-Y.; Kim, J.; Kim, H.; Kim, C.; Lee, S.-D. Low-Cost Flexible Pressure Sensor Based on Dielectric Elastomer Film with Micro-Pores. Sens. Actuators A Phys. 2016, 240, 103–109. [Google Scholar] [CrossRef]

| Sensor Number | Dielectric Layer | Laser Parameters | Main Module | Micro-Structures Height (μm) | |

|---|---|---|---|---|---|

| Speed (mm/s) | Power (%) | ||||

| PS1 | MCA(A20) | 100 | 30 | M1 | 4500 |

| PS2 | MCA(B20) | 100 | 40 | M2 | 3500 |

| PS3 | MCA(C20) | 100 | 50 | M3 | 2500 |

| PS4 | GMCA(A3B6C11) | 100 | 30, 40, 50 | M4 | 4500 |

| PS5 | GMCA(A2B5C13) | 100 | 30, 40, 50 | M5 | 4500 |

| Mass Ratio of PDMS and BaTiO3 | 0–2 Kpa | 2–15 Kpa | 15–50 Kpa |

|---|---|---|---|

| pure | 1.30 | 0.17 | 0.04 |

| 20:1 | 1.37 | 0.27 | 0.08 |

| 10:1 | 1.69 | 0.41 | 0.09 |

| Micro-Structure | Fabrication Method | Mechanism | Pressure Range | Sensitivity | Response Time | References |

|---|---|---|---|---|---|---|

| Tilted micropillar | Photolithography | Capacitive | 0–40 KPa | 0.42 KPa−1 | 70 ms (8 KPa) | [58] |

| Semi sphere | Electroless plating | Capacitive | 0–10 KPa | 0.13 KPa−1 | – | [59] |

| Micro-square | Photolithography | Capacitive | 0.5 Pa–3 KPa | 0.185 KPa−1 | – | [60] |

| Micro-porous | Chemical method | Capacitive | <0.02 KPa | 1.18 KPa−1 | 150 ms (0.6 KPa) | [61] |

| Micro-pyramid | Laser patterning | Capacitive | 0–0.1 KPa 0.1–1 KPa 1–10 KPa | 0.221% Pa−1 0.033% Pa−1 0.011% Pa−1 | 50 ms (0.02 KPa) | [51] |

| Gradient micro-cone | Laser engraving and molding | Capacitive | 0–2 KPa 2–15 KPa 15–50 KPa | 1.69 KPa−1 0.41 KPa−1 0.09 KPa−1 | 50 ms (0.1 KPa) | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Chen, S.; Zhou, J.; Tang, L.; Jiang, C.; Zhang, D.; Sheng, B. Flexible BaTiO3-PDMS Capacitive Pressure Sensor of High Sensitivity with Gradient Micro-Structure by Laser Engraving and Molding. Polymers 2023, 15, 3292. https://doi.org/10.3390/polym15153292

Li J, Chen S, Zhou J, Tang L, Jiang C, Zhang D, Sheng B. Flexible BaTiO3-PDMS Capacitive Pressure Sensor of High Sensitivity with Gradient Micro-Structure by Laser Engraving and Molding. Polymers. 2023; 15(15):3292. https://doi.org/10.3390/polym15153292

Chicago/Turabian StyleLi, Jiayi, Shangbi Chen, Jingyu Zhou, Lei Tang, Chenkai Jiang, Dawei Zhang, and Bin Sheng. 2023. "Flexible BaTiO3-PDMS Capacitive Pressure Sensor of High Sensitivity with Gradient Micro-Structure by Laser Engraving and Molding" Polymers 15, no. 15: 3292. https://doi.org/10.3390/polym15153292

APA StyleLi, J., Chen, S., Zhou, J., Tang, L., Jiang, C., Zhang, D., & Sheng, B. (2023). Flexible BaTiO3-PDMS Capacitive Pressure Sensor of High Sensitivity with Gradient Micro-Structure by Laser Engraving and Molding. Polymers, 15(15), 3292. https://doi.org/10.3390/polym15153292