Effects of Friction Stir Welding on the Mechanical Behaviors of Extrusion-Based Additive Manufactured Polymer Parts

Abstract

1. Introduction

2. Experiment

2.1. Materials and Equipment

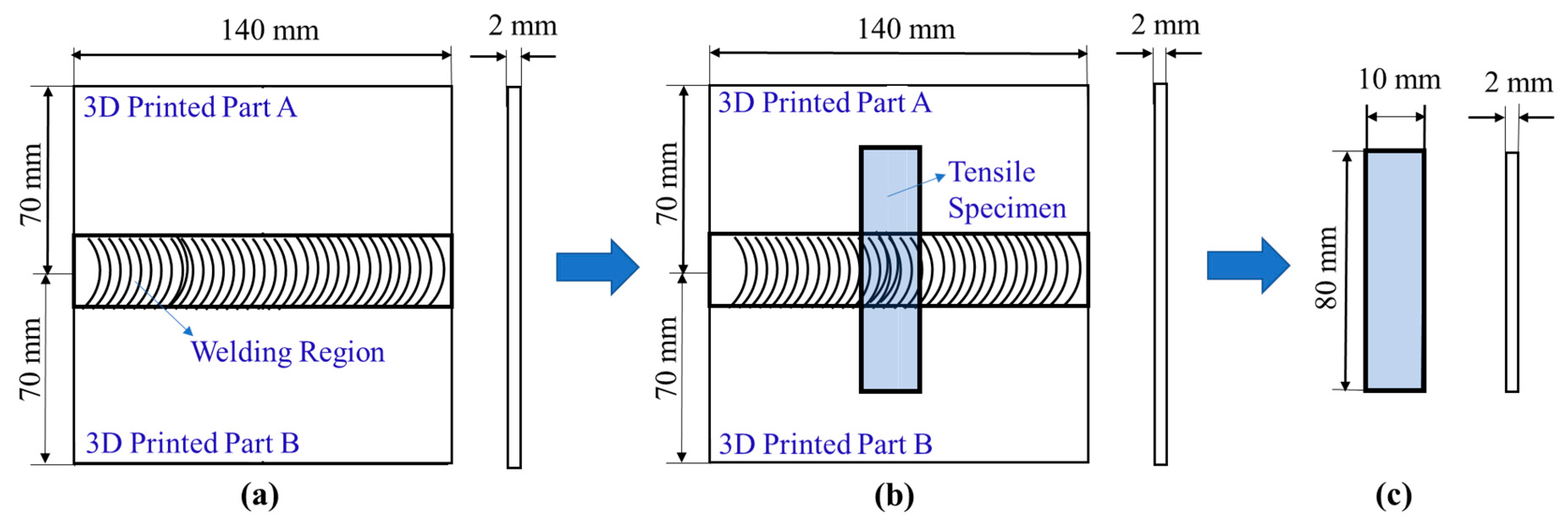

2.2. Experimental Process

2.3. Testing and Characterization

3. Results and Discussion

3.1. Porosity and Anisotropy of 3D-Printed Parts

3.2. Effect of Different Welding Tools on the Mechanical Properties of Printed Workpieces

3.3. Mechanism of Effect of FSW on the Mechanical Behaviors of 3D-Printed Parts

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Valino, A.D.; Dizon, J.R.C.; Espera, A.H.; Chen, Q.Y.; Messman, J.; Advincula, R.C. Advances in 3D printing of thermoplastic polymer composites and nanocomposites. Prog. Polym. Sci. 2019, 98, 101162. [Google Scholar] [CrossRef]

- Muthukumar, M. Trends in polymer physics and theory. Prog. Polym. Sci. 2020, 100, 101184. [Google Scholar] [CrossRef]

- Vaes, D.; Van Puyvelde, P. Semi-crystalline feedstock for filament-based 3D printing of polymers. Prog. Polym. Sci. 2021, 118, 101411. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Su, B.; Turng, L.S. Mechanical Properties, Fiber Orientation, and Length Distribution of Glass Fiber-Reinforced Polypropylene Parts: Influence of Water-Foaming Technology. Polym. Compos. 2018, 39, 4386–4399. [Google Scholar] [CrossRef]

- Huang, Y.X.; Meng, X.C.; Xie, Y.M.; Wan, L.; Lv, Z.; Cao, J.; Feng, J.C. Friction stir welding/processing of polymers and polymer matrix composites. Compos. Part A 2018, 105, 235–257. [Google Scholar] [CrossRef]

- Lambiase, F.; Derazkola, H.A.; Simchi, A. Friction Stir Welding and Friction Spot Stir Welding Processes of Polymers-State of the Art. Materials 2020, 13, 13102291. [Google Scholar] [CrossRef]

- Ghiya, R.; Badheka, V.J. A review of friction stir lap welding of polymer to metal. Polym.-Plast. Technol. Mater. 2021, 60, 1966–1995. [Google Scholar] [CrossRef]

- Prabhakar, D.A.P.; Shettigar, A.K.; Prakash, C.A. comprehensive review of friction stir techniques in structural materials and alloys: Challenges and trends. J. Mater. Res. Technol. 2022, 20, 3025–3060. [Google Scholar] [CrossRef]

- Montazerolghaem, H.; Badrossamay, M.; Tehrani, A.F.; Rad, S.Z.; Esfahani, M.S. Dual-Rotation Speed Friction Stir Welding: Experimentation and Modeling. Mater. Manuf. Process. 2015, 30, 1109–1114. [Google Scholar] [CrossRef]

- Mehta, K.P. A review on friction-based joining of dissimilar aluminum-steel joints. J. Mater. Res. 2019, 34, 78–96. [Google Scholar] [CrossRef]

- Zamrudi, F.H.; Setiawan, A.R. Effect of friction stir welding parameters on corrosion behaviour of aluminium alloys: An overview. Corros. Eng. Sci. Technol. 2022, 57, 696–707. [Google Scholar] [CrossRef]

- Sun, P.; Li, Y.; Qin, B. Super strong and multi-reusable supramolecular epoxy hot melt adhesives. ACS Mater. Lett. 2021, 3, 1003–1009. [Google Scholar] [CrossRef]

- Fernandes, F.A.O.; Pereira, A.B.; Guimarães, B. Laser welding of transmitting high-performance engineering thermoplastics. Polymers 2020, 12, 402. [Google Scholar] [CrossRef] [PubMed]

- Volkov, S.S. Ultrasonic butt welding of rigid plastics. Weld. Int. 2013, 27, 63–66. [Google Scholar] [CrossRef]

- Bilici, M.K. Effect of tool geometry on friction stir spot welding of polypropylene sheets. Expressed Polym. Lett. 2012, 6, 805–813. [Google Scholar] [CrossRef]

- Nath, R.K.; Maji, P.; Barma, J.D. Development of a Self-Heated Friction Stir Welding tool for welding of polypropylene sheets. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 553. [Google Scholar] [CrossRef]

- Bilici, M.K. Investigation of the effects of welding variables on the welding defects of the friction stir welded high density polyethylene sheets. J. Elastom. Plast. 2021, 54, 457–476. [Google Scholar] [CrossRef]

- Vibin, R.; Jaisingh, S.J.; Ramesh, G.; Jayabalakrishnan, D.; Arunprakash, V.R. Effect of Nanosilica and Weave Geometry on Weld Properties of Friction Stir Welded Nylon 6-6 Thick Plates. Silicon 2022, 14, 511–519. [Google Scholar] [CrossRef]

- Pereira, M.A.R.; Galvao, I.; Costa, J.D.; Amarco, A.M.; Leal, R.M. Leal RM. Joining of Fibre-Reinforced Thermoplastic Polymer Composites by Friction Stir Welding-A Review. Appl. Sci. 2022, 12, 2744. [Google Scholar] [CrossRef]

- Dias, L.V.; de Freitas, A.; Vaz, C.T. Parameter optimization in the friction stir welding of polycarbonate using cylindrical and conical tool pins. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 307. [Google Scholar] [CrossRef]

- Gao, J.C.; Cui, X.X.; Cheng, L.; Shen, Y.F. Application and exploration of friction stir welding/processing in plastics industry. Mater. Sci. Technol. 2017, 33, 1145–1158. [Google Scholar] [CrossRef]

- Iftikhar, S.H.; Mourad, A.H.I.; Vincent, S. A Comprehensive Review on Optimal Welding Conditions for Friction Stir Welding of Thermoplastic Polymers and Their Composites. Polymers 2021, 13, 1208. [Google Scholar] [CrossRef] [PubMed]

- Asmael, M.; Safaei, B.; Kalaf, O.; Zeeshan, Q.; Aldakheel, F.; Nasir, T.; Yang, Z. Recent developments in tensile properties of friction welding of carbon fiber-reinforced composite: A review. Nanotechnol. Rev. 2022, 11, 1408–1436. [Google Scholar] [CrossRef]

- Zhang, G.Q.; Wang, Y.H.; Chen, Z.W.; Xu, X.G.; Dong, K.; Xiong, Y. Robot-assisted conformal additive manufacturing for continuous fibre-reinforced grid-stiffened shell structures. Virtual Phys. Prototyp. 2023, 18, e2203695. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Huang, X. Effects of Continuous Printing on Fused Deposition-Modeled One-way Large-Sized Parts. J. Mater. Eng. Perform. 2021, 30, 5150–5158. [Google Scholar] [CrossRef]

- Gonzalez-Henriquez, C.M.; Sarabia-Vallejos, M.A.; Rodriguez-Hernandez, J. Polymers for additive manufacturing and 4D-printing: Materials, methodologies, and biomedical applications. Prog. Polym. Sci. 2019, 94, 57–116. [Google Scholar] [CrossRef]

- Shafighfard, T.; Mieloszyk, M. Experimental and numerical study of the additively manufactured carbon fibre reinforced polymers including fibre Bragg grating sensors. Compos. Struct. 2022, 299, 116027. [Google Scholar] [CrossRef]

- Mieloszyk, M.; Shafighfard, T.; Majewska, K.; Andrearczyk, A. An Influence of Temperature on Fiber Bragg Grating Sensor Embedded into Additive Manufactured Structure. In European Workshop on Structural Health Monitoring; Rizzo, P., Milazzo, A., Eds.; EWSHM 2022, LNCE 253; Springer International Publishing: Cham, Switzerland, 2023; pp. 495–501. [Google Scholar] [CrossRef]

- Ho, Q.B.; Kontopoulou, M. Improving the adhesion and properties in the material extrusion of polypropylene by blending with a polyolefin elastomer. Addit. Manuf. 2022, 55, 102818. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Su, B.; Turng, L.S. Depositing-Induced Effects of Isotactic Polypropylene and Polycarbonate Composites During Fused Deposition Modeling. Rapid Prototyp. J. 2017, 23, 869–880. [Google Scholar] [CrossRef]

- Romeijn, T.; Behrens, M.; Paul, G.; Wei, D. Instantaneous and long-term mechanical properties of Polyethylene Terephthalate Glycol (PETG) additively manufactured by pellet-based material extrusion. Addit. Manuf. 2022, 59, 103145. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Zou, J.R.; Wu, H.H.; Xu, B.P. Balance between Bonding and Deposition during Fused Deposition Modeling of Polycarbonate and Acrylonitrile-Butadiene-Styrene Composites. Polym. Compos. 2020, 41, 60–72. [Google Scholar] [CrossRef]

- Zhao, B. Analysis of temperature field in friction stir welding based on orthogonal ridgelet finite element method. J. Therm. Anal. Calorim. 2016, 123, 1751–1758. [Google Scholar] [CrossRef]

- Chen, X.; Chen, J.; Liu, Z.; Gao, Y.; Shi, M.; Zhou, Y.; Sun, Y.; Lu, S. Friction Stir Welding Device and Welding Method for Polymer Materials. Chinese Patent 202310051986.4, 2 February 2023. [Google Scholar]

- Zhou, Y.; Jiang, Z.; Yang, J.; Chen, S. Fiber Wires, Preparation Method and Equipment Suitable for Polymer Friction Stir Welding. Chinese Patent 202310197774.7, 3 March 2023. [Google Scholar]

- GB-T/1040.1-2006; Plastics—Determination of Tensile Properties—Part 1: General Principles. Standardization Administration of China (SAC): Beijing, China, 2006.

- Zhou, Y.G.; Chen, T.Y. Combining Foam Injection Molding with Batch Foaming to Improve Cell Density and Control Cellular Orientation via Multiple Gas Dissolution and Desorption Processes. Polym. Adv. Technol. 2020, 31, 2136–2151. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Cao, G.H.; Cheng, Y.F. Effect of Cellular Uniformity on the Necking Propagation of Foam Injection Molded PP/HDPE Blend Parts. J. Appl. Polym. Sci. 2020, 137, 49124. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Zhao, X.D.; Dong, B.B.; Liu, C.T. Improvement of the Dispersity of Micro-nano Particles for PP/PVC Composites using Gas-assisted Dispersion in a Controlled Foaming Process. Polym. Eng. Sci. 2020, 60, 524–534. [Google Scholar] [CrossRef]

- Mei, X.Y.; Zhou, Y.G.; Sun, H.L.; Dong, B.B.; Liu, C.T.; Turng, L.S. Evaluating the Gas-Laden Ability of Polymer Melt Under Atmospheric Conditions Using a Modified Torque Rheometer. J. Cell. Plast. 2022, 58, 237–261. [Google Scholar] [CrossRef]

- Wu, B.Y.; Li, Y.N.; Yang, J.M.; Zhou, Y.G. Mechanism of low-temperature brittle-ductile transition of polypropylene/low-density polyethylene blend foam under compressive stress caused by cells stretching. Adv. Eng. Mater. 2023, 25, 2300533. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Zhang, Y.L. Hybrid Reinforced Effect of Long Carbon Fiber and Short Glass Fiber on Polycarbonate Foams. Polym. Compos. 2023, 44, 27578. [Google Scholar] [CrossRef]

- Simoes, F.; Rodrigues, D.M. Material flow and thermo-mechanical conditions during Friction Stir Welding of polymers: Literature review, experimental results and empirical analysis. Mater. Des. 2014, 59, 344–351. [Google Scholar] [CrossRef]

- Banjare, P.N.; Sahlot, P.; Arora, A. An assisted heating tool design for FSW of thermoplastics. J. Mater. Process. Technol. 2017, 239, 83–91. [Google Scholar] [CrossRef]

- Eslami, S.; Tavares, P.J.; Moreira, P.M.G.P. Friction stir welding tooling for polymers: Review and prospects. Int. J. Adv. Manuf. Technol. 2017, 89, 1677–1690. [Google Scholar] [CrossRef]

- Gao, Y.; Morisada, Y.; Fujii, H.; Liao, J. Friction stir lap welding of plastic to metal using adjustable tool. Sci. Technol. Weld. Join. 2020, 25, 190–197. [Google Scholar] [CrossRef]

| Printing Direction | Parallel | Perpendicular |

|---|---|---|

| Melt temperature (°C) | 260 | 260 |

| Print speed (mm/s) | 30 | 40 |

| Hot bed temperature (°C) | 90 | 90 |

| Layer thickness (mm) | 0.1 | 0.2 |

| Parameter | |

|---|---|

| Rotation speed (r/min) | 3000 |

| Welding speed (mm/min) | 30 |

| Press amount (mm) | 0.2 |

| Welding tool | WTA/WTB |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.-F.; Zhou, Y.-G.; Chen, S.-J.; Ren, S.-Q.; Zou, J. Effects of Friction Stir Welding on the Mechanical Behaviors of Extrusion-Based Additive Manufactured Polymer Parts. Polymers 2023, 15, 3288. https://doi.org/10.3390/polym15153288

Liu J-F, Zhou Y-G, Chen S-J, Ren S-Q, Zou J. Effects of Friction Stir Welding on the Mechanical Behaviors of Extrusion-Based Additive Manufactured Polymer Parts. Polymers. 2023; 15(15):3288. https://doi.org/10.3390/polym15153288

Chicago/Turabian StyleLiu, Jin-Feng, Ying-Guo Zhou, Shu-Jin Chen, Shao-Qiang Ren, and Jun Zou. 2023. "Effects of Friction Stir Welding on the Mechanical Behaviors of Extrusion-Based Additive Manufactured Polymer Parts" Polymers 15, no. 15: 3288. https://doi.org/10.3390/polym15153288

APA StyleLiu, J.-F., Zhou, Y.-G., Chen, S.-J., Ren, S.-Q., & Zou, J. (2023). Effects of Friction Stir Welding on the Mechanical Behaviors of Extrusion-Based Additive Manufactured Polymer Parts. Polymers, 15(15), 3288. https://doi.org/10.3390/polym15153288