Effect of Strain Rate and Temperature on the Tensile Properties of Long Glass Fiber-Reinforced Polypropylene Composites

Abstract

:1. Introduction

2. Experimental Design and Characterization

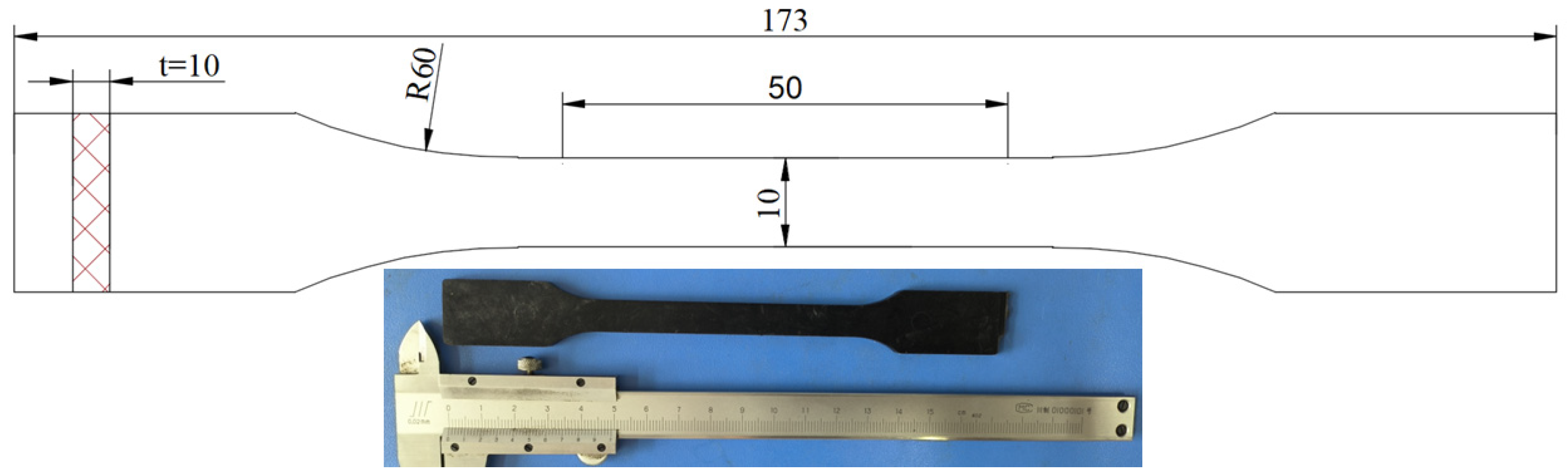

2.1. Sample Preparation

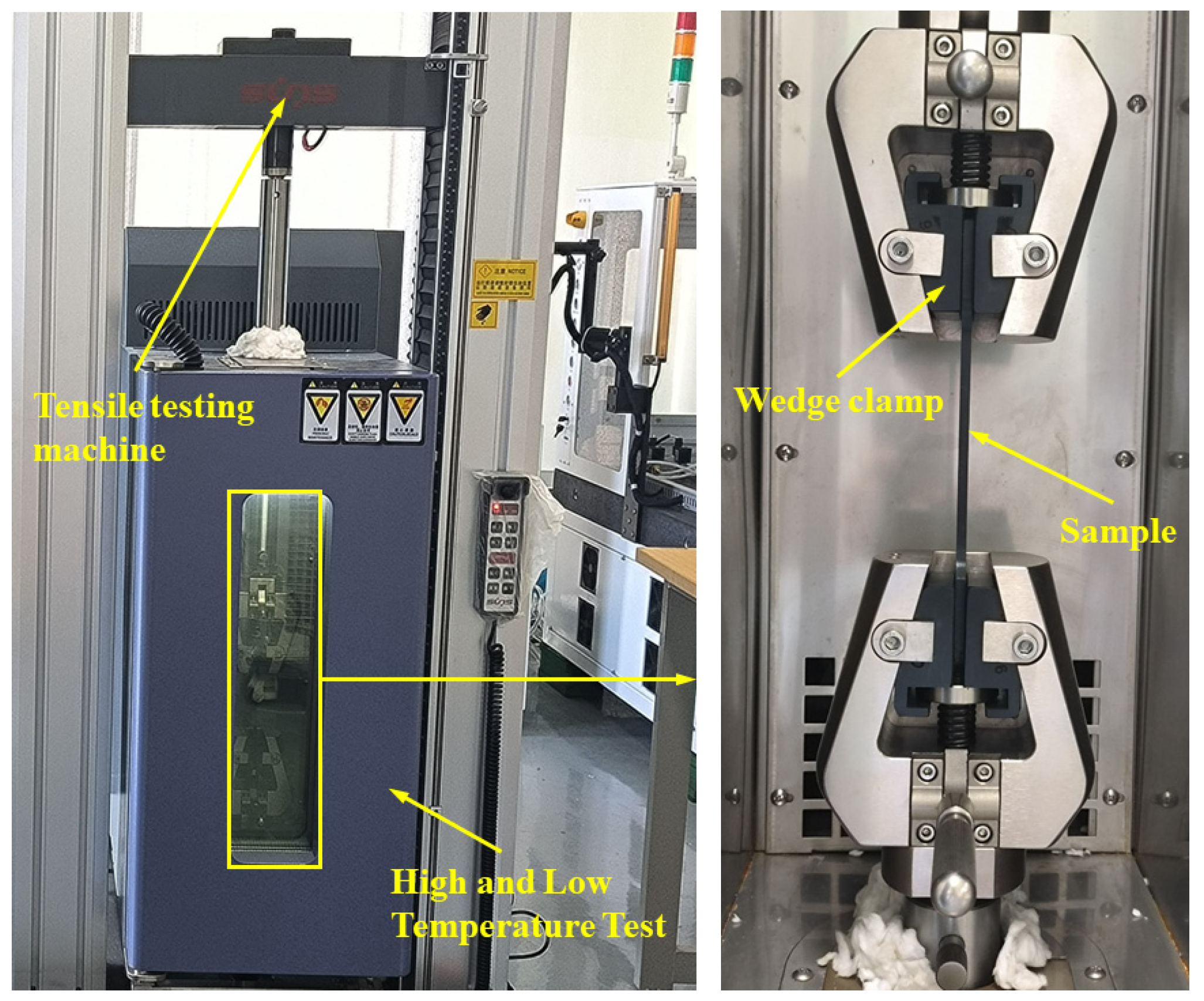

2.2. Tensile Test Design

2.3. Characterization of Experimental Results

3. Experimental Results and Analysis

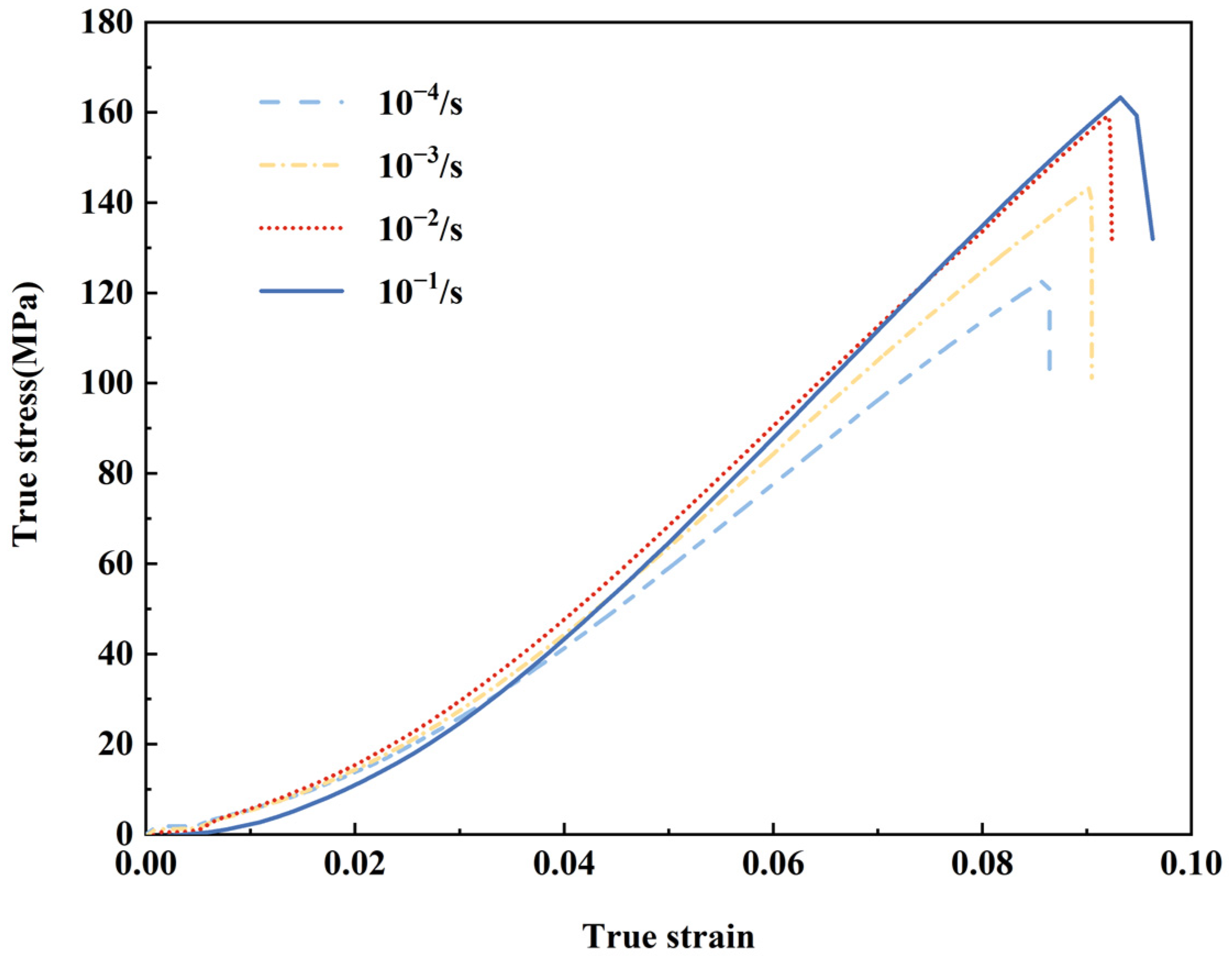

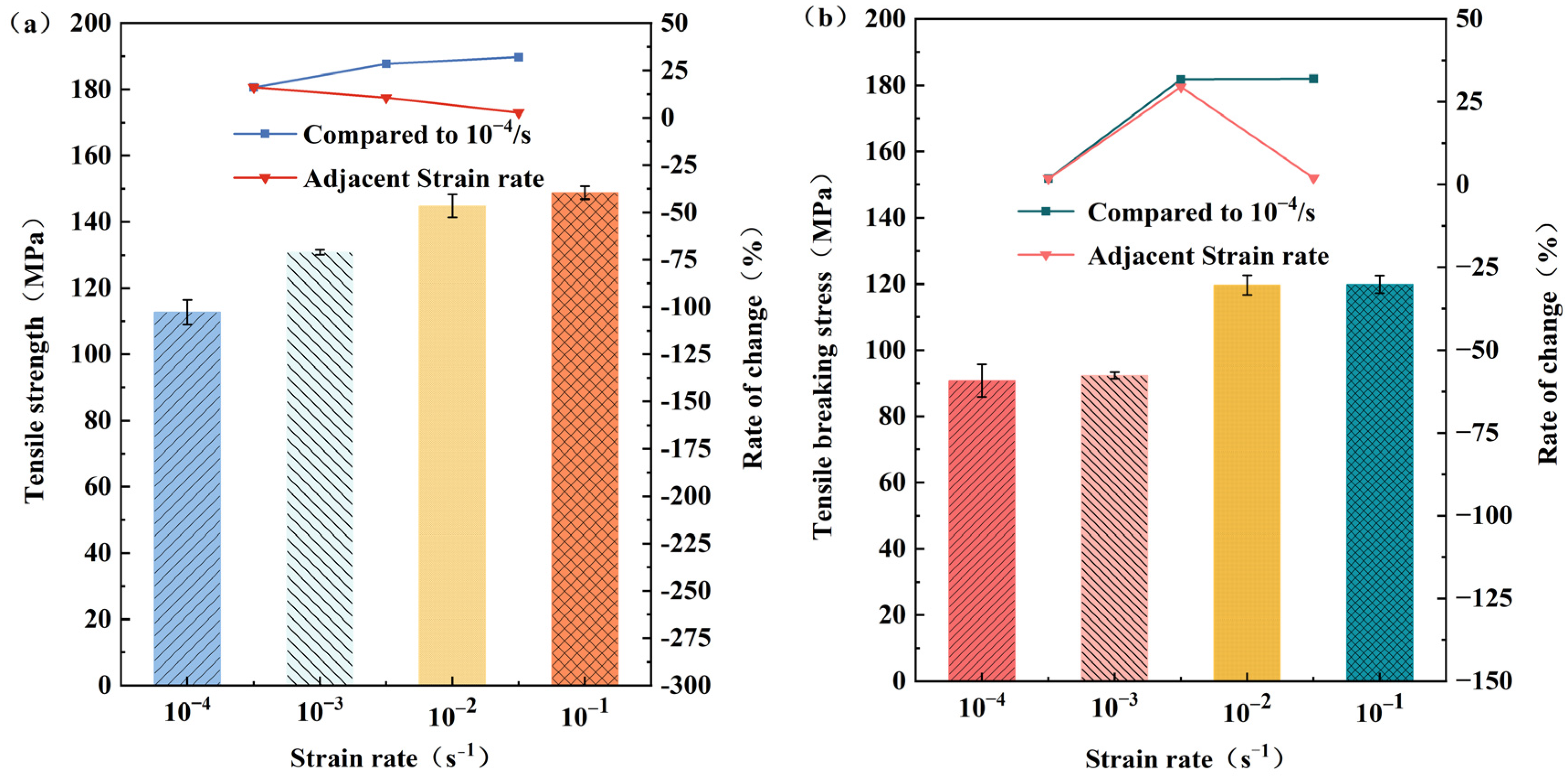

3.1. The Effect of Strain Rate on LGFPP

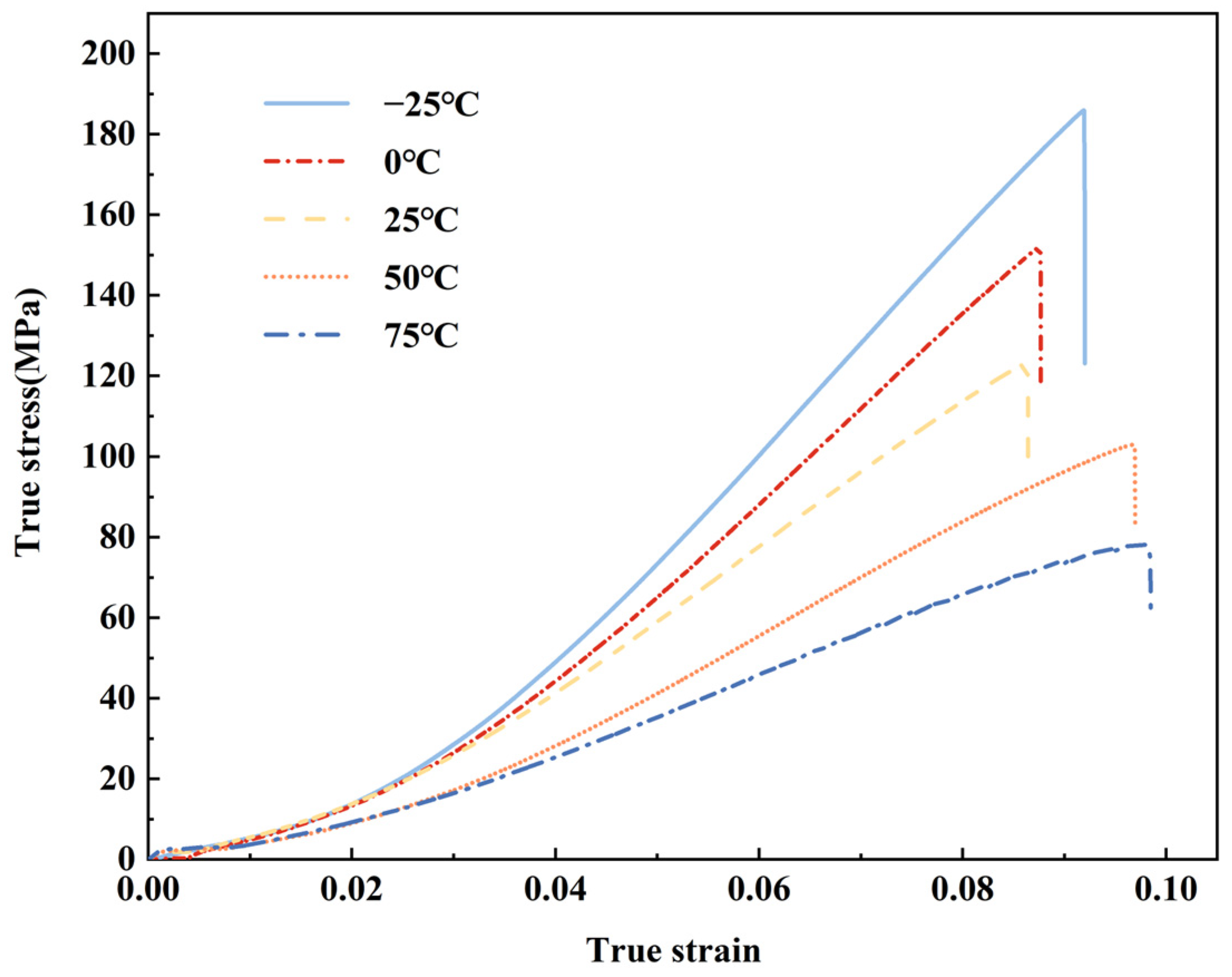

3.2. The Effect of Temperature on LGFPP

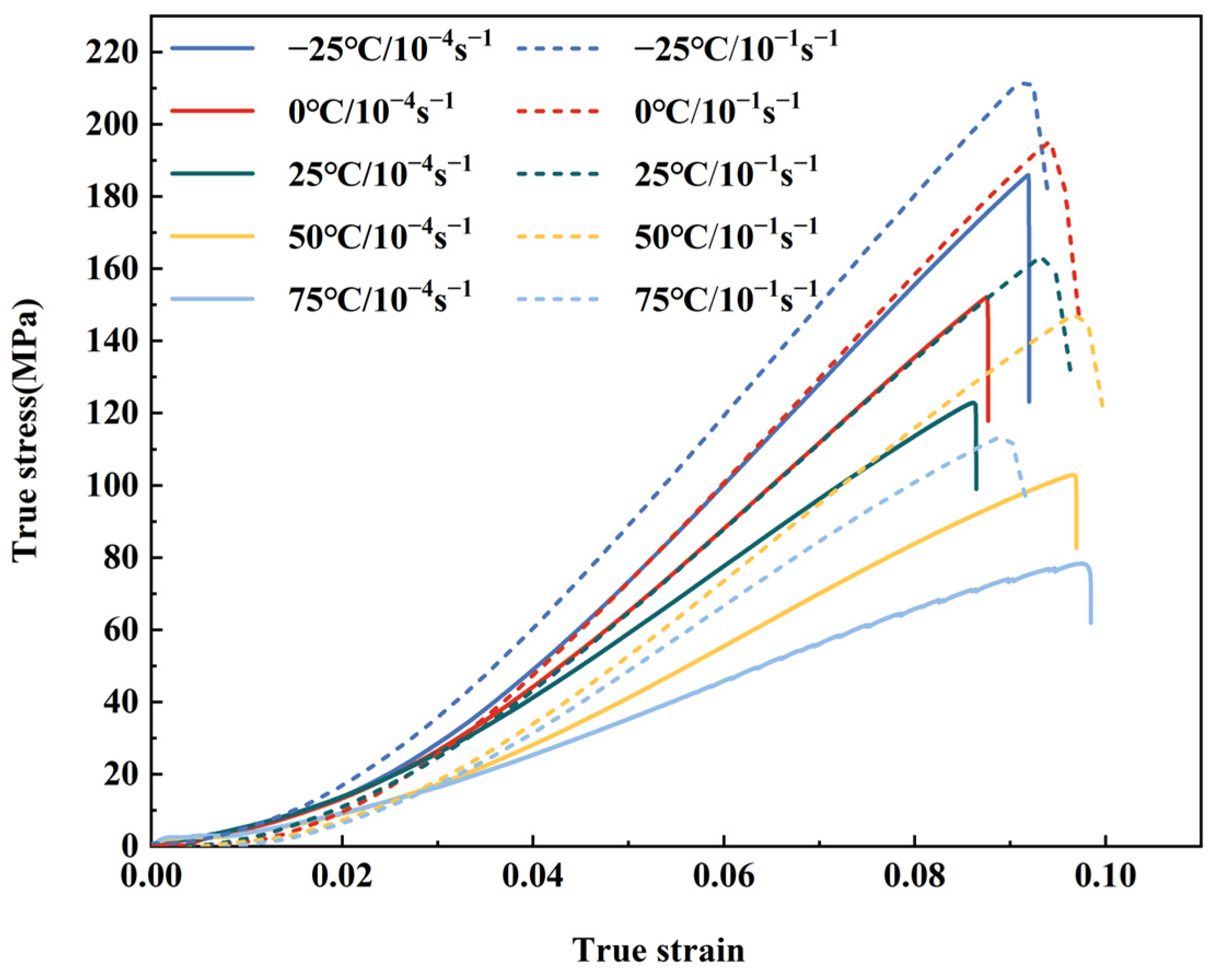

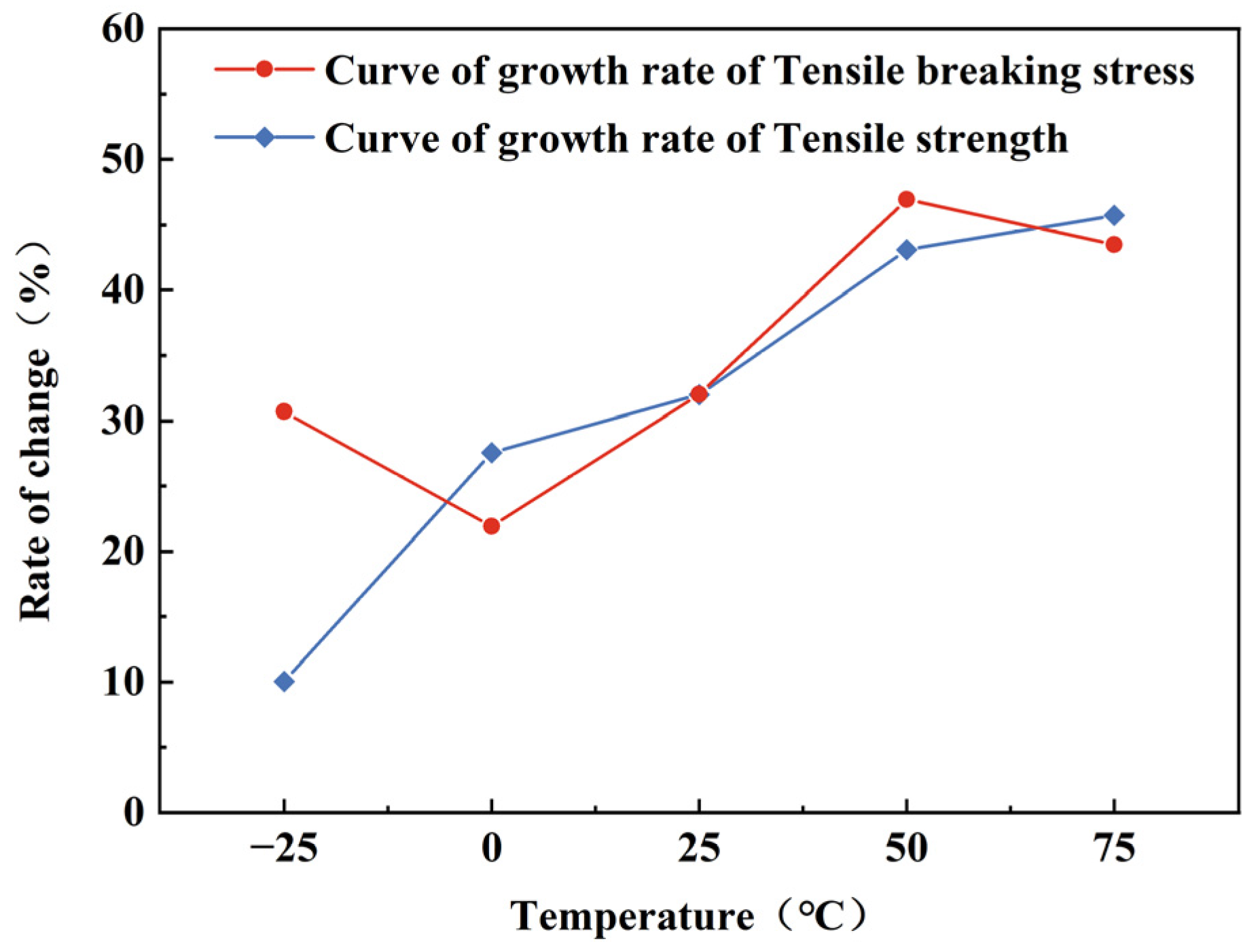

3.3. The Effect of Strain Rate Temperature Coupling on LGFPP

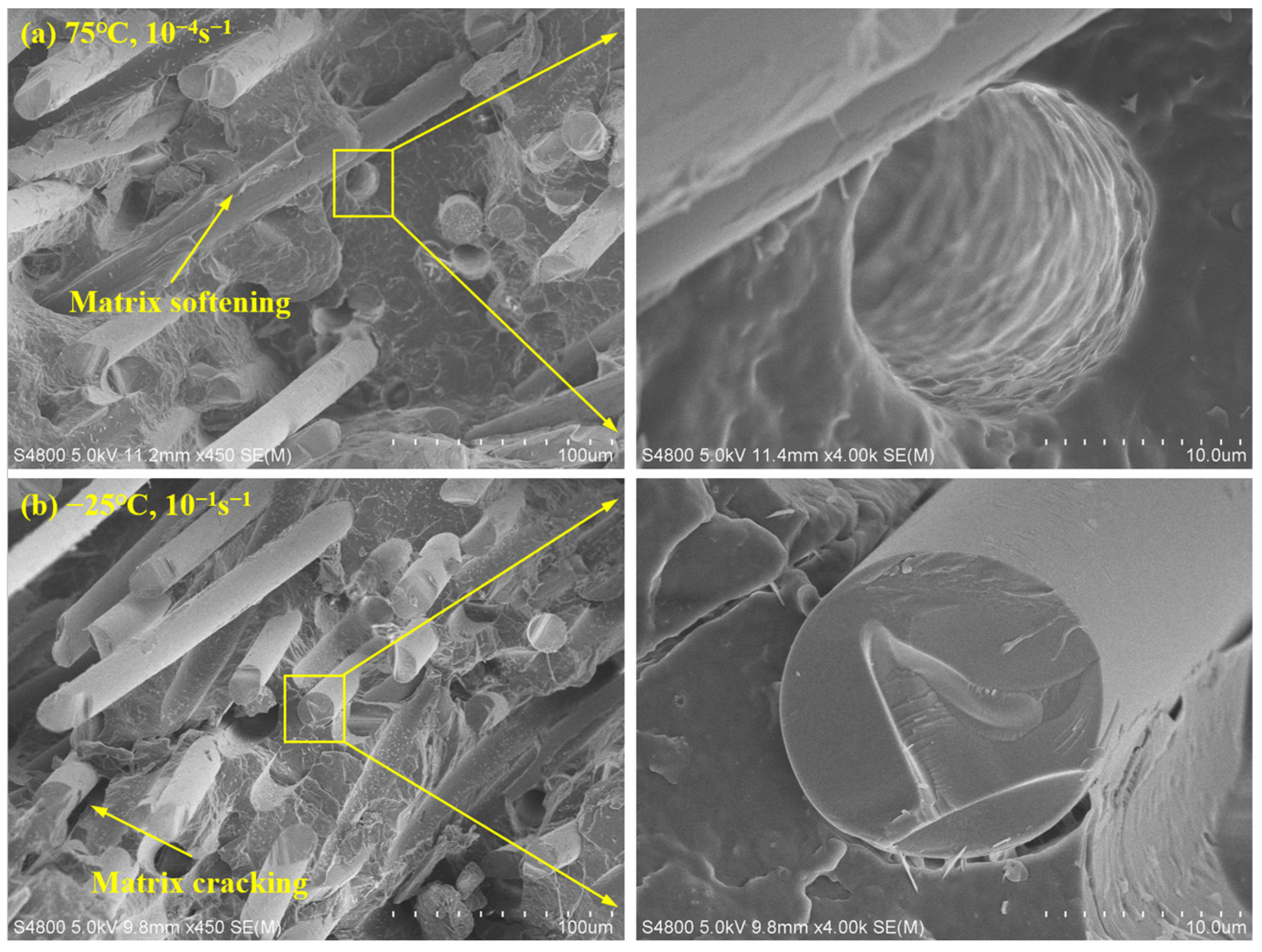

3.4. Microscopic Morphology of Fracture Surface

4. Conclusions

- (1)

- The strain rate exerts a significant influence on long glass fiber-reinforced polypropylene composites. As the strain rate increases from 10−4 to 10−1 s−1, the tensile stress, tensile strength, and tensile fracture stress demonstrate an upward trend.

- (2)

- Temperature variations affect the performance of long glass fiber-reinforced polypropylene composites. Notably, when the temperature rises to 75 °C compared to −25 °C, matrix cracks become evident, accompanied by a weakening of energy transfer between the long glass fibers and the substrate. Consequently, the tensile strength and tensile fracture stresses experience an increase.

- (3)

- The coupling of strain rate and temperature yields a combined effect on the tensile strength and tensile fracture stress. At temperatures ranging from −25 °C to 0 °C and from 50 °C to 75 °C, the growth rate of tensile fracture stress is significantly influenced by temperature. The strain rate demonstrates a considerable impact across the temperature range of 0 °C to 50 °C, with an overall increasing trend observed in the growth rate of tensile fracture stress. Additionally, the growth rate of tensile strength exhibits an upward trend when comparing a strain rate of 10−1 to 10−4 s−1.

- (4)

- The fracture morphology of the samples reveals that fiber failure predominantly occurs in the form of long glass fiber fracture and pull-out. Fiber pull-out is more prevalent at lower strain rates, while fiber breakage is observed at higher strain rates. The matrix tends to fracture at lower temperatures and undergoes softening at higher temperatures.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, T.; Mansfield, C.D.; Ju, L.; Baird, D.G. The influence of mechanical recycling on the properties of thermotropic liquid crystalline polymer and long glass fiber reinforced polypropylene. Compos. Part B Eng. 2020, 200, 108316. [Google Scholar] [CrossRef]

- Zhai, Z.; Jiang, B.; Drummer, D. Tensile Creep Behavior of Quasi-Unidirectional E-Glass Fabric Reinforced Polypropylene Composite. Polymers 2018, 10, 661. [Google Scholar] [CrossRef] [Green Version]

- Goh, G.D.; Yap, Y.L.; Agarwala, S.; Wai, Y.Y. Recent Progress in Additive Manufacturing of Fiber Reinforced Polymer Composite. Adv. Mater. Technol. 2019, 4, 1800271. [Google Scholar] [CrossRef] [Green Version]

- Zhu, D.; Zhang, X.; Zhang, H. Effects of strain rate and temperature on mechanical properties of Kevlar 49 aramid fabric reinforced epoxy polymers under dynamic tensile loading. Acta Mater. Compos. Sin. 2016, 33, 459–468. [Google Scholar]

- Duan, S.; Yang, X.; Tao, Y.; Mo, F.; Xiao, Z.; Wei, K. Experimental and numerical investigation of Long Glass Fiber Reinforced Polypropylene composite and application in automobile components. Transport 2018, 33, 1135–1143. [Google Scholar] [CrossRef] [Green Version]

- Teixeira, D.; Giovanela, M.; Gonella, L.B.; Crespo, J.S. Influence of flow restriction on the microstructure and mechanical properties of long glass fiber-reinforced polyamide 6.6 composites for automotive applications. Mater. Des. 2013, 47, 287–294. [Google Scholar] [CrossRef]

- Taub, A.I.; Luo, A.A. Advanced lightweight materials and manufacturing processes for automotive applications. MRS Bull. 2015, 40, 1045–1054. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Reale Batista, M.D.; Drzal, L.T.; Kiziltas, A.; Mielewski, D. Hybrid cellulose-inorganic reinforcement polypropylene composites: Lightweight materials for automotive applications. Polym. Compos. 2020, 41, 1074–1089. [Google Scholar] [CrossRef]

- Agarwal, J.; Sahoo, S.; Mohanty, S.; Nayak, S.K. Progress of novel techniques for lightweight automobile applications through innovative eco-friendly composite materials: A review. J. Thermoplast. Compos. Mater. 2019, 33, 978–1013. [Google Scholar] [CrossRef]

- Du, B.; Li, Z.; Bai, H.; Li, Q.; Zheng, C.; Liu, J.; Qiu, F.; Fan, Z.; Hu, H.; Chen, L. Mechanical Property of Long Glass Fiber Reinforced Polypropylene. Composite: From Material to Car Seat Frame and Bumper Beam. Polymers 2022, 14, 1814. [Google Scholar] [CrossRef] [PubMed]

- Duan, S.; Mo, F.; Yang, X.; Tao, Y.; Wu, D.; Peng, Y. Experimental and numerical investigations of strain rate effects on mechanical properties of LGFRP composite. Compos. Part B Eng. 2016, 88, 101–107. [Google Scholar] [CrossRef]

- Duan, S.; Mo, F.; Wei, K.; Xiao, Z.; Xiao, S.; Yang, X.; Tao, Y. Study on strain-rate-dependent behaviour and constitutive model of long glass fibre reinforced polypropylene composite. Int. J. Automot. Compos. 2018, 4, 1–14. [Google Scholar] [CrossRef]

- Cui, J.; Wang, S.; Wang, S.; Li, G.; Wang, P.; Liang, C. The Effects of Strain Rates on Mechanical Properties and Failure Behavior of Long Glass Fiber Reinforced Thermoplastic Composites. Polymers 2019, 11, 2019. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lu, X.; Yang, X.; Duan, S.; Deng, J. Strain Rate Sensitive Properties of Glass Fiber Peinforced Polypropylene Composites. J. Mater. Eng. 2018, 46, 146–151. [Google Scholar]

- Kim, D.H.; Kang, S.Y.; Kim, H.J.; Kim, H.S. Strain rate dependent mechanical behavior of glass fiber reinforced polypropylene composites and its effect on the performance of automotive bumper beam structure. Compos. Part B Eng. 2019, 166, 483–496. [Google Scholar] [CrossRef]

- Schoßig, M.; Bierögel, C.; Grellmann, W.; Mecklenburg, T. Mechanical behavior of glass-fiber reinforced thermoplastic materials under high strain rates. Polym. Test. 2008, 27, 893–900. [Google Scholar] [CrossRef]

- Zhai, Z.; Jiang, B.; Drummer, D. Strain rate-dependent mechanical behavior of quasi-unidirectional E-glass fabric reinforced polypropylene composites under off-axis tensile loading. Polym. Test. 2018, 69, 276–285. [Google Scholar] [CrossRef]

- Zhang, M.; Jiang, B.; Chen, C.; Drummer, D.; Zhai, Z. The Effect of Temperature and Strain Rate on the Interfacial Behavior of Glass Fiber Reinforced Polypropylene Composites: A Molecular Dynamics Study. Polymers 2019, 11, 1766. [Google Scholar] [CrossRef] [Green Version]

- Qin, W.; Du, B.; Zhu, S.; Chen, L.; Li, W.; Fan, Z. Effect of Environment Temperature on Uniaxial Tensile Properties of Long Glass Fiber Reinforced Polypropylene. Mater. Rep. 2023, 370, 012021. [Google Scholar]

- Reis, J.M.L.; Coelho, J.L.V.; Monteiro, A.H.; da Costa Mattos, H.S. Tensile behavior of glass/epoxy laminates at varying strain rates and temperatures. Compos. Part B Eng. 2012, 43, 2041–2046. [Google Scholar] [CrossRef]

- Yu, L.; Ma, Y. Loading rate and temperature dependence of flexural behavior in injection-molded glass fiber reinforced polypropylene composites. Compos. Part B Eng. 2019, 161, 285–299. [Google Scholar] [CrossRef]

- Bajracharya, R.M.; Manalo, A.C.; Karunasena, W.; Lau, K. Experimental and theoretical studies on the properties of injection moulded glass fibre reinforced mixed plastics composites. Compos. Part A Appl. Sci. Manuf. 2016, 84, 393–405. [Google Scholar] [CrossRef]

- Bajracharya, R.M.; Manalo, A.C.; Karunasena, W.; Lau, K. Durability characteristics and property prediction of glass fibre reinforced mixed plastics composites. Compos. Part B Eng. 2017, 116, 16–29. [Google Scholar] [CrossRef]

- Xie, W. On-Line Molding Process and Product Properties of Long Glass Fiber Reinforced Polypropylene Composites; Chongqing University: Chongqing, China, 2019. [Google Scholar]

- Gonçalves, R.M.; Martinho, A.; Oliveira, J.P. Recycling of Reinforced Glass Fibers Waste: Current Status. Materials 2022, 15, 1596. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Tu, S. Market Situation and Prospect of Polypropylene Resin Uesed for LFRP. Fiber Glass 2016, 272, 41–46. [Google Scholar]

- Sun, Y.; Li, Z.; Cui, G.; Feng, G. Repeated Collision Damage of Hull Structure at Low-Temperature Environment. Ship Eng. 2022, 44, 22–27+77. [Google Scholar]

- Han, Y.; Yang, L.; Peng, L.; Wang, M.; Yan, Q.; Liu, M. Study on dynamic mechanical behavior of LY315 steel at elevated temperature and high strain rate. J. Build. Struct. 2023, 44, 319–326. [Google Scholar]

- Xia, Y.; Jiang, W.; Cheng, Q.; Jiang, L.; Jin, L. Hot deformation behavior of Ti-6AL-4V-0.1Ru alloy during isothermal compression. Trans. Nonferrous Met. Soc. China 2020, 30, 134–146. [Google Scholar] [CrossRef]

- Li, F.; Liang, J.; Zhang, S.; Zhu, B. Tensile Properties of Polylactide/Poly(ethylene glycol) Blends. J. Polym. Environ. 2015, 23, 407–415. [Google Scholar] [CrossRef]

- Ai, J. Preparation and Properties of Self-Healing Hydrogels Based on Boronic Ester Lingkages; Guangxi University: Nanning, China, 2020. [Google Scholar]

- Shokrieh, M.M.; Omidi, M.J. Tension behavior of unidirectional glass/epoxy composites under different strain rates. Compos. Struct. 2009, 88, 595–601. [Google Scholar] [CrossRef]

- Lienhard, J.; Schulenberg, L. Strain rate dependent multiaxial characterization of long fiber reinforced plastic. Compos. Part B Eng. 2018, 141, 164–173. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Effects of fiber orientation and anisotropy on tensile strength and elastic modulus of short fiber reinforced polymer composites. Compos. Part B Eng. 2015, 72, 116–129. [Google Scholar] [CrossRef]

| Material | Density (g·cm−3) | Mass (g·cm−2) |

|---|---|---|

| Long Glass fiber | 2.54 | 760 |

| Polypropylene | 0.91 | 770 |

| Experimental Group | Strain Rates (s−1) | Temperature (°C) |

|---|---|---|

| 1 | 10−4 | 25 |

| 10−3 | ||

| 10−2 | ||

| 10−1 | ||

| 2 | 10−4 | −25 |

| 0 | ||

| 25 | ||

| 50 | ||

| 75 | ||

| 3 | 10−4/10−1 | −25 |

| 0 | ||

| 25 | ||

| 50 | ||

| 75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Wang, J.; Wang, A.; Zhou, C.; Hu, J.; Pan, F. Effect of Strain Rate and Temperature on the Tensile Properties of Long Glass Fiber-Reinforced Polypropylene Composites. Polymers 2023, 15, 3260. https://doi.org/10.3390/polym15153260

Wang Q, Wang J, Wang A, Zhou C, Hu J, Pan F. Effect of Strain Rate and Temperature on the Tensile Properties of Long Glass Fiber-Reinforced Polypropylene Composites. Polymers. 2023; 15(15):3260. https://doi.org/10.3390/polym15153260

Chicago/Turabian StyleWang, Qiaoyu, Jianbin Wang, Anheng Wang, Chaoqun Zhou, Jiale Hu, and Fei Pan. 2023. "Effect of Strain Rate and Temperature on the Tensile Properties of Long Glass Fiber-Reinforced Polypropylene Composites" Polymers 15, no. 15: 3260. https://doi.org/10.3390/polym15153260

APA StyleWang, Q., Wang, J., Wang, A., Zhou, C., Hu, J., & Pan, F. (2023). Effect of Strain Rate and Temperature on the Tensile Properties of Long Glass Fiber-Reinforced Polypropylene Composites. Polymers, 15(15), 3260. https://doi.org/10.3390/polym15153260