Development of Nonwoven Fibrous Materials Based on Poly-3-Hydroxybutyrate with a High Content of α-Tricalcium Phosphate

Abstract

:1. Introduction

2. Materials and Methods

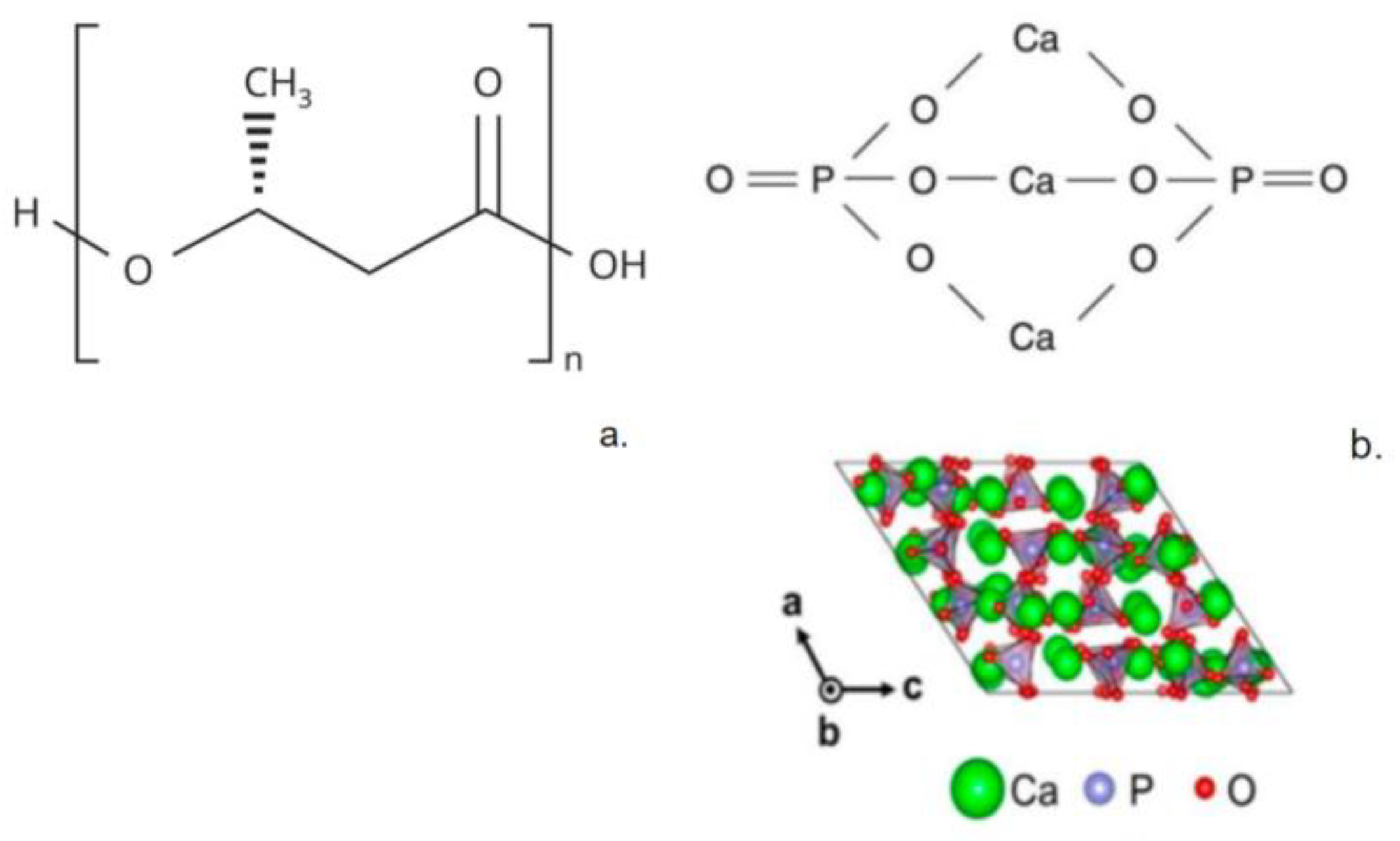

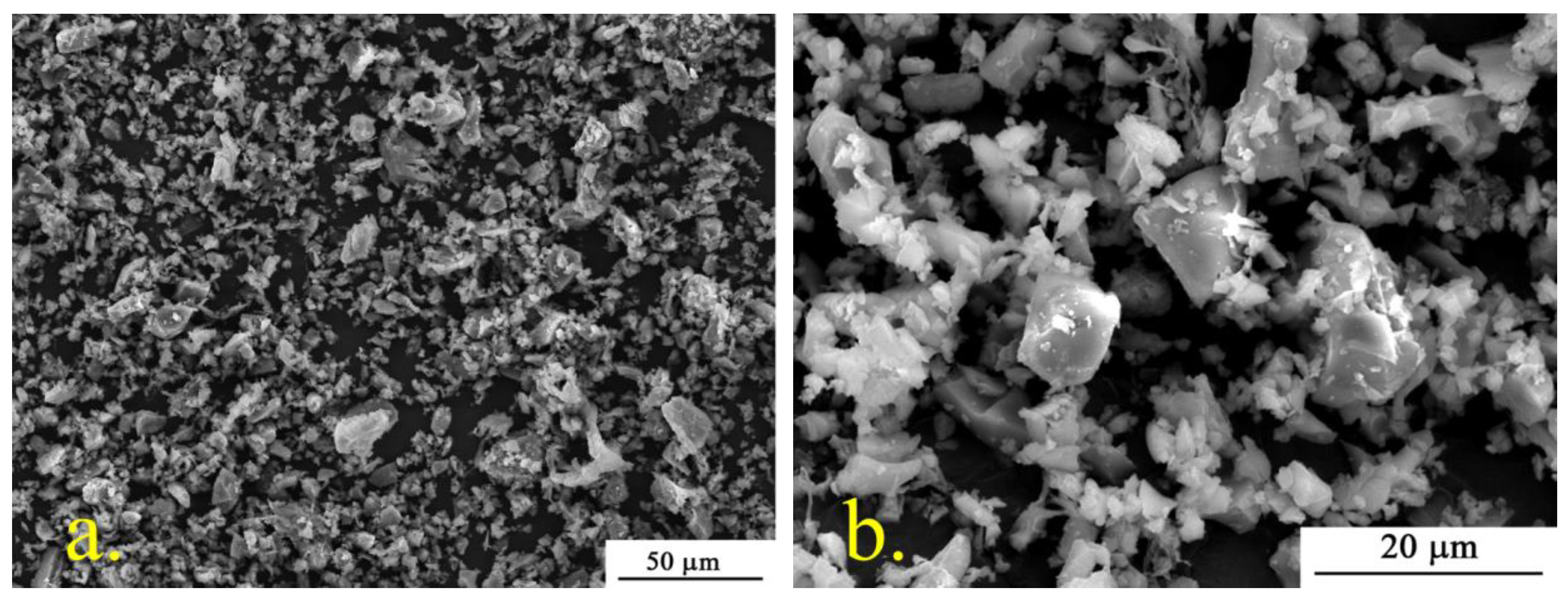

2.1. Materials

2.2. Methods

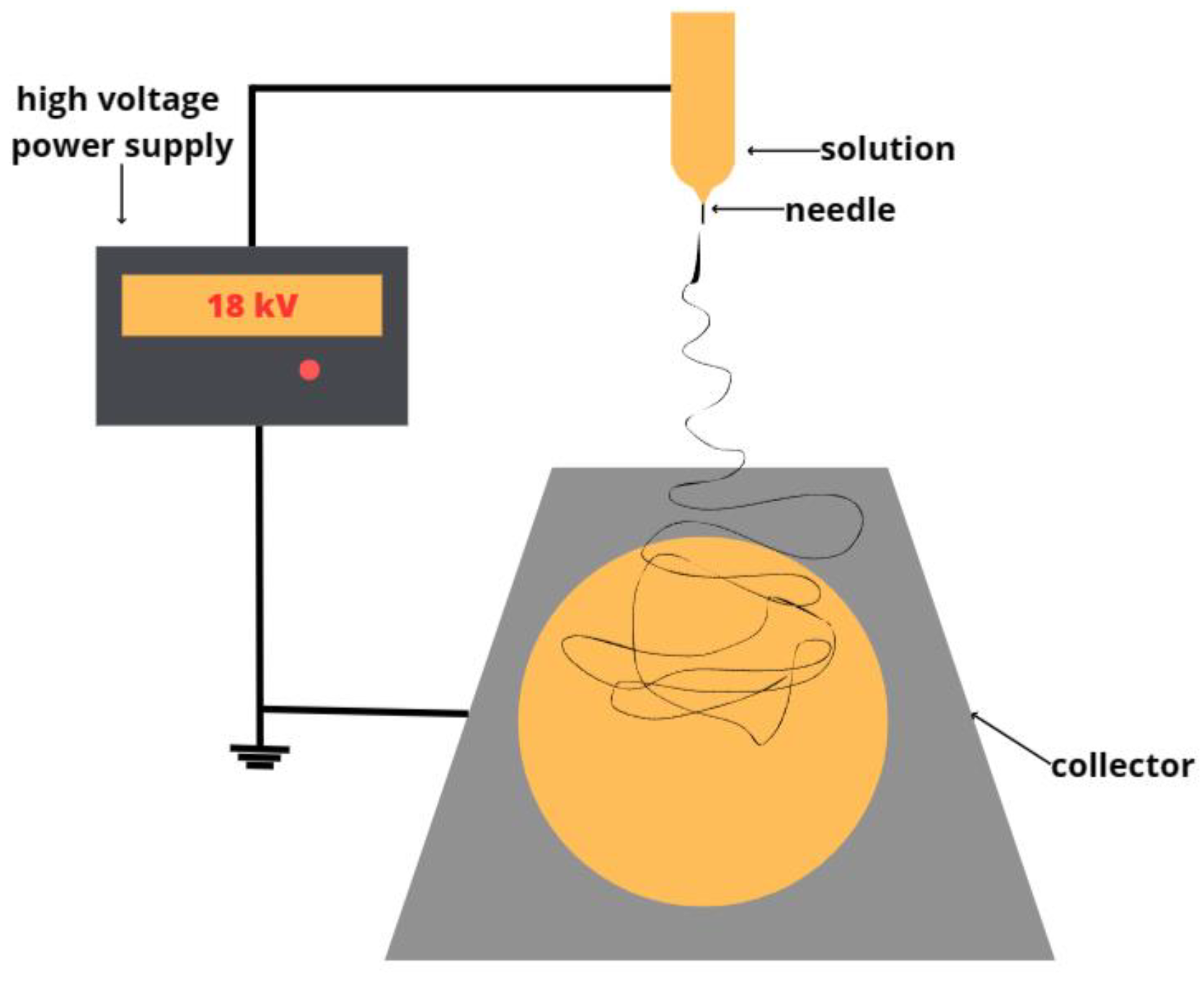

2.2.1. Obtaining of Fibrous Materials

2.2.2. Optical and Scanning Electron Microscopy

2.2.3. Surface Density

2.2.4. Fourier-Transform Infrared Spectroscopy (FTIR)

2.2.5. Differential Scanning Calorimetry (DSC)

2.2.6. X-ray Diffraction Analysis (XRD)

2.2.7. Mechanical Analysis

3. Results and Discussion

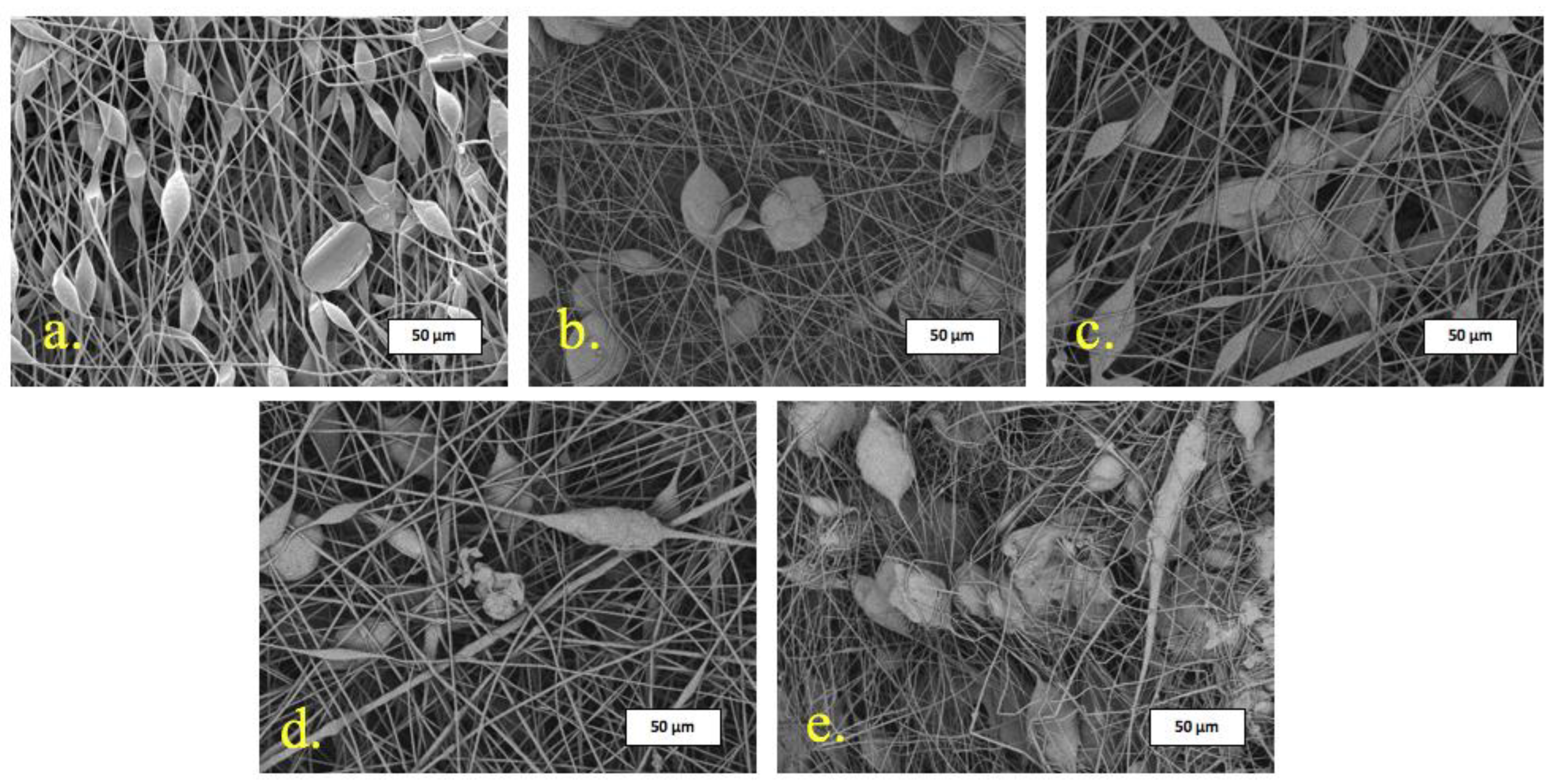

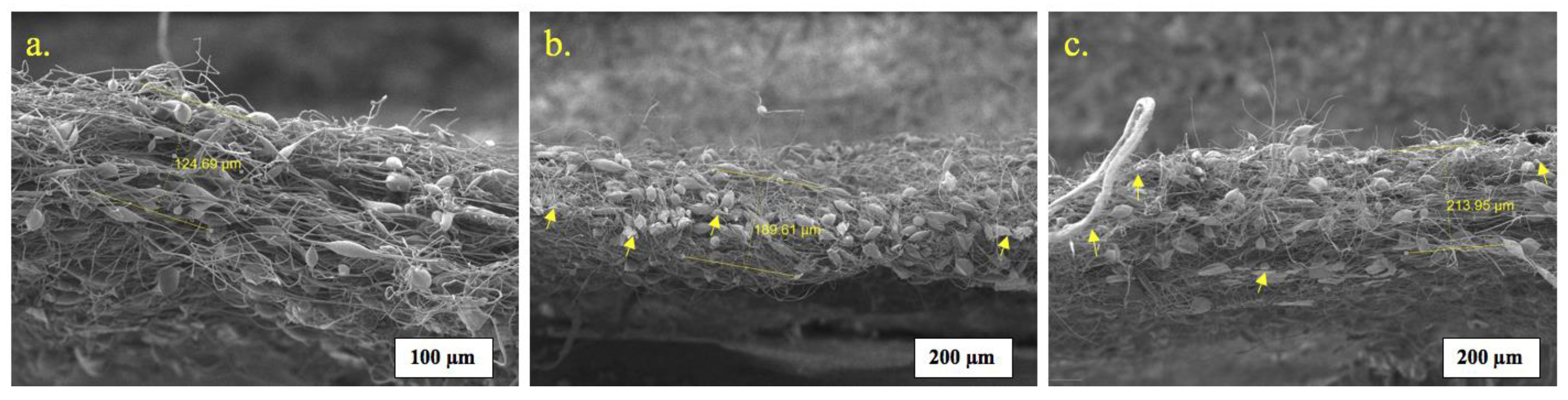

3.1. Morphological Characterizations of Electrospun PHB-α-TCP Materials

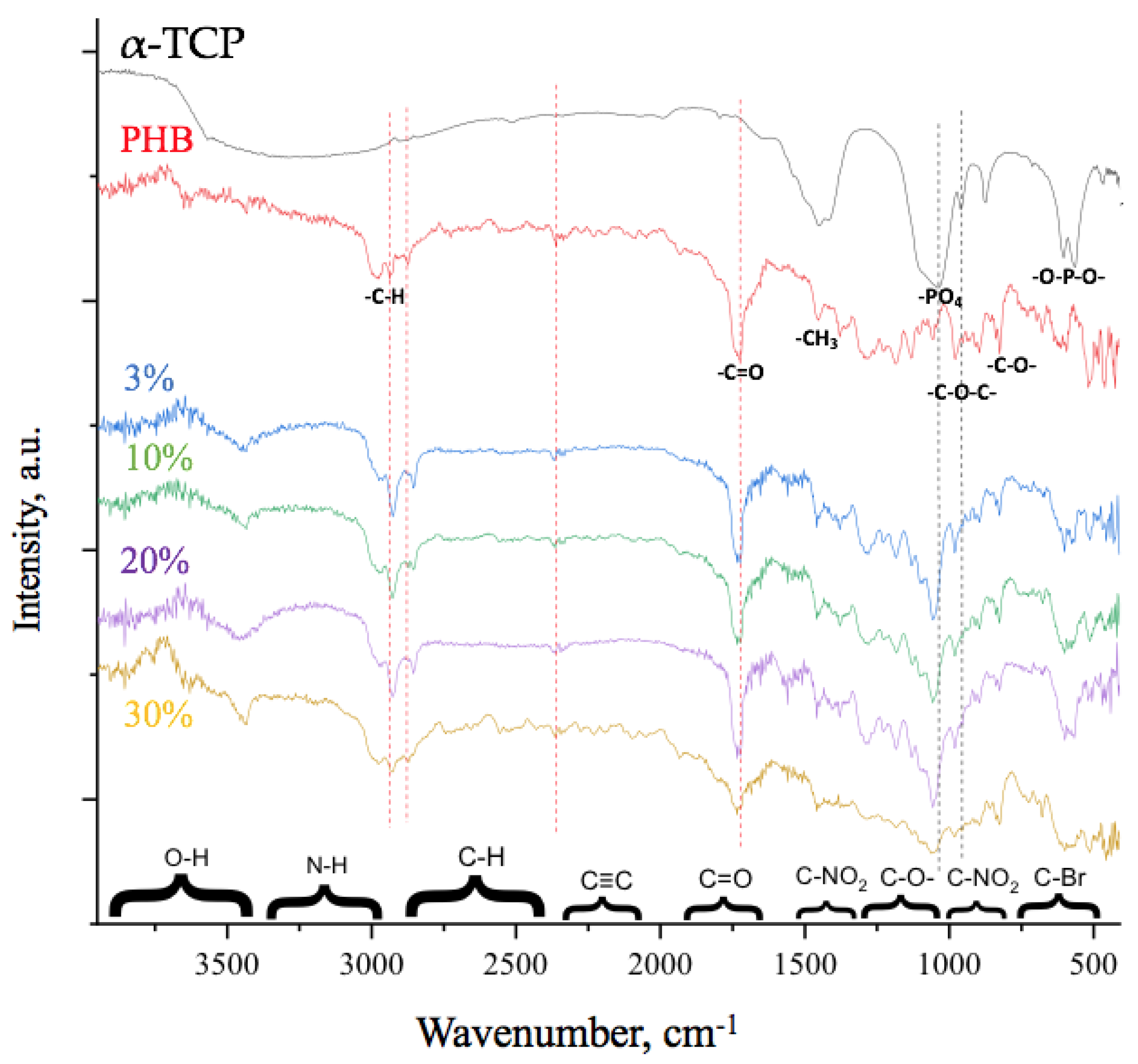

3.2. Chemical Characterizations of Electrospun PHB-α-TCP Materials

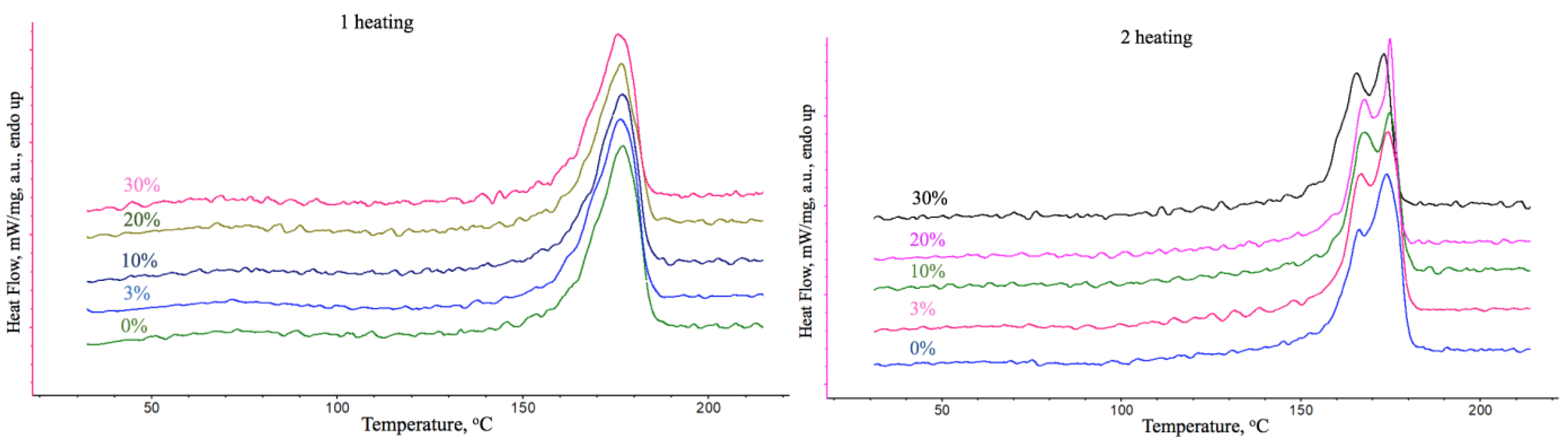

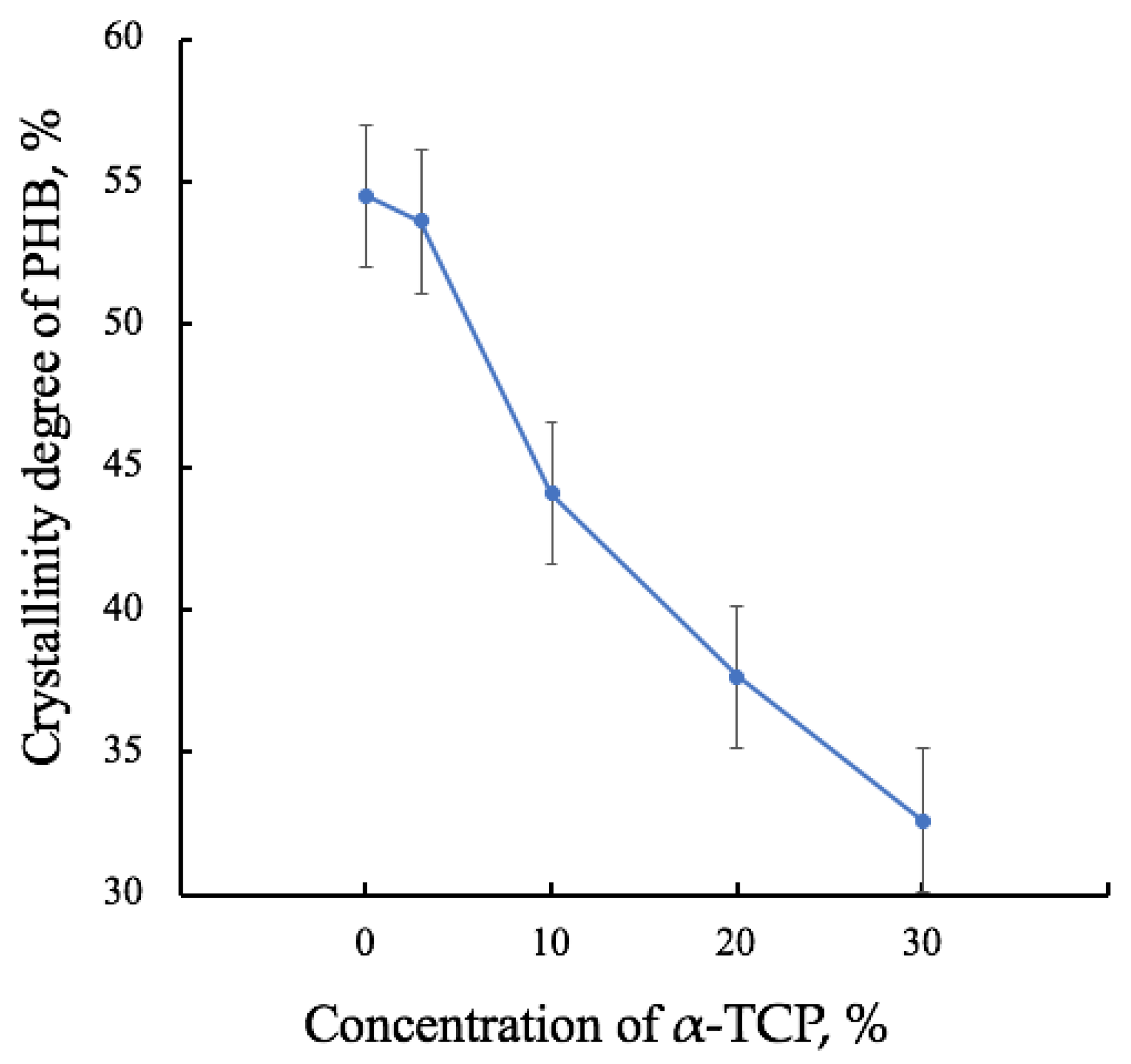

3.3. Thermophysical Properties of Electrospun PHB-α-TCP Materials

3.4. Mechanical Properties

4. Conclusions

- -

- Improved supramolecular structure, with the addition of α-TCP allowing better control of its crystallinity, results in enhanced mechanical properties and structural integrity.

- -

- The presence of α-TCP in the composite material enables a controlled release of calcium, making it a potentially suitable osteoconductive material for applications in living organisms.

- -

- α-TCP acts as a crystallization center, positively affecting the formation of the supramolecular structure in the nonwoven fibrous material, which could lead to improved properties of nonwoven material and controlled time of resistance to biodegradation or bioresorption.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pramanik, S.; Kharche, S.; More, N.; Ranglani, D.; Singh, G.; Kapusetti, G. Natural Biopolymers for Bone Tissue Engineering: A Brief Review. Eng. Regen. 2023, 4, 193–204. [Google Scholar] [CrossRef]

- Wankhede, K.; Bajaj, P.; Choudhari, M. Use of Biopolymers in Teeth Regeneration. J. Med. Dent. Sci. 2022, 10, 110–114. [Google Scholar]

- O’Brien, J.F. Biomaterials & scaffolds for tissue engineering. Mater. Today 2011, 14, 88–95. [Google Scholar]

- Walmsley, G.G.; Ransom, R.C.; Zielins, E.R.; Flacco, J.S.; Hu, M.S.; Lee, A.S.; Longaker, M.T.; Wan, D.C. Stem Cells in Bone Regeneration. Stem. Cell Rev. 2016, 12, 524–529. [Google Scholar] [CrossRef] [Green Version]

- Oliveira, É.R.; Nie, L.; Podstawczyk, D.; Allahbakhsh, A.; Ratnayake, J.; Brasil, D.L.; Shavandi, A. Advances in Growth Factor Delivery for Bone Tissue Engineering. Int. J. Mol. Sci. 2021, 22, 903. [Google Scholar] [CrossRef]

- Ginebra, M.; Espanol, M.; Maazouz, Y.; Bergez, V.; Pastorino, D. Bioceramics and bone healing. EFORT Open Rev. 2023, 3, 173–183. [Google Scholar] [CrossRef]

- Eivazzadeh-Keihan, R.; Maleki, A.; Guardia, M.; Bani, M.; Chenab, K.; Pashazadeh-Panahi, P.; Baradaran, B.; Mokhtarzadeh, A.; Hamblin, M. Carbon based nanomaterials for tissue engineering of bone: Building new bone on small black scaffolds: A review. J. Adv. Res. 2019, 18, 185–201. [Google Scholar] [CrossRef]

- Kevor, S.; Roger, I.; Klimkiewicz, M.; Brown, P. Formation and properties of a synthetic bone composite: Hydroxyapatite–collagen. J. Biomed. Mater. Res. 1995, 29, 803–810. [Google Scholar]

- Kong, X.D.; Cui, F.Z.; Wang, X.M.; Zhang, M.; Zhang, W. Silk fibroin regulated mineralization of hydroxyapatite nanocrystals. J. Cryst. Growth 2004, 270, 197–202. [Google Scholar] [CrossRef]

- Kim, S.; Park, M.S.; Jeon, O.; Choi, C.Y.; Kim, B. Poly(lactide-co-glycolide)/hydroxyapatite composite scaffolds for bone tissue engineering. Biomaterials 2006, 27, 1399–1409. [Google Scholar] [CrossRef]

- Zhang, R.; Ma, P.X. Poly(α-hydroxyl acids)/hydroxyapatite porous composites for bone-tissue engineering. I. Preparation and morphology. J. Biomed. Mater. Res. 1999, 44, 446–455. [Google Scholar] [CrossRef]

- Zheng, P.; Yao, Q.; Mao, F.; Liu, N.; Xu, Y.; Wei, B.; Wang, L. Adhesion, proliferation and osteogenic differentiation of mesenchymal stem cells in 3D printed poly-ε-caprolactone/hydroxyapatite scaffolds combined with bone marrow clots. Mol. Med. Rep. 2017, 16, 5078–5084. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jeong, J.; Kim, J.H.; Shim, J.H. Bioactive calcium phosphate materials and applications in bone regeneration. Biomater. Res. 2019, 23, 4. [Google Scholar] [CrossRef] [Green Version]

- Al-Sanabani, J.S.; Madfa, A.A.; Al-Sanabani, F.A. Application of Calcium Phosphate Materials in Dentistry. Int. J. Biomater. 2013, 2013, 876132. [Google Scholar] [CrossRef] [Green Version]

- Jonitz, A.; Wieding, J.; Lochner, K.; Cornelsen, M.; Seitz, H.; Hansmann, D.; Bader, R. Migration Capacity and Viability of Human Primary Osteoblasts in Synthetic Three-dimensional Bone Scaffolds Made of Tricalciumphosphate. Materials 2011, 4, 1249–1259. [Google Scholar] [CrossRef]

- Naal, F.D.; Steinhauser, E.; Schauwecker, J.; Diehl, P.; Mittelmeier, W. Tissue engineering von Knochen- und Knorpelgewebe: Die bedeutung von sauerstoff und hypoxie. Biomaterials 2004, 5, 34–37. [Google Scholar] [CrossRef]

- Dali, S.S.; Wong, S.K.; Chin, K.Y.; Ahmad, F. The Osteogenic Properties of Calcium Phosphate Cement Doped with Synthetic Materials: A Structured Narrative Review of Preclinical Evidence. Int. J. Mol. Sci. 2023, 12, 7161. [Google Scholar] [CrossRef]

- Draenert, M.; Draenert, A.; Draenert, K. Osseointegration of hydroxyapatite and remodeling-resorption of tricalciumphosphate ceramics. Microsc. Res. Tech. 2013, 7, 370–380. [Google Scholar] [CrossRef]

- Battafarano, G.; Rossi, M.; De Martino, V.; Marampon, F.; Borro, L.; Secinaro, A.; Del Fattore, A. Strategies for Bone Regeneration: From Graft to Tissue Engineering. Int. J. Mol. Sci. 2021, 22, 1128. [Google Scholar] [CrossRef] [PubMed]

- Jordana, F.; Le Visage, C.; Weiss, P. Substituts osseux [Bone substitutes]. Med. Sci. 2017, 33, 60–65. [Google Scholar]

- Xu, Z.L.; Huang, X.J. Optimizing allogeneic grafts in hematopoietic stem cell transplantation. Stem Cells Transl. Med. 2021, 10, 41–47. [Google Scholar] [CrossRef] [PubMed]

- Haugen, H.J.; Lyngstadaas, S.P.; Rossi, F.; Perale, G. Bone grafts: Which is the ideal biomaterial? J. Clin. Periodontol. 2019, 46, 92–102. [Google Scholar] [CrossRef]

- Hasanov, S.; Suvanov, K.; Halmanov, B.; Sadikova, H. Fundamentals of dental implantology. J. Clin. Dent. 2022, 22, 1–139. [Google Scholar]

- Mikaelyan, N.P.; Komarov, O.S. Biochemistry of Hard Tissues of the Oral Cavity in Normal and Pathological Conditions; Shestopalov, A.V., Ed.; N.N. Pirogov Federal state Budgetary Educational Institution of The Russian Ministry of Health: Moscow, Russia, 2019; pp. 1–72. [Google Scholar]

- Nowsheen, G.; Archana, B.; Pearl, P.; Sandra, R.; Dhanjay, J. Third generation poly(hydroxyacid) composite scaffolds for tissue engineering. J. Biomed. Mater. Res. 2016, 105, 1667–1684. [Google Scholar]

- Li, Z.; Yang, J.; Loh, X. Polyhydroxyalkanoates: Opening doors for a sustainable future. NPG Asia Mater. 2016, 8, 265. [Google Scholar] [CrossRef]

- Krutko, E.T.; Prokopchuk, N.R.; Globa, A.I. Technology of Biodegradable Polymer Materials, 1st ed.; Publishing House Belarusian State Technological University: Minsk, Belarus, 2014; p. 106. [Google Scholar]

- Ugur, A.; Sahin, N.; Beyatli, Y. Accumulation of poly-hydroxybutyrate in Streptomyces species during growth with different nitrogen sources. Turk. J. Biol. 2002, 23, 171–174. [Google Scholar]

- Mohan, A.; Girdhar, M.; Kumar, R.; Chaturvedi, H.S.; Vadhel, A.; Solanki, P.R.; Kumar, A.; Kumar, D.; Mamidi, N. Polyhydroxybutyrate-Based Nanocomposites for Bone Tissue Engineering. Pharmaceuticals 2021, 14, 1163. [Google Scholar] [CrossRef]

- Pulingam, T.; Appaturi, J.N.; Parumasivam, T.; Ahmad, A.; Sudesh, K. Biomedical Applications of Polyhydroxyalkanoate in Tissue Engineering. Polymers 2022, 14, 2141. [Google Scholar] [CrossRef]

- Rahmati, M.; Mills, D.K.; Urbanska, A.; Saeb, M.; Venugopal, J.R.; Ramakrishna, S.; Mozafari, M. Electrospinning for tissue engineering applications. Prog. Mater. Sci. 2021, 117, 100721. [Google Scholar] [CrossRef]

- Surmenev, R.; Ivanov, A.; Cecilia, A.; Baumbach, T.; Chernozem, R.; Mathur, S.; Surmeneva, M. Electrospun composites of poly-3-hydroxybutyrate reinforced with conductive fillers for in vivo bone regeneration. Open Ceram. 2022, 9, 100237. [Google Scholar] [CrossRef]

- Ramier, J.; Bouderlique, T.; Stoilova, O.; Manolova, N.; Rashkov, I.; Langlois, V.; Renard, E.; Albanese, P.; Grande, D. Biocomposite scaffolds based on electrospun poly(3-hydroxybutyrate) nanofibers and electrosprayed hydroxyapatite nanoparticles for bone tissue engineering applications. Mater. Sci. Eng. A 2014, 8, 161–169. [Google Scholar] [CrossRef] [PubMed]

- Siqueira, L.; Roberto, F.; Anderson, P.; Lobo, O.; Trichês, S. Morphological, thermal and bioactivity evaluation of electrospun PCL/β-TCP fibers for tissue regeneration. Polímeros 2019, 29, 2118. [Google Scholar] [CrossRef]

- Nathanael, A.J.; Oh, T.H. Encapsulation of Calcium Phosphates on Electrospun Nanofibers for Tissue Engineering Applications. Crystals 2021, 11, 199. [Google Scholar] [CrossRef]

- Filatov, Y.N. Electrospinning of Fibrous Materials, 1st ed.; Krivchenko, V.N., Ed.; Elsevier: Moscow, Russia, 2001; p. 231. [Google Scholar]

- Scandola, M.; Focarete, M.L.; Adamus, G.; Sikorska, W.; Baranowska, I.; Wierczek, S.; Gnatowski, M.; Kowalczuk, M.; Jedlin, Z. Polymer Blends of Natural Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and a Synthetic Atactic Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and a Synthetic Atactic Poly(3-hydroxybutyrate). Characterization and Biodegradation Studies. Macromolecules 1997, 30, 2568–2574. [Google Scholar] [CrossRef]

- Sill, T.; Recum, H. Electrospinning: Applications in drug delivery and tissue engineering. Biomaterials 2008, 29, 1989–2006. [Google Scholar] [CrossRef] [PubMed]

- Mahmoudi, N.; Simchi, A. On the biological performance of graphene oxide-modified chitosan/polyvinyl pyrrolidone nanocomposite membranes: In vitro and in vivo effects of graphene oxide. Mater. Sci. Eng. C 2017, 70, 121–131. [Google Scholar] [CrossRef]

- Xue, J.; Wu, T.; Dai, Y.; Xia, Y. Electrospinning and Electrospun Nanofibers: Methods, Materials, and Applications. Chem. Rev. 2019, 119, 5298–5415. [Google Scholar] [CrossRef]

- Arrieta, M.P.; López, J.; López, D.; Kenny, J.M.; Peponi, L. Development of flexible materials based on plasticized electrospun PLA–PHB blends: Structural, thermal, mechanical and disintegration properties. Eur. Polym. J. 2015, 73, 433–446. [Google Scholar] [CrossRef]

- El-hadi, A.M.; Al-Jabri, F.Y. Influence of Electrospinning Parameters on Fiber Diameter and Mechanical Properties of Poly(3-Hydroxybutyrate) (PHB) and Polyanilines (PANI) Blends. Polymers 2016, 8, 97. [Google Scholar] [CrossRef] [Green Version]

- Yeo, J.C.C.; Muiruri, J.K.; Thitsartarn, W.; Li, Z.; He, C. Recent advances in the development of biodegradable PHB-based toughening materials: Approaches, advantages and applications. Mater. Sci. Eng. C Mater. Biol. Appl. 2018, 92, 1092–1116. [Google Scholar] [CrossRef]

- Tyubaeva, P.; Varyan, I.; Krivandin, A.; Shatalova, O.; Karpova, S.; Lobanov, A.; Olkhov, A.; Popov, A. The Comparison of Advanced Electrospun Materials Based on Poly(-3-hydroxybutyrate) with Natural and Synthetic Additives. J. Funct. Biomater. 2022, 13, 23. [Google Scholar] [CrossRef] [PubMed]

- Tyubaeva, P.; Varyan, I.; Lobanov, A.; Olkhov, A.; Popov, A. Effect of the Hemin Molecular Complexes on the Structure and Properties of the Composite Electrospun Materials Based on Poly(3-hydroxybutyrate). Polymers 2021, 13, 4024. [Google Scholar] [CrossRef] [PubMed]

- Kalita, S.; Bhatt, H.; Dhamne, A. MgO–Na2O–P2O5-Based Sintering Additives for Tricalcium Phosphate Bioceramics. J. Am. Chem. Soc. 2006, 89, 875–881. [Google Scholar] [CrossRef]

- Mottina, A.; Ayresa, E.; Oréficec, R.; Câmara, J. What Changes in Poly(3-Hydroxybutyrate) (PHB) When Processed as Electrospun Nanofibers or Thermo-Compression Molded Film? Mater. Res. 2016, 19, 57–66. [Google Scholar] [CrossRef] [Green Version]

- Fitzgerald, A.V.L. Preparation, Characterisation and Secondary Crystallisation of PHB Based Copolymers and Carbohydrate Blends; University of Birmingham: Birmingham, UK, 2017. [Google Scholar]

- Panda, R.N.; Hsieh, M.F.; Chung, R.J.; Chin, T.S. FTIR, XRD, SEM and solid state NMR investigations of carbonate-containing hydroxyapatite nano-particles synthesized by hydroxide-gel technique. J. Phys. Chem. Solids 2003, 64, 193–199. [Google Scholar] [CrossRef]

- Szubert, M.; Adamska, K.; Szybowicz, M.; Jesionowski, T.; Buchwald, T.; Voelkel, A. The increase of apatite layer formation by the poly(3-hydroxybutyrate) surface modification of hydroxyapatite and β-tricalcium phosphate. Mater. Sci. Eng. C 2014, 34, 236–244. [Google Scholar] [CrossRef]

- Kongkhlang, T.; Tashiro, K.; Kotaki, M.; Chirachanchai, S. Electrospinning as a New Technique To Control the Crystal Morphology and Molecular Orientation of Polyoxymethylene Nanofibers. J. Am. Chem. Soc. 2008, 130, 15460–15466. [Google Scholar] [CrossRef] [PubMed]

- Reis, K.C.; Pereira, L.; Melo, I.C.; Marconcini, J.M. Particles of Coffee Wastes as Reinforcement in Polyhydroxybutyrate (PHB) Based Composites. Mater. Res. 2015, 18, 8. [Google Scholar] [CrossRef] [Green Version]

- Santos, A.J.; Oliveira, L.V.; Schulz, A.A.; Duarte, M.A. From Obtaining to Degradation of PHB: Material Properties. Ing. Cienc. 2017, 13, 26. [Google Scholar]

- Szewczyk, P.K.; Stachewicz, U. The impact of relative humidity on electrospun polymer fibers: From structural changes to fiber morphology. Adv. Colloid. Interface Sci. 2020, 20, 50. [Google Scholar] [CrossRef]

- Phongtamrug, S.; Tashiro, K. X-ray Crystal Structure Analysis of Poly(3-hydroxybutyrate) β-Form and the Proposition of a Mechanism of the Stress-Induced α-to-β Phase Transition. Macromolecules 2019, 52, 2995–3009. [Google Scholar] [CrossRef]

- Chernozem, R.V.; Romanyuk, K.N.; Grubova, I.; Chernozem, P.V.; Surmeneva, M.A. Enhanced piezoresponse and surface electric potential of hybrid biodegradable polyhydroxybutyrate scaffolds functionalized with reduced graphene oxide for tissue engineering. Nano Energy 2021, 89, 15. [Google Scholar] [CrossRef]

- Tyubaeva, P.M.; Zykova, A.K.; Morokov, E.S.; Olkhov, A.A.; Podmasteriev, V.V.; Popov, A.A.; Iordanskii, A.L. The Investigation of the Structure and Properties of Nonwoven Fibrous Materials Based on Polyhydroxybutyrate Biopolymer. Conf. Ser. Mater. Sci. Eng. 2021, 1093, 5. [Google Scholar] [CrossRef]

- Zykova, A.; Morokov, E.; Tyubaeva, P. Influence of Processing Methods on the Mechanical Behavior of Poly-3-hydroxybutyrate Nonwoven Scaffolds. Macromol. Symp. 2022, 404, 2100322. [Google Scholar] [CrossRef]

- Morokov, E.; Zykova, A.; Tyubaeva, P. The Influence of Microstructure in PHB Non-Woven Materials on Mechanical Behavior Under Tension. Macromol. Symp. 2021, 396, 2000245. [Google Scholar] [CrossRef]

- Khramtsova, E.; Morokov, E.; Antipova, C.; Krasheninnikov, S.; Lukanina, K.; Grigoriev, T. How the Nonwoven Polymer Volume Microstructure Is Transformed under Tension in an Aqueous Environment. Polymers 2022, 14, 3526. [Google Scholar] [CrossRef]

| Sample | Concentration of α-TCP, % | Average Diameter, µm Δ ± 0.04 µm | Surface Density, g/cm3 Δ ± 0.04 g/cm3 |

|---|---|---|---|

| PHB | 0 | 2.2 | 0.30 |

| PHB-α-TCP | 3 | 1.6 | 0.24 |

| PHB-α-TCP | 10 | 1.7 | 0.22 |

| PHB-α-TCP | 20 | 2.5 | 0.20 |

| PHB-α-TCP | 30 | 1.6 | 0.20 |

| Sample | Concentration of α-TCP, % | First Heating Run | Second Heating Run | ||

|---|---|---|---|---|---|

| Tm, °C | ΔH, J/g | Tm, °C | ΔH, J/g | ||

| PHB | 0 | 176 | 79.6 | 174 | 76.8 |

| PHB-α-TCP | 3 | 176 | 80.7 | 174 | 75.0 |

| PHB-α-TCP | 10 | 177 | 71.5 | 175 | 68.1 |

| PHB-α-TCP | 20 | 177 | 68.7 | 175 | 67.7 |

| PHB-α-TCP | 30 | 176 | 68.0 | 173 | 66.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tyubaeva, P.M.; Gasparyan, K.G.; Fedotov, A.Y.; Lobzhanidze, P.V.; Baranov, O.V.; Egorov, A.A.; Sirotinkin, V.P.; Komlev, V.S.; Olkhov, A.A. Development of Nonwoven Fibrous Materials Based on Poly-3-Hydroxybutyrate with a High Content of α-Tricalcium Phosphate. Polymers 2023, 15, 3167. https://doi.org/10.3390/polym15153167

Tyubaeva PM, Gasparyan KG, Fedotov AY, Lobzhanidze PV, Baranov OV, Egorov AA, Sirotinkin VP, Komlev VS, Olkhov AA. Development of Nonwoven Fibrous Materials Based on Poly-3-Hydroxybutyrate with a High Content of α-Tricalcium Phosphate. Polymers. 2023; 15(15):3167. https://doi.org/10.3390/polym15153167

Chicago/Turabian StyleTyubaeva, Polina M., Kristina G. Gasparyan, Alexander Yu. Fedotov, Pavel V. Lobzhanidze, Oleg V. Baranov, Alexey A. Egorov, Vladimir P. Sirotinkin, Vladimir S. Komlev, and Anatoly A. Olkhov. 2023. "Development of Nonwoven Fibrous Materials Based on Poly-3-Hydroxybutyrate with a High Content of α-Tricalcium Phosphate" Polymers 15, no. 15: 3167. https://doi.org/10.3390/polym15153167

APA StyleTyubaeva, P. M., Gasparyan, K. G., Fedotov, A. Y., Lobzhanidze, P. V., Baranov, O. V., Egorov, A. A., Sirotinkin, V. P., Komlev, V. S., & Olkhov, A. A. (2023). Development of Nonwoven Fibrous Materials Based on Poly-3-Hydroxybutyrate with a High Content of α-Tricalcium Phosphate. Polymers, 15(15), 3167. https://doi.org/10.3390/polym15153167