Adaptive Neuro-Fuzzy-Based Models for Predicting the Tribological Properties of 3D-Printed PLA Green Composites Used for Biomedical Applications

Abstract

:1. Introduction

2. Materials and Experimental Work

2.1. Sample Preparation

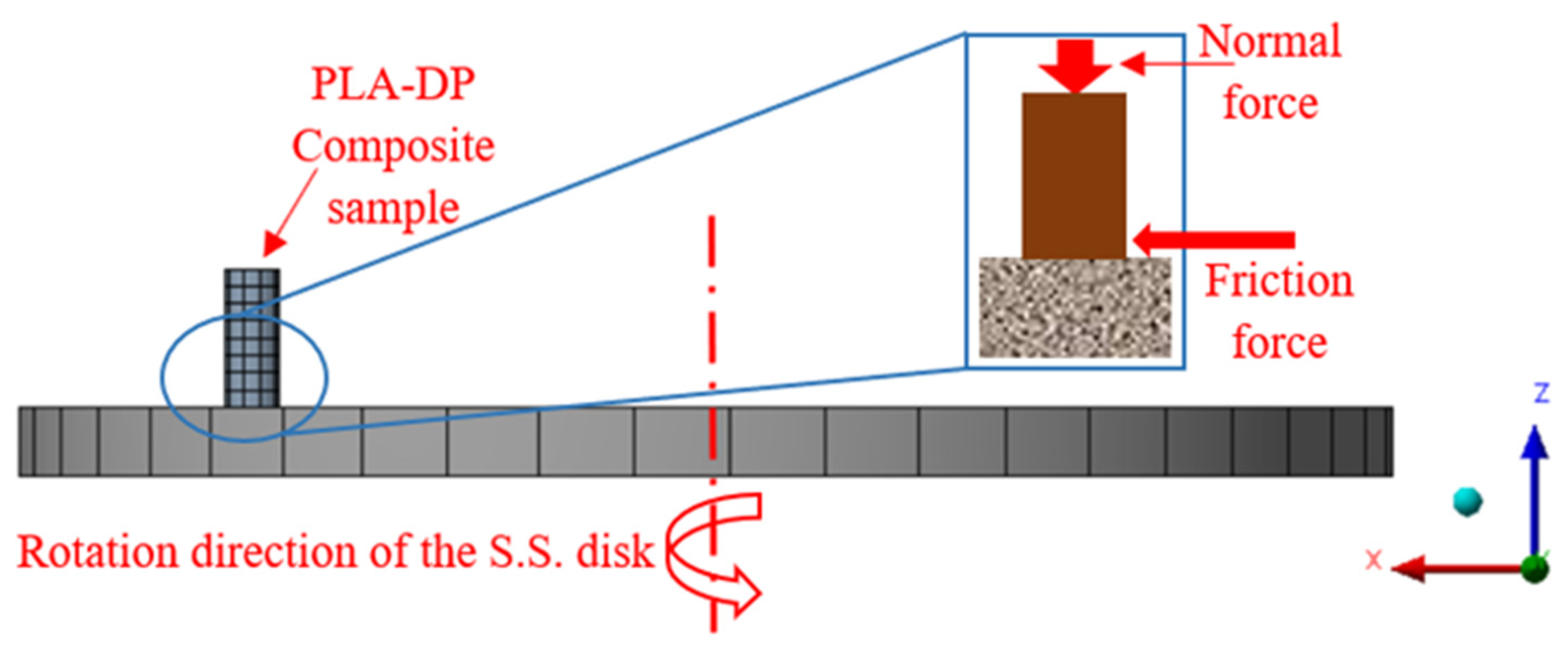

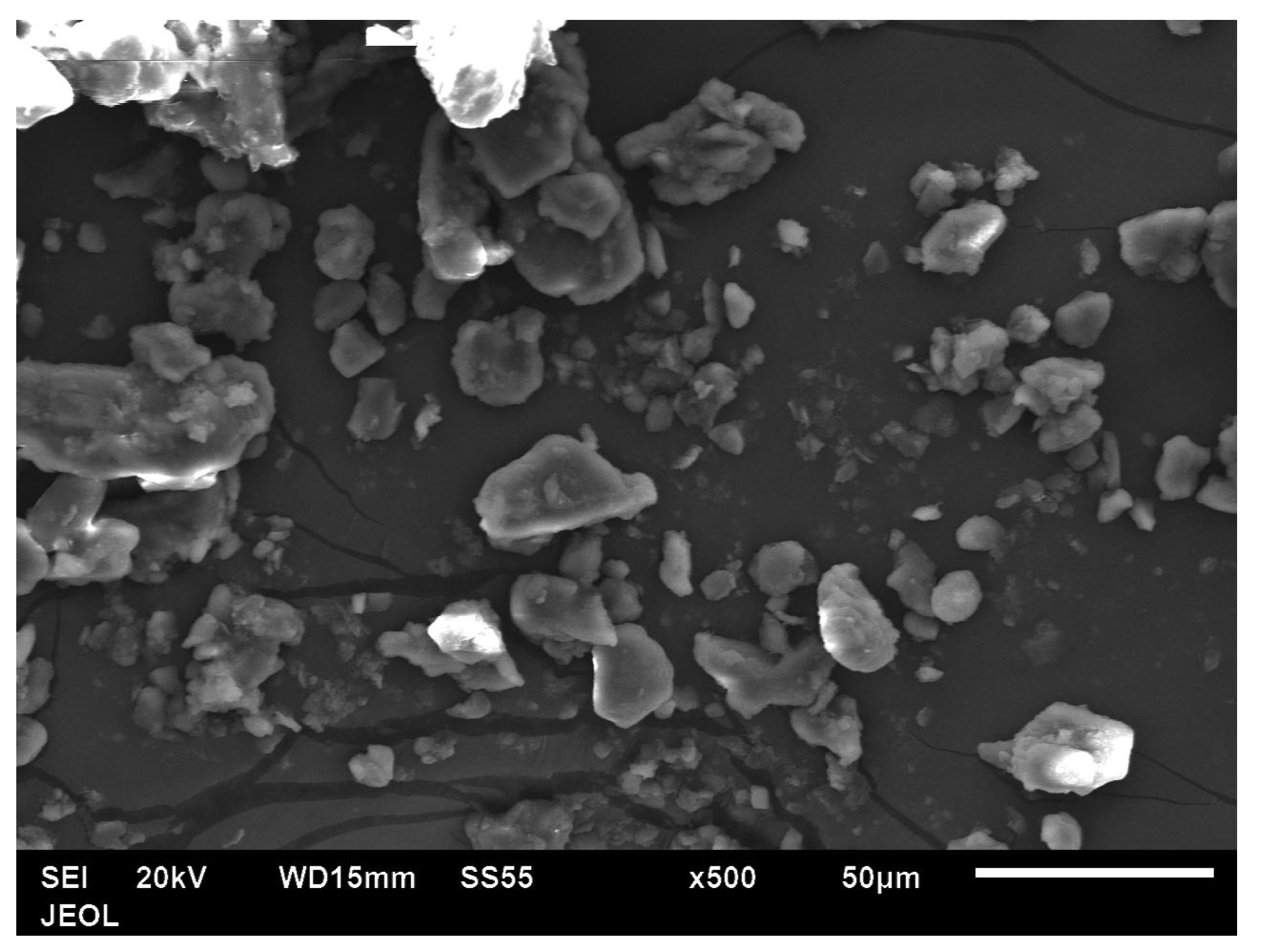

2.2. Characterization and Testing

2.3. Finite Element Analysis

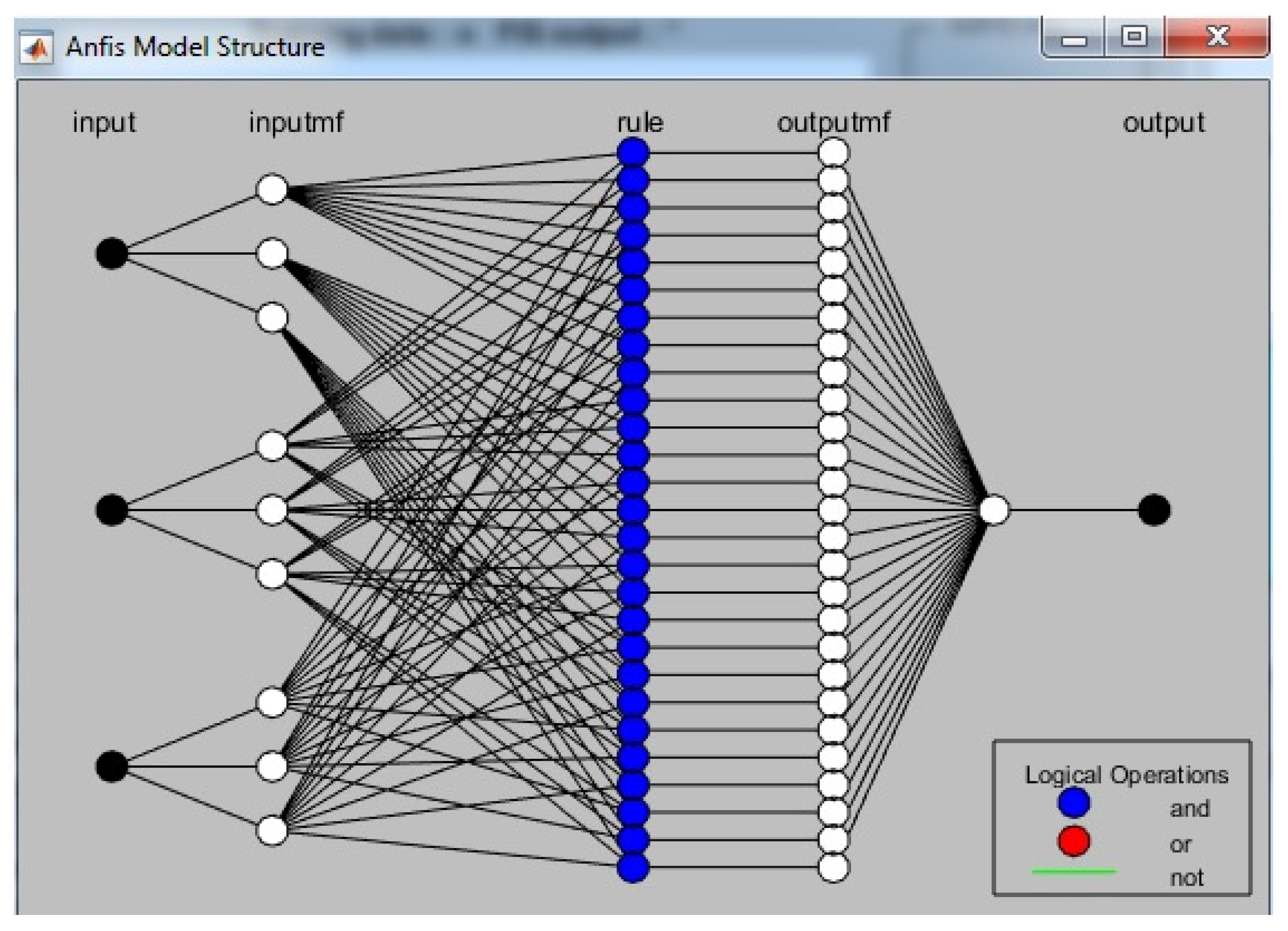

2.4. Adaptive Neuro-Fuzzy Inference System (ANFIS)

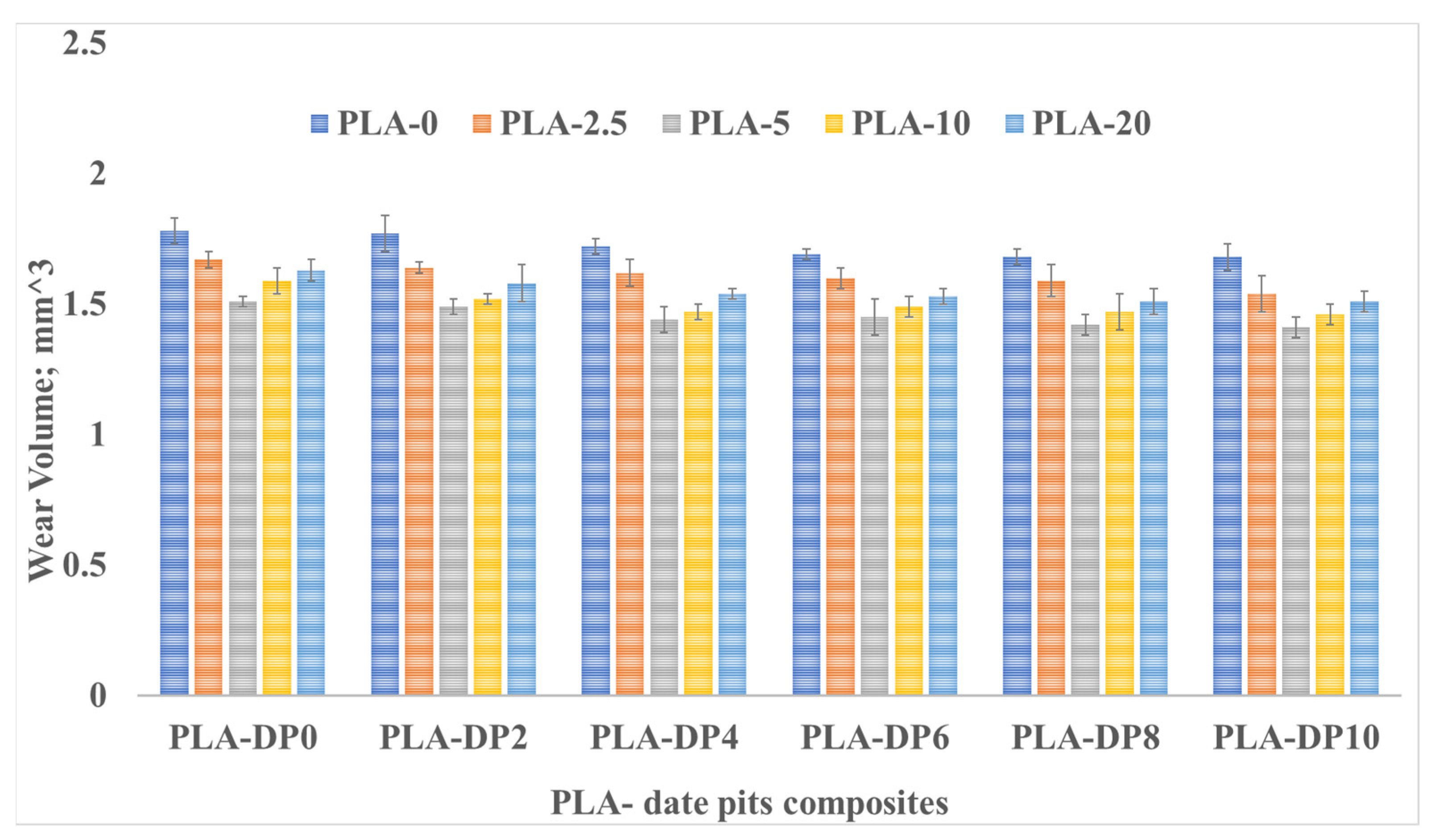

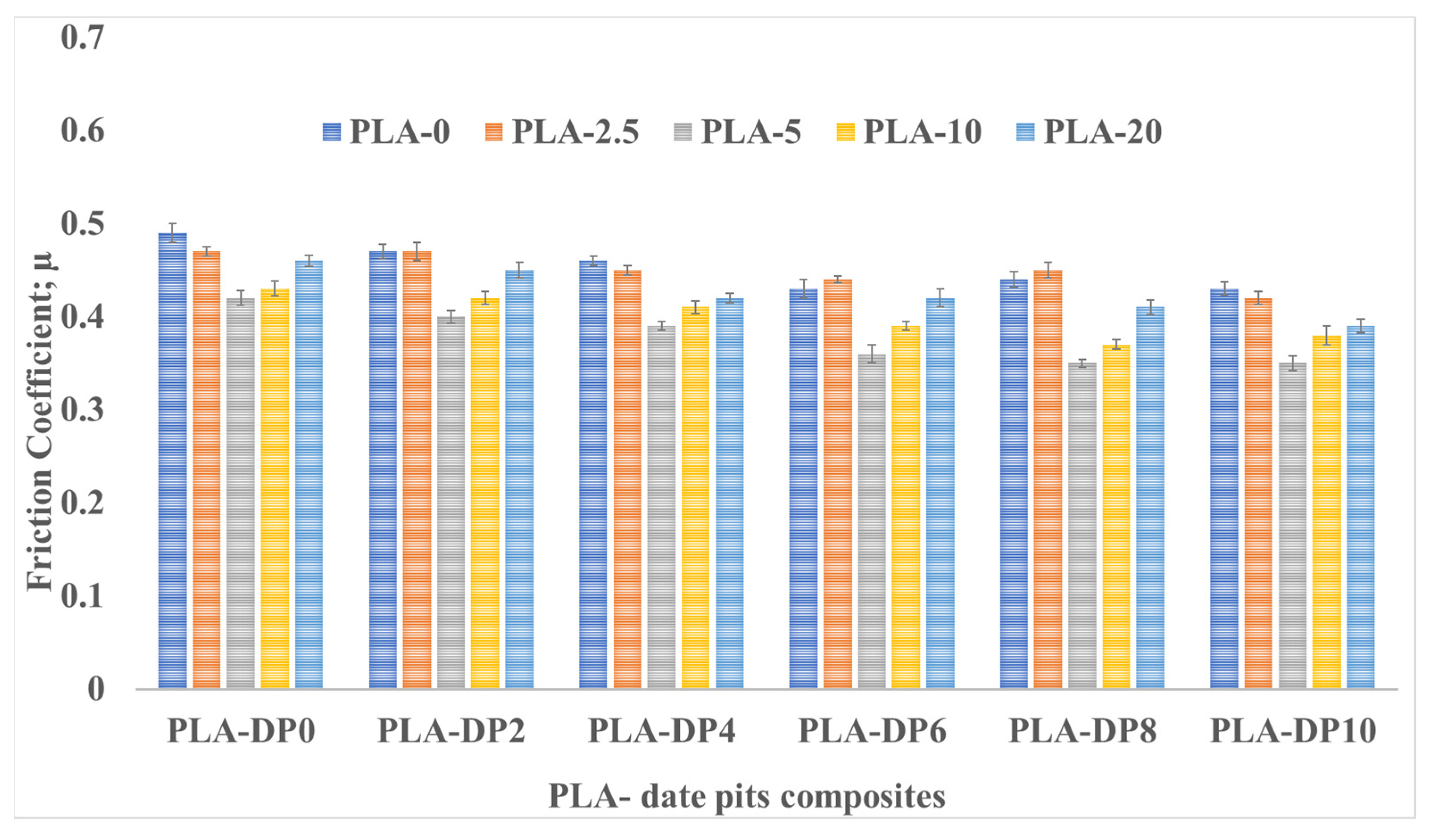

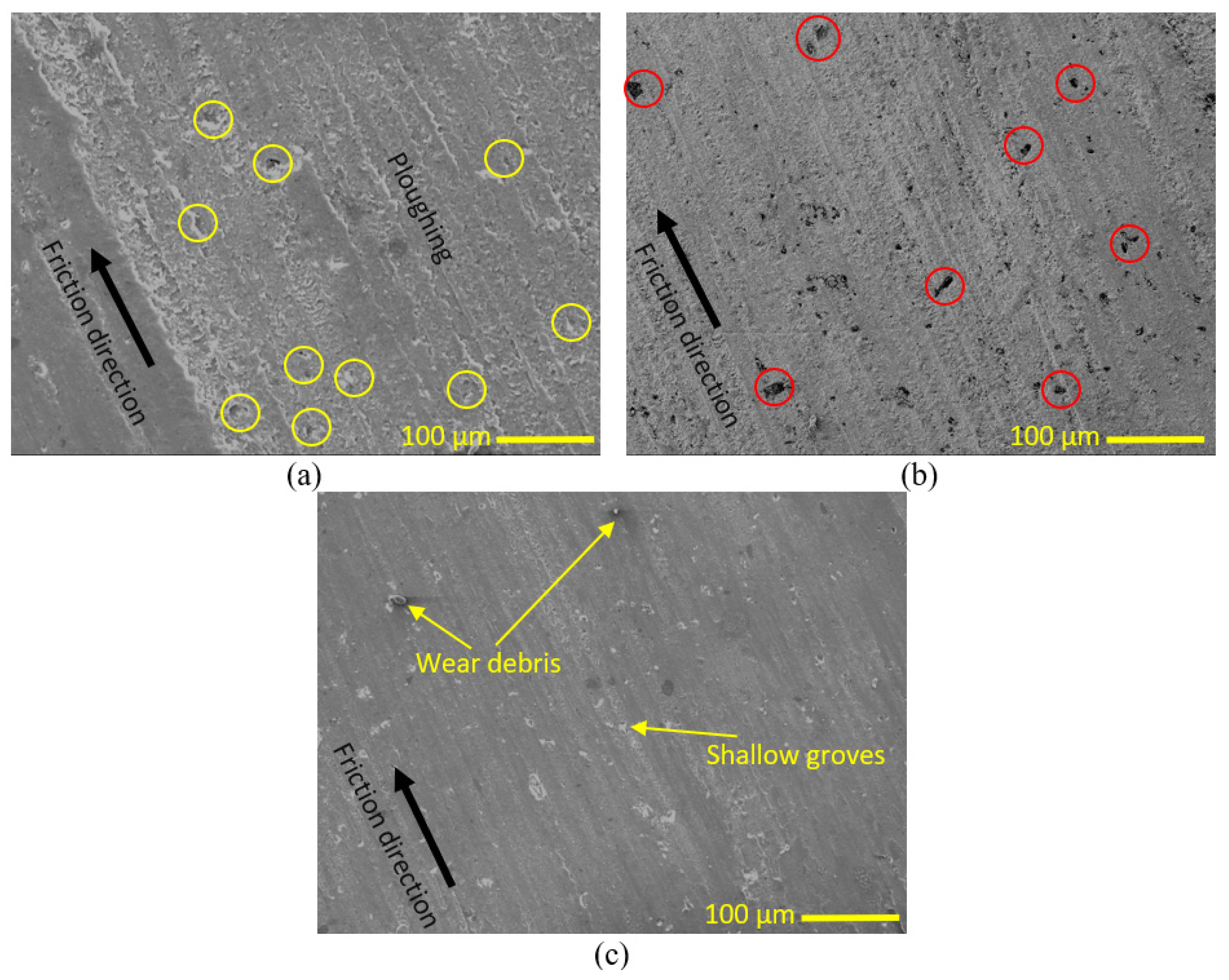

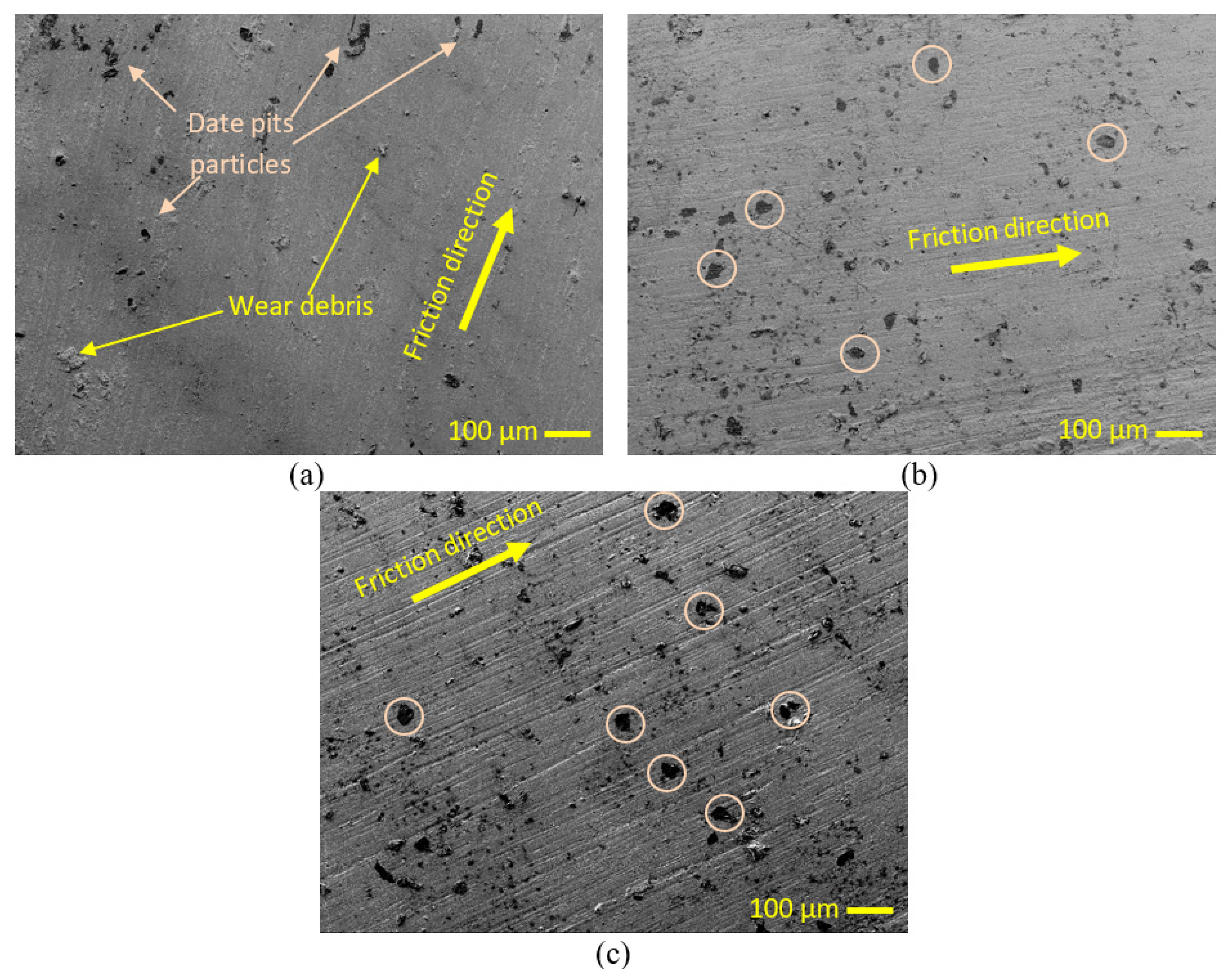

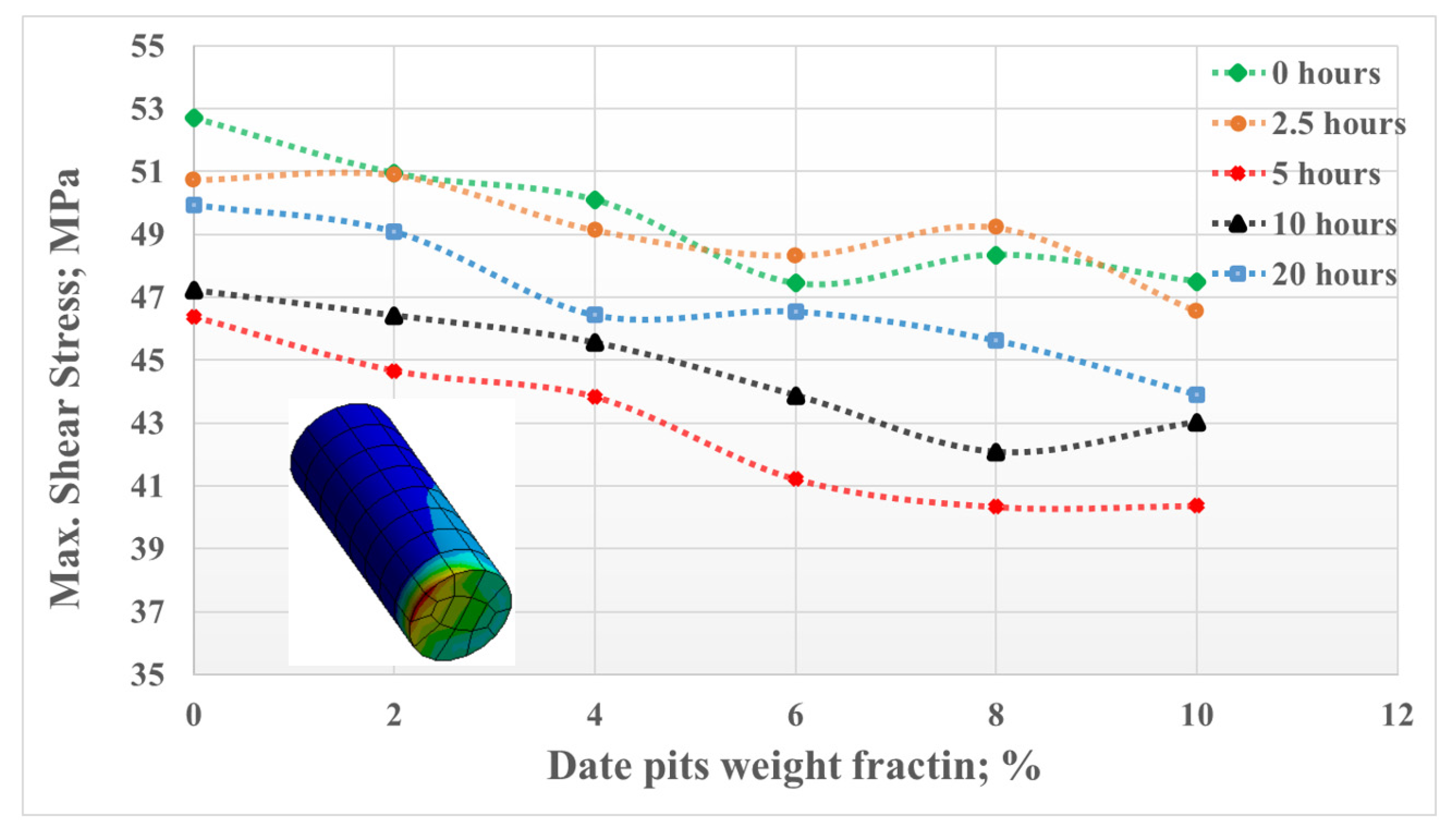

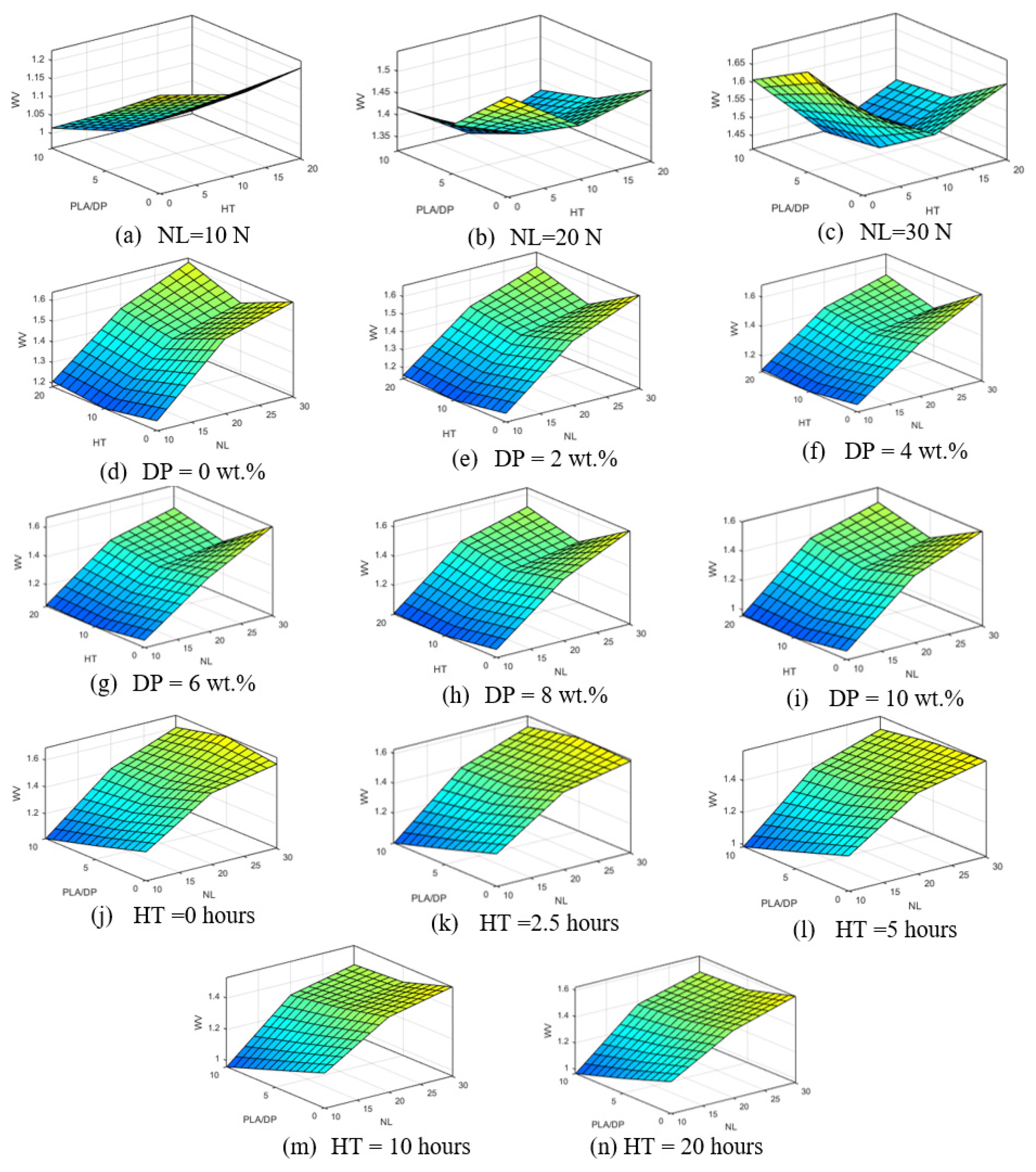

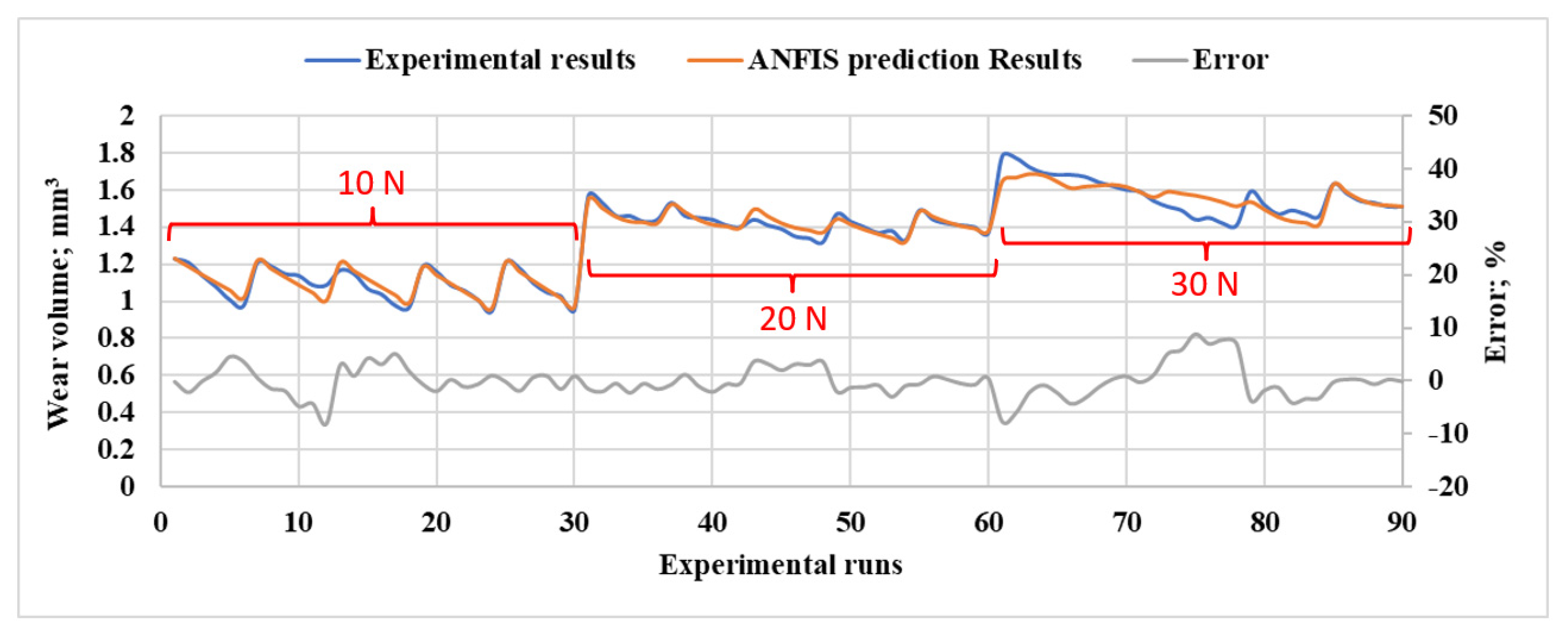

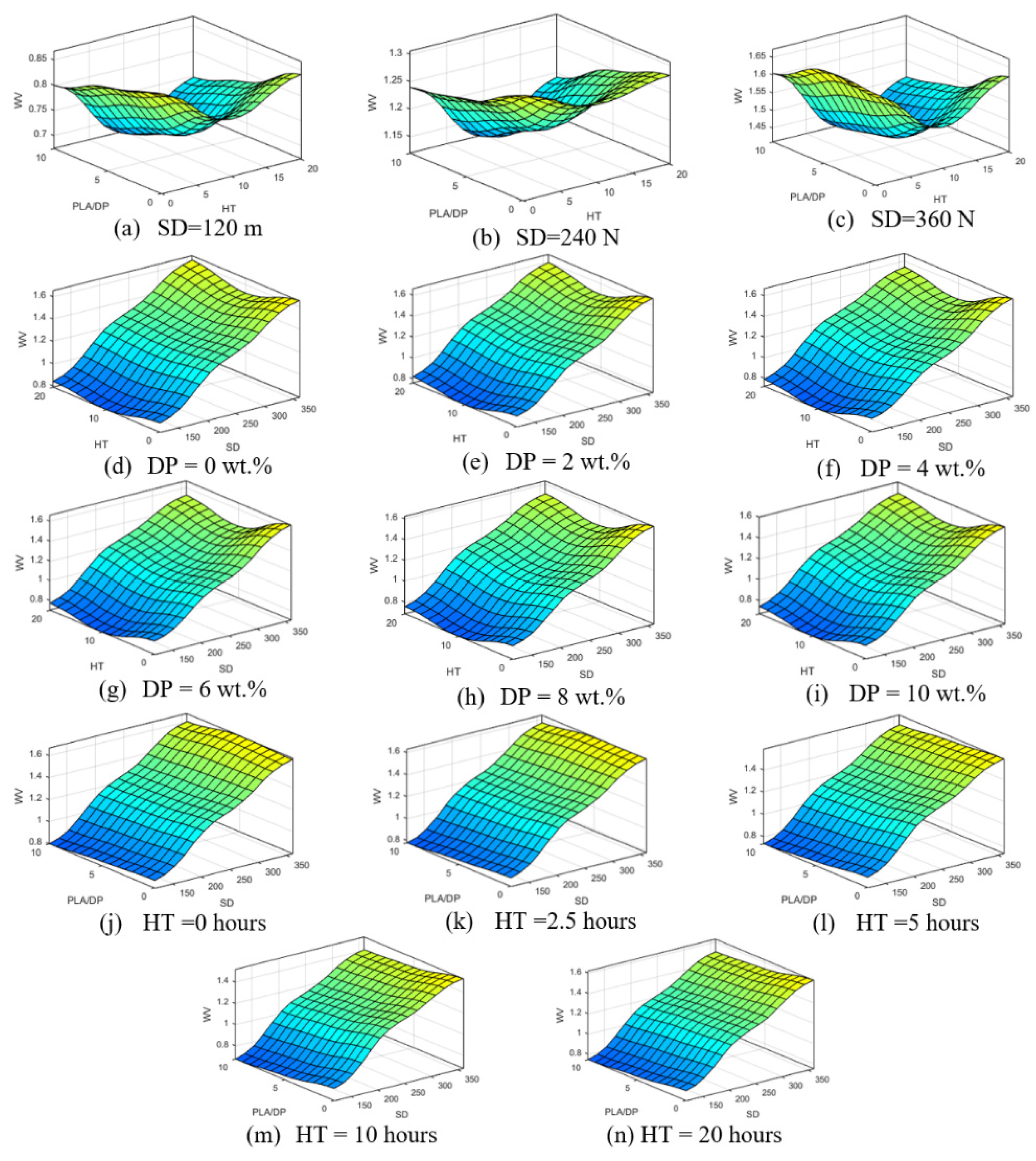

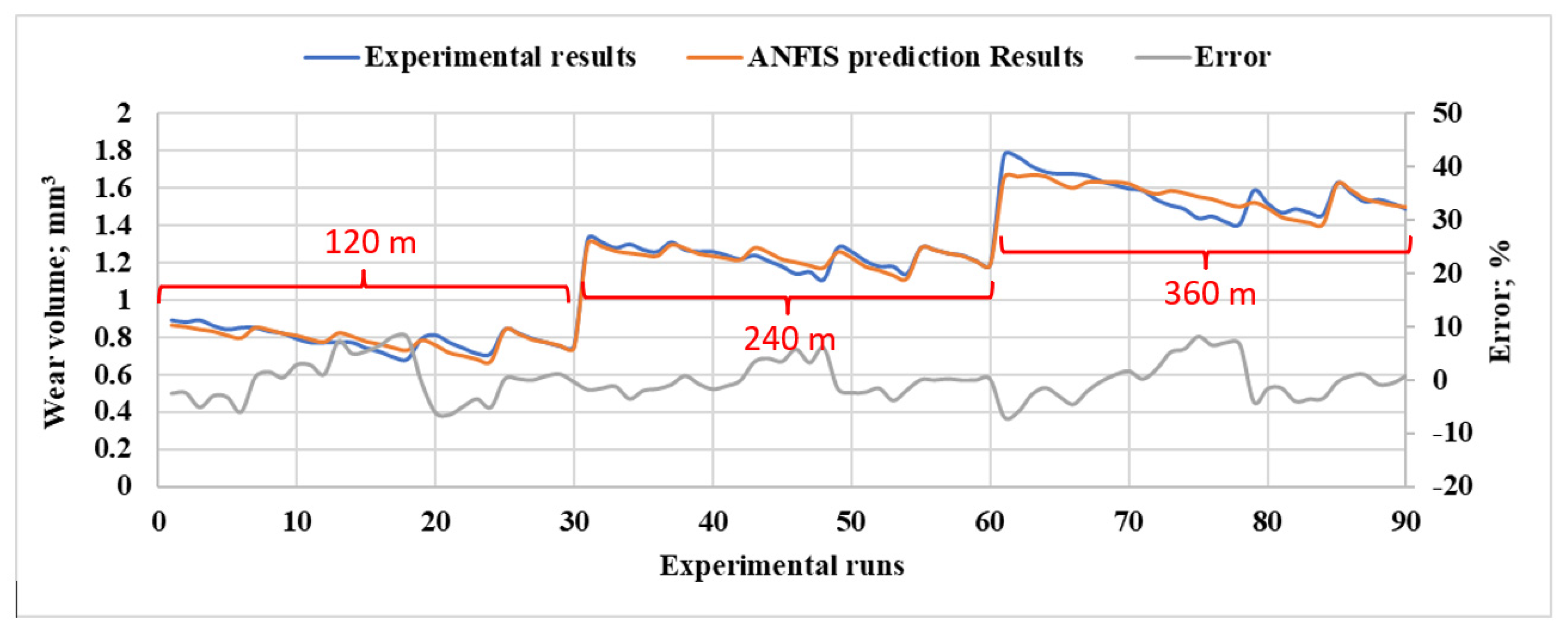

3. Results and Discussion

4. Conclusions

- ▪ ANFIS-based estimation models are proposed to predict the wear volume of PLA green composites. The models consider weight fractions of date pits, heat treatment durations, loads, and sliding distances. Experimental tribology testing provided the data for model training.

- ▪ A comprehensive production process of the PLA green composite was conducted, including heat treatment.

- ▪ The mechanical and tribological properties of PLA composites were determined through experimental testing.

- ▪ Finite element models were used to assess the load-carrying capacity of the composites.

- ▪ Incorporating 10% date pit particles increased hardness, Young’s modulus, and ultimate compressive strength.

- ▪ Heat treatment enhanced mechanical properties and reduced wear volume, improving tribological properties.

- ▪ Finite element analysis showed a decrease in contact stresses with date pit particle incorporation and heat treatment.

- ▪ The ANFIS model accurately predicted wear volume under different conditions. The model had an average percentage error of less than 9.31 × 10−3%.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gross, J.-B.; Guillaume, C.; Gegout-Pottie, P.; Mainard, D.; Presle, N. Synovial fluid levels of adipokines in osteoarthritis: Association with local factors of inflammation and cartilage maintenance. Biomed. Mater. Eng. 2014, 24, 17–25. [Google Scholar] [CrossRef]

- Espallargas, N.; Fischer, A.; Muñoz, A.I.; Mischler, S.; Wimmer, M.A. In-situ generated tribomaterial in metal/metal contacts: Current understanding and future implications for implants. Biotribology 2017, 10, 42–50. [Google Scholar] [CrossRef]

- Smith, A.J.; Dieppe, P.; Vernon, K.; Porter, M.; Blom, A.W. Failure rates of stemmed metal-on-metal hip replacements: Analysis of data from the National Joint Registry of England and Wales. Lancet 2012, 379, 1199–1204. [Google Scholar] [CrossRef]

- Zhao, W. Progress of stem cell research in knee osteoarthritis. Highlights Sci. Eng. Technol. 2023, 36, 1421–1426. [Google Scholar] [CrossRef]

- Hussain, O.; Ahmad, B.; Saleem, S.S. Biomaterials for artificial knee joint replacement: A review. Int. J. Mater. Eng. Innov. 2023, 14, 95–122. [Google Scholar] [CrossRef]

- Kurtz, S.M.; Ong, K.L.; Lau, E.; Bozic, K.J. Impact of the economic downturn on total joint replacement demand in the United States: Updated projections to 2021. JBJS 2014, 96, 624–630. [Google Scholar] [CrossRef] [PubMed]

- Mai, K.; Verioti, C.; Ezzet, K.A.; Copp, S.N.; Walker, R.H.; Colwell, C.W. Incidence of ‘squeaking’after ceramic-on-ceramic total hip arthroplasty. Clin. Orthop. Relat. Res. 2010, 468, 413–417. [Google Scholar] [CrossRef] [Green Version]

- Ji, R.; Qi, Z.; Chen, J.; Zhang, L.; Lin, K.; Lu, S.; Li, Y. Numerical and experimental investigation on the abrasive flow machining of artificial knee joint surface. Crystals 2023, 13, 430. [Google Scholar] [CrossRef]

- Pani, R.; Behera, R.R.; Roy, S. Corrosion Behaviour of Metallic Biomaterials in Physiological Environments. In Handbook of Research on Corrosion Sciences and Engineering; IGI Global: Hershey, PA, USA, 2023; pp. 246–273. [Google Scholar]

- Fouly, A.; Assaifan, K.A.; Alnaser, I.A.; Hussein, O.A.; Abdo, H.S. Evaluating the mechanical and tribological properties of 3D printed polylactic-acid (PLA) green-composite for artificial implant: Hip joint case study. Polymers 2022, 14, 5299. [Google Scholar] [CrossRef] [PubMed]

- Rao, A.J.; Gibon, E.; Ma, T.; Yao, Z.; Smith, R.L.; Goodman, S.B. Revision joint replacement, wear particles, and macrophage polarization. Acta Biomater. 2012, 8, 2815–2823. [Google Scholar] [CrossRef] [Green Version]

- Enab, T.A. A comparative study of the performance of metallic and FGM tibia tray components in total knee replacement joints. Comput. Mater. Sci. 2012, 53, 94–100. [Google Scholar] [CrossRef]

- Zietz, C.; Bergschmidt, P.; Lange, R.; Mittelmeier, W.; Bader, R. Third-body abrasive wear of tibial polyethylene inserts combined with metallic and ceramic femoral components in a knee simulator study. Int. J. Artif. Organs 2013, 36, 47–55. [Google Scholar] [CrossRef] [PubMed]

- Fouly, A.; Abdo, H.S.; Seikh, A.H.; Alluhydan, K.; Alkhammash, H.I.; Alnaser, I.A.; Abdo, M.S. Evaluation of Mechanical and Tribological Properties of Corn Cob-Reinforced Epoxy-Based Composites—Theoretical and Experimental Study. Polymers 2021, 13, 4407. [Google Scholar] [CrossRef] [PubMed]

- Fouly, A.; Nasr, M.N.; Fath El Bab, A.M.; Abouelsoud, A.A. Design and modeling of micro tactile sensor with three contact tips for self-compensation of contact error in soft tissue elasticity measurement. IEEJ Trans. Electr. Electron. Eng. 2015, 10, S144–S150. [Google Scholar] [CrossRef]

- Khalil, H.A.; Yahya, E.B.; Jummaat, F.; Adnan, A.S.; Olaiya, N.G.; Rizal, S.; Abdullah, C.K.; Pasquini, D.; Thomas, S. Biopolymers based aerogels: A review on revolutionary solutions for smart therapeutics delivery. Prog. Mater. Sci. 2022, 131, 101014. [Google Scholar] [CrossRef]

- Ahmed, F.; Alnaser, I.A.; Assaifan, A.K.; Abdo, H.S. Developing PMMA/coffee husk green composites to meet the individual requirements of people with disabilities: Hip spacer case study. J. Funct. Biomater. 2023, 14, 200. [Google Scholar]

- Premkumar, J.; SonicaSree, K.; Sudhakar, T. Polymers in Biomedical Use. In Handbook of Polymer and Ceramic Nanotechnology; Springer: Berlin/Heidelberg, Germany, 2021; pp. 1329–1355. [Google Scholar]

- Jacobs, J.J.; Roebuck, K.A.; Archibeck, M.; Hallab, N.J.; Glant, T.T. Osteolysis: Basic science. Clin. Orthop. Relat. Res. 2001, 393, 71–77. [Google Scholar] [CrossRef]

- Galliera, E.; Ragone, V.; Marazzi, M.G.; Selmin, F.; Banci, L.; Romanelli, M.M.C. Vitamin E-stabilized UHMWPE: Biological response on human osteoblasts to wear debris. Clin. Chim. Acta 2018, 486, 18–25. [Google Scholar] [CrossRef]

- Fouly, A.; Nabhan, A.; Badran, A. Mechanical and Tribological Characteristics of PMMA Reinforced by Natural Materials. Egypt. J. Chem. 2022, 65, 543–553. [Google Scholar] [CrossRef]

- Zeman, J.; Ranuša, M.; Vrbka, M.; Gallo, J.; Křupka, I.; Hartl, M. UHMWPE acetabular cup creep deformation during the run-in phase of THA’s life cycle. J. Mech. Behav. Biomed. Mater. 2018, 87, 30–39. [Google Scholar] [CrossRef] [PubMed]

- Bakhtiar, S.M.; Butt, H.A.; Zeb, S.; Quddusi, D.M.; Gul, S.; Dilshad, E. 3D printing technologies and their applications in biomedical science. In Omics Technologies and Bio-Engineering; Elsevier: Amsterdam, The Netherlands, 2018; pp. 167–189. [Google Scholar]

- Bozkurt, Y.; Karayel, E. 3D printing technology; methods, biomedical applications, future opportunities and trends. J. Mater. Res. Technol. 2021, 14, 1430–1450. [Google Scholar] [CrossRef]

- Subramaniam, S.R.; Samykano, M.; Selvamani, S.K.; Ngui, W.K.; Kadirgama, K.; Sudhakar, K.; Idris, M.S. 3D printing: Overview of PLA progress. AIP Conf. Proc. 2019, 2059, 020015. [Google Scholar]

- Radenkovic, D.; Solouk, A.; Seifalian, A. Personalized development of human organs using 3D printing technology. Med. Hypotheses 2016, 87, 30–33. [Google Scholar] [CrossRef] [Green Version]

- Fernandes, J.; Deus, A.M.; Reis, L.; Vaz, M.F.; Leite, M. Study of the influence of 3D printing parameters on the mechanical properties of PLA. In Proceedings of the 3rd International Conference on Progress in Additive Manufacturing (Pro-AM 2018), Singapore, 14–17 May 2018; pp. 14–17. [Google Scholar]

- Zhang, J.; Hori, N.; Takemura, A. Effect of natural biomass fillers on the stability, degradability, and elasticity of crop straws liquefied polyols-based polyurethane foams. J. Appl. Polym. Sci. 2023, 140, e53324. [Google Scholar] [CrossRef]

- Liu, Z.; Lei, Q.; Xing, S. Mechanical characteristics of wood, ceramic, metal and carbon fiber-based PLA composites fabricated by FDM. J. Mater. Res. Technol. 2019, 8, 3741–3751. [Google Scholar] [CrossRef]

- Fouly, A.; Alnaser, I.A.; Assaifan, A.K.; Abdo, H.S. Evaluating the Performance of 3D-Printed PLA Reinforced with Date Pit Particles for Its Suitability as an Acetabular Liner in Artificial Hip Joints. Polymers 2022, 14, 3321. [Google Scholar] [CrossRef]

- Leite, M.; Varanda, A.; Ribeiro, A.R.; Silva, A.; Vaz, M.F. Mechanical properties and water absorption of surface modified ABS 3D printed by fused deposition modelling. Rapid Prototyp. J. 2018, 24, 95–203. [Google Scholar] [CrossRef]

- Bhandari, S.; Lopez-Anido, R.A.; Gardner, D.J. Enhancing the interlayer tensile strength of 3D printed short carbon fiber reinforced PETG and PLA composites via annealing. Addit. Manuf. 2019, 30, 100922. [Google Scholar] [CrossRef]

- Srithep, Y.; Nealey, P.; Turng, L.-S. Effects of annealing time and temperature on the crystallinity and heat resistance behavior of injection-molded poly (lactic acid). Polym. Eng. Sci. 2013, 53, 580–588. [Google Scholar] [CrossRef]

- Jayanth, N.; Jaswanthraj, K.; Sandeep, S.; Mallaya, N.H.; Siddharth, S.R. Effect of heat treatment on mechanical properties of 3D printed PLA. J. Mech. Behav. Biomed. Mater. 2021, 123, 104764. [Google Scholar] [CrossRef] [PubMed]

- Atia, M.G.; Salah, O. Fuzzy logic with load compensation for upper limb exoskeleton control based on IMU data fusion. In Proceedings of the 2018 IEEE International Conference on Robotics and Biomimetics (ROBIO), Kuala Lumpur, Malaysia, 12–15 December 2018; pp. 2147–2152. [Google Scholar]

- Rajpurohit, S.R.; Dave, H.K. Prediction and optimization of tensile strength in FDM based 3D printing using ANFIS. In Optimization of Manufacturing Processes; Springer: Berlin/Heidelberg, Germany, 2020; pp. 111–128. [Google Scholar]

- Sahin, Y. The prediction of wear resistance model for the metal matrix composites. Wear 2005, 258, 1717–1722. [Google Scholar] [CrossRef]

- Vijayakumar, S.; Karunamoorthy, L. Modelling wear behaviour of Al–SiC metal matrix composites: Soft computing technique. Tribol.-Mater. Surf. Interfaces 2012, 6, 25–30. [Google Scholar] [CrossRef]

- Asker, A.; Salah, O.; El-Bab, A.M.F.; Ramadan, A.A.; Assal, S.M.; Sessa, S.; Abo-Ismail, A. ANFIS based jacobian for a parallel manipulator mobility assistive device. In Proceedings of the 2014 UKACC International Conference on Control (CONTROL), Loughborough, UK, 9–11 July 2014; pp. 395–400. [Google Scholar]

- Chhabra, D.; Deswal, S.; Kaushik, A.; Garg, R.K.; Kovács, A.; Khargotra, R.; Singh, T. Analysis of fused filament fabrication parameters for sliding wear performance of carbon reinforced polyamide composite material fabricated parts using a hybrid heuristic tool. Polym. Test. 2022, 118, 107910. [Google Scholar] [CrossRef]

- Ibrahim, M.A.; Şahin, Y.; Ibrahim, A.; Gidado, A.Y.; Yahya, M.N. Specific Wear Rate Modeling of Polytetraflouroethylene Composites Via Artificial Neural Network (ANN) and Adaptive Neuro Fuzzy Inference System (ANFIS) Tools. In Virtual Assistant; IntechOpen: London, UK, 2021. [Google Scholar]

- Ahmad, A.; Imtiaz, H. Chemical composition of date pits: Potential to extract and characterize the lipid fraction. In Sustainable Agriculture Reviews 34; Springer: Berlin/Heidelberg, Germany, 2019; pp. 55–77. [Google Scholar]

- Zhao, H.; Allanson, D.; Ren, X.J. Use of shore hardness tests for in-process properties estimation/monitoring of silicone rubbers. J. Mater. Sci. Chem. Eng. 2015, 3, 142–147. [Google Scholar] [CrossRef] [PubMed]

- ISO/DIS 14126; Fibre-Reinforced Plastic Composites—Determination of Compressive Properties in the In-Plane Direction. ISO: Geneva, Switzerland, 1999. Available online: https://www.iso.org/standard/80371.html (accessed on 14 January 2023).

- ASTM G99-17; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2008.

- Kuminek, T.; Aniołek, K.; Młyńczak, J. A numerical analysis of the contact stress distribution and physical modelling of abrasive wear in the tram wheel-frog system. Wear 2015, 328, 177–185. [Google Scholar] [CrossRef]

| (a) | (b) | ||

|---|---|---|---|

| Sample Code | DP (wt.%) | Sample Code | Hours |

| PLA-DP0 | 0 | PLA-0 | 0 |

| PLA-DP2 | 2 | PLA-2.5 | 2.5 |

| PLA-DP4 | 4 | PLA-5 | 5 |

| PLA-DP6 | 6 | PLA-10 | 10 |

| PLA-DP8 | 8 | PLA-20 | 20 |

| PLA-DP10 | 10 | ||

| PLA-0 | PLA-2.5 | PLA-5 | PLA-10 | PLA-20 | |

|---|---|---|---|---|---|

| PLA-DP0 | 79.5 ± 0.3 | 81.1 ± 0.7 | 86 ± 0.6 | 83.6 ± 0.8 | 85.4 ± 0.6 |

| PLA-DP2 | 91 ± 0.6 | 88.9 ± 0.8 | 93 ± 0.4 | 92.2 ± 0.5 | 91.6 ± 0.8 |

| PLA-DP4 | 92.6 ± 0.4 | 91.4 ± 0.8 | 94.2 ± 0.7 | 93.6 ± 0.6 | 92.7 ± 0.7 |

| PLA-DP6 | 93.6 ± 0.7 | 93.4 ± 0.5 | 95.4 ± 0.8 | 94.7 ± 0.8 | 94.1 ± 0.4 |

| PLA-DP8 | 93.8 ± 0.8 | 92.8 ± 0.4 | 95.7 ± 0.8 | 93.8 ± 0.7 | 94.2 ± 0.5 |

| PLA-DP10 | 95 ± 0.5 | 95.3 ± 0.6 | 96.7 ± 0.5 | 94.8 ± 0.4 | 95.4 ± 0.8 |

| PLA-0 | PLA-2.5 | PLA-5 | PLA-10 | PLA-20 | |

|---|---|---|---|---|---|

| PLA-DP0 | 1501 ± 6.3 | 1227 ± 8.4 | 1479 ± 10.2 | 1394 ± 12.4 | 1435 ± 9.4 |

| PLA-DP2 | 1613 ± 10.1 | 1520 ± 6.6 | 1630 ± 8.5 | 1580 ± 9.6 | 1533 ± 12.2 |

| PLA-DP4 | 1724 ± 8.6 | 1658 ± 7.8 | 1760 ± 12.1 | 1640 ± 12.5 | 1610 ± 8.3 |

| PLA-DP6 | 1839 ± 15.1 | 1805 ± 10.3 | 1873 ± 9.3 | 1863 ± 10.2 | 1835 ± 8.7 |

| PLA-DP8 | 1844 ± 10.3 | 1790 ± 12.5 | 1880 ± 10.4 | 1810 ± 8.4 | 1795 ± 9.1 |

| PLA-DP10 | 1944 ± 13.2 | 1868 ± 9.1 | 2064 ± 12.3 | 1951 ± 9.6 | 1923 ± 10.3 |

| PLA-0 | PLA-2.5 | PLA-5 | PLA-10 | PLA-20 | |

|---|---|---|---|---|---|

| PLA-DP0 | 47.9 ± 0.5 | 53.4 ± 0.6 | 60.22 ± 0.7 | 56.82 ± 0.5 | 57.37 ± 0.7 |

| PLA-DP2 | 48.94 ± 0.3 | 56.61 ± 0.8 | 60.87 ± 0.9 | 58.55 ± 0.7 | 57.52 ± 0.5 |

| PLA-DP4 | 51.52 ± 0.7 | 55.53 ± 0.4 | 61.23 ± 0.8 | 60.14 ± 0.5 | 60.24 ± 0.7 |

| PLA-DP6 | 53.41 ± 0.4 | 57.11 ± 0.5 | 61.88 ± 0.4 | 59.55 ± 0.8 | 58.16 ± 0.8 |

| PLA-DP8 | 57.52 ± 0.8 | 59.45 ± 0.7 | 63.11 ± 0.8 | 61.27 ± 0.6 | 60.71 ± 0.4 |

| PLA-DP10 | 59.99 ± 0.4 | 64.25 ± 0.6 | 68.21 ± 0.5 | 65.99 ± 0.5 | 65.15 ± 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Albahkali, T.; Abdo, H.S.; Salah, O.; Fouly, A. Adaptive Neuro-Fuzzy-Based Models for Predicting the Tribological Properties of 3D-Printed PLA Green Composites Used for Biomedical Applications. Polymers 2023, 15, 3053. https://doi.org/10.3390/polym15143053

Albahkali T, Abdo HS, Salah O, Fouly A. Adaptive Neuro-Fuzzy-Based Models for Predicting the Tribological Properties of 3D-Printed PLA Green Composites Used for Biomedical Applications. Polymers. 2023; 15(14):3053. https://doi.org/10.3390/polym15143053

Chicago/Turabian StyleAlbahkali, Thamer, Hany S. Abdo, Omar Salah, and Ahmed Fouly. 2023. "Adaptive Neuro-Fuzzy-Based Models for Predicting the Tribological Properties of 3D-Printed PLA Green Composites Used for Biomedical Applications" Polymers 15, no. 14: 3053. https://doi.org/10.3390/polym15143053

APA StyleAlbahkali, T., Abdo, H. S., Salah, O., & Fouly, A. (2023). Adaptive Neuro-Fuzzy-Based Models for Predicting the Tribological Properties of 3D-Printed PLA Green Composites Used for Biomedical Applications. Polymers, 15(14), 3053. https://doi.org/10.3390/polym15143053