Dynamic Impact Properties of Carbon-Fiber-Reinforced Phenolic Composites Containing Microfillers

Abstract

1. Introduction

2. Materials and Methodology

2.1. Materials

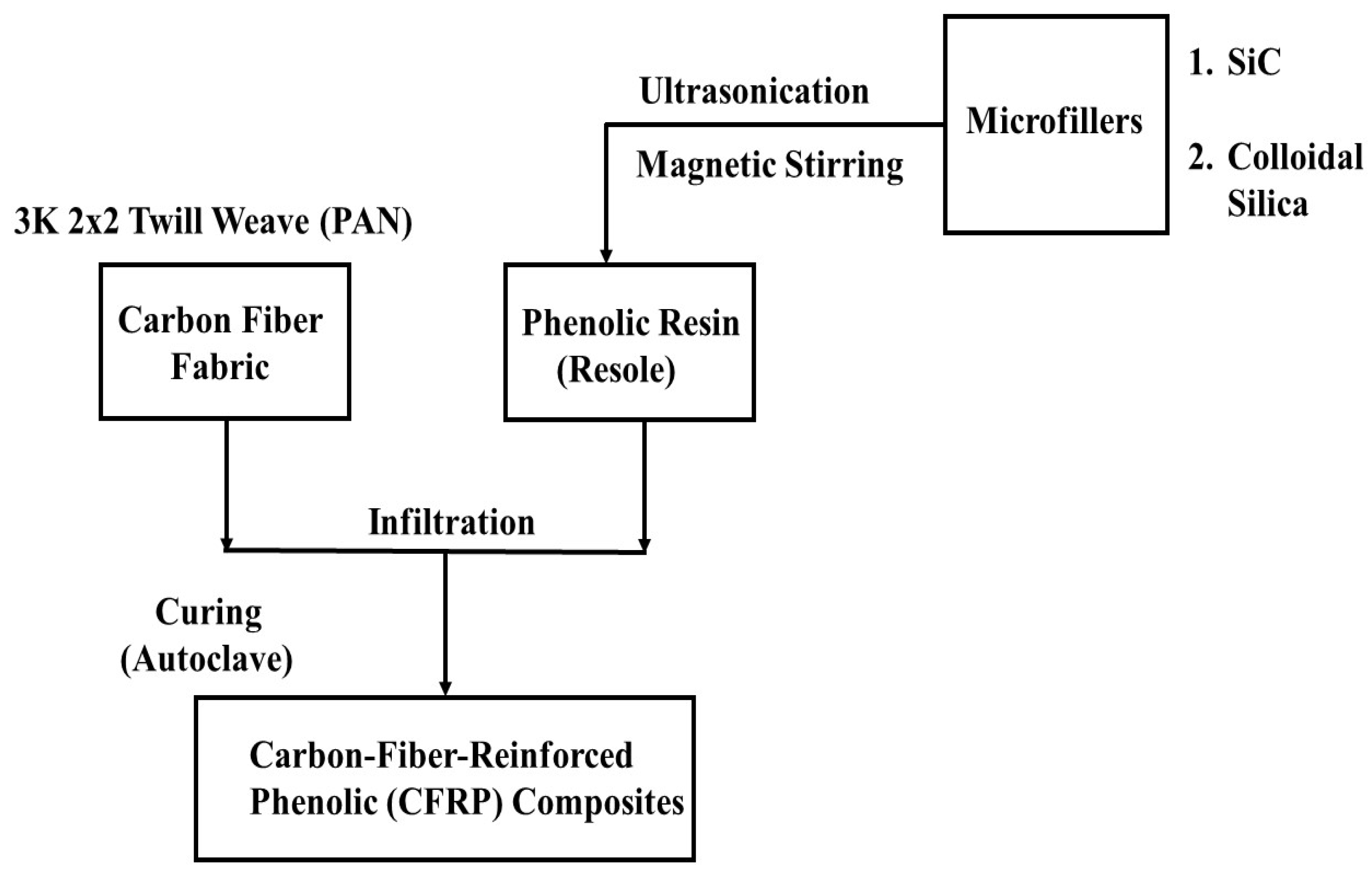

2.1.1. Dispersion of Microfillers in the Resole Phenolic Resins

2.1.2. Fabrication of CFRP Composites

2.2. Characterization of Fabricated Materials

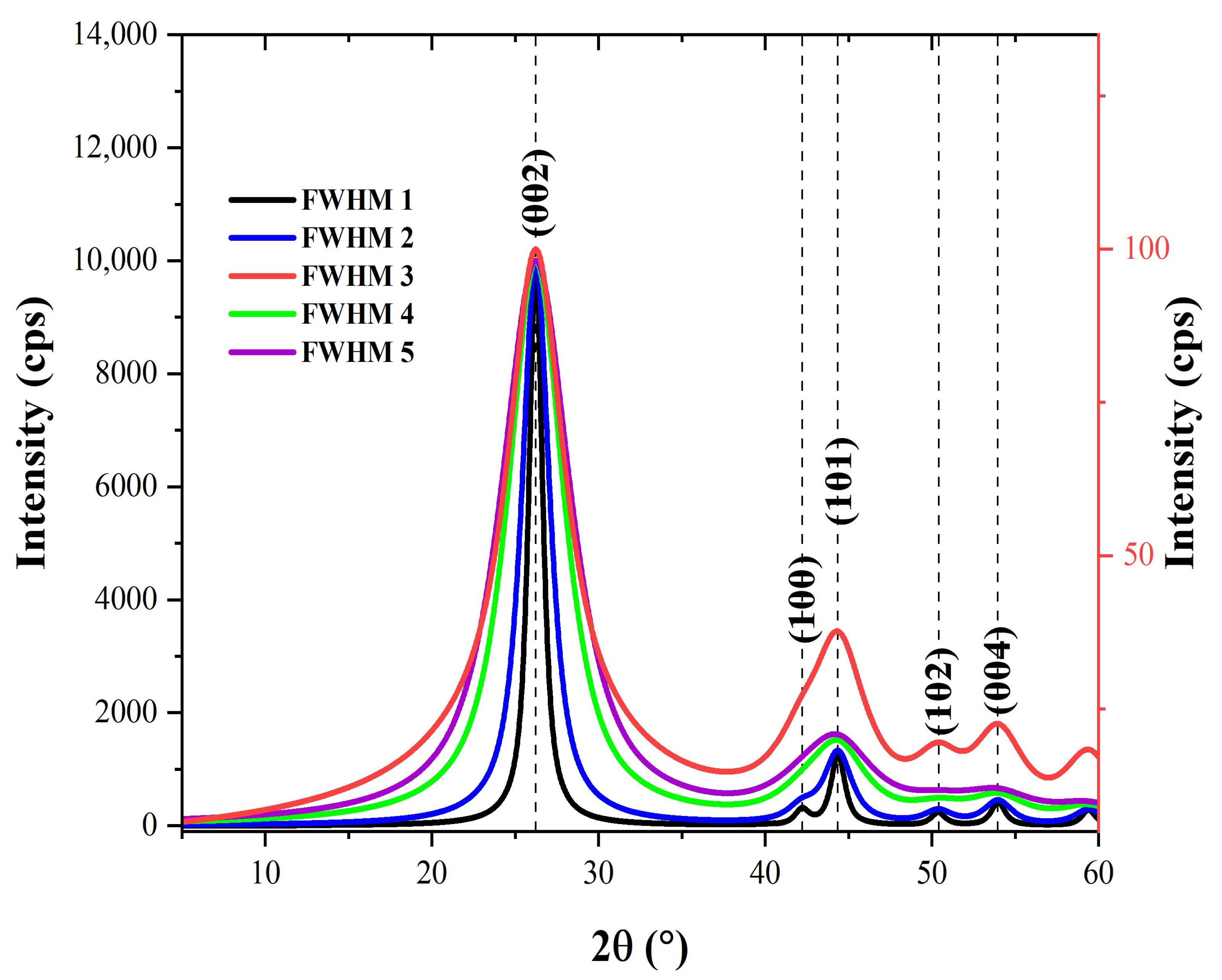

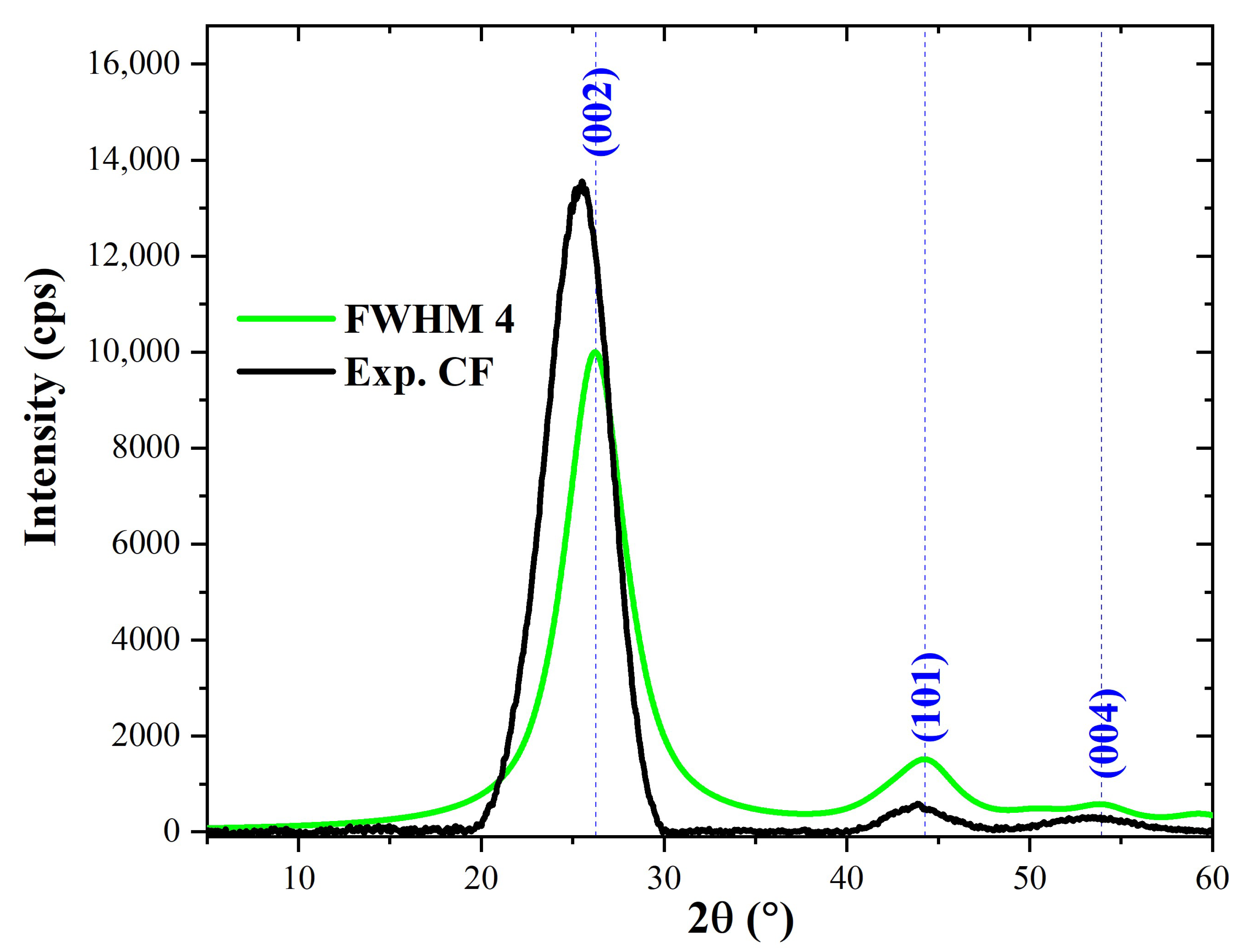

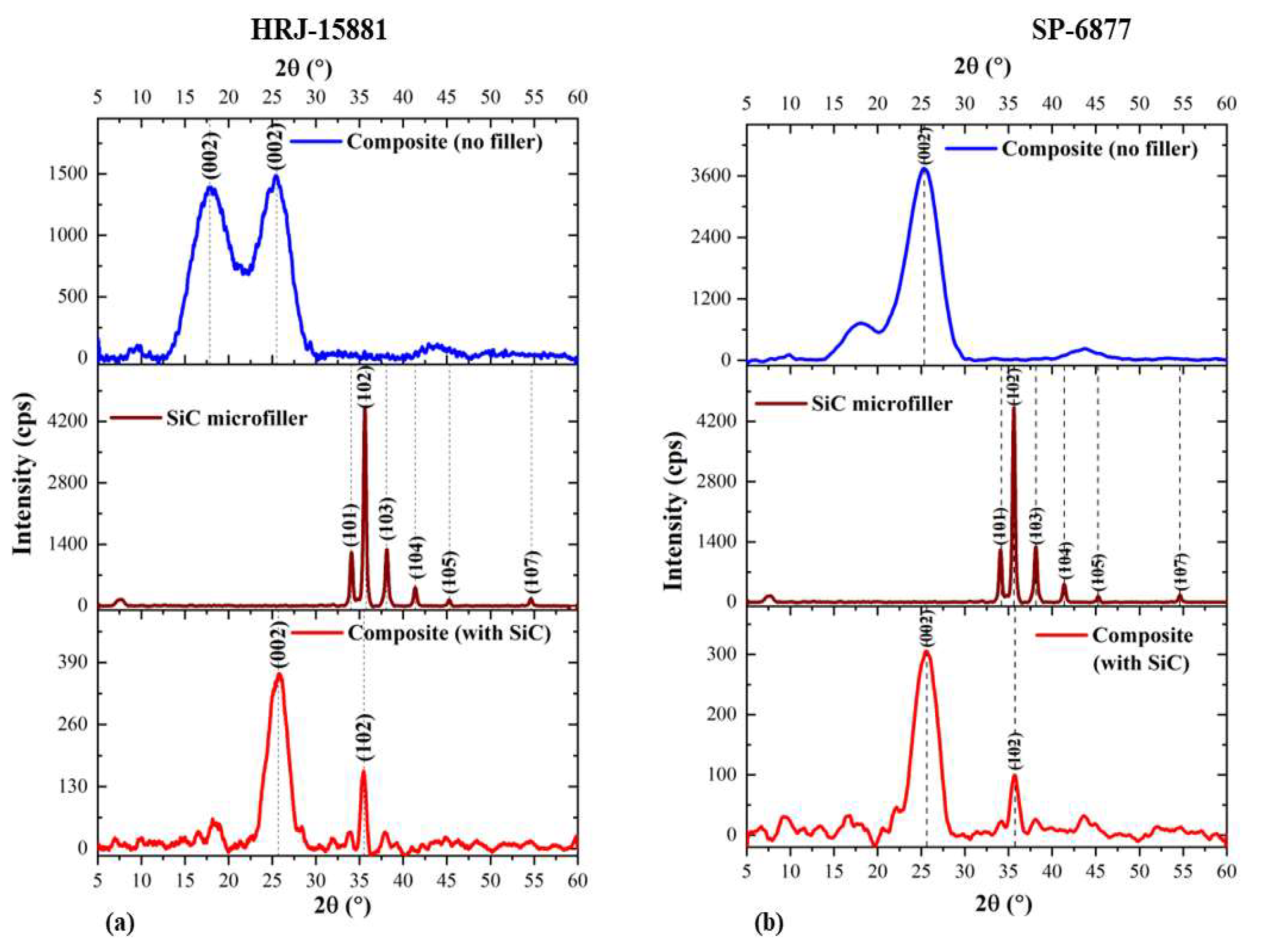

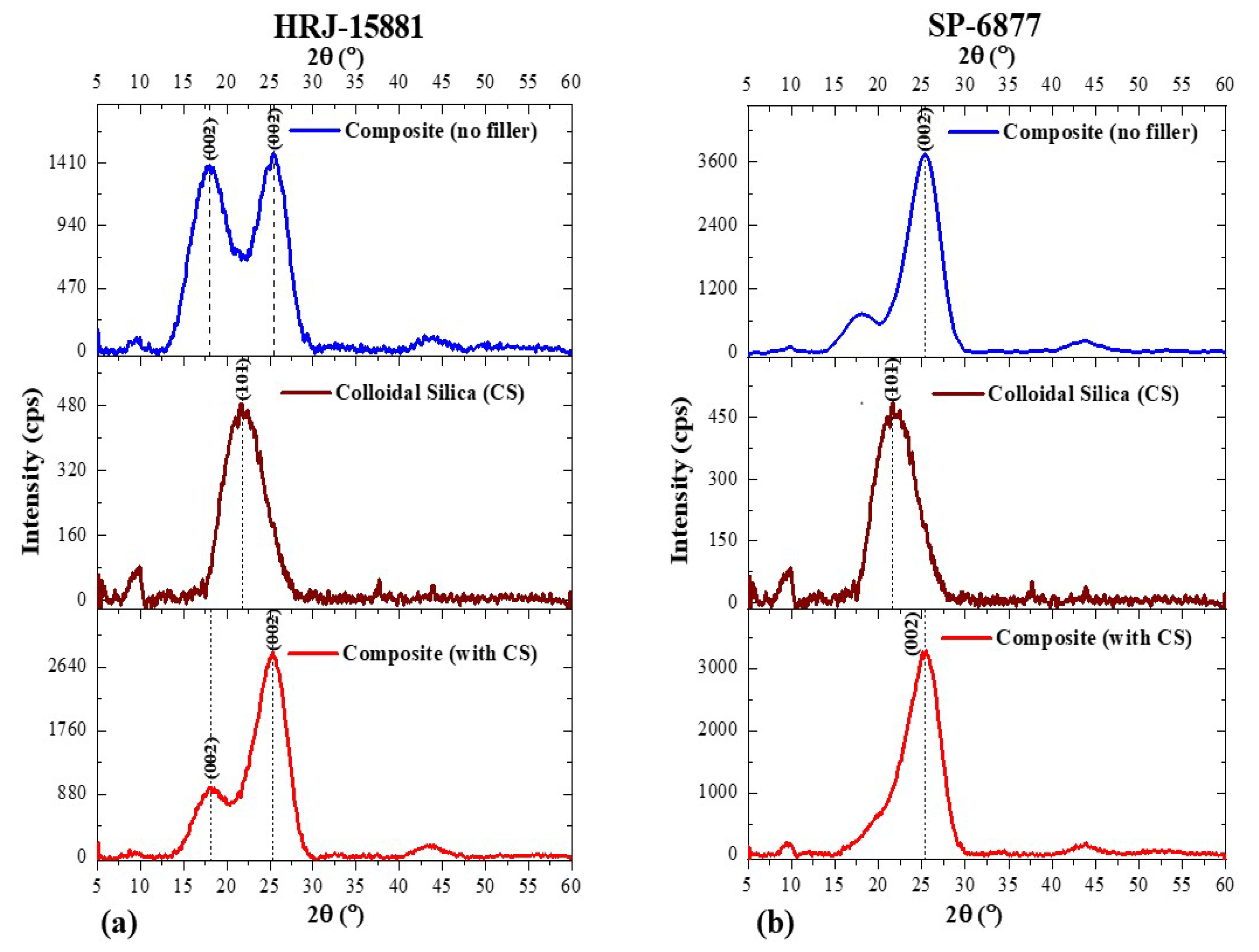

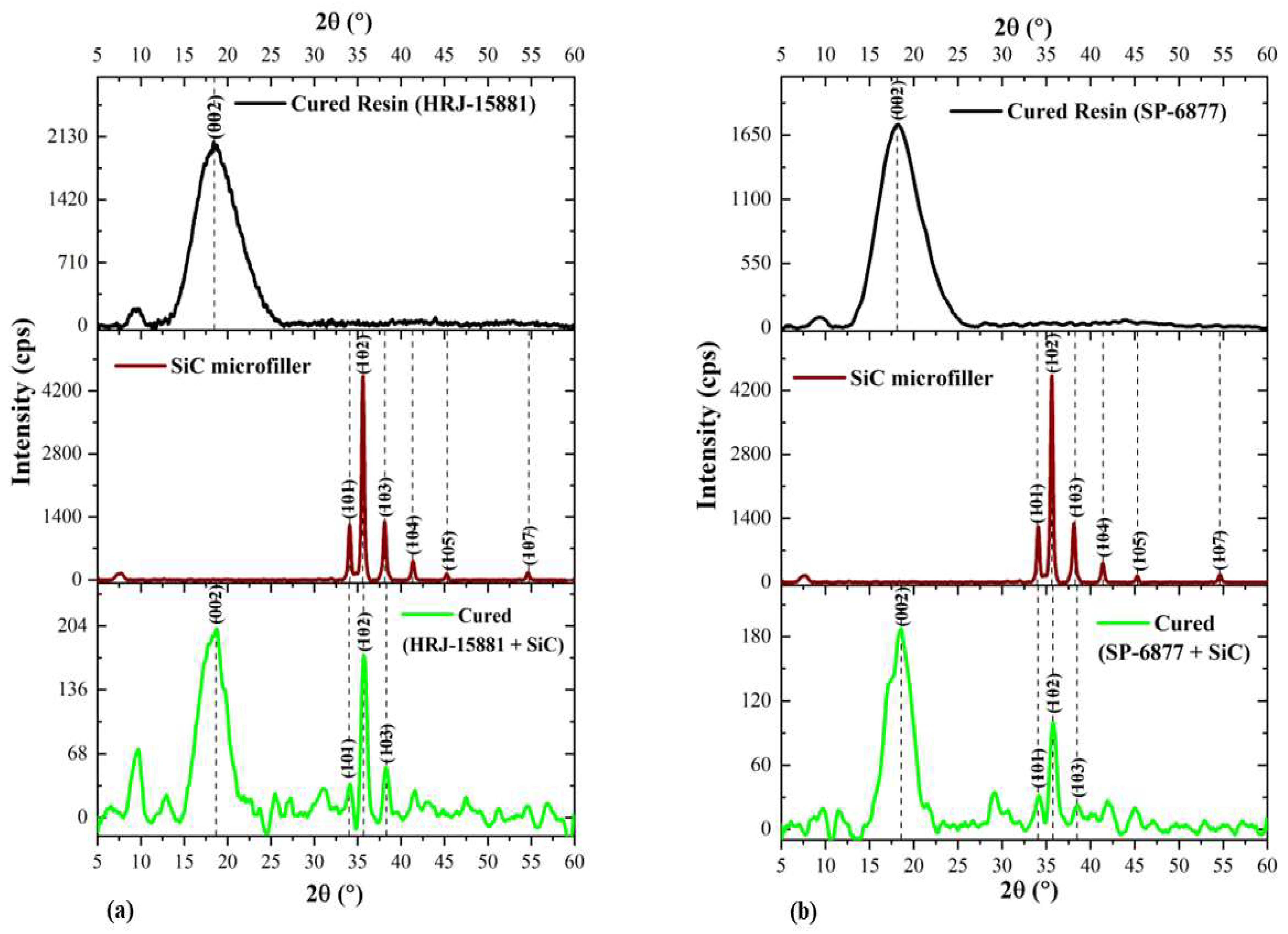

2.2.1. X-ray Diffraction (XRD)

2.2.2. Dynamic Impact Test

2.2.3. Microstructure Examination

3. Results and Discussion

3.1. XRD

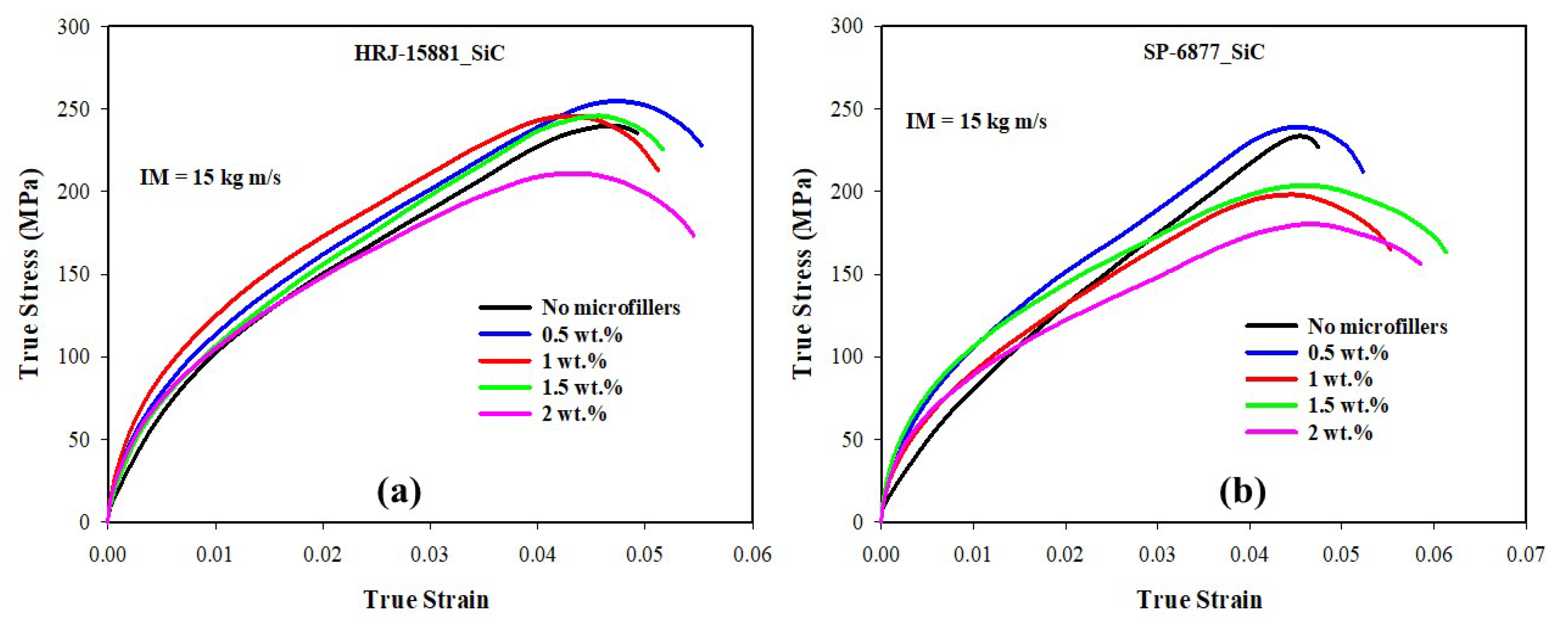

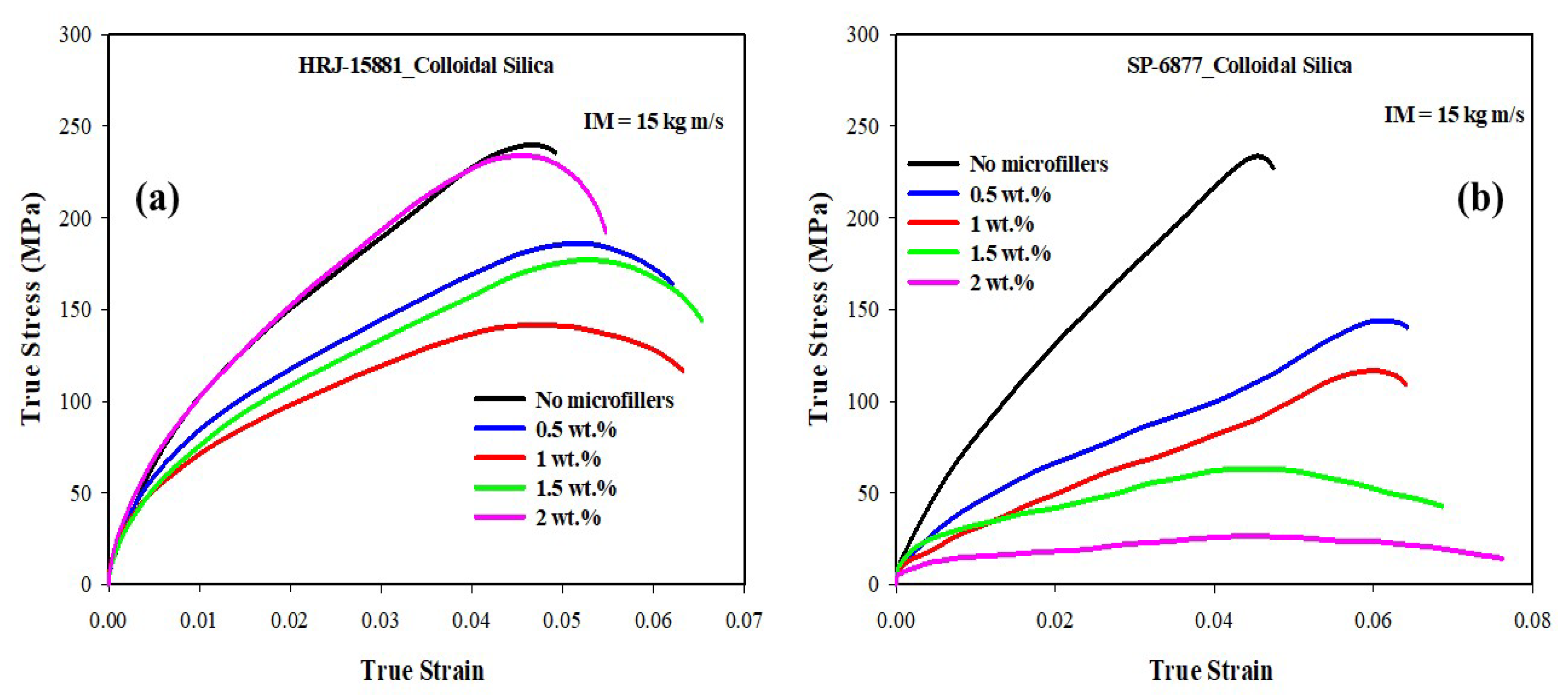

3.2. Dynamic Impact Properties

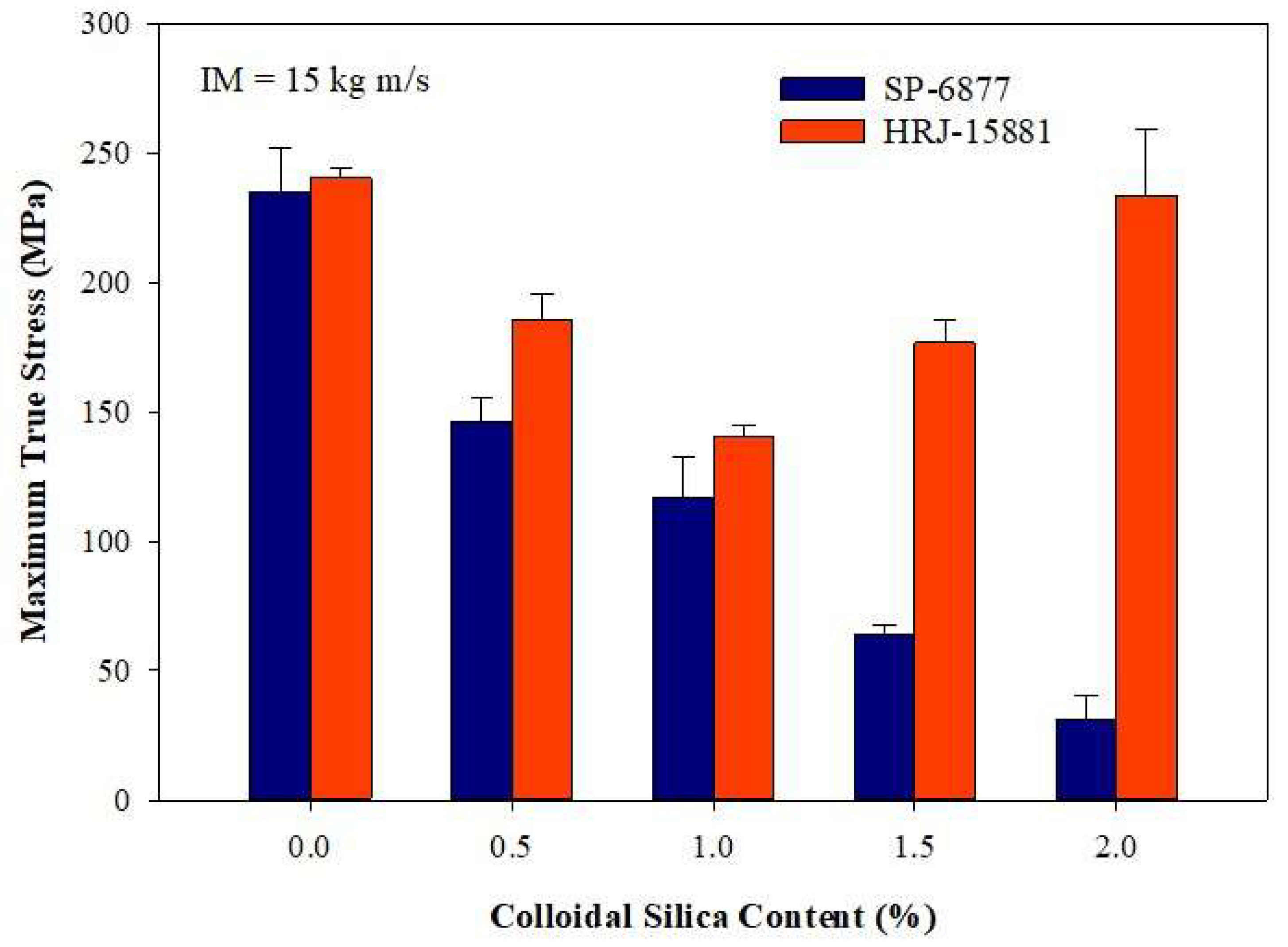

3.2.1. Impact Properties Obtained at a Momentum of 15 kg m/s

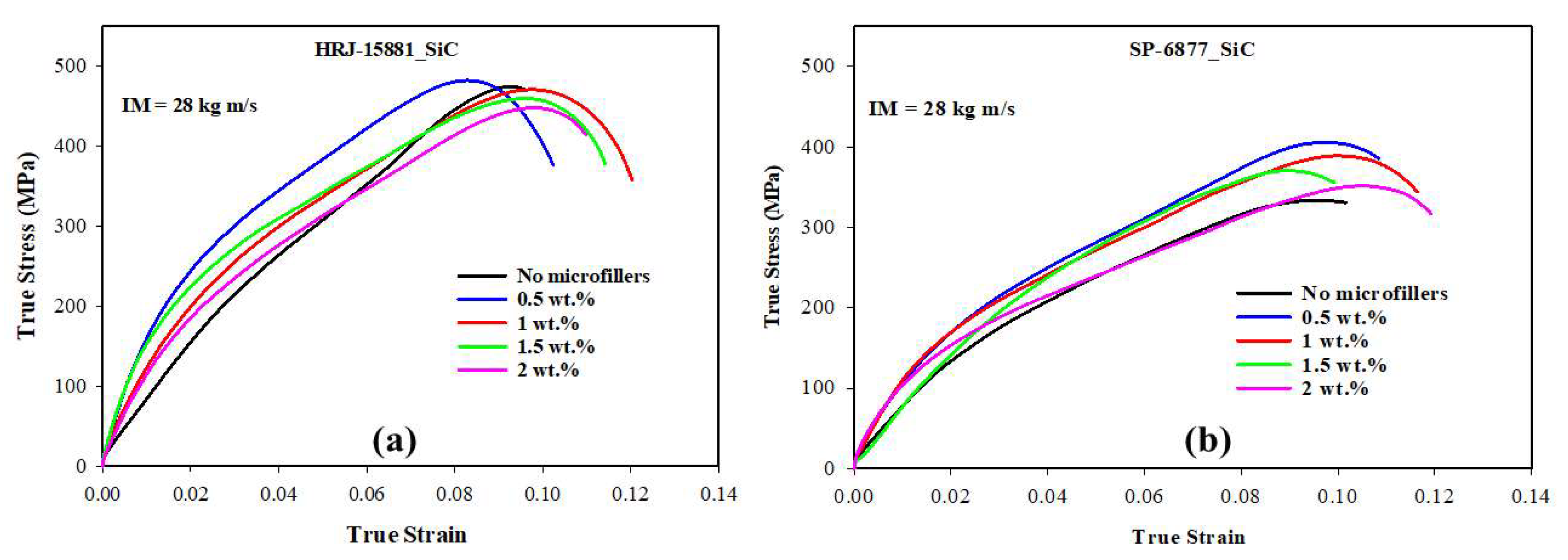

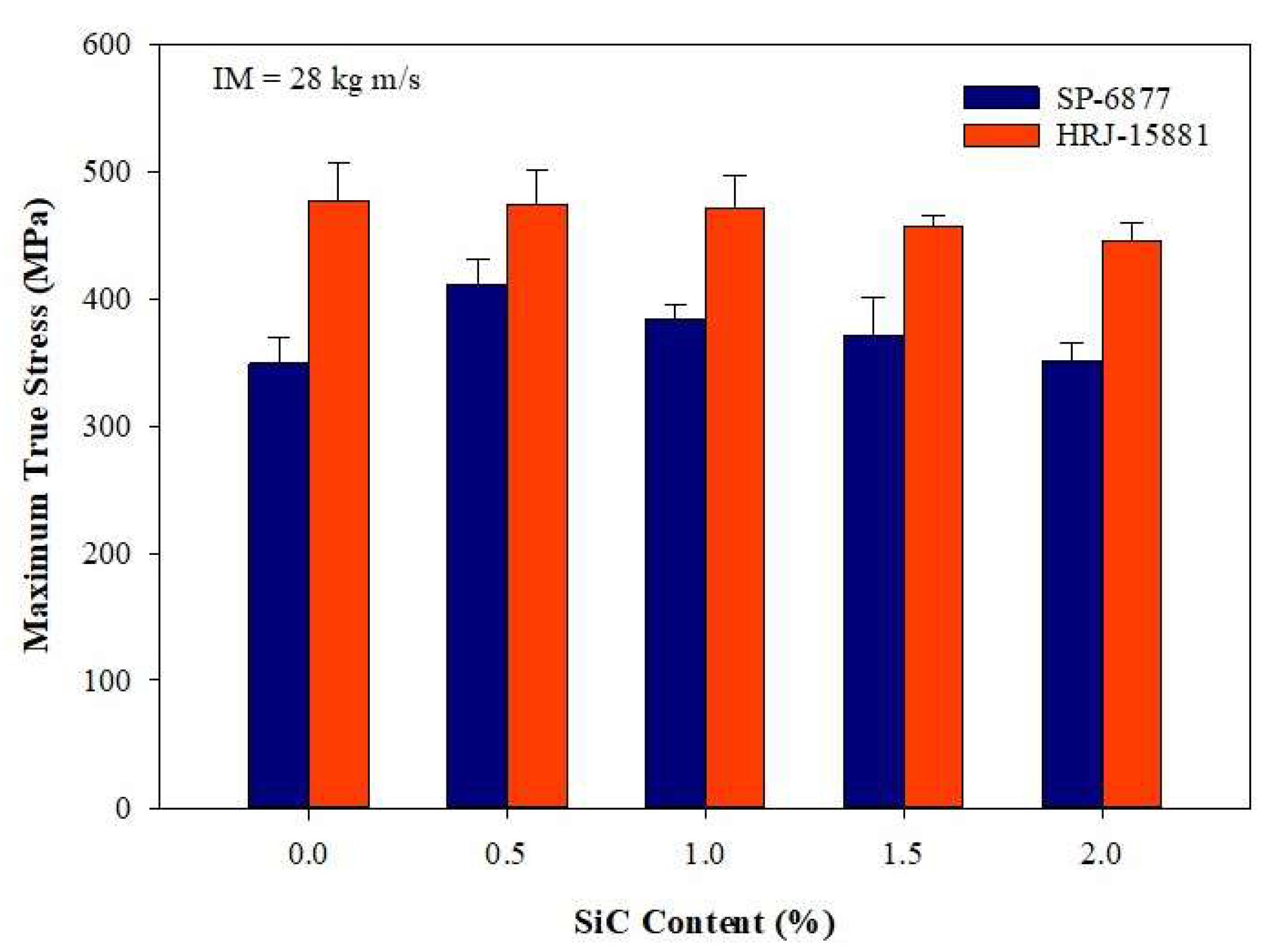

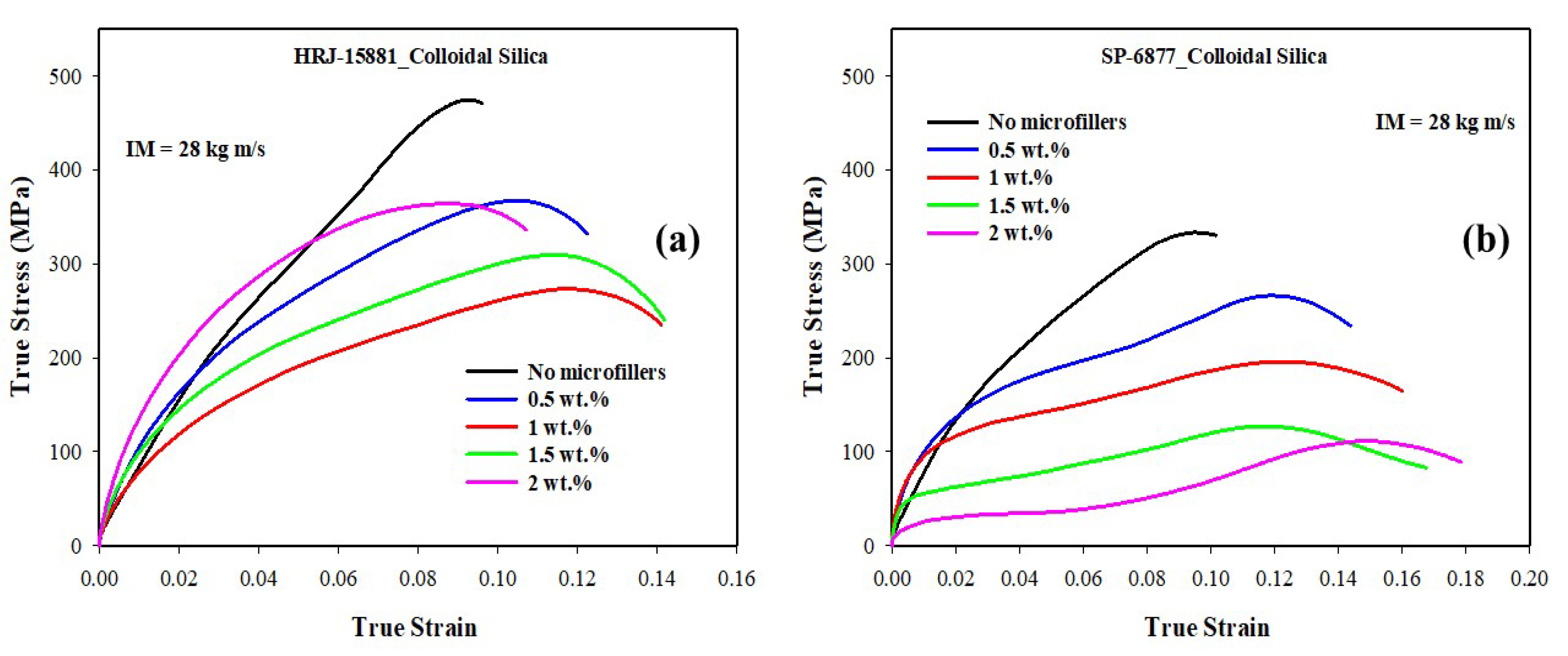

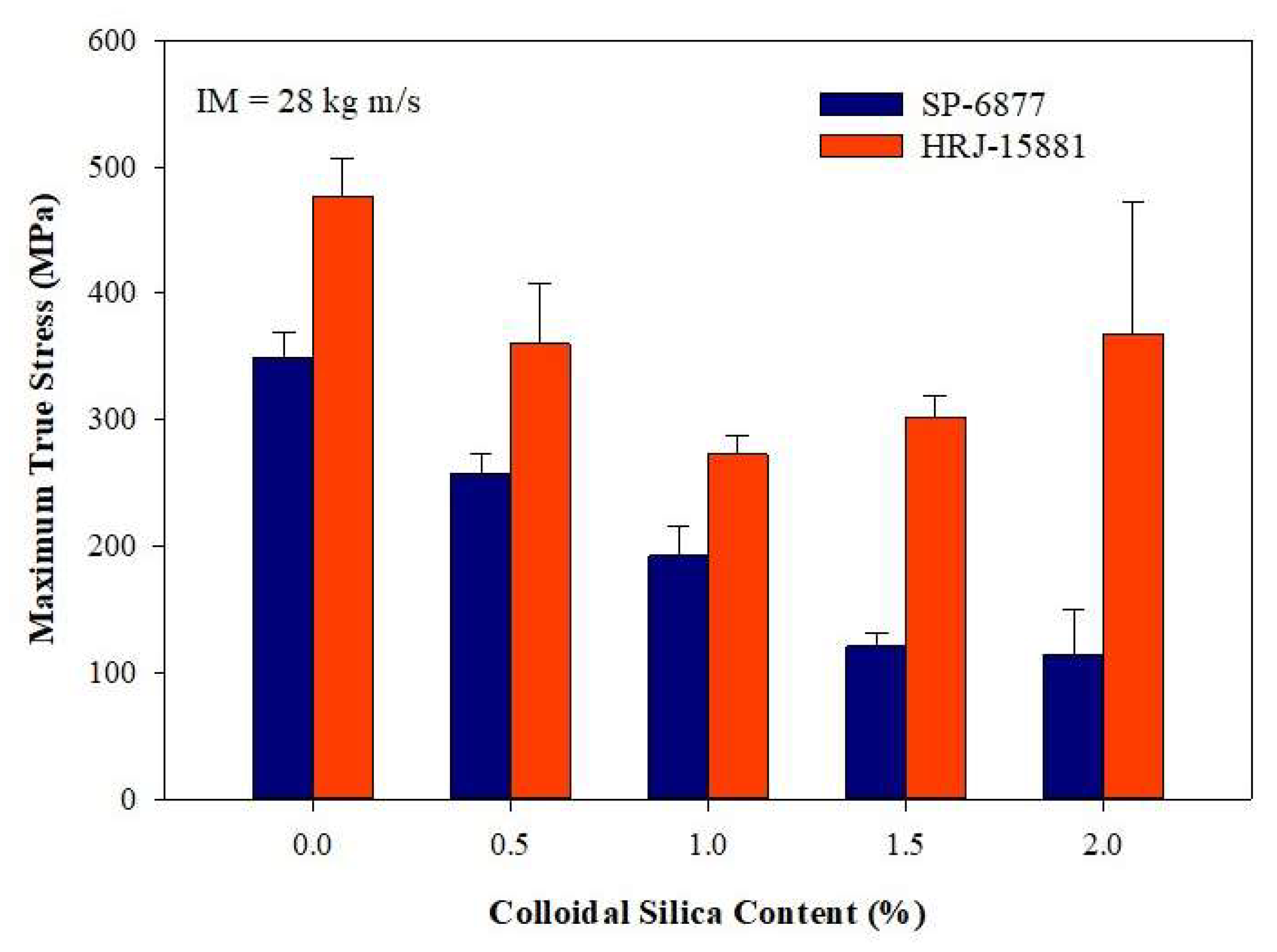

3.2.2. Impact Properties Obtained at a Momentum of 28 kg m/s

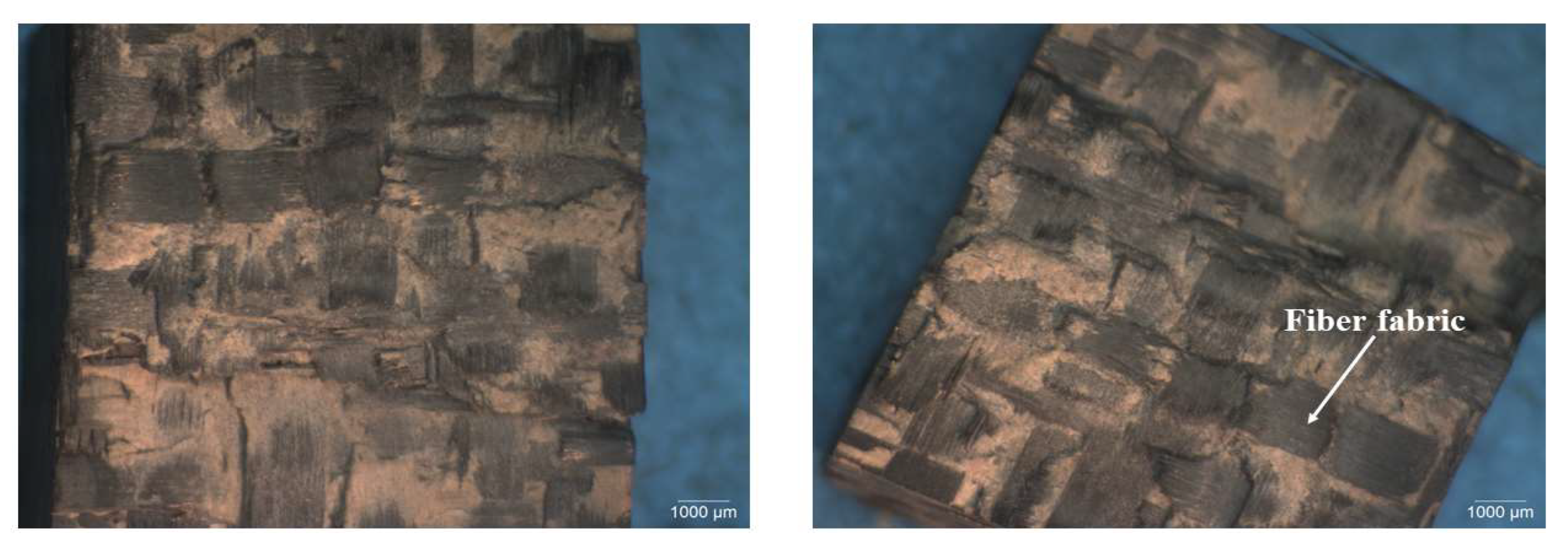

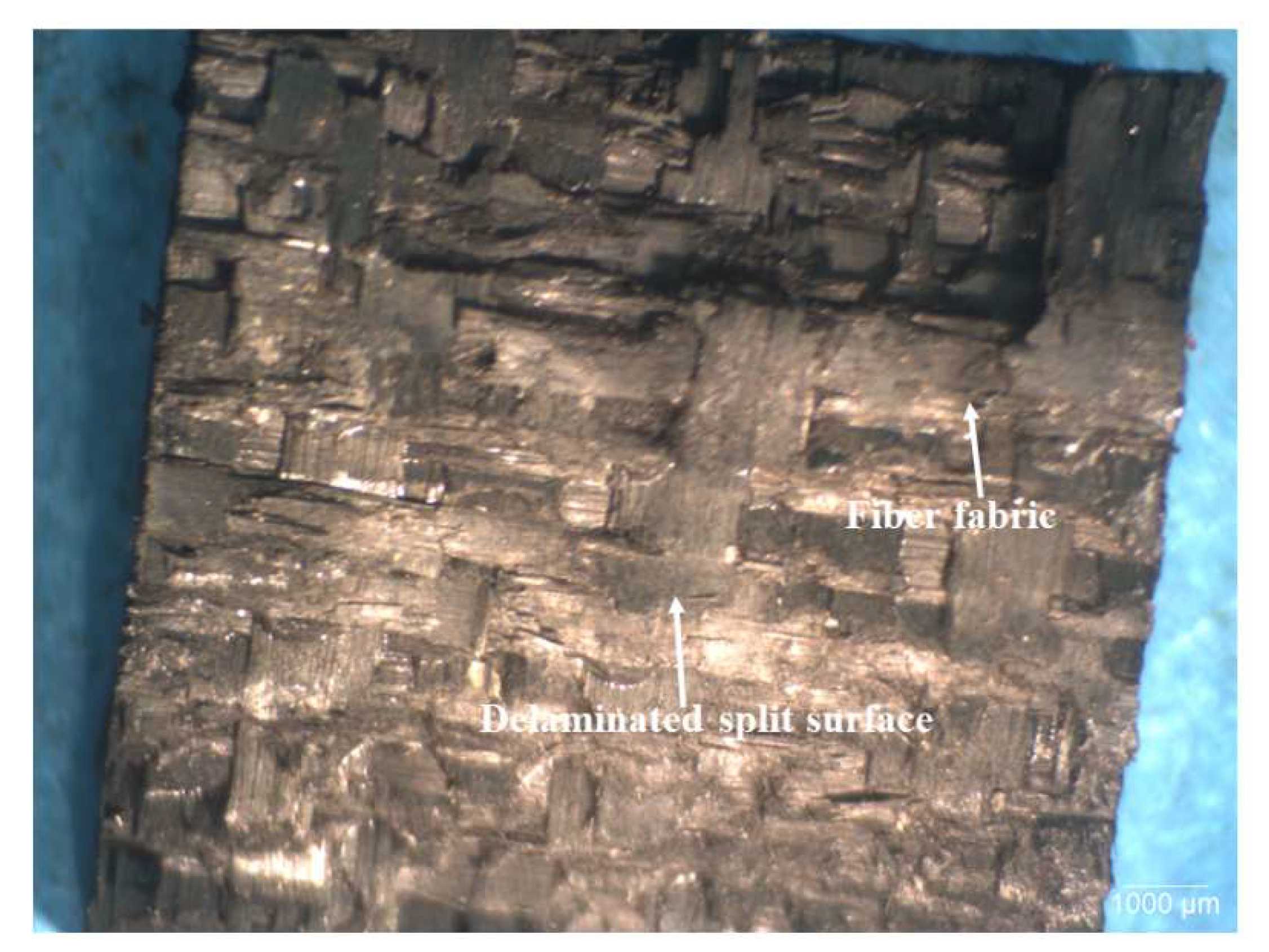

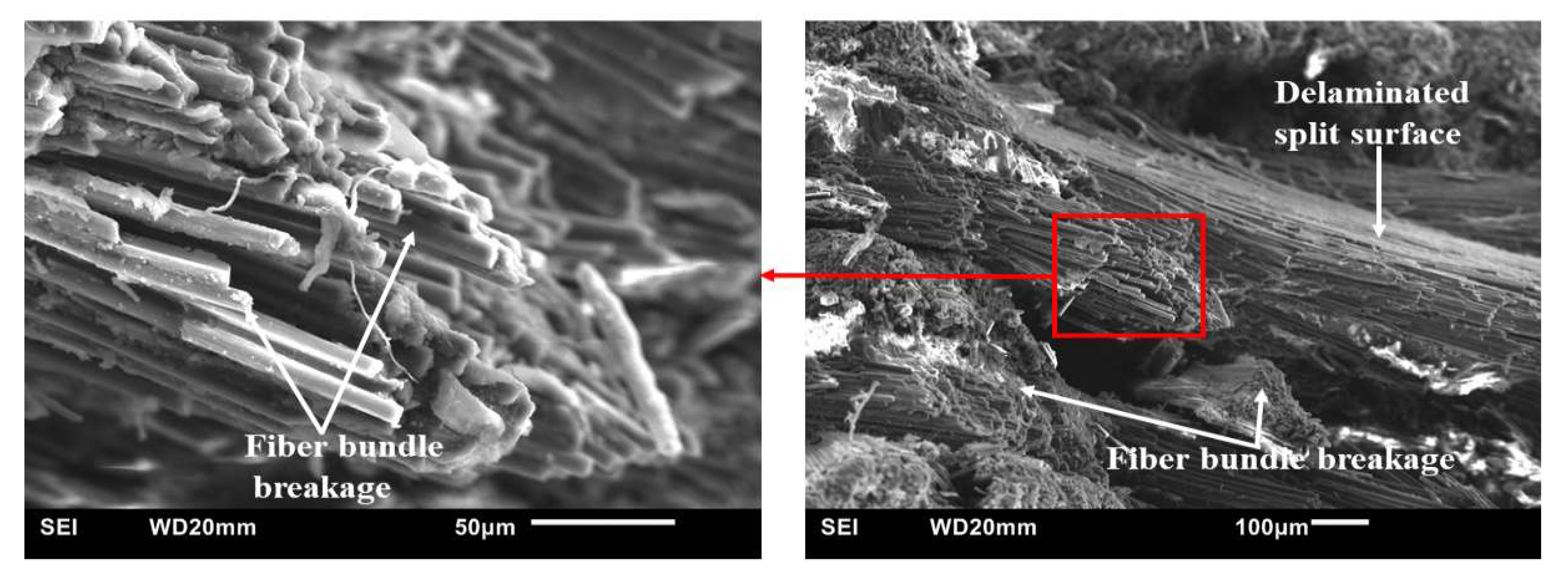

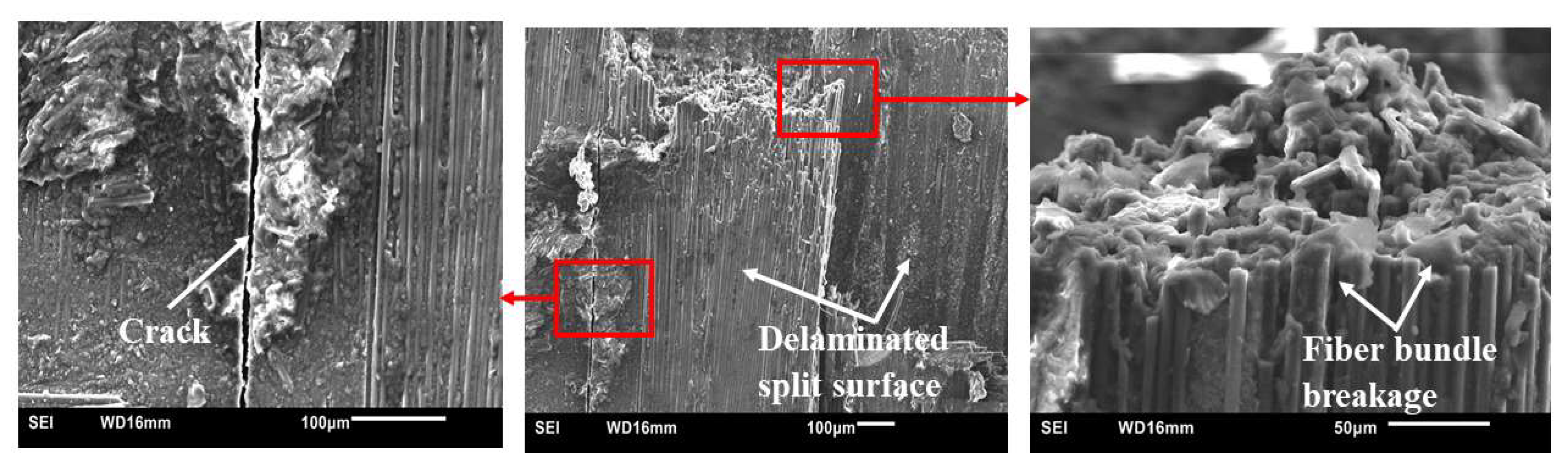

3.3. Microstructural Examination

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, R.; Li, C.; Xian, G. Water absorption and long-term thermal and mechanical properties of carbon/glass hybrid rod for bridge cable. Eng. Struct. 2023, 274, 115176. [Google Scholar] [CrossRef]

- Feng, B.; Wang, X.; Wu, Z.; Yang, Y.; Pan, Z. Performance of anchorage assemblies for CFRP cables under fatigue loads. Structures 2021, 29, 947–953. [Google Scholar] [CrossRef]

- Sun, Y.; Sun, Y. Precursor infiltration and pyrolysis cycle-dependent mechanical and microwave absorption performances of continuous carbon fibers-reinforced boron-containing phenolic resins for low-density carbon-carbon composites. Ceram. Int. 2020, 46, 15167–15175. [Google Scholar] [CrossRef]

- Nashchokin, A.V.; Malakho, A.P.; Garadzha, N.V.; Rogozin, A.D. Evolution of the physicochemical properties of carbon—Carbon composites based on phenol—Formaldehyde resins and discrete carbon fibers. Fibre Chem. 2016, 47, 465–471. [Google Scholar] [CrossRef]

- Qanati, M.V.; Rasooli, A. Microstructural and main mechanical properties of novalac based carbon–carbon composites as the pyrolysis heating rate. Ceram. Int. 2021, 47, 26808–26821. [Google Scholar] [CrossRef]

- De Souza, W.O.; Garcia, K.; De Avila Von Dollinger, C.F.; Pardini, L.C. Electrical behavior of carbon fiber/phenolic composite during pyrolysis. Mater. Res. 2015, 18, 1209–1216. [Google Scholar] [CrossRef]

- Xu, Y.; Guo, L.; Zhang, H.; Zhai, H.; Ren, H. Research status, industrial application demand and prospects of phenolic resin. RSC Adv. 2019, 9, 28924–28935. [Google Scholar] [CrossRef]

- Renda, C.G.; Bertholdo, R. Study of phenolic resin and their tendency for carbon graphitization. J. Polym. Res. 2018, 25, 241. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, X.; Bai, X.; Zhang, Y.; Wang, G.; Zhao, Y.; Li, X.; Zhu, J.; Rong, L.; Mi, C. Synthesis, characterization and properties of phthalonitrile-etherified resole resin. E-Polymers 2020, 20, 500–509. [Google Scholar] [CrossRef]

- Bhatnagar, A. Lightweight Ballistic Composites, Military and Law Enforcement Applications; Woodhead Publishing Limited: Cambridge UK, 2006. [Google Scholar]

- Duodu, E.A.; Gu, J.; Ding, W.; Shang, Z.; Tang, S. Comparison of Ballistic Impact Behavior of Carbon Fiber/Epoxy Composite and Steel Metal Structures. Iran. J. Sci. Technol.—Trans. Mech. Eng. 2018, 42, 13–22. [Google Scholar] [CrossRef]

- Borba, N.Z.; Körbelin, J.; Fiedler, B.; dos Santos, J.F.; Amancio-Filho, S.T. Low-velocity impact response of friction riveted joints for aircraft application. Mater. Des. 2020, 186, 108369. [Google Scholar] [CrossRef]

- Xu, F.; Zhu, S.; Liu, Y.; Ma, Z.; Li, H. Ablation behavior and mechanism of TaSi2-modified carbon fabric-reinforced phenolic composite. J. Mater. Sci. 2020, 55, 8553–8563. [Google Scholar] [CrossRef]

- Wang, S.; Huang, H.; Tian, Y.; Huang, J. Effects of SiC content on mechanical, thermal and ablative properties of carbon/phenolic composites. Ceram. Int. 2020, 46, 16151–16156. [Google Scholar] [CrossRef]

- Wang, S.; Huang, H.; Tian, Y. Effects of zirconium carbide content on thermal stability and ablation properties of carbon/phenolic composites. Ceram. Int. 2020, 46, 4307–4313. [Google Scholar] [CrossRef]

- Duan, L.; Zhao, X.; Wang, Y. Oxidation and ablation behaviors of carbon fiber/phenolic resin composites modified with borosilicate glass and polycarbosilane interface. J. Alloys Compd. 2020, 827, 154277. [Google Scholar] [CrossRef]

- Duan, L.; Luo, L.; Wang, Y. Oxidation and ablation behavior of a ceramizable resin matrix composite based on carbon fiber/phenolic resin. Mater. Today Commun. 2022, 33, 104901. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, J.; Yang, S.; Shi, M.; Li, J.; Shen, Q. Enhanced mechanical, thermal and ablation properties of carbon fiber/BPR composites modified by mica synergistic MoSi2 at 1500 °C. Ceram. Int. 2023, 49, 21213–21221. [Google Scholar] [CrossRef]

- Yang, T.; Dong, C.; Rong, Y.; Deng, Z.; Li, P.; Han, P.; Shi, M.; Huang, Z. Oxidation Behavior of Carbon Fibers in Ceramizable Phenolic Resin Matrix Composites at Elevated Temperatures. Polymers 2022, 14, 2785. [Google Scholar] [CrossRef] [PubMed]

- Nagaraja, K.C.; Rajanna, S.; Prakash, G.S.; Rajeshkumar, G. Improvement of mechanical and thermal properties of hybrid composites through addition of halloysite nanoclay for light weight structural applications. J. Ind. Text. 2022, 51, 4880S–4898S. [Google Scholar] [CrossRef]

- Lamorinière, S.; Jones, M.P.; Ho, K.; Kalinka, G.; Shaffer, M.S.P.; Bismarck, A. Carbon nanotube enhanced carbon Fibre-Poly(ether ether ketone) interfaces in model hierarchical composites. Compos. Sci. Technol. 2022, 221, 109327. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, G.; Shi, X.P.; Wang, X. Effects of carbon nanotubes on the interlaminar shear strength and fracture toughness of carbon fiber composite laminates: A review. J. Mater. Sci. 2022, 57, 2388–2410. [Google Scholar] [CrossRef]

- Tessema, A.; Mitchell, W.; Koohbor, B.; Ravindran, S.; Van Tooren, M.; Kidane, A. The Effect of Nano-Fillers on the In-Plane and Interlaminar Shear Properties of Carbon Fiber Reinforced Composite. J. Dyn. Behav. Mater. 2018, 4, 296–307. [Google Scholar] [CrossRef]

- Bilisik, K.; Erdogan, G.; Karaduman, N.; Sapanci, E. Developments of Multi-nanostitched 3D Carbon/epoxy Nanocomposites: Tensile/shear and Interlaminar Properties. Appl. Compos. Mater. 2022, 29, 3–26. [Google Scholar] [CrossRef]

- Kamae, T.; Drzal, L.T. Carbon fiber/epoxy composite property enhancement through incorporation of carbon nanotubes at the fiber-matrix interphase—Part II: Mechanical and electrical properties of carbon nanotube coated carbon fiber composites. Compos. Part A Appl. Sci. Manuf. 2022, 160, 107023. [Google Scholar] [CrossRef]

- Lyu, H.; Jiang, N.; Li, Y.; Lee, H.P.; Zhang, D. Enhanced interfacial and mechanical properties of carbon fiber/PEEK composites by hydroxylated PEEK and carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2021, 145, 106364. [Google Scholar] [CrossRef]

- Lyu, H.; Jiang, N.; Li, Y.; Zhang, D. Enhancing CF/PEEK interfacial adhesion by modified PEEK grafted with carbon nanotubes. Compos. Sci. Technol. 2021, 210, 108831. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Xiang, D.; Zhao, C.; Wang, B.; Li, H. Enhanced Electrical Conductivity and Interlaminar Fracture Toughness of CF/EP Composites via Interleaving Conductive Thermoplastic Films. Appl. Compos. Mater. 2021, 28, 17–37. [Google Scholar] [CrossRef]

- Kostagiannakopoulou, C.; Loutas, T.H.; Sotiriadis, G.; Kostopoulos, V. Effects of graphene geometrical characteristics to the interlaminar fracture toughness of CFRP laminates. Eng. Fract. Mech. 2021, 245, 107584. [Google Scholar] [CrossRef]

- Liu, Y.; Li, J.; Kuang, Y.; Zhao, Y.; Wang, M.; Wang, H.; Chen, X. Interlaminar properties of carbon nanotubes modified carbon fibre fabric reinforced polyimide composites. J. Compos. Mater. 2023, 57, 1277–1287. [Google Scholar] [CrossRef]

- Lertwassana, W.; Parnklang, T.; Mora, P.; Jubsilp, C.; Rimdusit, S. High performance aramid pulp/carbon fiber-reinforced polybenzoxazine composites as friction materials. Compos. Part B Eng. 2019, 177, 107280. [Google Scholar] [CrossRef]

- Lai, M.; Jiang, L.; Wang, X.; Zhou, H.; Huang, Z.; Zhou, H. Effects of multi-walled carbon nanotube/graphene oxide-based sizing on interfacial and tribological properties of continuous carbon fiber/poly(ether ether ketone) composites. Mater. Chem. Phys. 2022, 276, 125344. [Google Scholar] [CrossRef]

- Wenbin, L.; Jianfeng, H.; Jie, F.; Zhenhai, L.; Liyun, C.; Chunyan, Y. Effect of aramid pulp on improving mechanical and wet tribological properties of carbon fabric/phenolic composites. Tribol. Int. 2016, 104, 237–246. [Google Scholar] [CrossRef]

- Rao, G.R.; Srikanth, I.; Reddy, K.L. Effect of organo-modified montmorillonite nanoclay on mechanical, thermal and ablation behavior of carbon fiber/phenolic resin composites. Def. Technol. 2021, 17, 812–820. [Google Scholar] [CrossRef]

- Eslami, Z.; Yazdani, F.; Mirzapour, M.A. Thermal and mechanical properties of phenolic-based composites reinforced by carbon fibres and multiwall carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2015, 72, 22–31. [Google Scholar] [CrossRef]

- Chen, Z.; Dai, X.J.; Magniez, K.; Lamb, P.R.; Rubin De Celis Leal, D.; Fox, B.L.; Wang, X. Improving the mechanical properties of epoxy using multiwalled carbon nanotubes functionalized by a novel plasma treatment. Compos. Part A Appl. Sci. Manuf. 2013, 45, 145–152. [Google Scholar] [CrossRef]

- Feng, P.; Kong, Y.; Liu, M.; Peng, S.; Shuai, C. Dispersion strategies for low-dimensional nanomaterials and their application in biopolymer implants. Mater. Today Nano 2021, 15, 100127. [Google Scholar] [CrossRef]

- Shi, X.; Bai, S.; Li, Y.; Yu, X.; Naito, K.; Zhang, Q. Effect of polyethylene glycol surface modified nanodiamond on properties of polylactic acid nanocomposite films. Diam. Relat. Mater. 2020, 109, 108092. [Google Scholar] [CrossRef]

- Shin, G.J.; Kim, D.H.; Kim, J.W.; Kim, S.H.; Lee, J.H. Enhancing vertical thermal conductivity of carbon fiber reinforced polymer composites using cauliflower-shaped copper particles. Mater. Today Commun. 2023, 35, 105792. [Google Scholar] [CrossRef]

- Cha, J.; Jin, S.; Shim, J.H.; Park, C.S.; Ryu, H.J.; Hong, S.H. Functionalization of carbon nanotubes for fabrication of CNT/epoxy nanocomposites. Mater. Des. 2016, 95, 1–8. [Google Scholar] [CrossRef]

- Ali, A.; Rahimian Koloor, S.S.; Alshehri, A.H.; Arockiarajan, A. Carbon nanotube characteristics and enhancement effects on the mechanical features of polymer-based materials and structures—A review. J. Mater. Res. Technol. 2023, 24, 6495–6521. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, Z.; Mao, J.; Wang, S.; Zheng, Y. Quantitative evaluation of inclusion homogeneity in composites and the applications. J. Mater. Res. Technol. 2020, 9, 6790–6807. [Google Scholar] [CrossRef]

- Marinkovic, F.S.; Popovic, D.M.; Jovanovic, J.D.; Stankovic, B.S.; Adnadjevic, B.K. Methods for quantitative determination of filler weight fraction and filler dispersion degree in polymer composites: Example of low-density polyethylene and NaA zeolite composite. Appl. Phys. A Mater. Sci. Process. 2019, 125, 611. [Google Scholar] [CrossRef]

- Garrido-Regife, L.; Rivero-Antúnez, P.; Morales-Flórez, V. The dispersion of carbon nanotubes in composite materials studied by computer simulation of Small Angle Scattering. Phys. B Condens. Matter 2023, 649, 414450. [Google Scholar] [CrossRef]

- Batool, M.; Haider, M.N.; Javed, T. Applications of Spectroscopic Techniques for Characterization of Polymer Nanocomposite: A Review. J. Inorg. Organomet. Polym. Mater. 2022, 32, 4478–4503. [Google Scholar] [CrossRef]

- Zaman, A.C.; Kaya, F.; Kaya, C. A study on optimum surfactant to multiwalled carbon nanotube ratio in alcoholic stable suspensions via UV–Vis absorption spectroscopy and zeta potential analysis. Ceram. Int. 2020, 46, 29120–29129. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, P.; Dang, H.; Nie, H.; Guo, Z.; Zhang, C.; Li, Y. Effects of loading rate and loading direction on the compressive failure behavior of a 2D triaxially braided composite. Int. J. Impact Eng. 2021, 156, 103928. [Google Scholar] [CrossRef]

- Mohsin, M.A.A.; Iannucci, L.; Greenhalgh, E.S. On the dynamic tensile behaviour of thermoplastic composite carbon/polyamide 6.6 using split hopkinson pressure bar. Materials 2021, 14, 1653. [Google Scholar] [CrossRef]

- Rouf, K.; Suratkar, A.; Imbert-Boyd, J.; Wood, J.; Worswick, M.; Montesano, J. Effect of strain rate on the transverse tension and compression behavior of a unidirectional non-crimp fabric carbon fiber/snap-cure epoxy composite. Materials 2021, 14, 7314. [Google Scholar] [CrossRef]

- Lomakin, E.; Fedulov, B.; Fedorenko, A. Strain rate influence on hardening and damage characteristics of composite materials. Acta Mech. 2021, 232, 1875–1887. [Google Scholar] [CrossRef]

- Rouf, K.; Worswick, M.J.; Montesano, J. Experimentally verified dual-scale modelling framework for predicting the strain rate-dependent nonlinear anisotropic deformation response of unidirectional non-crimp fabric composites. Compos. Struct. 2023, 303, 116384. [Google Scholar] [CrossRef]

- Li, X.; Yan, Y.; Guo, L.; Xu, C. Effect of strain rate on the mechanical properties of carbon/epoxy composites under quasi-static and dynamic loadings. Polym. Test. 2016, 52, 254–264. [Google Scholar] [CrossRef]

- Chihi, M.; Tarfaoui, M.; Qureshi, Y.; Bouraoui, C.; Benyahia, H. Effect of carbon nanotubes on the in-plane dynamic behavior of a carbon/epoxy composite under high strain rate compression using SHPB. Smart Mater. Struct. 2020, 29, 085012. [Google Scholar] [CrossRef]

- Abdulganiyu, I.A.; Oguocha, I.N.A.; Odeshi, A.G. Influence of microfillers addition on the flexural properties of carbon fiber reinforced phenolic composites. Compos. Mater. 2021, 55, 3973–3988. [Google Scholar] [CrossRef]

- Lee, Y.S.; Wetzel, E.D.; Wagner, N.J. The ballistic impact characteristics of Kevlar woven fabrics impregnated with a colloidal shear thickening fluid. J. Mater. Sci. 2003, 38, 2825–2833. [Google Scholar] [CrossRef]

- Khan, M.M.; Iqbal, M.A. Design, development, and calibration of split Hopkinson pressure bar system for Dynamic material characterization of concrete. Int. J. Prot. Struct. 2023, 1–29. [Google Scholar] [CrossRef]

- Wang, M.; Cai, X.; Lu, Y.; Noori, A.; Chen, F.; Chen, L.; Jiang, X. Mechanical behavior and failure modes of bamboo scrimber under quasi-static and dynamic compressive loads. Eng. Fail. Anal. 2023, 146, 107006. [Google Scholar] [CrossRef]

- Ramesh, K.T. High Rates and Impact Experiments. In Springer Handbook of Experimental Solid Mechanics; Sharpe, J., William, N., Eds.; Springer: New York, NY, USA, 2008; pp. 929–959. [Google Scholar]

- Foti, G. Silicon carbide: From amorphous to crystalline material. Appl. Surf. Sci. 2001, 184, 20–26. [Google Scholar] [CrossRef]

- Muranaka, T.; Kikuchi, Y.; Yoshizawa, T.; Shirakawa, N.; Akimitsu, J. Superconductivity in carrier-doped silicon carbide. Sci. Technol. Adv. Mater. 2008, 9, 044204. [Google Scholar] [CrossRef]

- Anthony, J.W.; Bideaux, R.A.; Bladh, K.W.; Nichols, M.C. Handbook of Mineralogy, Mineralogical Society of America; Mineral Data Publishing: Chantilly, VA, USA, 1995. [Google Scholar]

- Munasir; Triwikantoro; Zainuri, M. Darminto Synthesis of SiO2 nanopowders containing quartz and cristobalite phases from silica sands. Mater. Sci. Pol. 2015, 33, 47–55. [Google Scholar] [CrossRef]

- Jeon, D.; Yum, W.S.; Song, H.; Yoon, S.; Bae, Y.; Oh, J.E. Use of coal bottom ash and cao-cacl2-activated ggbfs binder in the manufacturing of artificial fine aggregates through cold-bonded pelletization. Materials 2020, 13, 5598. [Google Scholar] [CrossRef]

- Sekhar, N.C.; Varghese, L.A. Mechanical, thermal, and rheological studies of phenolic resin modified with intercalated graphite prepared via liquid phase intercalation. Polym. Test. 2019, 79, 106010. [Google Scholar] [CrossRef]

- Ki Park, S.; Nakhanivej, P.; Seok Yeon, J.; Ho Shin, K.; Dose, W.M.; De Volder, M.; Bae Lee, J.; Jin Kim, H.; Park, H.S. Electrochemical and structural evolution of structured V2O5 microspheres during Li-ion intercalation. J. Energy Chem. 2021, 55, 108–113. [Google Scholar] [CrossRef]

| Characteristics | HRJ-15881 | SP-6877 |

|---|---|---|

| Solids (%) | 76.09 | 76.09 |

| Phenol (%) | 13.61 | 13.61 |

| pH | 8.1 | 8.1 |

| Viscosity Brookfield (cP) | 906 | 53.1 |

| Gel Time (min.) | 12.5 | 12.5 |

| Formaldehyde (HCHO, (%)) | 0.5 | 1.3 |

| Momentum | Filler Content | Did Fracture Occur? | |

|---|---|---|---|

| HRJ-15881 | SP-6877 | ||

| 15 kg m/s | None | No | No |

| 28 kg m/s | Yes | Yes | |

| 15 kg m/s | 0.5 wt.% SiC | No | No |

| 1.0 wt.% SiC | No | No | |

| 1.5 wt.% SiC | No | No | |

| 2.0 wt.% SiC | No | No | |

| 28 kg m/s | 0.5 wt.% SiC | Yes | Yes |

| 1.0 wt.% SiC | Yes | Yes | |

| 1.5 wt.% SiC | No | No | |

| 2.0 wt.% SiC | No | No | |

| 15 kg m/s | 0.5 wt.% CS | No | No |

| 1.0 wt.% CS | No | No | |

| 1.5 wt.% CS | No | No | |

| 2.0 wt.% CS | No | No | |

| 28 kg m/s | 0.5 wt.% CS | No | No |

| 1.0 wt.% CS | No | No | |

| 1.5 wt.% CS | No | No | |

| 2.0 wt.% CS | Yes | Yes | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdulganiyu, I.A.; Adesola, O.E.; Oguocha, I.N.A.; Odeshi, A.G. Dynamic Impact Properties of Carbon-Fiber-Reinforced Phenolic Composites Containing Microfillers. Polymers 2023, 15, 3038. https://doi.org/10.3390/polym15143038

Abdulganiyu IA, Adesola OE, Oguocha INA, Odeshi AG. Dynamic Impact Properties of Carbon-Fiber-Reinforced Phenolic Composites Containing Microfillers. Polymers. 2023; 15(14):3038. https://doi.org/10.3390/polym15143038

Chicago/Turabian StyleAbdulganiyu, Ibraheem A., Oluwasegun. E. Adesola, Ikechukwuka N. A. Oguocha, and Akindele G. Odeshi. 2023. "Dynamic Impact Properties of Carbon-Fiber-Reinforced Phenolic Composites Containing Microfillers" Polymers 15, no. 14: 3038. https://doi.org/10.3390/polym15143038

APA StyleAbdulganiyu, I. A., Adesola, O. E., Oguocha, I. N. A., & Odeshi, A. G. (2023). Dynamic Impact Properties of Carbon-Fiber-Reinforced Phenolic Composites Containing Microfillers. Polymers, 15(14), 3038. https://doi.org/10.3390/polym15143038