Effects of Pre-Curing on the Structure and Properties of Paper-Based Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Sample Preparation

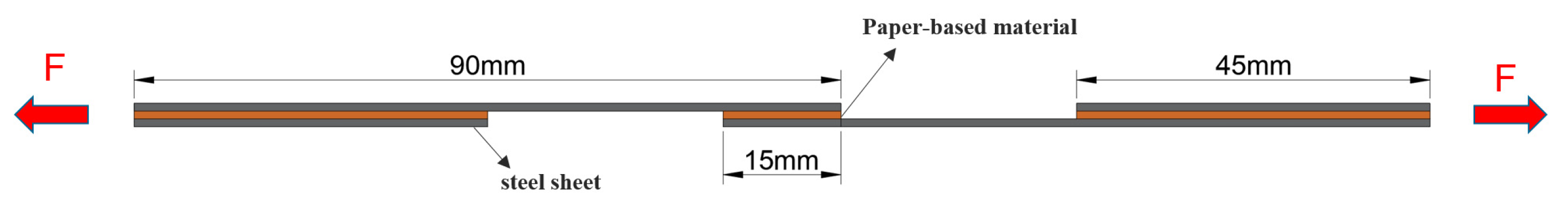

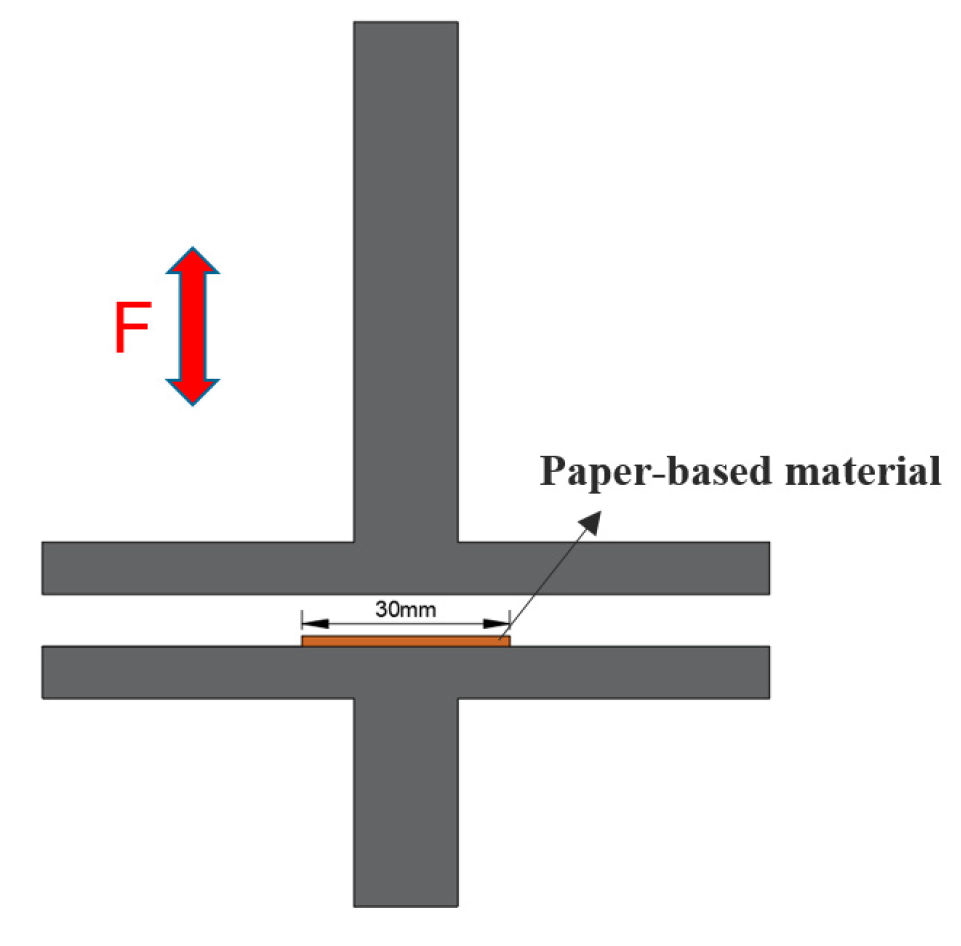

2.3. Testing Method and Equipment

3. Results and Discussion

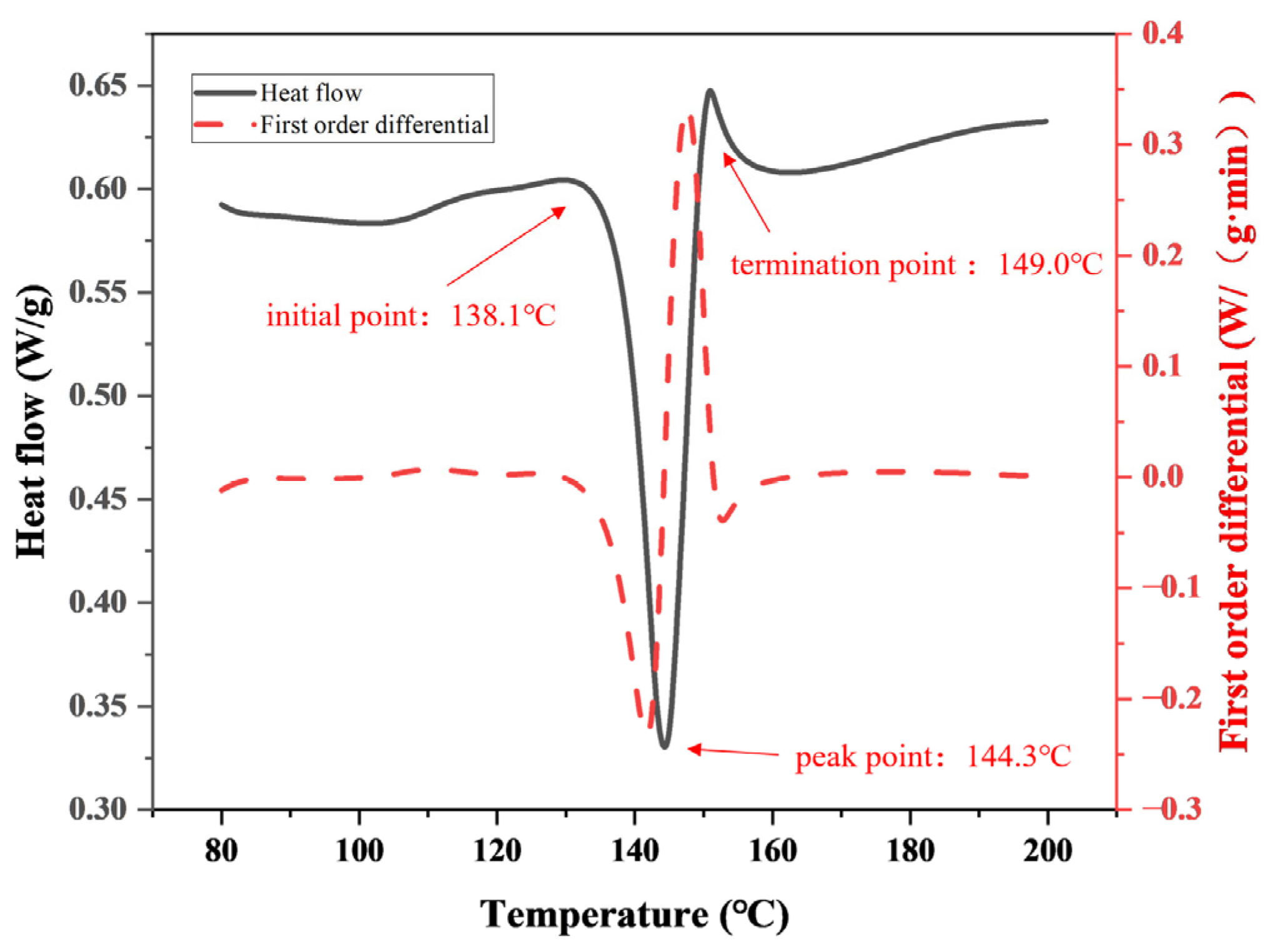

3.1. Curing Reactions of CMPR

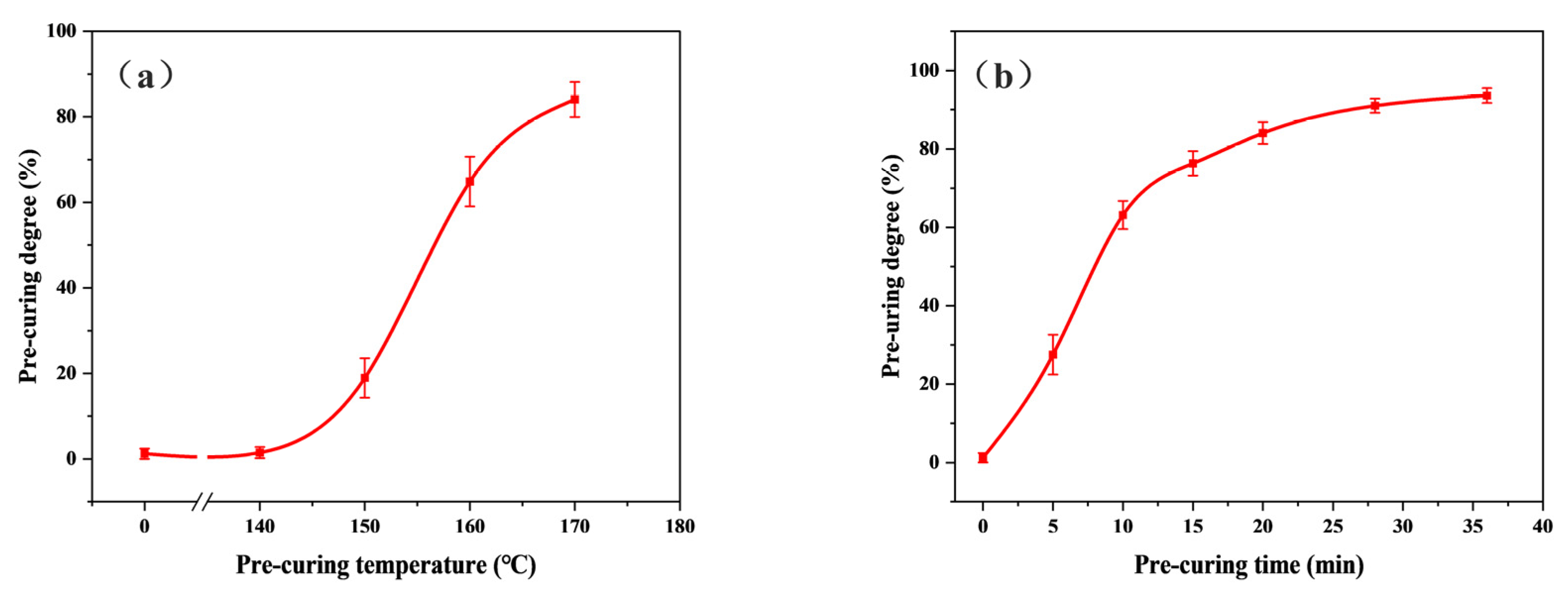

3.2. Effects of Pre-Curing Conditions on the Pre-Curing Degree of Materials

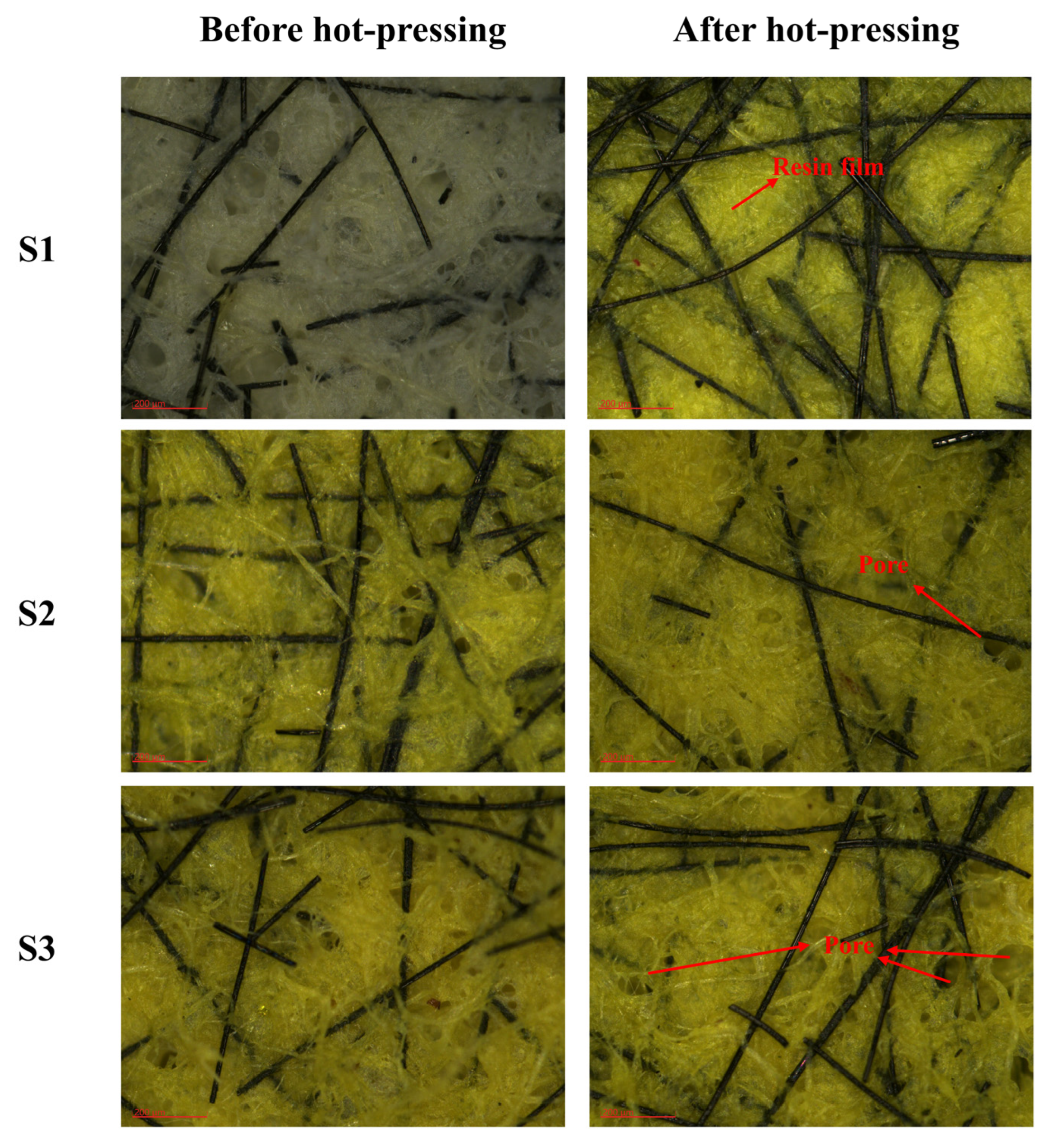

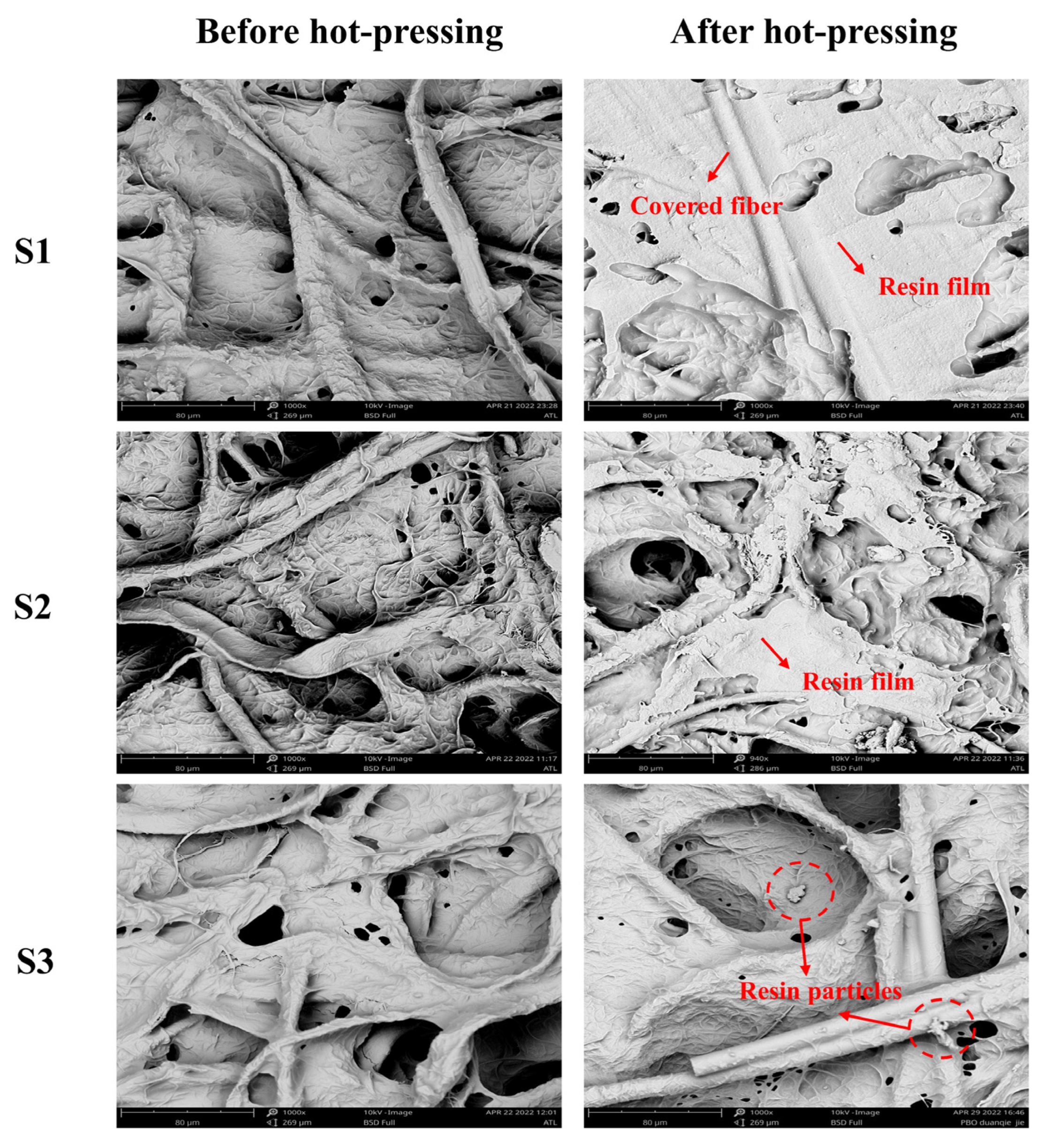

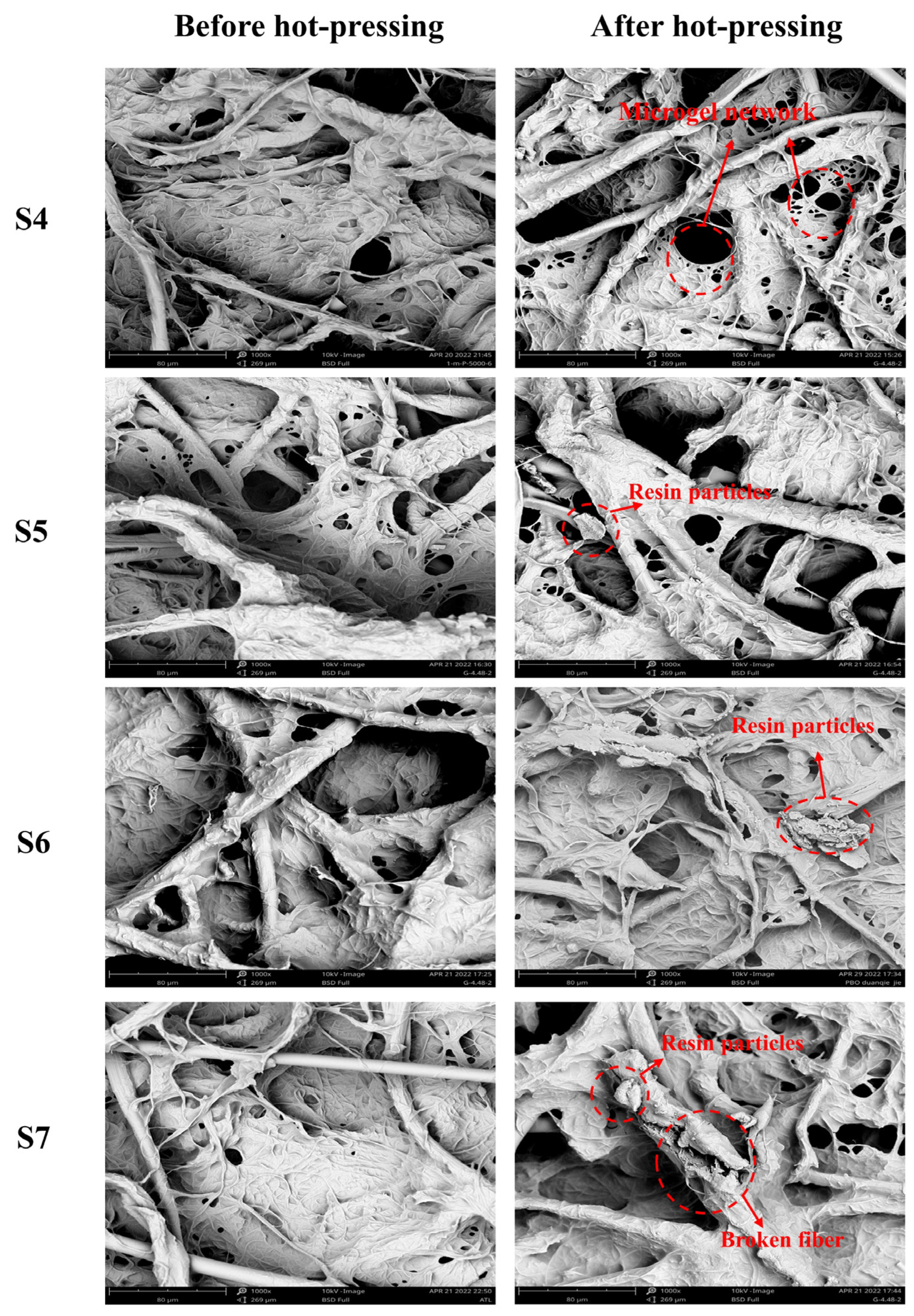

3.3. Effects of Pre-Curing on the Morphology of Materials before and after Hot-Pressing

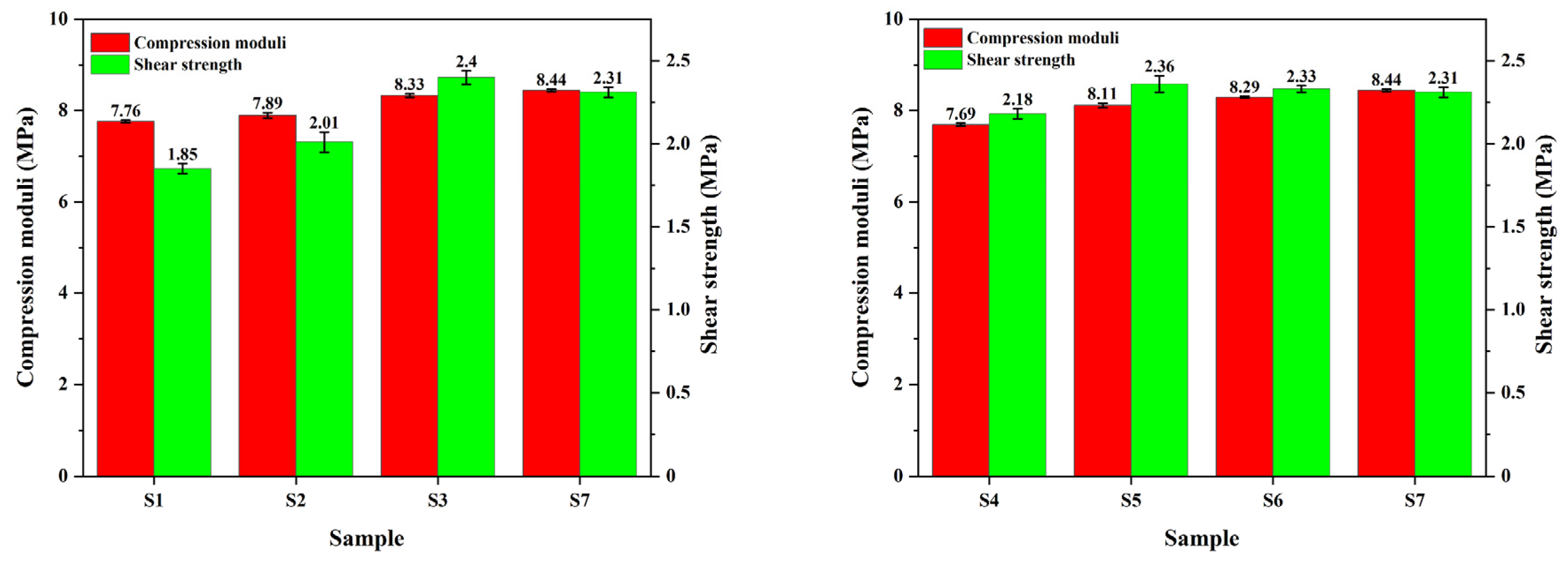

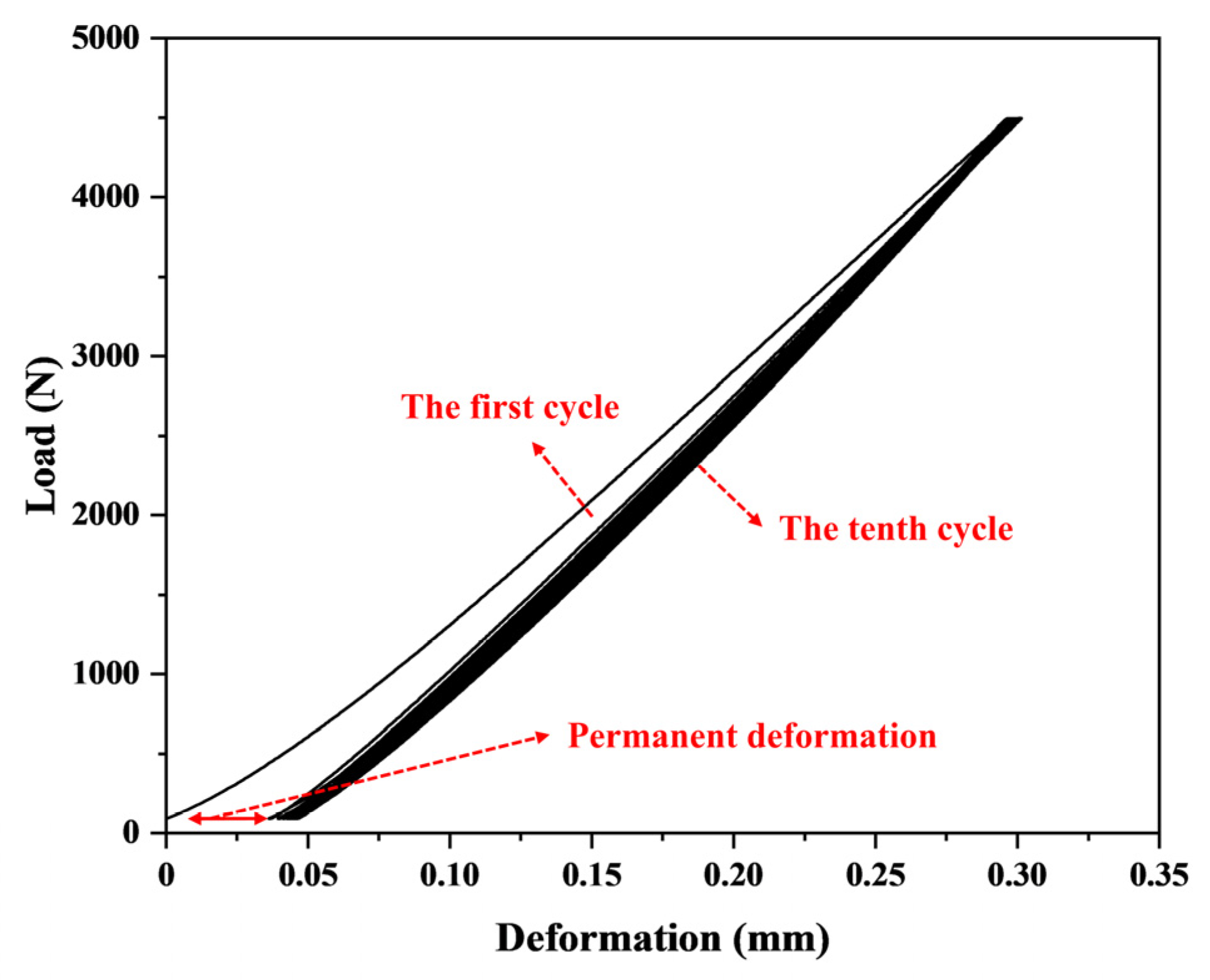

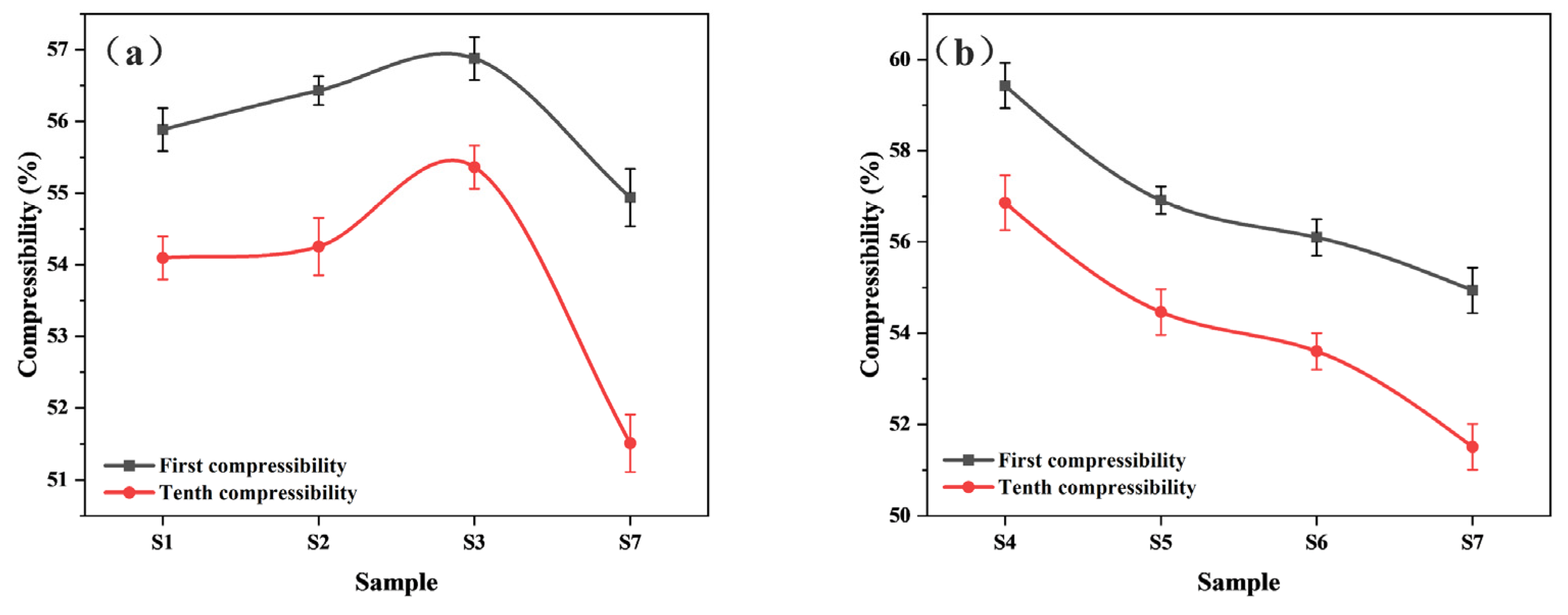

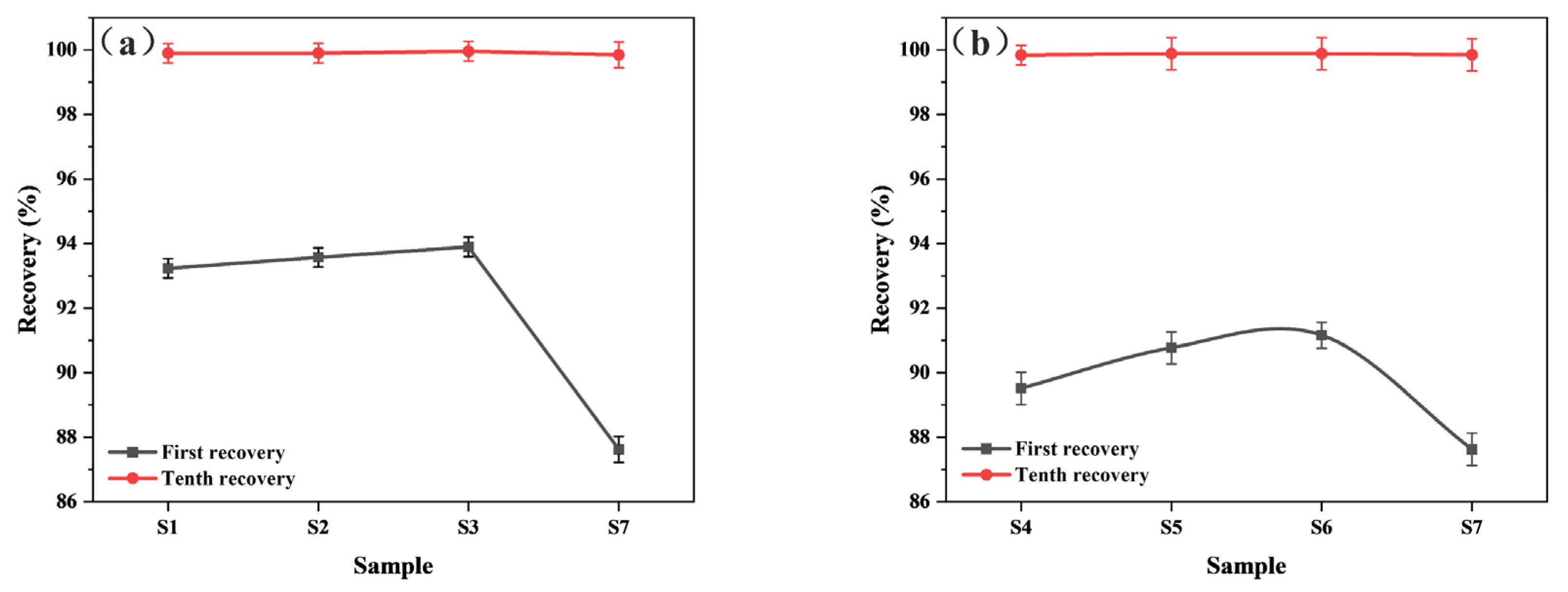

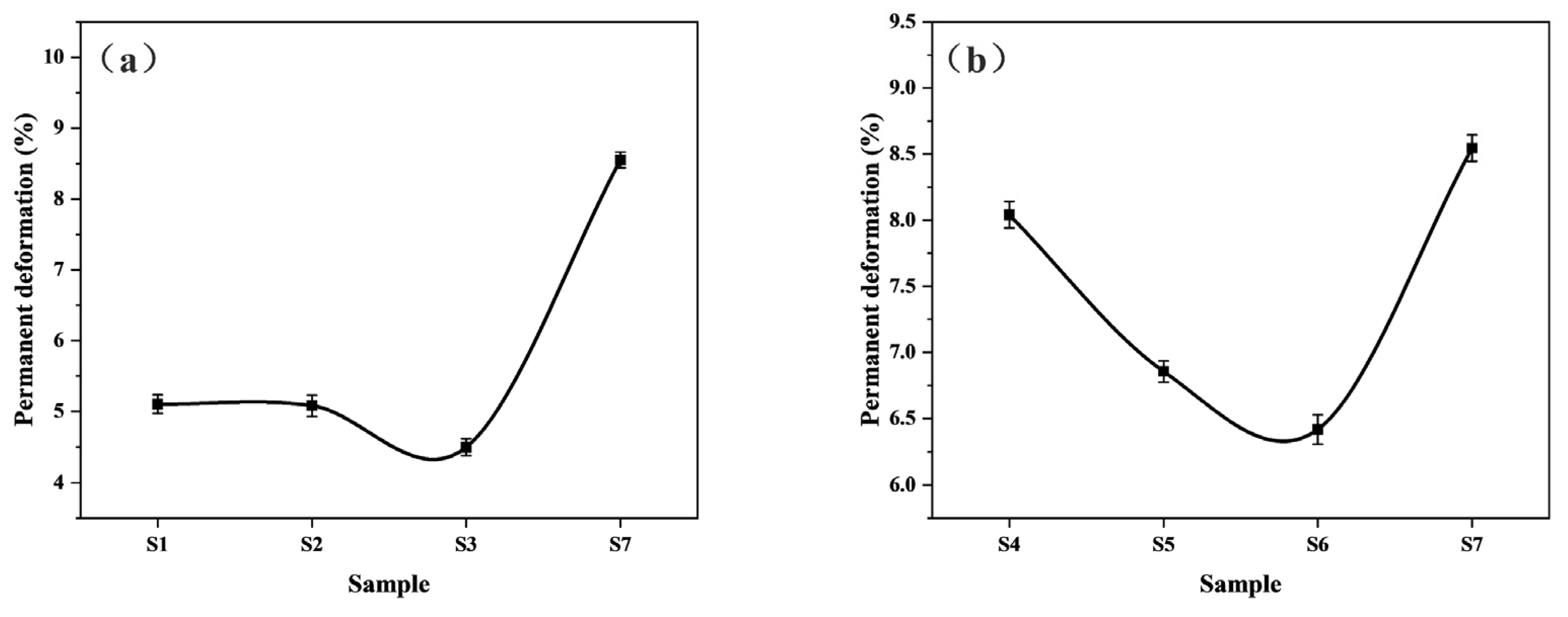

3.4. Effects of Pre-Curing on the Mechanical Properties of Materials

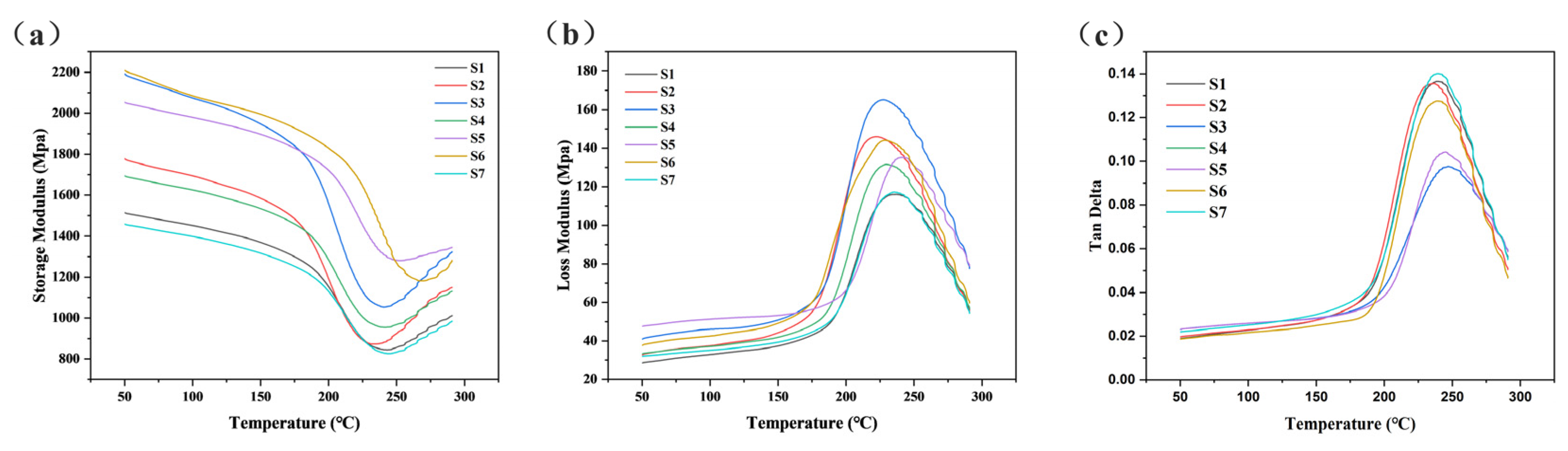

3.5. Effects of Pre-Curing on the Dynamic Mechanical Properties of Materials

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fei, J.; Li, H.; Fu, Y.; Qi, L.; Zhang, Y. Effect of phenolic resin content on performance of carbon fiber reinforced paper-based friction material. Wear 2010, 269, 534–540. [Google Scholar] [CrossRef]

- Fei, J.; Li, H.; Qi, L.; Fu, Y.; Li, X. Carbon-Fiber Reinforced Paper-Based Friction Material: Study on Friction Stability as a Function of Operating Variables. J. Tribol. 2008, 130, 4. [Google Scholar] [CrossRef]

- Kimura, Y.; Otani, C. Contact and wear of paper-based friction materials for oil-immersed clutches—Wear model for composite materials. Tribol. Int. 2005, 38, 943–950. [Google Scholar] [CrossRef]

- Bijwe, J.; Nidhi; Majumdar, N.; Satapathy, B.K. Influence of modified phenolic resins on the fade and recovery behavior of friction materials. Wear 2005, 259, 1068–1078. [Google Scholar] [CrossRef]

- Li, W.; Huang, J.; Fei, J.; Wang, W.; Cao, L. Effects of Modified-Phenolic on the Tribological Properties of Carbon Fiber Reinforced Phenolic Friction Materials. Mater. Sci. Forum. 2016, 852, 698–703. [Google Scholar] [CrossRef]

- ÖztürkS, B.; Öztürk, S. Effects of Resin Type and Fiber Length on the Mechanical and Tribological Properties of Brake Friction Materials. Tribol. Lett. 2011, 42, 339–350. [Google Scholar] [CrossRef]

- Kim, Y.; Cho, M.; Kim, S.; Jang, H. The effect of phenolic resin, potassium titanate, and CNSL on the tribological properties of brake friction materials. Wear 2008, 264, 204–210. [Google Scholar] [CrossRef]

- Tian, H.; Fei, J.; Li, C.; Qi, L.; Cai, X.; Li, B.; Fu, Y. Significant improvement of thermal and tribological performance with polyimide as the matrix of paper-based friction materials. Polym. Compos. 2022, 43, 2303–2317. [Google Scholar] [CrossRef]

- Lu, J.; Li, Y.; Wang, Y.; Fu, Y. Effect of LNBR Content on the Properties of the Carbon Fiber–Reinforced Paper-Based Friction Materials. Tribol. T. 2019, 62, 537–547. [Google Scholar] [CrossRef]

- Lu, J.; Li, Y.; Wang, Y.; Fu, Y. Effect of pre-impregnated organosilicon layer on friction and wear properties of paper-based friction materials. Wear 2018, 416, 6–13. [Google Scholar] [CrossRef]

- Zhang, D.; Li, C.; Cao, Y.; Lu, Z.; Cui, Q. Tribological Performance Comparison and Analysis on Friction Material: Four Modified Phenolic (PF) Resins. Key Eng. Mater. 2016, 693, 653–661. [Google Scholar] [CrossRef]

- Thébault, M.; Kandelbauer, A.; Müller, U.; Zikulnig-Rusch, E.; Lammer, H. Factors influencing the processing and technological properties of laminates based on phenolic resin impregnated papers. Eur. J. Wood. Wood. Prod. 2017, 75, 785–806. [Google Scholar] [CrossRef]

- Li, C.; Fei, J.; Zhou, E.; Lu, R.; Cai, X.; Fu, Y.; Li, H. Optimization of pore structure and wet tribological properties of paper-based friction materials using chemical foaming technology. Friction 2022, 10, 18. [Google Scholar] [CrossRef]

- Li, C.; Fu, Y.; Wang, B.; Zhang, W.; Bai, Y.; Zhang, L.; Qi, L. Effect of pore structure on mechanical and tribological properties of paper-based friction materials. Tribol. Int. 2020, 148, 106307. [Google Scholar] [CrossRef]

- Muc, A.; Romanowicz, P.; Chwal, M. Description of the Resin Curing Process—Formulation and Optimization. Polymers 2019, 11, 127. [Google Scholar] [CrossRef]

- Wang, C.; Wang, R.; Wang, Y.; Fu, Y. Study on Curing Process of Resin Nanocomposites Key. Eng. Mater. 2012, 501, 349–354. [Google Scholar]

- Zhang, C.; Zhang, G.; Xu, J.; Shi, X.; Wang, X. Review of curing deformation control methods for carbon fiber reinforced resin composites. Polym. Compos. 2022, 43, 3350–3370. [Google Scholar] [CrossRef]

- Pablo, M.P.; Laura, C.; Raúl, O.; Maite, I.; Isabel, C.A. Cure kinetics of a composite friction material with phenolic resin/rubber compounds as organic binder. Plast. Rubber. Compos. 2022, 51, 507–519. [Google Scholar]

- Nidhi; Bijwe, J.; Mazumdar, N. Influence of amount and modification of resin on fade and recovery behavior of non-asbestos organic (NAO) friction materials. Tribol. Lett. 2006, 23, 215–222. [Google Scholar] [CrossRef]

- Alonso, M.; Oliet, M.; García, J.; Rodríguez, F.; Echeverría, J. Master curve and time–temperature–transformation cure diagram of lignin–phenolic and phenolic resol resins. J. Appl. Polym. Sci. 2007, 103, 3362–3369. [Google Scholar] [CrossRef]

- Hirano, K.; Asami, M. Phenolic resins—100 years of progress and their future. React. Funct. Polym. 2013, 73, 256–269. [Google Scholar] [CrossRef]

- Zheng, Y.; Jiang, Z.; Sun, Z.; Ren, H. Effect of microwave-assisted curing on bamboo glue strength: Bonded by thermosetting phenolic resin. Constr. Build. Mater. 2014, 68, 320–325. [Google Scholar] [CrossRef]

- Mohan, P. A Critical Review: The Modification, Properties, and Applications of Epoxy Resins. Polym-Plast. Technol. 2013, 52, 107–125. [Google Scholar] [CrossRef]

- Koranteng, K.; Li, H.; Ma, B.; Ma, C. Coefficient of friction and wear rate of paper-based composite friction material against 65Mn steel. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 544–550. [Google Scholar] [CrossRef]

- Rahmani, N.; Willard, B.; Lease, K.; Legesse, E.T.; Soltani, S.A.; Keshavanarayana, S. The effect of post cure temperature on fiber/matrix adhesion of T650/Cycom 5320-1 using the micro-droplet technique. Polym. Test. 2015, 46, 14–20. [Google Scholar] [CrossRef]

- Park, H.; Koo-Hyun, C. Effect of Normal Force and Temperature on Tribological Properties of Wet Clutch Friction Material. Tribol. Lubr. 2019, 35, 30–36. [Google Scholar]

- Fujii, T.; Tohgo, K.; Wang, Y.; Shibata, J.; Shimamura, Y.; Katayama, N.; Ito, Y. Fatigue strength of a paper-based friction material under shear–compressive loading. Strength. Fract. Comp. 2011, 7, 185–193. [Google Scholar] [CrossRef]

- Matsumoto, T. A Study of the Durability of a Paper—Based Friction Material Influenced by Porosity. J. Tribol-T. Asme. 1995, 117, 272. [Google Scholar] [CrossRef]

- Bressan, J.D.; Genint, G.; Williams, J.A. The Influence of Pressure, Boundary Film Shear Strength and Elasticity on the Friction between a Hard Asperity and a Deforming Softer Surface. Tribol. Ser. 1999, 36, 79–90. [Google Scholar]

- Sendler, E.; Greening, B.; Greening, C. Continued Study of the Effect of Humidity Levels on the Compressibility of Automotive Brake Friction Materials. SAE. Tech. Pap. 2022, 1, 1164. [Google Scholar]

- Chiba, N.; Kano, M.; Inoue, M. Mechanism of compression fatigue of wet friction materials. JSAE Rev. 2001, 22, 169–174. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

| Samples | Pre-Curing Temperature/°C | Pre-Curing Time/min |

|---|---|---|

| S1 | 140 | 20 |

| S2 | 150 | 20 |

| S3 | 160 | 20 |

| S4 | 170 | 5 |

| S5 | 170 | 10 |

| S6 | 170 | 15 |

| S7 | 170 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, M.; Zhou, W.; Yao, Y.; Chen, J.; Zhang, C. Effects of Pre-Curing on the Structure and Properties of Paper-Based Materials. Polymers 2023, 15, 2702. https://doi.org/10.3390/polym15122702

Lin M, Zhou W, Yao Y, Chen J, Zhang C. Effects of Pre-Curing on the Structure and Properties of Paper-Based Materials. Polymers. 2023; 15(12):2702. https://doi.org/10.3390/polym15122702

Chicago/Turabian StyleLin, Mingcen, Wenling Zhou, Ye Yao, Jingxiang Chen, and Chunhui Zhang. 2023. "Effects of Pre-Curing on the Structure and Properties of Paper-Based Materials" Polymers 15, no. 12: 2702. https://doi.org/10.3390/polym15122702

APA StyleLin, M., Zhou, W., Yao, Y., Chen, J., & Zhang, C. (2023). Effects of Pre-Curing on the Structure and Properties of Paper-Based Materials. Polymers, 15(12), 2702. https://doi.org/10.3390/polym15122702