Development of Sustainable Engineered Cementitious Composites by Incorporating Local Recycled Fine Aggregate

Abstract

1. Introduction

2. Materials and Methods

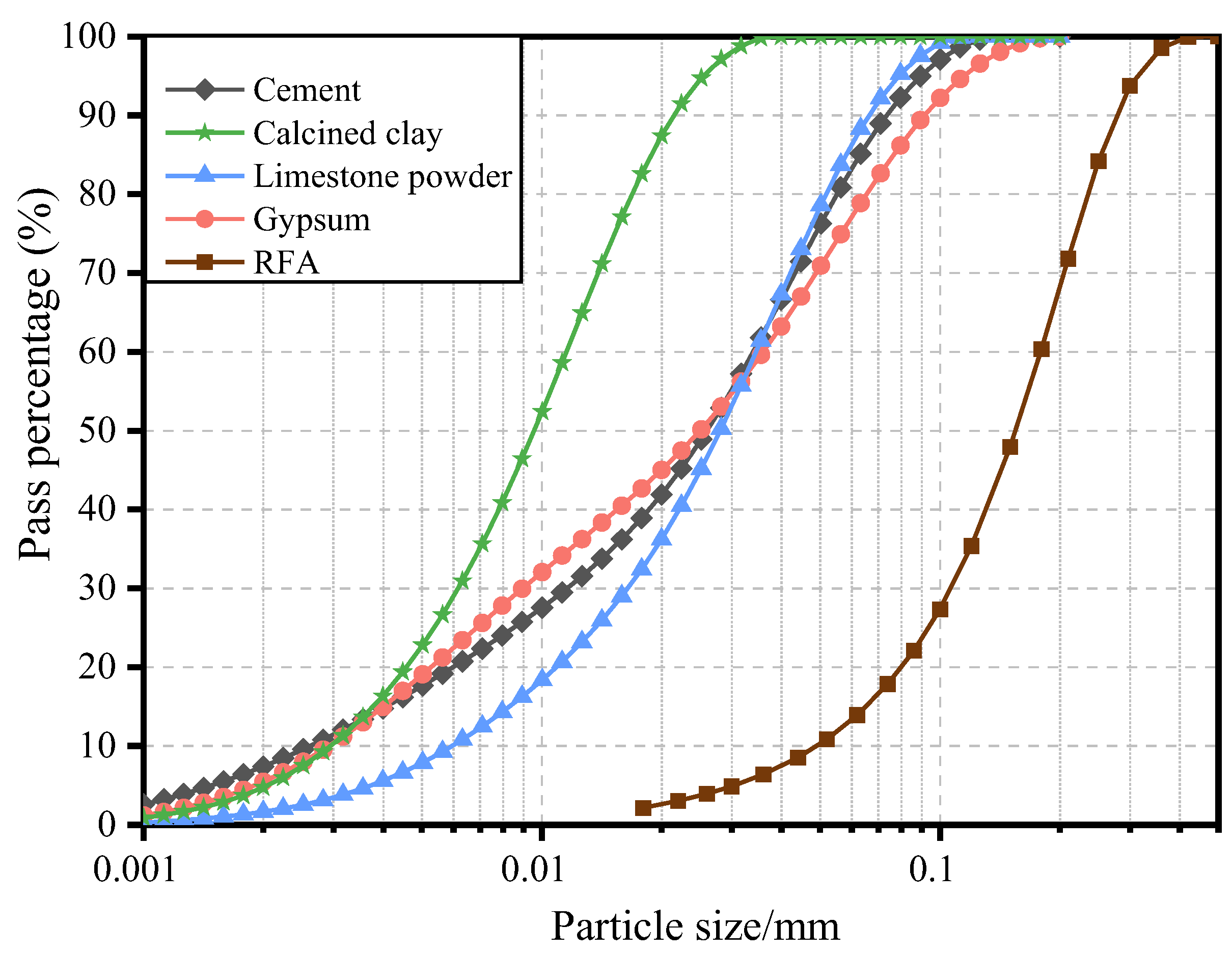

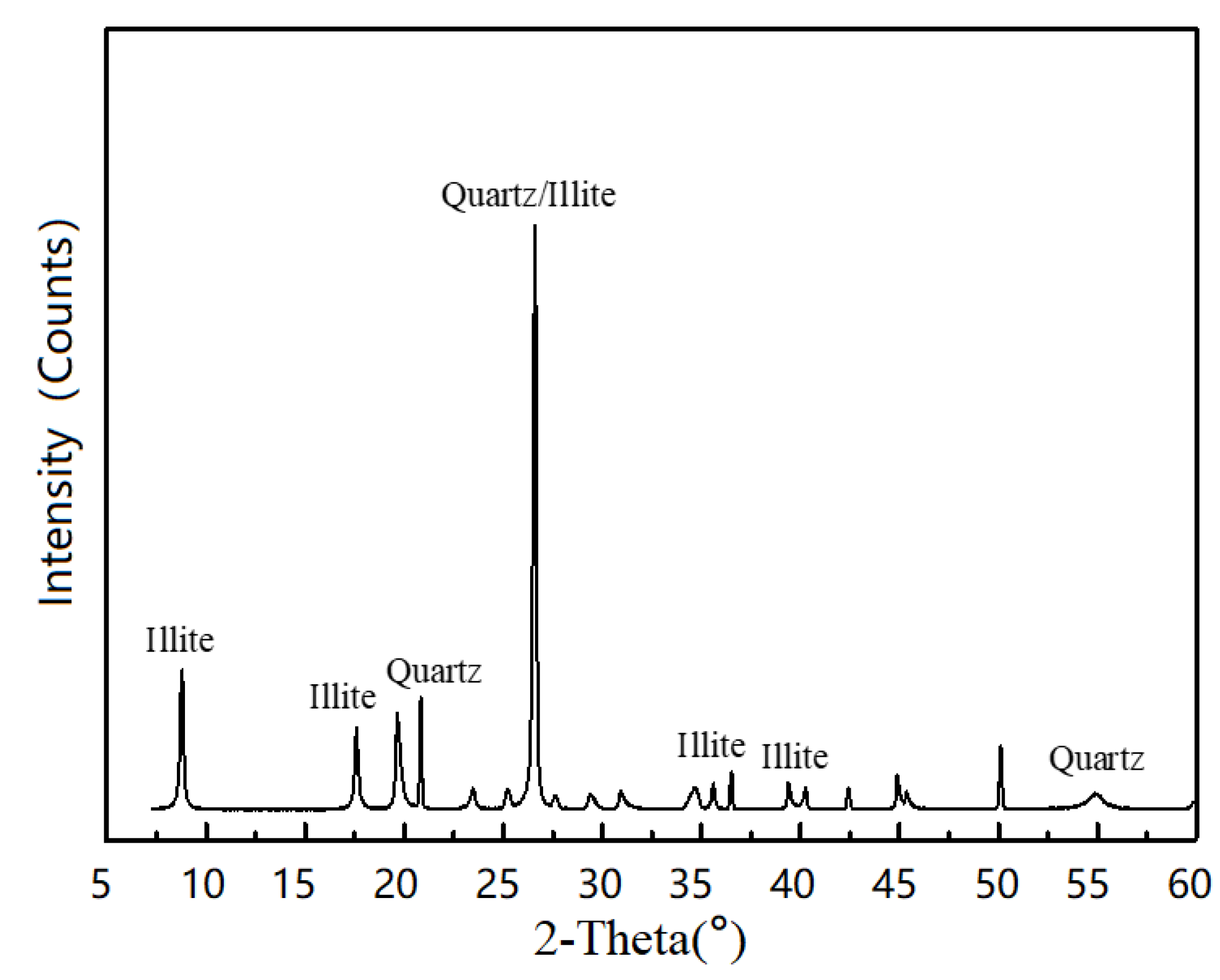

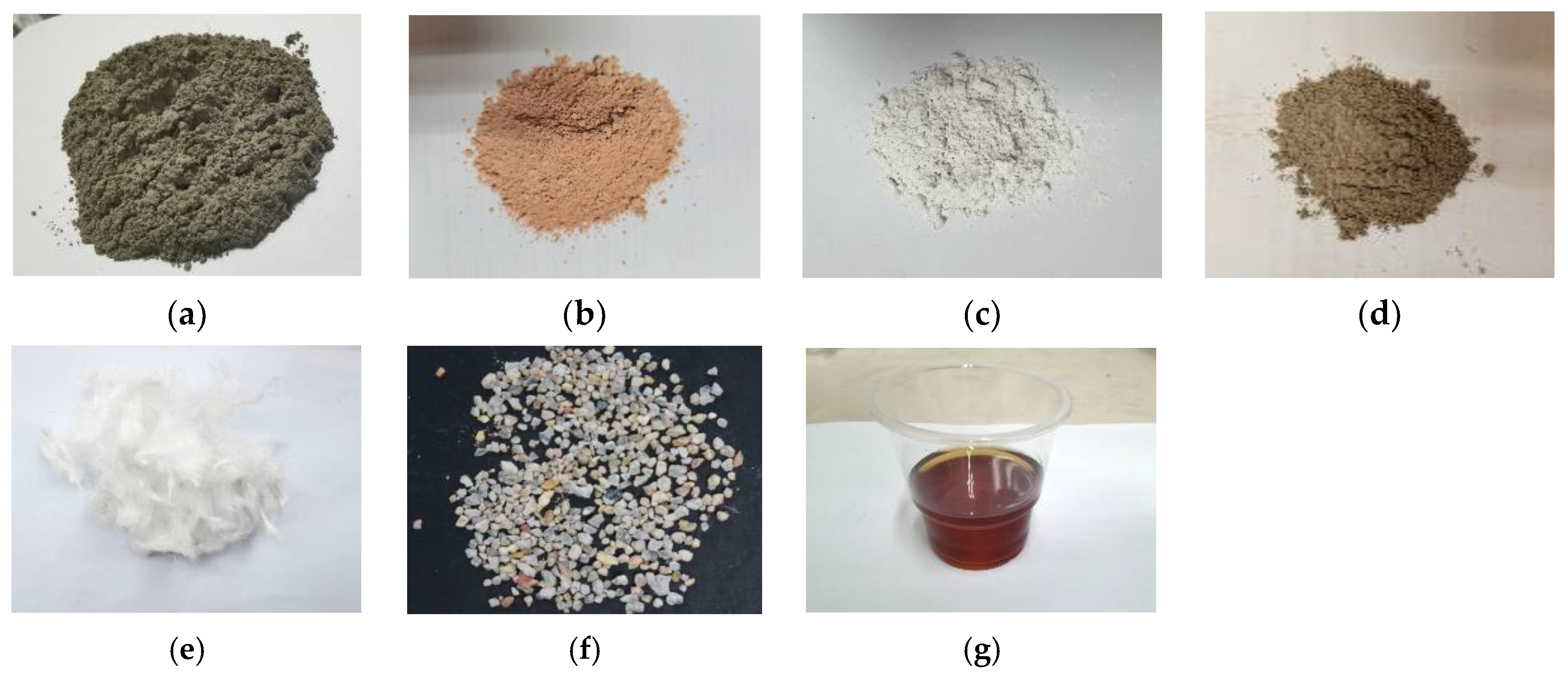

2.1. Materials and Mixture Proportion

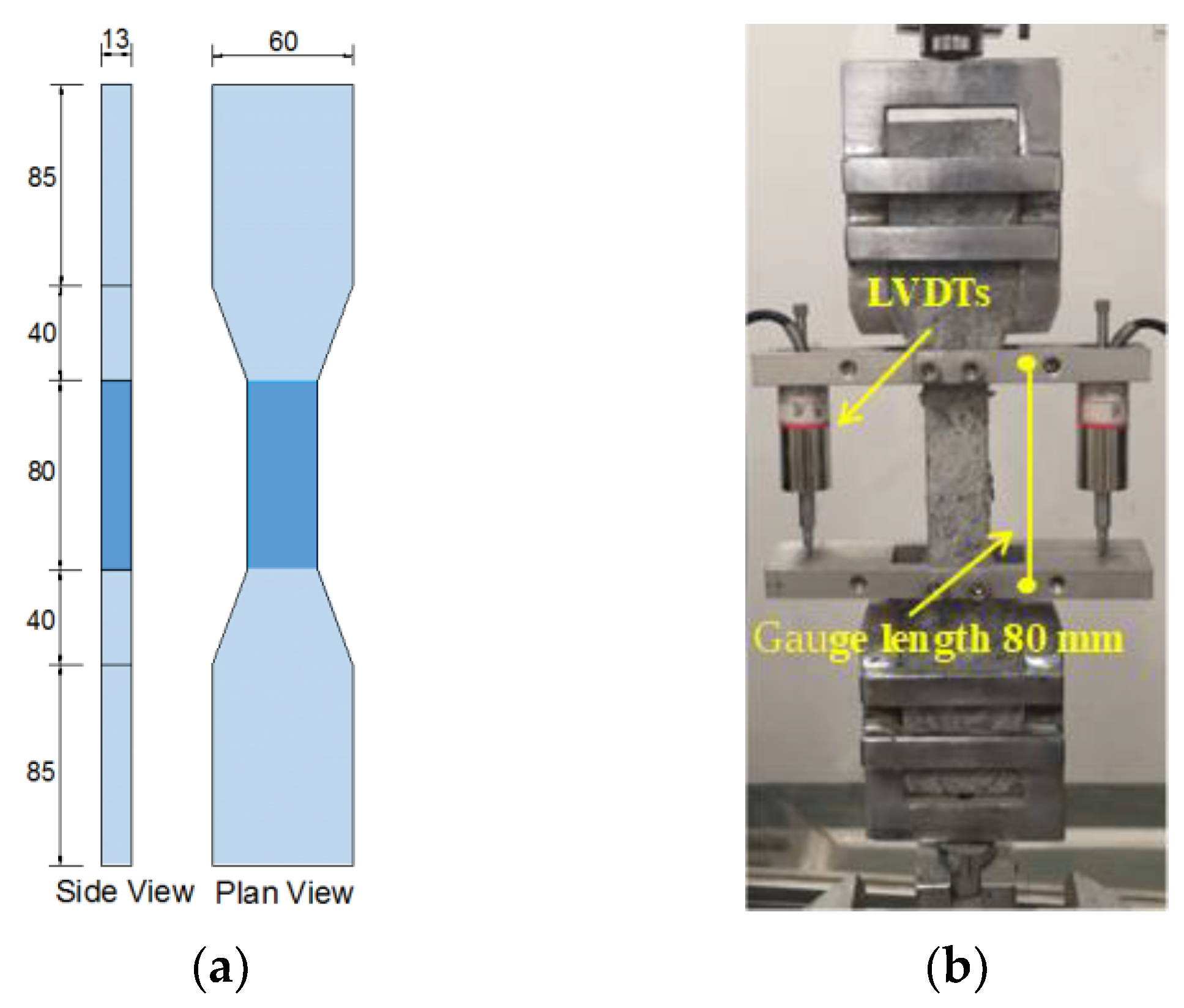

2.2. Macroscopic Mechanical Testing

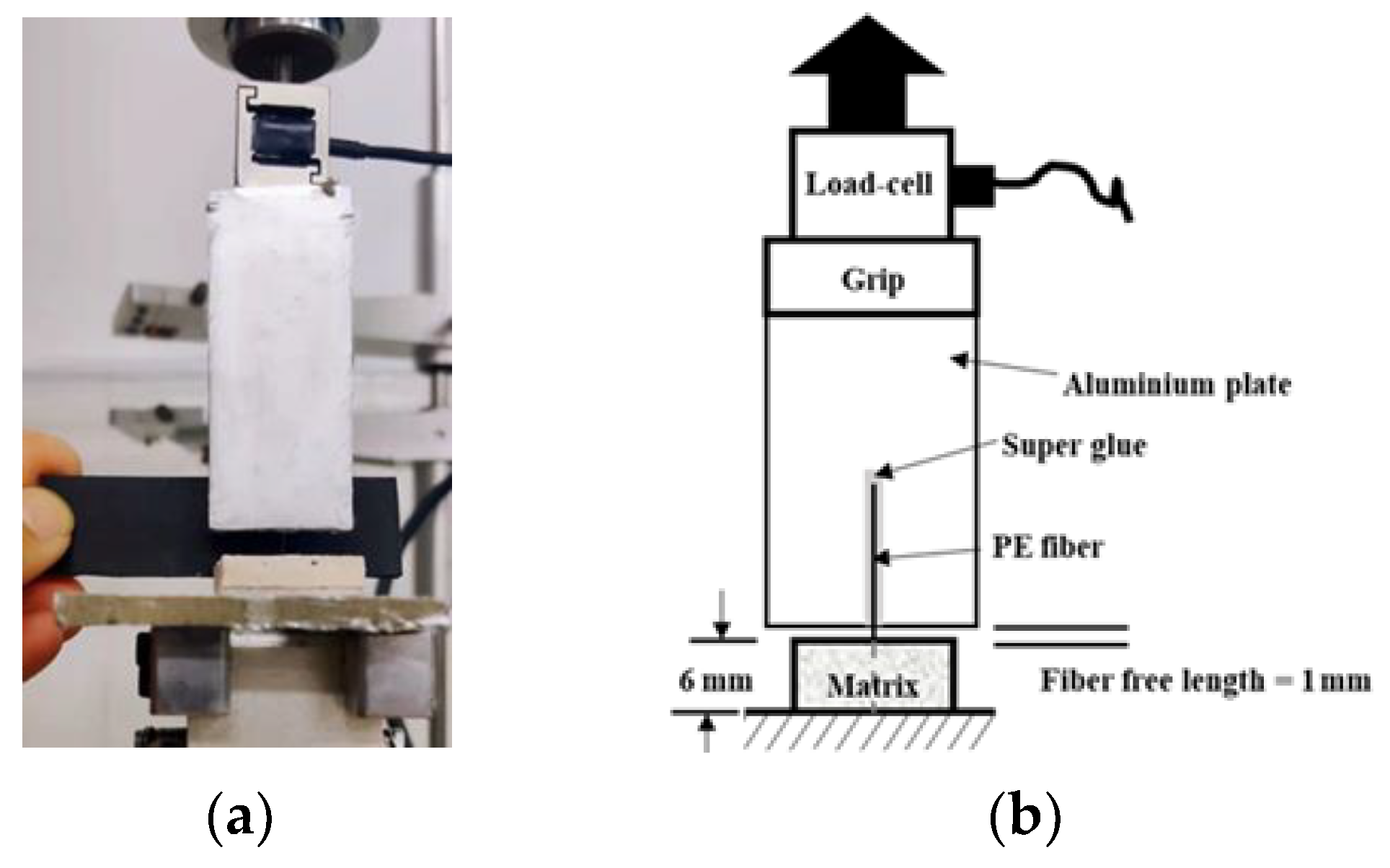

2.3. Single Fiber Pullout Test

2.4. X-ray Diffraction Analysis

2.5. Methodologies of Environmental Impact Assessment

3. Results and Discussions

3.1. Flowability

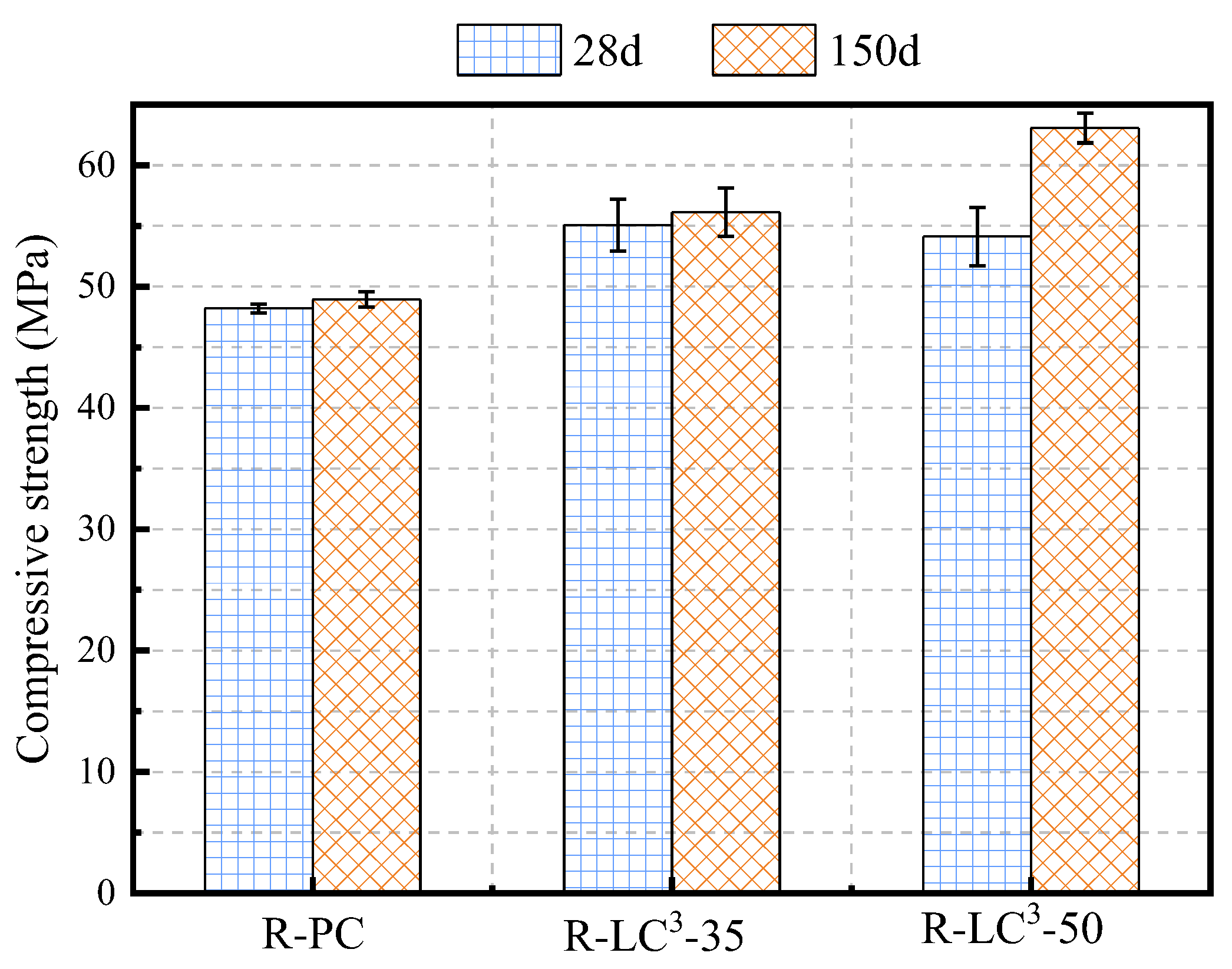

3.2. Compressive Strength

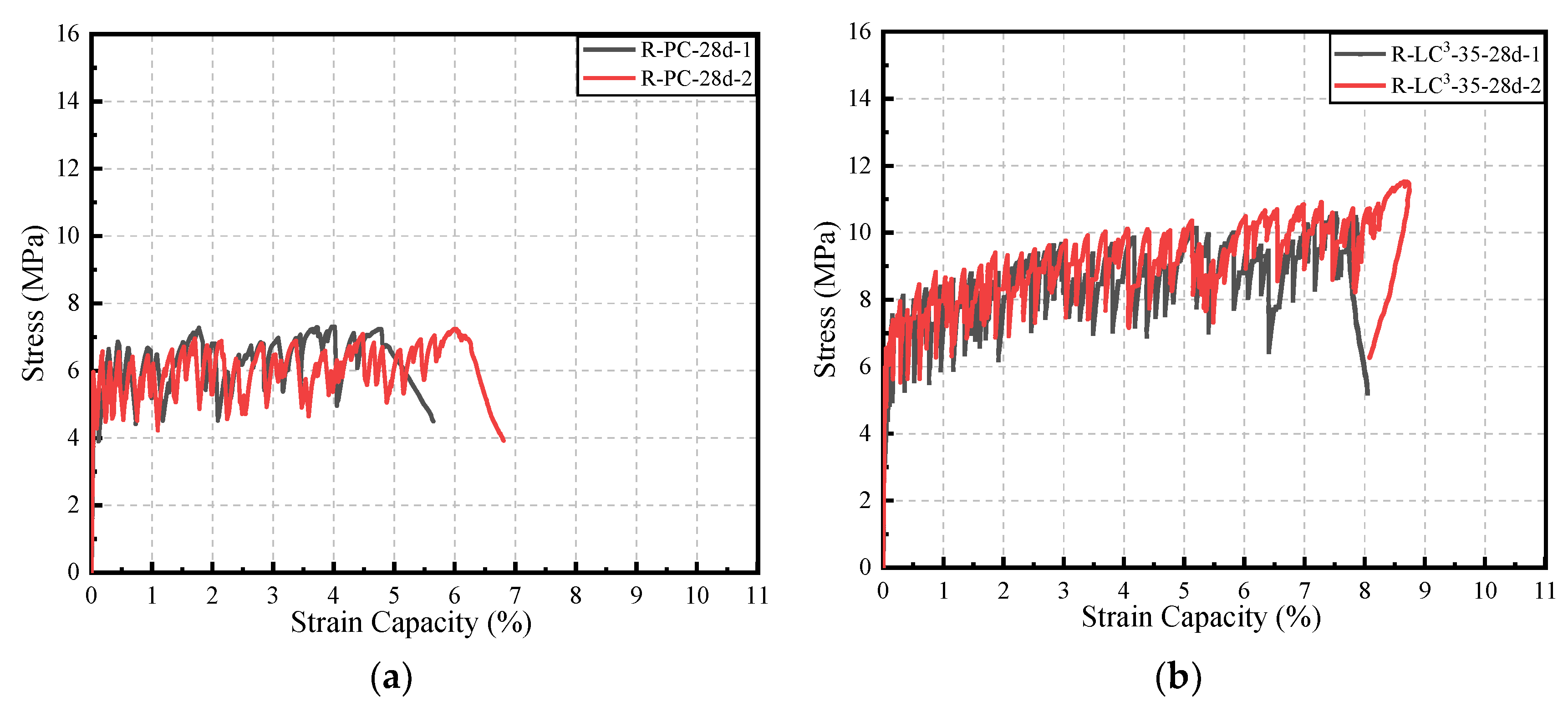

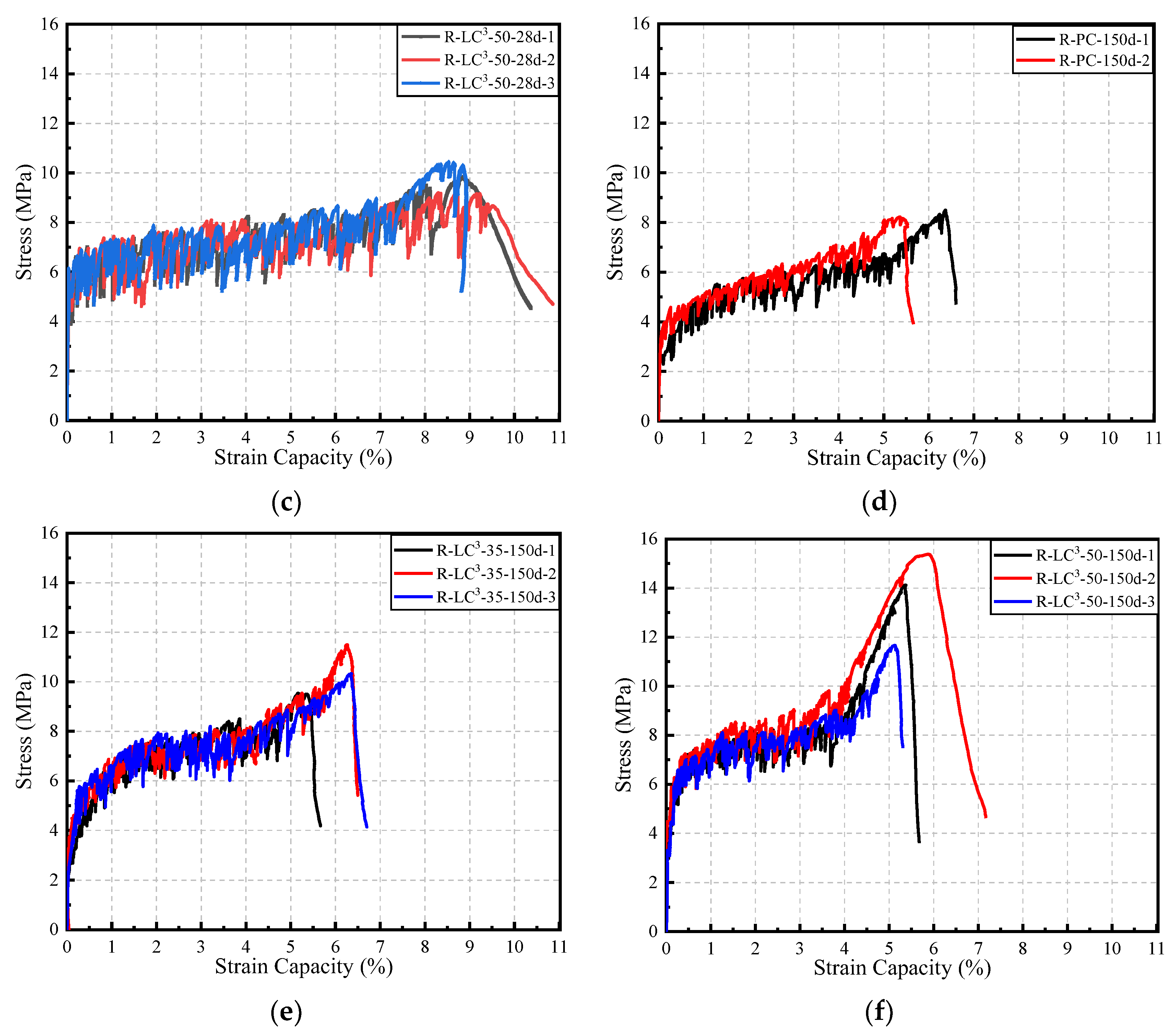

3.3. Tensile Properties

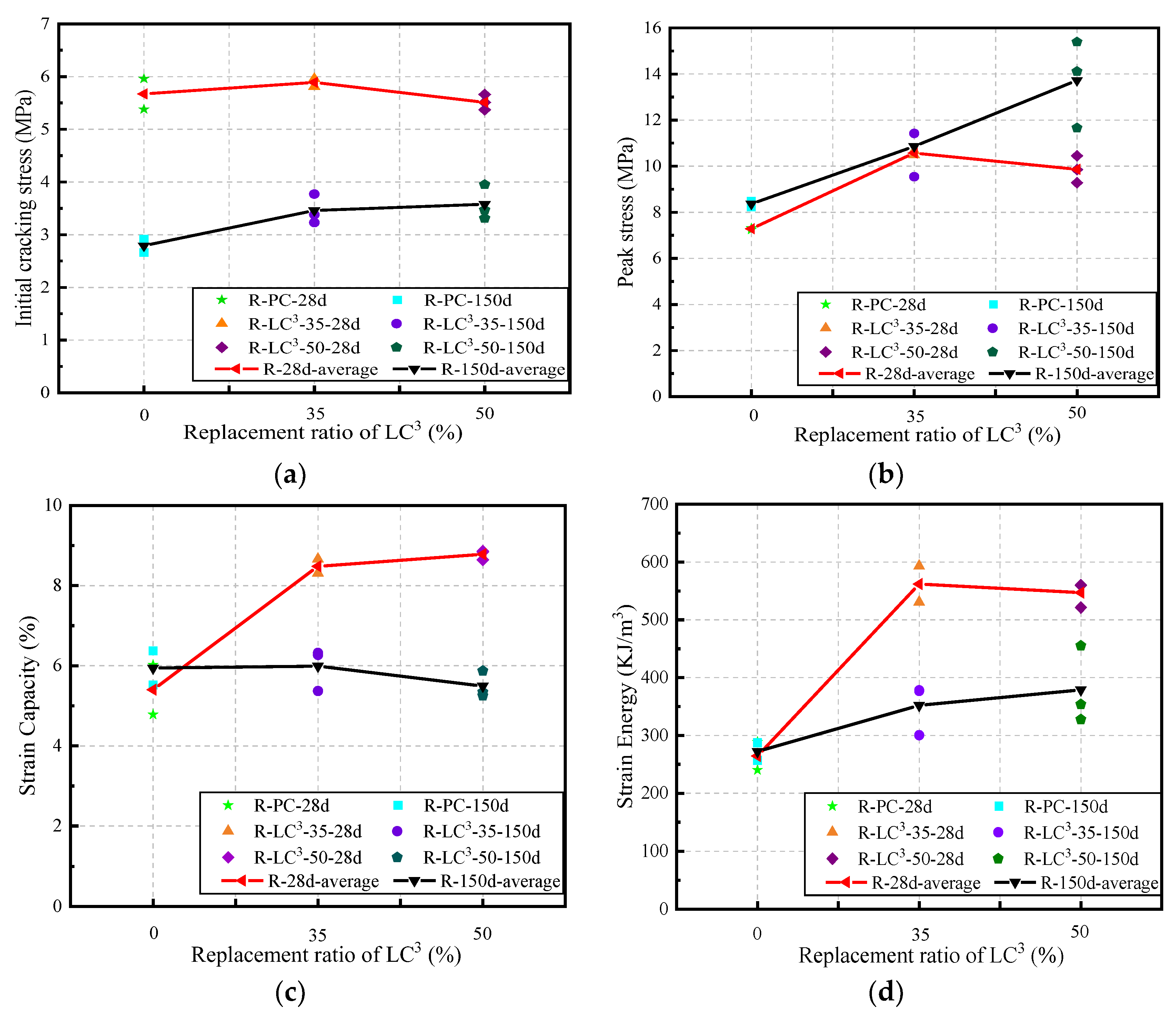

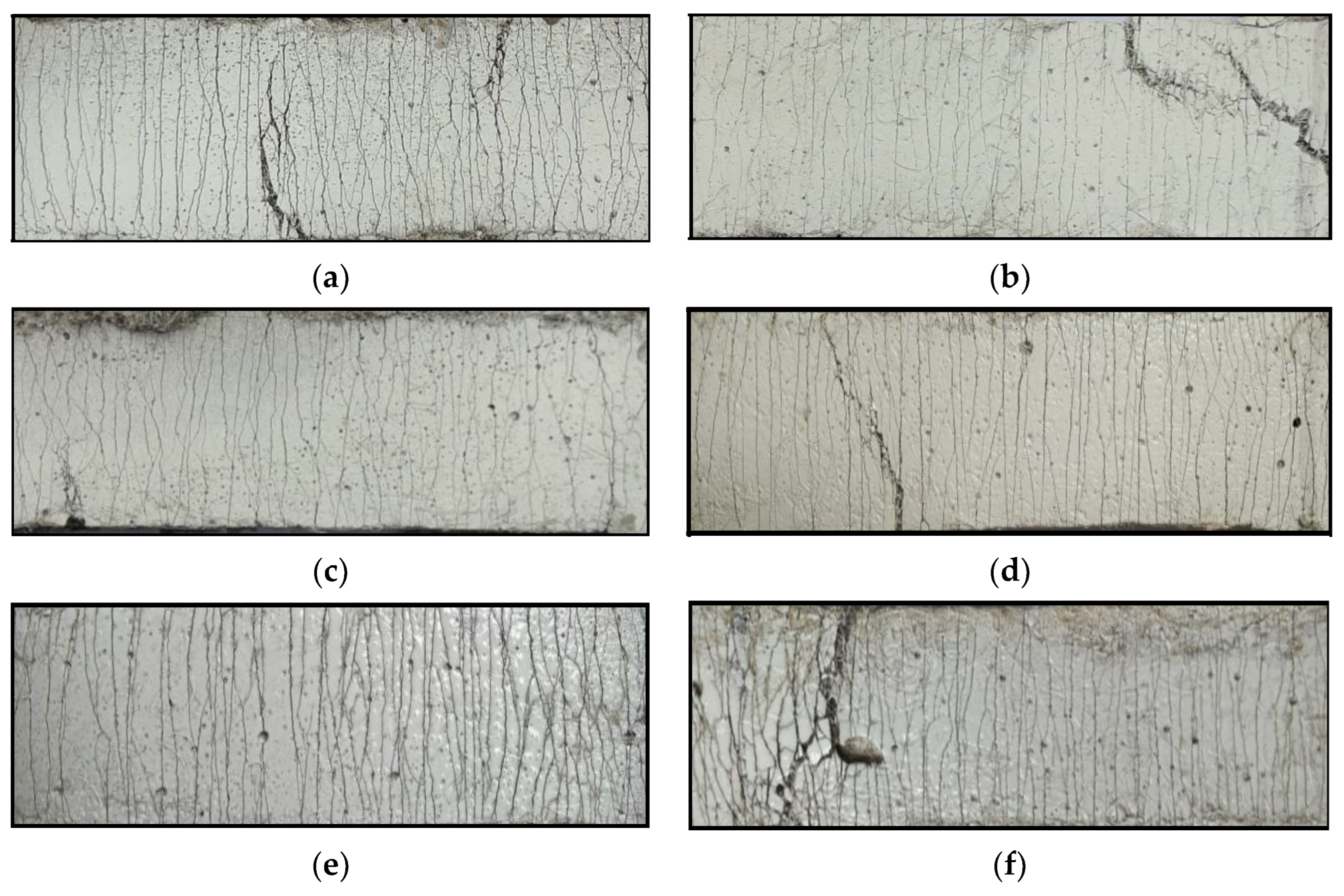

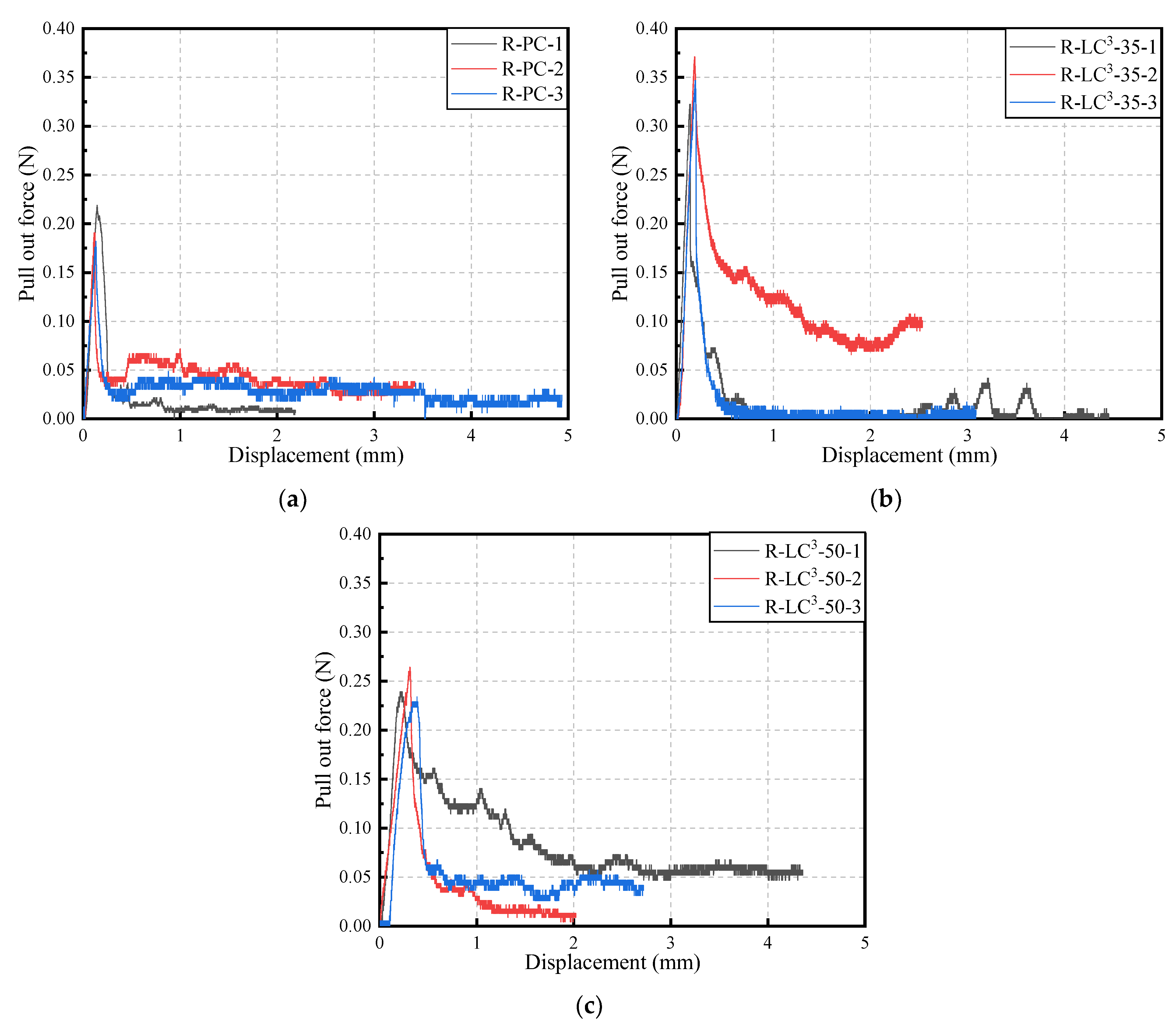

3.4. Fiber-Matrix Interface Performance

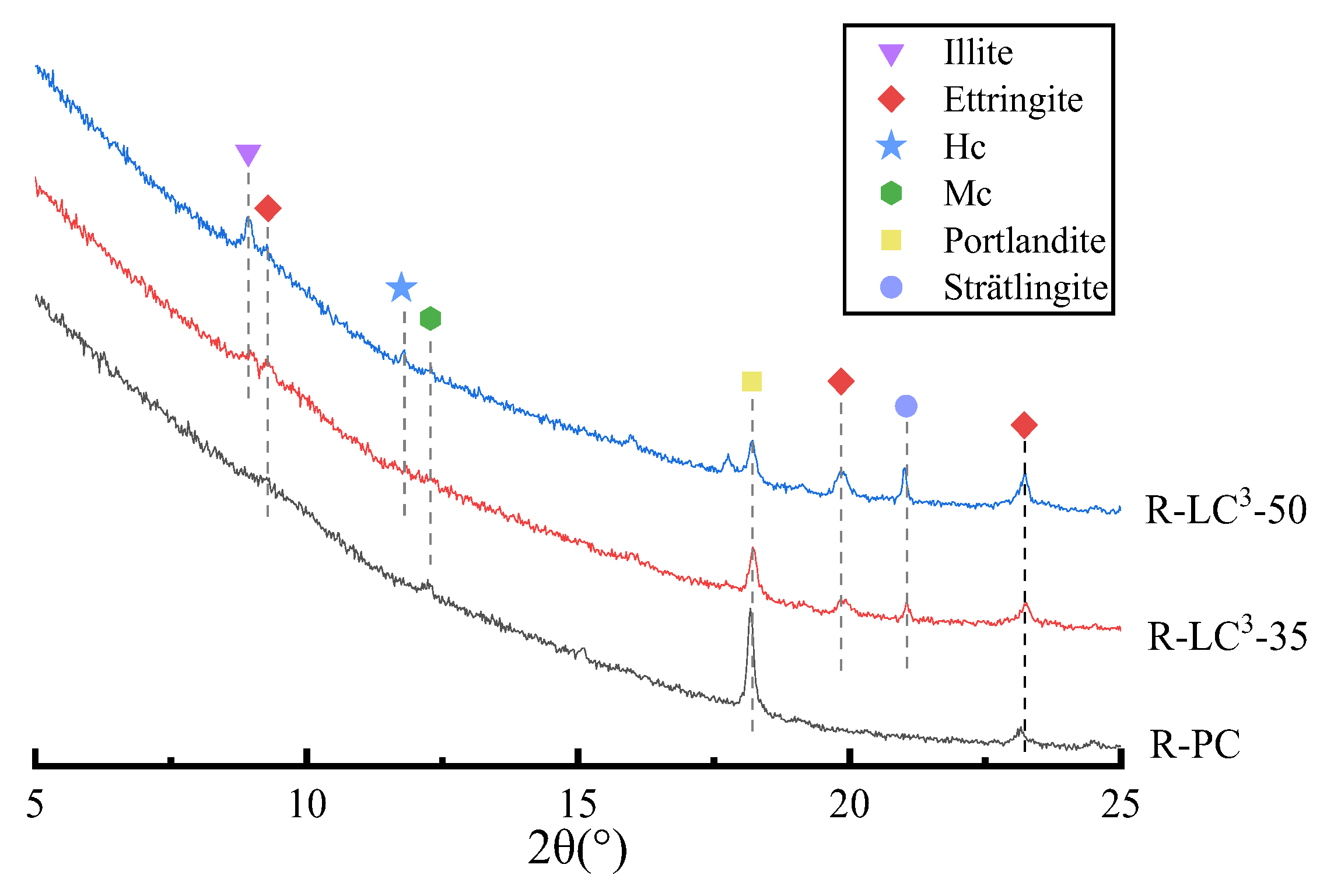

3.5. XRD Results

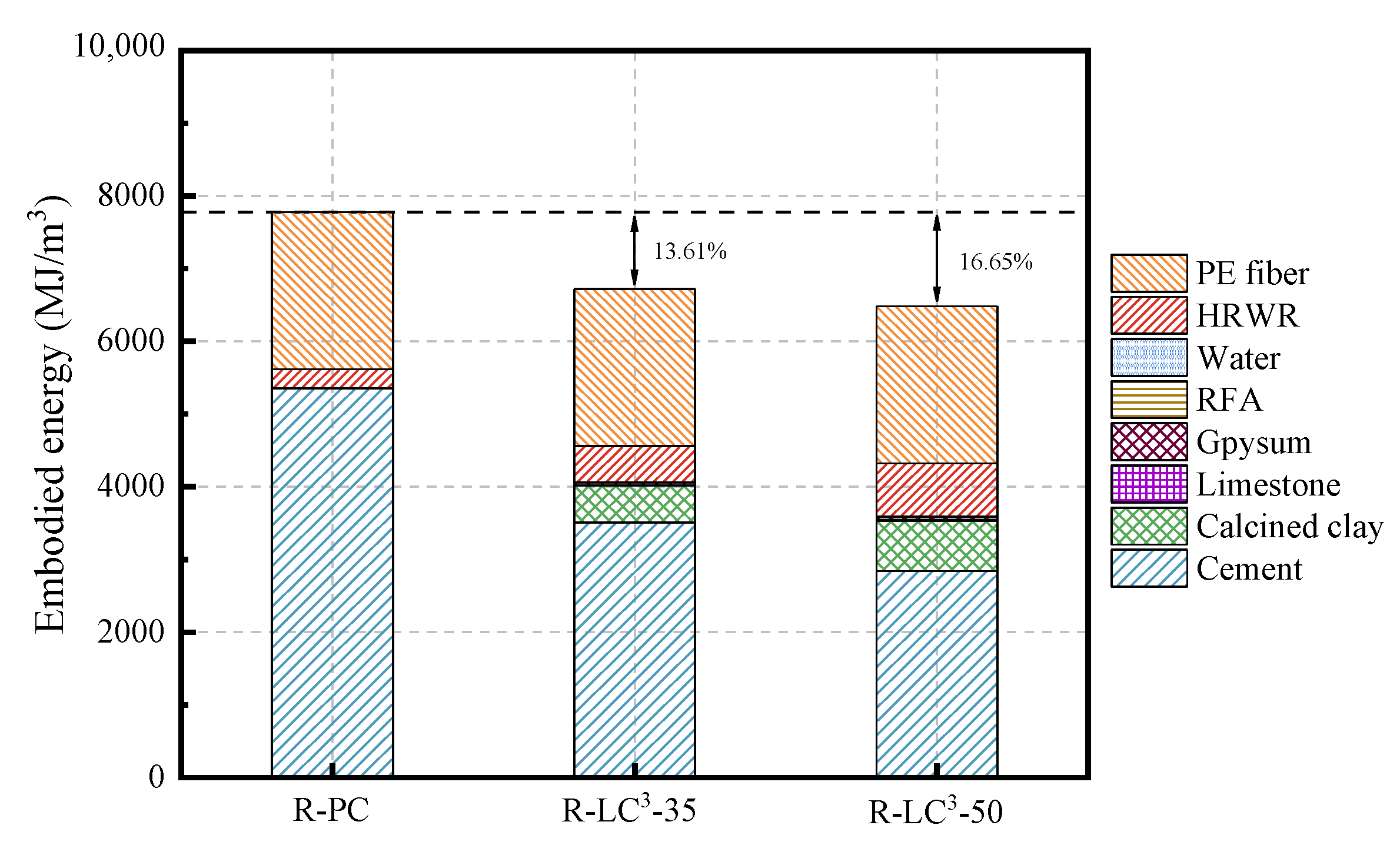

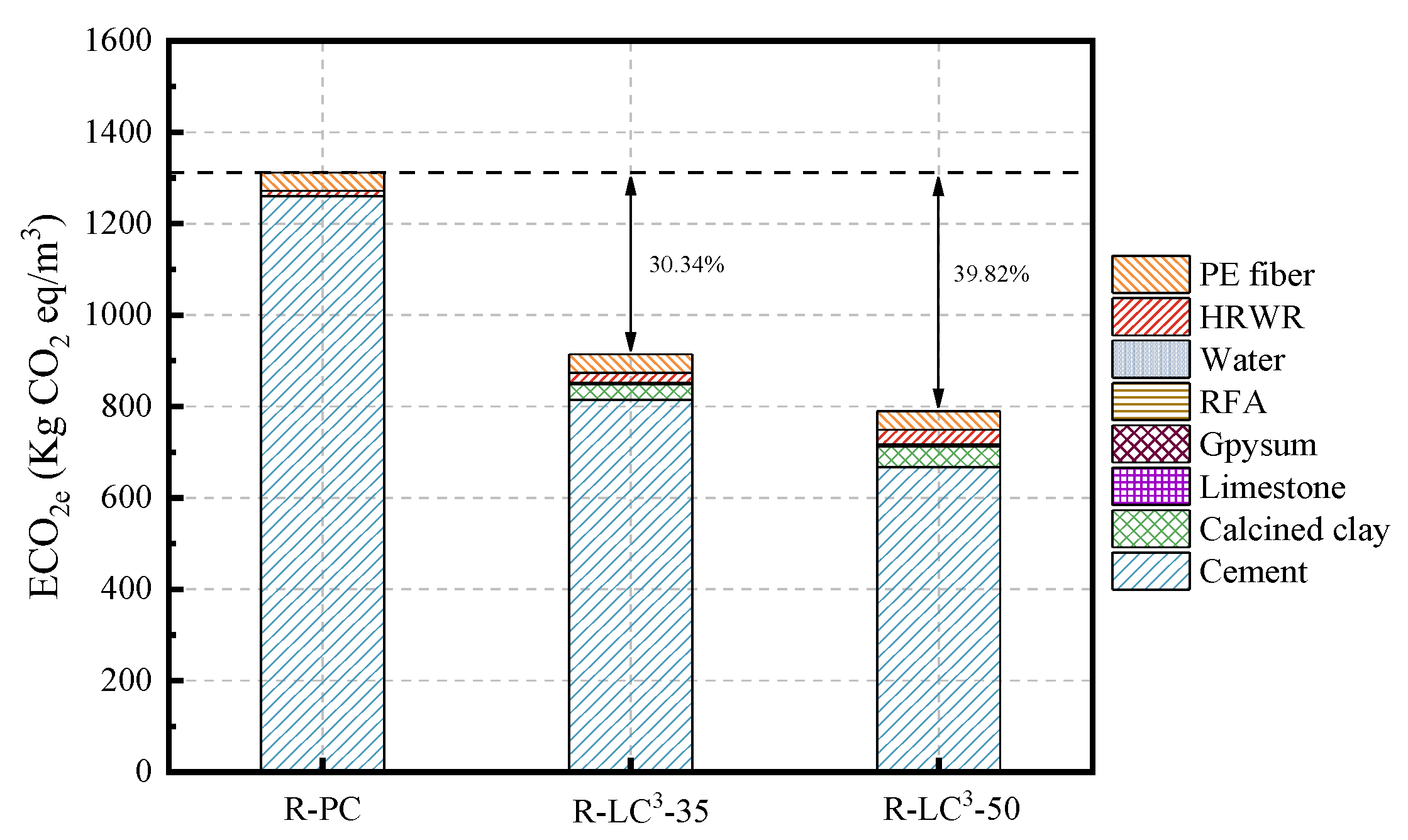

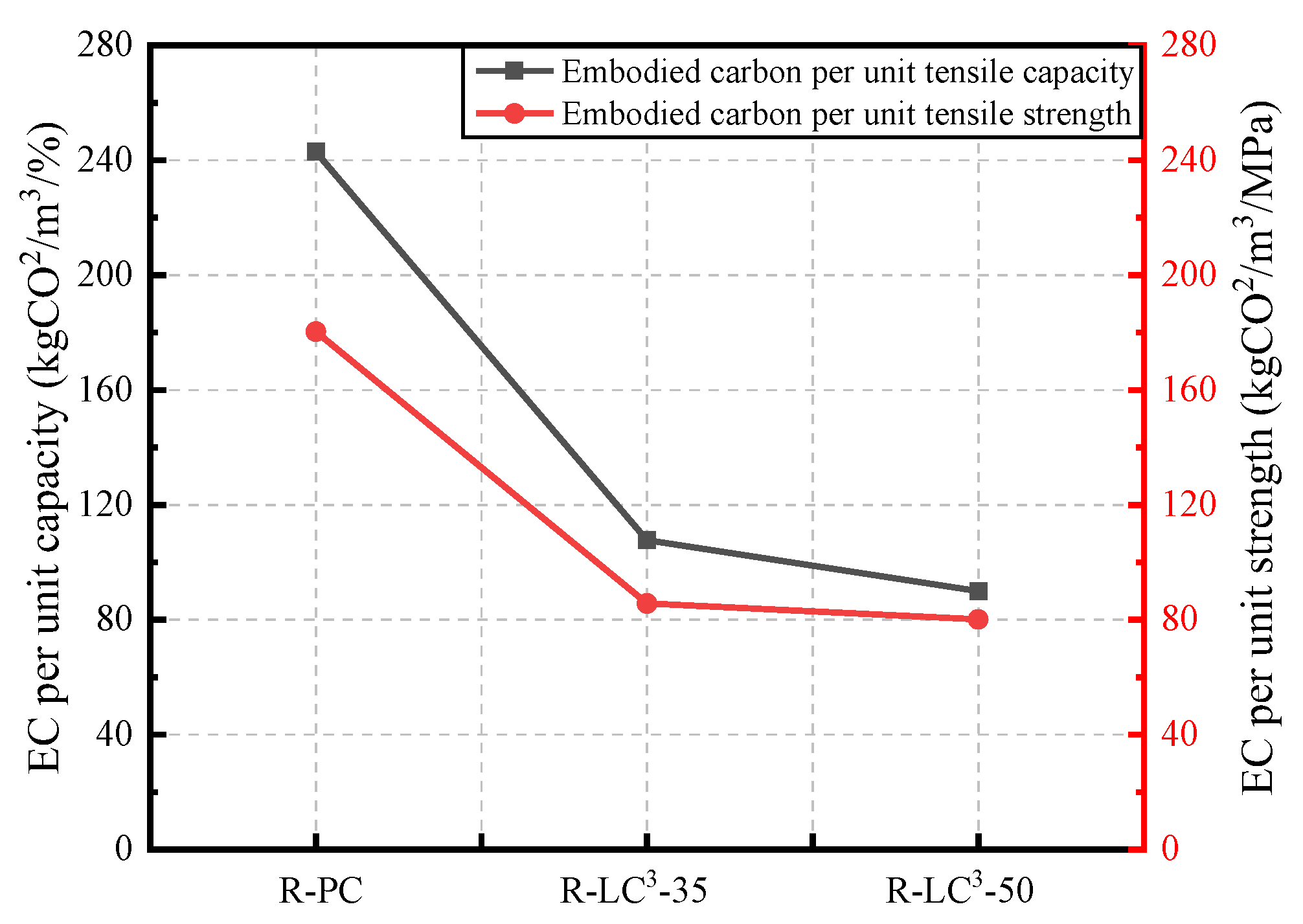

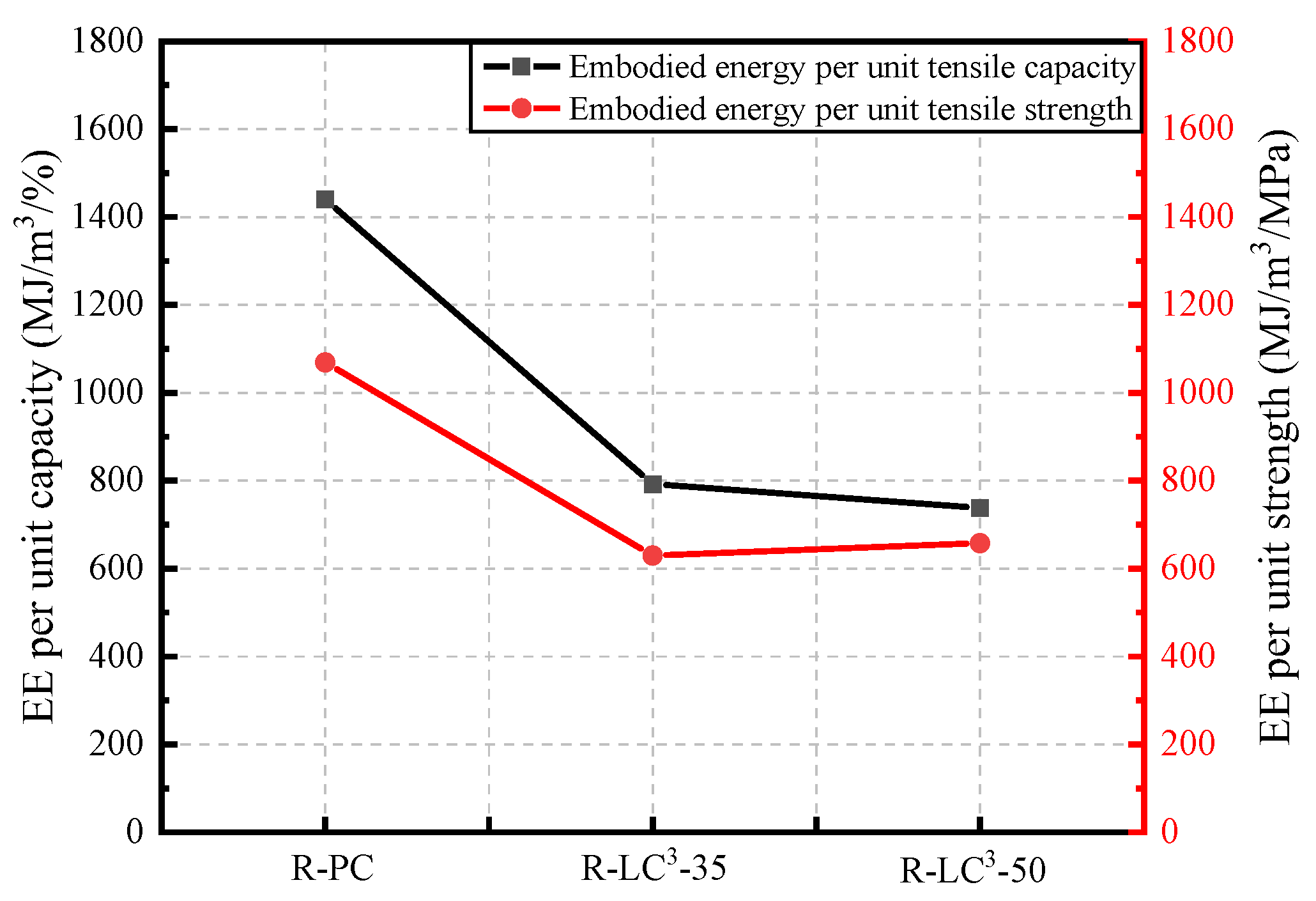

3.6. Environmental Impact Assessment

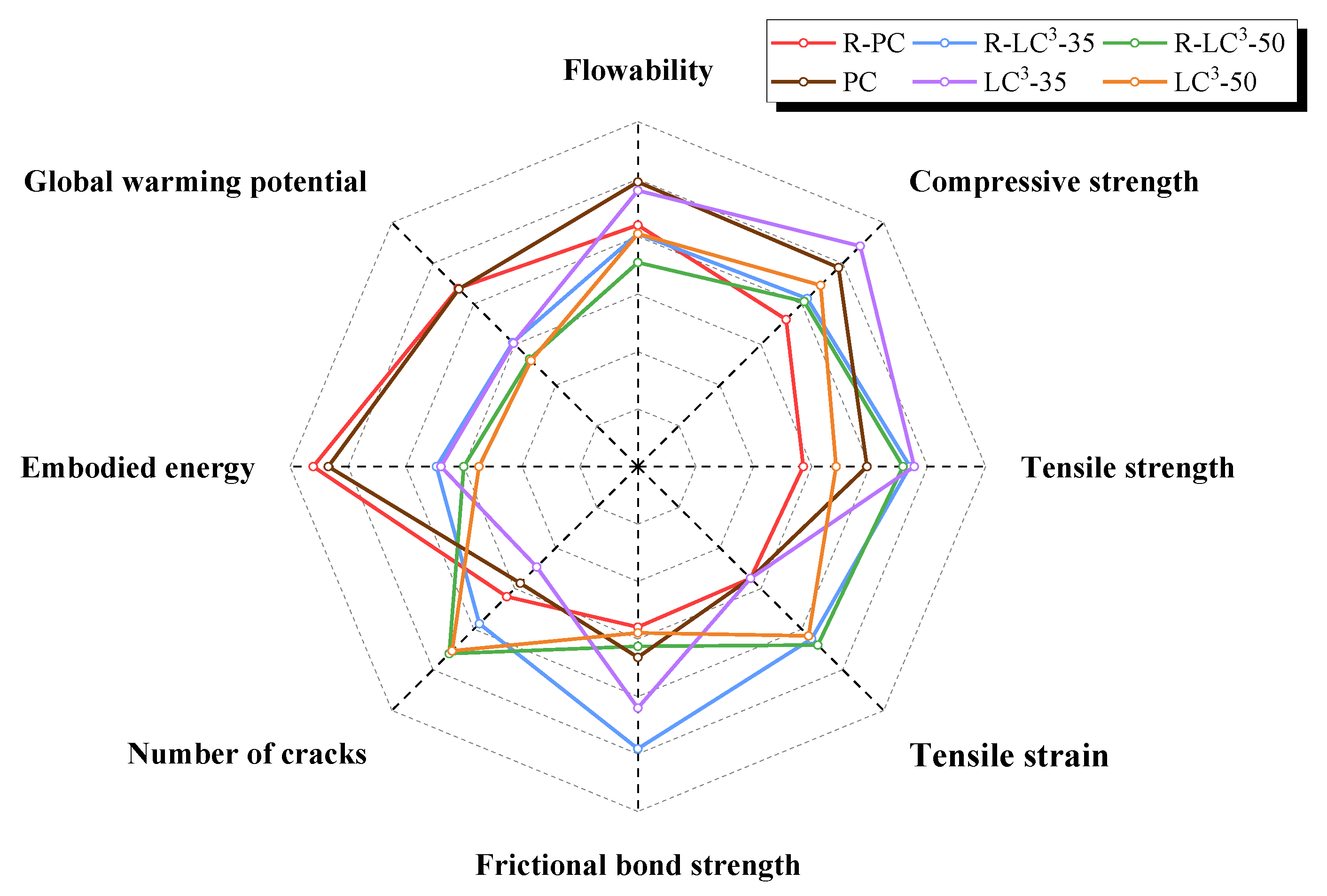

3.7. Comprehensive Performance Evaluation

4. Conclusions

- (1)

- Compared to RFA-ECC, the incorporation of LC3 increases the compressive strength, tensile strength, and tensile strain capacity. The improvement of strength could be explained by the formation of additional hydrates due to the pozzolanic activity of calcined clay as well as the refined pore structure of ECC matrix. The frictional bond strength between fiber and matrix also increases with addition of LC3.

- (2)

- At the age of 150 days, the tensile stress-strain curves of ECC containing LC3 and RFA shifted from a bilinear model to a trilinear model. The hydrophobic PE fiber exhibited hydrophilic bonding performance when embedded in RFA-LC3-ECC matrix. This phenomenon is due to the fact that the self-cementing properties of RFA lead to the formation of additional hydration products and that the frictional bonding between fiber and matrix is enhanced. The tensile ductility of LC3-ECC incorporating RFA is higher than that of LC3-ECC using quartz sand.

- (3)

- Environmental assessment revealed that the incorporation of LC3 significantly reduces the energy consumption and carbon emission. Although the usage of RFA slightly increases the values of EE and ECO2e due to the requirement of more water reducer, this impact is rather limited. By comparing the EE and ECO2e of unit tensile strength and unit tensile strain, the environmental impact of ECC incorporating LC3 and RFA is remarkably reduced, and the comprehensive properties of ECC are improved.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Q.; Li, V.C. Adhesive bonding of fire-resistive engineered cementitious composites (ECC) to steel. Constr. Build. Mater. 2014, 64, 431–439. [Google Scholar] [CrossRef]

- Zhou, J.; Qian, S.; Sierra Beltran, M.G.; Ye, G.; van Breugel, K.; Li, V.C. Development of engineered cementitious composites with limestone powder and blast furnace slag. Mater. Struct. 2010, 43, 803–814. [Google Scholar] [CrossRef]

- Qiu, J.; Yang, E. Micromechanics-based investigation of fatigue deterioration of engineered cementitious composite (ECC). Cem. Concr. Res. 2017, 95, 65–74. [Google Scholar] [CrossRef]

- Sherir, M.A.A.; Hossain, K.M.A.; Lachemi, M. The influence of MgO-type expansive agent incorporated in self-healing system of Engineered cementitious Composites. Constr. Build. Mater. 2017, 149, 164–185. [Google Scholar] [CrossRef]

- Khan, M.I.; Abbas, Y.M.; Fares, G. Review of high and ultrahigh performance cementitious composites incorporating various combinations of fibers and ultrafines. J. King Saud Univ. Eng. Sci. 2017, 29, 339–347. [Google Scholar] [CrossRef]

- Cai, J.; Pan, J.; Zhou, X. Flexural behavior of basalt FRP reinforced ECC and concrete beams. Constr. Build. Mater. 2017, 142, 423–430. [Google Scholar] [CrossRef]

- Yu, J.; Li, H.D.; Leung, C.K.Y.; Lin, X.; Lam, J.Y.K.; Sham, I.M.L.; Shih, K. Matrix design for waterproof Engineered Cementitious Composites (ECCs). Constr. Build. Mater. 2017, 139, 438–446. [Google Scholar] [CrossRef]

- Kobayashi, K.; Kojima, Y. Effect of fine crack width and water cement ratio of SHCC on chloride ingress and rebar corrosion. Cem. Concr. Compos. 2017, 80, 235–244. [Google Scholar] [CrossRef]

- Liu, J.; Tan, K.H.; Zhang, D. Multi-response optimization of post-fire performance of strain hardening cementitious composite. Cem. Concr. Compos. 2017, 80, 80–90. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, V.C. Development of durable spray-applied fire-resistive Engineered Cementitious Composites (SFR-ECC). Cem. Concr. Compos. 2015, 60, 10–16. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Q.; Li, V.; Su, H.; Gu, C. Durability study on engineered cementitious composites (ECC) under sulfate and chloride environment. Constr. Build. Mater. 2017, 133, 171–181. [Google Scholar] [CrossRef]

- Tosun-Felekoğlu, K.; Gödek, E.; Keskinateş, M.; Felekoğlu, B. Utilization and selection of proper fly ash in cost effective green HTPP-ECC design. J. Clean. Prod. 2017, 149, 557–568. [Google Scholar] [CrossRef]

- Ohno, M.; Li, V.C. An integrated design method of Engineered Geopolymer Composite. Cem. Concr. Compos. 2018, 88, 73–85. [Google Scholar] [CrossRef]

- Huang, X.; Ranade, R.; Ni, W.; Li, V.C. On the use of recycled tire rubber to develop low E-modulus ECC for durable concrete repairs. Constr. Build. Mater. 2013, 46, 134–141. [Google Scholar] [CrossRef]

- Kewalramani, M.A.; Mohamed, O.A.; Syed, Z.I. Engineered Cementitious Composites for Modern Civil Engineering Structures in Hot Arid Coastal Climatic Conditions. Proced. Eng. 2017, 180, 767–774. [Google Scholar] [CrossRef]

- Li, V.C.; Kanda, T. Engineered cementitious composites for structural applications. J. Mater. Civ. Eng. 1998, 10, 66–69. [Google Scholar] [CrossRef]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined clay limestone cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Vizcaino, L.; Sánchez, S.; Damas-Carrera, S.; Perez-Hernandez, A.; Scrivener, K.; Martirena Hernandez, J.F. Industrial trial to produce a low clinker, low carbon cement. Mater. Constr. 2015, 65, 317. [Google Scholar]

- Zhu, H.; Zhang, D.; Wang, T.; Wu, H.; Li, V.C. Mechanical and self-healing behavior of low carbon engineered cementitious composites reinforced with PP-fibers. Constr. Build. Mater. 2020, 259, 119805. [Google Scholar] [CrossRef]

- Zhang, D.; Jaworska, B.; Zhu, H.; Dahlquist, K.; Li, V.C. Engineered Cementitious Composites (ECC) with limestone calcined clay cement (LC3). Cem. Concr. Compos. 2020, 114, 103766. [Google Scholar] [CrossRef]

- Pereira, P.; Evangelista, L.; de Brito, J. The effect of superplasticizers on the mechanical performance of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2012, 34, 1044–1052. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.A.; de Brito, J.; Fiol, F. Micro- and macro-porosity of dry- and saturated-state recycled aggregate concrete. J. Clean. Prod. 2019, 211, 932–940. [Google Scholar] [CrossRef]

- Rodrigues, F.; Carvalho, M.T.; Evangelista, L.; de Brito, J. Physical–chemical and mineralogical characterization of fine aggregates from construction and demolition waste recycling plants. J. Clean. Prod. 2013, 52, 438–445. [Google Scholar] [CrossRef]

- Bogas, J.A.; de Brito, J.; Ramos, D. Freeze–thaw resistance of concrete produced with fine recycled concrete aggregates. J. Clean. Prod. 2016, 115, 294–306. [Google Scholar] [CrossRef]

- Long, W.; Zheng, D.; Duan, H.; Han, N.; Xing, F. Performance enhancement and environmental impact of cement composites containing graphene oxide with recycled fine aggregates. J. Clean. Prod. 2018, 194, 193–202. [Google Scholar] [CrossRef]

- Poon, C.; Qiao, X.C.; Chan, D. The cause and influence of self-cementing properties of fine recycled concrete aggregates on the properties of unbound sub-base. Waste Manag. 2006, 26, 1166–1172. [Google Scholar] [CrossRef] [PubMed]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Use of recycled aggregates arising from construction and demolition waste in new construction applications. J. Clean. Prod. 2019, 236, 117629. [Google Scholar] [CrossRef]

- Li, J.; Yang, E. Macroscopic and microstructural properties of engineered cementitious composites incorporating recycled concrete fines. Cem. Concr. Compos. 2017, 78, 33–42. [Google Scholar] [CrossRef]

- Wu, H.; Yu, J.; Zhang, D.; Zheng, J.; Li, V.C. Effect of morphological parameters of natural sand on mechanical properties of engineered cementitious composites. Cem. Concr. Compos. 2019, 100, 108–119. [Google Scholar] [CrossRef]

- Çelik, A.İ.; Özkılıç, Y.O.; Zeybek, Ö.; Karalar, M.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Bejinariu, C. Mechanical Behavior of Crushed Waste Glass as Replacement of Aggregates. Materials 2022, 15, 8093. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Al Dughaishi, H.; Alosta, M.; Sabri, M.M.; Alkhatib, F.; Milad, A. Concrete Containing Waste Glass as an Environmentally Friendly Aggregate: A Review on Fresh and Mechanical Characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef]

- Zeybek, Ö.; Özkılıç, Y.O.; Karalar, M.; Çelik, A.O.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Burduhos-Nergis, D.P. Influence of Replacing Cement with Waste Glass on Mechanical Properties of Concrete. Materials 2022, 15, 7513. [Google Scholar] [CrossRef] [PubMed]

- Karalar, M.; Bilir, T.; Çavuşlu, M.; Özkılıç, Y.; Sabri, M. Use of Recycled Coal Bottom Ash in Reinforced Concrete Beams as Replacement for Aggregate. Front. Mater. 2022, 9, 1064604. [Google Scholar] [CrossRef]

- Fayed, S.; Madenci, E.; Özkılıç, Y.; Mansour, W. Improving bond performance of ribbed steel bars embedded in recycled aggregate concrete using steel mesh fabric confinement. Constr. Build. Mater. 2023, 369, 130452. [Google Scholar] [CrossRef]

- Qaidi, S.; Al-Kamaki, Y.; Hakeem, I.; Dulaimi, A.; Özkılıç, Y.; Sabri, M.; Sergeev, V. Investigation of the physical-mechanical properties and durability of high-strength concrete with recycled PET as a partial replacement for fine aggregates. Front. Mater. 2023, 10, 1101146. [Google Scholar] [CrossRef]

- Zhou, Y.; Gong, G.; Huang, Y.; Chen, C.; Huang, D.; Chen, Z.; Guo, M. Feasibility of incorporating recycled fine aggregate in high performance green lightweight engineered cementitious composites. J. Clean. Prod. 2021, 280, 124445. [Google Scholar] [CrossRef]

- Zhou, Y.; Zheng, S.; Huang, X.; Xi, B.; Huang, Z.; Guo, M. Performance enhancement of green high-ductility engineered cementitious composites by nano-silica incorporation. Constr. Build. Mater. 2021, 281, 122618. [Google Scholar] [CrossRef]

- Krishnan, S.; Bishnoi, S. A numerical approach for designing composite cements with calcined clay and limestone. Cem. Concr. Res. 2020, 138, 106232. [Google Scholar] [CrossRef]

- Yokota, H.; Rokugo, K.; Sakata, N. JSCE Recommendations for Design and Construction of High Performance Fiber Reinforced Cement Composite with Multiple Fine Cracks. In High Performance Fiber Reinforced Cement Composites; Springer: Tokyo, Japan, 2008; Volume 2. [Google Scholar]

- Lu, Z.; Yao, J.; Leung, C.K.Y. Using graphene oxide to strengthen the bond between PE fiber and matrix to improve the strain hardening behavior of SHCC. Cem. Concr. Res. 2019, 126, 105899. [Google Scholar] [CrossRef]

- Gu, Y.; Li, J.; Peng, J.; Xing, F.; Long, W.; Khayat, K.H. Immobilization of hazardous ferronickel slag treated using ternary limestone calcined clay cement. Constr. Build. Mater. 2020, 250, 118837. [Google Scholar] [CrossRef]

- Zhang, D.; Yu, J.; Wu, H.; Jaworska, B.; Ellis, B.R.; Li, V.C. Discontinuous micro-fibers as intrinsic reinforcement for ductile Engineered Cementitious Composites (ECC). Compos. Part B Eng. 2020, 184, 107741. [Google Scholar] [CrossRef]

- Gong, G.; Guo, M.; Zhou, Y.; Zheng, S.; Hu, B.; Zhu, Z.; Huang, Z. Multiscale Investigation on the Performance of Engineered Cementitious Composites Incorporating PE Fiber and Limestone Calcined Clay Cement (LC3). Polymers 2022, 14, 1291. [Google Scholar] [CrossRef] [PubMed]

- Tsivilis, S.; Batis, G.; Chaniotakis, E.; Grigoriadis, G.; Theodossis, D. Properties and behavior of limestone cement concrete and mortar. Cem. Concr. Res. 2000, 30, 1679–1683. [Google Scholar] [CrossRef]

- Sahmaran, M.; Li, M.; Li, V. Transport Properties of Engineered Cementitious Composites Under Chloride Exposure. ACI Mater. J. 2011, 104, 604–611. [Google Scholar]

- Yang, Y.; Yang, E.; Li, V.C. Autogenous healing of engineered cementitious composites at early age. Cem. Concr. Res. 2011, 41, 176–183. [Google Scholar] [CrossRef]

- Marshall, D.B.; Cox, B.N.; Evans, A.G. The mechanics of matrix cracking in brittle-matrix fiber composites. Acta Metall. 1985, 33, 2013–2021. [Google Scholar] [CrossRef]

- Redon, C.; Li, V.; Wu, C.; Hoshiro, H.; Saito, T.; Ogawa, A. Measuring and Modifying Interface Properties of PVA Fibers in ECC Matrix. J. Mater. Civil Eng. 2001, 13, 399–406. [Google Scholar] [CrossRef]

| Mixture Type | Cement | Calcined Clay | Gypsum | Effective Water | Limestone | RFA | PE | HRWRA |

|---|---|---|---|---|---|---|---|---|

| R-PC | 1382 | 0 | 0 | 328 | 0 | 500 | 20 | 9 |

| R-LC3-35 | 905 | 304 | 21 | 328 | 152 | 500 | 20 | 17 |

| R-LC3-50 | 732 | 415 | 28 | 328 | 207 | 500 | 20 | 25 |

| Property | Cement | Calcined Clay | Gypsum | Limestone |

|---|---|---|---|---|

| MgO (%) | 1.775 | 0.307 | 3.394 | 0.769 |

| Na2O (%) | 0.281 | - | - | - |

| Al2O3 (%) | 3.509 | 39.405 | 5.828 | 0.130 |

| SiO2 (%) | 15.406 | 53.732 | 14.046 | 0.309 |

| P2O5 (%) | 0.065 | 0.037 | 0.050 | - |

| SO3 (%) | 4.212 | 0.087 | 35.867 | - |

| K2O (%) | 0.0950 | 4.229 | 1.403 | 0.040 |

| CaO (%) | 69.862 | 0.102 | 37.048 | 98.715 |

| Fe2O3 (%) | 3.741 | 2.056 | 2.032 | - |

| CuO (%) | 0.029 | - | - | - |

| ZnO (%) | 0.100 | - | - | - |

| SrO (%) | 0.070 | - | 0.333 | 0.037 |

| Rb2O (%) | - | 0.037 | - | - |

| Y2O3 (%) | - | 0.001 | - | - |

| ZrO2 (%) | - | 0.008 | - | - |

| Property | Value |

|---|---|

| Length Lf, mm | 18 |

| Diameter df, µm | 25 |

| Aspect ratio Lf/df | 720 |

| Fiber strength, MPa | 2900 |

| Modulus of elasticity, GPa | 116 |

| Specific gravity, g/cm3 | 0.97 |

| Melting temperature, °C | 150 |

| Material | Data for Each Material | |

|---|---|---|

| EE (MJ/kg) | ECO2e (kg CO2 eq/kg) | |

| Superplasticizer [41] | 29.42 | 1.309 |

| RFA [25] | 0.0034 | 0.0003 |

| PE [42] | 108 | 2.0 |

| Mixture ID | Average Value (mm) |

|---|---|

| R-PC | 144 |

| R-LC3–35 | 141 |

| R-LC3–50 | 134 |

| Sample | R-PC-28d | R-LC3-35-28d | R-LC3-50-28d | R-PC-150d | R-LC3-35-150d | R-LC3-50-150d |

|---|---|---|---|---|---|---|

| Nc | 48 ± 4 | 58 ± 3 | 69 ± 7 | 35 ± 4 | 44 ± 3 | 53 ± 6 |

| Wc/μm | 93 ± 7 | 117 ± 6 | 103 ± 9 | 137 ± 15 | 110 ± 7 | 86 ± 9 |

| Sc/mm | 1.68 ± 0.14 | 1.38 ± 0.07 | 1.17 ± 0.12 | 2.32 ± 0.27 | 1.83 ± 0.13 | 1.53 ± 0.17 |

| Mixtures ID | Average Value | Standard Deviation |

|---|---|---|

| R-PC | 0.419 | 0.041 |

| R-LC3–35 | 0.736 | 0.052 |

| R-LC3–50 | 0.469 | 0.057 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Guo, W.; Zheng, S.; Xing, F.; Guo, M.; Zhu, Z. Development of Sustainable Engineered Cementitious Composites by Incorporating Local Recycled Fine Aggregate. Polymers 2023, 15, 2701. https://doi.org/10.3390/polym15122701

Zhou Y, Guo W, Zheng S, Xing F, Guo M, Zhu Z. Development of Sustainable Engineered Cementitious Composites by Incorporating Local Recycled Fine Aggregate. Polymers. 2023; 15(12):2701. https://doi.org/10.3390/polym15122701

Chicago/Turabian StyleZhou, Yingwu, Wenhui Guo, Shuyue Zheng, Feng Xing, Menghuan Guo, and Zhongfeng Zhu. 2023. "Development of Sustainable Engineered Cementitious Composites by Incorporating Local Recycled Fine Aggregate" Polymers 15, no. 12: 2701. https://doi.org/10.3390/polym15122701

APA StyleZhou, Y., Guo, W., Zheng, S., Xing, F., Guo, M., & Zhu, Z. (2023). Development of Sustainable Engineered Cementitious Composites by Incorporating Local Recycled Fine Aggregate. Polymers, 15(12), 2701. https://doi.org/10.3390/polym15122701