Recent Advances in Flexible Piezoresistive Arrays: Materials, Design, and Applications

Abstract

1. Introduction

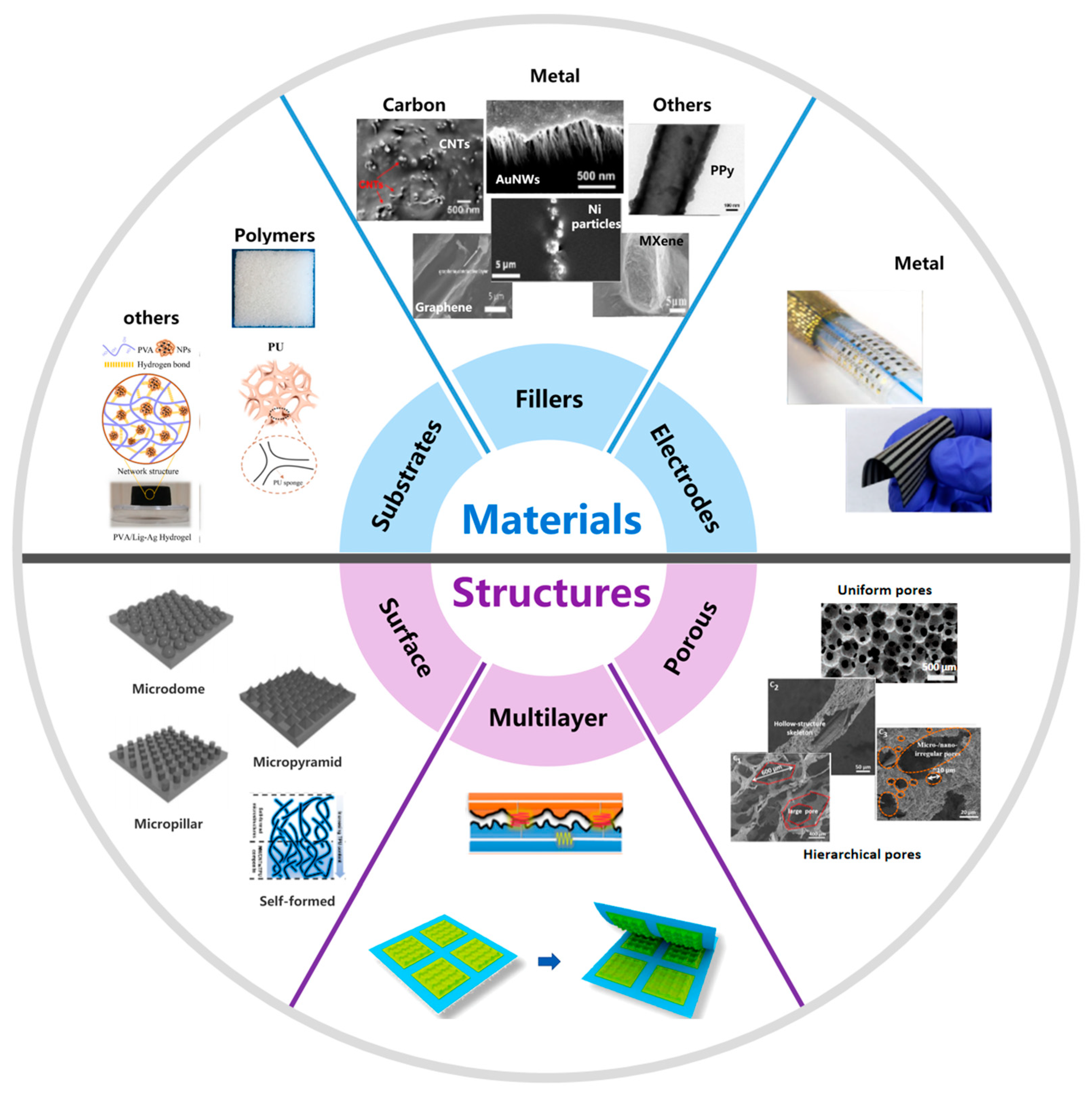

2. Piezoresistive Materials and Microstructures

2.1. Performance Metrics of Pressure Sensors

2.2. Piezoresistive Materials and Microstructure Design

3. Piezoresistive Array Design and Fabrication

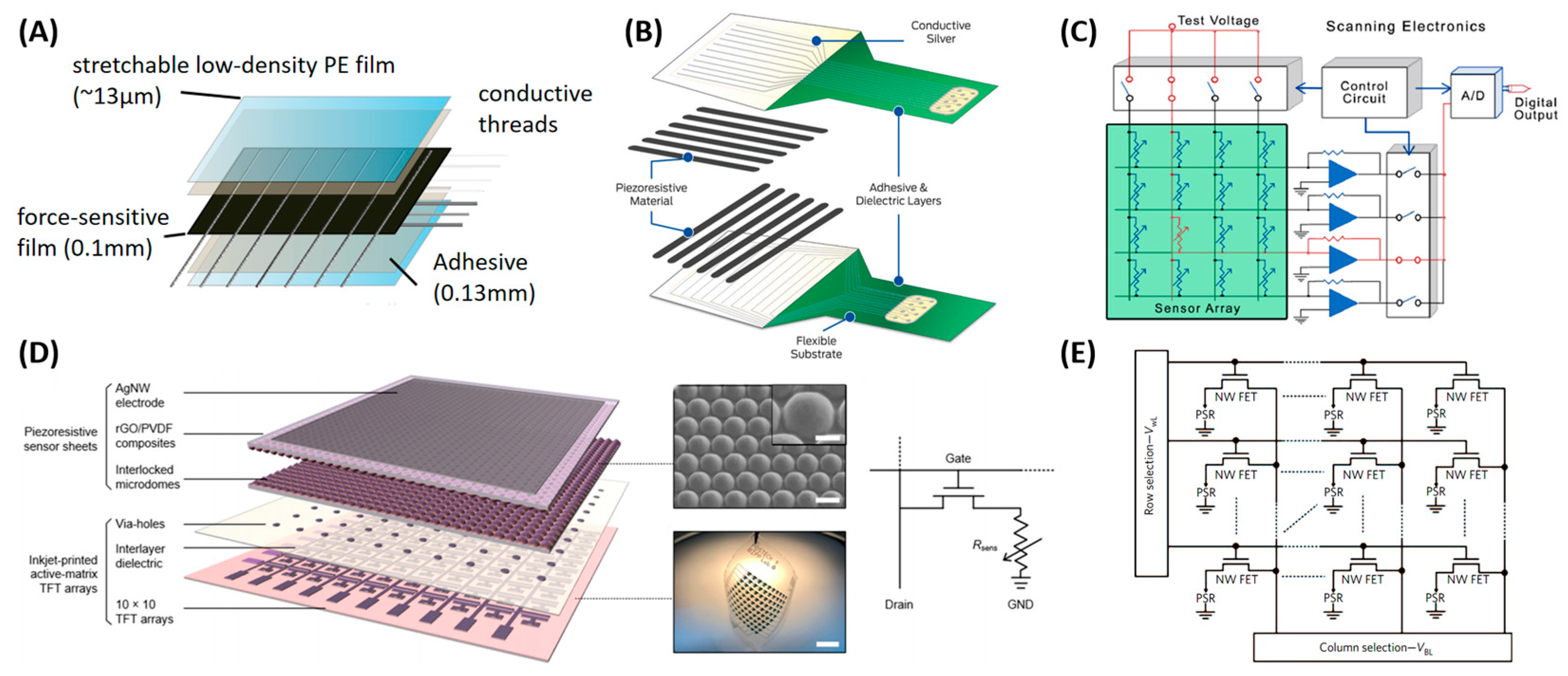

3.1. Design

3.1.1. Passive and Active Arrays

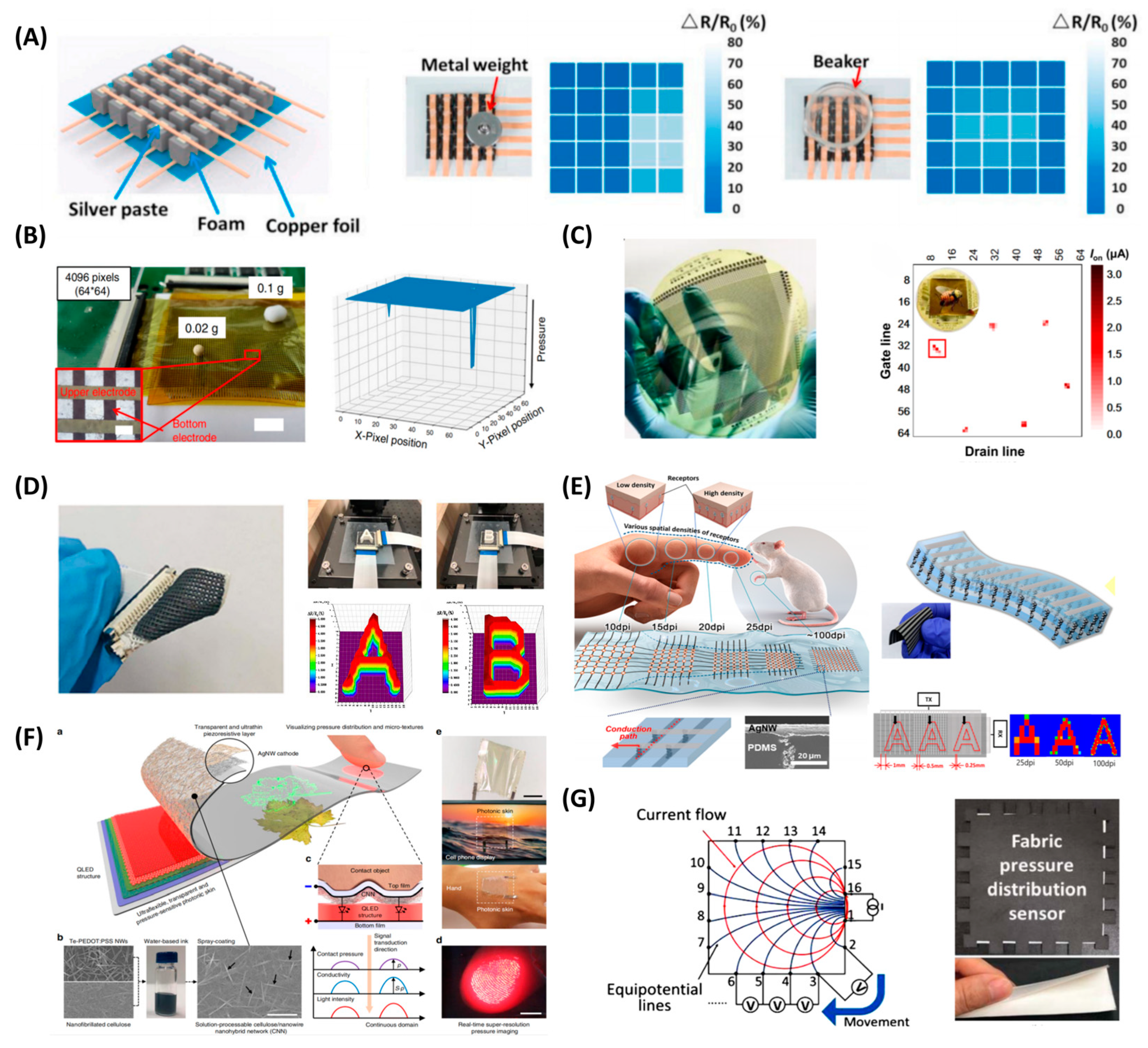

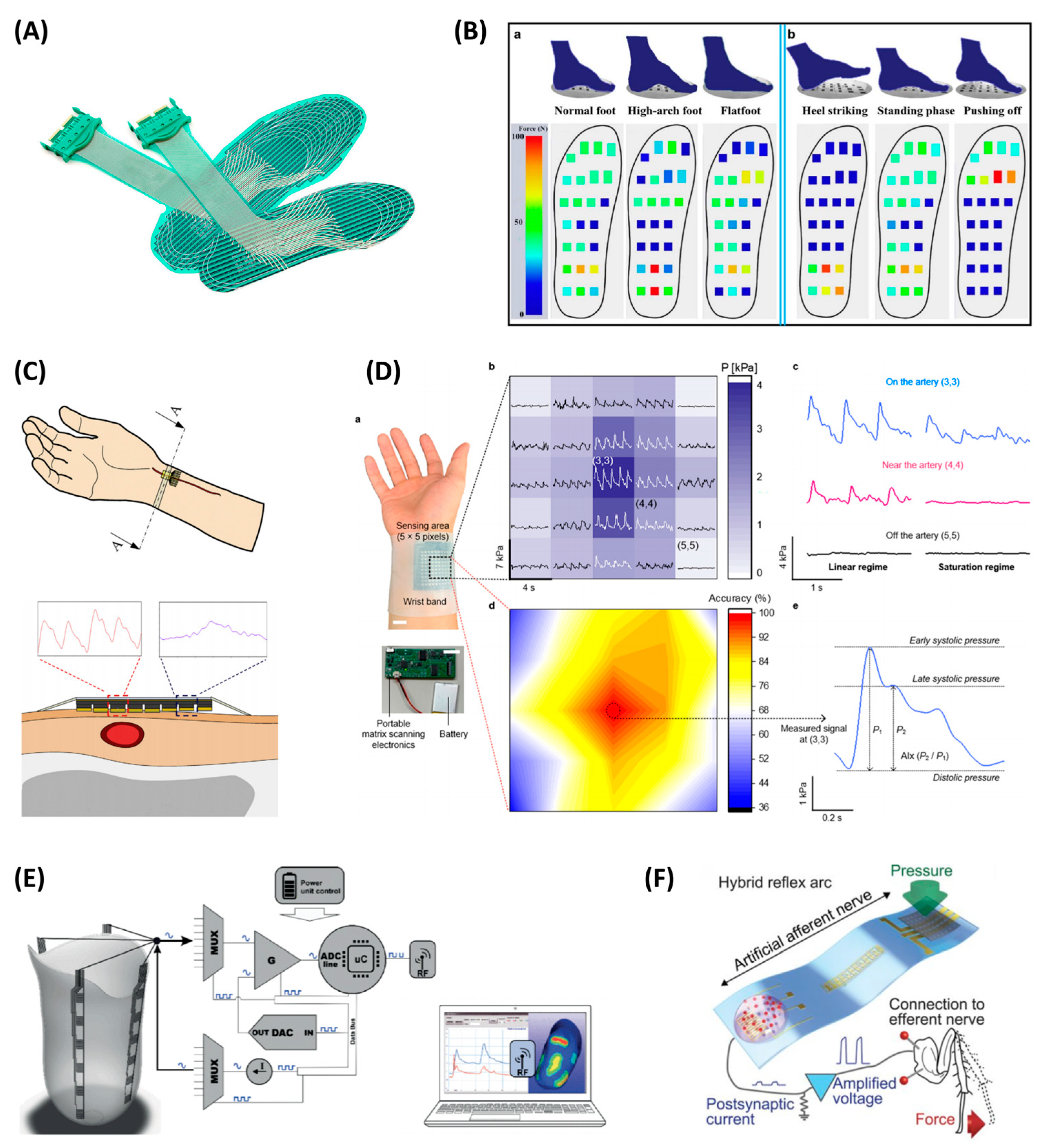

3.1.2. Structure Designs and Measuring Mechanisms

3.1.3. Crosstalk and Suppression

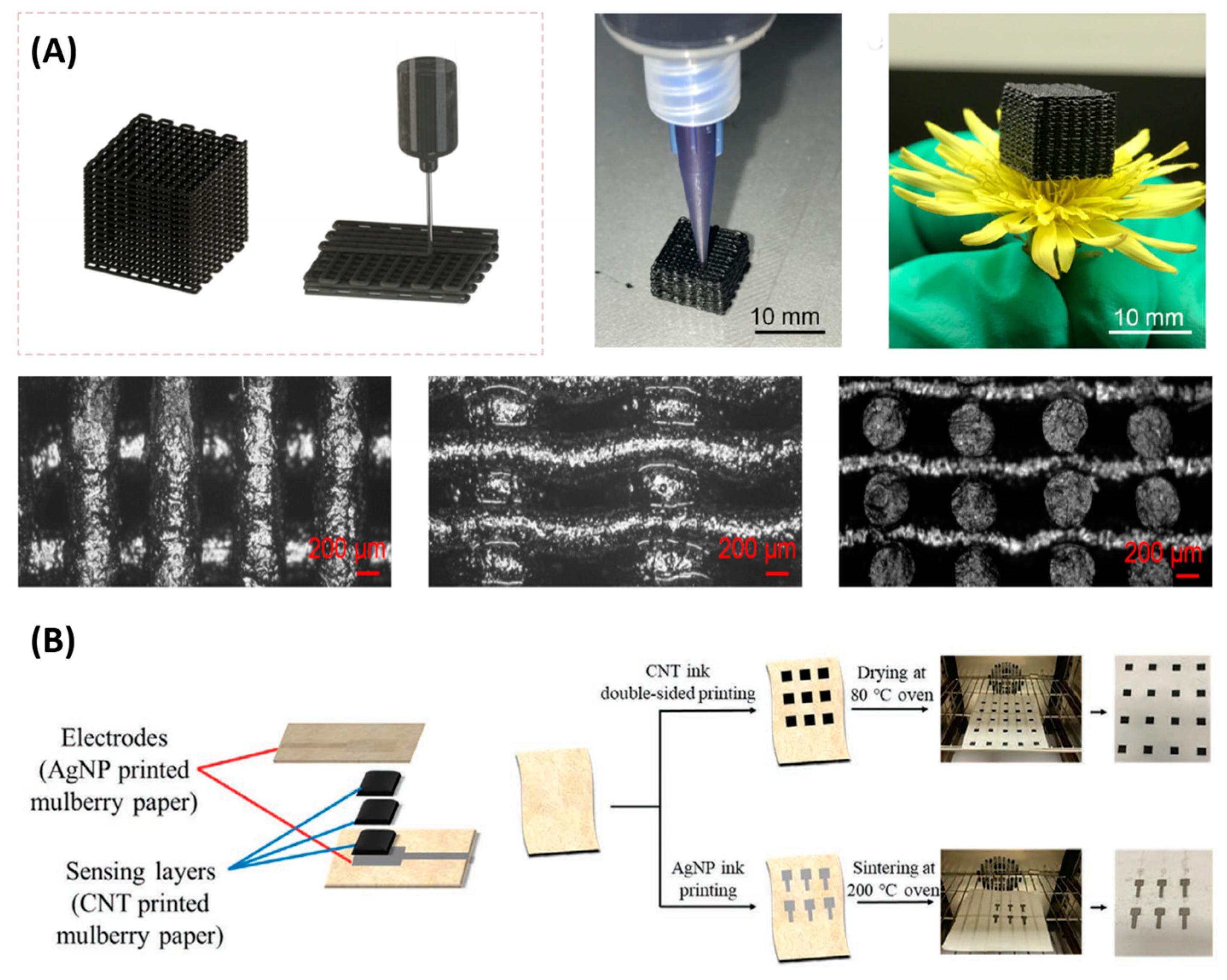

3.2. Fabrication Strategies

3.2.1. Printing

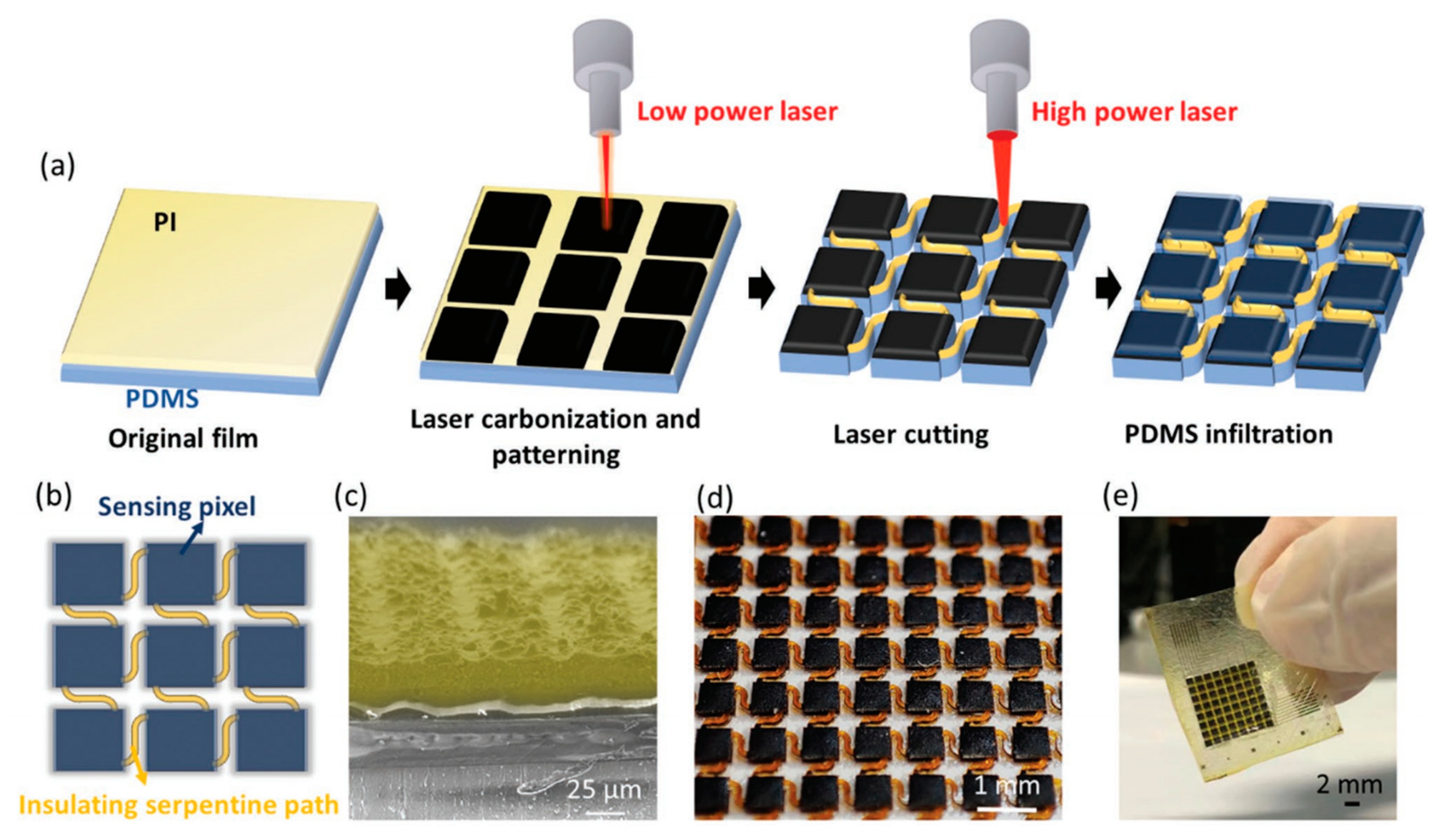

3.2.2. Field-Assisted Processing

3.2.3. Laser-Assisted Processing

4. Applications

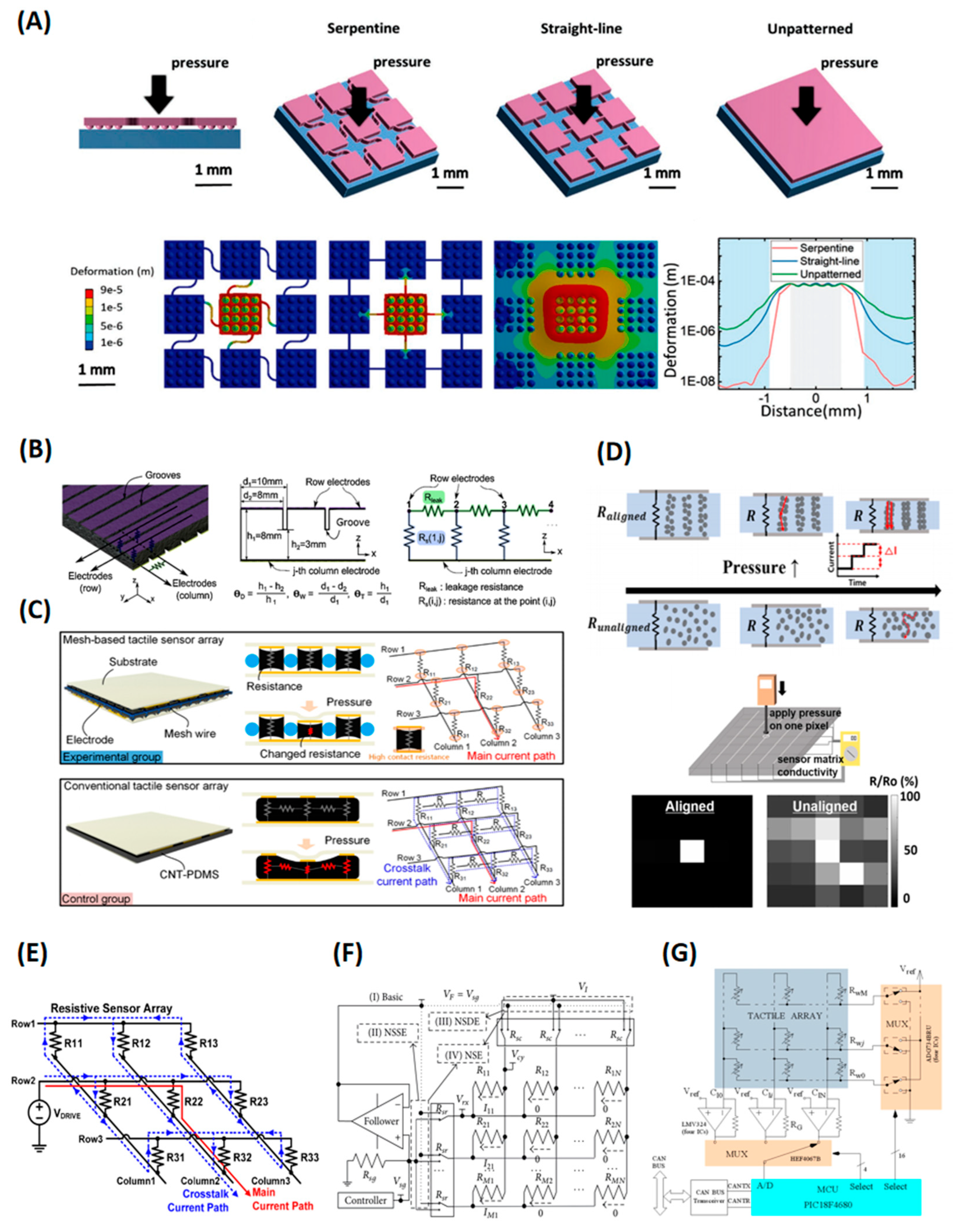

4.1. Human-Interactive System

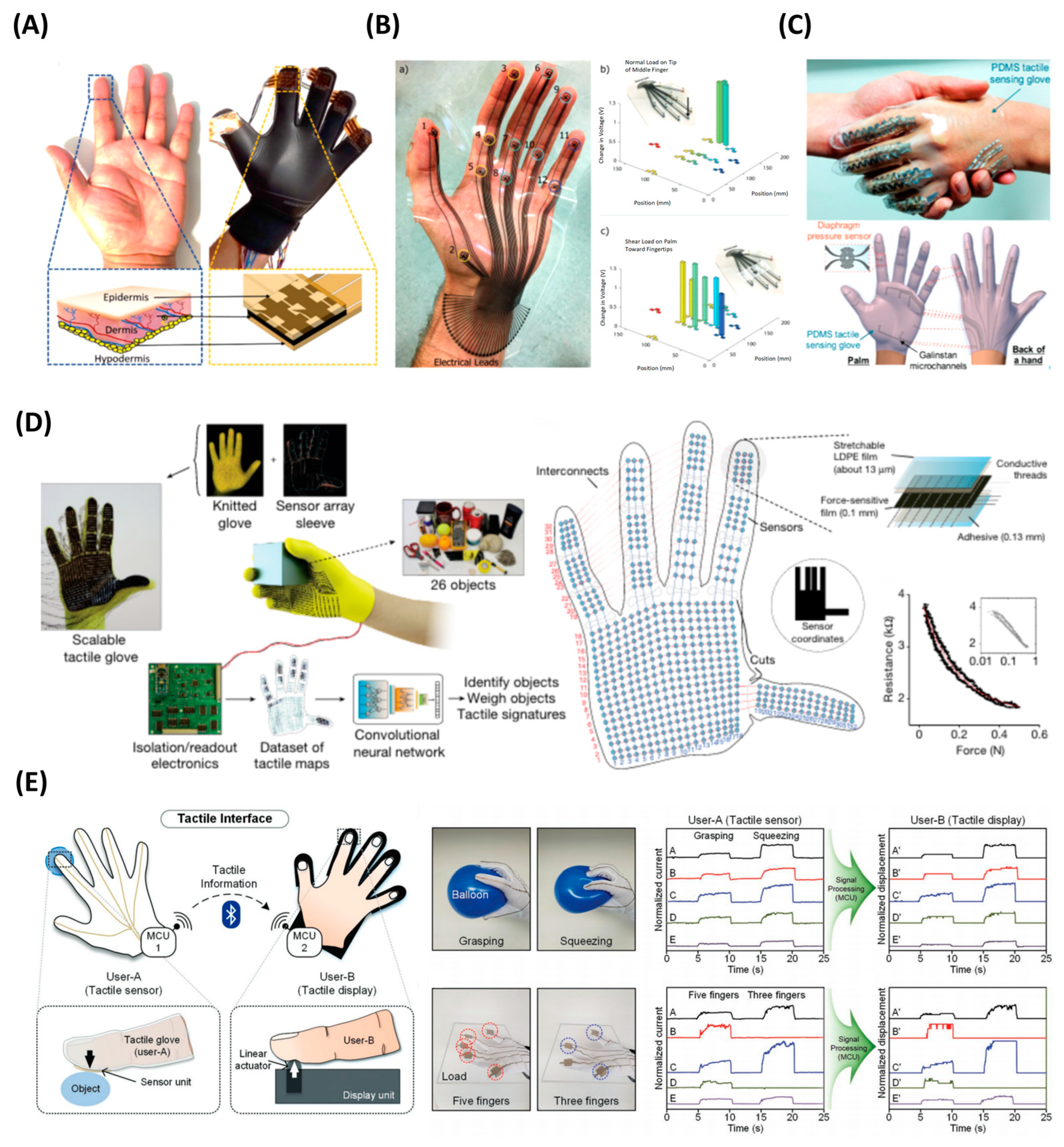

4.2. Healthcare

4.3. Others

5. Conclusions and Outlooks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Oh, H.; Yi, G.-C.; Yip, M.; Dayeh, S.A. Scalable Tactile Sensor Arrays on Flexible Substrates with High Spatiotemporal Resolution Enabling Slip and Grip for Closed-Loop Robotics. Sci. Adv. 2020, 6, eabd7795. [Google Scholar] [CrossRef]

- Qu, X.; Liu, Z.; Tan, P.; Wang, C.; Liu, Y.; Feng, H.; Luo, D.; Li, Z.; Wang, Z.L. Artificial Tactile Perception Smart Finger for Material Identification Based on Triboelectric Sensing. Sci. Adv. 2022, 8, eabq2521. [Google Scholar] [CrossRef] [PubMed]

- Yin, R.; Wang, D.; Zhao, S.; Lou, Z.; Shen, G. Wearable Sensors-Enabled Human–Machine Interaction Systems: From Design to Application. Adv. Funct. Mater. 2021, 31, 2008936. [Google Scholar] [CrossRef]

- Sundaram, S.; Kellnhofer, P.; Li, Y.; Zhu, J.-Y.; Torralba, A.; Matusik, W. Learning the Signatures of the Human Grasp Using a Scalable Tactile Glove. Nature 2019, 569, 698–702. [Google Scholar] [CrossRef]

- Baek, S.; Lee, Y.; Baek, J.; Kwon, J.; Kim, S.; Lee, S.; Strunk, K.-P.; Stehlin, S.; Melzer, C.; Park, S.-M.; et al. Spatiotemporal Measurement of Arterial Pulse Waves Enabled by Wearable Active-Matrix Pressure Sensor Arrays. ACS Nano 2022, 16, 368–377. [Google Scholar] [CrossRef]

- Chen, J.; Dai, Y.; Grimaldi, N.S.; Lin, J.; Hu, B.; Wu, Y.; Gao, S. Plantar Pressure-Based Insole Gait Monitoring Techniques for Diseases Monitoring and Analysis: A Review. Adv. Mater. Technol. 2022, 7, 2100566. [Google Scholar] [CrossRef]

- Fiorillo, A.S.; Critello, C.D.; Pullano, S.A. Theory, Technology and Applications of Piezoresistive Sensors: A Review. Sens. Actuators A Phys. 2018, 281, 156–175. [Google Scholar] [CrossRef]

- Li, G.; Chen, D.; Li, C.; Liu, W.; Liu, H. Engineered Microstructure Derived Hierarchical Deformation of Flexible Pressure Sensor Induces a Supersensitive Piezoresistive Property in Broad Pressure Range. Adv. Sci. 2020, 7, 2000154. [Google Scholar] [CrossRef]

- Mishra, R.B.; El-Atab, N.; Hussain, A.M.; Hussain, M.M. Recent Progress on Flexible Capacitive Pressure Sensors: From Design and Materials to Applications. Adv. Mater. Technol. 2021, 6, 2001023. [Google Scholar] [CrossRef]

- Pyo, S.; Choi, J.; Kim, J. Flexible, Transparent, Sensitive, and Crosstalk-Free Capacitive Tactile Sensor Array Based on Graphene Electrodes and Air Dielectric. Adv. Electron. Mater. 2018, 4, 1700427. [Google Scholar] [CrossRef]

- Lin, W.; Wang, B.; Peng, G.; Shan, Y.; Hu, H.; Yang, Z. Skin-Inspired Piezoelectric Tactile Sensor Array with Crosstalk-Free Row + Column Electrodes for Spatiotemporally Distinguishing Diverse Stimuli. Adv. Sci. 2021, 8, 2002817. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Jiang, J.; Zhang, C.; Sun, M.; Han, S.; Zhang, R.; Liang, N.; Sun, D.; Liu, H. Energy-Efficient, Fully Flexible, High-Performance Tactile Sensor Based on Piezotronic Effect: Piezoelectric Signal Amplified with Organic Field-Effect Transistors. Nano Energy 2020, 76, 105050. [Google Scholar] [CrossRef]

- Tao, J.; Bao, R.; Wang, X.; Peng, Y.; Li, J.; Fu, S.; Pan, C.; Wang, Z.L. Self-Powered Tactile Sensor Array Systems Based on the Triboelectric Effect. Adv. Funct. Mater. 2019, 29, 1806379. [Google Scholar] [CrossRef]

- He, J.; Xie, Z.; Yao, K.; Li, D.; Liu, Y.; Gao, Z.; Lu, W.; Chang, L.; Yu, X. Trampoline Inspired Stretchable Triboelectric Nanogenerators as Tactile Sensors for Epidermal Electronics. Nano Energy 2021, 81, 105590. [Google Scholar] [CrossRef]

- Huang, Y.; Fan, X.; Chen, S.; Zhao, N. Emerging Technologies of Flexible Pressure Sensors: Materials, Modeling, Devices, and Manufacturing. Adv. Funct. Mater. 2019, 29, 1808509. [Google Scholar] [CrossRef]

- Oh, J.; Kim, J.; Kim, Y.; Choi, H.B.; Yang, J.C.; Lee, S.; Pyatykh, M.; Kim, J.; Sim, J.Y.; Park, S. Highly Uniform and Low Hysteresis Piezoresistive Pressure Sensors Based on Chemical Grafting of Polypyrrole on Elastomer Template with Uniform Pore Size. Small 2019, 15, 1901744. [Google Scholar] [CrossRef]

- Park, K.; Kim, S.; Lee, H.; Park, I.; Kim, J. Low-Hysteresis and Low-Interference Soft Tactile Sensor Using a Conductive Coated Porous Elastomer and a Structure for Interference Reduction. Sens. Actuators A Phys. 2019, 295, 541–550. [Google Scholar] [CrossRef]

- Chang, S.; Li, J.; He, Y.; Liu, H.; Cheng, B. A High-Sensitivity and Low-Hysteresis Flexible Pressure Sensor Based on Carbonized Cotton Fabric. Sens. Actuators A Phys. 2019, 294, 45–53. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, J.; Hu, J.; Luo, N.; Sun, F.; Venkatesan, H.; Zhao, N.; Zhang, Y. Ultrafast-Response/Recovery Flexible Piezoresistive Sensors with DNA-Like Double Helix Yarns for Epidermal Pulse Monitoring. Adv. Mater. 2022, 34, 2104313. [Google Scholar] [CrossRef]

- Klimm, W.; Kwok, K. Mechanism of Resistance Relaxation and Hysteresis in Viscoelastic Piezoresistive Polymer Nanocomposites. Int. J. Mech. Mater. Des. 2022, 18, 769–783. [Google Scholar] [CrossRef]

- Paredes-Madrid, L.; Fonseca, J.; Matute, A.; Gutiérrez Velásquez, E.; Palacio, C. Self-Compensated Driving Circuit for Reducing Drift and Hysteresis in Force Sensing Resistors. Electronics 2018, 7, 146. [Google Scholar] [CrossRef]

- Oliveri, A.; Maselli, M.; Lodi, M.; Storace, M.; Cianchetti, M. Model-Based Compensation of Rate-Dependent Hysteresis in a Piezoresistive Strain Sensor. IEEE Trans. Ind. Electron. 2019, 66, 8205–8213. [Google Scholar] [CrossRef]

- Pyo, S.; Lee, J.; Bae, K.; Sim, S.; Kim, J. Recent Progress in Flexible Tactile Sensors for Human-Interactive Systems: From Sensors to Advanced Applications. Adv. Mater. 2021, 33, 2005902. [Google Scholar] [CrossRef]

- Li, L.; Fu, X.; Chen, S.; Uzun, S.; Levitt, A.S.; Shuck, C.E.; Han, W.; Gogotsi, Y. Hydrophobic and Stable MXene–Polymer Pressure Sensors for Wearable Electronics. ACS Appl. Mater. Interfaces 2020, 12, 15362–15369. [Google Scholar] [CrossRef]

- Li, Y.; Long, J.; Chen, Y.; Huang, Y.; Zhao, N. Crosstalk-Free, High-Resolution Pressure Sensor Arrays Enabled by High-Throughput Laser Manufacturing. Adv. Mater. 2022, 34, 2200517. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Choi, S.; Lee, B.; Seo, J.; Lee, S.; Yoon, J.; Hong, Y. Nonpatterned Soft Piezoresistive Films with Filamentous Conduction Paths for Mimicking Multiple-Resolution Receptors of Human Skin. ACS Appl. Mater. Interfaces 2022, 14, 55088–55097. [Google Scholar] [CrossRef]

- He, J.; Zhang, Y.; Zhou, R.; Meng, L.; Chen, T.; Mai, W.; Pan, C. Recent Advances of Wearable and Flexible Piezoresistivity Pressure Sensor Devices and Its Future Prospects. J. Mater. 2020, 6, 86–101. [Google Scholar] [CrossRef]

- Pierre Claver, U.; Zhao, G. Recent Progress in Flexible Pressure Sensors Based Electronic Skin. Adv. Eng. Mater. 2021, 23, 2001187. [Google Scholar] [CrossRef]

- He, F.; You, X.; Wang, W.; Bai, T.; Xue, G.; Ye, M. Recent Progress in Flexible Microstructural Pressure Sensors toward Human–Machine Interaction and Healthcare Applications. Small Methods 2021, 5, 2001041. [Google Scholar] [CrossRef]

- Bauhofer, W.; Kovacs, J.Z. A Review and Analysis of Electrical Percolation in Carbon Nanotube Polymer Composites. Compos. Sci. Technol. 2009, 69, 1486–1498. [Google Scholar] [CrossRef]

- Haghgoo, M.; Hassanzadeh-Aghdam, M.K.; Ansari, R. A Comprehensive Evaluation of Piezoresistive Response and Percolation Behavior of Multiscale Polymer-Based Nanocomposites. Compos. Part A Appl. Sci. Manuf. 2020, 130, 105735. [Google Scholar] [CrossRef]

- Long, Z.; Liu, X.; Xu, J.; Huang, Y.; Wang, Z. High-Sensitivity Flexible Piezoresistive Pressure Sensor Using PDMS/MWNTS Nanocomposite Membrane Reinforced with Isopropanol for Pulse Detection. Sensors 2022, 22, 4765. [Google Scholar] [CrossRef]

- Wang, L.; Peng, H.; Wang, X.; Chen, X.; Yang, C.; Yang, B.; Liu, J. PDMS/MWCNT-Based Tactile Sensor Array with Coplanar Electrodes for Crosstalk Suppression. Microsyst. Nanoeng. 2016, 2, 16065. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, H.; Yang, S.; Shi, X.; Zhang, D.; Shan, C.; Mi, L.; Liu, C.; Shen, C.; Guo, Z. Ultrasensitive and Highly Compressible Piezoresistive Sensor Based on Polyurethane Sponge Coated with a Cracked Cellulose Nanofibril/Silver Nanowire Layer. ACS Appl. Mater. Interfaces 2019, 11, 10922–10932. [Google Scholar] [CrossRef]

- Zhai, Y.; Yu, Y.; Zhou, K.; Yun, Z.; Huang, W.; Liu, H.; Xia, Q.; Dai, K.; Zheng, G.; Liu, C.; et al. Flexible and Wearable Carbon Black/Thermoplastic Polyurethane Foam with a Pinnate-Veined Aligned Porous Structure for Multifunctional Piezoresistive Sensors. Chem. Eng. J. 2020, 382, 122985. [Google Scholar] [CrossRef]

- Zhao, Z.; Tang, J.; Yuan, J.; Li, Y.; Dai, Y.; Yao, J.; Zhang, Q.; Ding, S.; Li, T.; Zhang, R.; et al. Large-Scale Integrated Flexible Tactile Sensor Array for Sensitive Smart Robotic Touch. ACS Nano 2022, 16, 16784–16795. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Lv, Z.; Ran, F.; Dai, L.; Li, C.; Si, C. Green and Stable Piezoresistive Pressure Sensor Based on Lignin-Silver Hybrid Nanoparticles/Polyvinyl Alcohol Hydrogel. Int. J. Biol. Macromol. 2021, 176, 78–86. [Google Scholar] [CrossRef] [PubMed]

- Duan, L.; Spoerk, M.; Wieme, T.; Cornillie, P.; Xia, H.; Zhang, J.; Cardon, L.; D’hooge, D.R. Designing Formulation Variables of Extrusion-Based Manufacturing of Carbon Black Conductive Polymer Composites for Piezoresistive Sensing. Compos. Sci. Technol. 2019, 171, 78–85. [Google Scholar] [CrossRef]

- Li, S.; Li, R.; González, O.G.; Chen, T.; Xiao, X. Highly Sensitive and Flexible Piezoresistive Sensor Based on c-MWCNTs Decorated TPU Electrospun Fibrous Network for Human Motion Detection. Compos. Sci. Technol. 2021, 203, 108617. [Google Scholar] [CrossRef]

- Dai, H.; Thostenson, E.T. Large-Area Carbon Nanotube-Based Flexible Composites for Ultra-Wide Range Pressure Sensing and Spatial Pressure Mapping. ACS Appl. Mater. Interfaces 2019, 11, 48370–48380. [Google Scholar] [CrossRef]

- Chen, K.-Y.; Xu, Y.-T.; Zhao, Y.; Li, J.-K.; Wang, X.-P.; Qu, L.-T. Recent Progress in Graphene-Based Wearable Piezoresistive Sensors: From 1D to 3D Device Geometries. Nano Mater. Sci. 2022. [Google Scholar] [CrossRef]

- Pang, Y.; Zhang, K.; Yang, Z.; Jiang, S.; Ju, Z.; Li, Y.; Wang, X.; Wang, D.; Jian, M.; Zhang, Y.; et al. Epidermis Microstructure Inspired Graphene Pressure Sensor with Random Distributed Spinosum for High Sensitivity and Large Linearity. ACS Nano 2018, 12, 2346–2354. [Google Scholar] [CrossRef] [PubMed]

- Ke, K.; Yue, L.; Shao, H.; Yang, M.-B.; Yang, W.; Manas-Zloczower, I. Boosting Electrical and Piezoresistive Properties of Polymer Nanocomposites via Hybrid Carbon Fillers: A Review. Carbon 2021, 173, 1020–1040. [Google Scholar] [CrossRef]

- Zhu, B.; Ling, Y.; Yap, L.W.; Yang, M.; Lin, F.; Gong, S.; Wang, Y.; An, T.; Zhao, Y.; Cheng, W. Hierarchically Structured Vertical Gold Nanowire Array-Based Wearable Pressure Sensors for Wireless Health Monitoring. ACS Appl. Mater. Interfaces 2019, 11, 29014–29021. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, L.; Li, H.; Lai, X.; Zeng, X. Skin-Inspired Flexible and High-Performance MXene@polydimethylsiloxane Piezoresistive Pressure Sensor for Human Motion Detection. J. Colloid Interface Sci. 2022, 617, 478–488. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Ma, Y.; Jia, G.; Zhao, S.; Yue, Y.; Cheng, F.; Zhang, C.; Cao, M.; Xiong, Y.; Shen, P.; et al. Bionic MXene Based Hybrid Film Design for an Ultrasensitive Piezoresistive Pressure Sensor. Chem. Eng. J. 2022, 431, 133458. [Google Scholar] [CrossRef]

- Qin, Z.; Lv, Y.; Fang, X.; Zhao, B.; Niu, F.; Min, L.; Pan, K. Ultralight Polypyrrole Crosslinked Nanofiber Aerogel for Highly Sensitive Piezoresistive Sensor. Chem. Eng. J. 2022, 427, 131650. [Google Scholar] [CrossRef]

- Li, L.; Bao, X.; Meng, J.; Zhang, C.; Liu, T. Sponge-Hosting Polyaniline Array Microstructures for Piezoresistive Sensors with a Wide Detection Range and High Sensitivity. ACS Appl. Mater. Interfaces 2022, 14, 30228–30235. [Google Scholar] [CrossRef] [PubMed]

- Kweon, O.Y.; Lee, S.J.; Oh, J.H. Wearable High-Performance Pressure Sensors Based on Three-Dimensional Electrospun Conductive Nanofibers. NPG Asia Mater. 2018, 10, 540–551. [Google Scholar] [CrossRef]

- Han, M.; Chen, L.; Aras, K.; Liang, C.; Chen, X.; Zhao, H.; Li, K.; Faye, N.R.; Sun, B.; Kim, J.-H.; et al. Catheter-Integrated Soft Multilayer Electronic Arrays for Multiplexed Sensing and Actuation during Cardiac Surgery. Nat. Biomed. Eng. 2020, 4, 997–1009. [Google Scholar] [CrossRef]

- Shi, L.; Li, Z.; Chen, M.; Qin, Y.; Jiang, Y.; Wu, L. Quantum Effect-Based Flexible and Transparent Pressure Sensors with Ultrahigh Sensitivity and Sensing Density. Nat. Commun. 2020, 11, 3529. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.; Jia, S.; Zhou, C.; Li, B. 3D Printing of Highly Sensitive and Large-Measurement-Range Flexible Pressure Sensors with a Positive Piezoresistive Effect. ACS Appl. Mater. Interfaces 2020, 12, 28669–28680. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Lu, C.; Guohui, Y.; Sha, J.; Tan, J.; Xuan, F. Laser Micro-Structured Pressure Sensor with Modulated Sensitivity for Electronic Skins. Nanotechnology 2019, 30, 325502. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Wu, K.; Xu, Z.; Wang, Z.; Meng, Y.; Li, L. Ultrahigh-Sensitivity Piezoresistive Pressure Sensors for Detection of Tiny Pressure. ACS Appl. Mater. Interfaces 2018, 10, 20826–20834. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Kim, J.; Hong, J.; Lee, H.; Lee, Y.; Cho, S.; Kim, S.-W.; Kim, J.J.; Kim, S.Y.; Ko, H. Tailoring Force Sensitivity and Selectivity by Microstructure Engineering of Multidirectional Electronic Skins. NPG Asia Mater. 2018, 10, 163–176. [Google Scholar] [CrossRef]

- Chen, M.; Li, K.; Cheng, G.; He, K.; Li, W.; Zhang, D.; Li, W.; Feng, Y.; Wei, L.; Li, W.; et al. Touchpoint-Tailored Ultrasensitive Piezoresistive Pressure Sensors with a Broad Dynamic Response Range and Low Detection Limit. ACS Appl. Mater. Interfaces 2019, 11, 2551–2558. [Google Scholar] [CrossRef]

- Niu, H.; Zhang, H.; Yue, W.; Gao, S.; Kan, H.; Zhang, C.; Zhang, C.; Pang, J.; Lou, Z.; Wang, L.; et al. Micro-Nano Processing of Active Layers in Flexible Tactile Sensors via Template Methods: A Review. Small 2021, 17, 2100804. [Google Scholar] [CrossRef]

- dos Santos, A.; Pinela, N.; Alves, P.; Santos, R.; Fortunato, E.; Martins, R.; Águas, H.; Igreja, R. Piezoresistive E-Skin Sensors Produced with Laser Engraved Molds. Adv. Electron. Mater. 2018, 4, 1800182. [Google Scholar] [CrossRef]

- Yao, H.; Yang, W.; Cheng, W.; Tan, Y.J.; See, H.H.; Li, S.; Ali, H.P.A.; Lim, B.Z.H.; Liu, Z.; Tee, B.C.K. Near–Hysteresis-Free Soft Tactile Electronic Skins for Wearables and Reliable Machine Learning. Proc. Natl. Acad. Sci. USA 2020, 117, 25352–25359. [Google Scholar] [CrossRef]

- Du, D.; Ma, X.; An, W.; Yu, S. Flexible Piezoresistive Pressure Sensor Based on Wrinkled Layers with Fast Response for Wearable Applications. Measurement 2022, 201, 111645. [Google Scholar] [CrossRef]

- Charara, M.; Luo, W.; Saha, M.C.; Liu, Y. Investigation of Lightweight and Flexible Carbon Nanofiber/Poly Dimethylsiloxane Nanocomposite Sponge for Piezoresistive Sensor Application. Adv. Eng. Mater. 2019, 21, 1801068. [Google Scholar] [CrossRef]

- Dai, S.-W.; Gu, Y.-L.; Zhao, L.; Zhang, W.; Gao, C.-H.; Wu, Y.-X.; Shen, S.-C.; Zhang, C.; Kong, T.-T.; Li, Y.-T.; et al. Bamboo-Inspired Mechanically Flexible and Electrically Conductive Polydimethylsiloxane Foam Materials with Designed Hierarchical Pore Structures for Ultra-Sensitive and Reliable Piezoresistive Pressure Sensor. Compos. Part B. Eng. 2021, 225, 109243. [Google Scholar] [CrossRef]

- Li, W.; Jin, X.; Han, X.; Li, Y.; Wang, W.; Lin, T.; Zhu, Z. Synergy of Porous Structure and Microstructure in Piezoresistive Material for High-Performance and Flexible Pressure Sensors. ACS Appl. Mater. Interfaces 2021, 13, 19211–19220. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Hon, M.; Yao, H.; Tee, B.C.K. An Atlas for Large-Area Electronic Skins: From Materials to Systems Design, 1st ed.; Cambridge University Press: Cambridge, UK, 2020; ISBN 978-1-108-78239-5. [Google Scholar]

- Takei, K.; Takahashi, T.; Ho, J.C.; Ko, H.; Gillies, A.G.; Leu, P.W.; Fearing, R.S.; Javey, A. Nanowire Active-Matrix Circuitry for Low-Voltage Macroscale Artificial Skin. Nature Mater. 2010, 9, 821–826. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.; Wang, L.; Dai, Z.; Zhao, L.; Du, M.; Li, H.; Fang, Y. Multiscale Hierarchical Design of a Flexible Piezoresistive Pressure Sensor with High Sensitivity and Wide Linearity Range. Small 2018, 14, 1800819. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Li, X.; Liu, T.; Lu, Y.; Shang, C.; Ding, X.; Zhang, J.; Feng, Y.; Xu, F.-J. Wearable, Washable, and Highly Sensitive Piezoresistive Pressure Sensor Based on a 3D Sponge Network for Real-Time Monitoring Human Body Activities. ACS Appl. Mater. Interfaces 2021, 13, 46848–46857. [Google Scholar] [CrossRef]

- Liu, W.C.; Watt, A.A.R. Solvodynamically Printed Silver Nanowire/Ethylene-Co-Vinyl Acetate Composite Films as Sensitive Piezoresistive Pressure Sensors. ACS Appl. Nano Mater. 2021, 4, 7905–7916. [Google Scholar] [CrossRef]

- Kim, J.-S.; So, Y.; Lee, S.; Pang, C.; Park, W.; Chun, S. Uniform Pressure Responses for Nanomaterials-Based Biological on-Skin Flexible Pressure Sensor Array. Carbon 2021, 181, 169–176. [Google Scholar] [CrossRef]

- Pei, Z.; Zhang, Q.; Li, Q.; Ji, C.; Liu, Y.; Yang, K.; Zhuo, K.; Zhang, W.; Sang, S. A Fully 3D Printed Electronic Skin with Bionic High Resolution and Air Permeable Porous Structure. J. Colloid Interface Sci. 2021, 602, 452–458. [Google Scholar] [CrossRef]

- Fan, B.; Chen, S.; Gao, J.; Guo, X. Accurate Recognition of Lightweight Objects with Low Resolution Pressure Sensor Array. IEEE Sens. J. 2020, 20, 3280–3284. [Google Scholar] [CrossRef]

- Lee, B.; Oh, J.-Y.; Cho, H.; Joo, C.W.; Yoon, H.; Jeong, S.; Oh, E.; Byun, J.; Kim, H.; Lee, S.; et al. Ultraflexible and Transparent Electroluminescent Skin for Real-Time and Super-Resolution Imaging of Pressure Distribution. Nat. Commun. 2020, 11, 663. [Google Scholar] [CrossRef]

- Silvera-Tawil, D.; Rye, D.; Soleimani, M.; Velonaki, M. Electrical Impedance Tomography for Artificial Sensitive Robotic Skin: A Review. IEEE Sens. J. 2015, 15, 2001–2016. [Google Scholar] [CrossRef]

- Lee, H.; Kwon, D.; Cho, H.; Park, I.; Kim, J. Soft Nanocomposite Based Multi-Point, Multi-Directional Strain Mapping Sensor Using Anisotropic Electrical Impedance Tomography. Sci. Rep. 2017, 7, 39837. [Google Scholar] [CrossRef] [PubMed]

- Jeong, Y.J.; Kim, Y.E.; Kim, K.J.; Woo, E.J.; Oh, T.I. Multilayered Fabric Pressure Sensor for Real-Time Piezo-Impedance Imaging of Pressure Distribution. IEEE Trans. Instrum. Meas. 2020, 69, 565–572. [Google Scholar] [CrossRef]

- Liu, K.; Wu, Y.; Wang, S.; Wang, H.; Chen, H.; Chen, B.; Yao, J. Artificial Sensitive Skin for Robotics Based on Electrical Impedance Tomography. Adv. Intell. Syst. 2020, 2, 1900161. [Google Scholar] [CrossRef]

- Sinha, A.K.; Goh, G.L.; Yeong, W.Y.; Cai, Y. Ultra-Low-Cost, Crosstalk-Free, Fast-Responding, Wide-Sensing-Range Tactile Fingertip Sensor for Smart Gloves. Adv. Mater. Interfaces 2022, 9, 2200621. [Google Scholar] [CrossRef]

- Yin, Y.M.; Li, H.Y.; Xu, J.; Zhang, C.; Liang, F.; Li, X.; Jiang, Y.; Cao, J.W.; Feng, H.F.; Mao, J.N.; et al. Facile Fabrication of Flexible Pressure Sensor with Programmable Lattice Structure. ACS Appl. Mater. Interfaces 2021, 13, 10388–10396. [Google Scholar] [CrossRef]

- Bae, K.; Jeong, J.; Choi, J.; Pyo, S.; Kim, J. Large-Area, Crosstalk-Free, Flexible Tactile Sensor Matrix Pixelated by Mesh Layers. ACS Appl. Mater. Interfaces 2021, 13, 12259–12267. [Google Scholar] [CrossRef]

- Kim, J.-S.; Kwon, D.-Y.; Choi, B.-D. High-Accuracy, Compact Scanning Method and Circuit for Resistive Sensor Arrays. Sensors 2016, 16, 155. [Google Scholar] [CrossRef]

- Tanaka, A.; Matsumoto, S.; Tsukamoto, N.; Itoh, S.; Chiba, K.; Endoh, T.; Nakazato, A.; Okuyama, K.; Kumazawa, Y.; Hijikawa, M.; et al. Infrared Focal Plane Array Incorporating Silicon IC Process Compatible Bolometer. IEEE Trans. Electron. Devices 1996, 43, 1844–1850. [Google Scholar] [CrossRef]

- Tise, B. A Compact High Resolution Piezoresistive Digital Tactile Sensor. In Proceedings of the 1988 IEEE International Conference on Robotics and Automation, Philadelphia, PA, USA, 24–29 April 1988. [Google Scholar]

- Wu, J.; Wang, L.; Li, J. General Voltage Feedback Circuit Model in the Two-Dimensional Networked Resistive Sensor Array. J. Sens. 2015, 2015, 913828. [Google Scholar] [CrossRef]

- Vidal-Verdú, F.; Oballe-Peinado, Ó.; Sánchez-Durán, J.A.; Castellanos-Ramos, J.; Navas-González, R. Three Realizations and Comparison of Hardware for Piezoresistive Tactile Sensors. Sensors 2011, 11, 3249–3266. [Google Scholar] [CrossRef] [PubMed]

- Shu, L.; Tao, X.; Feng, D.D. A New Approach for Readout of Resistive Sensor Arrays for Wearable Electronic Applications. IEEE Sens. J. 2015, 15, 442–452. [Google Scholar] [CrossRef]

- Shah, M.A.; Lee, D.-G.; Lee, B.-Y.; Hur, S. Classifications and Applications of Inkjet Printing Technology: A Review. IEEE Access 2021, 9, 140079–140102. [Google Scholar] [CrossRef]

- Saadi, M.A.S.R.; Maguire, A.; Pottackal, N.T.; Thakur, M.S.H.; Ikram, M.M.; Hart, A.J.; Ajayan, P.M.; Rahman, M.M. Direct Ink Writing: A 3D Printing Technology for Diverse Materials. Adv. Mater. 2022, 34, 2108855. [Google Scholar] [CrossRef]

- Lee, T.; Kang, Y.; Kim, K.; Sim, S.; Bae, K.; Kwak, Y.; Park, W.; Kim, M.; Kim, J. All Paper-Based, Multilayered, Inkjet-Printed Tactile Sensor in Wide Pressure Detection Range with High Sensitivity. Adv. Mater. Technol. 2022, 7, 2100428. [Google Scholar] [CrossRef]

- Chung, S.; Cho, K.; Lee, T. Recent Progress in Inkjet-Printed Thin-Film Transistors. Adv. Sci. 2019, 6, 1801445. [Google Scholar] [CrossRef]

- Theron, A.; Zussman, E.; Yarin, A.L. Electrostatic Field-Assisted Alignment of Electrospun Nanofibres. Nanotechnology 2001, 12, 384–390. [Google Scholar] [CrossRef]

- Han, Z.; Cheng, Z.; Chen, Y.; Li, B.; Liang, Z.; Li, H.; Ma, Y.; Feng, X. Fabrication of Highly Pressure-Sensitive, Hydrophobic, and Flexible 3D Carbon Nanofiber Networks by Electrospinning for Human Physiological Signal Monitoring. Nanoscale 2019, 11, 5942–5950. [Google Scholar] [CrossRef]

- Wang, S.; Chen, G.; Niu, S.; Chen, K.; Gan, T.; Wang, Z.; Wang, H.; Du, P.; Leung, C.W.; Qu, S. Magnetic-Assisted Transparent and Flexible Percolative Composite for Highly Sensitive Piezoresistive Sensor via Hot Embossing Technology. ACS Appl. Mater. Interfaces 2019, 11, 48331–48340. [Google Scholar] [CrossRef]

- Vivaldi, F.M.; Dallinger, A.; Bonini, A.; Poma, N.; Sembranti, L.; Biagini, D.; Salvo, P.; Greco, F.; Di Francesco, F. Three-Dimensional (3D) Laser-Induced Graphene: Structure, Properties, and Application to Chemical Sensing. ACS Appl. Mater. Interfaces 2021, 13, 30245–30260. [Google Scholar] [CrossRef]

- Wang, F.; Wang, K.; Zheng, B.; Dong, X.; Mei, X.; Lv, J.; Duan, W.; Wang, W. Laser-Induced Graphene: Preparation, Functionalization and Applications. Mater. Technol. 2018, 33, 340–356. [Google Scholar] [CrossRef]

- Luo, S.; Hoang, P.T.; Liu, T. Direct Laser Writing for Creating Porous Graphitic Structures and Their Use for Flexible and Highly Sensitive Sensor and Sensor Arrays. Carbon 2016, 96, 522–531. [Google Scholar] [CrossRef]

- Bae, G.Y.; Pak, S.W.; Kim, D.; Lee, G.; Kim, D.H.; Chung, Y.; Cho, K. Linearly and Highly Pressure-Sensitive Electronic Skin Based on a Bioinspired Hierarchical Structural Array. Adv. Mater. 2016, 28, 5300–5306. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.; He, T.; Lee, C. Technologies toward next Generation Human Machine Interfaces: From Machine Learning Enhanced Tactile Sensing to Neuromorphic Sensory Systems. Appl. Phys. Rev. 2020, 7, 031305. [Google Scholar] [CrossRef]

- Guo, Y.; Guo, Z.; Zhong, M.; Wan, P.; Zhang, W.; Zhang, L. A Flexible Wearable Pressure Sensor with Bioinspired Microcrack and Interlocking for Full-Range Human-Machine Interfacing. Small 2018, 14, 1803018. [Google Scholar] [CrossRef]

- Pyo, S.; Lee, J.; Kim, W.; Jo, E.; Kim, J. Multi-Layered, Hierarchical Fabric-Based Tactile Sensors with High Sensitivity and Linearity in Ultrawide Pressure Range. Adv. Funct. Mater. 2019, 29, 1902484. [Google Scholar] [CrossRef]

- Heo, J.S.; Eom, J.; Kim, Y.-H.; Park, S.K. Recent Progress of Textile-Based Wearable Electronics: A Comprehensive Review of Materials, Devices, and Applications. Small 2018, 14, 1703034. [Google Scholar] [CrossRef] [PubMed]

- O’Flynn, B.; Torres, J.; Connolly, J.; Condell, J.; Curran, K.; Gardiner, P. Novel Smart Sensor Glove for Arthritis Rehabiliation. In Proceedings of the 2013 IEEE International Conference on Body Sensor Networks, Cambridge, MA, USA, 6–9 May 2013; pp. 1–6. [Google Scholar]

- Charalambides, A.; Bergbreiter, S. Rapid Manufacturing of Mechanoreceptive Skins for Slip Detection in Robotic Grasping. Adv. Mater. Technol. 2017, 2, 1600188. [Google Scholar] [CrossRef]

- Gao, Y.; Ota, H.; Schaler, E.W.; Chen, K.; Zhao, A.; Gao, W.; Fahad, H.M.; Leng, Y.; Zheng, A.; Xiong, F.; et al. Wearable Microfluidic Diaphragm Pressure Sensor for Health and Tactile Touch Monitoring. Adv. Mater. 2017, 29, 1701985. [Google Scholar] [CrossRef] [PubMed]

- Pacchierotti, C.; Sinclair, S.; Solazzi, M.; Frisoli, A.; Hayward, V.; Prattichizzo, D. Wearable Haptic Systems for the Fingertip and the Hand: Taxonomy, Review, and Perspectives. IEEE Trans. Haptics 2017, 10, 580–600. [Google Scholar] [CrossRef] [PubMed]

- Bartolozzi, C.; Natale, L.; Nori, F.; Metta, G. Robots with a Sense of Touch. Nat. Mater. 2016, 15, 921–925. [Google Scholar] [CrossRef] [PubMed]

- Zhao, G.; Yang, J.; Chen, J.; Zhu, G.; Jiang, Z.; Liu, X.; Niu, G.; Wang, Z.L.; Zhang, B. Keystroke Dynamics Identification Based on Triboelectric Nanogenerator for Intelligent Keyboard Using Deep Learning Method. Adv. Mater. Technol. 2019, 4, 1800167. [Google Scholar] [CrossRef]

- Thuruthel, T.G.; Shih, B.; Laschi, C.; Tolley, M.T. Soft Robot Perception Using Embedded Soft Sensors and Recurrent Neural Networks. Sci. Robot. 2019, 4, eaav1488. [Google Scholar] [CrossRef] [PubMed]

- Shih, B.; Shah, D.; Li, J.; Thuruthel, T.G.; Park, Y.-L.; Iida, F.; Bao, Z.; Kramer-Bottiglio, R.; Tolley, M.T. Electronic Skins and Machine Learning for Intelligent Soft Robots. Sci. Robot. 2020, 5, eaaz9239. [Google Scholar] [CrossRef]

- Wen, F.; Zhang, Z.; He, T.; Lee, C. AI Enabled Sign Language Recognition and VR Space Bidirectional Communication Using Triboelectric Smart Glove. Nat. Commun. 2021, 12, 5378. [Google Scholar] [CrossRef]

- Zhu, M.; Sun, Z.; Zhang, Z.; Shi, Q.; He, T.; Liu, H.; Chen, T.; Lee, C. Haptic-Feedback Smart Glove as a Creative Human-Machine Interface (HMI) for Virtual/Augmented Reality Applications. Sci. Adv. 2020, 6, eaaz8693. [Google Scholar] [CrossRef]

- Urry, S. Plantar Pressure-Measurement Sensors. Meas. Sci. Technol. 1999, 10, R16–R32. [Google Scholar] [CrossRef]

- Xiao, Y.; Jiang, S.; Liu, P.; Xue, Z.; Zhu, Y.; Yu, J.; Qiu, J.; Zhang, W. Highly Sensitive and Stable Printed Pressure Sensor with Microstructured Grid Arrays. Smart Mater. Struct. 2019, 28, 105027. [Google Scholar] [CrossRef]

- Lazzarini, P.A.; Crews, R.T.; van Netten, J.J.; Bus, S.A.; Fernando, M.E.; Chadwick, P.J.; Najafi, B. Measuring Plantar Tissue Stress in People with Diabetic Peripheral Neuropathy: A Critical Concept in Diabetic Foot Management. J. Diabetes Sci. Technol. 2019, 13, 869–880. [Google Scholar] [CrossRef]

- Alkhatib, R.; Diab, M.; Moslem, B.; Corbier, C.; Badaoui, M.E. Gait-Ground Reaction Force Sensors Selection Based on ROC Curve Evaluation. J. Comput. Commun. 2015, 3, 13–19. [Google Scholar] [CrossRef]

- Shalin, G.; Pardoel, S.; Nantel, J.; Lemaire, E.D.; Kofman, J. Prediction of Freezing of Gait in Parkinson’s Disease from Foot Plantar-Pressure Arrays Using a Convolutional Neural Network. In Proceedings of the 2020 42nd Annual International Conference of the IEEE Engineering in Medicine & Biology Society (EMBC), Montreal, QC, Canada, 20–24 July 2020; pp. 244–247. [Google Scholar]

- Luo, N.; Dai, W.; Li, C.; Zhou, Z.; Lu, L.; Poon, C.C.Y.; Chen, S.-C.; Zhang, Y.; Zhao, N. Pulse-6-Flexible Piezoresistive Sensor Patch Enabling Ultralow Power Cuffless Blood Pressure Measurement. Adv. Funct. Mater. 2016, 26, 1178–1187. [Google Scholar] [CrossRef]

- Huang, K.-H.; Chang, C.-M.; Lee, F.-W.; Wang, T.-D.; Yang, Y.-J. Highly-Sensitive Linear Tactile Array for Continuously Monitoring Blood Pulse Waves. Sens. Actuators A Phys. 2018, 280, 261–270. [Google Scholar] [CrossRef]

- Chortos, A.; Liu, J.; Bao, Z. Pursuing Prosthetic Electronic Skin. Nat. Mater. 2016, 15, 937–950. [Google Scholar] [CrossRef] [PubMed]

- Marasco, P.D.; Kim, K.; Colgate, J.E.; Peshkin, M.A.; Kuiken, T.A. Robotic Touch Shifts Perception of Embodiment to a Prosthesis in Targeted Reinnervation Amputees. Brain 2011, 134, 747–758. [Google Scholar] [CrossRef]

- Flor, H.; Denke, C.; Schaefer, M.; Grüsser, S. Effect of Sensory Discrimination Training on Cortical Reorganisation and Phantom Limb Pain. Lancet 2001, 357, 1763–1764. [Google Scholar] [CrossRef]

- Antfolk, C.; D’Alonzo, M.; Rosén, B.; Lundborg, G.; Sebelius, F.; Cipriani, C. Sensory Feedback in Upper Limb Prosthetics. Expert Rev. Med. Devices 2013, 10, 45–54. [Google Scholar] [CrossRef]

- Saal, H.P.; Bensmaia, S.J. Biomimetic Approaches to Bionic Touch through a Peripheral Nerve Interface. Neuropsychologia 2015, 79, 344–353. [Google Scholar] [CrossRef]

- Ferreira, A.; Correia, V.; Mendes, E.; Lopes, C.; Vaz, J.F.V.; Lanceros-Mendez, S. Piezoresistive Polymer-Based Materials for Real-Time Assessment of the Stump/Socket Interface Pressure in Lower Limb Amputees. IEEE Sens. J. 2017, 17, 2182–2190. [Google Scholar] [CrossRef]

- Kim, Y.; Chortos, A.; Xu, W.; Liu, Y.; Oh, J.Y.; Son, D.; Kang, J.; Foudeh, A.M.; Zhu, C.; Lee, Y.; et al. A Bioinspired Flexible Organic Artificial Afferent Nerve. Science 2018, 360, 998–1003. [Google Scholar] [CrossRef]

- Osborn, L.; Nguyen, H.; Betthauser, J.; Kaliki, R.; Thakor, N. Biologically Inspired Multi-Layered Synthetic Skin for Tactile Feedback in Prosthetic Limbs. In Proceedings of the 2016 38th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Orlando, FL, USA, 16–20 August 2016; pp. 4622–4625. [Google Scholar]

- Chung, H.; Lee, J.; Lee, W.Y. A Review: Marine Bio-Logging of Animal Behaviour and Ocean Environments. Ocean Sci. J. 2021, 56, 117–131. [Google Scholar] [CrossRef]

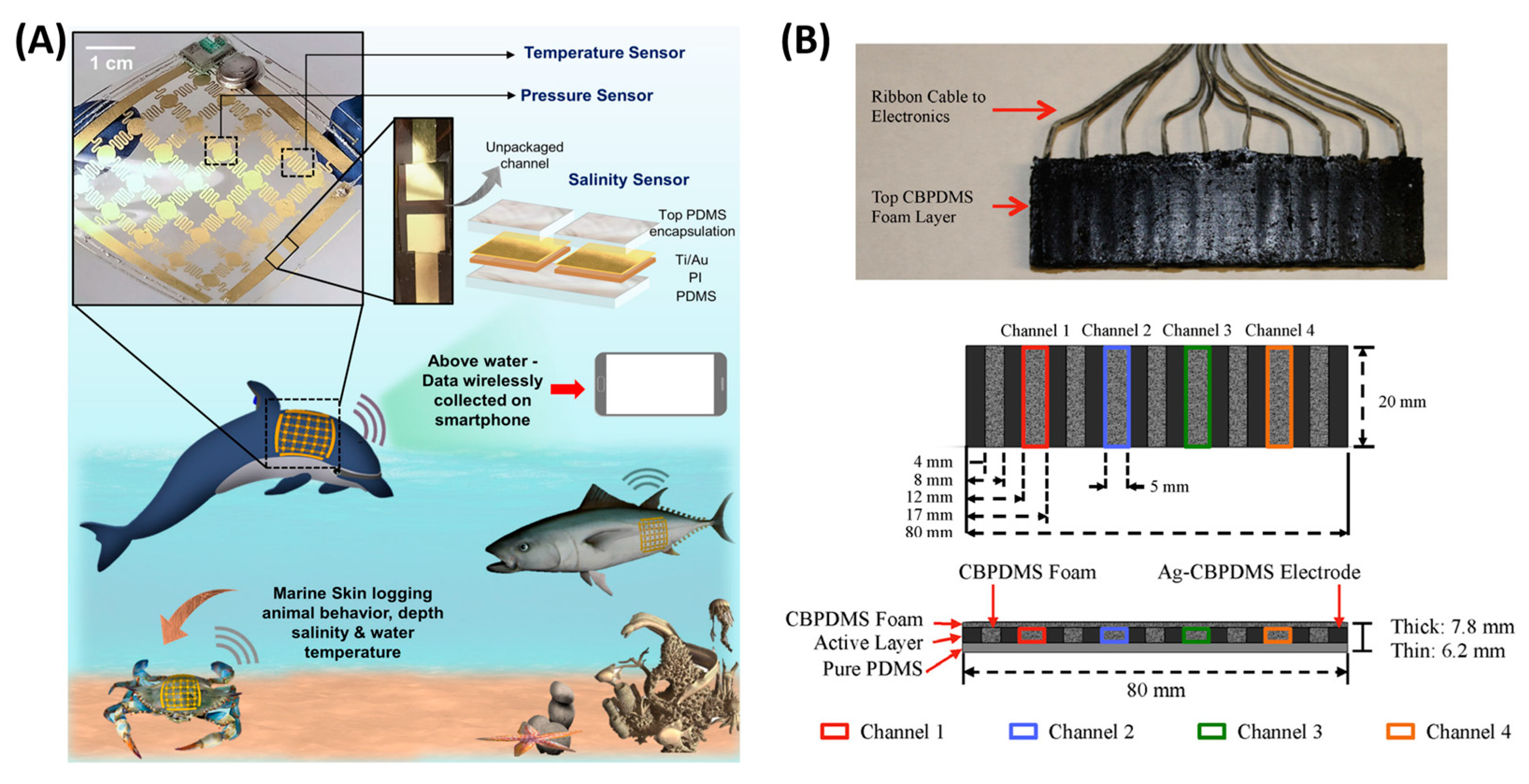

- Nassar, J.M.; Khan, S.M.; Velling, S.J.; Diaz-Gaxiola, A.; Shaikh, S.F.; Geraldi, N.R.; Torres Sevilla, G.A.; Duarte, C.M.; Hussain, M.M. O-3-Compliant Lightweight Non-Invasive Standalone “Marine Skin” Tagging System. npj Flex. Electron. 2018, 2, 13. [Google Scholar] [CrossRef]

- Dusek, J.E.; Triantafyllou, M.S.; Lang, J.H. Piezoresistive Foam Sensor Arrays for Marine Applications. Sens. Actuators A Phys. 2016, 248, 173–183. [Google Scholar] [CrossRef]

- Li, W.-D.; Pu, J.-H.; Zhao, X.; Jia, J.; Ke, K.; Bao, R.-Y.; Liu, Z.-Y.; Yang, M.-B.; Yang, W. Scalable Fabrication of Flexible Piezoresistive Pressure Sensors Based on Occluded Microstructures for Subtle Pressure and Force Waveform Detection. J. Mater. Chem. C 2020, 8, 16774–16783. [Google Scholar] [CrossRef]

- Wang, L.; Huang, X.; Wang, D.; Zhang, W.; Gao, S.; Luo, J.; Guo, Z.; Xue, H.; Gao, J. Lotus Leaf Inspired Superhydrophobic Rubber Composites for Temperature Stable Piezoresistive Sensors with Ultrahigh Compressibility and Linear Working Range. Chem. Eng. J. 2021, 405, 127025. [Google Scholar] [CrossRef]

- Chen, H.; Ginzburg, V.V.; Yang, J.; Yang, Y.; Liu, W.; Huang, Y.; Du, L.; Chen, B. Thermal Conductivity of Polymer-Based Composites: Fundamentals and Applications. Prog. Polym. Sci. 2016, 59, 41–85. [Google Scholar] [CrossRef]

| Array Structure | Spatial Resolution | Material | Microstructure | Sensitivity and Working Range | Response Time/Relaxation Time (ms) | Ref. |

|---|---|---|---|---|---|---|

| Discrete material elements | 3 × 3 array, pixel size: 3 × 3 mm2, center-to-center distance: 4.5 mm | graphene ink on patterned PDMS | lotus leaf, two layers stacked face to face | 1.2 kPa−1 (pressure range 0~25 kPa) | / | [66] |

| 4 × 4 array in 6 cm × 6 cm area | carbon nanostructure on patterned PDMS | anisotropic wavy microstructures, two layers stacked face to face | 1.214 kPa−1 (pressure range: 0~100 Pa) 0.301 kPa−1 (pressure range: 0.1~1 kPa) | 266/766 | [129] | |

| 5 × 5 array, pixel size: 1.0 × 1.0 cm2 | carbon nanofibers/PDMS | hierarchical pore structures | 0.60 kPa−1 (pressure range: 0~1 kPa) 0.08 kPa−1 (pressure range: 1~6 kPa) 0.01 kPa−1 (pressure range: 6~20 kPa) | 30/25 | [62] | |

| 6 × 6 array | MXene on patterned PDMS | sandpaper, two layers stacked face to face | 2.6 kPa−1 (pressure range: 0~30 kPa) | 40/40 | [45] | |

| 8 × 8 array, pixel size: 0.4 mm, center-to-center distance: 0.7 mm | laser-induced graphene foam | / | 1.37 kPa−1 (pressure range: 80 kPa) | 20/~30 | [25] | |

| 10 × 10 array in 7 cm × 7 cm area | MXene@ P(VDF-TrFE) | / | 817.4 kPa−1 (pressure range: 0.072~0.74 kPa) 2213.68 kPa−1(pressure range: 0.74~3.083 kPa) | 16/16 | [24] | |

| Continuous piece | 6.6, 8.1, 10.6 ppi | rGO/PVDF | interlocked microdomes | 16.8 kPa−1 (pressure range < 1 kPa) 1.25 kPa−1 (pressure range > 2 kPa) | <200 | [5] |

| 64 × 64, 28.2 ppi | MWCNTs/TPU | self-formed surface structure | 10 kPa−1 (pressure range 15~1400 kPa) | 5/3 | [36] | |

| up to 100 dpi | aligned Ni/PDMS | / | 0.72 kPa−1 at 357 kPa working range of up to 373 kPa | ~12/~20 | [26] | |

| 400 cm−2 | hollow carbon spheres/PDMS | / | 260.3 kPa−1 at 1 Pa >1 kPa−1 (pressure range: 1~800 Pa) >0.1 kPa−1 (pressure range: 800~10,000 Pa) | 60/30 | [51] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, S.; Xu, Z.; Li, D.; Cui, T.; Li, X.; Yang, Y.; Liu, H.; Ren, T. Recent Advances in Flexible Piezoresistive Arrays: Materials, Design, and Applications. Polymers 2023, 15, 2699. https://doi.org/10.3390/polym15122699

Xu S, Xu Z, Li D, Cui T, Li X, Yang Y, Liu H, Ren T. Recent Advances in Flexible Piezoresistive Arrays: Materials, Design, and Applications. Polymers. 2023; 15(12):2699. https://doi.org/10.3390/polym15122699

Chicago/Turabian StyleXu, Shuoyan, Zigan Xu, Ding Li, Tianrui Cui, Xin Li, Yi Yang, Houfang Liu, and Tianling Ren. 2023. "Recent Advances in Flexible Piezoresistive Arrays: Materials, Design, and Applications" Polymers 15, no. 12: 2699. https://doi.org/10.3390/polym15122699

APA StyleXu, S., Xu, Z., Li, D., Cui, T., Li, X., Yang, Y., Liu, H., & Ren, T. (2023). Recent Advances in Flexible Piezoresistive Arrays: Materials, Design, and Applications. Polymers, 15(12), 2699. https://doi.org/10.3390/polym15122699