Development and Characterization of Biosorbent Film from Eggshell/Orange Waste Enriched with Banana Starch

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Eggshell and Orange Peel

2.3. Extraction of Starch from Banana Saba (Musa acuminata x balbisiana)

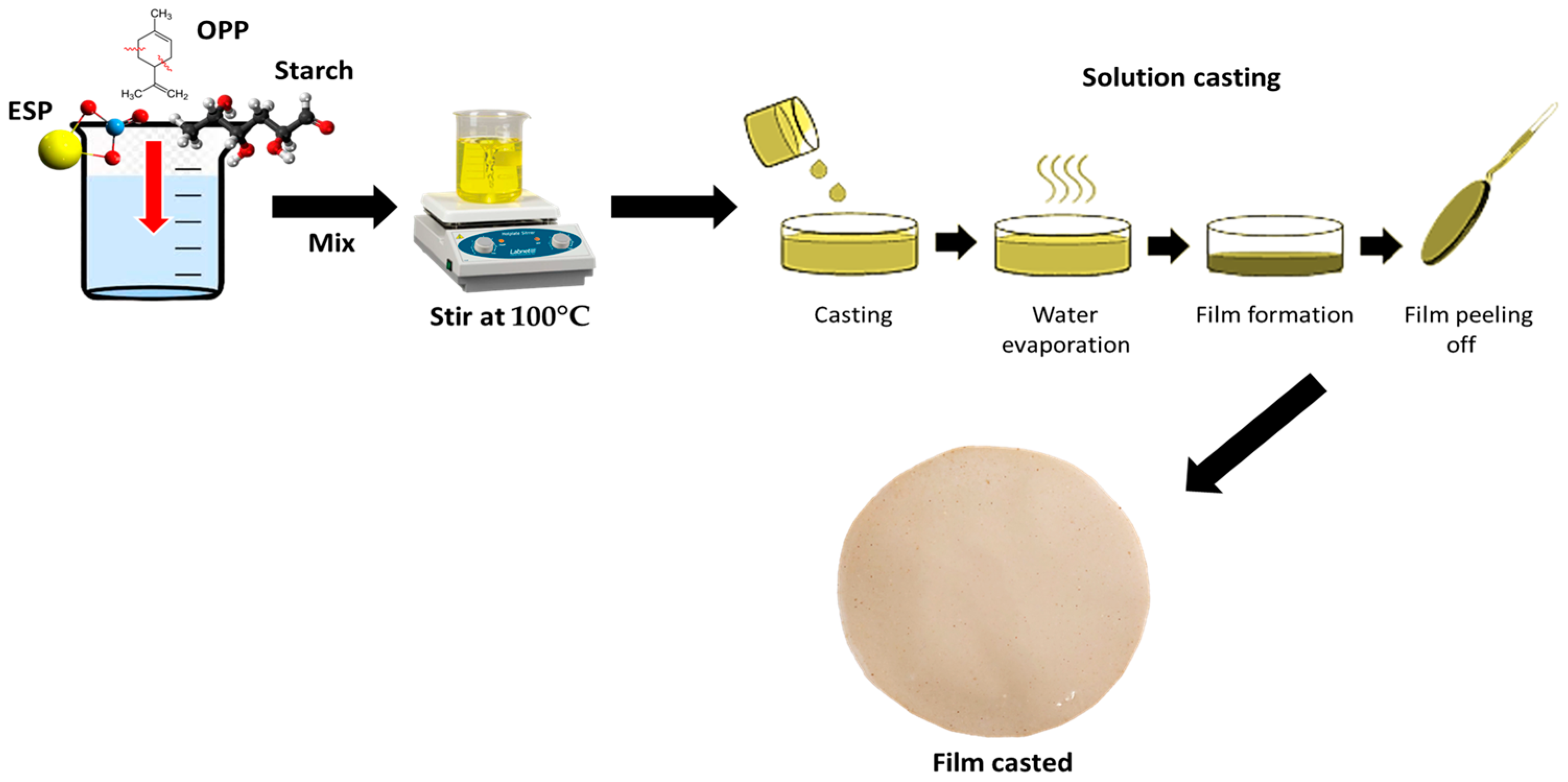

2.4. Fabrication of Film

2.5. Method Characterization

2.5.1. Thickness and Density

2.5.2. Color Measurement

2.5.3. Porosity Measurement

2.5.4. Moisture Content and Water Solubility Analysis

2.5.5. Water Absorption and Water Vapor Permeability

2.6. Removal Efficiency Studies

2.7. Statistical Analysis

3. Results and Discussion

3.1. The Yield of Eggshell and Orange Peel Powder and Banana Starch

3.2. Optical and Appearance of the Film

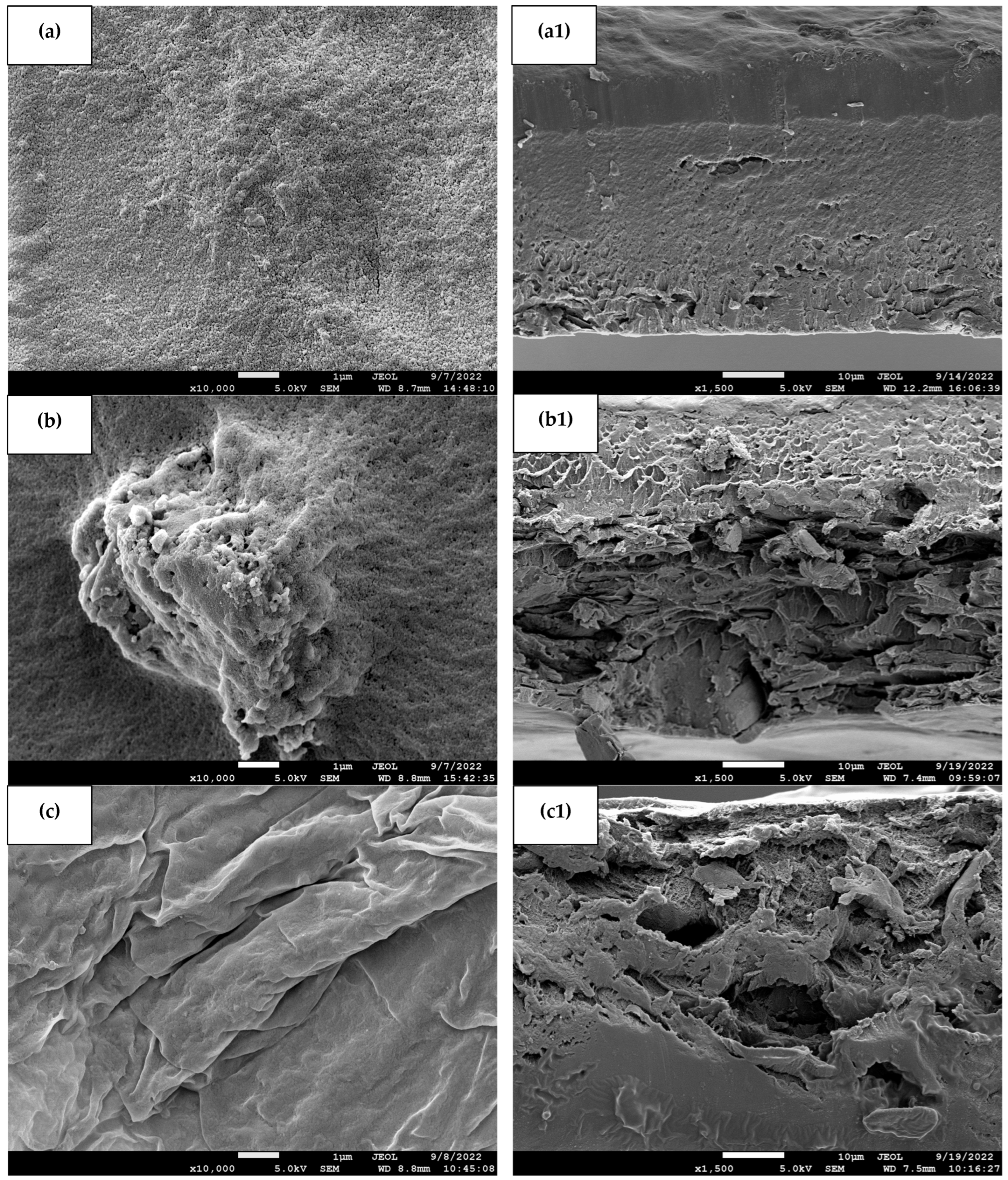

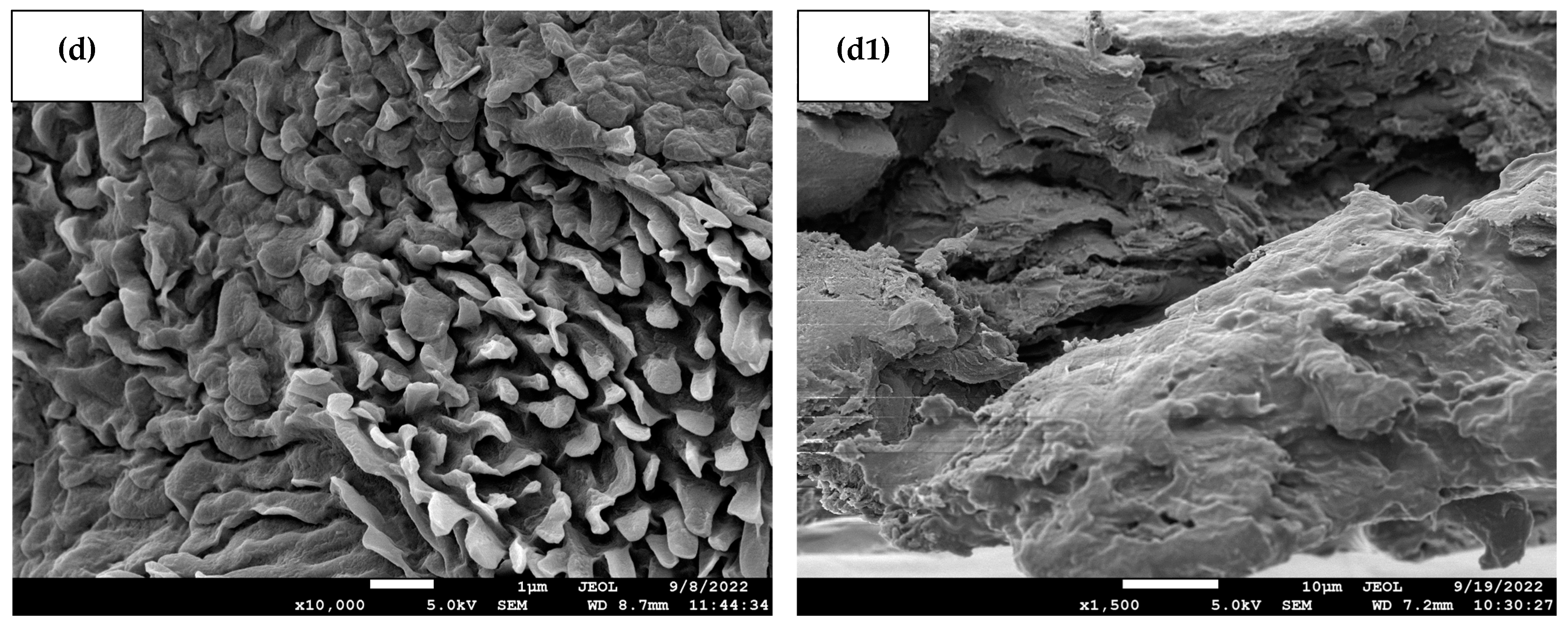

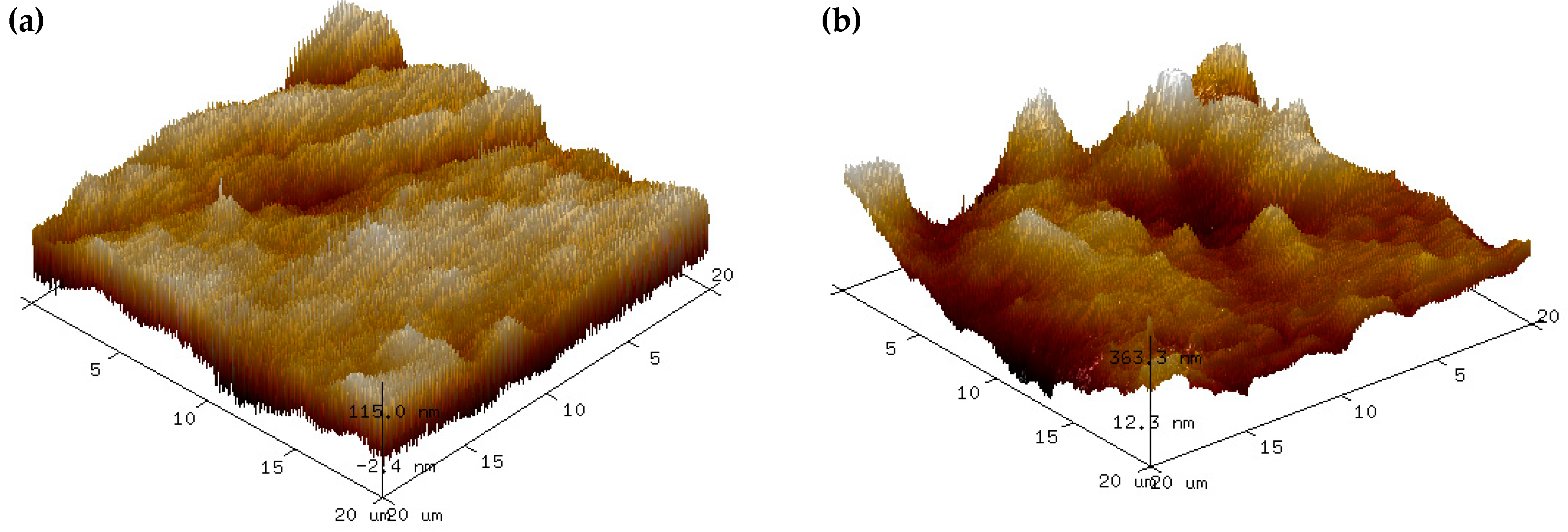

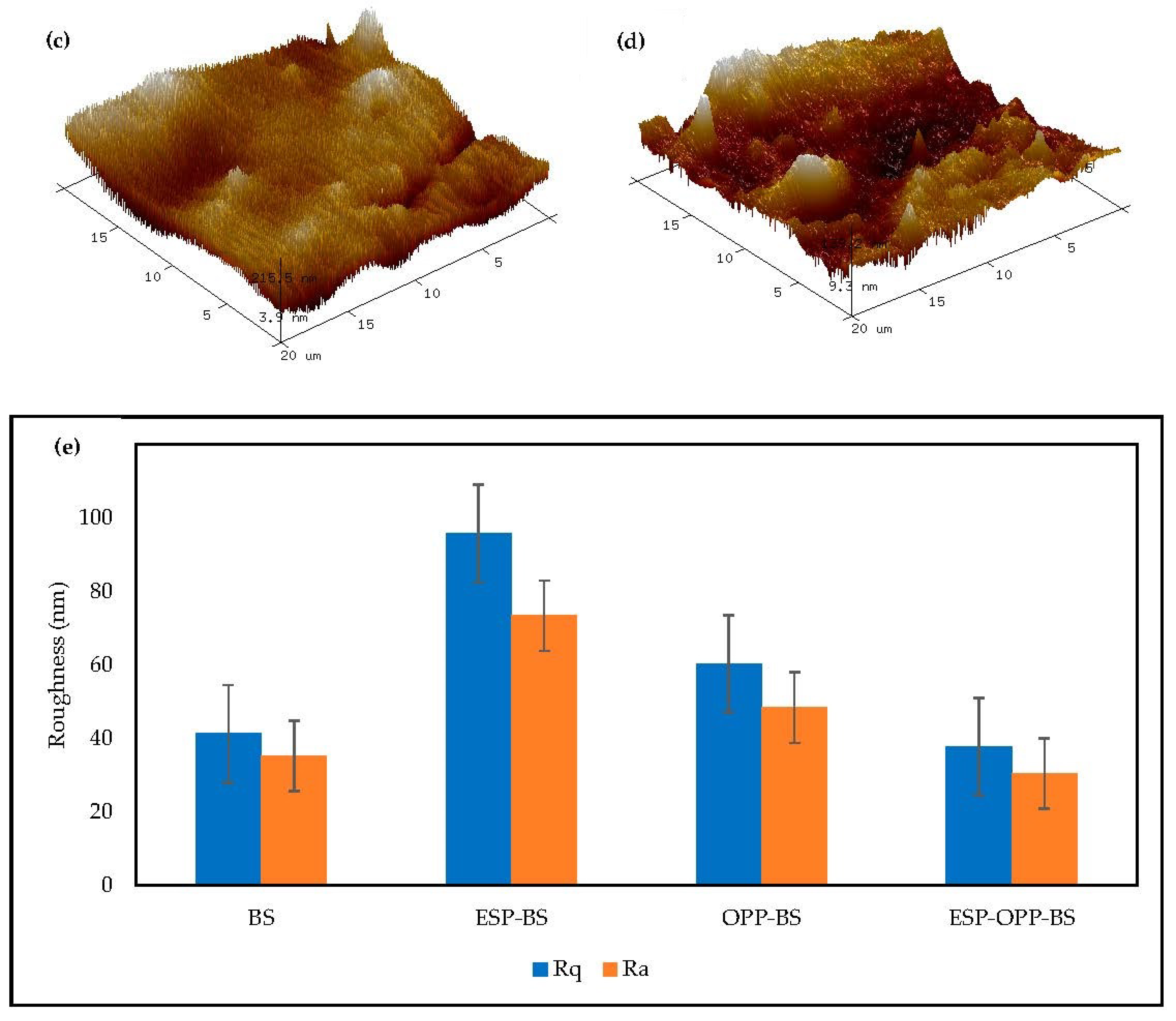

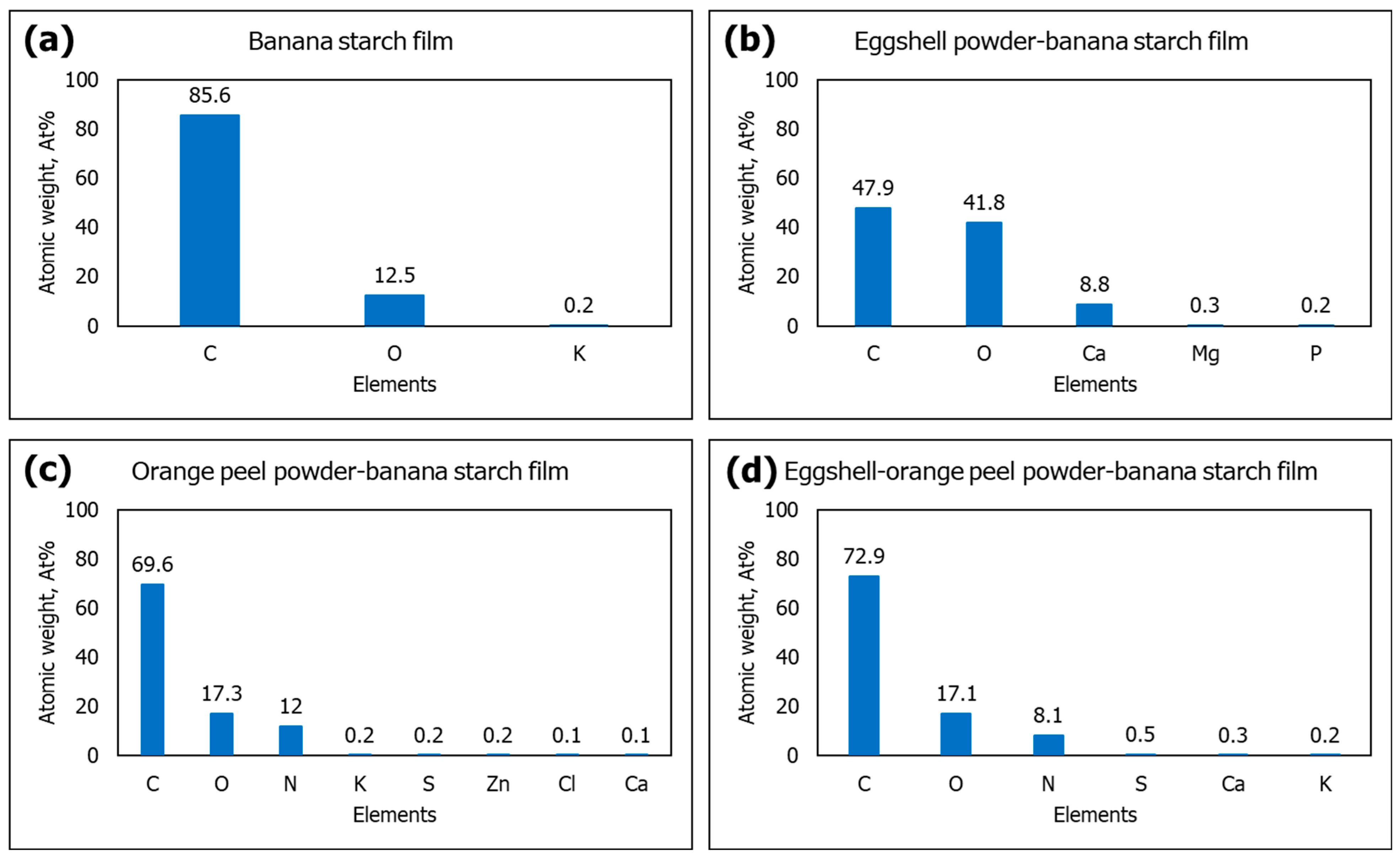

3.3. Morphology Analysis

3.4. Infrared Spectroscopy

3.5. Thickness, Density, Porosity, and Water Barrier Property

3.6. Effects on pH, Biosorbent Dosage, Contact Time and Initial Concentration

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Food and Agriculture Organization (FAO). Strategic Work of FAO for Sustainable Food and Agriculture; Food and Agriculture Organization: Rome, Italy, 2017. [Google Scholar]

- Duque-Acevedo, M.; Belmonte-Urena, L.J.; Cortés-García, F.J.; Camacho-Ferre, F. Agricultural waste: Review of the evolution, approaches and perspectives on alternative uses. Glob. Ecol. Conserv. 2020, 22, e00902. [Google Scholar] [CrossRef]

- Musonge, P.; Harripersadth, C. The Applicability of Eggshell Waste as a Sustainable Biosorbent Medium in Wastewater Treatment—A Review. Adv. Wastewater Treat. I 2021, 91, 171–192. [Google Scholar] [CrossRef]

- Mahani, N.A.A.M.; Hamidon, N. Eggshell Powder as an Adsorbent for Removal of Lead (II) in Panchor’ s River. J. Adv. Manuf. Technol. 2021, 2, 42–49. [Google Scholar] [CrossRef]

- Mittal, A.; Teotia, M.; Soni, R.K.; Mittal, J. Applications of egg shell and egg shell membrane as adsorbents: A review. J. Mol. Liq. 2016, 223, 376–387. [Google Scholar] [CrossRef]

- Wang, G.; Liu, N.; Zhang, S.; Zhu, J.; Xiao, H.; Ding, C. Preparation and application of granular bentonite-eggshell composites for heavy metal removal. J. Porous Mater. 2022, 29, 817–826. [Google Scholar] [CrossRef]

- Marković, M.; Gorgievski, M.; Štrbac, N.; Grekulović, V.; Božinović, K.; Zdravković, M.; Vuković, M. Raw Eggshell as an Adsorbent for Copper Ions Biosorption—Equilibrium, Kinetic, Thermodynamic and Process Optimization Studies. Metals 2023, 13, 206. [Google Scholar] [CrossRef]

- Annane, K.; Lemlikchi, W.; Tingry, S. Efficiency of eggshell as a low-cost adsorbent for removal of cadmium: Kinetic and isotherm studies. Biomass Convers. Biorefin. 2021, 1–12. [Google Scholar] [CrossRef]

- Xiao, K.; Liu, H.; Li, Y.; Yi, L.; Zhang, X.; Hu, H.; Yao, H. Correlations between hydrochar properties and chemical constitution of orange peel waste during hydrothermal carbonization. Bioresour. Technol. 2018, 265, 432–436. [Google Scholar] [CrossRef] [PubMed]

- Khalifa, E.B.; Rzig, B.; Chakroun, R.; Nouagui, H.; Hamrouni, B. Application of response surface methodology for chromium removal by adsorption on low-cost biosorbent. Chemom. Intell. Lab. Syst. 2019, 189, 18–26. [Google Scholar] [CrossRef]

- Tang, H.; Zhang, Y.; Zhang, Y.; Xiao, Q.; Zhao, X.; Yang, S. Turning waste into adsorbent: Modification of discarded orange peel for highly efficient removal of Cd (II) from aqueous solution. Biochem. Eng. J. 2022, 185, 108497. [Google Scholar] [CrossRef]

- Altunkaynak, Y.; Canpolat, M.; Yavuz, Ö. Adsorption of cobalt (II) ions from aqueous solution using orange peel waste: Equilibrium, kinetic and thermodynamic studies. J. Iran. Chem. Soc. 2022, 19, 2437–2448. [Google Scholar] [CrossRef]

- Pavithra, S.; Thandapani, G.; Sugashini, S.; Sudha, P.N.; Alkhamis, H.H.; Alrefaei, A.F.; Almutairi, M.H. Batch adsorption studies on surface tailored chitosan/orange peel hydrogel composite for the removal of Cr (VI) and Cu (II) ions from synthetic wastewater. Chemosphere 2021, 271, 129415. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.; Chen, L.; Ye, Z.; Chen, X.; Wang, X.; Wei, Y. Film-like chitin/polyethylenimine biosorbent for highly efficient removal of uranyl-carbonate compounds from water. J. Environ. Chem. Eng. 2021, 9, 105340. [Google Scholar] [CrossRef]

- Hu, Y.; Shi, L.; Ren, Z.; Hao, G.; Chen, J.; Weng, W. Characterization of emulsion films prepared from soy protein isolate at different preheating temperatures. J. Food Eng. 2021, 309, 110697. [Google Scholar] [CrossRef]

- Vonnie, J.M.; Jing Ting, B.; Rovina, K.; Erna, K.H.; Felicia, W.X.L.; Nur ‘Aqilah, N.M.; Abdul Wahab, R. Development of Aloe Vera-Green Banana Saba-Curcumin Composite Film for Colorimetric Detection of Ferrum (II). Polymers 2022, 14, 2353. [Google Scholar] [CrossRef]

- Jridi, M.; Boughriba, S.; Abdelhedi, O.; Nciri, H.; Nasri, R.; Kchaou, H.; Kaya, M.; Sebai, H.; Zouari, N.; Nasri, M. Investigation of physicochemical and antioxidant properties of gelatin edible film mixed with blood orange (Citrus sinensis) peel extract. Food Packag. Shelf Life 2019, 21, 100342. [Google Scholar] [CrossRef]

- Akubor, P.I.; Igba, T. Effect of pre gelatinization and annealing on the chemical composition, functional and pasting properties of starch prepared from unripe banana fruits. South Asian J. Food Technol. Environ. 2019, 5, 807–816. [Google Scholar] [CrossRef]

- Rovina, K.; Vonnie, J.M.; Shaeera, S.N.; Yi, S.X.; Abd Halid, N.F. Development of biodegradable hybrid polymer film for detection of formaldehyde in seafood products. Sens. Bio-Sens. Res. 2020, 27, 100310. [Google Scholar] [CrossRef]

- Sert, D.; Üçok, G.; Kara, Ü.; Mercan, E.M.İ.N. Development of gelatine-based edible film by addition of whey powders with different demineralisation ratios: Physicochemical, thermal, mechanical and microstructural characteristics. Int. J. Dairy Technol. 2021, 74, 414–424. [Google Scholar] [CrossRef]

- Dutta, J.; Devi, N. Preparation, optimization, and characterization of chitosan-sepiolite nanocomposite films for wound healing. Int. J. Biol. Macromol. 2021, 186, 244–254. [Google Scholar] [CrossRef]

- Khedri, S.; Sadeghi, E.; Rouhi, M.; Delshadian, Z.; Mortazavian, A.M.; de Toledo Guimarães, J.; Mohammadi, R. Bioactive edible films: Development and characterization of gelatin edible films incorporated with casein phosphopeptides. LWT 2021, 138, 110649. [Google Scholar] [CrossRef]

- Sree, G.V.; Nagaraaj, P. Enhancement of PVA packaging properties using calcined eggshell waste as filler and nanonutrient. Mater. Chem. Phys. 2022, 291, 126611. [Google Scholar] [CrossRef]

- Cazón, P.; Vázquez, M.; Velazquez, G. Novel composite films based on cellulose reinforced with chitosan and polyvinyl alcohol: Effect on mechanical properties and water vapour permeability. Polym. Test. 2018, 69, 536–544. [Google Scholar] [CrossRef]

- Chávez-Salazar, A.; Bello-Pérez, L.A.; Agama-Acevedo, E.; Castellanos-Galeano, F.J.; Álvarez-Barreto, C.I.; Pacheco-Vargas, G. Isolation and Partial Characterization of Starch from Banana Cultivars Grown in Colombia. Int. J. Biol. Macromol. 2017, 98, 240–246. [Google Scholar] [CrossRef] [PubMed]

- Alias, N.F.; Ismail, H. Glutaraldehyde Crosslinked Polyvinyl Alcohol/Eggshell Powder Biocomposite Films: Properties and Biodegradability. J. Phys. Sci. 2020, 31, 45–60. [Google Scholar] [CrossRef]

- Durmus, D. CIELAB color space boundaries under theoretical spectra and 99 test color samples. Color Res. Appl. 2020, 45, 796–802. [Google Scholar] [CrossRef]

- Chareonsuk, P.; Mamaka, N.; Kulwongwit, N.; Wiriya-amornchai, A.; Bunroek, P. The study of environmental stabilization for natural color dyed of eggshell powder filled in polylactic acid bio-composites. Mater. Today Proc. 2021, 47, 3570–3576. [Google Scholar] [CrossRef]

- Kevij, H.T.; Salami, M.; Mohammadian, M.; Khodadadi, M.; Emam-Djomeh, Z. Mechanical, physical, and bio-functional properties of biopolymer films based on gelatin as affected by enriching with orange peel powder. Polym. Bull. 2021, 78, 4387–4402. [Google Scholar] [CrossRef]

- Terzioğlu, P.; Güney, F.; Parın, F.N.; Şen, İ.; Tuna, S. Biowaste orange peel incorporated chitosan/polyvinyl alcohol composite films for food packaging applications. Food Packag. Shelf Life 2021, 30, 100742. [Google Scholar] [CrossRef]

- Tibolla, H.; Pelissari, F.M.; Martins, J.T.; Lanzoni, E.M.; Vicente, A.A.; Menegalli, F.C.; Cunha, R.L. Banana starch nanocomposite with cellulose nanofibers isolated from banana peel by enzymatic treatment: In vitro cytotoxicity assessment. Carbohydr. Polym. 2019, 207, 169–179. [Google Scholar] [CrossRef]

- Wongphan, P.; Harnkarnsujarit, N. Characterization of starch, agar and maltodextrin blends for controlled dissolution of edible films. Int. J. Biol. Macromol. 2020, 156, 80–93. [Google Scholar] [CrossRef]

- Jiang, B.; Li, S.; Wu, Y.; Song, J.; Chen, S.; Li, X.; Sun, H. Preparation and characterization of natural corn starch-based composite films reinforced by eggshell powder. CyTA-J. Food. 2018, 16, 1045–1054. [Google Scholar] [CrossRef]

- Afolabi, F.O.; Musonge, P.; Bakare, B.F. Application of the response surface methodology in the removal of Cu2+ and Pb2+ from aqueous solutions using orange peels. Sci. Afr. 2021, 13, e00931. [Google Scholar] [CrossRef]

- Yaradoddi, J.S.; Banapurmath, N.R.; Ganachari, S.V.; Soudagar, M.E.M.; Sajjan, A.M.; Kamat, S.; Mujtaba, M.A.; Shettar, A.S.; Anqi, A.E.; Safaei, M.R.; et al. Bio-based material from fruit waste of orange peel for industrial applications. J. Mater. Res. Technol. 2022, 17, 3186–3197. [Google Scholar] [CrossRef]

- Rápó, E.; Aradi, L.E.; Szabó, Á.; Posta, K.; Szép, R.; Tonk, S. Adsorption of remazol brilliant violet-5R textile dye from aqueous solutions by using eggshell waste biosorbent. Sci. Rep. 2020, 10, 8385. [Google Scholar] [CrossRef]

- Sankaran, R.; Show, P.L.; Ooi, C.W.; Ling, T.C.; Shu-Jen, C.; Chen, S.Y.; Chang, Y.K. Feasibility assessment of removal of heavy metals and soluble microbial products from aqueous solutions using eggshell wastes. Clean Technol. Environ. Policy 2020, 22, 773–786. [Google Scholar] [CrossRef]

- Pongsuwan, C.; Boonsuk, P.; Sermwittayawong, D.; Aiemcharoen, P.; Mayakun, J.; Kaewtatip, K. Banana inflorescence waste fiber: An effective filler for starch-based bioplastics. Ind. Crops Prod. 2022, 180, 114731. [Google Scholar] [CrossRef]

- Kim, D.; Hwang, S.J.; Kim, Y.; Jeong, C.H.; Hong, Y.P.; Ryoo, K.S. Removal of Heavy Metals from Water Using Chicken Egg Shell Powder as a Bio-Adsorbent. Bull. Korean Chem. Soc. 2019, 40, 1156–1161. [Google Scholar] [CrossRef]

- Ji, M.; Li, F.; Li, J.; Li, J.; Zhang, C.; Sun, K.; Guo, Z. Enhanced mechanical properties, water resistance, thermal stability, and biodegradation of the starch-sisal fibre composites with various fillers. Mater. Des. 2021, 198, 109373. [Google Scholar] [CrossRef]

- Dey, S.; Basha, S.R.; Babu, G.V.; Nagendra, T. Characteristic and biosorption capacities of orange peels biosorbents for removal of ammonia and nitrate from contaminated water. Clean. Mater. 2021, 1, 100001. [Google Scholar] [CrossRef]

- Patel, D.H.; Naik, J.H.; Amaresan, N. Synergistic effect of root-associated bacteria on plant growth and certain physiological parameters of banana plant (Musa acuminata). Arch. Agron. Soil Sci. 2018, 64, 1021–1031. [Google Scholar] [CrossRef]

- Khoza, M.; Kayitesi, E.; Dlamini, B.C. Physicochemical characteristics, microstructure and health promoting properties of green banana flour. Foods 2021, 10, 2894. [Google Scholar] [CrossRef]

- Akinhanmi, T.F.; Ofudje, E.A.; Adeogun, A.I.; Aina, P.; Joseph, I.M. Orange peel as low-cost adsorbent in the elimination of Cd (II) ion: Kinetics, isotherm, thermodynamic and optimization evaluations. Bioresour. Bioprocess. 2020, 7, 34. [Google Scholar] [CrossRef]

- Iwase, K.; Mori, K. Crystal structure, microhardness, and toughness of biomineral CaCO3. Cryst. Growth Des. 2020, 20, 2091–2098. [Google Scholar] [CrossRef]

- Asri, N.P.; Podjojono, B.; Fujiani, R. Utilization of eggshell waste as low-cost solid base catalyst for biodiesel production from used cooking oil. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2017; Volume 67. [Google Scholar] [CrossRef]

- Adeogun, A.I.; Akande, J.A.; Idowu, M.A.; Kareem, S.O. Magnetic tuned sorghum husk biosorbent for effective removal of cationic dyes from aqueous solution: Isotherm, kinetics, thermodynamics and optimization studies. Appl. Water Sci. 2019, 9, 160. [Google Scholar] [CrossRef]

- Alimi, B.A.; Workneh, T.S.; Zubair, B.A. Microstructural and physicochemical properties of biodegradable films developed from false banana (Ensete ventricosum) starch. Heliyon 2022, 8, e09148. [Google Scholar] [CrossRef] [PubMed]

- Pelissari, F.M.; Andrade-Mahecha, M.M.; do Amaral Sobral, P.J.; Menegalli, F.C. Nanocomposites based on banana starch reinforced with cellulose nanofibers isolated from banana peels. J. Colloid Interface Sci. 2017, 505, 154–167. [Google Scholar] [CrossRef] [PubMed]

- Onwubu, S.C.; Vahed, A.; Singh, S.; Kanny, K.M. Physicochemical characterization of a dental eggshell powder abrasive material. J. Appl. Biomater. Funct. Mater. 2017, 15, e341–e346. [Google Scholar] [CrossRef] [PubMed]

- Alimi, B.A.; Workneh, T.S. Structural and physicochemical properties of heat moisture treated and citric acid modified acha and iburu starches. Food Hydrocoll. 2018, 81, 449–455. [Google Scholar] [CrossRef]

- Vonnie, J.M.; Rovina, K.; Azhar, R.A.; Huda, N.; Erna, K.H.; Felicia, W.X.L.; Nur’Aqilah, M.N.; Halid, N.F.A. Development and Characterization of the Biodegradable Film Derived from Eggshell and Cornstarch. J. Funct. Biomater. 2022, 13, 67. [Google Scholar] [CrossRef] [PubMed]

- Fehlberg, J.; Lee, C.L.; Matuana, L.M.; Almenar, E. Orange peel waste from juicing as raw material for plastic composites intended for use in food packaging. J. Appl. Polym. Sci. 2020, 137, 48841. [Google Scholar] [CrossRef]

- Chang, Q.; Li, C.; Sui, J.; Waterhouse, G.I.; Zhang, Z.M.; Yu, L.M. Cage-like eggshell membrane-derived Co-CoxSy-Ni/N, S-codoped carbon composites for electromagnetic wave absorption. Chem. Eng. J. 2022, 430, 132650. [Google Scholar] [CrossRef]

- Özcan, S.; Çelebi, H.; Özcan, Z. Removal of heavy metals from simulated water by using eggshell powder. Desalin. Water Treat. 2018, 127, 75–82. [Google Scholar] [CrossRef]

- Wang, R.; Li, X.; Liu, L.; Chen, W.; Bai, J.; Ma, F.; Liu, X.; Kang, W. Preparation and characterization of edible films composed of Dioscorea opposita Thunb. mucilage and starch. Polym. Test. 2020, 90, 106708. [Google Scholar] [CrossRef]

- Rasti, A.; Pineda, M.; Razavi, M. Assessment of soil moisture content measurement methods: Conventional laboratory oven versus halogen moisture analyzer. J. Soil Water Conserv. 2020, 4, 151–160. [Google Scholar] [CrossRef]

- Shafqat, A.; Al-Zaqri, N.; Tahir, A.; Alsalme, A. Synthesis and characterization of starch based bioplatics using varying plant-based ingredients, plasticizers and natural fillers. Saudi J. Biol. Sci. 2021, 28, 1739–1749. [Google Scholar] [CrossRef]

- Nogueira, G.F.; Fakhouri, F.M.; de Oliveira, R.A. Effect of incorporation of blackberry particles on the physicochemical properties of edible films of arrowroot starch. Dry. Technol. 2019, 37, 448–457. [Google Scholar] [CrossRef]

- Vonnie, J.M.; Li, C.S.; Erna, K.H.; Yin, K.W.; Felicia, W.X.L.; Aqilah, M.N.N.; Rovina, K. Development of Eggshell-Based Orange Peel Activated Carbon Film for Synergetic Adsorption of Cadmium (II) Ion. Nanomaterials 2022, 12, 2750. [Google Scholar] [CrossRef]

- Leites, L.C.; Frick, P.J.M.; Cristina, T.I. Influence of the incorporation form of waste from the production of orange juice in the properties of cassava starch-based films. Food Hydrocoll. 2021, 117, 106730. [Google Scholar] [CrossRef]

- Chhatariya, H.F.; Srinivasan, S.; Choudhary, P.M.; Begum, S.S. Corn starch biofilm reinforced with orange peel powder: Characterization of physicochemical and mechanical properties. Mater. Today Proc. 2022, 59, 884–892. [Google Scholar] [CrossRef]

- Noshirvani, N.; Ghanbarzadeh, B.; Fasihi, H.; Almasi, H. Starch–PVA nanocomposite film incorporated with cellulose nanocrystals and MMT: A comparative study. Int. J. Food Eng. 2016, 12, 37–48. [Google Scholar] [CrossRef]

- Bhutto, A.A.; Baig, J.A.; Kazi, T.G.; Sierra-Alvarez, R.; Akhtar, K.; Perveen, S.; Afridi, H.I.; Ali, H.E.; Hol, A.; Samejo, S. Biosynthesis of aluminium oxide nanobiocomposite and its application for the removal of toxic metals from drinking water. Ceram. Int. 2023, 49, 14615–14623. [Google Scholar] [CrossRef]

- Wattanakornsiri, A.; Rattanawan, P.; Sanmueng, T.; Satchawan, S.; Jamnongkan, T.; Phuengphai, P. Local fruit peel biosorbents for lead (II) and cadmium (II) ion removal from waste aqueous solution: A kinetic and equilibrium study. S. Afr. J. Chem. Eng. 2022, 42, 306–317. [Google Scholar] [CrossRef]

- Angelis, G.D.; Medeghini, L.; Conte, A.M.; Mignardi, S. Recycling of eggshell waste into low-cost adsorbent for Ni removal from wastewater. J. Clean. Prod. 2017, 164, 1497–1506. [Google Scholar] [CrossRef]

- Mahmoodi, N.M.; Taghizadeh, M.; Taghizadeh, A. Mesoporous activated carbons of low-cost agricultural bio-wastes with high adsorption capacity: Preparation and artificial neural network modeling of dye removal from single and multicomponent (binary and ternary) systems. J. Mol. Liq. 2018, 269, 217–228. [Google Scholar] [CrossRef]

| Powder | Yield (%) | Photo |

|---|---|---|

| Eggshell | 96.64 ± 1.94 |  |

| Orange peel | 21.69 ± 1.47 |  |

| Banana starch | 13.59 ± 0.99 |  |

| Film | BS | ESP-BS | OPP-BS | ESP-OPP-BS |

|---|---|---|---|---|

| L | 93.32 ± 1.53 d | 72.50 ± 1.70 b | 84.90 ± 2.75 c | 61.06 ± 1.17 a |

| a | −5.68 ± 0.30 a | 3.86 ± 0.15 b | −5.52 ± 0.44 a | −3.86 ± 0.11 b |

| b | 11.14 ± 1.54 a | 13.54 ± 0.91 b | 19.66 ± 0.15 c | 23.26 ± 0.33 d |

| ΔE | 9.68 ± 1.56 a | 24.65 ± 1.45 c | 19.86 ± 1.43 b | 39.22 ± 0.86 d |

| Yellowness index | 17.09 ± 2.61 a | 26.68 ± 1.69 b | 33.11 ± 1.18 c | 54.43 ± 0.57 d |

| Whiteness index | 85.80 ± 1.98 d | 69.08 ± 1.43 b | 74.53 ± 1.71 c | 54.47 ± 0.86 a |

| Color | White | Light brown | Light yellow | Yellow-brown |

| Texture | Dry, smooth | Dry, rough, brittle | Dry, smooth | Dry, hard, rough |

| Smell | Odorless | Sulfur smell | Orange fragrance | Soft orange fragrance |

| Appearance |  |  |  |  |

| Parameters | BS | ESP-BS | OPP-BS | ESP-OPP-BS |

|---|---|---|---|---|

| Thickness (mm) | 0.02 ± 0.01 a | 0.05 ± 0.01 b | 0.04 ± 0.01 b | 0.07 ± 0.01 c |

| Density (g/cm3) | 0.26 ± 0.14 b | 0.13 ± 0.03 ab | 0.20 ± 0.08 ab | 0.09 ± 0.01 a |

| Porosity (%) | 36.52 ± 1.82 a | 78.51 ± 3.24 bc | 76.57 ± 2.92 b | 82.53 ± 3.94 c |

| Moisture content (%) | 11.23 ± 0.72 a | 9.98 ± 0.46 bc | 10.59 ± 0.41 ab | 10.23 ± 0.40 bc |

| Water solubility (%) | 20.10 ± 2.29 c | 13.06 ± 1.31 a | 16.66 ± 1.64 b | 13.58 ± 1.01 a |

| Water adsorption (%) | 164.07 ± 47.30 b | 88.64 ± 8.87 a | 123.29 ± 28.83 ab | 93.88 ± 28.48 a |

| Water vapor permeability (gs−1 m Pa) (×10−12) | 2.20 ± 0.41 a | 5.22 ± 2.08 a | 3.95 ± 2.29 a | 6.47 ± 2.59 a |

| Biowaste Biosorbents | Target Analytes | Removal Percentage (%) | References |

|---|---|---|---|

| Eggshell powder | Pb(II) | 48.21 | [4] |

| Granular bentonite-eggshell composites | Pb(II) | 99.90 | [6] |

| Raw eggshell | Cu(II) | 97.06 | [7] |

| Orange peel | Cr(VI) | 97.00 | [10] |

| Modified orange peel | Cd(II) | 98.00 | [11] |

| Chitosan/orange peel hydrogel composite | Cr(VI), Cu(II) | 80.43, 82.47 | [13] |

| Orange peel | Cu(II), Pb(II) | 88.00, 90.00 | [34] |

| Orange peel | Cd(II) | 88.34 | [44] |

| Dragon fruit peel, rambutan peel, and passion fruit peel | Pb(II), Cd(II) | 97.87, 97.10 | [65] |

| Eggshell waste | Ni(II) | 91.00 | [66] |

| Kiwi, cucumber, and potato peel | Methylene blue | 99.90 | [67] |

| Eggshell and orange peel powder film | Cd(II) | 99.95 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vonnie, J.M.; Rovina, K.; ‘Aqilah, N.M.N.; Felicia, X.W.L. Development and Characterization of Biosorbent Film from Eggshell/Orange Waste Enriched with Banana Starch. Polymers 2023, 15, 2414. https://doi.org/10.3390/polym15112414

Vonnie JM, Rovina K, ‘Aqilah NMN, Felicia XWL. Development and Characterization of Biosorbent Film from Eggshell/Orange Waste Enriched with Banana Starch. Polymers. 2023; 15(11):2414. https://doi.org/10.3390/polym15112414

Chicago/Turabian StyleVonnie, Joseph Merillyn, Kobun Rovina, Nasir Md Nur ‘Aqilah, and Xia Wen Ling Felicia. 2023. "Development and Characterization of Biosorbent Film from Eggshell/Orange Waste Enriched with Banana Starch" Polymers 15, no. 11: 2414. https://doi.org/10.3390/polym15112414

APA StyleVonnie, J. M., Rovina, K., ‘Aqilah, N. M. N., & Felicia, X. W. L. (2023). Development and Characterization of Biosorbent Film from Eggshell/Orange Waste Enriched with Banana Starch. Polymers, 15(11), 2414. https://doi.org/10.3390/polym15112414