Synthesis, Thermal Behavior, and Mechanical Properties of Fully Biobased Poly(Hexamethylene 2,5-Furandicarboxylate-Co-Sebacate) Copolyesters

Abstract

:1. Introduction

2. Experimental

2.1. Materials

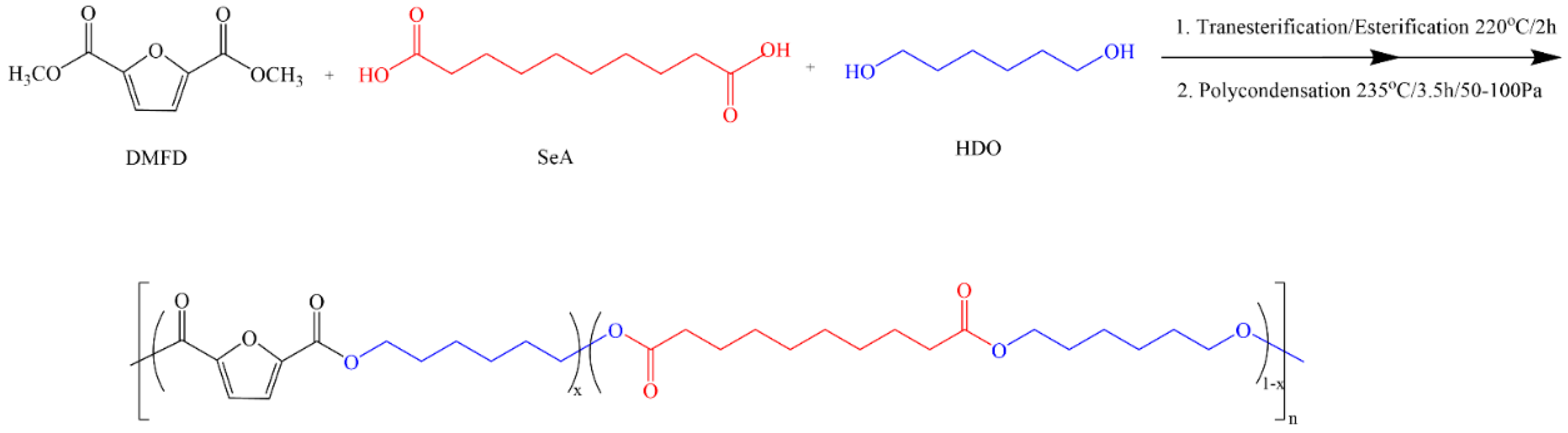

2.2. Synthesis of PHFSe Copolyesters

2.3. Characterizations

3. Results and Discussion

3.1. Composition and [η] Values of PHF and PHFSe Copolyesters

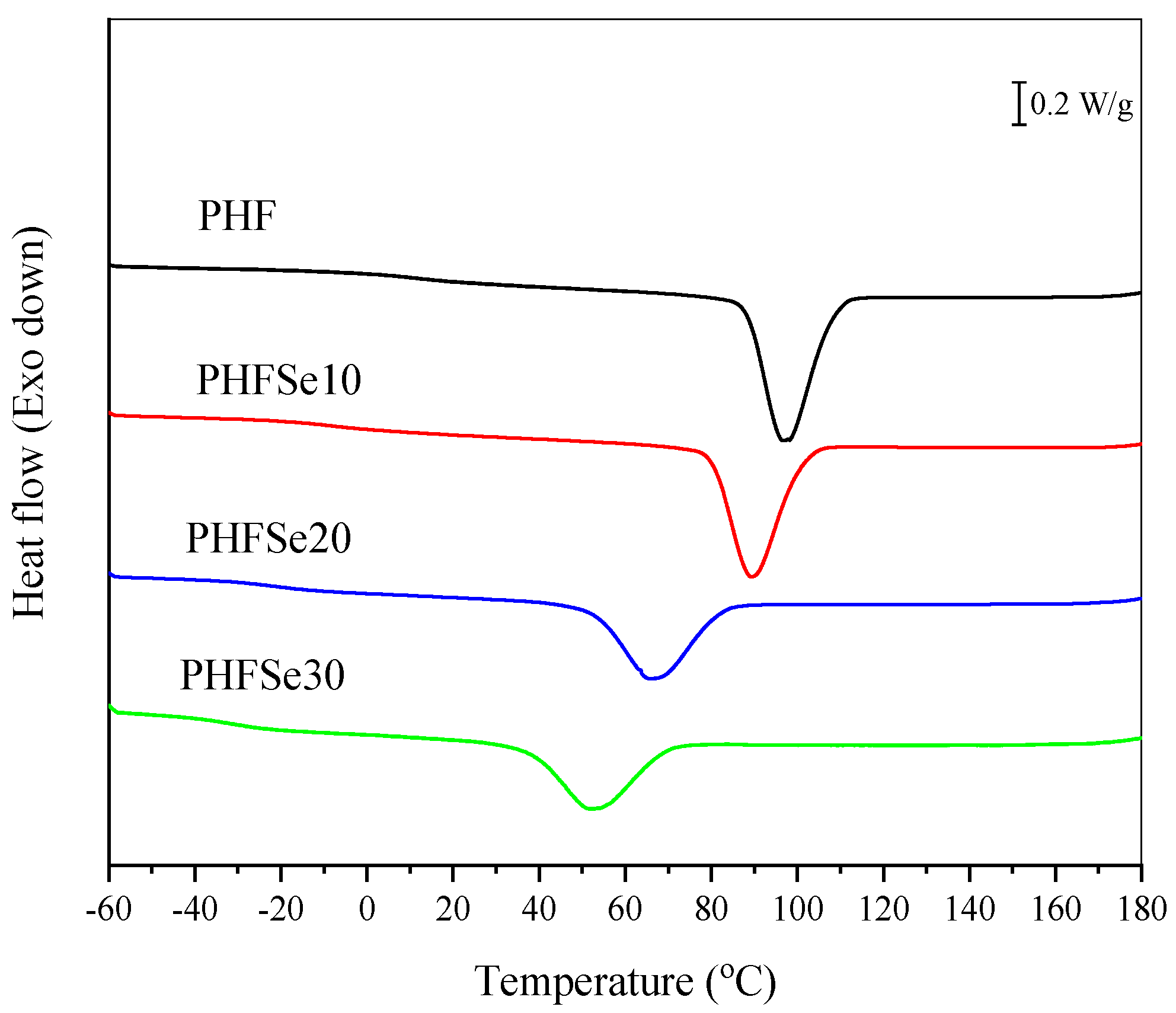

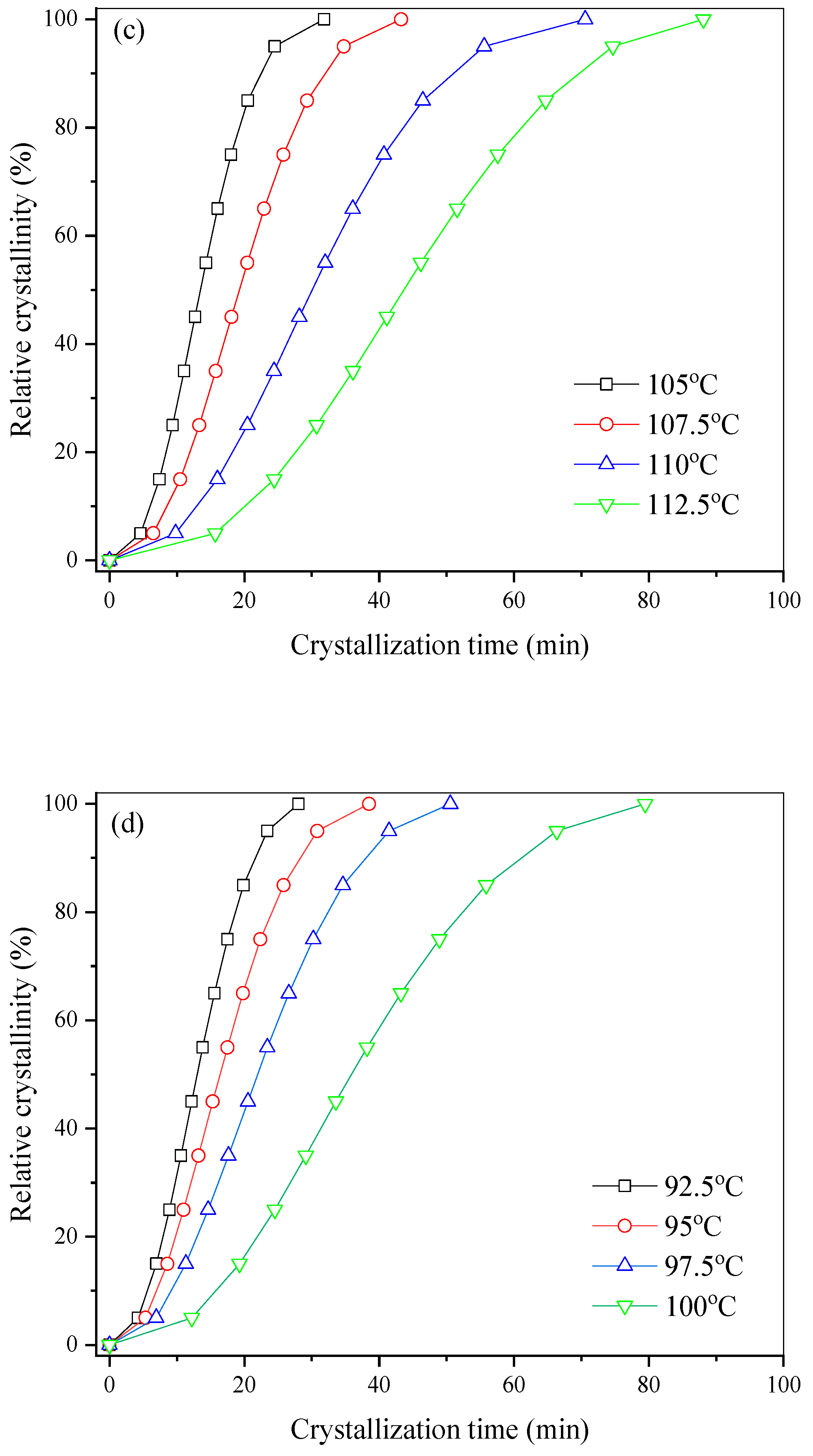

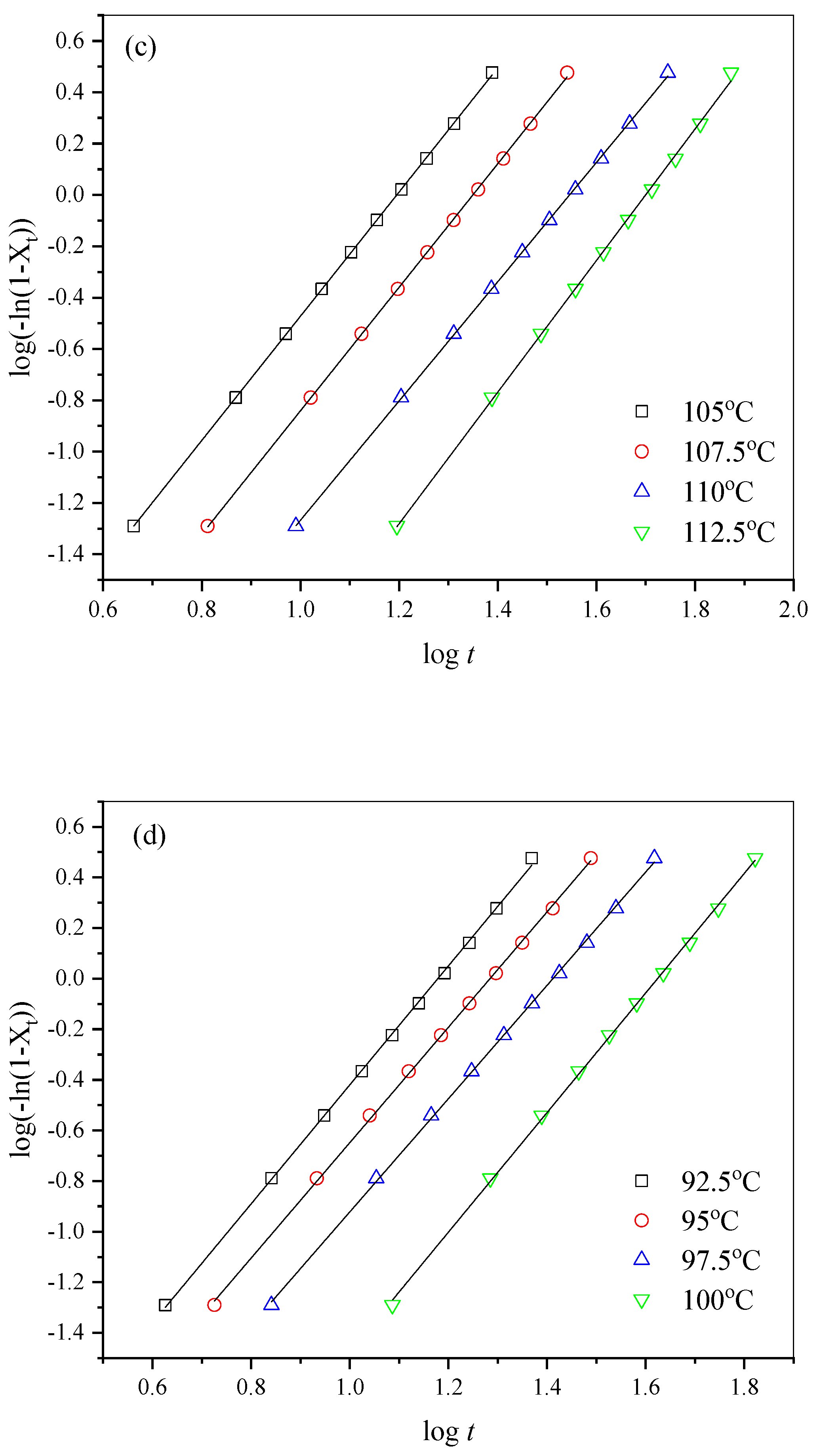

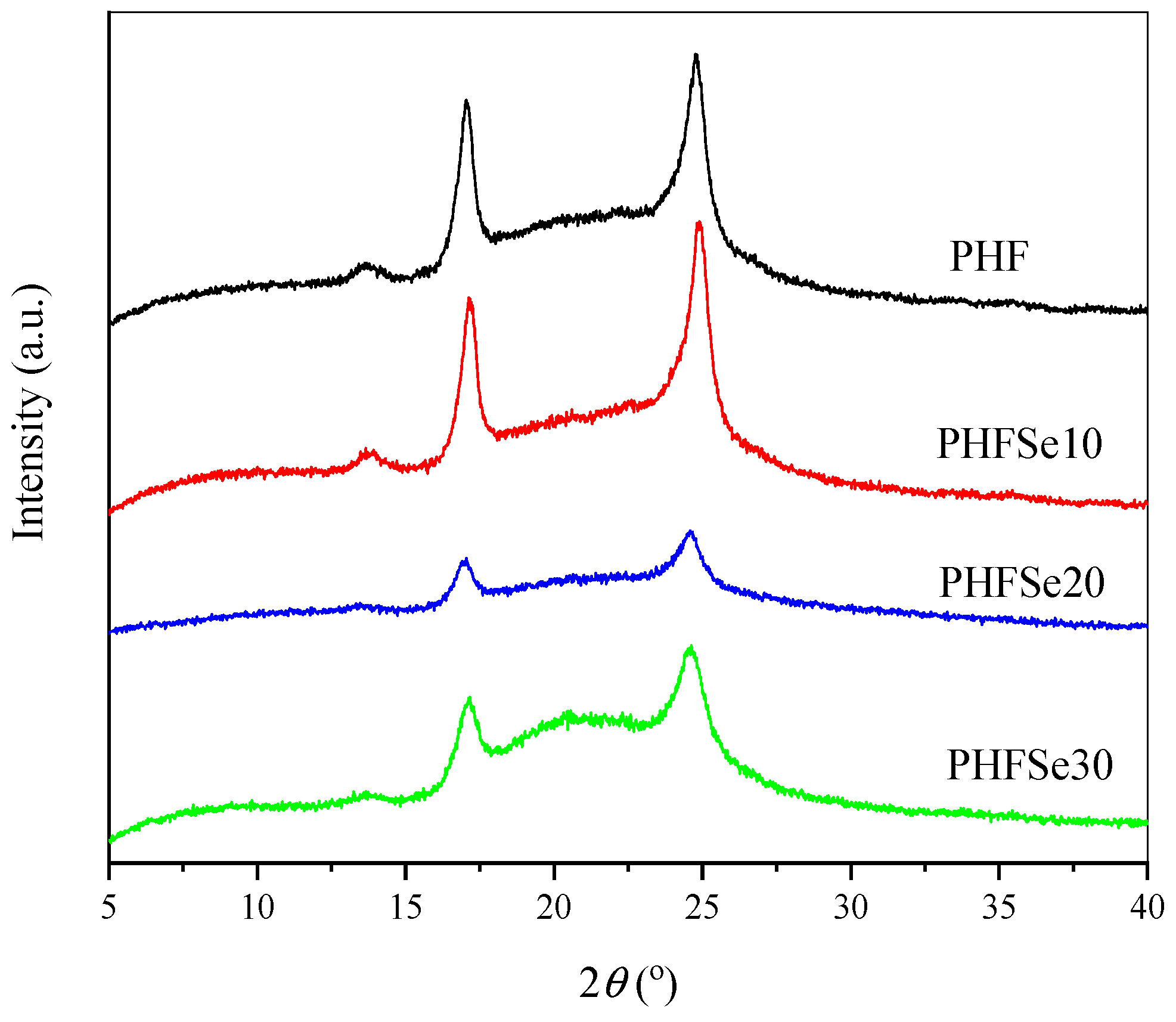

3.2. Thermal Properties and Crystal Structure Studies

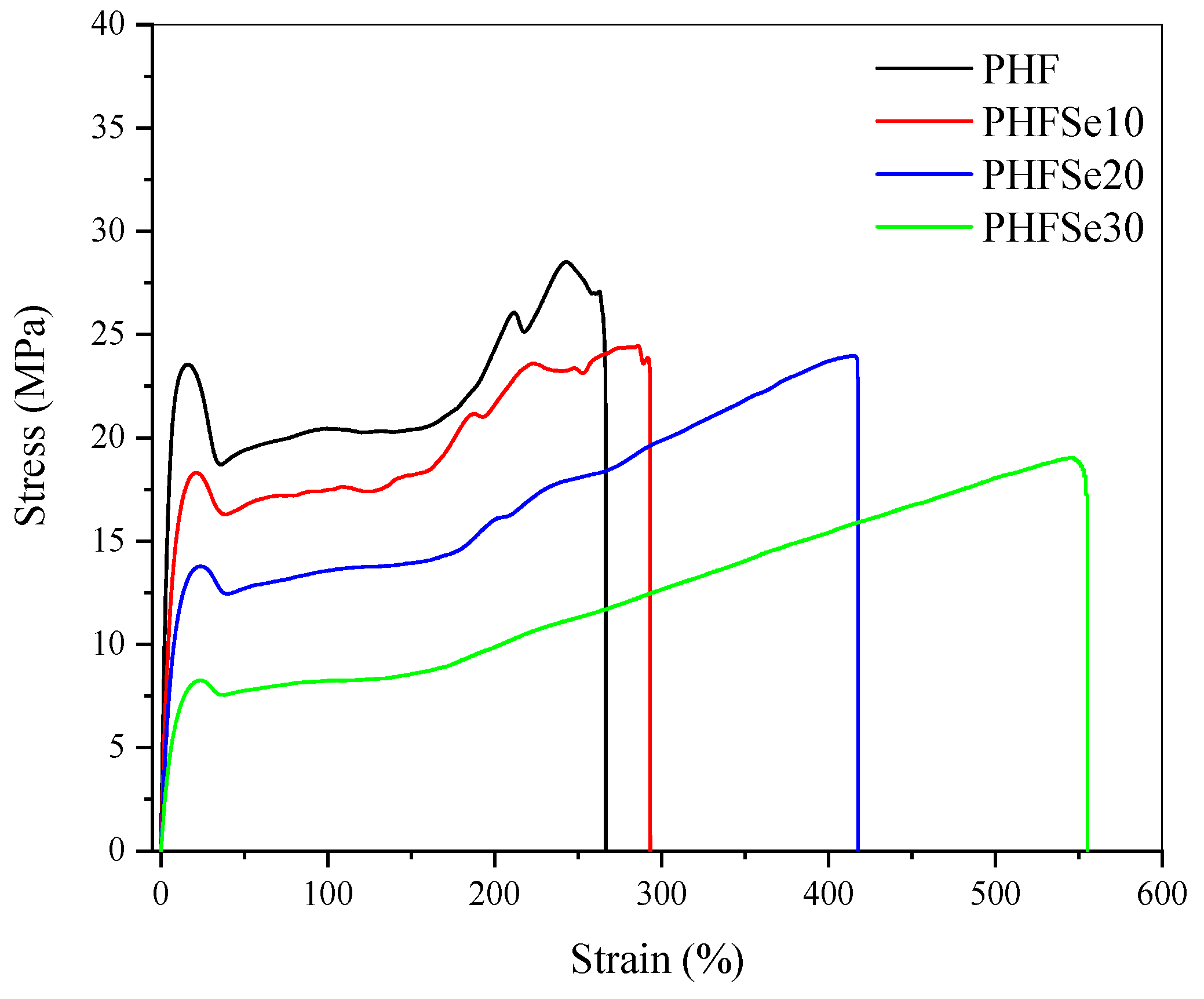

3.3. Tensile Mechanical Property Study

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bilo, F.; Pandini, S.; Sartore, L.; Depero, L.; Gargiulo, G.; Bonassi, A.; Federici, S.; Bontempi, E. A sustainable bioplastic obtained from rice straw. J. Clean. Prod. 2018, 200, 357–368. [Google Scholar] [CrossRef]

- Su, B.; Chen, Z.; Huang, J. Impact attribution of climate change: The new cognition from IPCC AR6 WGⅡ. J. Trans. Atmos. Sci. 2022, 45, 512–519. [Google Scholar]

- Sheldon, R. Utilisation of biomass for sustainable fuels and chemicals: Molecules, methods and metrics. Catal. Today 2011, 167, 3–13. [Google Scholar] [CrossRef]

- Gallezot, P. ChemInform abstract: Conversion of biomass to selected chemical products. Chem. Soc. Rev. 2012, 41, 1538–1558. [Google Scholar] [CrossRef]

- Iwata, T. Biodegradable and bio-based polymers: Future prospects of eco-friendly plastics. Angew. Chem. Int. Ed. 2015, 54, 3210–3215. [Google Scholar] [CrossRef]

- Bond, J.; Alonso, D.; Wang, D.; West, R.; Dumesic, J. Integrated catalytic conversion of gamma-valerolactone to liquid alkenes for transportation fuels. Science 2010, 327, 1110–1114. [Google Scholar] [CrossRef] [PubMed]

- Motagamwala, A.; Won, W.; Sener, C.; Alonso, D.; Maravelias, C.; Dumesic, J. Toward biomass-derived renewable plastics: Production of 2,5-furandicarboxylic acid from fructose. Sci. Adv. 2018, 4, 9722. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kasmi, N.; Ainali, N.; Agapiou, E.; Papadopoulos, L.; Papageorgiou, G.; Bikiaris, D. Novel high Tg fully biobased poly(hexamethylene-co-isosorbide-2,5-furan dicarboxylate) copolyesters: Synergistic effect of isosorbide insertion on thermal performance enhancement. Polym. Degrad. Stab. 2019, 169, 108983. [Google Scholar] [CrossRef]

- Wu, J.; Xie, H.; Wu, L.; Li, B.; Dubois, P. Correction: DBU-catalyzed biobased poly(ethylene 2,5-furandicarboxylate) polyester with rapid melt crystallization: Synthesis, crystallization kinetics and melting behavior. RSC Adv. 2017, 7, 13877. [Google Scholar] [CrossRef] [Green Version]

- Lotti, N.; Munari, A.; Gigli, M.; Gazzano, M.; Tsanaktsis, V.; Bikiaris, D.; Papageorgiou, G. Thermal and structural response of in situ prepared biobased poly(ethylene 2,5-furandicarboxylate) nanocomposites. Polymer 2016, 103, 288–298. [Google Scholar] [CrossRef]

- Van Berkel, J.; Guigo, N.; Kolstad, J.; Sipos, L.; Wang, B.; Dam, M.; Sbirrazzuoli, N. Isothermal crystallization kinetics of poly (ethylene 2,5-furandicarboxylate). Macromol. Mater. Eng. 2015, 300, 466–474. [Google Scholar] [CrossRef]

- Codou, A.; Guigo, N.; Van Berkel, J.; De Jong, E.; Sbirrazzuoli, N. Non-isothermal crystallization kinetics of biobased poly(ethylene 2,5-furandicarboxylate) synthesized via the direct esterification process. Macromol. Chem. Phys. 2015, 215, 2065–2074. [Google Scholar] [CrossRef]

- Knoop, R.; Vogelzang, W.; Haveren, J.; Es, D. High molecular weight poly(ethylene-2,5-furanoate); Critical aspects in synthesis and mechanical property determination. J. Polym. Sci. Polym. Chem. 2013, 51, 4191–4199. [Google Scholar] [CrossRef]

- Burgess, S.; Karvan, O.; Johnson, J.; Kriegel, R.; Koros, W. Oxygen sorption and transport in amorphous poly(ethylene furanoate). Polymer 2014, 55, 4748–4756. [Google Scholar] [CrossRef]

- Burgess, S.; Kriegel, R.; Koros, W. Carbon dioxide sorption and transport in amorphous poly(ethylene furanoate). Macromolecules 2015, 48, 2184–2193. [Google Scholar] [CrossRef]

- Jiang, M.; Liu, Q.; Zhang, Q.; Ye, C.; Zhou, G. A series of furan-aromatic polyesters synthesized via direct esterification method based on renewable resources. J. Polym. Sci. Polym. Chem. 2012, 50, 1026–1036. [Google Scholar] [CrossRef]

- Wang, J.; Liu, X.; Zhang, Y.; Liu, F.; Zhu, J. Modification of poly(ethylene 2,5- furandicarboxylate) with 1,4-cyclohexanedimethylene: Influence of composition on mechanical and barrier properties. Polymer 2016, 103, 1–8. [Google Scholar] [CrossRef]

- Wang, G.; Jiang, M.; Zhang, Q.; Wang, R.; Zhou, G. Biobased copolyesters: Synthesis, crystallization behavior, thermal and mechanical properties of poly(ethylene glycol sebacate-co-ethylene glycol 2,5-furan dicarboxylate). RSC Adv. 2017, 7, 13798–13807. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.; Zhang, K.; Jiang, Z.; Qiu, Z. Biobased poly(1,3-propylene 2,5-furandicarboxylate)-carbon nanotubes nanocomposites with enhanced thermal, mechanical properties and crystallization behavior. J. Polym. Environ. 2022, 30, 555–561. [Google Scholar] [CrossRef]

- Parageogious, G.; Papageorgiou, D.; Tsanaksis, V.; Bikiaris, D. Synthesis of the bio-based polyester poly(propylene 2,5-furan dicarboxylate). comparison of thermal behavior and solid state structure with its terephthalate and naphthalate homologues. Polymer 2015, 62, 28–38. [Google Scholar]

- Righetti, M.; Marchese, P.; Vannini, M.; Celli, A.; Lorenzetti, C.; Cavallo, D. Polymorphism and multiple melting behavior of bio-based poly(propylene 2,5-furandicarboxylate). Biomacromolecules 2020, 21, 2622–2634. [Google Scholar] [CrossRef] [PubMed]

- Wu, B.; Xu, Y.; Bu, Z.; Wu, L.; Li, B.; Dubois, P. Biobased poly(butylene 2,5-furandicarboxylate) and poly(butylene adipate-co-butylene 2,5-furandicarboxylate)s: From synthesis using highly purified 2,5-furandicarboxylic acid to thermo-mechanical properties. Polymer 2014, 55, 3648–3655. [Google Scholar] [CrossRef]

- Poulopoulou, N.; Nikolaidis, G.; Ioannidis, R.; Efstathiadou, V.; Terzopoulou, Z.; Papageorgiou, D.; Kapnisti, M.; Papageorgiou, G. Aromatic but sustainable: Poly(butylene 2,5-furandicarboxylate) as a crystallizing thermoplastic in the bioeconomy. Ind. Eng. Chem. Res. 2022, 61, 13461–13473. [Google Scholar] [CrossRef]

- Bi, T.; Qiu, Z. Synthesis thermal and mechanical properties of fully biobased poly(butylene-co-propylene 2,5-furandicarboxylate) copolyesters with low contents of propylene 2,5-furandicarboxylate units. Polymer 2020, 186, 122053. [Google Scholar] [CrossRef]

- Papageorgiou, G.; Tsanaktsis, V.; Papageorgiou, D.; Chrissafis, K.; Exarhopoulos, S.; Bikiaris, D. Furan-based polyesters from renewable resources: Crystallization and thermal degradation behavior of poly(hexamethylene 2,5-furan-dicarboxylate). Eur. Polym. J. 2015, 67, 383–396. [Google Scholar] [CrossRef]

- Zhang, J.; Liang, Q.; Xie, W.; Peng, L.; He, L.; He, Z. An eco-friendly method to get a bio-based dicarboxylic acid monomer 2,5-furandicarboxylic acid and its application in the synthesis of Poly(hexylene 2,5-furandicarboxylate) (PHF). Polymers 2019, 11, 197. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guidotti, G.; Soccio, M.; Garcia-Gutierrez, M.C.; Ezquerra, T.; Siracusa, V.; Gutierrez-Fernandez, E. Fully biobased superpolymers of 2,5-furandicarboxylic acid with different functional properties: From rigid to flexible, high performant packaging materials. ACS Sustain. Chem. Eng. 2020, 8, 9558–9568. [Google Scholar] [CrossRef]

- Qiu, S.; Su, Z.; Qiu, Z. Isothermal and nonisothermal crystallization kinetics of novel biobased poly(ethylene succinate-co-ethylene sebacate) copolymers from the amorphous state. J. Therm. Anal. Calorim. 2017, 129, 801–808. [Google Scholar] [CrossRef]

- Shang, Y.; Jiang, Z.; Qiu, Z. Synthesis, thermal and mechanical properties of novel biobased, biodegradable and double crystalline poly(butylene succinate)-b-Poly (butylene sebacate) multiblock copolymers. Polymer 2021, 214, 123248. [Google Scholar] [CrossRef]

- Papadopoulos, L.; Magaziotis, A.; Nerantzaki, M.; Terzopoulou, Z.; Papageorgiou, G.; Bikiaris, D. Synthesis and characterization of novel poly(ethylene furanoate-co-adipate) random copolyesters with enhanced biodegradability. Polym. Degrad. Stab. 2018, 156, 32–42. [Google Scholar] [CrossRef]

- Terzopoulou, Z.; Tsanaktsis, V.; Bikiaris, D.; Exarhopoulos, S.; Papageorgiou, D.; Papageorgiou, G. Biobased poly(ethylene furanoate-co-ethylene succinate) copolyesters: Solid state structure, melting point depression and biodegradability. RSC Adv. 2016, 6, 84003. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.; Jiang, M.; Zhang, Q.; Wang, R.; Tong, X.; Xue, S.; Zhou, G. Biobased copolyesters: Synthesis, sequence distribution, crystal structure, thermal and mechanical properties of poly(butylene sebacate-co-butylene furandicarboxylate). Polym. Degrad. Stab. 2017, 143, 1–8. [Google Scholar] [CrossRef]

- Hu, H.; Zhang, R.; Wang, J.; Ying, W.; Zhu, J. Fully bio-based poly(propylene succinate-co-propylene furandicarboxylate) copolyesters with proper mechanical, degradation and barrier properties for green packaging applications. Eur. Polym. J. 2018, 102, 101–110. [Google Scholar] [CrossRef]

- Hu, H.; Zhang, R.; Jiang, Y.; Shi, L.; Wang, J.; Ying, W.; Zhu, J. Toward biobased, biodegradable, and smart barrier packaging material: Modification of poly(neopentyl glycol 2,5-furandicarboxylate) with succinic acid. ACS Sustain. Chem. Eng. 2019, 7, 4255–4265. [Google Scholar] [CrossRef]

- Terzopoulou, Z.; Papadopoulos, L.; Zamboulis, A.; Papageorgiou, D.; Papageorgiou, G.; Bikiaris, D. Tuning the properties of furandicarboxylic acid-based polyesters with copolymerization: A review. Polymers 2020, 12, 1209. [Google Scholar] [CrossRef]

- Little, A.; Pellis, A.; Comerford, J.; Naranjo-Valles, E.; Hafezi, N.; Mascal, M.; Farmer, T. Effects of methyl branching on the properties and performance of furandioate-adipate copolyesters of bio-based secondary diols. ACS Sustain. Chem. Eng. 2020, 8, 14471–14483. [Google Scholar] [CrossRef]

- Xie, H.; Wu, L.; Li, B.; Dubois, P. Biobased poly(ethylene-co-hexamethylene 2,5- furandicarboxylate) (PEHF) copolyesters with superior tensile properties. Ind. Eng. Chem. Res. 2018, 57, 13094–13102. [Google Scholar] [CrossRef]

- Chen, M.; Jiang, Z.; Qiu, Z. Synthesis and properties of poly(hexamethylene 2,5-furandicarboxylate-co-adipate) copolyesters. Eur. Polym. J. 2021, 161, 110860. [Google Scholar] [CrossRef]

- Pamies, R.; Cifre, J.H.; Martínez, M.C.L.; de la Torre, J.G. Determination of intrinsic viscosities of macromolecules and nanoparticles. Comparison of single-point and dilution procedures. Colloid Polym. Sci. 2008, 286, 1223–1231. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of phase change. II transformation-time relations for random distribution of nuclei. J. Chem. Phys. 1940, 8, 212–224. [Google Scholar] [CrossRef]

- Avrami, M. Granulation, phase change, and microstructure kinetics of phase change. III. J. Chem. Phys. 1941, 9, 177–184. [Google Scholar] [CrossRef]

- Hoffman, J.; Weeks, J. Melting process and the equilibrium melting temperature of polychlorotrifluoroethylene. J. Res. Natl. Bur. Stand. 1962, 66, 13. [Google Scholar] [CrossRef]

| Samples | DMFD/SeA in Feed (mol%) | HF/HSe in Copolyesters (mol%) | [η] (dL/g) |

|---|---|---|---|

| PHF | 100/0 | 100/0 | 0.63 |

| PHFSe10 | 90/10 | 90/10 | 0.68 |

| PHFSe20 | 80/20 | 81/19 | 0.62 |

| PHFSe30 | 70/30 | 71/29 | 0.63 |

| Samples | Td (°C) | Tmax (°C) | Tg (°C) | Tch (°C) | ΔHch (J/g) | Tm (°C) | ΔHm (J/g) | Tcc (°C) | ΔHcc (J/g) | Tm° (°C) |

|---|---|---|---|---|---|---|---|---|---|---|

| PHF | 374.6 | 393.6 | 12.3 | 55.4 | 12.3 | 147.4 | 48.1 | 97.2 | 52.6 | 154.3 |

| PHFSe10 | 379.4 | 401.9 | −0.9 | 40.4 | 4.5 | 136.8 | 42.7 | 89.2 | 47.2 | 148.6 |

| PHFSe20 | 379.8 | 403.3 | −8.4 | 33.1 | 23.6 | 126.0 | 41.2 | 69.2 | 42.0 | 144.5 |

| PHFSe30 | 385.1 | 408.1 | −21.0 | 22.3 | 22.5 | 111.2 | 35.3 | 51.8 | 36.5 | 142.3 |

| Samples | Tc (°C) | n | k (min−n) | t0.5 (min) |

|---|---|---|---|---|

| PHF | 125.0 127.5 130.0 132.5 | 2.6 2.7 2.7 2.8 | 1.50 × 10−3 4.93 × 10−4 1.50 × 10−4 2.72 × 10−5 | 10.21 15.21 21.93 37.68 |

| PHFSe10 | 115.0 117.5 120.0 122.5 | 2.6 2.7 2.6 2.8 | 2.04 × 10−3 5.69 × 10−4 1.88 × 10−4 1.70 × 10−5 | 9.26 14.54 22.95 42.27 |

| PHFSe20 | 105.0 107.5 110.0 112.5 | 2.4 2.4 2.3 2.6 | 1.28 × 10−3 5.66 × 10−4 2.56 × 10−4 4.39 × 10−5 | 13.48 19.21 30.00 43.42 |

| PHFSe30 | 92.5 95.0 97.5 100.0 | 2.4 2.3 2.2 2.4 | 1.69 × 10−3 1.17 × 10−3 6.88 × 10−4 1.45 × 10−4 | 12.91 16.39 21.92 36.02 |

| Samples | Et (MPa) | σy (MPa) | εy (%) | σb (MPa) | εb (%) |

|---|---|---|---|---|---|

| PHF | 565.6 ± 23.1 | 24.2 ± 0.6 | 16.2 ± 1.2 | 30.3 ± 1.4 | 261.6 ± 8.3 |

| PHFSe10 | 320.0 ± 10.3 | 19.1 ± 0.8 | 21.9 ± 0.3 | 24.4 ± 0.4 | 274.6 ± 18.5 |

| PHFSe20 | 205.7 ± 8.5 | 13.7 ± 0.2 | 23.0 ± 1.4 | 23.6 ± 2.4 | 435.8 ± 18.2 |

| PHFSe30 | 114.9 ± 1.5 | 8.1 ± 0.2 | 22.3 ± 1.9 | 17.3 ± 1.4 | 513.2 ± 33.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, S.; Jiang, Z.; Qiu, Z. Synthesis, Thermal Behavior, and Mechanical Properties of Fully Biobased Poly(Hexamethylene 2,5-Furandicarboxylate-Co-Sebacate) Copolyesters. Polymers 2023, 15, 85. https://doi.org/10.3390/polym15010085

Feng S, Jiang Z, Qiu Z. Synthesis, Thermal Behavior, and Mechanical Properties of Fully Biobased Poly(Hexamethylene 2,5-Furandicarboxylate-Co-Sebacate) Copolyesters. Polymers. 2023; 15(1):85. https://doi.org/10.3390/polym15010085

Chicago/Turabian StyleFeng, Shiwei, Zhiguo Jiang, and Zhaobin Qiu. 2023. "Synthesis, Thermal Behavior, and Mechanical Properties of Fully Biobased Poly(Hexamethylene 2,5-Furandicarboxylate-Co-Sebacate) Copolyesters" Polymers 15, no. 1: 85. https://doi.org/10.3390/polym15010085

APA StyleFeng, S., Jiang, Z., & Qiu, Z. (2023). Synthesis, Thermal Behavior, and Mechanical Properties of Fully Biobased Poly(Hexamethylene 2,5-Furandicarboxylate-Co-Sebacate) Copolyesters. Polymers, 15(1), 85. https://doi.org/10.3390/polym15010085