Effect of Sunlight on the Change in Color of Unsteamed and Steamed Beech Wood with Water Steam

Abstract

:1. Introduction

2. Material and Methods

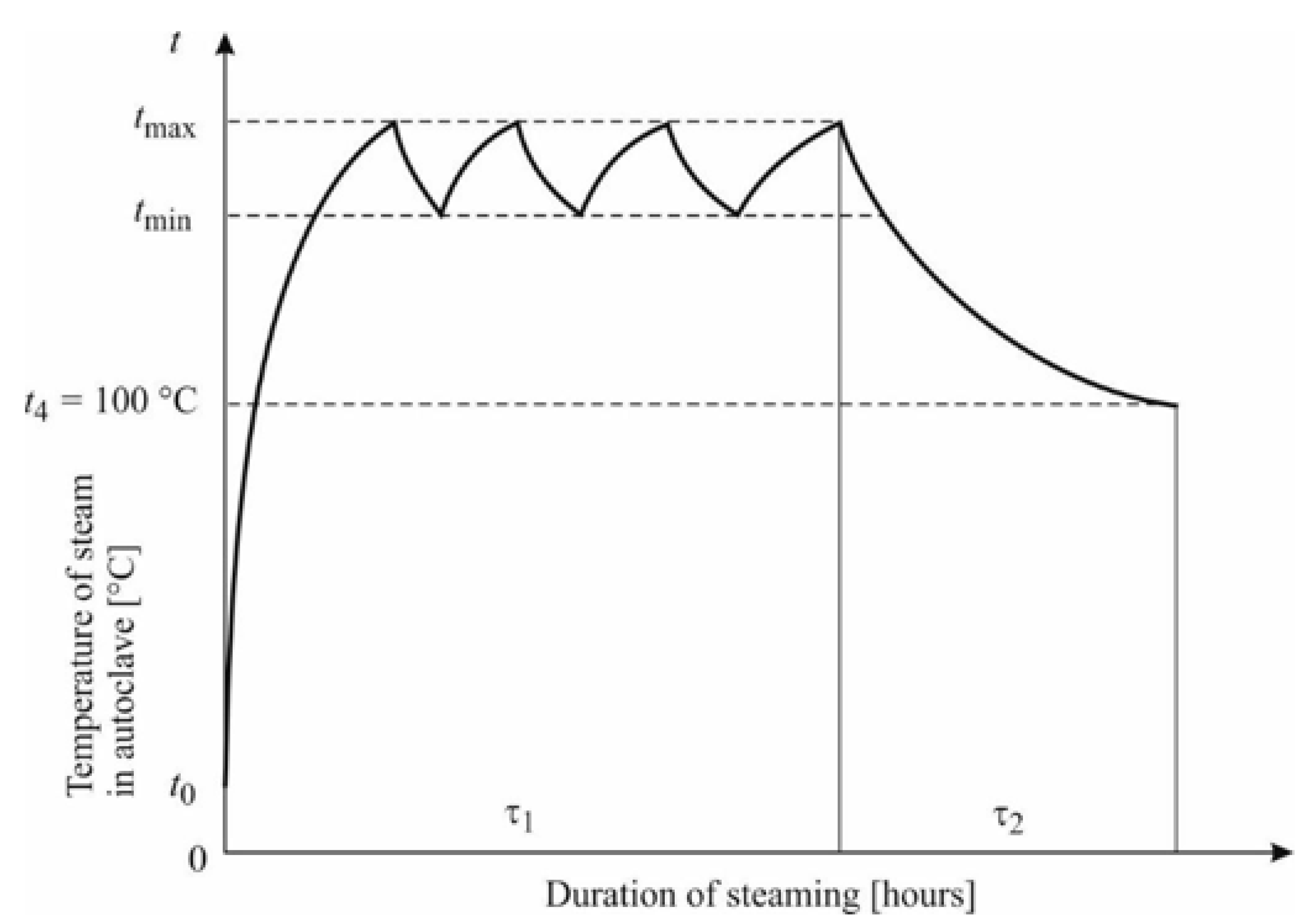

2.1. Material and Technology of Beech Wood Steaming

2.2. Conditions of Beech Wood Exposure

2.3. Color Measurement of Beech Wood

2.4. Mathematical-Statistical Evaluation of Measured Data

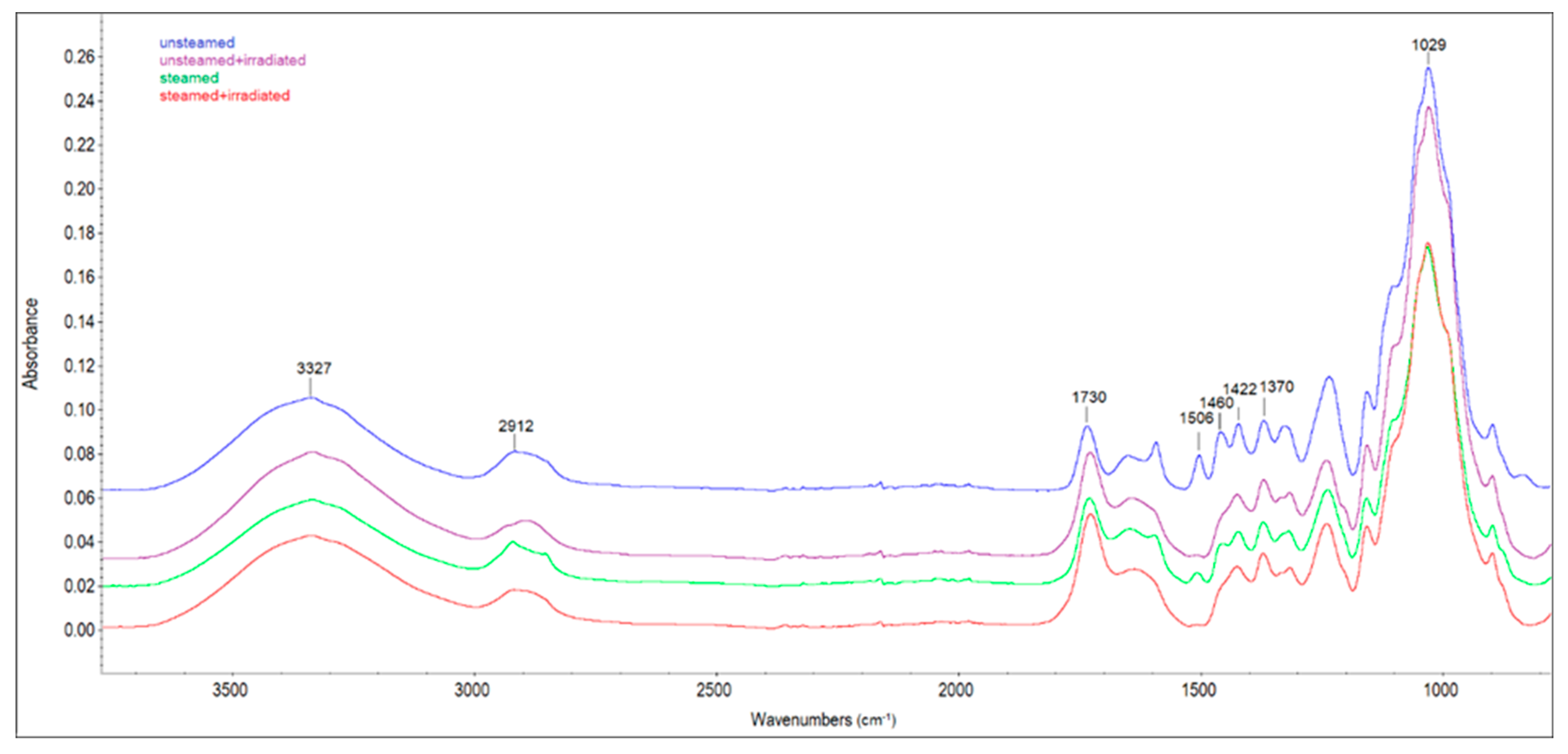

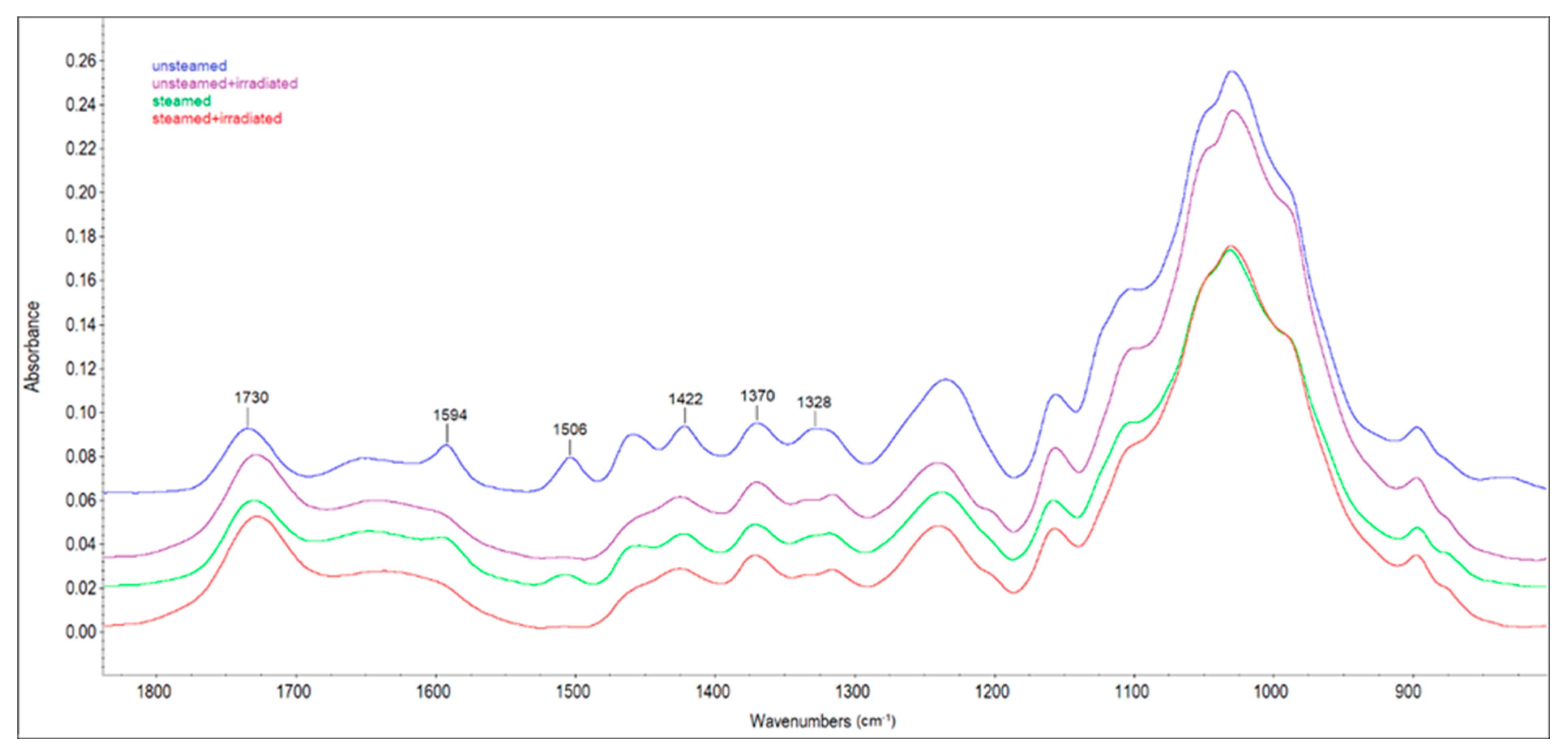

2.5. Analysis of Changes in Lignin-Cellulose Matrix of Wood ATR-FTIR Spectroscopy

3. Results and Discussion

4. Conclusions

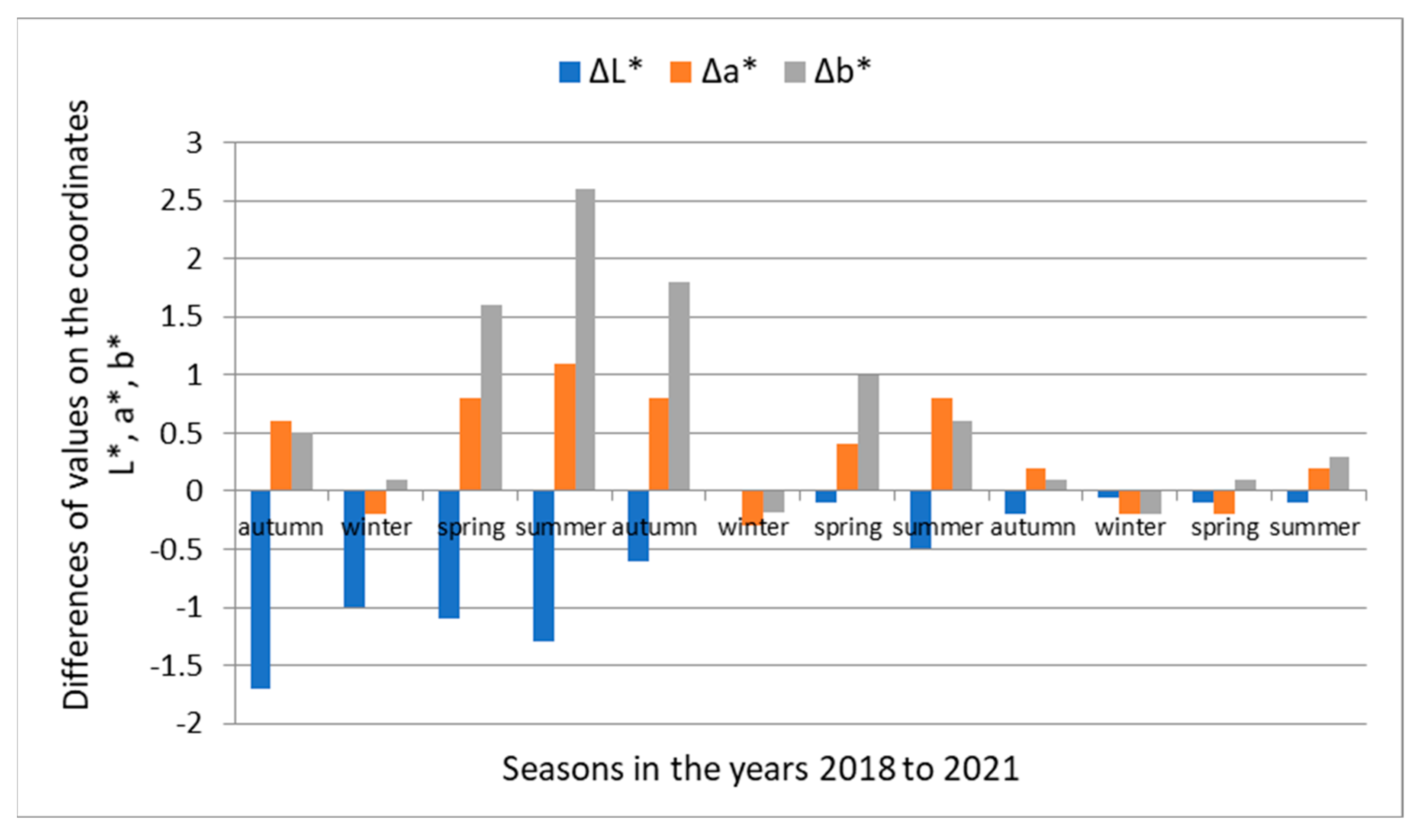

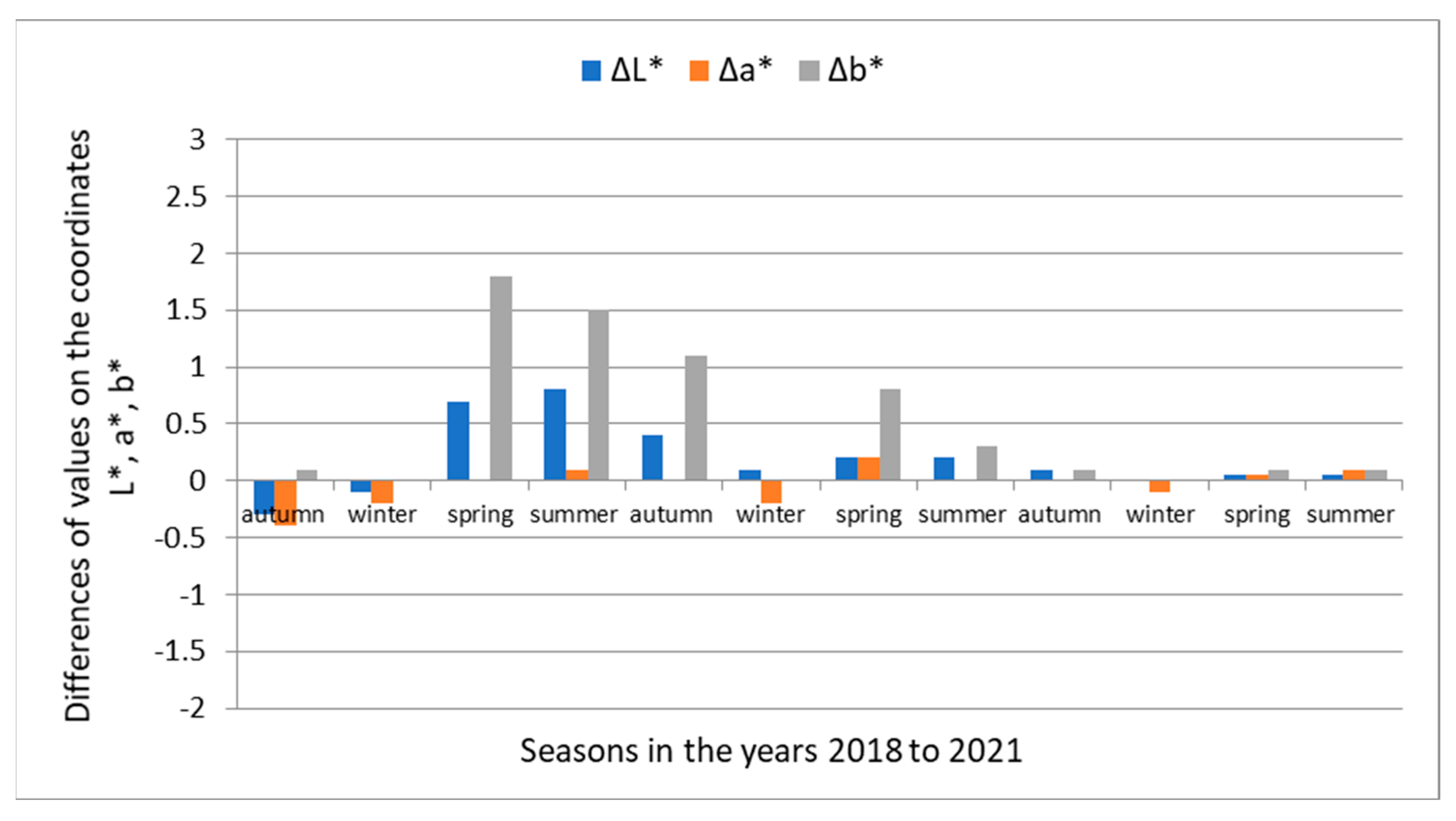

- The color surface of unsteamed beech wood changed under the influence of daylight during the exposure. The wood darkened and browned into a brown-yellow color shade. The opposite tendency, i.e., lightening, occurred during exposure on steamed beech wood samples.

- The measured changes in the values at the coordinates of the color space CIE L*a*b* caused by solar radiation in unsteamed beech wood are: ΔL* = −5.3; Δa* = +4.4; Δb* = +10.0. Changes were recorded also for steamed beech wood: ΔL* = +1.9; Δa* = -0.4; Δb* = 5.7.

- The evaluation of the color change of beech wood in the form of the total color difference ΔE* shows that the surface of steamed beech wood shows approximately 52.2% less color change than the total color difference of unsteamed beech wood.

- The decrease in the values of ΔL*, Δa*, and Δb* and the total color difference ΔE* of steamed beech wood indicate a positive effect of steaming of wood on the partial resistance of steamed beech wood to the initiation of photochemical reactions induced by wavelengths daylight.

- The lightfastness of wood is greatly affected by lignin. The main change in the ATR-FTIR spectra is the decrease in lignin absorption bands in parallel with the increase in unconjugated carbonyl absorption after irradiation of unsteamed and steamed beech wood with daylight components. Photodegradation of irradiated unsteamed and steamed wood was associated with a reduction in the ratio of lignin to carbohydrates while at the same time increasing the ratio of unconjugated carbonyl to carbohydrates, which may affect the partial resistance of steamed beech wood to daylight.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Hon, D.S.N. Weathering and Photochemistry in Wood. In Wood and Cellulosic Chemistry, 2nd ed.; Hon, D.S.N., Shiraishi, N., Eds.; Marcel Dekker: New York, NY, USA, 2001; pp. 513–546. [Google Scholar]

- Reinprecht, L. Wood Protection; Technical University in Zvolen: Zvolen, Slovakia, 2008; 450p. [Google Scholar]

- Baar, J.; Gryc, V. The analysis of tropical wood discoloration caused by simulated sunlight. Eur. J. Wood Wood Prod. 2011, 70, 263–269. [Google Scholar] [CrossRef]

- Hrvoľ, J.; Tomlain, J. Radiation in the Atmosphere, 1st ed.; Comenius University in Bratislava: Bratislava, Slovakia, 1997; 136p. [Google Scholar]

- Gandelová, L.; Horáček, P.; Šlezingerová, J. The Science of Wood; Mendel University of Agriculture and Forestry in Brno: Brno, Czech Republic, 2009; 176p. [Google Scholar]

- Persze, L.; Tolvaj, L. Photodegradation of wood at elevated temperature: Colour change. J. Photochem. Photobiol. B Biol. 2012, 108, 44–47. [Google Scholar] [CrossRef] [PubMed]

- Denes, L.; Lang, E.M. Photodegradation of heat-treated hardwood veneers. J. Photochem. Photobiol. B Biol. 2013, 118, 9–15. [Google Scholar] [CrossRef] [PubMed]

- Geffertová, J.; Geffert, A.; Vybohová, E. The effect of UV irradiation on the colour change of the spruce wood. Acta Fac. Xylologiae Zvolen 2018, 60, 41–50. [Google Scholar]

- Dzurenda, L. Mode for hot air drying of alder blanks that retain the color acquired during the steaming process. Ann. Wars. Univ. Life Sci. For. Wood Technol. 2021, 114, 86–92. [Google Scholar]

- Makovíny, I. Useful Properties and Use of Different Types of Wood; Technical University in Zvolen: Zvolen, Slovakia, 2010; 104p. [Google Scholar]

- Klement, I.; Réh, R.; Detvaj, J. Basic Characteristics of Forest Trees—Wood Raw Material Processing in the Wood Processing Industry; National Forestry Center: Zvolen, Slovakia, 2010; 82p. [Google Scholar]

- Trebula, P. Wood Drying and Hydrothermal Treatment; Technical University in Zvolen: Zvolen, Slovakia, 1986; 255p. [Google Scholar]

- Tolvaj, L.; Nemeth, R.; Varga, D.; Molnar, S. Colour homogenisation of beech wood by steam treatment. Drewno 2009, 52, 5–17. [Google Scholar]

- Dzurenda, L. Colouring of Beech Wood during Thermal Treatment using Saturated Water Steams. Acta Fac. Xylologiae Zvolen 2014, 56, 13–22. [Google Scholar]

- Banski, A.; Dudiak, M. Dependence of Color on the Time and Temperature of Saturated Water Steam in the Process of Thermal Modification of Beech Wood. AIP Conf. Proc. 2019, 2118, 030003. [Google Scholar]

- Dzurenda, L.; Dudiak, M. Cross-correlation of color and acidity of wet beech wood in the process of thermal treatment with saturated steam. Wood Res. 2021, 66, 105–116. [Google Scholar] [CrossRef]

- Babiak, M.; Kubovský, I.; Mamoňová, M. Color space of selected local woods. Interaction of Wood with Various Forms of Energy; Technical University in Zvolen: Zvolen, Slovakia, 2004; pp. 113–117. [Google Scholar]

- Meints, T.; Teischinger, A.; Stingl, R.; Hansmann, C. Wood colour of central European wood species: CIELAB characterisation and colour intensification. Eur. J. Wood Prod. 2017, 75, 499–509. [Google Scholar] [CrossRef]

- Chang, T.-C.; Chang, H.-T.; Wu, C.-L.; Chang, S.-T. Influences of extractives on the photodegradation of wood. Polym. Degrad. Stab. 2010, 95, 516–521. [Google Scholar] [CrossRef]

- Kúdela, J.; Kubovský, I. Accelerated-ageing-induced photo-degradation of beech wood surface treated with selected coating materials. Acta Fac. Xylologiae Zvolen 2016, 2, 27–36. [Google Scholar]

- Dzurenda, L.; Dudiak, M.; Banski, A. Influence of UV radiation on color stability of natural and thermally treated maple wood with saturated water steam. Innov. Woodwork. Eng. Des. Int. Sci. J. 2020, 36–41. [Google Scholar]

- Varga, D.; Tolvaj, L.; Molnar, Z.; Pasztory, Z. Leaching efect of water on photodegraded hardwood species monitored by IR spectroscopy. Wood Sci. Technol. 2020, 54, 1407–1421. [Google Scholar] [CrossRef]

- Dzurenda, L.; Dudiak, M.; Výbohová, E. Influence of UV Radiation on the Color Change of the Surface of Steamed Maple Wood with Saturated Water Steam. Polymers 2022, 14, 217. [Google Scholar] [CrossRef] [PubMed]

- Li, M.-Y.; Cheng, S.-C.; Li, D.; Wang, S.-N.; Huang, A.-M.; Sun, S.-Q. Structural characterization of steam-heat treated Tectona grandis wood analyzed by FT-IR and 2D-IR correlation spectroscopy. Chin. Chem. Lett. 2015, 26, 221–225. [Google Scholar]

- Müller, G.; Schöpper, C.; Vos, H.; Kharazipour, A.P.; Polle, A. FTIR-ATR spectroscopic analyses of changes in wood properties during particle and fibreboard production of hard and softwood trees. BioResources 2009, 4, 49–71. [Google Scholar] [CrossRef]

- Esteves, B.; Velez Marques, A.; Domingos, I.; Pereira, H. Chemical changes of heat treated Pine and Eucalypt wood monitored by FTIR. Maderas-Cienc. Technol. 2013, 15, 245–258. [Google Scholar] [CrossRef] [Green Version]

- Mattos, B.D.; Lourençon, T.V.; Serrano, L.; Labidi, J.; Gatto, D.A. Chemical modification of fast-growing eucalyptus wood. Wood Sci. Technol. 2015, 2, 273–288. [Google Scholar] [CrossRef]

- Zborowska, M.; Stachowiak-Wencek, A.; Waliszewska, B.; Prądzyński, W. Colorimetric and FTIR ATR spectroscopy studies of degradative effects of ultraviolet light on the surface of exotic ipe (tabebuia sp.) wood. Cellul. Chem. Technol. 2014, 50, 71–76. [Google Scholar]

- Pandey, K.K.; Vuorinen, T. Comparative study of photodegradation of wood by a UV laser and axenon light source. Polym. Degrad. Stab. 2008, 93, 2138–2146. [Google Scholar] [CrossRef]

- Srinivas, K.; Pandey, K.K. Photodegradation of thermally modified wood. J. Photochem. Photobiol. B 2012, 117, 140–145. [Google Scholar] [CrossRef] [PubMed]

- Agresti, G.; Bonifazi, G.; Calienno, L.; Capobianco, G.; Lo Monaco, A.; Pelosi, C.; Picchio, R.; Serranti, S. Surface investigation of photo-degraded wood by color monitoring, infrared spectroscopy, and hyperspectral imaging. J. Spectrosc. 2013, 2013, 380536. [Google Scholar] [CrossRef]

- Timar, M.C.; Varodi, A.M.; Gurău, L. Comparative study of photodegradation of six wood species after short-time UV exposure. Wood Sci. Technol. 2016, 50, 135–163. [Google Scholar] [CrossRef]

- Báder, M.; Németh, R.; Sandak, J.; Sandak, A. FTIR analysis of chemical changes in wood induced by steaming and longitudinal compression. Cellulose 2020, 27, 6811–6829. [Google Scholar] [CrossRef]

- Chang, T.C.; Chang, H.T.; Wu, C.L.; Lin, H.Y.; Chang, S.T. Stabilizing effect of extractives on the photo-oxidation of Acacia confusa wood. Polym. Degrad. Stab. 2010, 95, 1518–1522. [Google Scholar] [CrossRef]

- Chang, T.C.; Lin, H.Y.; Wang, S.Y.; Chang, S.T. Study on inhibition mechanisms of light-induced woodradicals by Acacia confusa heartwood extracts. Polym. Degrad. Stab. 2014, 105, 42–47. [Google Scholar] [CrossRef]

- Tolvaj, L.; Varga, D. Photodegradation of timber of three hardwood species caused by different lightsources. Acta Silv. Lign. Hung. 2012, 8, 145–155. [Google Scholar] [CrossRef] [Green Version]

- Tolvaj, L.; Molnar, Z.; Nemeth, R. Photodegradation of wood at elevated temperature: Infrared spectroscopic study. J. Photochem. Photobiol. B 2013, 12, 132–136. [Google Scholar] [CrossRef]

- ISO 11664-4; Colorimetry—Part 4: CIE 1976 L*a*b* Color space. Internation Organization for Standardization: Geneve, Switzerland, 2008.

| Mode | Temperature of Saturated Water Steam (°C) | Time of Operation (h) | ||||

|---|---|---|---|---|---|---|

| tmin | tmax | t4 | τ1-Phase I | τ2-Phase II | Total Time | |

| Mode | 132.5 | 137.5 | 100 | 6.0 | 1.0 | 7.5 |

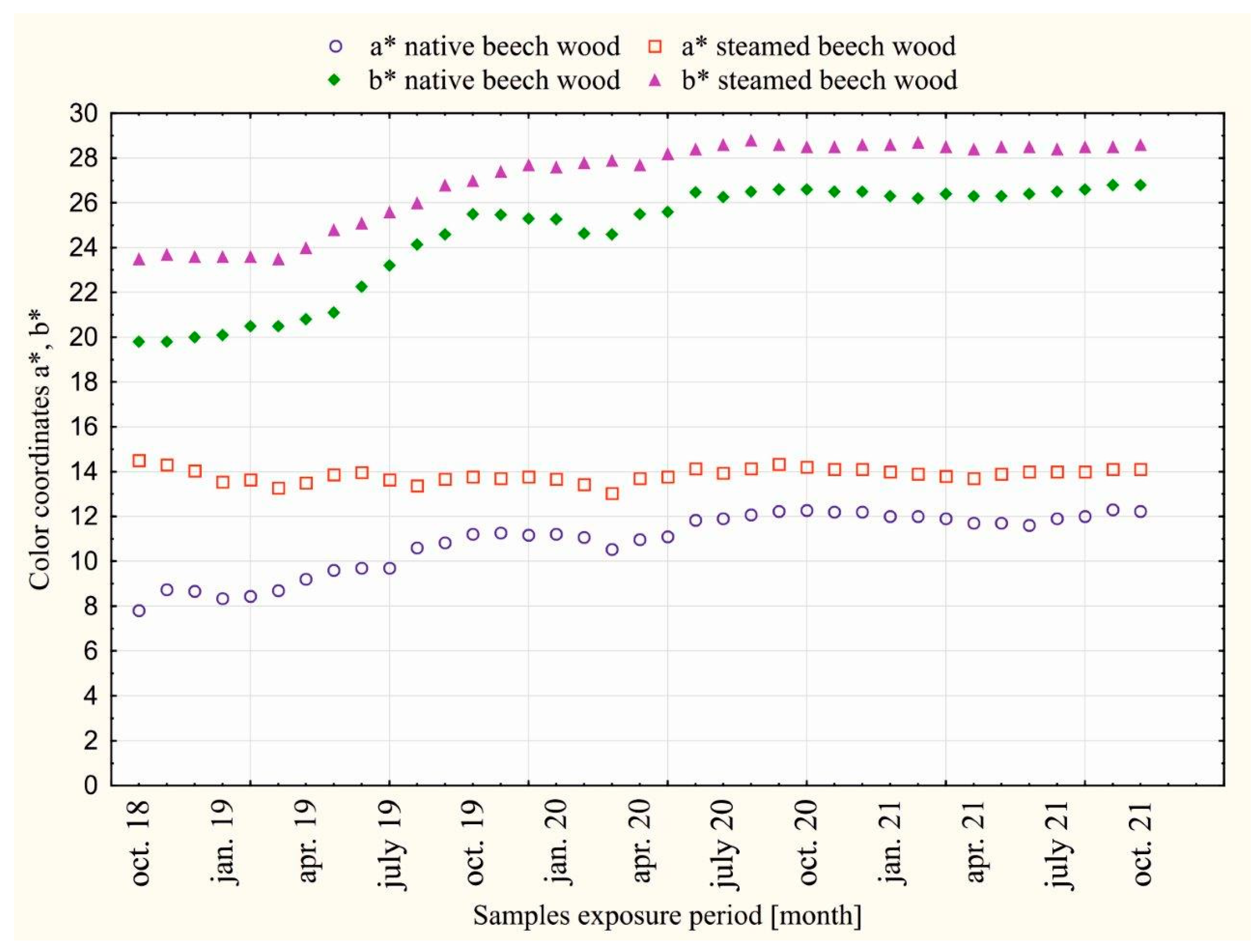

| Beech Wood | Unsteamed Beech Wood | Steamed Beech Wood | ||||

|---|---|---|---|---|---|---|

| Coordinates of Color Space CIE L*a*b* | ||||||

| L* | a* | b* | L* | a* | b* | |

| Before exposure | 76.6 ± 1.7 | 7.8 ± 1.5 | 19.8 ± 1.7 | 55.3 ± 1.6 | 14.5 ± 1.0 | 23.5 ± 0.8 |

| After exposure | 71.3 ± 0.9 | 12.2 ± 0.6 | 26.8 ± 0.9 | 57.6 ± 0.9 | 14.1 ± 0.8 | 27.5 ± 0.6 |

| Assignment | Ratio of Intensities | Unsteamed | Unsteamed + Irradiated | Steamed | Steamed + Irradiated |

|---|---|---|---|---|---|

| Nonconjugated carbonyl/carbohydrates | 1730/1370 | 2.04 | 2.72 | 2.49 | 3.19 |

| Lignin/carbohydrates | 1506/1370 | 1.03 | 0.08 | 0.43 | 0.03 |

| Nonconjugated carbonyl/lignin | 1730/1506 | 1.98 | 33.40 | 5.78 | 119.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dudiak, M.; Dzurenda, L.; Kučerová, V. Effect of Sunlight on the Change in Color of Unsteamed and Steamed Beech Wood with Water Steam. Polymers 2022, 14, 1697. https://doi.org/10.3390/polym14091697

Dudiak M, Dzurenda L, Kučerová V. Effect of Sunlight on the Change in Color of Unsteamed and Steamed Beech Wood with Water Steam. Polymers. 2022; 14(9):1697. https://doi.org/10.3390/polym14091697

Chicago/Turabian StyleDudiak, Michal, Ladislav Dzurenda, and Viera Kučerová. 2022. "Effect of Sunlight on the Change in Color of Unsteamed and Steamed Beech Wood with Water Steam" Polymers 14, no. 9: 1697. https://doi.org/10.3390/polym14091697

APA StyleDudiak, M., Dzurenda, L., & Kučerová, V. (2022). Effect of Sunlight on the Change in Color of Unsteamed and Steamed Beech Wood with Water Steam. Polymers, 14(9), 1697. https://doi.org/10.3390/polym14091697