Mechanical Behavior and Energy Dissipation of Woven and Warp-Knitted Pvc Membrane Materials under Multistage Cyclic Loading

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation and Experimental Methods

3. Results and Discussion

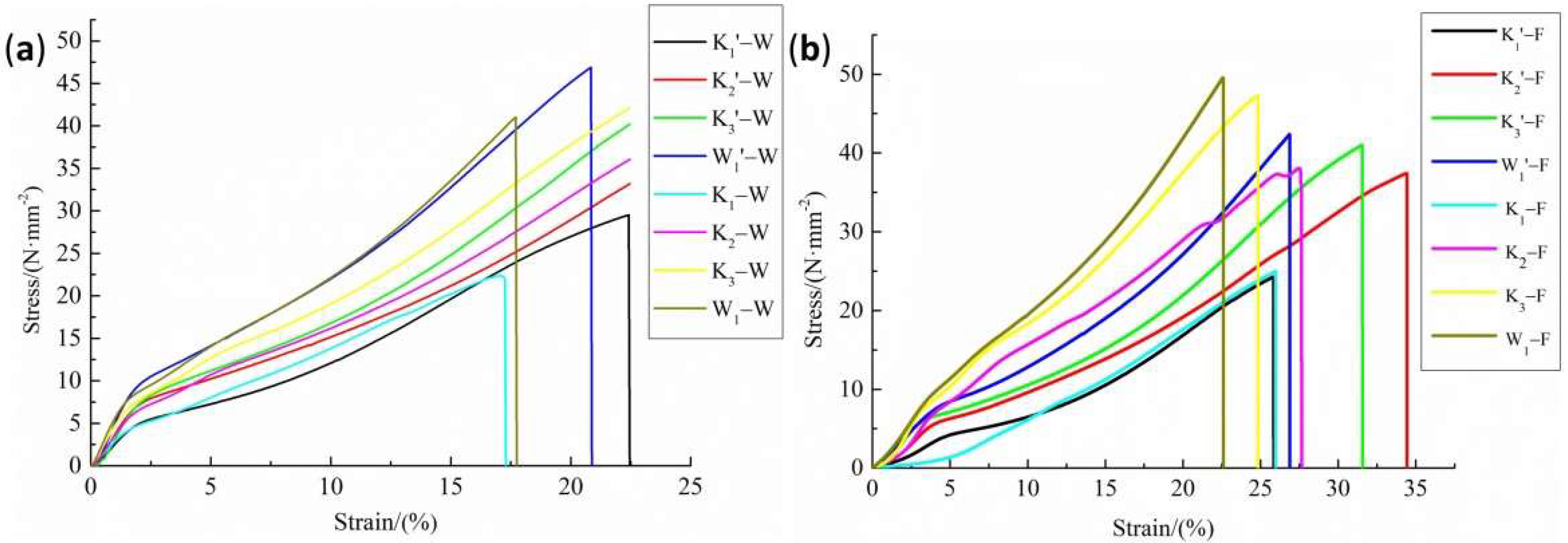

3.1. Analysis of Relaxation Characteristics

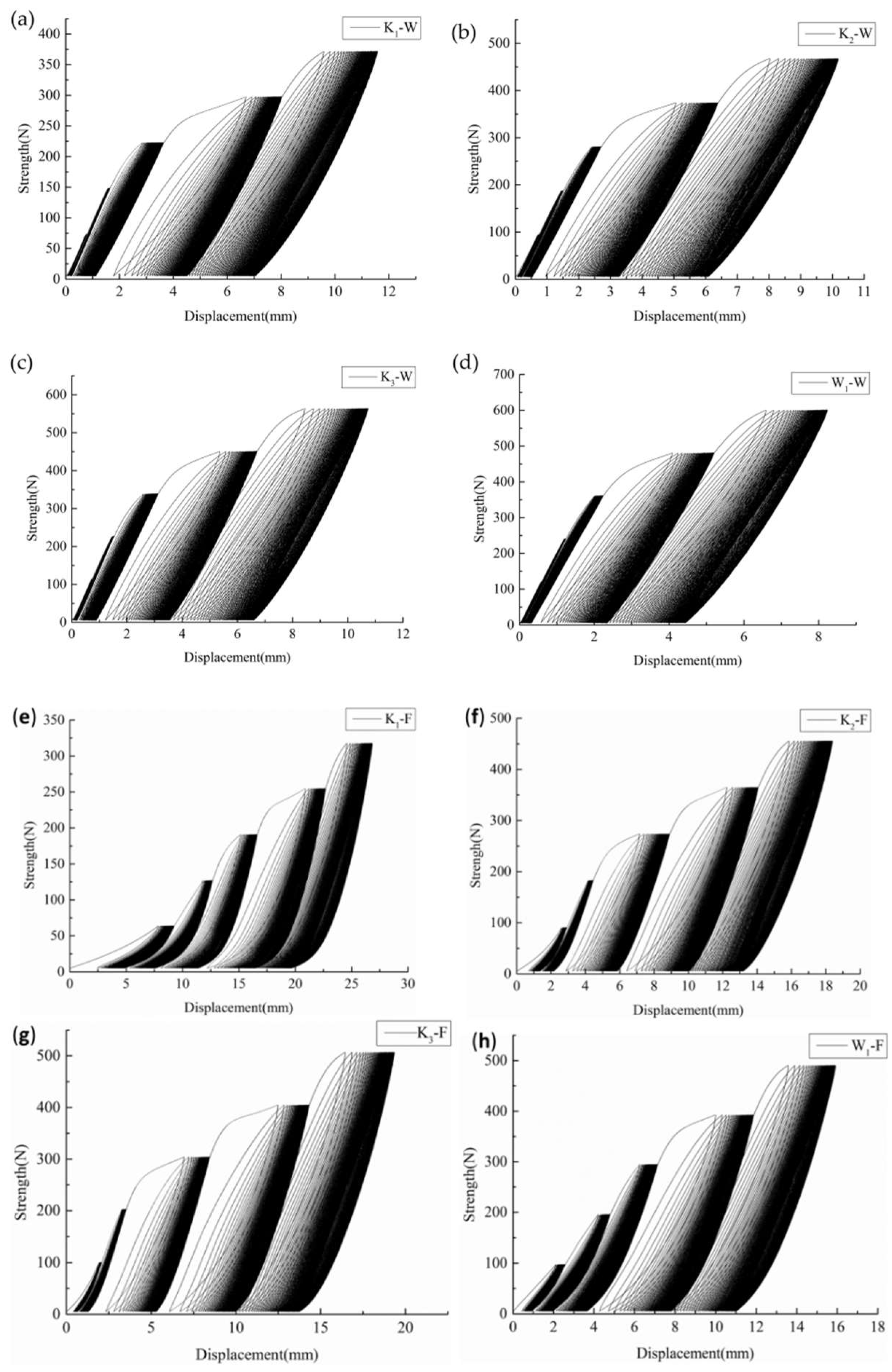

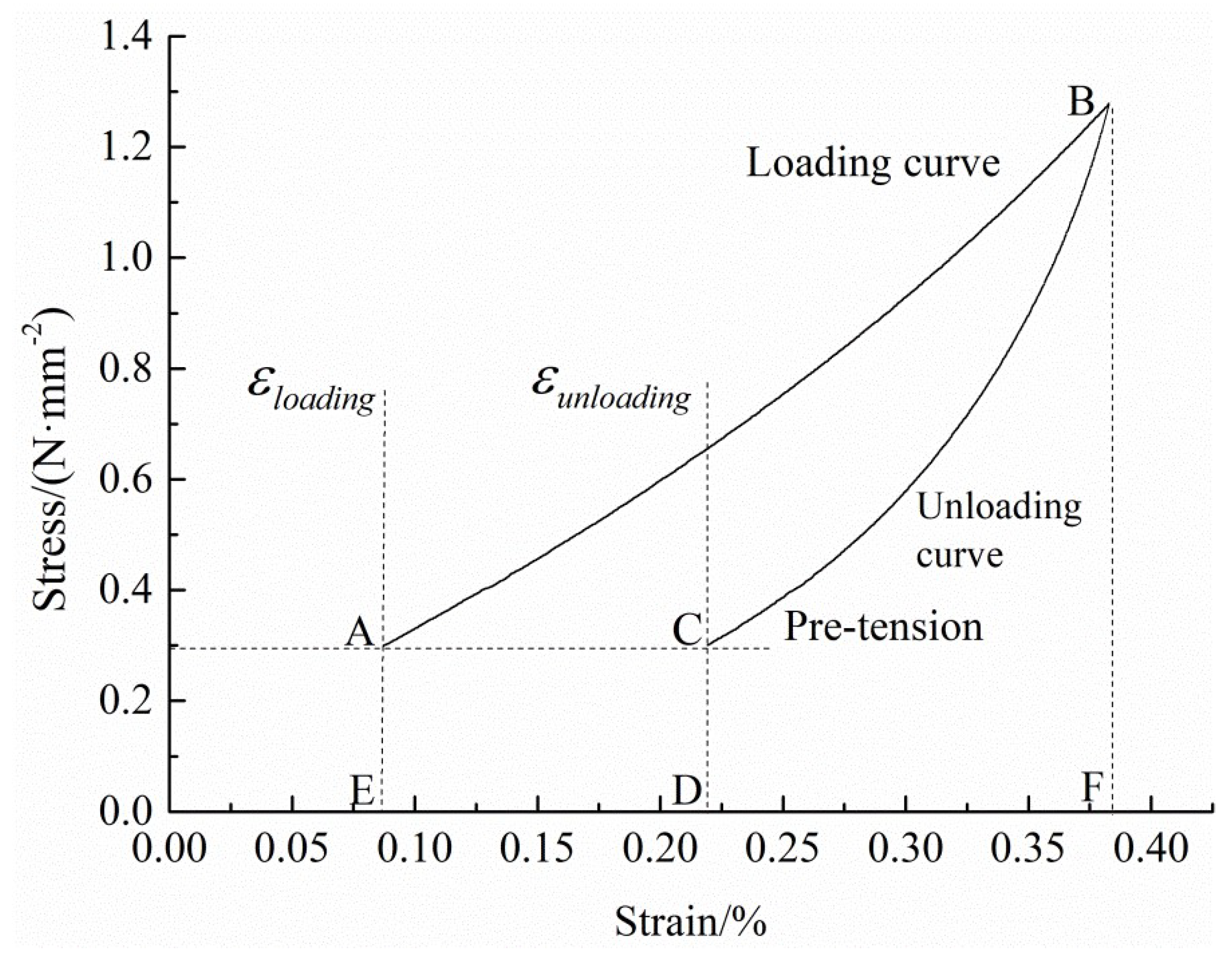

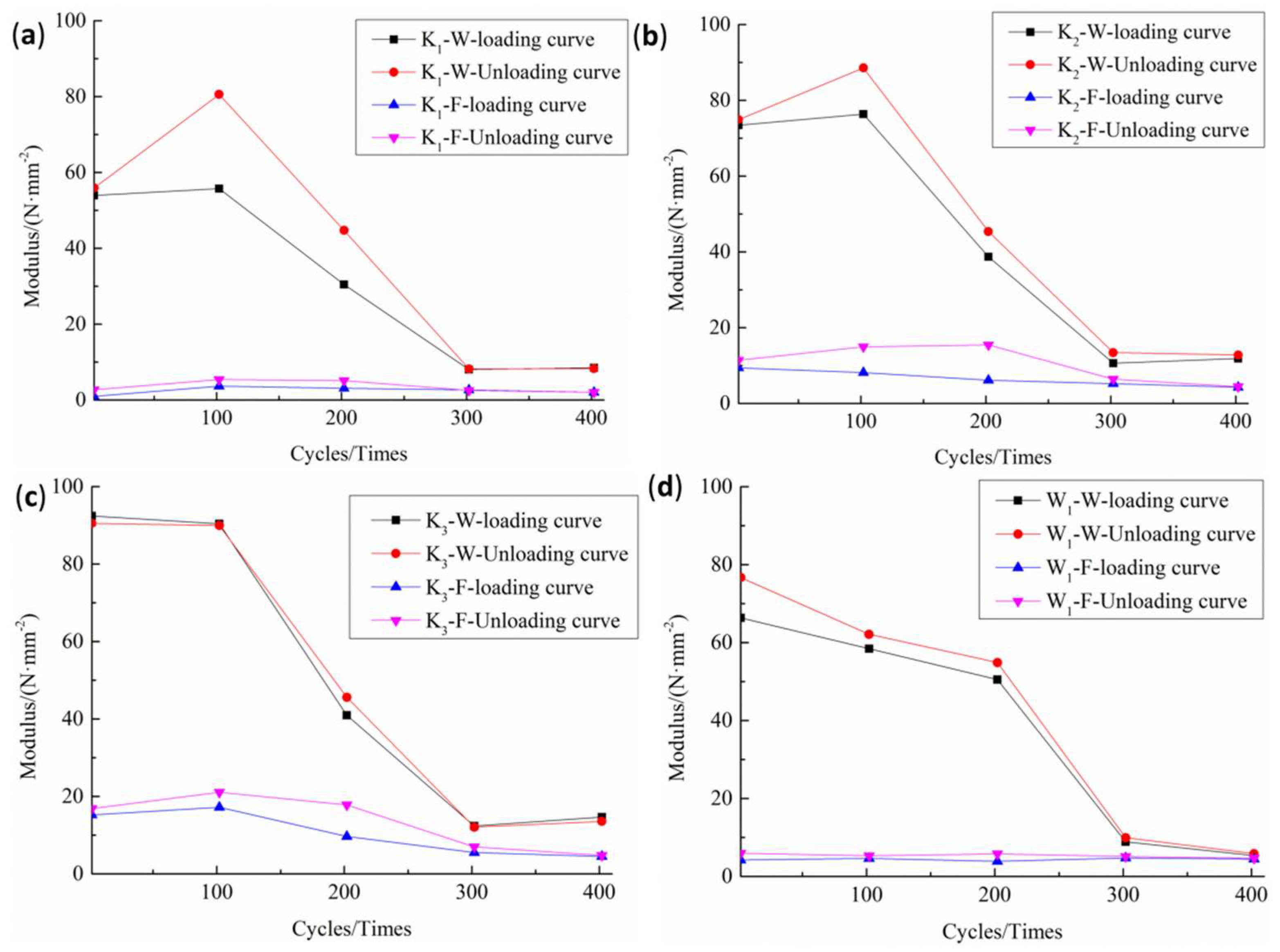

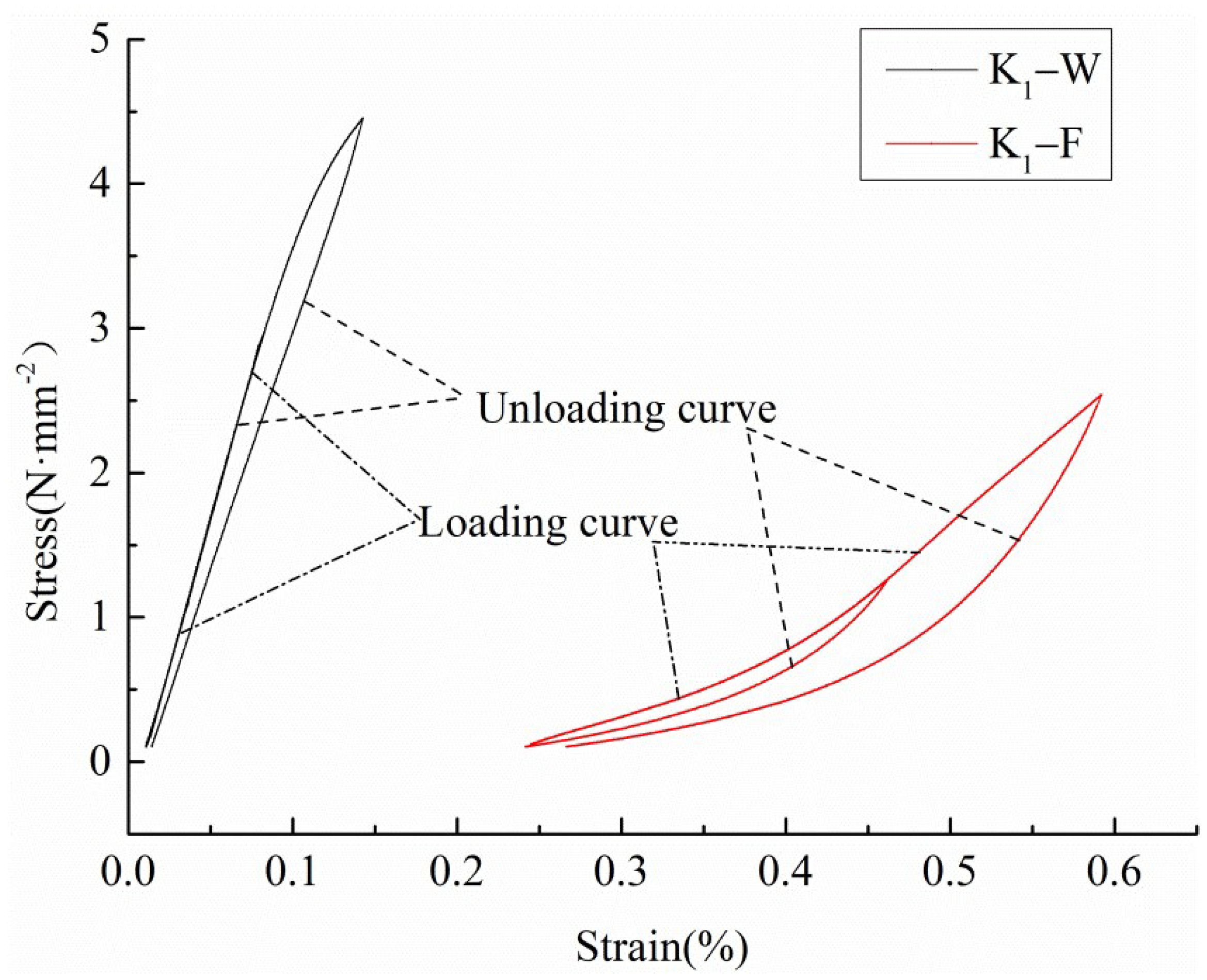

3.2. Analysis of the Cyclic Elastic Modulus

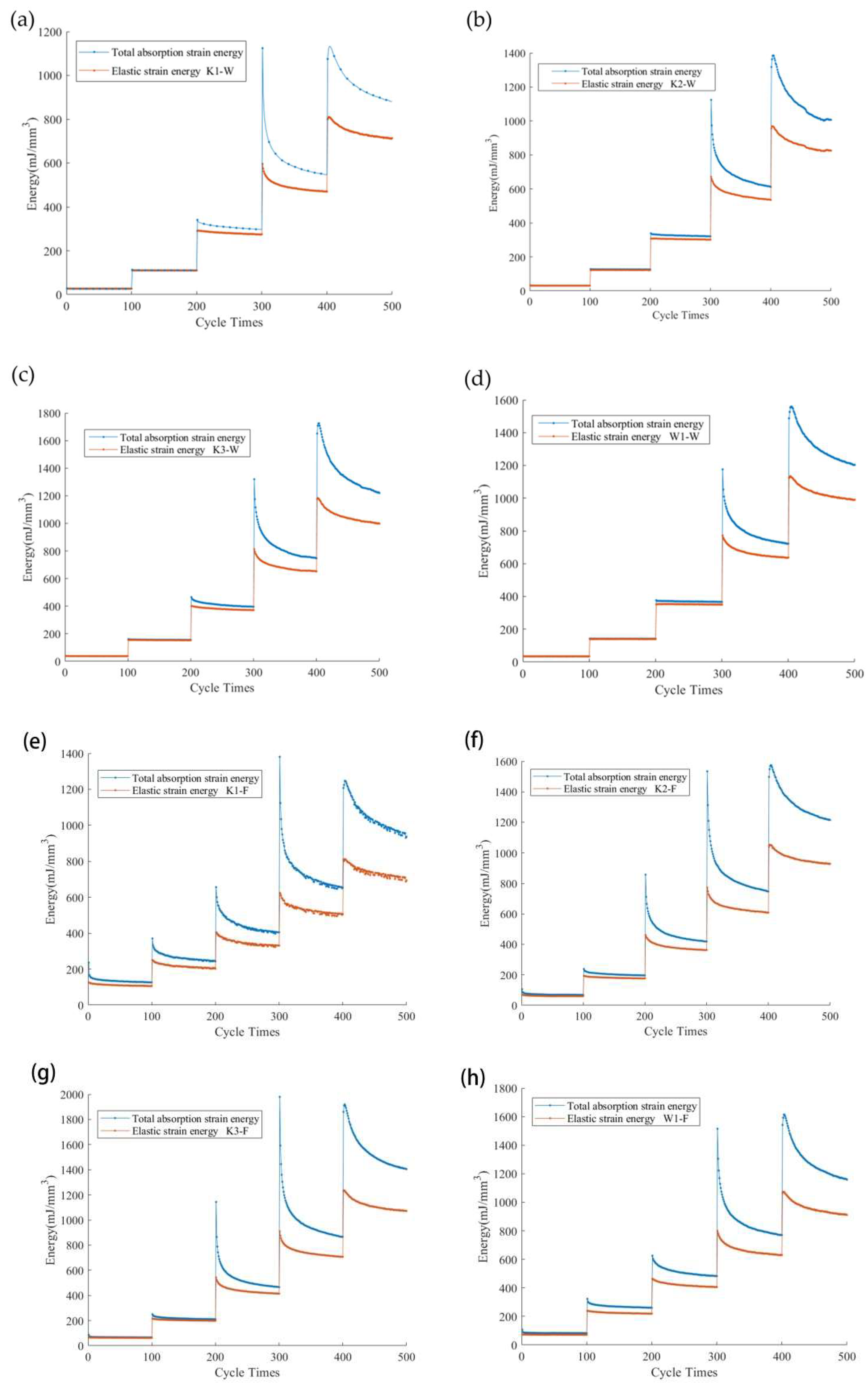

3.3. The Characteristics of Energy Dissipation

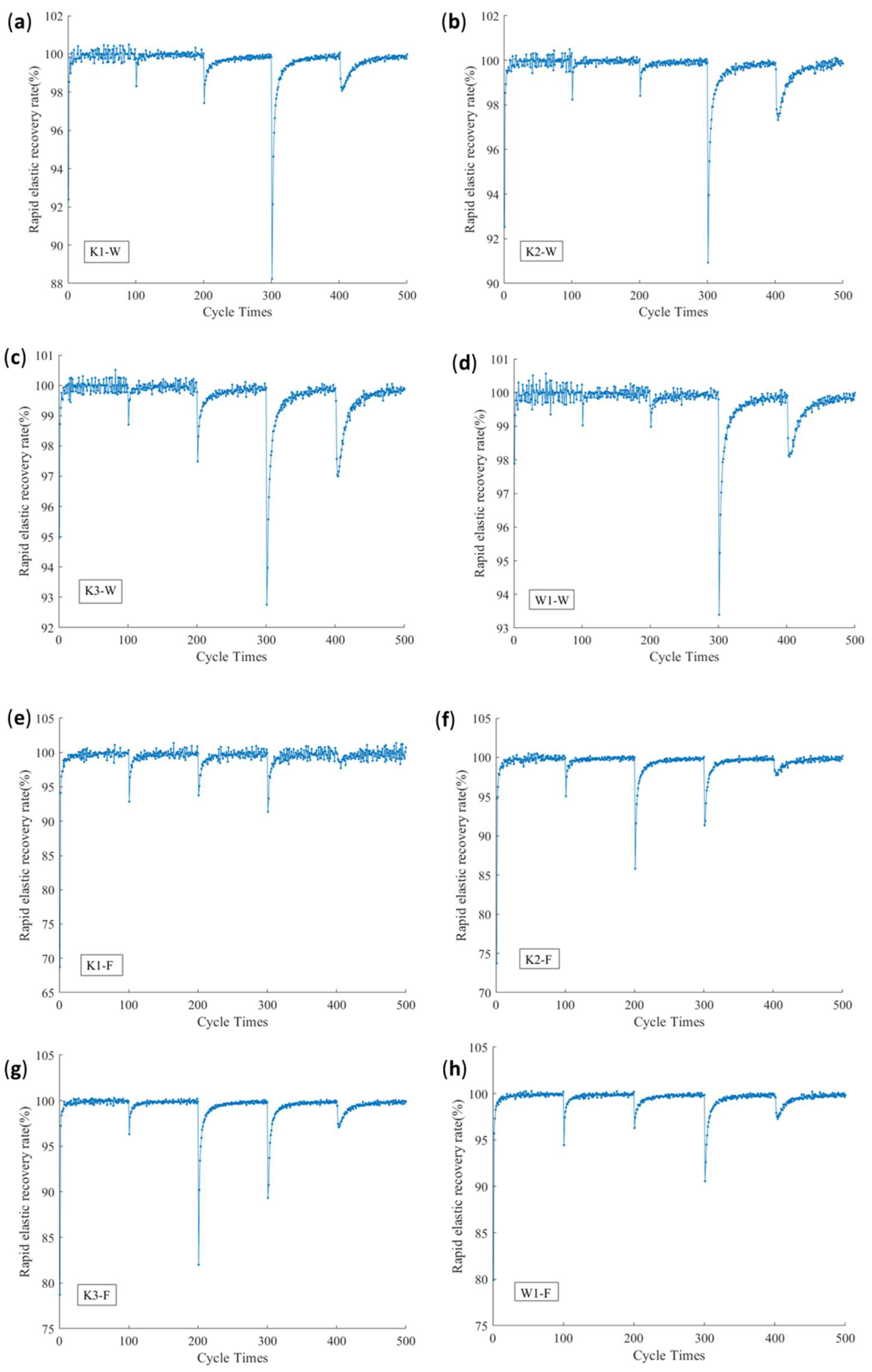

3.4. The Rule of Rapid Elastic Recovery Rate

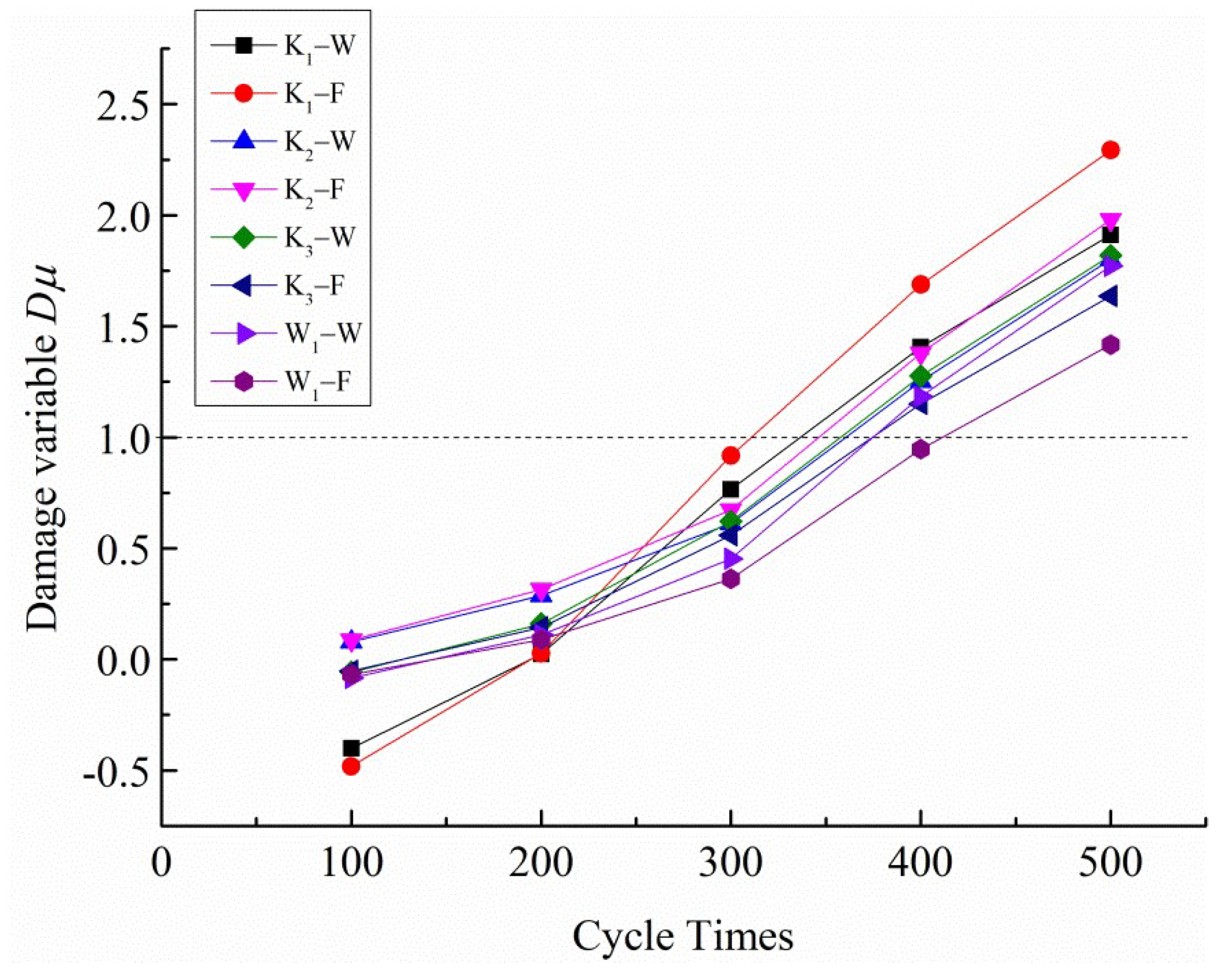

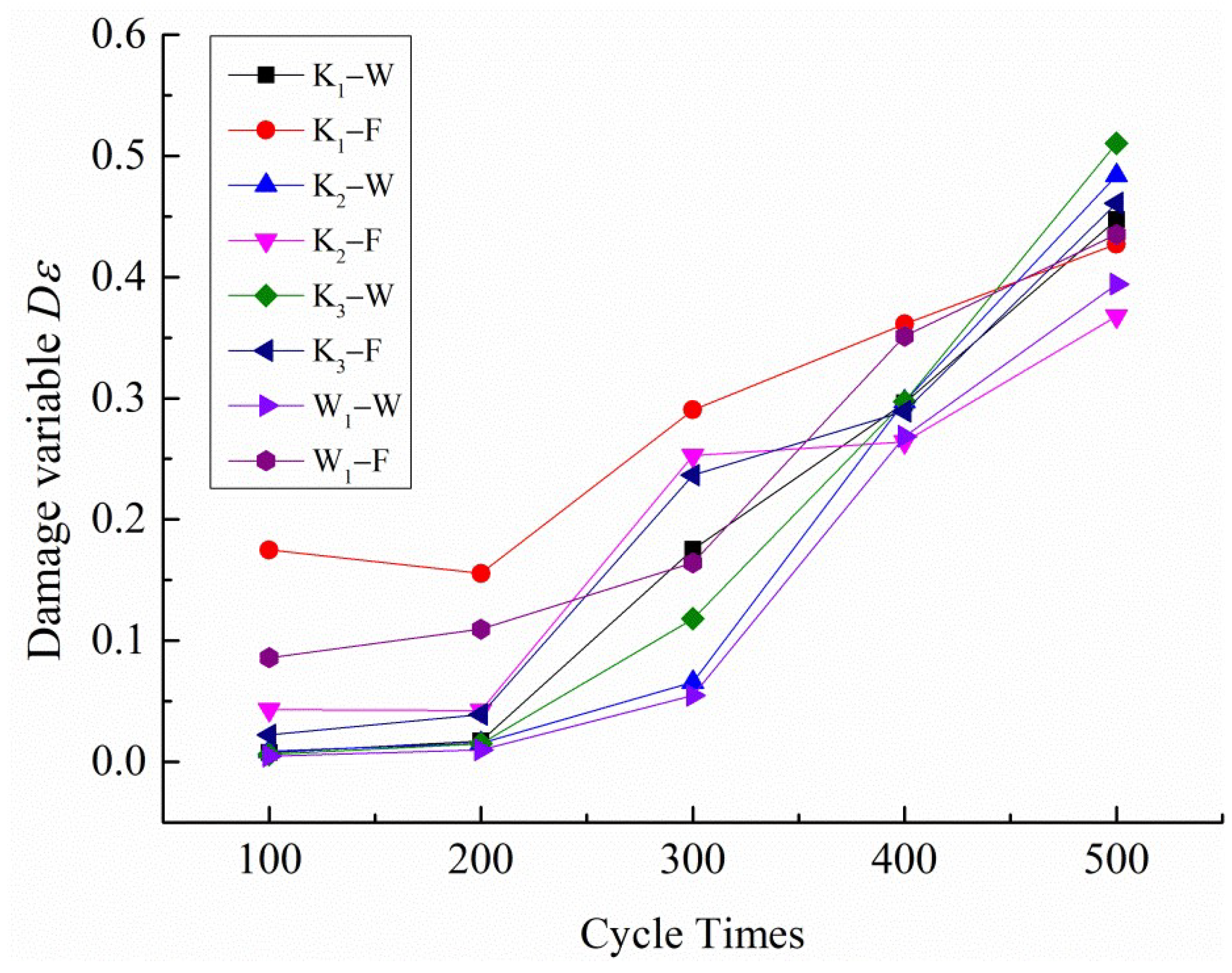

3.5. Definition and Analysis of Damage Variables

4. Conclusions

- (1)

- For the four PVC membrane materials selected in this paper, the multistage cyclic fracture peak strengths of the warp-direction samples are lower than the original tensile strengths, while those for the fill-direction samples are higher than the direct tensile strengths, which is mainly due to the tension difference between the warp and weft yarns during weaving and coating processing. The overall trend of the dissipated energy of the K1, K2, K3, and W1 samples is consistent, increasing with the increase in fabric density. Similarly, the fill values are larger than the warp values. According to the analysis of the energy dissipation rate, PVC membrane materials’ use strength should be controlled below a 15% stress level under long-term external force loading.

- (2)

- The loading and unloading curves of the PVC membrane materials are obviously nonlinear, so it is more reasonable to use the linear fitting method to obtain the loading and unloading moduli compared with the approximate equivalent calculation method. For warp knitting materials, the loading and unloading moduli increase with the increase in density, and the values are K3 > K2 > K1. At the same density, the loading and the unloading moduli of the woven material are lower than those of the warp knitting material (W1 < K3).

- (3)

- Due to the peak strength of multistage cyclic loading being different from that of cyclic loading and unloading, the deformation processes of the warp and fill samples of the four kinds of PVC membrane materials are at different stages at the same cyclic loading times. However, the variation trends of energy and stress show the same law, that is, the total absorbed strain energy, elastic strain energy, and dissipation energy of the warp samples are higher than those of the fill samples under a low load level but lower under a high load level.

- (4)

- Under multistage cyclic loading, the four PVC membrane materials are in the elastic–plastic deformation stage. It is more reasonable to define the damage variable based on the accumulation of plastic deformation than the change in elastic modulus and dissipation energy. Under the same cyclic load peak conditions, the damage levels of the fill samples are higher than those of the warp samples. The damage level of K3 is higher than that of W1 for the same density of woven and warp-knitted membrane materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jafaripour, M.; Taheri-Behrooz, F. Creep Behavior Modeling of Polymeric Composites Using Schapery Model Based on Micro-Macromechanical Approaches. Eur. J. Mech. A/Solids 2020, 81, 103963. [Google Scholar] [CrossRef]

- Miller, S.A. Natural Fiber Textile Reinforced Bio-Based Composites: Mechanical Properties, Creep, and Environmental Impacts. J. Clean. Prod. 2018, 198, 612–623. [Google Scholar] [CrossRef]

- Guo, S.; Shen, W.; Li, R.; Shao, H.; Jiang, J.; Chen, N. Characterization of Tensile Creep Behavior of Fabric-Reinforced PVC Flexible Composites. J. Text. Inst. 2021, 2, 1–8. [Google Scholar] [CrossRef]

- Jain, N.; Ali, S.; Singh, V.K.; Singh, K.; Bisht, N.; Chauhan, S. Creep and Dynamic Mechanical Behavior of Cross-Linked Polyvinyl Alcohol Reinforced with Cotton Fiber Laminate Composites. J. Polym. Eng. 2019, 39, 326–335. [Google Scholar] [CrossRef]

- Rafiee, R.; Ghorbanhosseini, A. Developing a Micro-Macromechanical Approach for Evaluating Long-Term Creep in Composite Cylinders. Thin-Walled Struct. 2020, 151, 106714. [Google Scholar] [CrossRef]

- Borowiec, M.; Gawryluk, J.; Bochenski, M. Influence of Mechanical Couplings on the Dynamical Behavior and Energy Harvesting of a Composite Structure. Polymers 2020, 13, 66. [Google Scholar] [CrossRef]

- Ambroziak, A. Mechanical Properties of Precontraint 1202S Coated Fabric under Biaxial Tensile Test with Different Load Ratios. Constr. Build. Mater. 2015, 80, 210–224. [Google Scholar] [CrossRef]

- Yang, T.; Luo, M.; Zou, Z.; Ma, P. Mechanical Properties of the Surface Membrane of Lattice Spacer-Fabric Flexible Inflatable Composites. Text. Res. J. 2021, 92, 1088–1097. [Google Scholar] [CrossRef]

- Beter, J.; Schrittesser, B.; Lechner, B.; Mansouri, M.R.; Marano, C.; Fuchs, P.F.; Pinter, G. Viscoelastic Behavior of Glass-Fiber-Reinforced Silicone Composites Exposed to Cyclic Loading. Polymers 2020, 12, 1862. [Google Scholar] [CrossRef]

- Cardile, G.; Moraci, N.; Pisano, M. In-Air Tensile Load-Strain Behaviour of HDPE Geogrids Under Cyclic Loading. Procedia Eng. 2016, 158, 266–271. [Google Scholar] [CrossRef][Green Version]

- Strizhius, V. Models of Nonlinear Fatigue Damage Accumulation Under Cyclic Block Loadings of Layered Composites. Mech. Compos. Mater. 2020, 56, 111–120. [Google Scholar] [CrossRef]

- Faria, H.; Guedes, R.M. Long-Term Behaviour of GFRP Pipes: Reducing the Prediction Test Duration. Polym. Test. 2010, 29, 337–345. [Google Scholar] [CrossRef]

- Wang, C.; Cao, X.; Shen, H. Experimental and Numerical Investigation of PA66 Fabrics Coated/Uncoated PVC by Biaxial Tensile Tests. Fibers Polym. 2021, 22, 2194–2205. [Google Scholar] [CrossRef]

- Chen, J.; Chen, W.; Zhang, D. Experimental Study on Uniaxial and Biaxial Tensile Properties of Coated Fabric for Airship Envelopes. J. Reinf. Plast. Compos. 2014, 33, 630–647. [Google Scholar] [CrossRef]

- Wang, F.; Chen, Y.; Xu, W.; Song, Z.; Fu, G. Experimental Study on Uniaxial Tensile and Welding Performance of a New Coated Fabric for Airship Envelopes. J. Ind. Text. 2017, 46, 1474–1497. [Google Scholar] [CrossRef]

- Yingying, Z.; Qilin, Z.; Ke, L.; Bei-lei, K. Experimental Analysis of Tensile Behaviors of Polytetrafluoroethylene-Coated Fabrics Subjected to Monotonous and Cyclic Loading. Text. Res. J. 2014, 84, 231–245. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, M. Aging Properties of Polyvinylidenefluoride-Coated Polyesters Used in Tensioned Membrane Structure: Effect of Loading Protocol and Environment. Adv. Mater. Sci. Eng. 2017, 2017, 8789247. [Google Scholar] [CrossRef]

- Ambroziak, A.; Kłosowski, P. Mechanical Properties of Polyvinyl Chloride-Coated Fabric under Cyclic Tests. J. Reinf. Plast. Compos. 2014, 33, 225–234. [Google Scholar] [CrossRef]

- Byun, J.-H.; Wang, Y.-Q.; Um, M.-K.; Lee, S.-K.; Song, J.-I.; Kim, B.-S. Stitching Effect on Flexural and Interlaminar Properties of MWK Textile Composites. Compos. Res. 2015, 28, 136–141. [Google Scholar] [CrossRef][Green Version]

- Wan, Y.; Zhang, F.; Gu, B.; Sun, B.; Wang, Y. Predicting Dynamic In-Plane Compressive Properties of Multi-Axial Multi-Layer Warp-Knitted Composites with a Meso-Model. Compos. Part B Eng. 2015, 77, 278–290. [Google Scholar] [CrossRef]

- Li, D.; Jiang, N.; Jiang, L.; Lu, N. Experimental Study on the Bending Properties and Failure Mechanism of 3D Multi-Axial Warp Knitted Composites at Room and Liquid Nitrogen Temperatures. J. Compos. Mater. 2016, 50, 557–571. [Google Scholar] [CrossRef]

- Beter, J.; Schrittesser, B.; Maroh, B.; Sarlin, E.; Fuchs, P.F.; Pinter, G. Comparison and Impact of Different Fiber Debond Techniques on Fiber Reinforced Flexible Composites. Polymers 2020, 12, 472. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Hu, H. Mechanical Properties of PVC Coated Bi-Axial Warp Knitted Fabric with and without Initial Cracks under Multi-Axial Tensile Loads. Compos. Struct. 2009, 89, 536–542. [Google Scholar] [CrossRef]

- Upadhyaya, P.; Upadhyay, C.S. A Three-Dimensional Micromechanical Model to Predict the Viscoelastic Behavior of Woven Composites. Compos. Struct. 2011, 93, 2733–2739. [Google Scholar] [CrossRef]

- Asayesh, A.; Jeddi, A.A.A. Modeling the Creep Behavior of Plain Woven Fabrics Constructed from Textured Polyester Yarn. Text. Res. J. 2010, 80, 642–650. [Google Scholar] [CrossRef]

- Yang, Y.; Fu, C.; Xu, F. A Finite Strain Model Predicts Oblique Wrinkles in Stretched Anisotropic Films. Int. J. Eng. Sci. 2020, 155, 103354. [Google Scholar] [CrossRef]

- Prioglio, G.; Agnelli, S.; Conzatti, L.; Balasooriya, W.; Schrittesser, B.; Galimberti, M. Graphene Layers Functionalized with A Janus Pyrrole-Based Compound in Natural Rubber Nanocomposites with Improved Ultimate and Fracture Properties. Polymers 2020, 12, 944. [Google Scholar] [CrossRef]

- Lemaitre, J. A Continuous Damage Mechanics Model for Ductile Fracture. J. Eng. Mater. Technol. 1985, 107, 83–89. [Google Scholar] [CrossRef]

- Mansouri, M.R.; Fuchs, P.F.; Criscione, J.C.; Schrittesser, B.; Beter, J. The Contribution of Mechanical Interactions to the Constitutive Modeling of Fiber-Reinforced Elastomers. Eur. J. Mech. A/Solids 2021, 85, 104081. [Google Scholar] [CrossRef]

| Samples | Warp and Fill Lining Fine- Ness/(Tex) | Warp and Fill Yarn Fine- Ness/(Tex) | Fabric Density/(Yarns/Inch2) | Thickness/(mm) | Area Density/(g/m2) |

|---|---|---|---|---|---|

| K1′ | 111.11 | / | 9 × 9 | 0.41 | 365.10 |

| K2′ | 111.11 | / | 12 × 12 | 0.46 | 436.53 |

| K3′ | 111.11 | / | 18 × 18 | 0.51 | 651.16 |

| W1′ | / | 111.11 | 18 × 18 | 0.50 | 635.73 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, S.; Wang, L.; Shao, G.; Shao, H.; Jiang, J.; Chen, N. Mechanical Behavior and Energy Dissipation of Woven and Warp-Knitted Pvc Membrane Materials under Multistage Cyclic Loading. Polymers 2022, 14, 1666. https://doi.org/10.3390/polym14091666

Guo S, Wang L, Shao G, Shao H, Jiang J, Chen N. Mechanical Behavior and Energy Dissipation of Woven and Warp-Knitted Pvc Membrane Materials under Multistage Cyclic Loading. Polymers. 2022; 14(9):1666. https://doi.org/10.3390/polym14091666

Chicago/Turabian StyleGuo, Shanshan, Linlin Wang, Guangwei Shao, Huiqi Shao, Jinhua Jiang, and Nanliang Chen. 2022. "Mechanical Behavior and Energy Dissipation of Woven and Warp-Knitted Pvc Membrane Materials under Multistage Cyclic Loading" Polymers 14, no. 9: 1666. https://doi.org/10.3390/polym14091666

APA StyleGuo, S., Wang, L., Shao, G., Shao, H., Jiang, J., & Chen, N. (2022). Mechanical Behavior and Energy Dissipation of Woven and Warp-Knitted Pvc Membrane Materials under Multistage Cyclic Loading. Polymers, 14(9), 1666. https://doi.org/10.3390/polym14091666